High-hardness Cu-based material containing interface layers and preparation method thereof

An interface layer, high hardness technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of difficulty in practical engineering, low hardness and strength of Cu, achieve high hardness, improve mechanical Performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

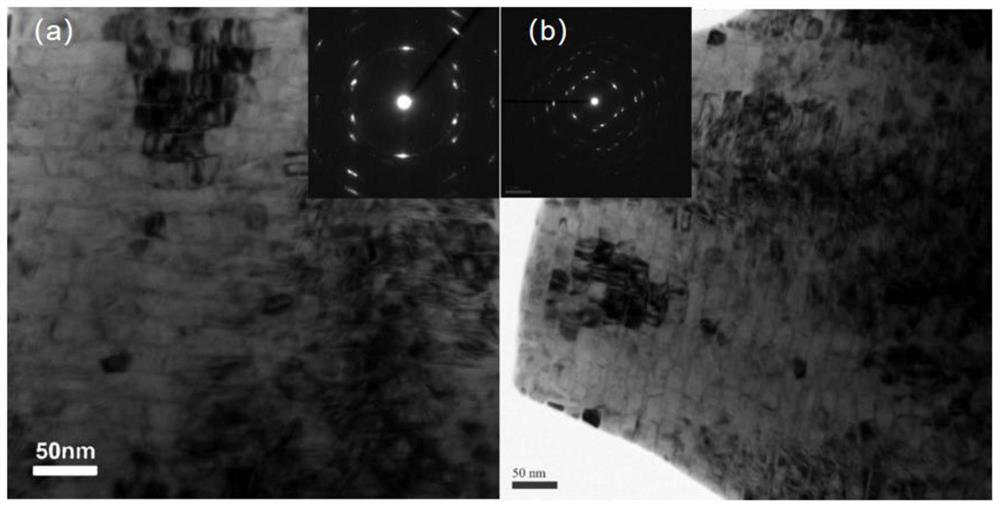

[0035] Cu-based composites with Nb interfacial layer were prepared by high-vacuum multi-chamber magnetron sputtering thin film deposition system TRP450.

[0036] Alcohol is used to pre-clean the silicon wafer, and the pre-cleaned silicon wafer is placed on the reverse sputtering target, and the pressure of argon gas is 0.4Pa, and the reverse sputtering time is 10 minutes; the reverse sputtering power is 80W.

[0037] Place the silicon wafer in the sputtering chamber, preset parameters: the argon pressure in the sputtering chamber is 0.4Pa, the sputtering temperature is 25°C, the bias voltage is -100V, and the rotation speed of the sample stage is 10r / min.

[0038]Cu and Nb two kinds of targets are sputtered alternately, the magnetron power of fixed Cu power supply is 20W, and the magnetron power of Nb power supply is 60W. Alternate growth of Cu layer and Nb layer film. The sputtering time of the Cu target is fixed at 180s, and the sputtering time of the Nb target is 10s.

[...

Embodiment 2

[0045] Cu-based composites with Nb interfacial layer were prepared by high-vacuum multi-chamber magnetron sputtering thin film deposition system TRP450.

[0046] Alcohol is used to pre-clean the silicon wafer, and the pre-cleaned silicon wafer is placed on the reverse sputtering target, and the pressure of argon gas is 0.4Pa, and the reverse sputtering time is 10 minutes; the reverse sputtering power is 80W.

[0047] Place the silicon wafer in the sputtering chamber, preset parameters: the argon pressure in the sputtering chamber is 0.4Pa, the sputtering temperature is 25°C, the bias voltage is -100V, and the rotation speed of the sample stage is 10r / min.

[0048] Cu and Nb two kinds of targets are sputtered alternately, the magnetron power of fixed Cu power supply is 20W, and the magnetron power of Nb power supply is 60W. Alternate growth of Cu layer and Nb layer film. The sputtering time of the Cu target is fixed at 180s, and the sputtering time of the Nb target is 7s.

[...

Embodiment 3

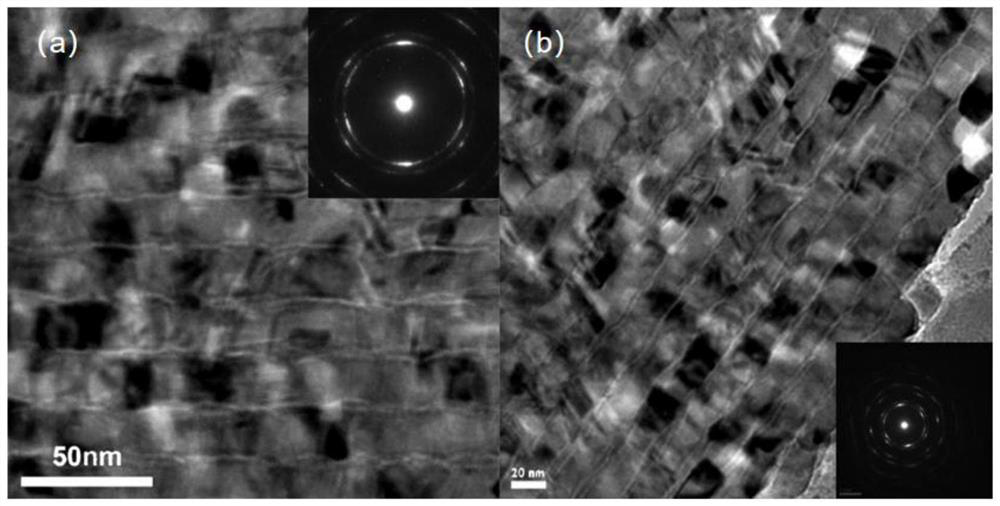

[0055] Cu-based composites with Nb interfacial layer were prepared by high-vacuum multi-chamber magnetron sputtering thin film deposition system TRP450. .

[0056] Alcohol is used to pre-clean the silicon wafer, and the pre-cleaned silicon wafer is placed on the reverse sputtering target, and the pressure of argon gas is 0.4Pa, and the reverse sputtering time is 10 minutes; the reverse sputtering power is 80W.

[0057] Place the silicon wafer in the sputtering chamber, preset parameters: the argon pressure in the sputtering chamber is 0.4Pa, the sputtering temperature is 25°C, the bias voltage is -100V, and the rotation speed of the sample stage is 10r / min.

[0058] Cu and Nb two kinds of targets are sputtered alternately, the magnetron power of fixed Cu power supply is 20W, and the magnetron power of Nb power supply is 60W. Alternate growth of Cu layer and Nb layer film. The sputtering time of the Cu target is fixed at 180s, and the sputtering time of the Nb target is 5s. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com