Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "High degree of removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrolysis denitrification denitrification system and method

InactiveCN102276061AHigh degree of removalImprove biodegradabilityTreatment with aerobic and anaerobic processesChemistryOxidation ditch

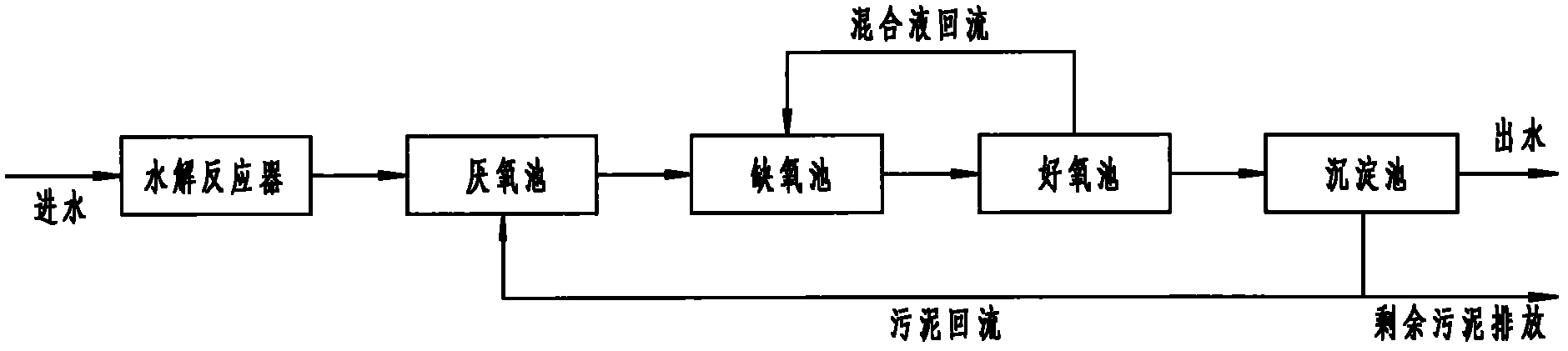

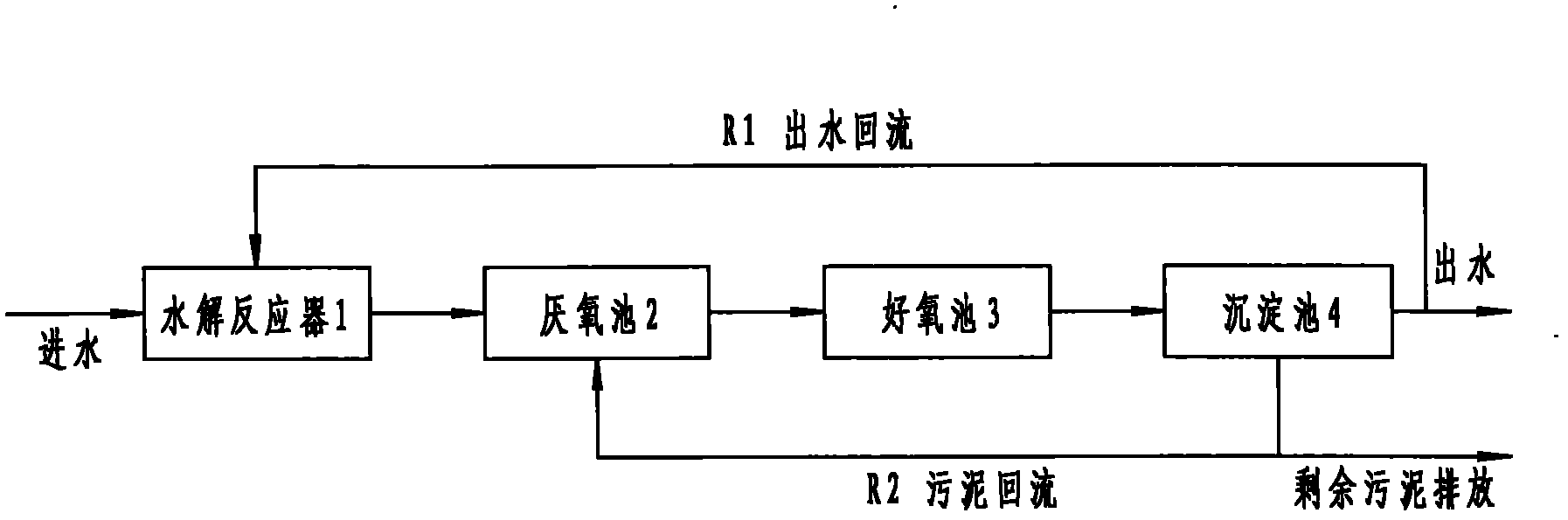

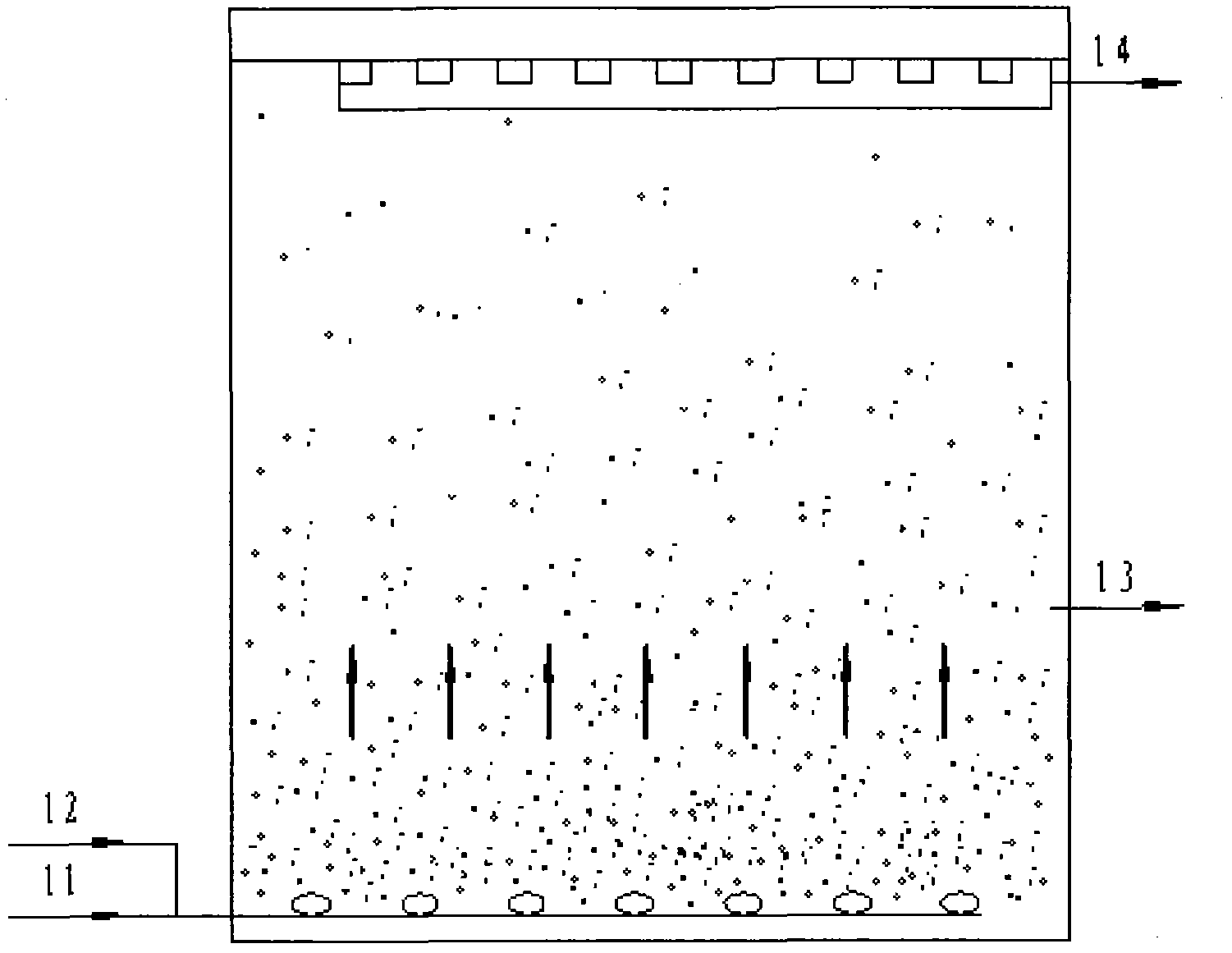

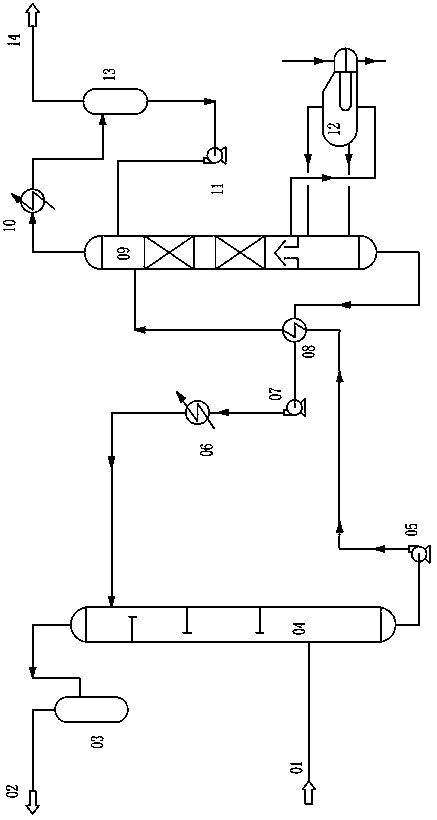

A hydrolysis denitrification denitrification system and method. The system replaces the traditional anoxic tank with an upflow sludge bed hydrolysis reactor. The hydrolysis reactor includes: an effluent return channel, which is arranged between the sedimentation tank and the hydrolysis reactor, so that the discharged water from the sedimentation tank contains The nitrate supernatant is used as reflux to flow back into the hydrolysis reactor for hydrolysis, denitrification and denitrification. In the present invention, the hydrolysis reactor is used as the functional area of pre-denitrification denitrification, and the good anaerobic environment in the hydrolysis reactor, the rapid recovery ability of the denitrification bacteria function and the sufficient supply capacity of organic matter are used to realize efficient and stable hydrolysis reaction. Nitrification and denitrification. The invention makes full use of the carbon source in the sewage, improves the denitrification efficiency, and reduces the energy consumption of the whole sewage treatment process. The invention can be combined with common urban sewage treatment processes such as AAO and oxidation ditch, and is convenient for upgrading and reforming existing facilities of sewage treatment plants.

Owner:贾立敏 +7

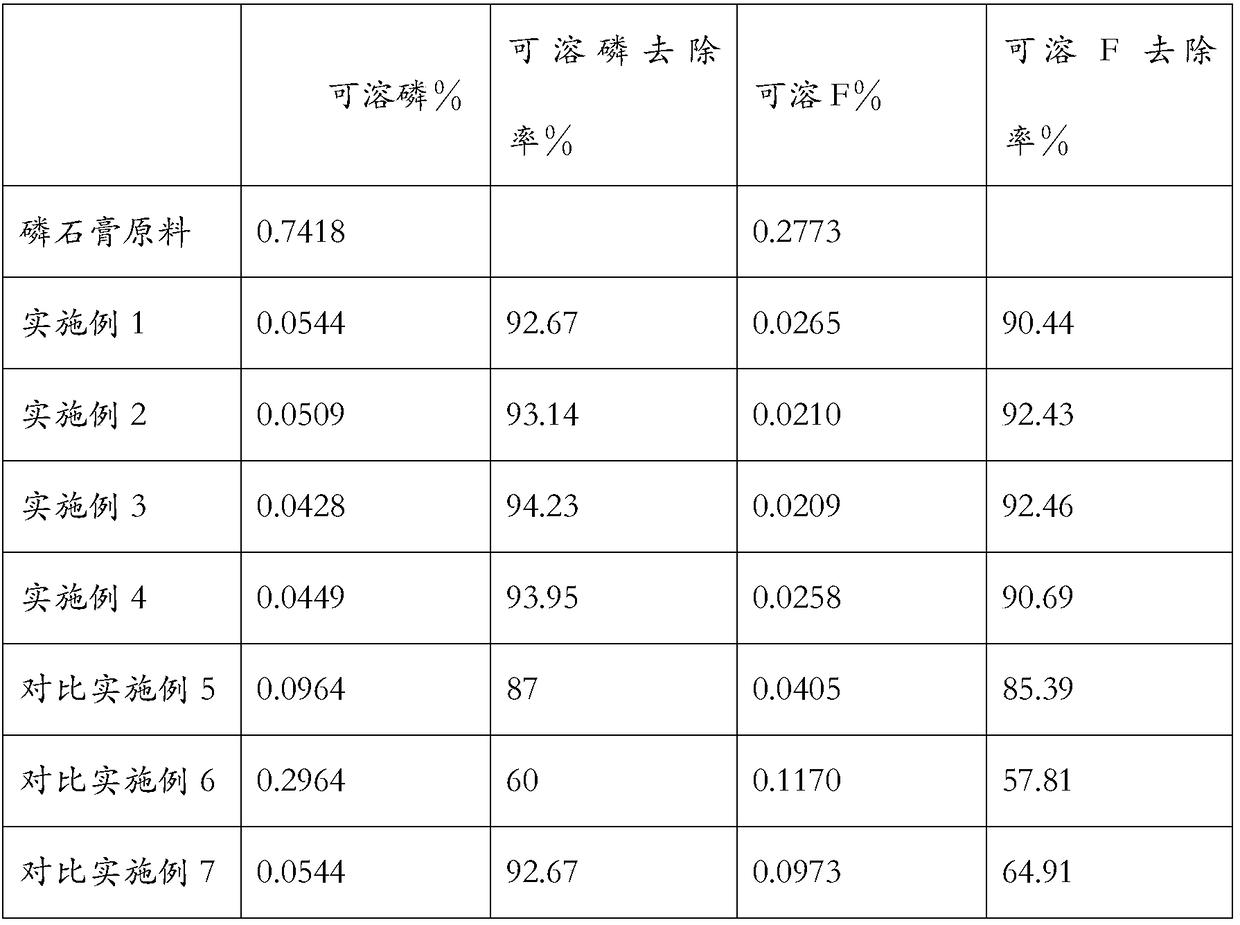

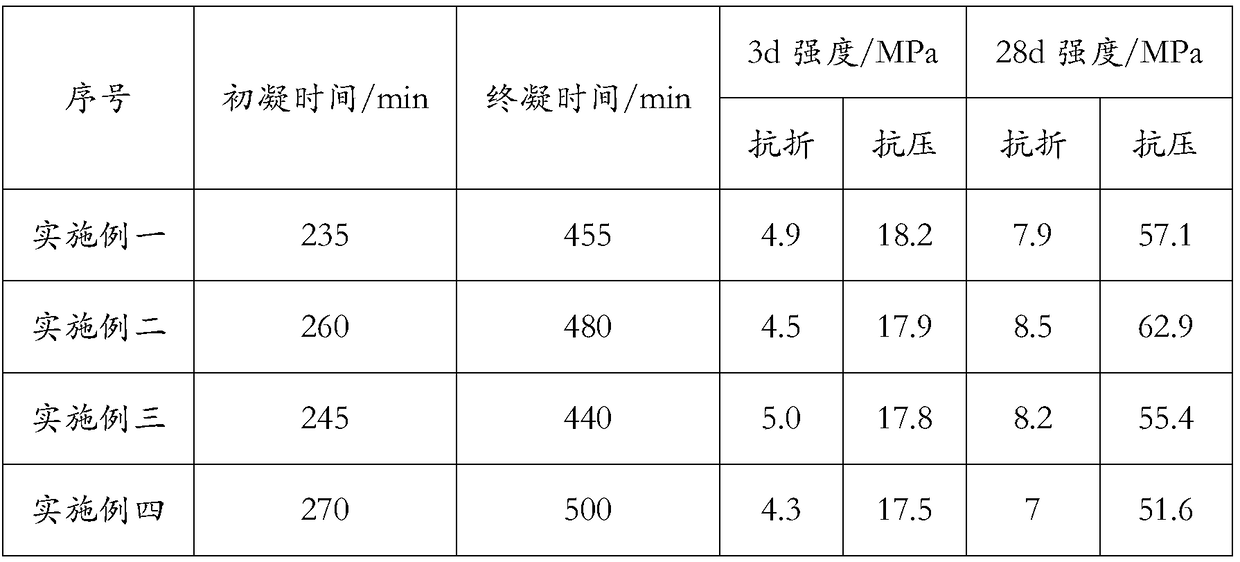

Ardealite supersulfated cement and preparation method thereof

The invention discloses an ardealite supersulfated cement and a preparation method thereof. The ardealite supersulfated cement disclosed by the invention contains the following components by weight percent: 50%-80% of superfine slag powder, 10%-40% of modified ardealite, 0%-10% of mineral admixture, 1%-8% of alkaline excitant and 0.1%-0.5% of early strength agent. The preparation method disclosedby the invention comprises the following steps: (1) modifying ardealite: neutralizing by doping calcium hydroxide or calcium carbonate into ardealite, performing high-temperature calcinations on the neutralized ardealite, cooling and then milling till the specific area is not less than 400m2 / kg, thereby acquiring the modified ardealite; (2) mixing superfine slag powder, modified ardealite, mineraladmixture, alkaline excitant and early strength agent in parts by weight, and then uniformly stirring, thereby acquiring the ardealite supersulfated cement. According to the preparation method disclosed by the invention, the influence of harmful elements in ardealite can be effectively eliminated and the ardealite is fully utilized.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

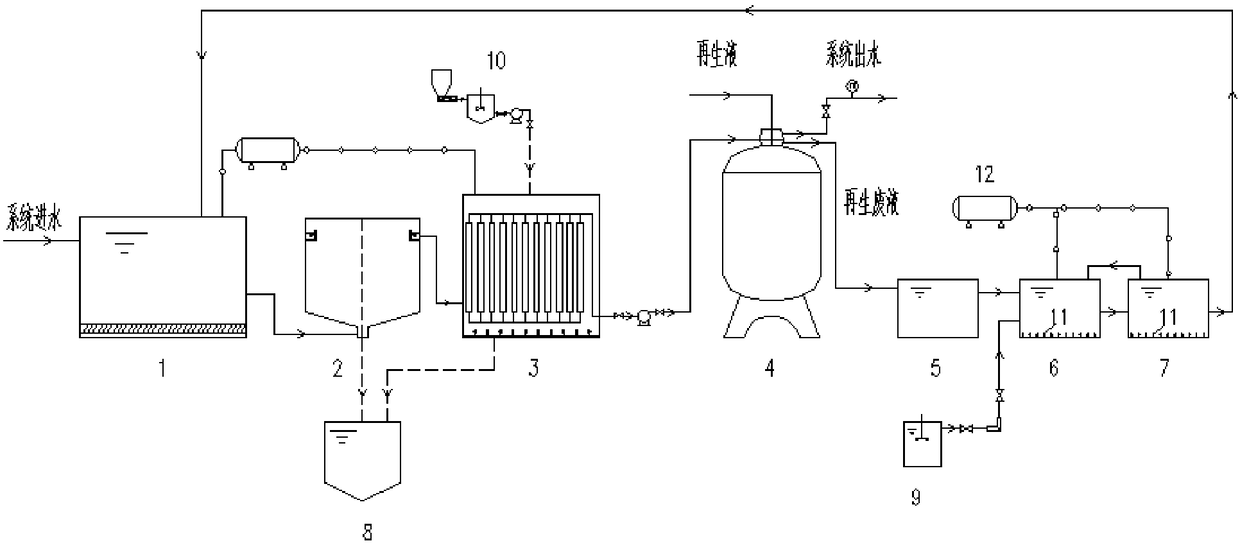

System and method for deeply treating sewage and recycling resin regeneration waste liquid

PendingCN108341556AMature technologySimple technologyWater contaminantsMultistage water/sewage treatmentLiquid wasteActivated sludge

The invention discloses a system and a method for deeply treating sewage and recycling resin regeneration waste liquid. The system comprises a biochemical pool, a settling pond, a powder activated carbon membrane biological reactor, a resin tank, a waste liquid collecting pool, a denitrification pool, a nitration pool and a sludge concentration pool. The method is characterized in that the incoming water of a sewage treatment plant is pre-treated and then enters the biochemical pool, thus the CODcr can be degraded under the effect of activated sludge; supernate flows into the powder activatedcarbon membrane biological reactor after settling, and thus pollutants can be further adsorbed through the powder activated carbon; chroma, suspension substances and CODcr are removed by interceptingthrough a membrane assembly; the water drained by the membrane is fed into the resin tank, and nitrate in the sewage can be removed under the adsorption effect of special nitrate ion exchange resin, and the clean water is directly drained; the resin regeneration waste liquid flows into the waste liquid collecting pool and is then fed into the denitrification pool for denitrification; the water subjected to denitrification flows into the nitration pool for nitration, thus ammonia nitrogen can be reduced, and CODcr can be degraded; the liquid subjected to nitration flows back to the denitrification pool; and the water drained by the nitration pool flows back to the biochemical pool at the front end, thus realizing the recycling of the resin regeneration waste liquid.

Owner:HUBEI JUNJI WATER TREATMENT

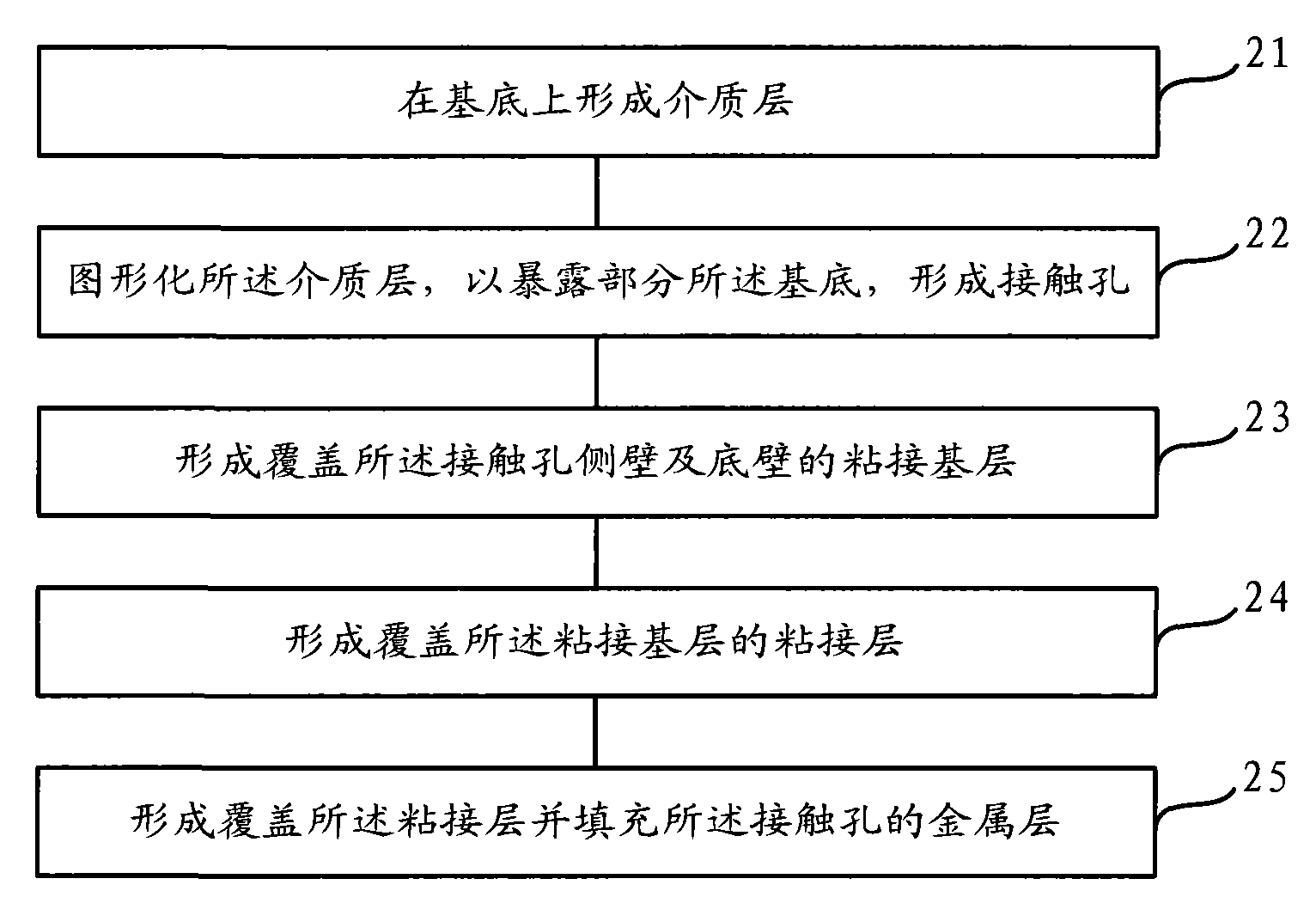

Method for forming via

ActiveCN101593723AReduce contact resistanceReduce damageSemiconductor/solid-state device manufacturingSemiconductor devicesComposite materialContact hole

A method for forming via comprises the following steps: forming a medium layer on a substrate; imaging the medium layer and forming a contact hole; forming an adhesive substratum covering the side wall and bottom wall of the contact hole; forming a first adhesive layer undergoing inorganic operation on the adhesive substratum; forming a second adhesive layer undergoing inorganic operation on the first adhesive layer; forming a metal layer covering the second adhesive layer and filling the contact hole. The method can reduce the contact resistance of the devices containing the via.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

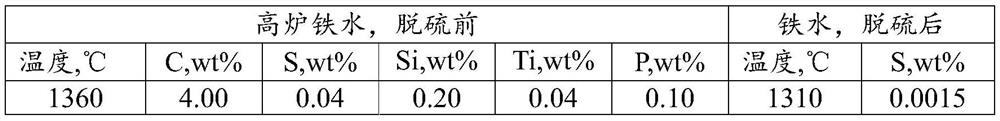

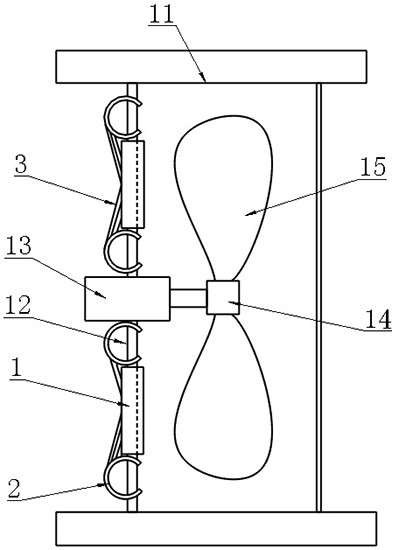

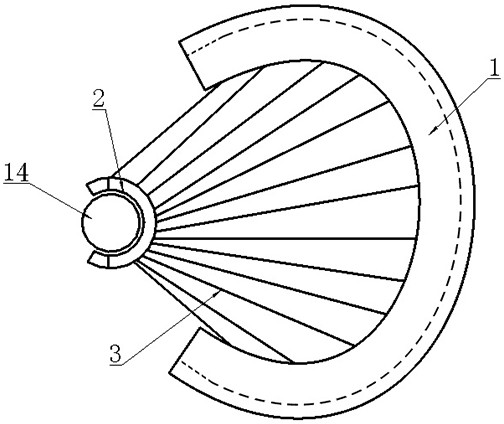

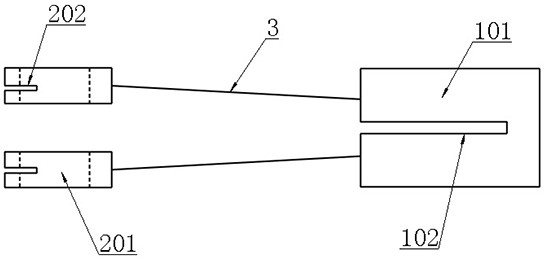

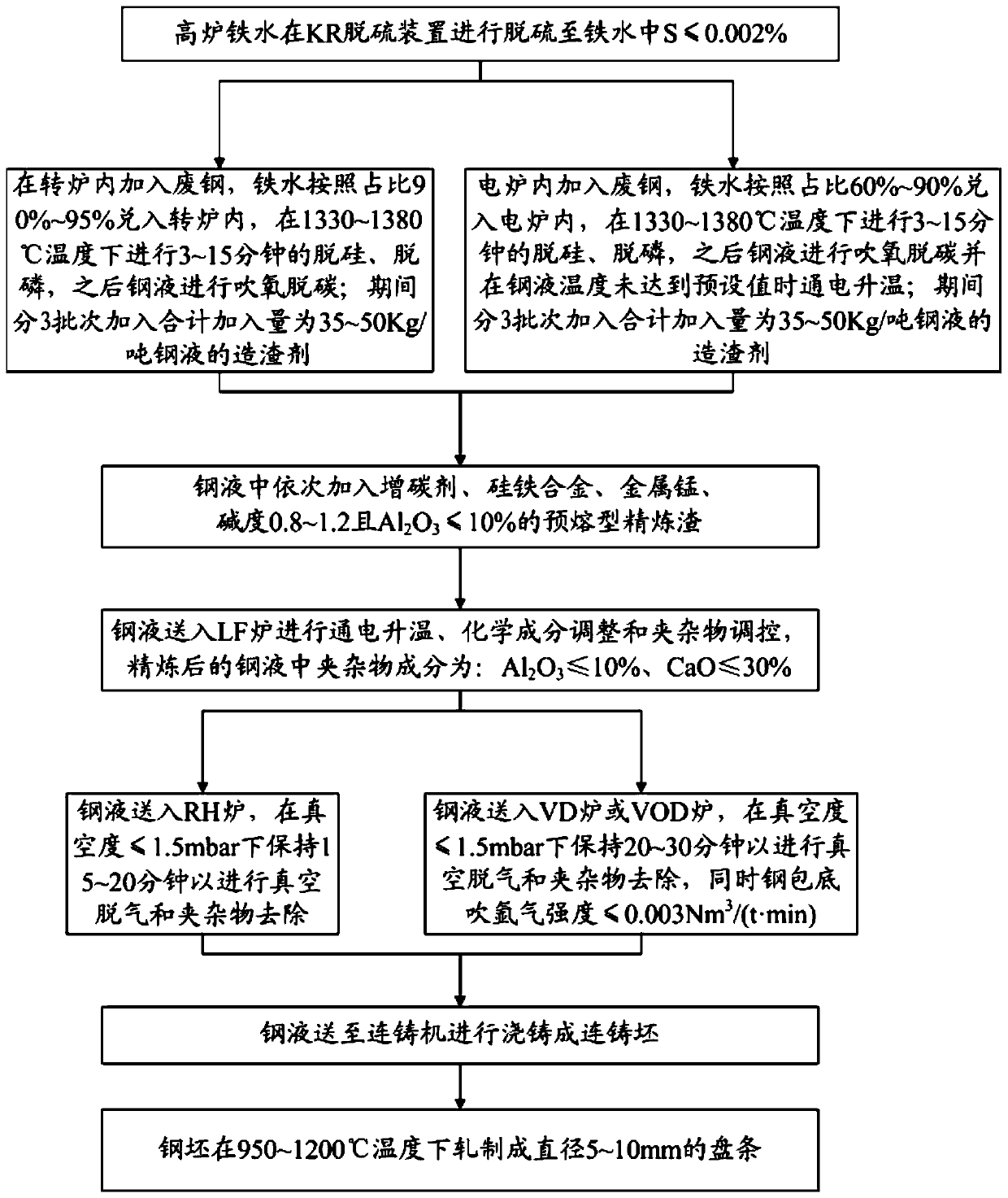

Sawing wire, steel for sawing wire, and production method thereof

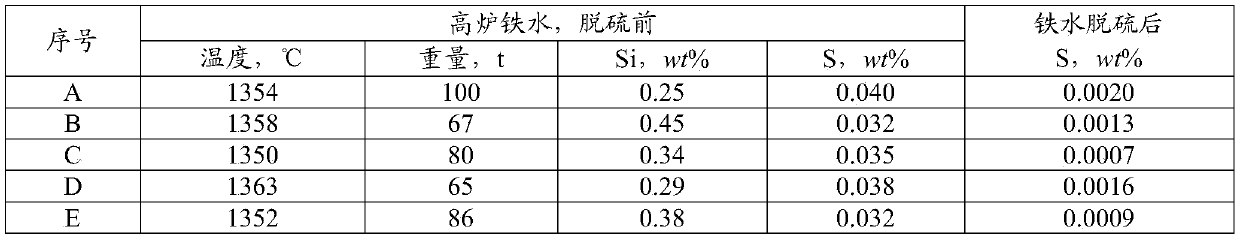

ActiveCN110117748AEasy to controlHigh degree of removalManufacturing convertersProcess efficiency improvementMolten steelOxygen

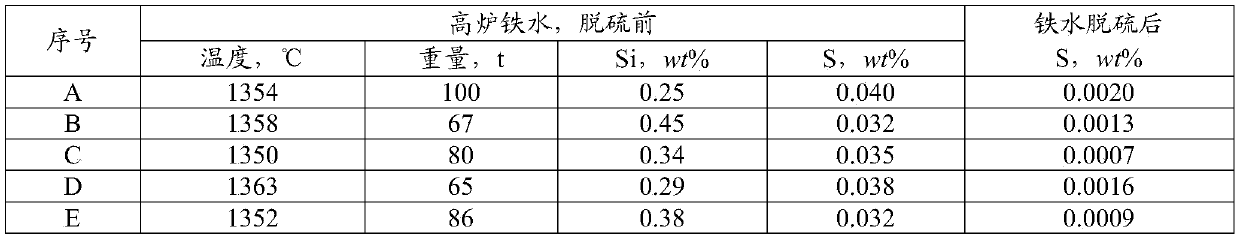

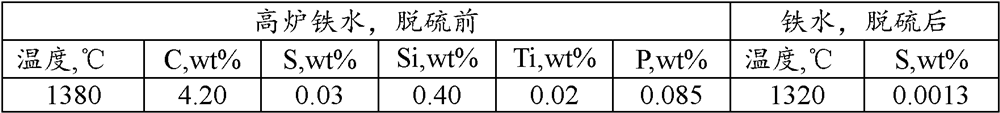

The invention discloses a sawing wire, steel for the sawing wire, and a production method thereof. The production method comprises the steps of desulfurizing molten iron till S in the molten iron is no more than 0.002%; mixing the desulfurized molten iron and steel scrap into molten steel, and desiliconizing and dephosphorizing the molten steel at 1330 DEG C-1380 DEG C; then, decarburizing the molten steel by blowing oxygen, and obtaining the molten steel comprising no less than 0.3% of C, no more than 0.01% of P and no more than 0.01% of S, wherein the temperature of the molten steel is no lower than 1650 DEG C; adding desoxidants and slagging media to the molten steel for deoxidation alloying; then, refining the molten steel for regulating chemical components and inclusions, wherein thecomponents of the inclusions comprise no more than 10% of Al2O3 and no more than 30% of CaO; degassing the refined molten steel and removing the inclusions to obtain the molten steel, wherein the sizeof the inclusions of the molten steel is no more than 10 [mu]m, and the number density of the inclusions is no more than 0.5 g / m<3>; and casting the molten steel into steel billets. The steel, prepared with the production method, for the sawing wire can be used as base metal for producing the sawing wire with the diameter of no more than 100 <mu>m and the tensile strength of no lower than 4600 MPa; and the length of the continuous wire in the process of manufacturing the sawing wire is no less than 200 km.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Method of removing astringent tastes of peanut skins

ActiveCN106107421APreserve nutrition and health care and medicinal functionsExpand the scope of applicationFood scienceEnzymePre treatment

The present invention discloses a method of removing astringent tastes of peanut skins. The method comprises the following steps: the peanut skins are soaked using water, the soaked peanut skins are subjected to a microwave pretreatment, tannase is added, then zinc lactate and calcium lactate are added, the mixture is subjected to a microwave assisted enzymatic treatment, the treated mixture is filtered, and the filtered mixture is centrifuged to remove the astringent tastes of the peanut skins to obtain a peanut skin extract free of the astringent tastes. The present invention provides the high-efficient peanut skin astringent taste removing method. The method is good in astringent taste removing effects, at the same time can obtain the peanut skin extract free of the astringent tastes and rich in proanthocyanidin, and can widen the application of the peanut skins in food. The prepared astringent taste removing peanut skins can be applied in the food industry of health-care products, peanut drink, peanut ice cream, peanut milk tea, etc.

Owner:张初署 +1

Method for promoting removal of COS and CS2 in natural gas

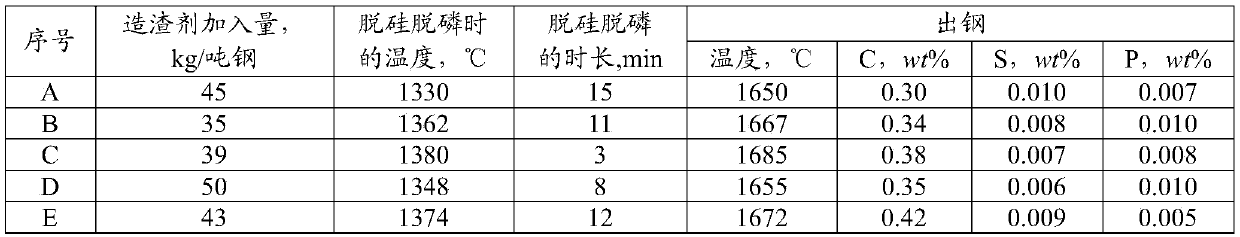

InactiveCN108993133AImprove the degree of removalReduce total sulfurDispersed particle separationGaseous fuelsCatalytic hydrolysisHigh absorption

In the invention, a hydrolysis catalysis section is added in the middle of a common absorption tower commonly used in an alcohol-amine method, i.e. the one hydrolysis catalysis section is added nearbythe position with higher absorption temperature, a catalytic hydrolysis section is filled with100-300 mm of a hydrolysis catalyst of COS and CS2, and the catalytic hydrolysis is accelerated by utilizing the heat of an absorption reaction, so that the removal degree of COS and CS2 is increased to 70%-80% under the normal condition and is nearly increased twice when being compared with the traditional manner, and the bottleneck that the load of an absorption device cannot be increased due to lower removal degree of COS and CS2 and higher total sulfur is removed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving removal rate of COS and CS2 in natural gas

InactiveCN111876210AHigh degree of removalReduce total sulfurGas treatmentGaseous fuelsPtru catalystAlcohol

The invention belongs to the technical field of gas purification, and aims to provide an improved process for solving the problem that the traditional COS and CS2 catalytic hydrolysis process flow isinconvenient to adopt under the conditions that the removal degree of COS and CS2 is low and the total sulfur content is high in alcohol amine method natural gas purification. In the method, COS and CS2 hydrolysis catalysts are used for modifying a tower plate or filler in a deposition-impregnation or coating mode, wherein the modified tower plate or filler replaces a conventional tower plate or filler, so that the removal degree of COS and CS2 is improved to 80% or above and is nearly one time higher than that of the traditional tower plate or packing; therefore, a good COS and CS2 technicaleffect is achieved. The method provided by the invention is very convenient for technical transformation of high total sulfur and influence on product quality caused by low removal degree of COS and CS2 in the existing alcohol amine method device.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

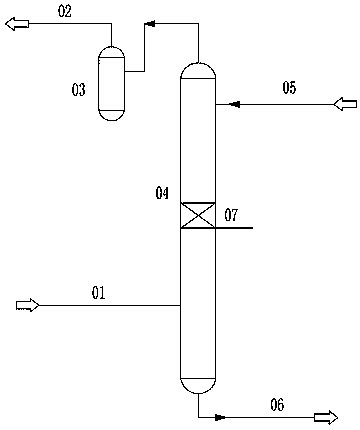

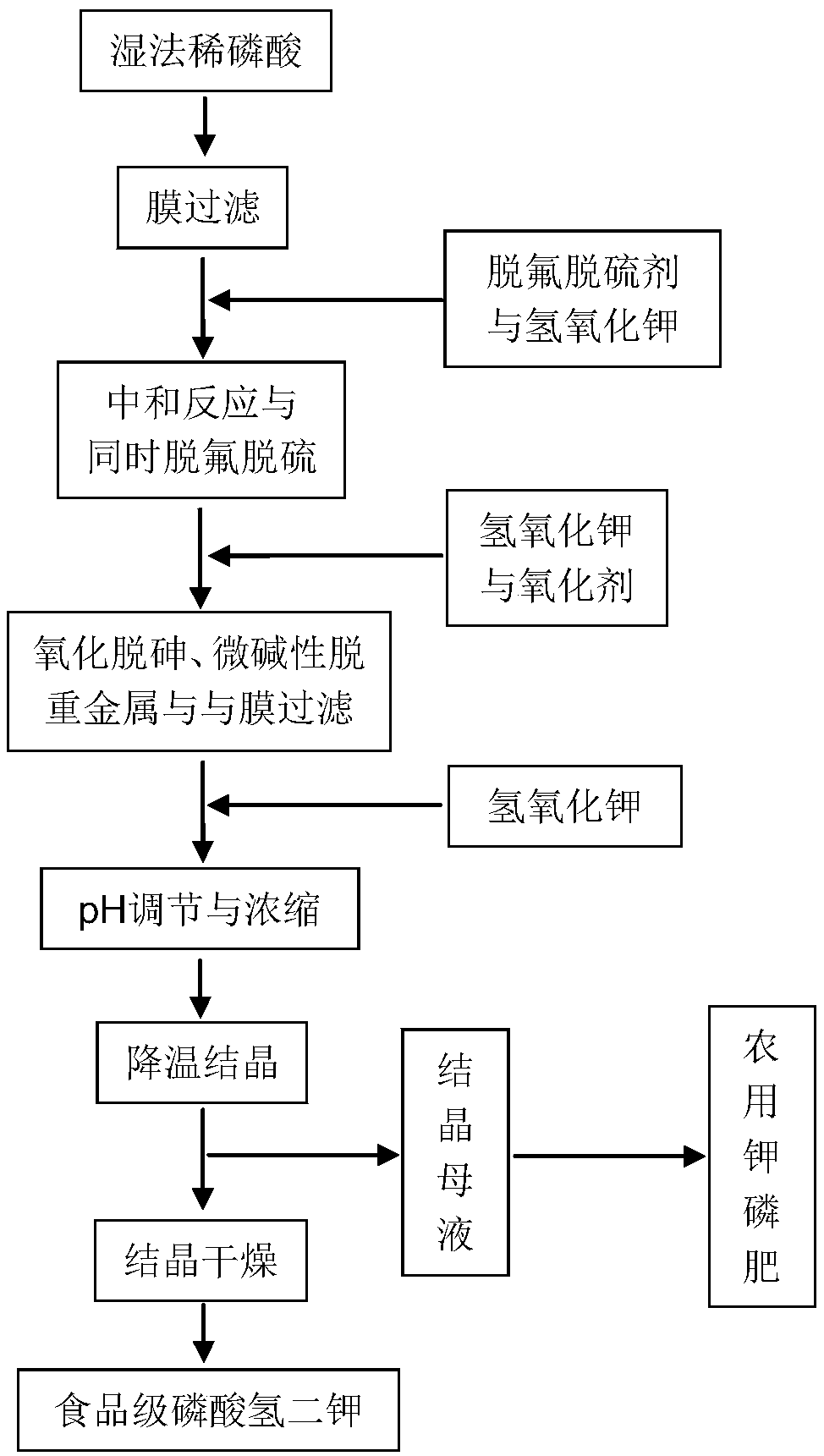

Method for producing food-grade disodium hydrogen phosphate by using wet-process dilute phosphoric acid

The invention discloses a method for producing food-grade disodium hydrogen phosphate by using wet-process dilute phosphoric acid. The method comprises the steps as follows: (1) membrane filtration: placing wet-process dilute phosphoric acid in an acid-resistant container, and filtering the wet-process dilute phosphoric acid by membrane filtration equipment to obtain purified wet-process dilute phosphoric acid; (2) neutralization reaction and simultaneous defluorination and desulfurization: placing the dilute phosphoric acid in an acid-resistant container, adding a defluorination and desulfurization agent and a potassium hydroxide solution, and carrying out stirring to obtain a neutralization solution; (3) oxidative arsenic removal, slightly alkaline heavy metal removal and membrane filtration: carrying out stirring, adding an oxidizing agent, adjusting the pH value to slight alkalinity, and carrying out heating, cooling and membrane filtration to obtain alkaline heavy metal removal and oxidative arsenic removal solution; (4) pH regulation and concentration: adjusting the pH of the slightly alkaline heavy metal removal and oxidative arsenic removal solution to obtain a disodium hydrogen phosphate concentrated solution; (5) cooling crystallization: transferring the disodium hydrogen phosphate concentrated solution in equipment, decreasing the temperature, and continuing crystallization; and (6) crystallization and drying. The method is easy to implement, simple and convenient to operate, low in cost and high in purity, arsenic and heavy metal ions are fully removed, the solubility property is good and mechanization can be realized.

Owner:HUBEI UNIV OF TECH

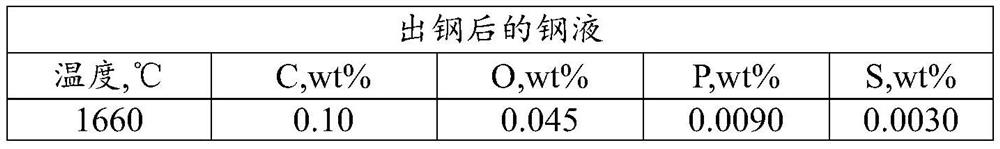

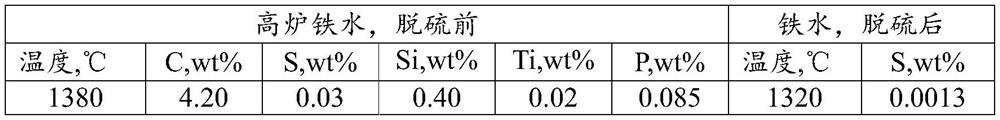

High-cleanliness spring steel and production method thereof

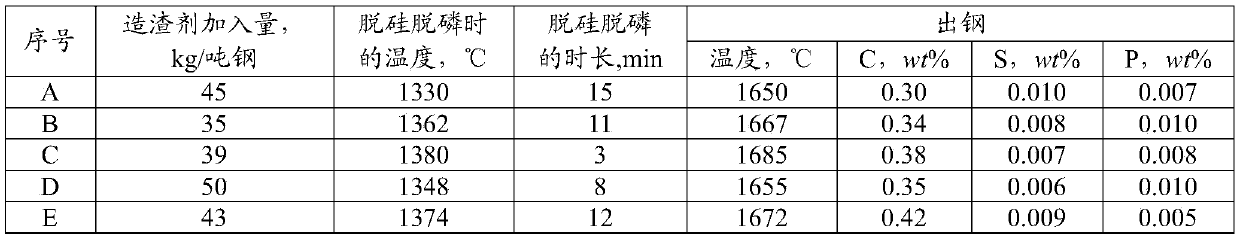

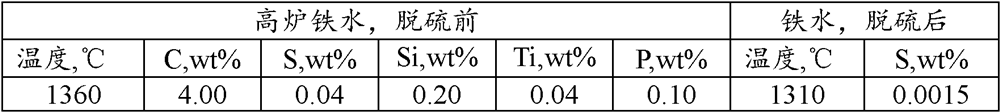

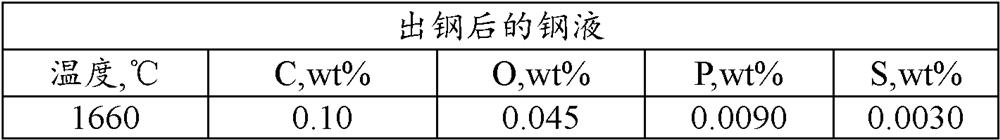

ActiveCN113061799ASmall sizeImprove purityManufacturing convertersProcess efficiency improvementSlagMolten steel

The invention discloses high-cleanliness spring steel and a production method thereof. The production method comprises the following steps: pretreatment: desulfurizing molten iron until the content of S in the molten iron is less than or equal to 0.0015%; mixing the molten iron and waste steel into molten steel, carrying out desiliconization, dephosphorization and oxygen blowing decarburization, obtaining the molten steel with the temperature of 111011110 DEG C, the C content of 0.1010.15%, the O content of smaller than or equal to 0.045%, the P content of smaller than or equal to 0.011% and the S content of 0.00110.008%, carrying out slag stopping tapping, carrying out deoxidation alloying, and the flow of argon blowing at the bottom of a steel ladle during tapping and the flow of argon blowing at the bottom of the steel ladle after tapping are 80011000 NL / min and 1001200 NL / min respectively; refining the molten steel to adjust chemical components and inclusions, and the flow rates of the argon blowing at the bottom of the steel ladle are respectively 1001500 NL / min, 2001100 NL / min and 501100 NL / min in other time when slag charge adding and alloying treatment are carried out and the temperature is increased by electrifying; then carrying out vacuum refining and vacuum breaking soft stirring in sequence, and the flow of the argon blowing at the bottom of the steel ladle is 20150 NL / min and 501100 NL / min; and casting into a steel billet. In the high-cleanliness spring steel prepared through the production method, the density of inclusions with the size larger than 5 micrometers is smaller than or equal to 0.5pcs / mm < 2 >, the length-width product of the maximum inclusions is smaller than or equal to 900 micrometers < 2 >, and the high-cleanliness spring steel has high cleanliness.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

Rice processing method for removing impurities efficiently

InactiveCN109046521AHigh bonding strengthHigh degree of removalGrain millingSodium bicarbonateFiltration

The invention discloses a rice processing method for removing impurities efficiently. The method comprises the steps that coal gangue and water are mixed, concentrated nitric acid is added in a stirring state, stirring is carried out during boiling, filtration, washing and solid drying are carried out, a sodium hydroxide solution is added, stirring, filtration, washing and drying are carried out,P-aminophenyl trimethoxysilane, sodium dodecyl benzene sulfonate and water are added to be mixed evenly, the system pH value is adjusted to be 4-5, the temperature is adjusted, stirring, filtration, washing, drying and calcination are carried out, and a first material is obtained; sodium bicarbonate and water are stirred, impurity-removed unhulled rice is added in a stirring state, and stirring continues to be carried out to obtain a second material; the second material is dried and added into the first material to be mixed evenly, the mixture is fed into a rice huller for hulling, the distance of rubber rollers of the rice huller is 0.8-1.2mm, coarse rice is separated from unhulled rice through a rice-hull separation machine, and hulling, whitening and polishing are carried out.

Owner:怀宁县佳禾米业有限公司

Method for producing food-grade sodium dihydrogen phosphate by using wet-process dilute phosphoric acid

The invention discloses a method for producing food-grade sodium dihydrogen phosphate by using wet-process dilute phosphoric acid. The method comprises the steps as follows: (1) membrane filtration: carrying out filtration by membrane filtration equipment; (2) neutralization reaction and defluorination and desulfuration: taking purified wet-process dilute phosphoric acid in an acid-resistant container, adding a defluorination and desulfuration agent and a potassium hydroxide solution, carrying out stirring and membrane filtration to obtain a neutralization solution; (3) oxidation arsenic removal, slightly alkaline heavy metal removal and membrane filtration: adding an oxidizing agent to the neutralization solution, adjusting pH to slight alkalinity, and carrying out heating, cooling and membrane filtration to obtain a slightly alkaline heavy metal removal and oxidation arsenic removal solution; (4) pH regulation and concentration: regulating pH of the slightly alkaline heavy metal removal and oxidation arsenic removal solution with phosphoric acid, and performing concentration to obtain a sodium dihydrogen phosphate concentrated solution; (5) cooling crystallization: transferring the concentrated solution in crystallization equipment, and crystallizing the sodium dihydrogen phosphate at crystallization metastable zone temperature of sodium dihydrogen phosphate until no crystalsare produced; and (6) crystallization and drying. The method is easy to implement, low in cost, high in purity, high in utilization rate of raw materials, good in solubility property and prone to mechanization.

Owner:HUBEI UNIV OF TECH

System and method for modification treatment and recycling of produced water in oil and gas field

PendingCN110316863AHigh degree of removalMature technologyWaste water treatment from quariesTreatment involving filtrationProduced waterWater treatment

The invention relates to the technical field of treatment of produced water of oil and gas fields, in particular to a system and method for modification treatment and recycling of produced water in anoil and gas field. The system for modification treatment and recycling of the produced water in the oil and gas field is provided with a sedimentation pool, a pH regulating pool, a first-stage filtering tank, a second-stage filtering tank, a resin tank and a clean water regulating pool which are all sequentially communicated with one another along the water treatment process; the second-stage filtering tank is communicated with the clean water regulating pool; a supernatant of the sedimentation pool is discharged into the pH regulating pool; outflow water of the pH regulating pool is sequentially discharged into the first-stage filtering tank and the second-stage filtering tank; outflow water of the second-stage filtering tank is discharged into the resin tank; outflow water of the resintank and the outflow water of the second-stage filtering tank are mixed in certain proportion, and the outflow water is sent to the clean water regulating pool for recycling. The system for modification treatment and recycling of the produced water in the oil and gas field has the advantages that various scaling cation removal processes are combined to treat the produced water in the oil and gas field, and the problems are effectively solved that in actual engineering, when produced water is conveyed by pipelines, the pipelines are blocked due to self-scaling, and the produced water cannot bere-injected for recycling.

Owner:HUBEI JUNJI WATER TREATMENT

Method for manufacturing food-grade dipotassium hydrogen phosphate by using wet-process dilute phosphoric acid

InactiveCN110817823AIncrease profitFully removedPhosphorus compoundsDipotassium hydrogen phosphateO-Phosphoric Acid

The invention discloses a method for manufacturing food-grade dipotassium hydrogen phosphate by using wet-process dilute phosphoric acid. The steps are as follows: (1) performing membrane filtration:taking the wet-process dilute phosphoric acid into an acid-resistant container, and performing precision-filtering with membrane filtration equipment to obtain purified wet-process dilute phosphoric acid; (2) carrying out a neutralization reaction and performing simultaneous defluorination and desulfurization: adding a defluorination and desulfurization agent and a potassium hydroxide solution, performing stirring and filtering to obtain a filtered neutralization solution; (3) performing arsenic removal by oxidation, heavy metal removal under slightly alkaline conditions, and membrane filtration: adding an oxidant into the filtered neutralization solution, adjusting the pH value to slightly alkaline, performing heating, cooling and membrane filtration to obtain a solution after arsenic removal by oxidation, and heavy metal removal under slightly alkaline conditions; (4) performing pH adjustment and concentration: adjusting the pH value of the solution after arsenic removal by oxidation, and heavy metal removal under slightly alkaline conditions, and performing concentration to obtain a concentrated solution of dipotassium hydrogen phosphate; (5) performing cooling crystallization:crystallizing dipotassium hydrogen phosphate in the temperature range of a dipotassium hydrogen phosphate crystallization metastable zone, and then performing continue crystallization until no crystallization occurs; and (6) drying crystals. According to the method, the cost is low, the purity is high, hygiene and safety are high, the method is easy to implement, the operation is simple and convenient, the raw material utilization rate is high, the dissolving performance is good, and mechanization can be realized.

Owner:HUBEI UNIV OF TECH

Method for extracting stevioside from stevia rebaudiana

InactiveCN108047286AHigh purityIncrease the maximum leaching capacitySugar derivativesSugar derivatives preparationWater bathsSilica gel

The invention discloses a method for extracting stevioside from stevia rebaudiana. The method comprises the following steps: crushing dry leaves of stevia rebaudiana, adding water for soaking, addingcellulase for enzymolysis, and adjusting the pH value of the system to 5.6-6.5, and performing heating extraction, cooling, settling centrifugation and filtering to obtain an extract solution; heatingthe extract solution in a water bath, adding a flocculant, stirring the mixture uniformly, and adjusting the pH value of the system to 7.5-8.2, performing flocculating, centrifugally settling and filtering, adding a composite adsorbent, performing boiling in a normal pressure reflux state, and performing filtering and concentrating to obtain a concentrated solution; treating the concentrated solution on a silica gel chromatography column, performing eluting with a mixed solvent, collecting fractions, and performing vacuum concentrating and vacuum drying to obtain stevioside. The method has the advantages of simple process, low cost and high operability, and is suitable for factory production, the residual quantity of an organic solvent is quite low, obtained stevioside is white or off-white powder, and the purity and yield are high.

Owner:BENGBU HUADONG BIOLOGICAL TECH

Method for reducing sulfur content in sulfur recovery device tail gas

InactiveCN108568191AHigh degree of removalImprove the co-absorption rateGas treatmentDispersed particle separationInorganic sulfideChemistry

The invention belongs to the technical field of waste gas pollutant control. In the prior art, the environmental protection management on the tail gas discharge sulfides of the Claus sulfur recovery device is increasingly strict, and the treatment of H2S, COS and other sulfides in Claus tail gas by using the absorption method has disadvantages. Based on the problems in the prior art, the inventionprovides a new solution scheme. According to the present invention, by adopting the functional absorption liquid and the preferred process parameters, the absorbent and the method capable of improving the removal degree of H2S and other sulfides, reducing the CO2 co-adsorption rate and improving the H2S concentration in the regeneration acid gas in the case of no change of the original pressure of the tail gas, ie., under the low pressure, can be provided while the treatment load of the device can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stevioside extraction and purification method

InactiveCN107936071AHigh purityIncrease the maximum leaching capacitySugar derivativesSugar derivatives preparationWater bathsPurification methods

The invention discloses a stevioside extraction and purification method, which comprises the following steps of crushing stevia rebaudiana dry leaves; adding water for soaking; adding cellulase for enzymolysis so as to obtain enzymolysis liquid; regulating the pH value of the enzymolysis liquid to be 5.6 to 6.5; raising the temperature for digestion; performing cooling, sedimentation centrifugation and filtering to obtain digestion liquid; uniformly mixing jute stalks, zeolite, palygorskite, rectorite and bentonite; performing roasting; lowering the temperature; performing crushing; adding water for mixed milling; performing spray drying to obtain composite adsorbents; performing water bath heating on the digestion liquid; adding flocculating agents; performing uniform stirring; regulatingthe system pH value to be 7.5 to 8.2; performing flocculating treatment, centrifugal sedimentation and filtering; adding composite adsorbents; performing boiling in a normal pressure backflow state;performing filtering and concentration to obtain concentration liquid; feeding the concentration liquid onto a silica gel chromatography column; then, performing elution by a mixed solvent; collectingfractions; performing vacuum concentration and vacuum drying to obtain the stevioside.

Owner:BENGBU HUADONG BIOLOGICAL TECH

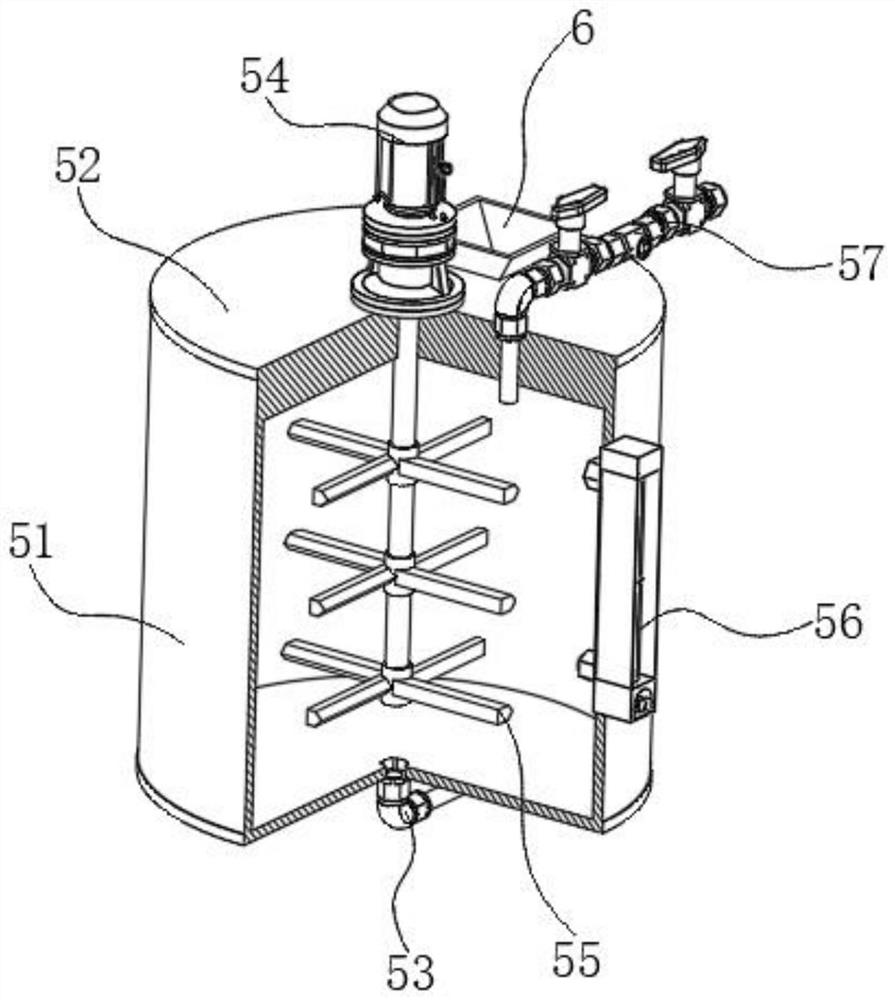

Calcium removing equipment and process in cobalt wet metallurgy process

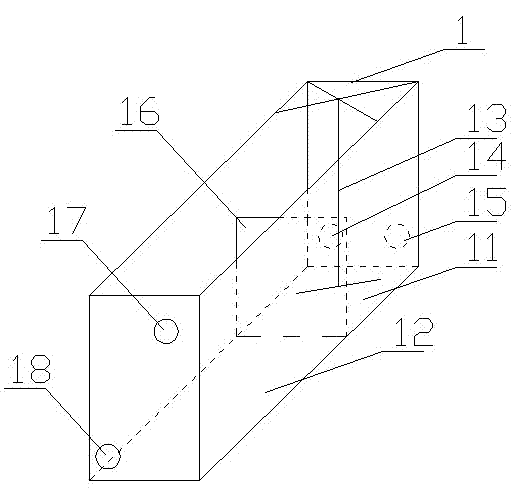

The invention relates to calcium removing equipment and process in a cobalt wet metallurgy process. The calcium removing equipment comprises an extracting tank and an alkali adjusting agitating tank which are communicated by a pipeline, wherein the extracting tank comprises a plurality of grades of extracting grooves which are connected in series. The calcium removing equipment is characterized in that each extracting groove comprises a mixing chamber and a clarifying chamber; a cobalt washing acid feeding opening, a washing liquid feeding opening and a liquid alkali feeding opening are formed in the top face of the alkali adjusting agitating tank; a filter pressing outlet is formed in the bottom of the alkali adjusting agitating tank; the filter pressing outlet is connected with a filter press.

Owner:GEM JIANGSU COBALT IND CO LTD

Cleaning method of optical lens middle piece

InactiveCN110142271ASimple processHigh degree of removalFlexible article cleaningCleaning using liquidsSolution treatmentEngineering

The invention relates to a cleaning method of an optical lens middle piece. The cleaning method comprises the steps of clear water pretreatment, solvent solution treatment, cleaning agent treatment, natural plant glue solution treatment, drying, cooling and the like. According to the method, a natural plant glue solution such as guar gum is adopted to treat an optical lens, the natural plant gluesolution has certain viscosity, and pollutants on the surface of the optical lens middle piece can be attracted. Meanwhile, the aqueous solution of the guar gum is of a network-like molecular structure so that the pollutants can be wrapped during a large amount of water catch, and therefore the pollutant removal degree of the surface of the optical lens middle piece can be improved.

Owner:苏州五方光电材料有限公司

An improved kitchen exhaust fan for smart kitchen and bathroom construction

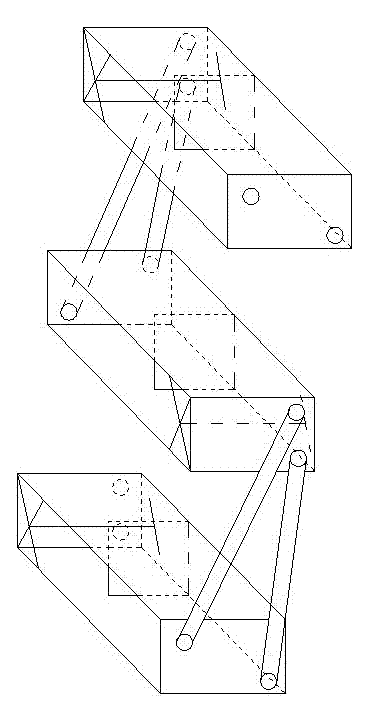

ActiveCN111706534BEasy to disassemble and useHigh degree of removalPump componentsPump installationsFan bladeSmart kitchen

The invention belongs to the technical field of intelligent kitchen and bathroom devices, and in particular relates to an improved kitchen exhaust fan for building an intelligent kitchen and bathroom. In the present invention, a set of grease removal structure is composed of elastic strip unit, open mounting ring unit and annular brush body unit, and then the grease removal structure is placed on the radial mounting plate when idle, and then installed on the fan blade when grease removal is required , to achieve the effect of effectively removing the grease on the surface of the fan blade. The present invention has a grease removal structure that has a good overall removal effect on the two sides of the fan blade and the edge. The grease removal structure has little influence on the ventilation volume when it is idle. The grease removal structure itself has high stability and is convenient to disassemble and use. After the fan blades are opened, it is automatically completed, the oil dirt is removed to a high degree, and the whole exhaust fan has the advantages of compact structure and high degree of intelligence.

Owner:海南凯玉酒店厨房设备工程有限公司

Cutting steel wire, steel material for cutting steel wire and production method thereof

ActiveCN110117748BEasy to controlHigh degree of removalManufacturing convertersElectric furnaceMolten steelDecarburization

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

High cleanliness spring steel and production method thereof

ActiveCN113061799BSmall sizeImprove purityManufacturing convertersProcess efficiency improvementChemical compositionSlag

The invention discloses a high cleanliness spring steel and a production method thereof. The production method includes pretreatment: desulfurizing molten iron to the extent that S≤0.0015% in molten iron; mixing molten iron and scrap steel into molten steel for desiliconization, dephosphorization, oxygen blowing and decarburization, and obtaining a temperature of 1630-1660° C., C 0.10-0.35 %, O≤0.045%, P≤0.011%, S 0.003~0.008% of molten steel, slag blocking and tapping and deoxidation alloying, the flow rate of argon blowing at the bottom of the ladle during tapping and after tapping is respectively 800~ 1000NL / min, 100~200NL / min; after that, the molten steel is refined to adjust the chemical composition and inclusions, and the flow rate of argon blowing at the bottom of the ladle is 300~500NL during the addition of slag and alloying treatment, when electrifying and heating up, and during the rest of the time. / min, 200~300NL / min, 50~100NL / min; then vacuum refining and air-breaking soft stirring are carried out in sequence, and the flow rate of argon blowing at the bottom of the ladle is 20~50NL / min, 50~100NL / min respectively; billet. In the high-cleanness spring steel prepared by the production method, the density of inclusions with a size of 5 μm or more is ≤ 0.5 pieces / mm 2 , the length-width product of the largest inclusion is less than or equal to 900 μm 2 , with high cleanliness.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

Single-color gradient film and preparation method, cover plate, device and application thereof

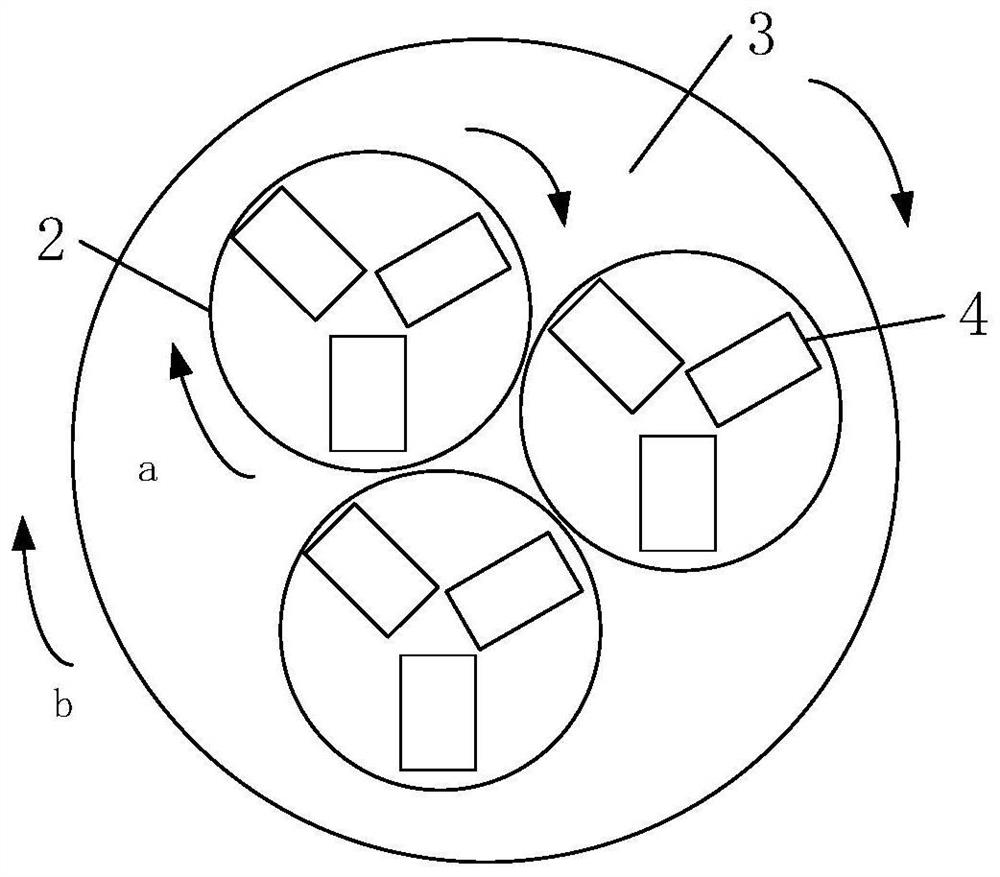

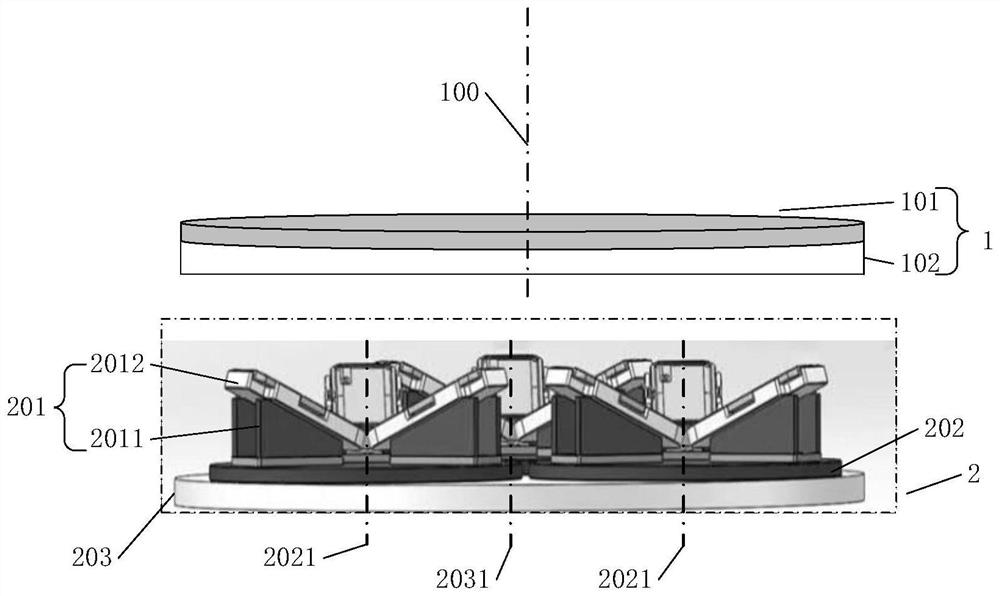

PendingCN114454658AGood effectReduced polishing removalPolishing machinesLight effect designsColor filmFilm-coated tablet

The invention relates to the technical field of surface treatment, in particular to a single-color gradient film, a preparation method thereof, a cover plate, a device and application. The preparation method of the single-color gradient film comprises the following steps: S1, plating a color film on the surface of a cover plate substrate to obtain a plated cover plate; and S2, a certain inclination angle is formed between the color plating cover plate and the horizontal plane, the color plating cover plate is fixed, the color plating cover plate is pressed downwards on the color plating cover plate, and an elastic polishing layer of a polishing tool is rotated and moved to polish the color plating cover plate, the rotating axis of the elastic polishing layer is vertical and is located on one side of the whole color plating cover plate. According to the method, the single-color gradient cover plate is obtained in a physical polishing mode for the first time, the gradient effect after polishing treatment is more natural, and the cost is lower; and a transition gradual change method which cannot be realized by film coating from no color to color is realized.

Owner:LENS TECH CHANGSHA

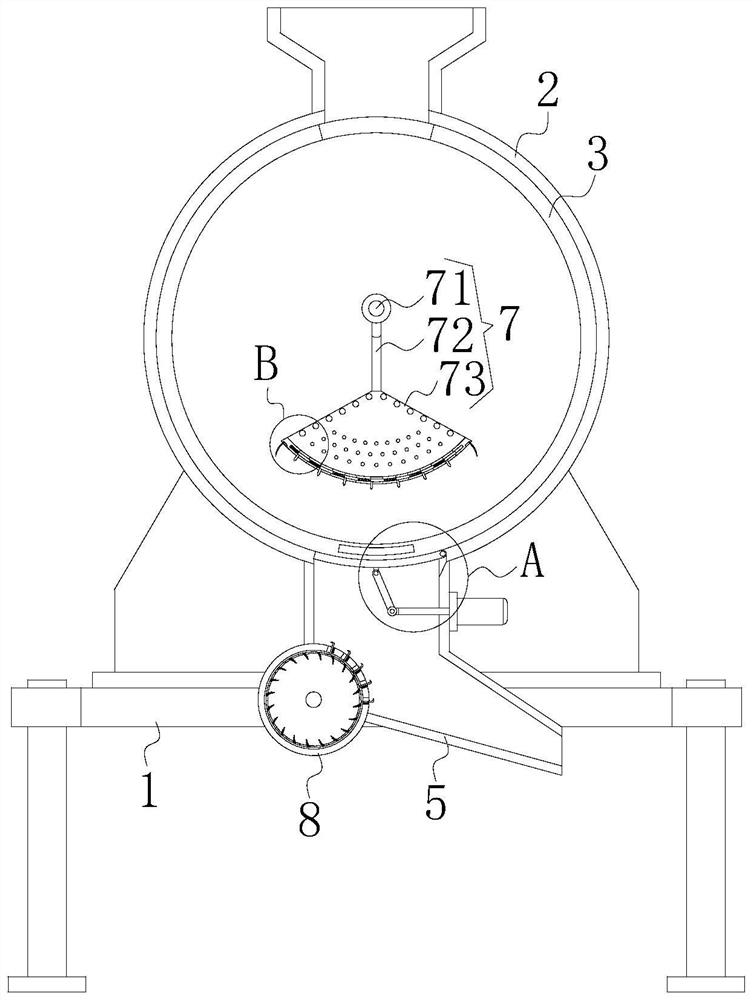

Bone surface meat and tendon treatment device for bone glue processing

InactiveCN112058852AGuaranteed separation effectImprove cullingSolid waste disposalDrive motorBiomedical engineering

The invention discloses a bone surface meat and tendon treatment device for bone glue processing, and relates to the technical field of bone glue processing. The bone surface meat and tendon treatmentdevice for bone glue processing comprises a fixing frame, wherein a shell is fixedly installed on the fixing frame; a feeding hopper communicating with an inner cavity of the shell is welded at the top of the shell; a rotating drum is arranged in the shell, and the outer surface of the rotating drum is slidably connected with the inner wall of the shell; a feeding port achieving communication ofan inner cavity of the rotating drum and an inner cavity of the feeding hopper is formed in the top of the rotating drum; and a driving motor is fixedly installed in the front side of the shell, and an output shaft of the driving motor penetrates through the shell and is fixedly connected with the axis of the front surface of the rotating drum. According to the bone surface meat and tendon treatment device for bone glue processing, when residual meat and tendons on a bone surface are processed, a meat and tendon separating mechanism is matched with a bone discharging mechanism, so that the removal degree of the residual meat and tendons on the bone surface is effectively improved, and the separated meat and tendons are effectively collected after the processing is completed.

Owner:孔水生

Rice production method capable of reducing broken rice rate

InactiveCN112934309AHigh bonding strengthHigh adsorption activityGrain treatmentsAgricultural engineeringBroken rice

The invention discloses a rice production method capable of reducing the broken rice rate. The rice production method capable of reducing the broken rice rate is characterized by comprising the following steps: removing impurities in unhusked rice by using a roller precleaner and a vibrating screen to obtain pretreated unhulled rice; stirring potassium carbonate and water, adding the pretreated unhulled rice in a stirring state, and continuously stirring to obtain alkali-treated unhusked rice; drying the unhusked alkali-treated rice, adding a high-hardness adsorption compound, uniformly mixing, hulling, separating brown rice from the unhusked rice through a husked rice separator, adding automatic grading to separate rice grains and rice husks through the difference of specific gravity, granularity and the surface friction coefficient between the rice grains and the rice husks under the action of a working plate which tilts in two directions and reciprocates; peeling and whitening the rice grains, automatically sorting out and removing different-color grains in the rice grains, and then classifying the rice grains into rice, medium rice, small rice and broken rice according to the sizes of the rice grains by using an automatic sorting machine; and packaging.

Owner:桃源县爱来米业有限公司

Potassium feldspar deironing technique

ActiveCN109133076AThe iron removal method is firstly removed by ore washingEfficient removalAluminium silicatesMineral SourcesSludge

The invention belongs to the technical field of comprehensive utilization of mineral resources and particularly discloses a potassium feldspar deironing technique, comprising the steps of (1) washingthe mineral, to be specific, washing mud from the raw potassium feldspar, and removing water; (2) crushing secondarily; (3) ball milling, to be specific, ball milling until particle size of 80-150 mesh; (4) treating under high pressure, to be specific, introducing carbon dioxide to form high pressure to treat potassium feldspar particles; (5) treating with sulfuric acid, to be specific, mixing thepotassium feldspar particles, sulfuric acid solution and carbon dioxide under vacuum assistance; (6) drying. The potassium feldspar deironing technique helps effectively remove iron in the potassiumfeldspar, the sulfuric acid is utilized more efficiently, and acid content of wastewater is lowered.

Owner:贺州市骏鑫矿产品有限责任公司

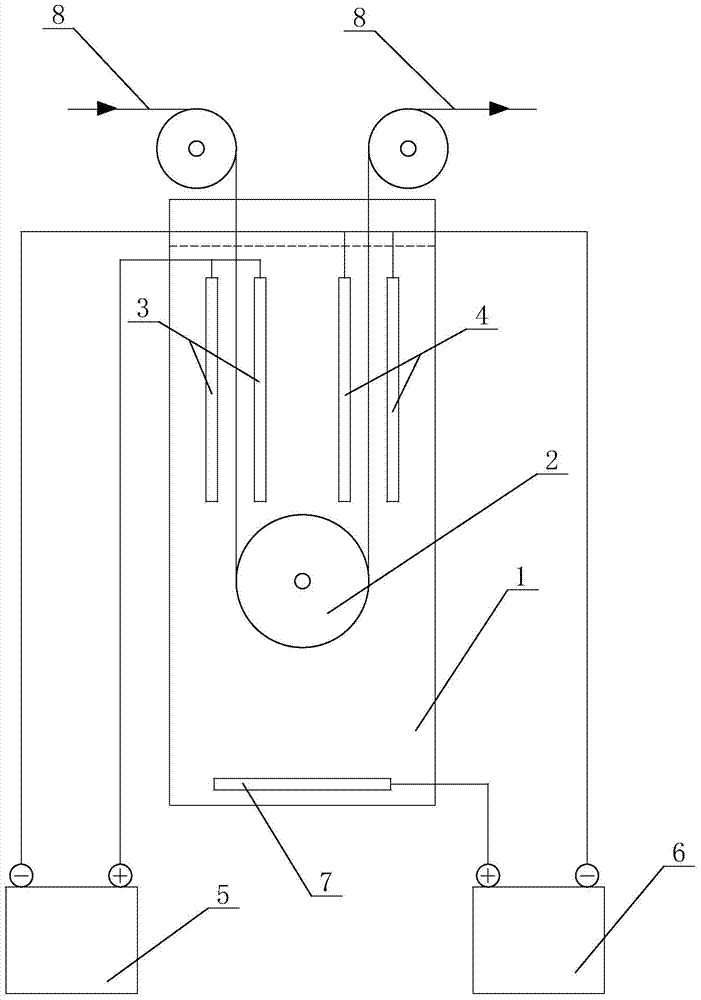

A treatment system for pahs in groundwater and a method for using the same

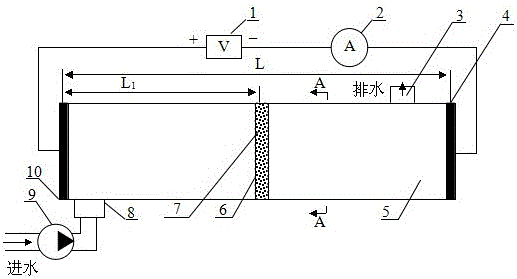

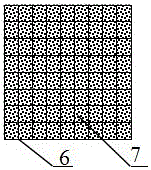

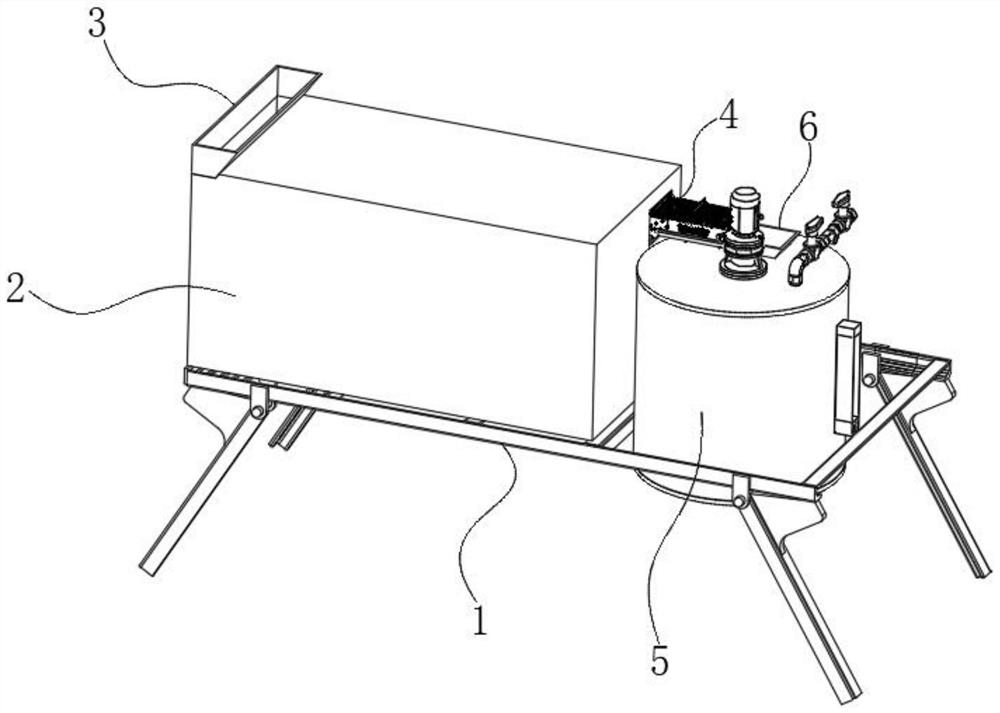

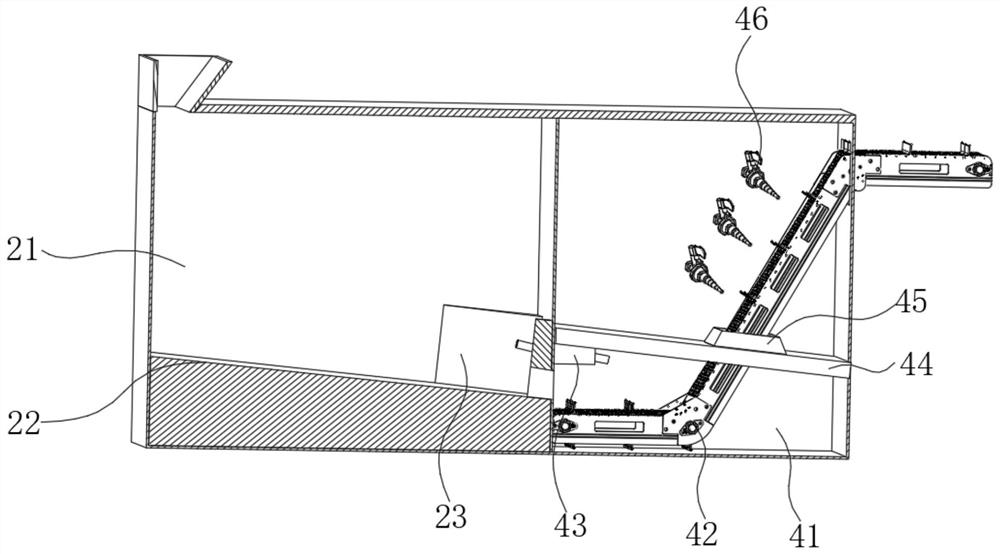

ActiveCN104478069BAchieve degradationGuaranteed uptimeTreatment by combined electrochemical biological processesWater contaminantsGraphite electrodeEnvironmental engineering

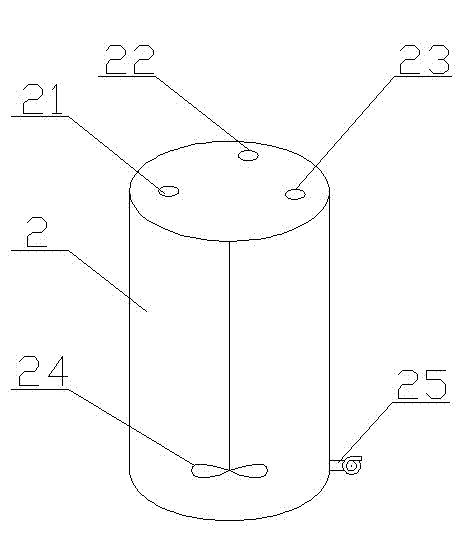

The invention relates to a treatment system for PAHs in groundwater and a method for using the same. Its technical scheme is: an anode graphite electrode (10) is provided on one side of the water tank (5), a cathode graphite electrode (4) is provided on the other side of the water tank (5), and the anode graphite electrode (10) and the cathode graphite electrode (4) face each other Set, a grid-like grid (6) is housed between the anode graphite electrode (10) and the cathode graphite electrode (4), and the grid-like grid (6) is filled with immobilized laccase (7); A water inlet (8) is provided at the bottom of the water tank (5) at the graphite electrode (10), and a constant flow pump (9) is installed at the water inlet (8). The upper part of the water tank (5) at the electrode (4) is provided with a drain port (3). The flow velocity of the groundwater in the treatment system passing through the mesh grille (6) is 0.01-0.5m / min, and the voltage of the DC stabilized power supply is 4-8V. The invention has the characteristics of reliable operation, high efficiency and no secondary pollution.

Owner:WUHAN UNIV OF SCI & TECH

A Method for Removing the Astringent Taste of Peanut Red Coat

The present invention discloses a method of removing astringent tastes of peanut skins. The method comprises the following steps: the peanut skins are soaked using water, the soaked peanut skins are subjected to a microwave pretreatment, tannase is added, then zinc lactate and calcium lactate are added, the mixture is subjected to a microwave assisted enzymatic treatment, the treated mixture is filtered, and the filtered mixture is centrifuged to remove the astringent tastes of the peanut skins to obtain a peanut skin extract free of the astringent tastes. The present invention provides the high-efficient peanut skin astringent taste removing method. The method is good in astringent taste removing effects, at the same time can obtain the peanut skin extract free of the astringent tastes and rich in proanthocyanidin, and can widen the application of the peanut skins in food. The prepared astringent taste removing peanut skins can be applied in the food industry of health-care products, peanut drink, peanut ice cream, peanut milk tea, etc.

Owner:张初署 +1

Carrageenan extraction equipment and process

InactiveCN113521798AIncrease the degree of fragmentationImprove solubilityRotary stirring mixersMixer accessoriesCarrageenanProcess engineering

The invention discloses carrageenan extraction equipment, and relates to the technical field of carrageenan preparation.The carrageenan extraction equipment comprises a base, a raw material treatment bin, a cleaning assembly, a colloid boiling assembly and an extruding assembly.The raw material treatment bin and the colloid boiling assembly are fixed to the upper end face of the base; a raw material inlet is fixed to the upper end face of the side, away from the colloid boiling assembly, of the raw material treatment bin; and one side of the raw material inlet inclines towards the side wall of the raw material treatment bin, so that raw materials can slide into the raw material treatment bin along the side wall of the raw material treatment bin; the extruding assembly is arranged on one side of the upper end face of the colloid boiling assembly; and the cleaning assembly is arranged in the side, close to the colloid boiling assembly, of the raw material treatment bin; and one end of the cleaning assembly penetrates through the raw material treatment bin and extends to the position above the extruding assembly, so that the cleaned raw materials can be put into the colloid boiling assembly through the extruding assembly.

Owner:南京同歌网络科技有限公司

A degreasing method in the surface treatment process of rolled copper foil

ActiveCN105483812BImprove surface qualityGuaranteed or improved surface qualityElectrolysis componentsHydrogenCopper foil

The invention discloses a degreasing method adopted in the rolled copper foil surface treatment process. Rolled copper foil is subjected to cathode electrolytic degreasing and anode electrolytic degreasing in sequence, and anode electrolytic degreasing is added compared with the prior art, so that the rolled copper foil is subjected to degreasing treatment performed through hydrogen and oxygen in sequence. Obviously, both the total molar weight and the total kinetic energy of hydrogen and oxygen are larger than the molar weight and the kinetic energy of single hydrogen, the removing degree of remaining grease is remarkably increased, the grease remaining amount of the degreased surfaces of the rolled copper foil is reduced, the single-face grease remaining amount of the rolled copper foil can be reduced by 3 mg / m<2>, normal operation of the following electroplating process such as roughing treatment is facilitated, and the surface quality, the inner quality, the mechanical performance, the electrochemical performance and the like of the rolled copper foil produced after the following electroplating process such as roughing treatment are further guaranteed or improved.

Owner:中色正锐(山东)铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com