Self-cooling cable tray with good cable gathering convenience

A cable tray and self-heating technology, applied in the direction of electrical components, etc., can solve the problems of troublesome cable detection and maintenance, easy to distinguish wiring, troublesome and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

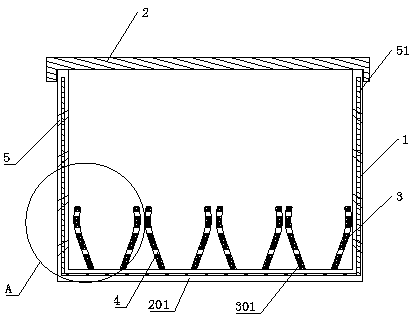

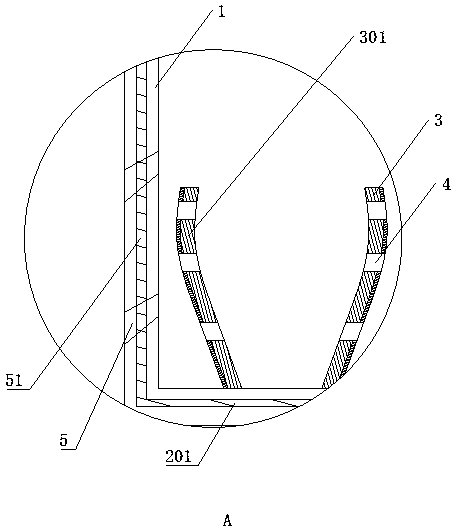

[0022] Embodiment 1: A self-heating cable tray that is convenient for gathering wires, such as figure 1 with 2 As shown, the bridge body includes a bridge body, and the bridge body includes a pair of side plates 1 and a pair of cover plates to accommodate wire chambers 6, and the wire chambers 6 are used to place cables.

[0023] The cover plate includes an upper cover plate 2 and a lower cover plate 201. On the lower cover plate 201, there are several wire binding parts groups evenly distributed along its length direction. The wire binding parts groups include several wire binding parts for binding cables. Evenly arranged along the length direction of the lower cover plate 201.

[0024] The tying parts include a set of Velcro groups that cooperate with each other. The Velcro group includes suede Velcro 3 and hook Velcro 301. One end of the suede Velcro 3 and hook Velcro 301 is fixed to the lower cover 201. connection, the other end is a free end.

[0025] Cable binding pro...

Embodiment 2

[0037] Embodiment 2: A self-heating cable tray that is convenient for gathering wires, such as figure 1 with 2 As shown, the bridge body includes a bridge body, and the bridge body includes a pair of side plates 1 and a pair of cover plates to accommodate wire chambers 6, and the wire chambers 6 are used to place cables.

[0038] The cover plate includes an upper cover plate 2 and a lower cover plate 201. On the lower cover plate 201, there are several wire binding parts groups evenly distributed along its length direction. The wire binding parts groups include several wire binding parts for binding cables. Evenly arranged along the length direction of the lower cover plate 201.

[0039] The tying parts include a set of Velcro groups that cooperate with each other. The Velcro group includes suede Velcro 3 and hook Velcro 301. One end of the suede Velcro 3 and hook Velcro 301 is fixed to the lower cover 201. connection, the other end is a free end.

[0040] Cable binding pro...

Embodiment 3

[0052] Embodiment 3: A self-heating cable tray that is convenient for gathering wires, such as figure 1 with 2 As shown, the bridge body includes a bridge body, and the bridge body includes a pair of side plates 1 and a pair of cover plates to accommodate wire chambers 6, and the wire chambers 6 are used to place cables.

[0053] The cover plate includes an upper cover plate 2 and a lower cover plate 201. On the lower cover plate 201, there are several wire binding parts groups evenly distributed along its length direction. The wire binding parts groups include several wire binding parts for binding cables. Evenly arranged along the length direction of the lower cover plate 201.

[0054] The tying parts include a set of Velcro groups that cooperate with each other. The Velcro group includes suede Velcro 3 and hook Velcro 301. One end of the suede Velcro 3 and hook Velcro 301 is fixed to the lower cover 201. connection, the other end is a free end.

[0055] Cable binding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com