Method for reducing sulfur content in sulfur recovery device tail gas

A technology for sulfur recovery and sulfur content, applied in separation methods, air quality improvement, chemical instruments and methods, etc., can solve the problems of limited absorption selectivity, limited processing load of the device, insufficient removal degree, etc., and reduce the co-absorption rate. , the effect of increasing the processing load and increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

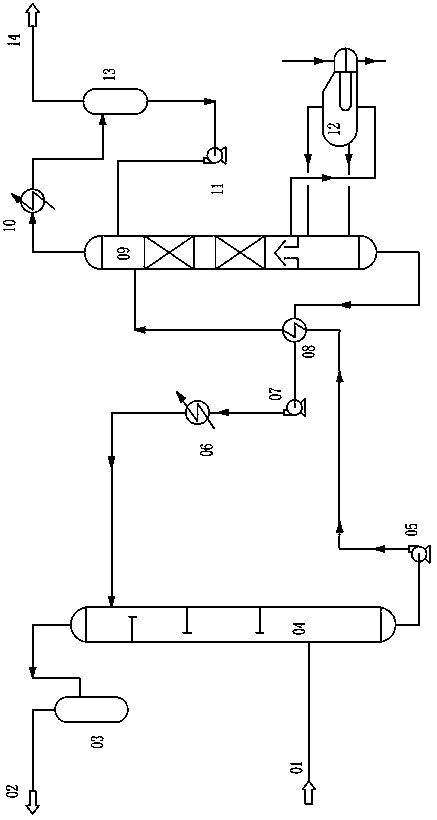

Image

Examples

Embodiment 1

[0031] The conditions of the exhaust gas used in the test are the same as those in Comparative Example 1. The absorption liquid is prepared with an aqueous solution with a mass fraction of 30% based on the polyamide-amine molecular structural formula b mentioned in the above specification as the absorption liquid. The temperature of the absorption liquid entering the absorption tower is 29~31°C, and the temperature at the bottom of the rich liquid regeneration tower is 100~101°C . During the test, the circulation volume of the solution was fixed, and the test results under the conditions of different gas-liquid ratios (i.e. processing load) were shown in formula 1 in Table 2.

Embodiment 2

[0033] The conditions of the exhaust gas used in the test are the same as those in Comparative Example 1. The absorption liquid is prepared as an aqueous solution with a total mass fraction of 30% of polyamide-amine molecular structure b and MDEA as the absorption liquid, wherein the mass fraction of b is 3%, and MDEA is 27%. The temperature of the absorption liquid entering the absorption tower is 29~31°C, and the bottom temperature of the rich liquid regeneration tower is 100~101°C. During the test, the circulation volume of the solution was fixed, and the test results under the conditions of different gas-liquid ratios (that is, processing load) were shown in formula 2 in Table 2.

Embodiment 3

[0035] The conditions of the exhaust gas used in the test are the same as those in Comparative Example 1. The absorption liquid is prepared with the modified polyamide-amine molecular structure formula d whose mass fraction is 30% as mentioned in the above description. The temperature at the bottom of the tower is 100~101°C. During the test, the circulation volume of the solution was fixed, and the test results under the conditions of different gas-liquid ratios (i.e. processing load) were shown in formula 3 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com