Preparation method of ferrite-twin-crystal martensite low-carbon steel

A technology of low-carbon steel and martensite, applied in the field of low-carbon steel preparation, can solve the problems of high toughness and plasticity, reduced toughness and plasticity, and low hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Select Q345b low-carbon steel, the weight percentage of its chemical composition is: C 0.20%, Si 0.36%, Mn0.60%, Cr 0.20%, P 0.035%, S 0.030%, the balance is Fe, heated to 940 ° C for 1 Hours, quenched by 10% sodium chloride aqueous solution to obtain lath martensite; cold rolling at room temperature, the deformation amount is 75%, to obtain deformed lath martensite; heat deformation at 700°C to achieve recrystallization; then elastic stress at 210MPa At 700°C for 40 minutes, an ultra-fine equiaxed ferrite + twin martensite structure is obtained, and there is no carbide such as cementite in the steel.

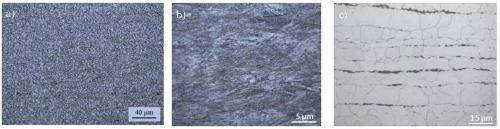

[0021] Such as figure 1 As shown, a) is the prepared ultrafine equiaxed ferrite + twinned martensite without carbide. b) is a conventional quenched martensite structure, the length of the lath bundle is the original austenite grain size, about 20.1 μm; c) is a conventional annealed ferrite + pearlite structure. The white ferrite grain size is about 19 μm, and the black...

Embodiment 2

[0030] Choose No. 15 low-carbon steel, the weight percentage of its chemical composition is: C 0.13%, Si 0.46%, Mn 0.26%, P 0.021%, S 0.025%, Cr 0.001%, Cu 0.014%, the balance is Fe, heated to Insulate at 940°C for 1 hour, quench with 10% sodium chloride aqueous solution to obtain lath martensite; cold-roll at room temperature, the deformation amount is 75%, and obtain deformed lath martensite; Under the elastic stress of 220MPa, heat preservation at 710°C for 40 minutes, an ultra-fine equiaxed ferrite + twin martensite structure is obtained, and there is no carbide such as cementite in the steel.

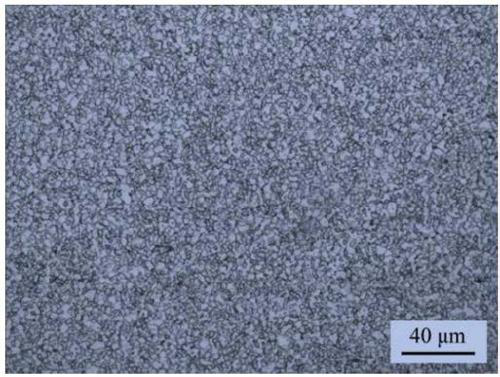

[0031] Such as Figure 6 As shown, the preparation is carbide-free ultrafine equiaxed ferrite + twinned martensite, which is an optical metallographic structure, and the polygonal grain boundary shows ultrafine equiaxed grains, and the grain size is about 2.2 μm;

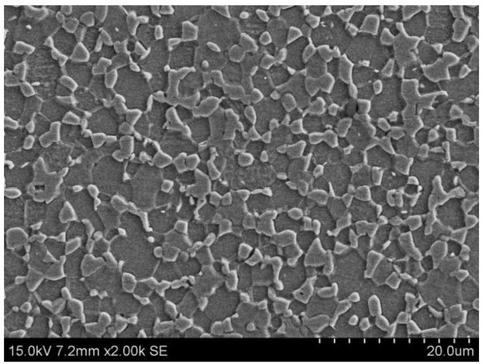

[0032] Such as Figure 7 As shown, due to the different degrees of corrosion, the ultrafine equiaxed grains show une...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com