Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "High degree of homogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

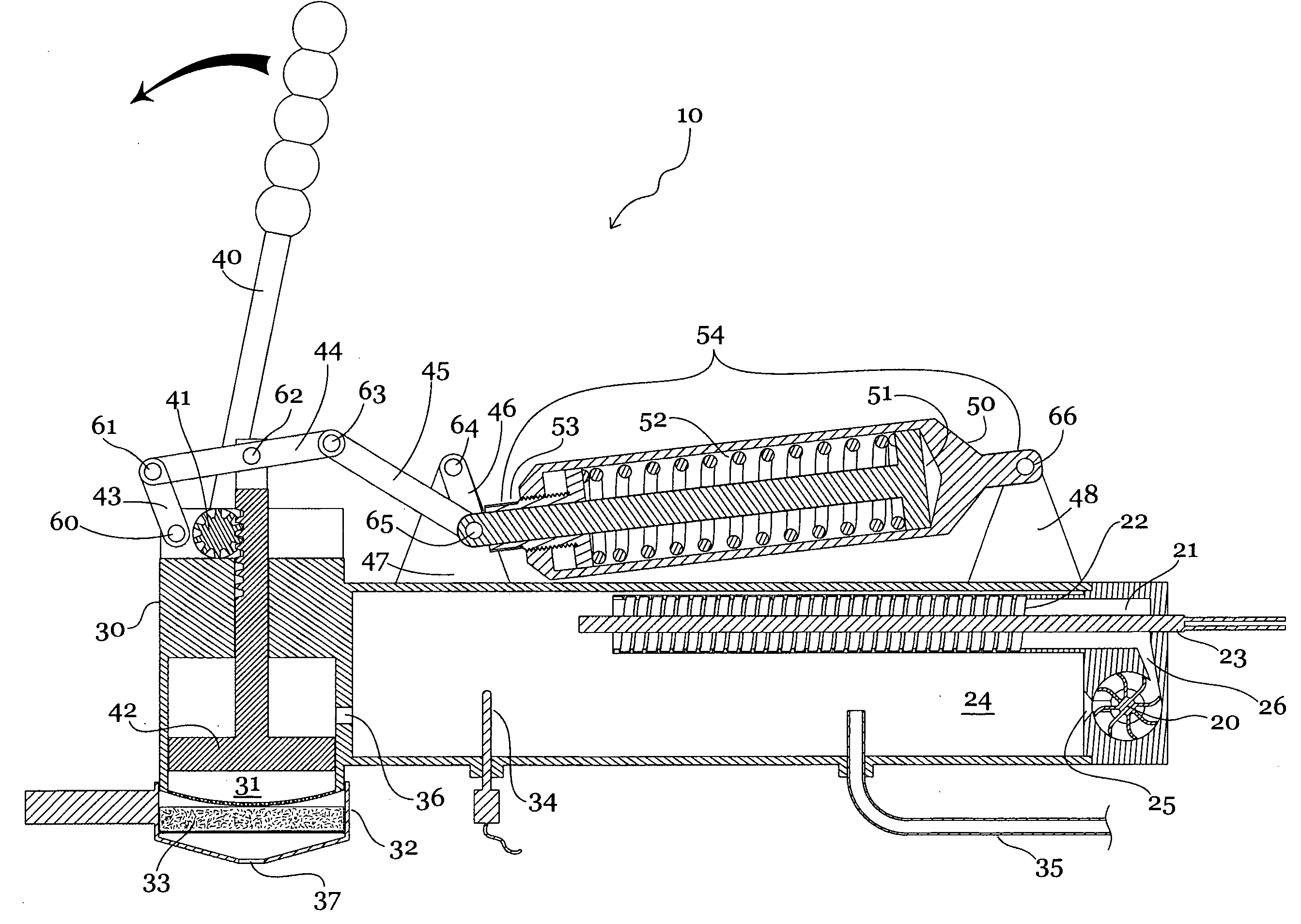

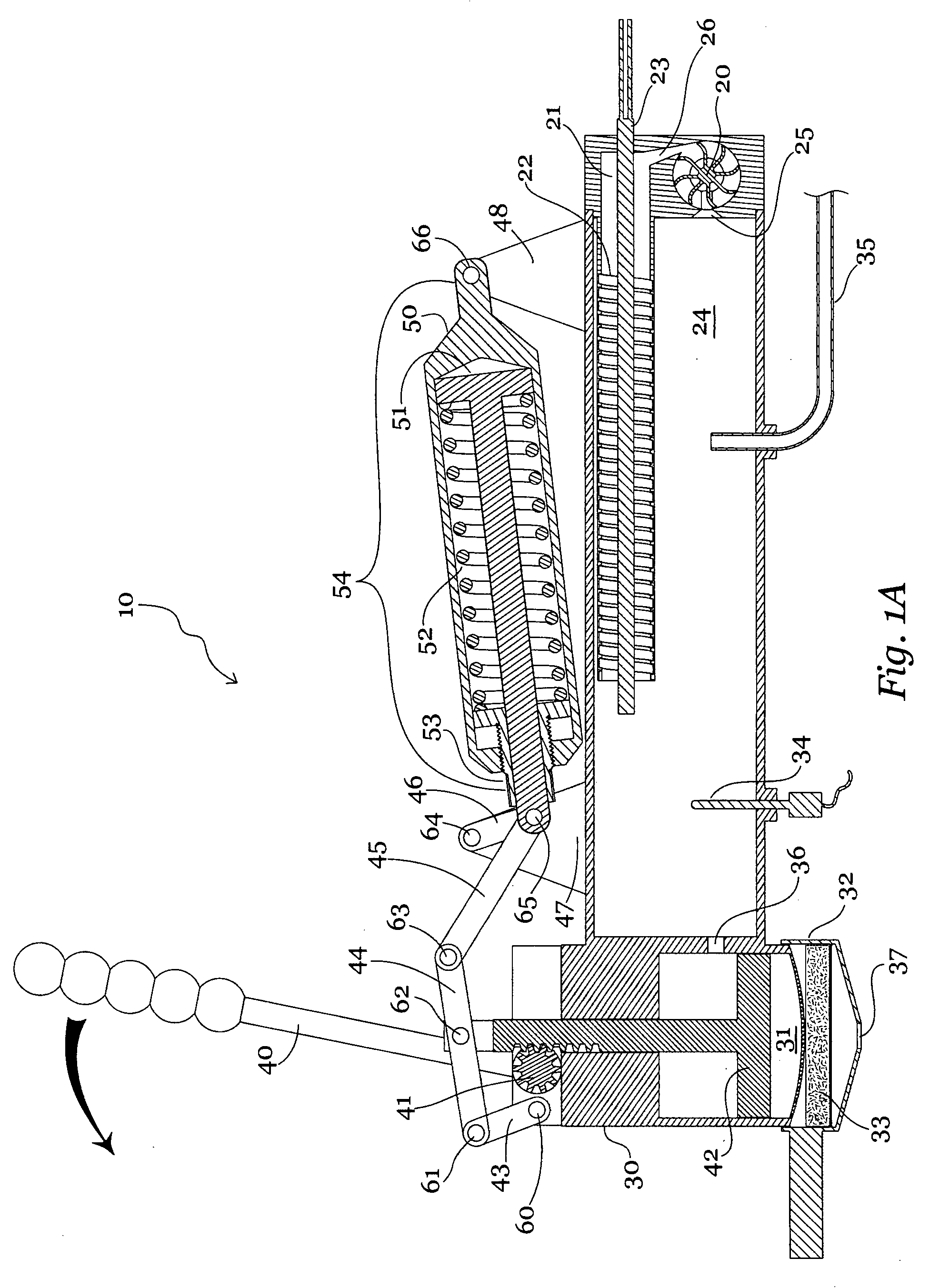

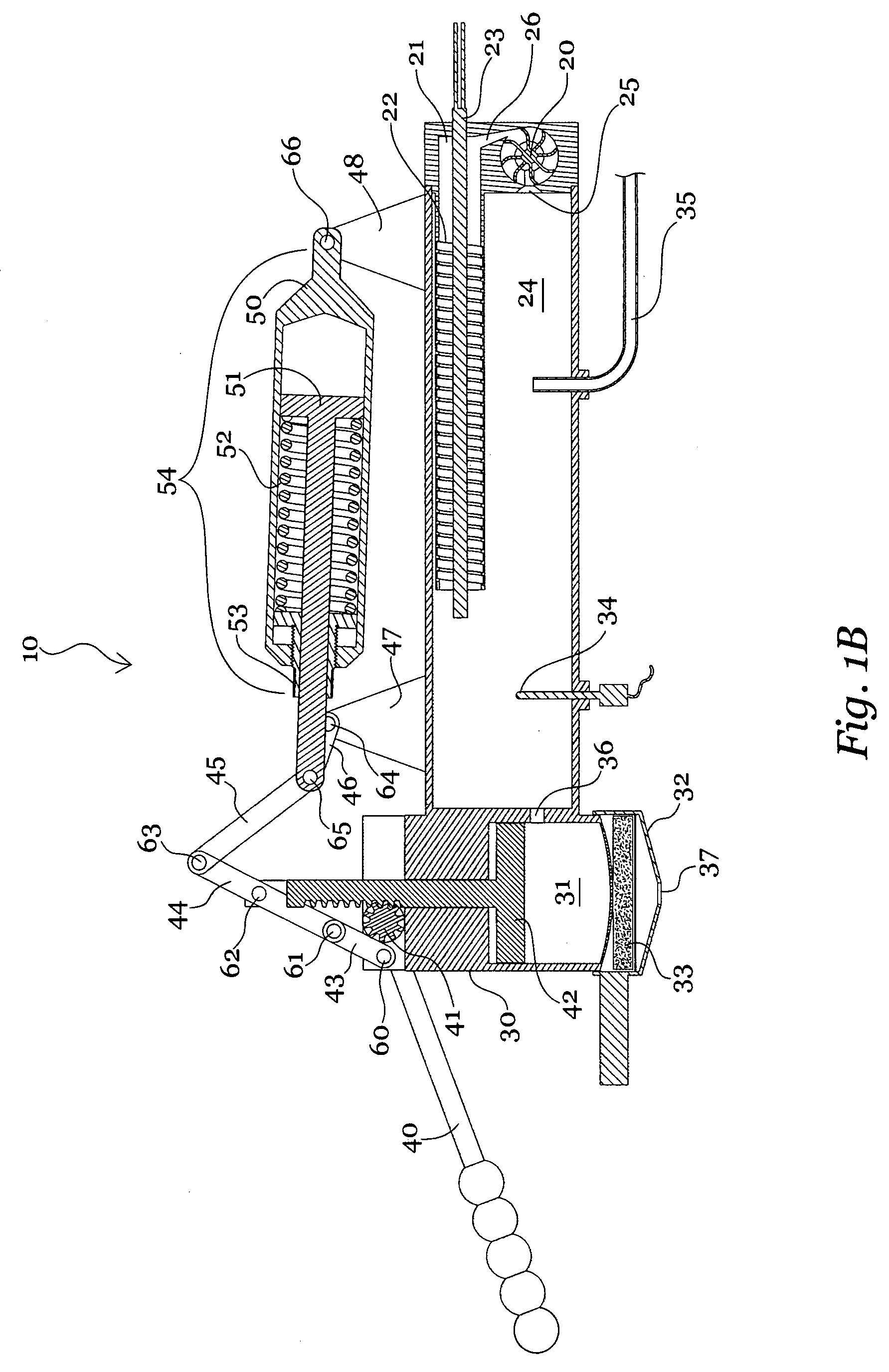

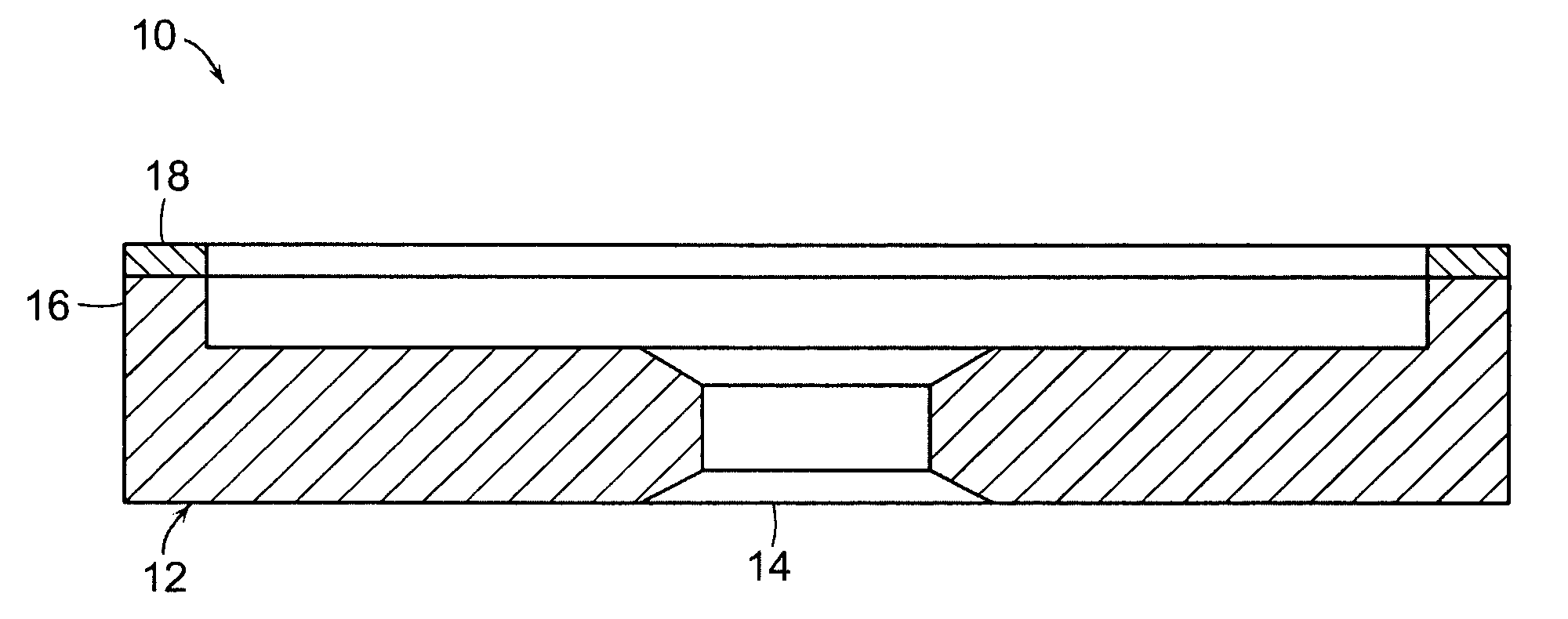

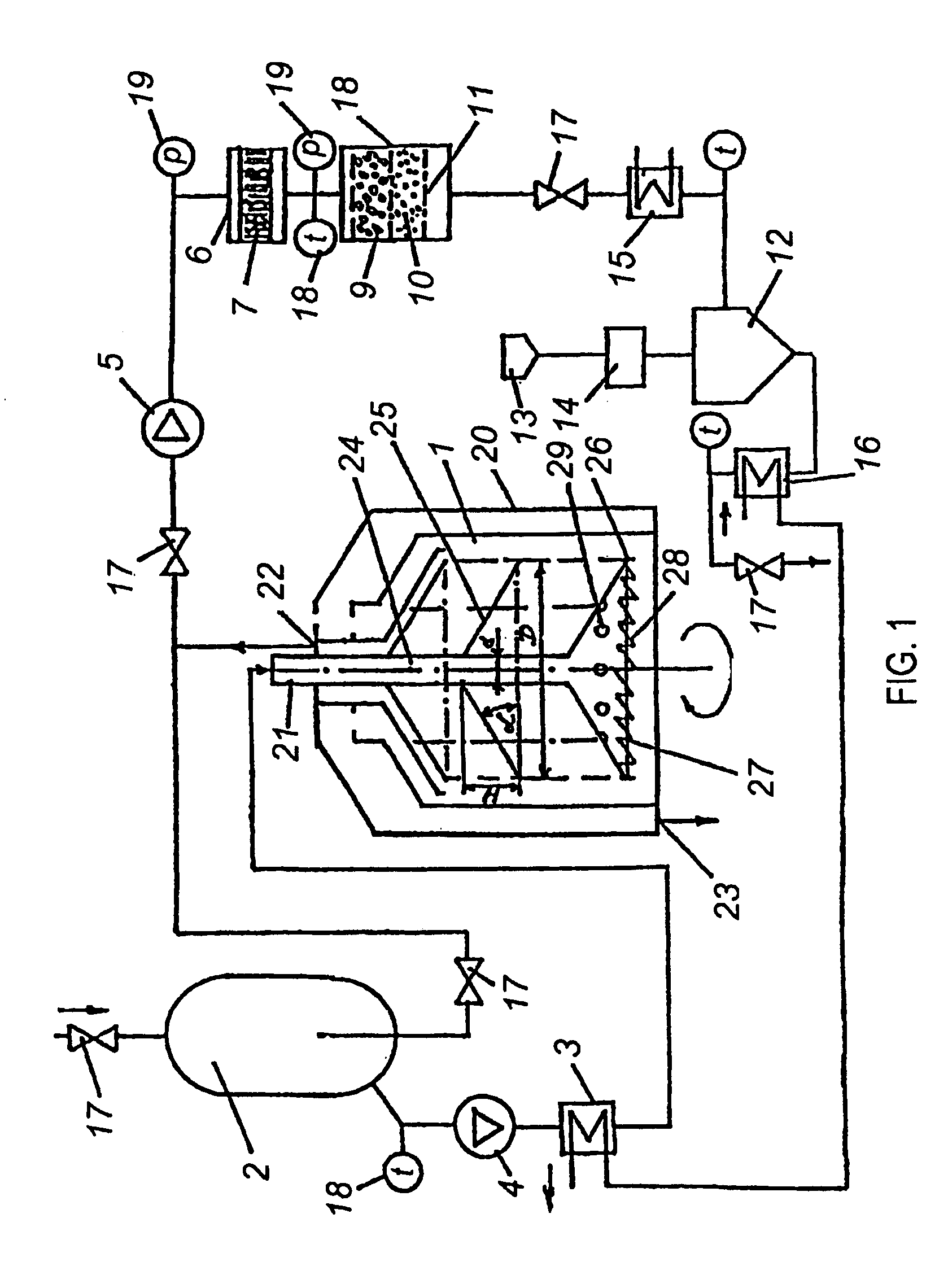

Espresso coffee-making machine and associated method

InactiveUS20070227363A1Improve stabilityGood repeatabilityBeverage vesselsEspresso coffeeEngineering

An espresso-coffee making apparatus comprising a brew water tank at least one heating device for the purpose of heating the brew water, and a pump operatively engaged to the brew water tank with both its inlet and outlet. The pump outlet is attached to a housing such that the pump's discharge moves past the heating device for effective mixing at the heat source. The housing may also include turbulators for further enhanced mixing. Thus, maximum temperature homogeneity within the brew water tank is achieved. The apparatus may further comprise a biasing device operatively engaged to a piston-type pump via a linkage mechanism. Wherein the biasing device is energized by the operator, by means of a lever and the pressurized water produced used to brew espresso. Further, the pressure of the water produced by the pump is modified by the linkage mechanism such that the brew pressure as a function of displaced liquid is controlled. Thus more optimal brewing pressure profiles can be achieved.

Owner:VERNA RAFFAELLO

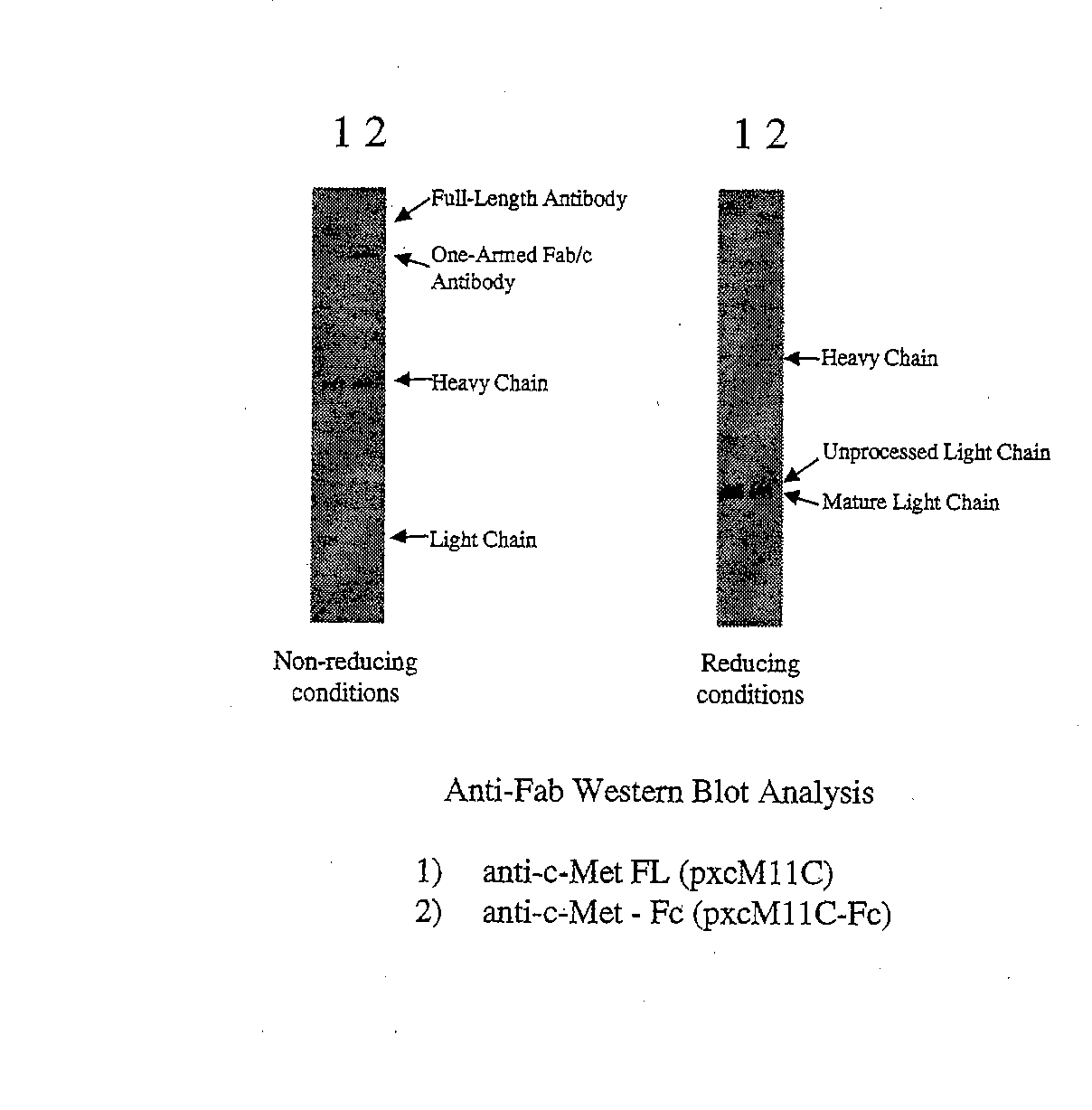

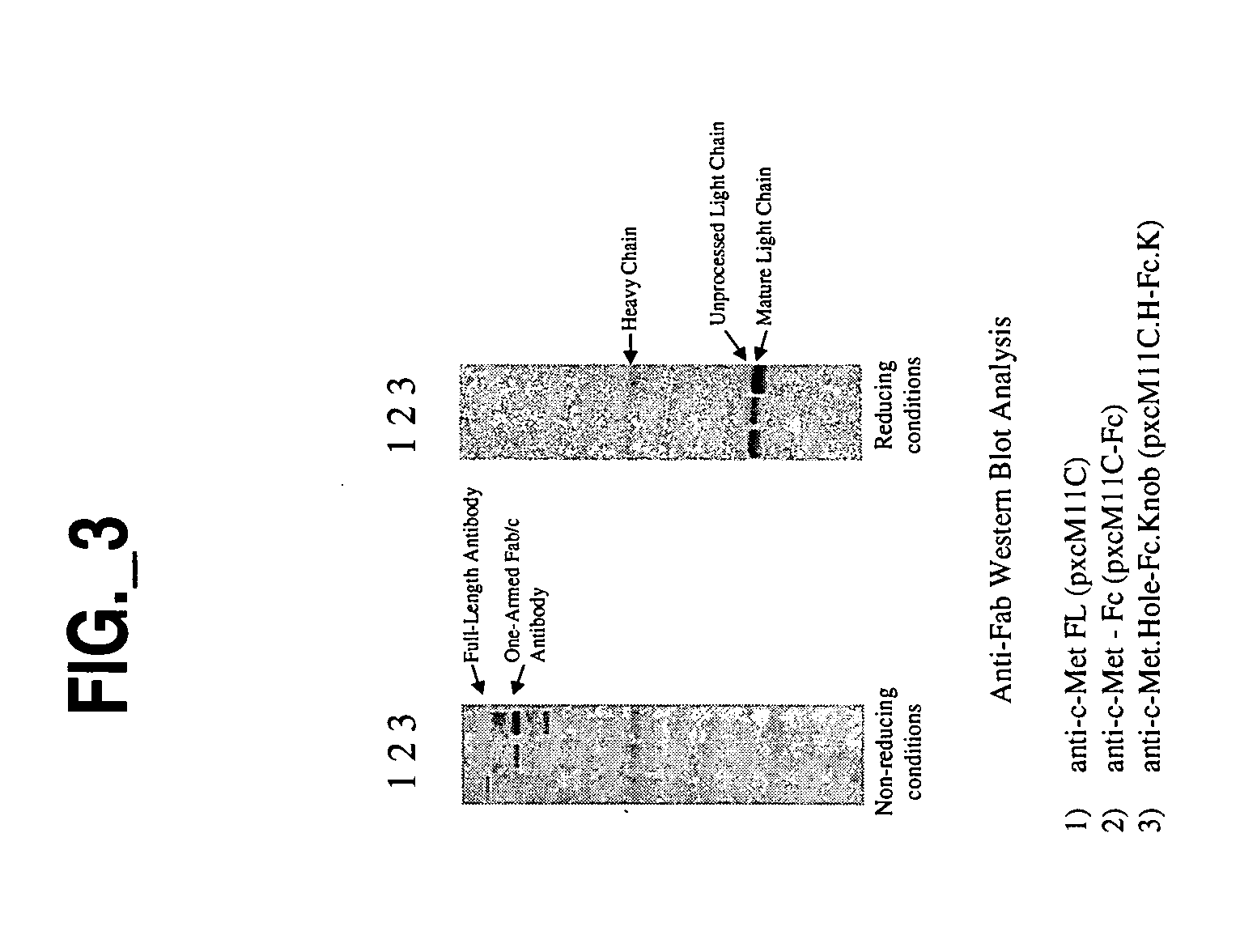

Monovalent antibody fragments useful as therapeutics

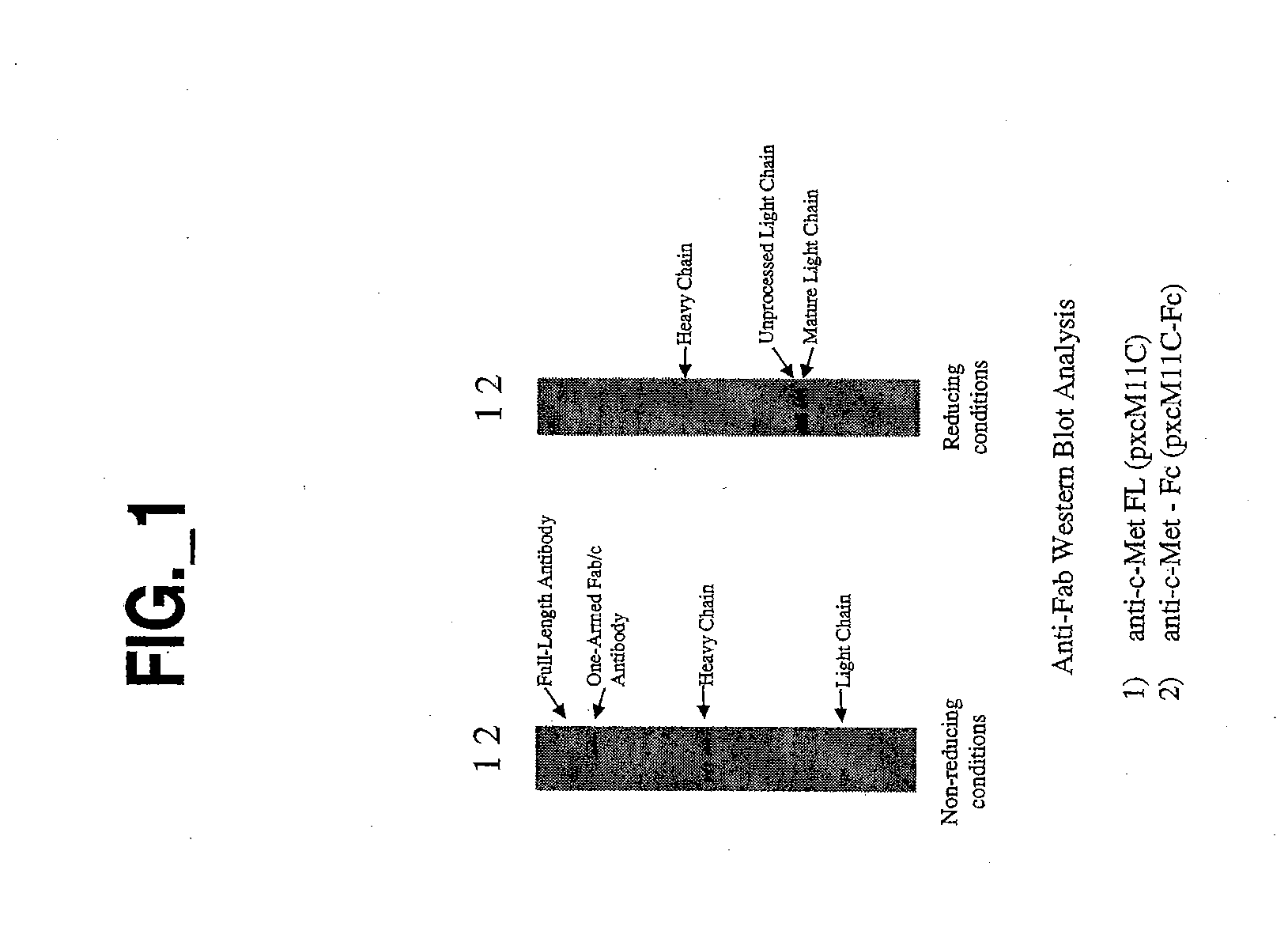

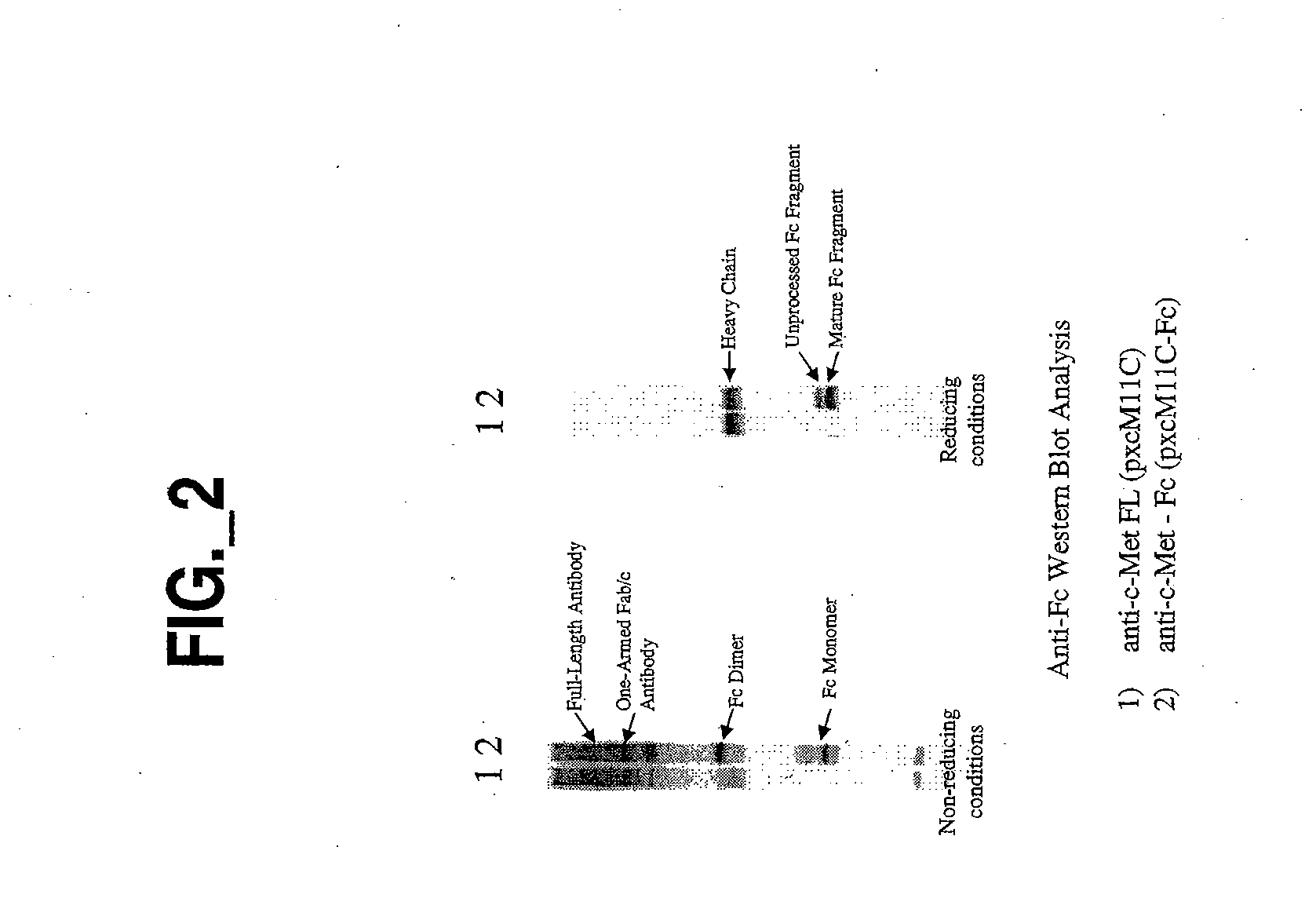

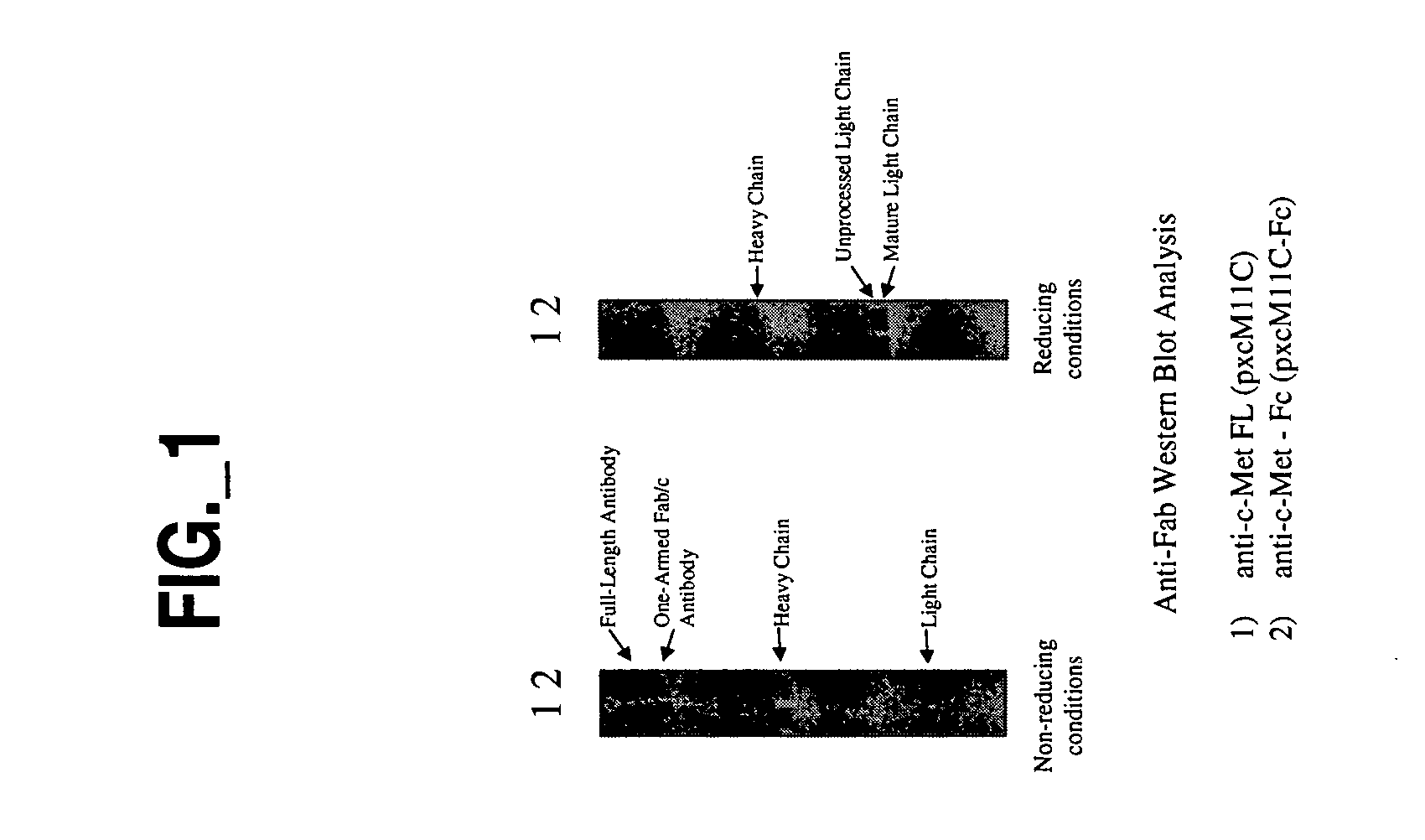

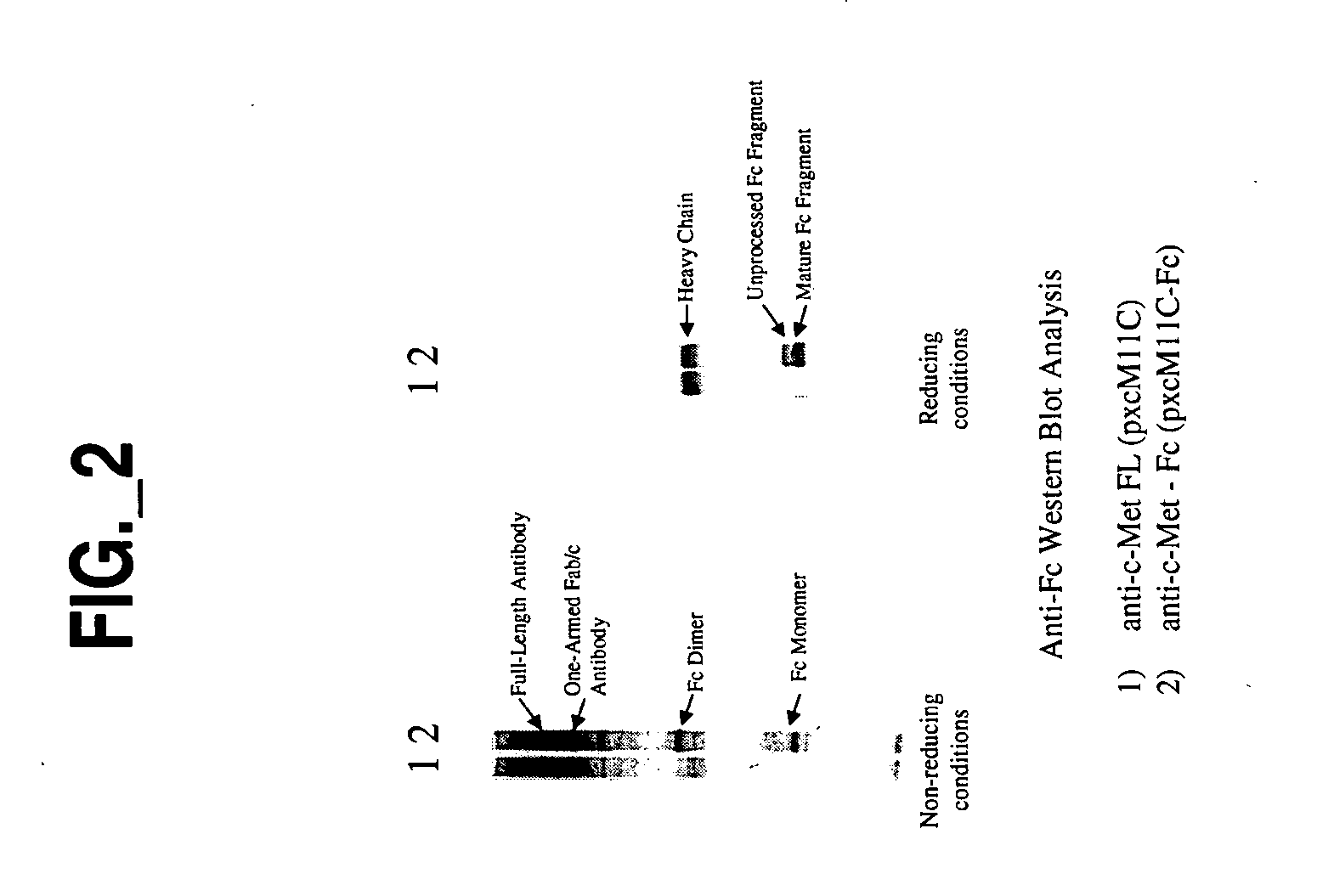

InactiveUS20080063641A1Superior pharmacokinetic attributeExtended half-lifeSugar derivativesBacteriaAntibody fragmentsChemistry

The invention provides methods and compositions comprising a novel stabilized monovalent antibody fragment.

Owner:HUANG ARTHUR JYH YEN +2

Monovalent antibody fragments useful as therapeutics

InactiveUS20050227324A1Superior pharmacokinetic attributeExtended half-lifeBacteriaAntibody mimetics/scaffoldsAntibody fragmentsChemistry

The invention provides methods and compositions comprising a novel stabilized monovalent antibody fragment.

Owner:GENENTECH INC

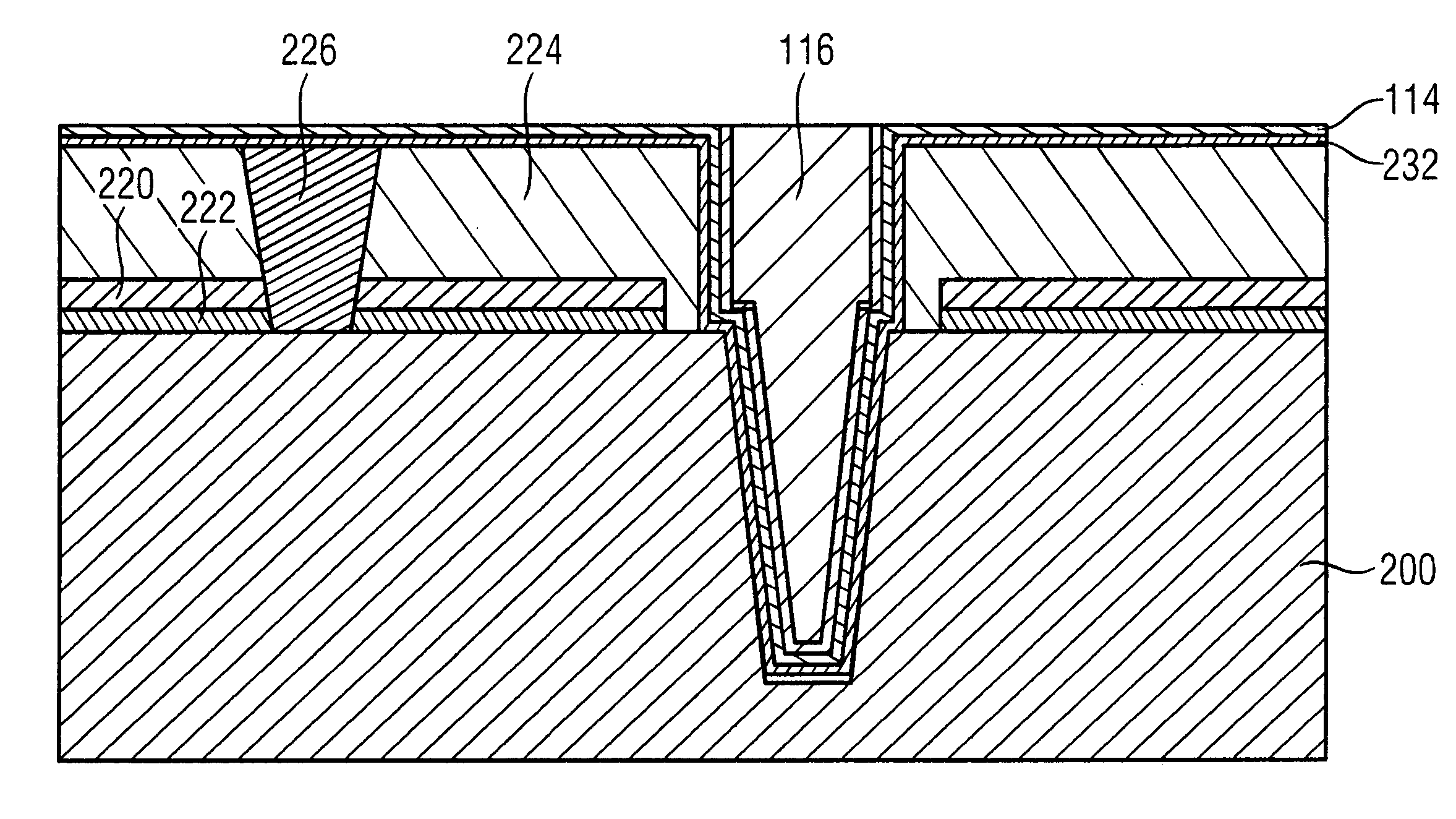

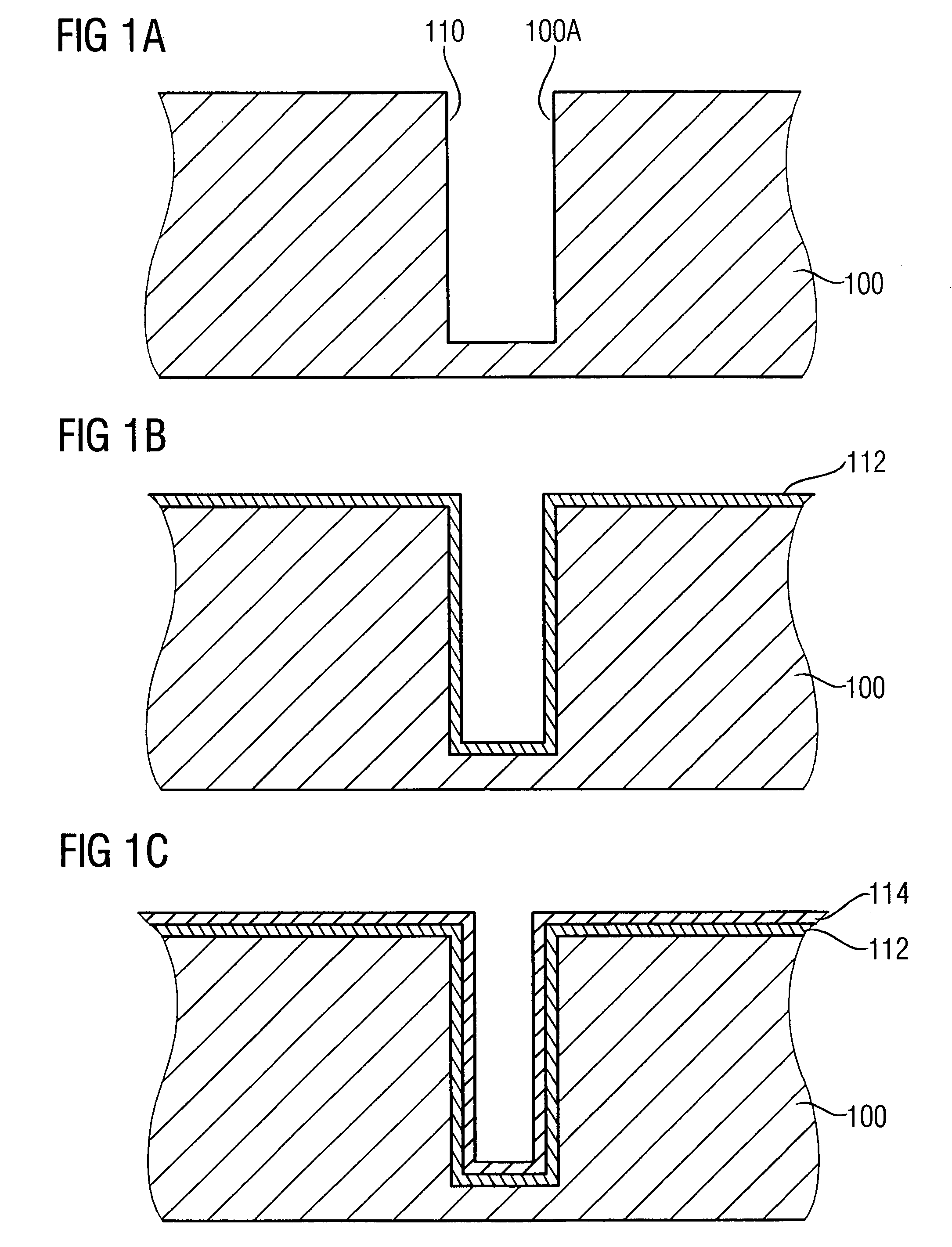

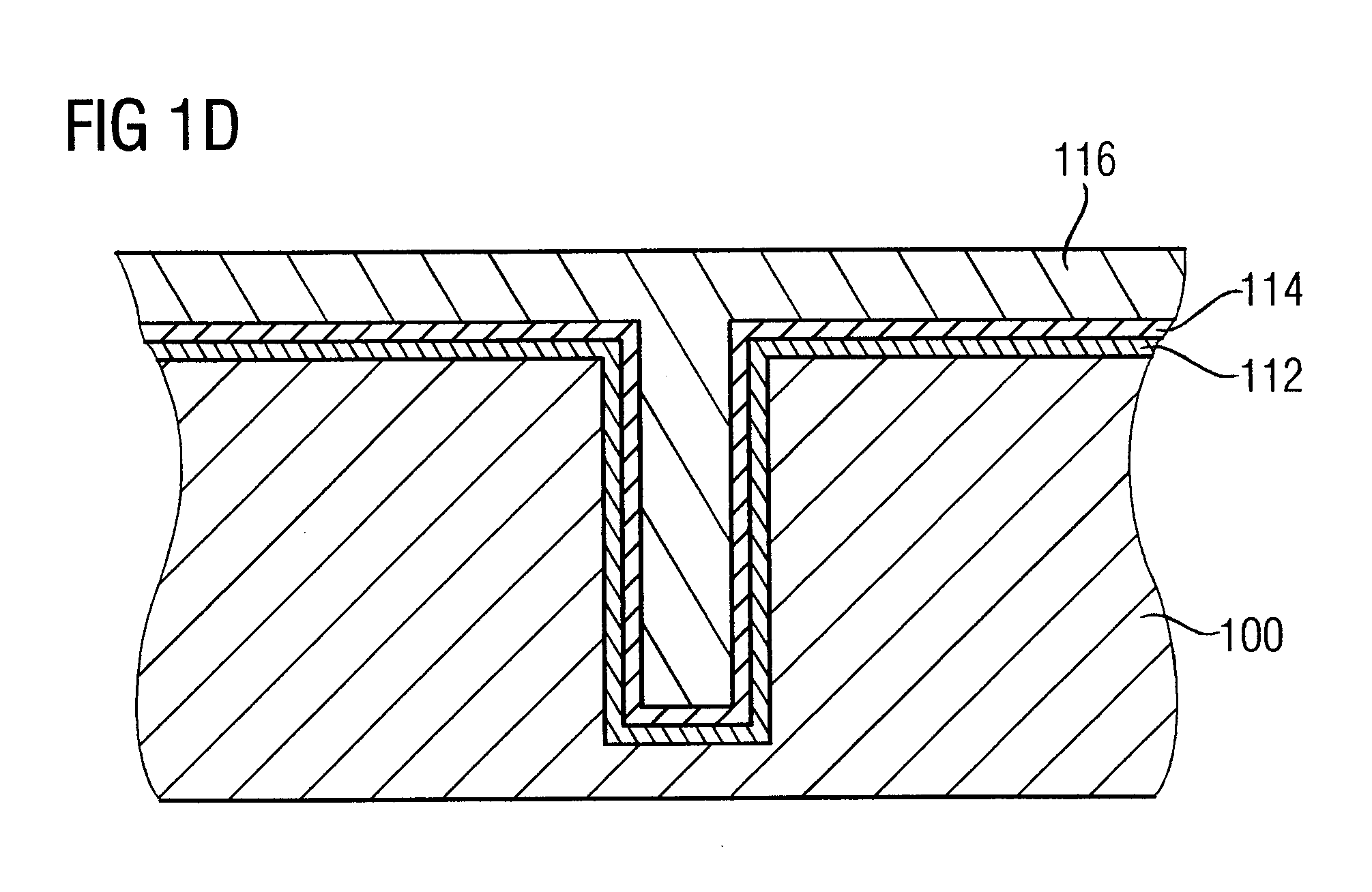

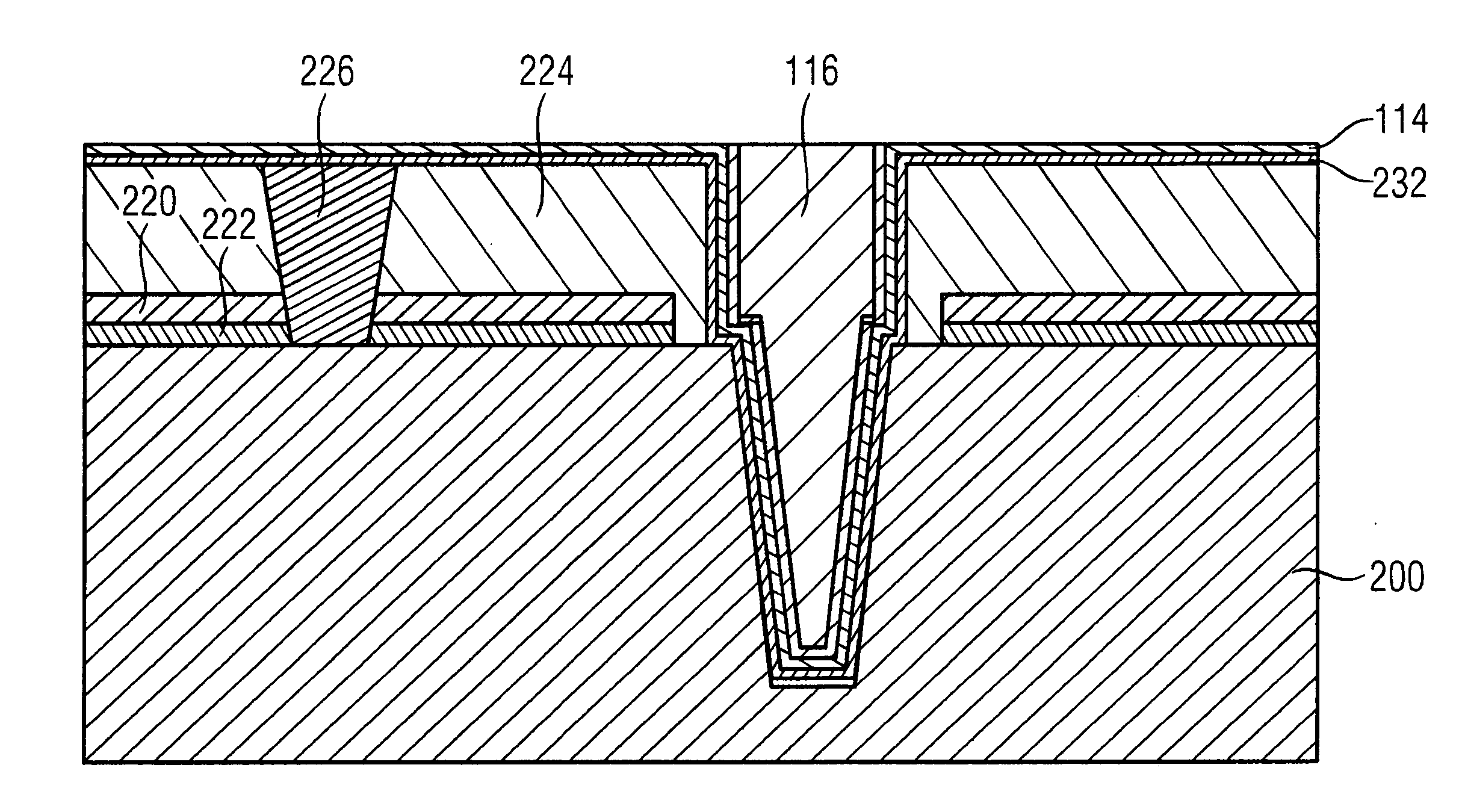

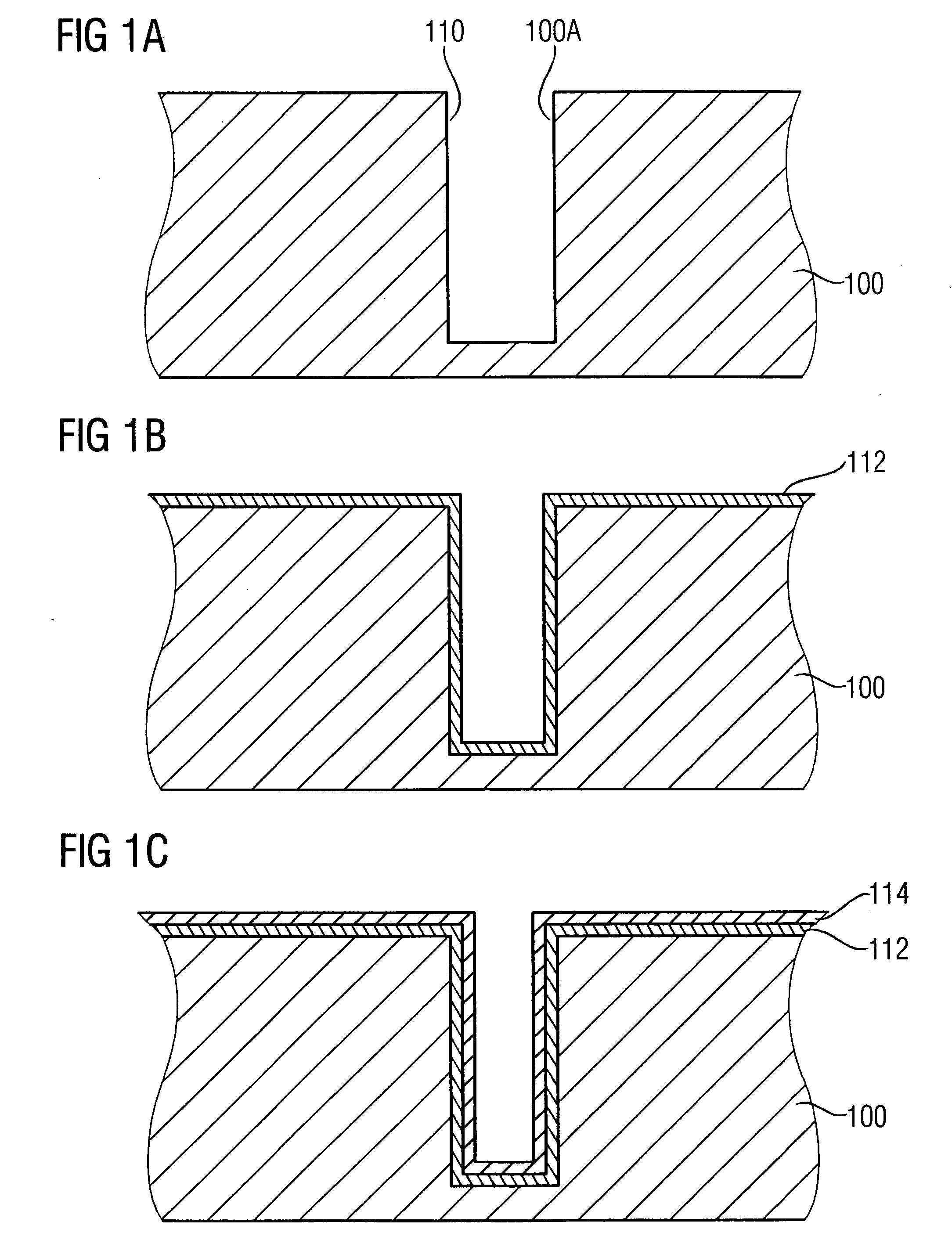

Method for fabrication of a contact structure

ActiveUS7176128B2Small thicknessHigh-quality electroplatingSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsTungsten

Owner:INFINEON TECH AG

Process for making polyvinylidene fluoride power coatings and coating formulations

InactiveUS6340720B1High degree of homogeneityBetter to abrasionLiquid surface applicatorsElectric shock equipmentsPolymer sciencePolyvinylidene difluoride

A process for making a PVDF-based powder coating compositions using a co-coagulation process and compositions comprising co-coagulated PVDF, co-coagulated PVDF-based powder coating compositions and substances coated with these compositions. Vinylidene fluoride polymer latex compositions are mixed with compatible thermoplastic polymer latex, such as acrylic polymer latex, and a coagulant is added. The coagulant precipitates the vinylidene fluoride and polymer, and the precipitant is filtered and dried forming the powder coating. The powder coating is homogenous. The coating comprises no solvents and can be applied to a number of substrates.

Owner:SOLVAY SOLEXIS

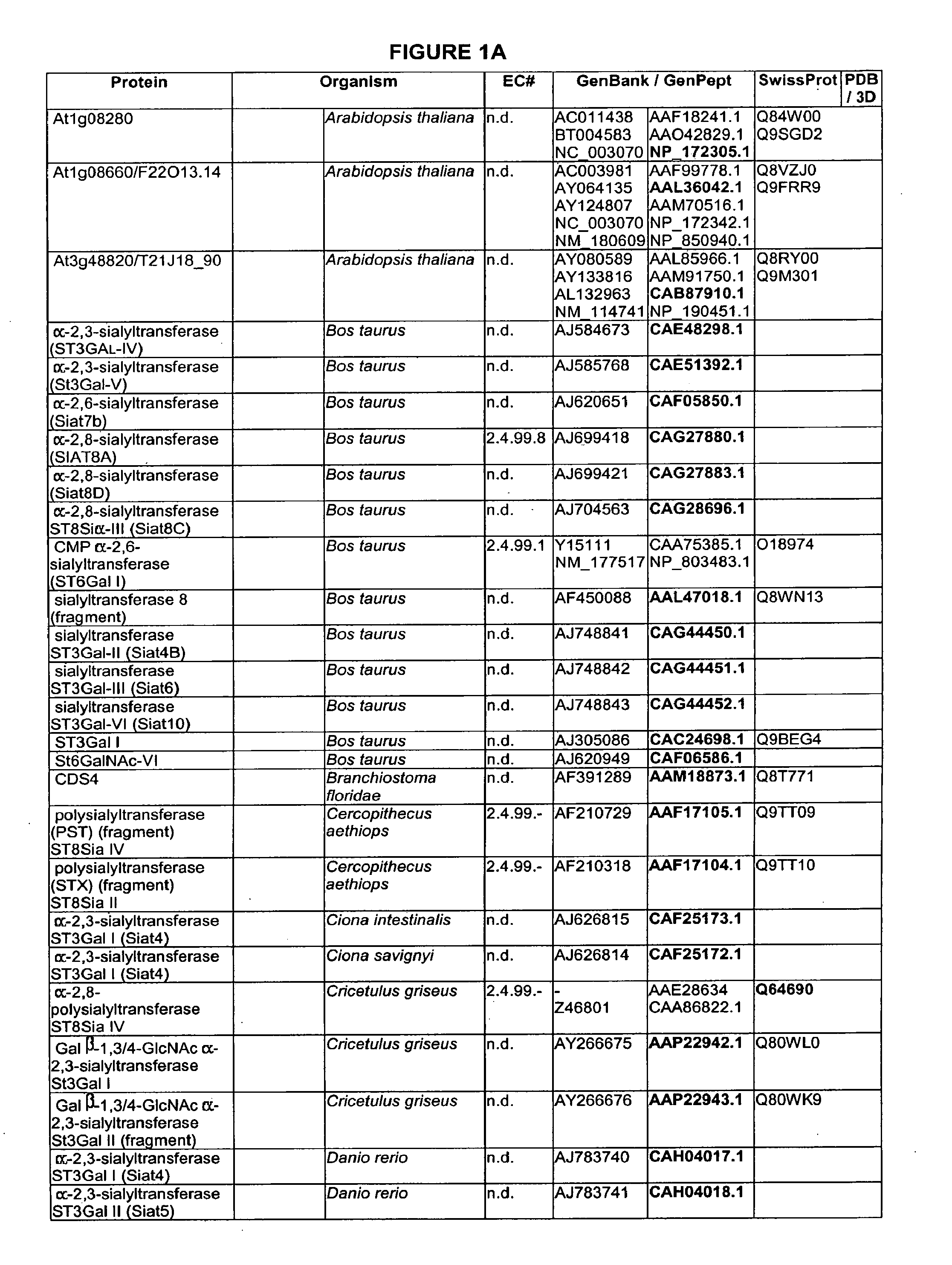

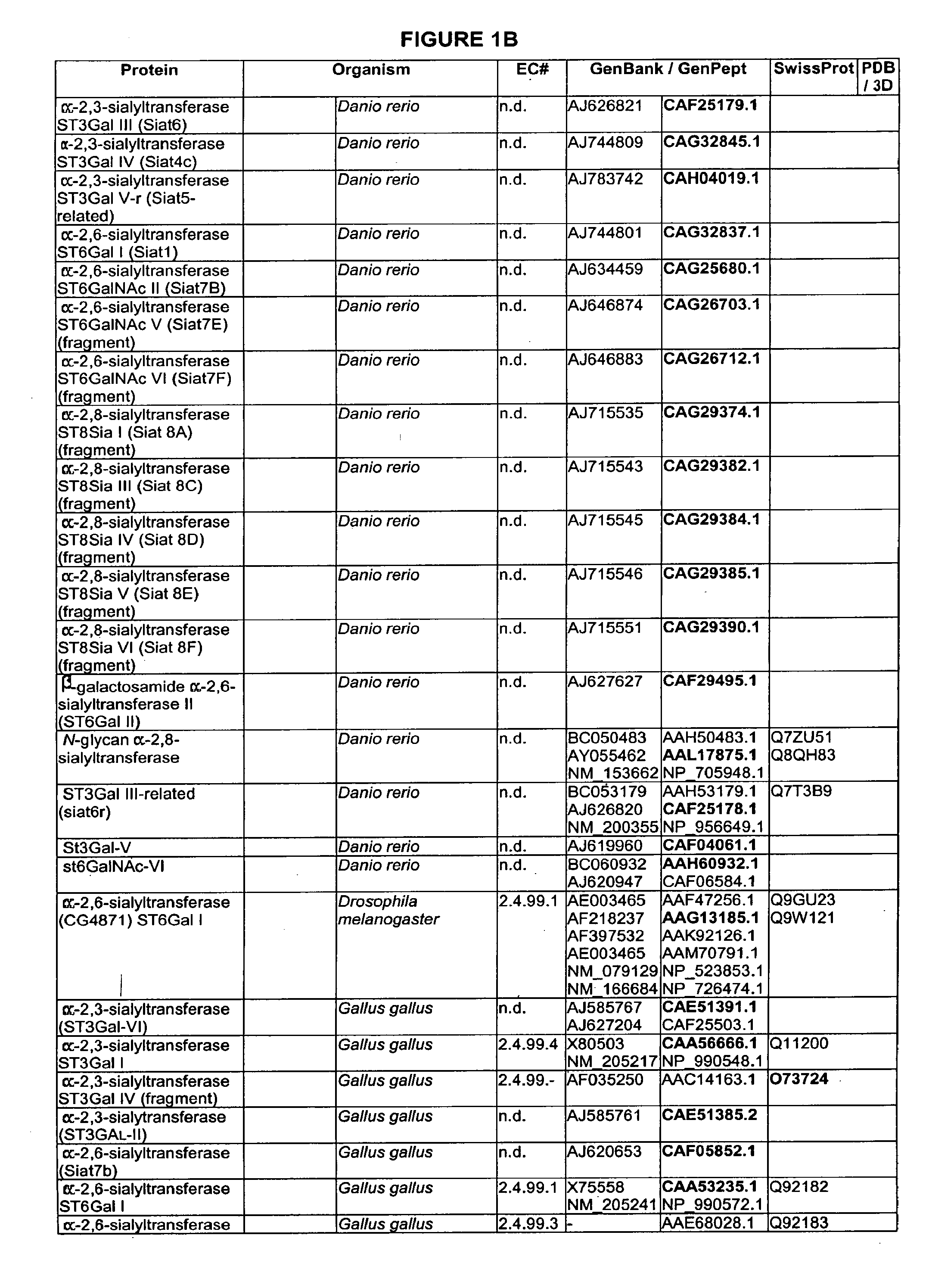

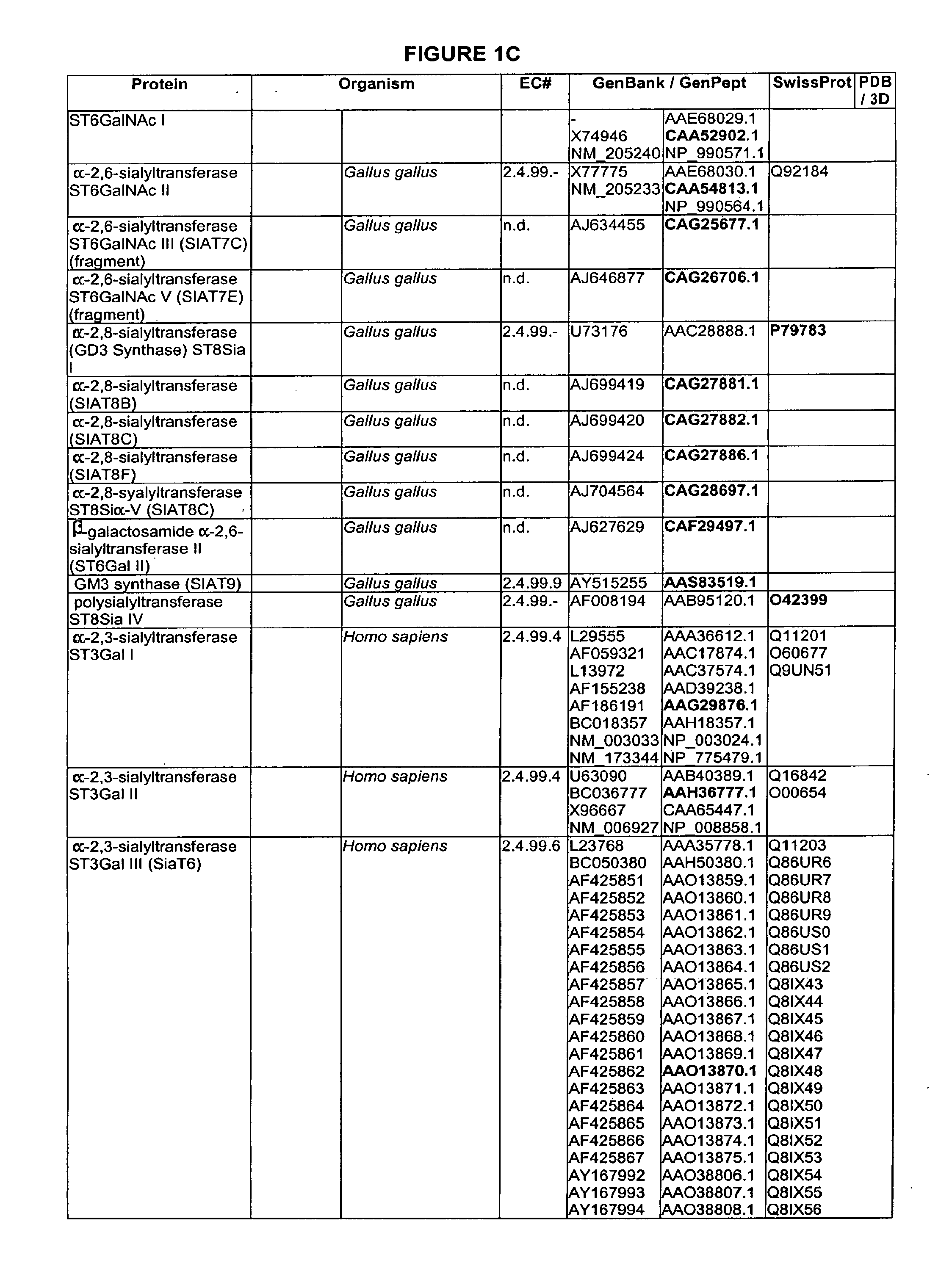

Enzymatic modification of glycopeptides

InactiveUS20110318780A1Improve homogeneityHigh degree of homogeneityFermentationLipid formationGlycopeptide

The present invention provides glycoconjugates that are formed through the enzymatically-mediated coupling of a glycosyl moiety, e.g., on a peptide or lipid, and a modifying group that includes an acyl group. The conjugates include the modifying group tethered to the glycosyl moiety through a linking moiety that includes an acyl residue. Also provided are methods for preparing the conjugates of the invention

Owner:RATIOPHARM GMBH

Method for fabrication of a contact structure

ActiveUS20050153546A1Small thicknessHigh-quality electroplatingSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsAdemetionine

A method for producing a contact structure on a structured surface comprising producing a first conductive layer on the structured surface, wherein the first conductive layer comprising tungsten. A conductive seed layer is produced on the first conductive layer, the contact structure being produced by electroplating on the seed layer. The first conductive layer serves as an etch stop for selectively removing substrate material from the backside.

Owner:INFINEON TECH AG

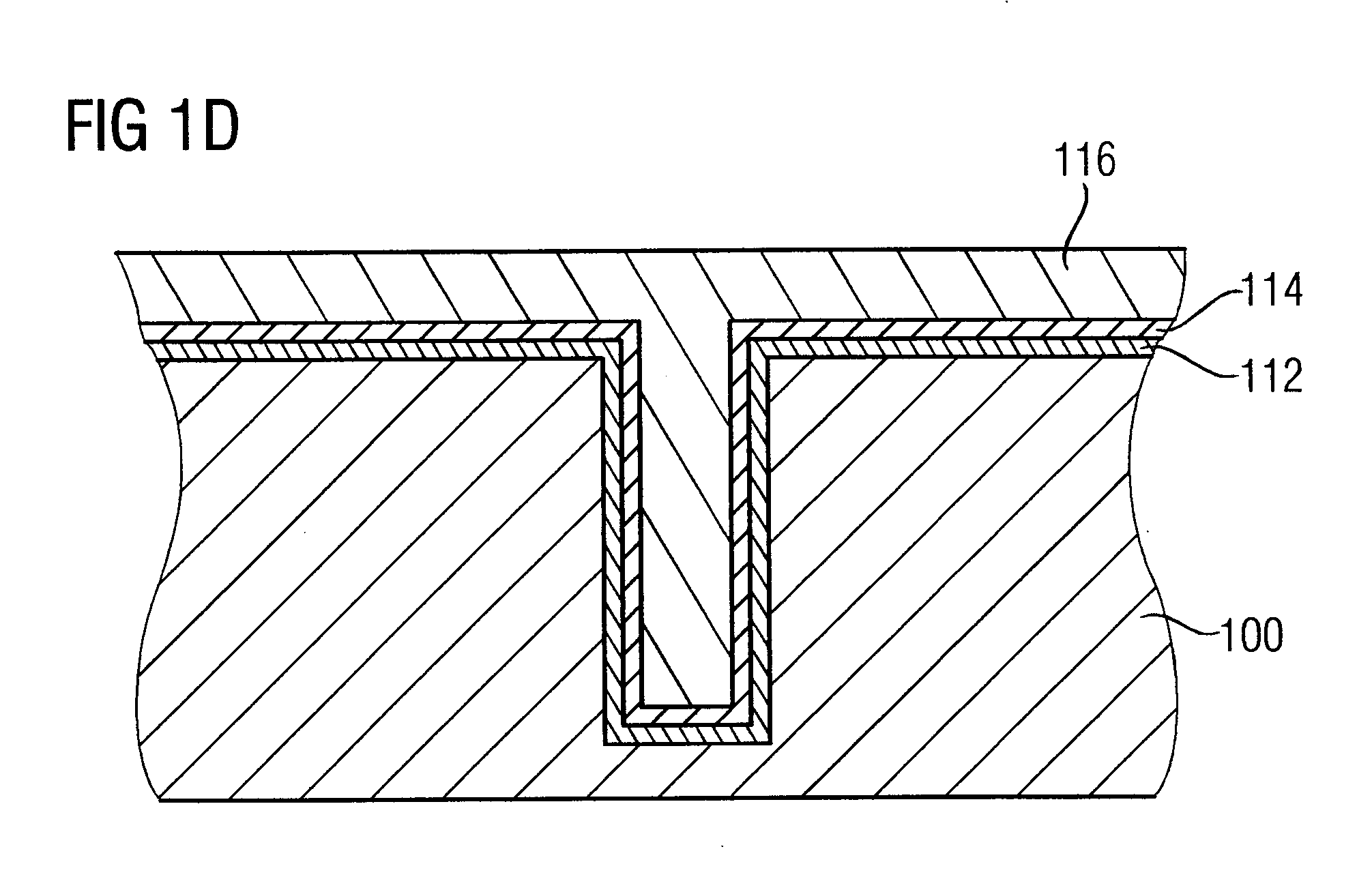

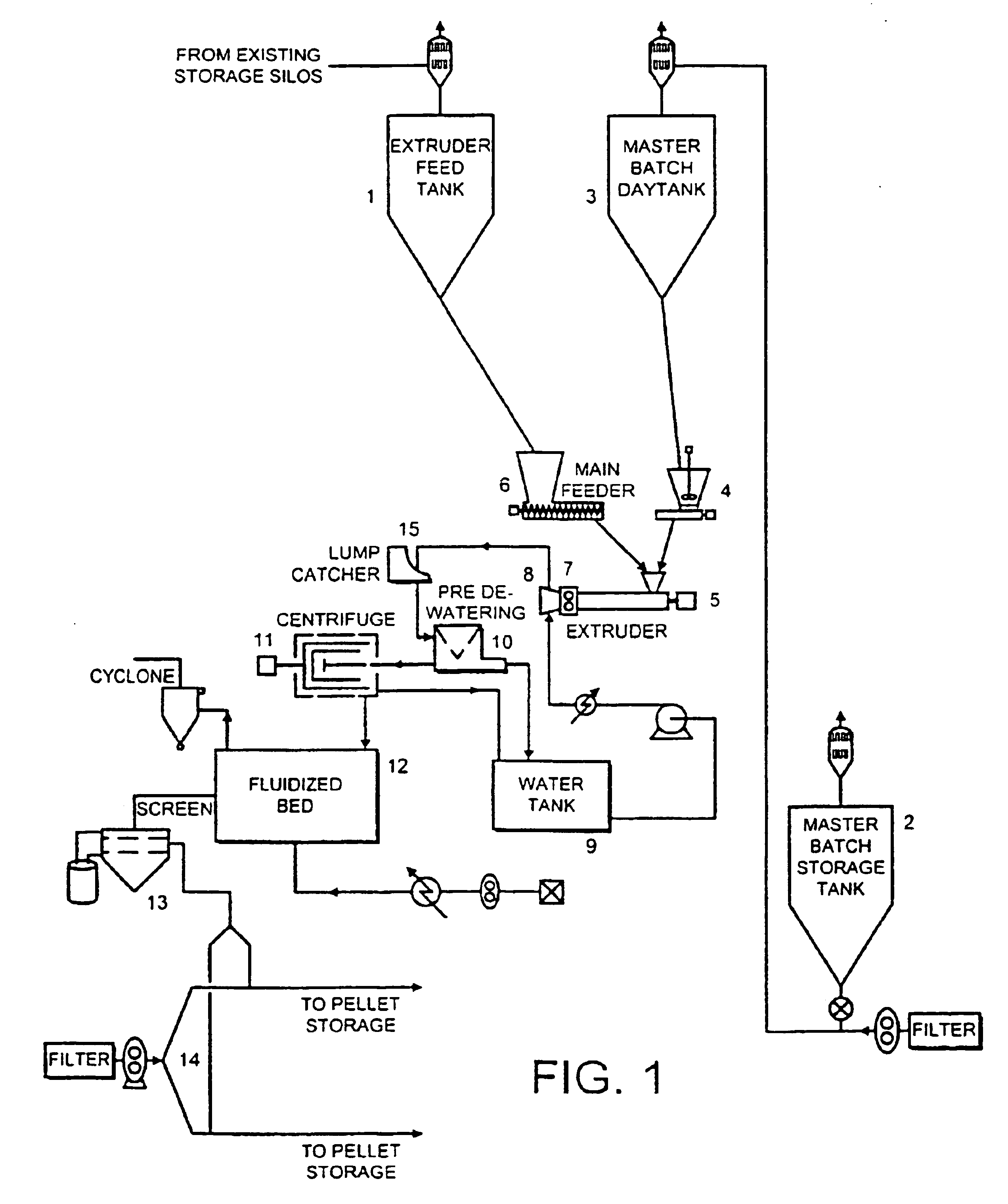

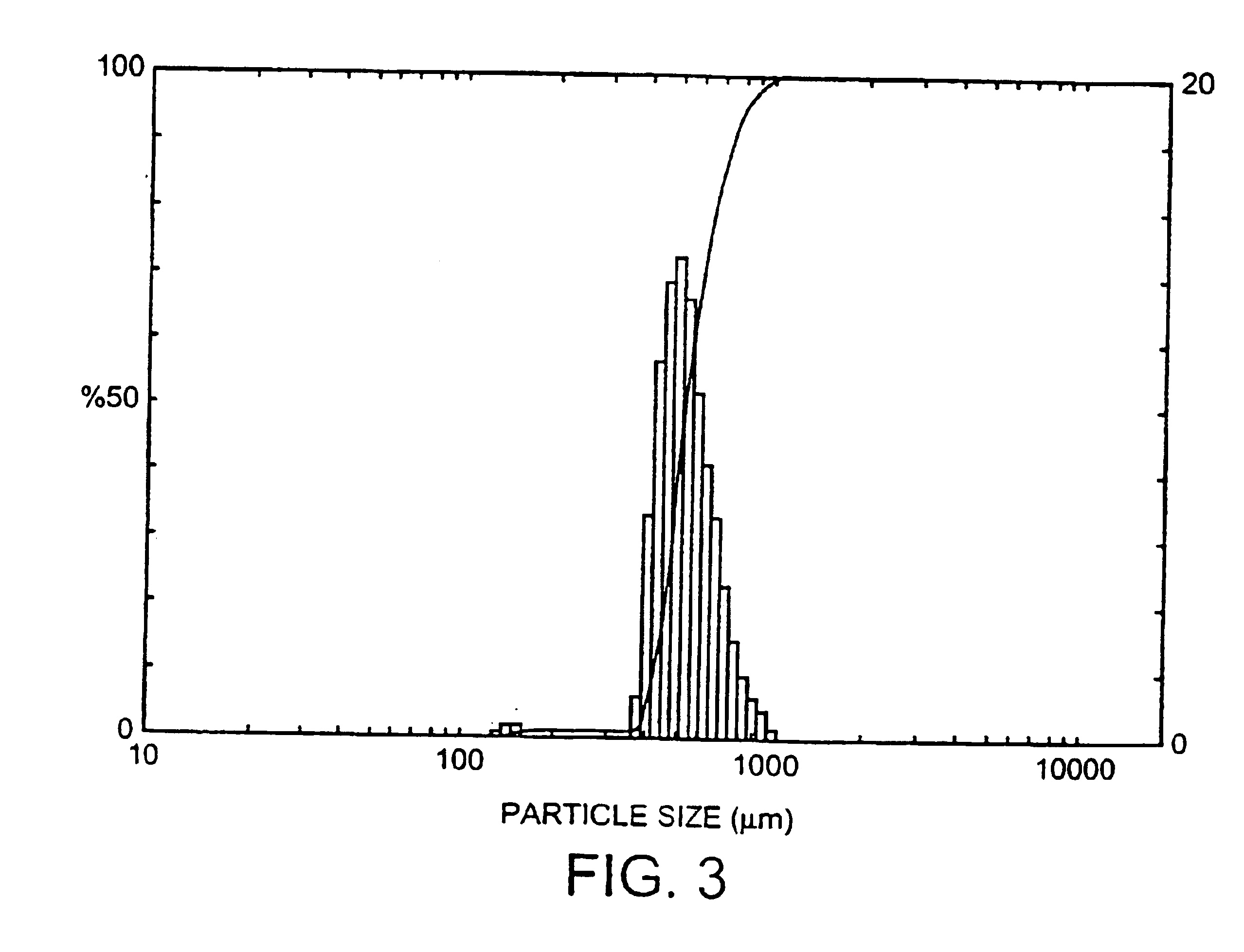

Method of producing pelletized polyolefin

Rotational moulded products are prepared by producing a mixture of a polyolefin and optionally at least one additive, extruding this mixture in melt form through orifices in a die, pelletizing the mixture extruded through the orifices to form micropellets having a particle size distribution D(v, 0.5) of 0.1 to 1 mm, and a value of the ratio of D(v, 0.9)-D(v, 0.1) to D(v, 0.5) of no more than 1, drying the micropellets to a residual water content of no more than 1% weight, and if desired packaging the micropellets.

Owner:BOREALIS TECH OY

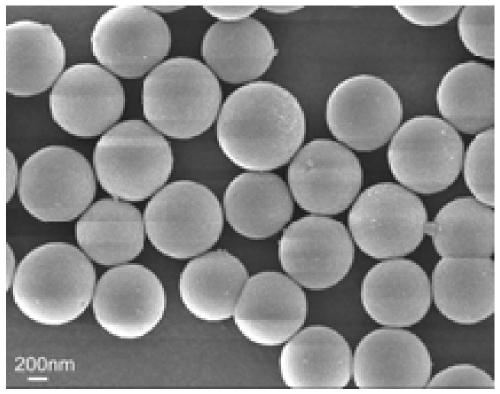

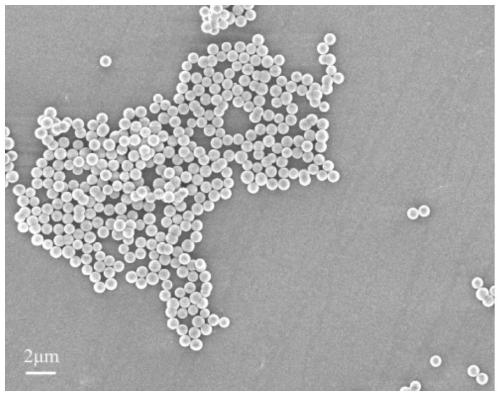

Preparation method for small-particle-size magnetic agarose microspheres

ActiveCN103483602AGood technical effectHigh magnetic responseOther chemical processesOrganic/organic-metallic materials magnetismMicrosphereOil phase

The invention discloses a preparation method for small-particle-size magnetic agarose microspheres. According to the preparation method, emulgator and hydrophobic organic solvent serve as an oil phase, mixed liquor of agarose and superparamagnetic Fe3O4 aqueous solutions serves as an aqueous phase, the aqueous phase is added into the oil phase under mechanical stirring to carry out pre-dispersion, then ultrasonication is carried out on pre-dispersion emulsion, and cooling, magnetic separation and purification are carried out on the crushed emulsion to obtain the small-particle-size magnetic agarose microspheres. The magnetic agarose microspheres prepared according to the preparation method have high magnetic response and superparamagnetism, and compared with commercially available products, the magnetic agarose microspheres have smaller particle sizes, larger specific surface areas, more active sites, and broad application prospects. Due to the fact that hydrophilic magnetic cores are adopted, through the modes of vortex vibration, ultrasonic dispersion, microwave heating, mechanical stirring pre-dispersion, ultrasonication carried out by a cell disruption instrument and the like, not only can the fact that the magnetic cores can be uniformly dispersed in the agarose solutions be guaranteed, but also the fact that the obtained magnetic agarose is small in particle size is guaranteed, and distribution is narrow.

Owner:BEAVERNANO TECH

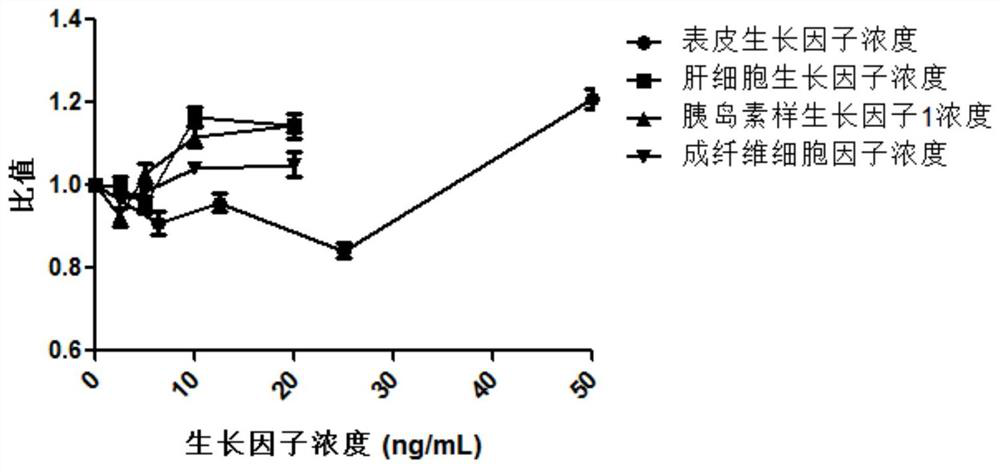

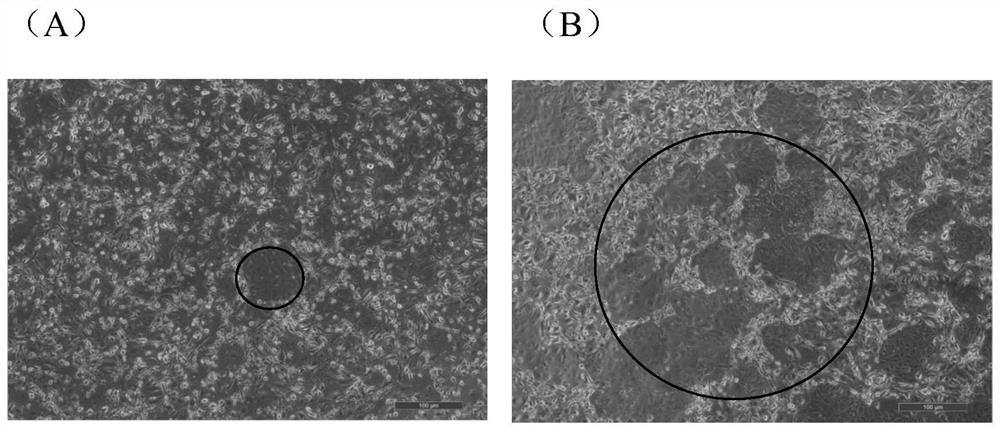

Culture medium for epithelial cells of esophageal squamous carcinoma, culture method and application thereof

ActiveCN113528444AThere will be no interference with the test resultsShort duration of actionCompound screeningApoptosis detectionMatrigelCell culture media

The invention provides a primary cell culture medium for culturing primary esophageal squamous carcinoma epithelial cells and containing a combination of an MST1 / 2 kinase inhibitor and a ROCK kinase inhibitor, and a culture method using the primary cell culture medium. According to the culture method, the primary cells are cultured on a culture vessel coated with extracellular matrigel by using the primary cell culture medium, so that the primary cells are rapidly proliferated. The cell model obtained by the primary cell culture medium and the primary cell culture method can be used for evaluating and screening curative effects of medicines.

Owner:PRECEDO PHARMA CO LTD

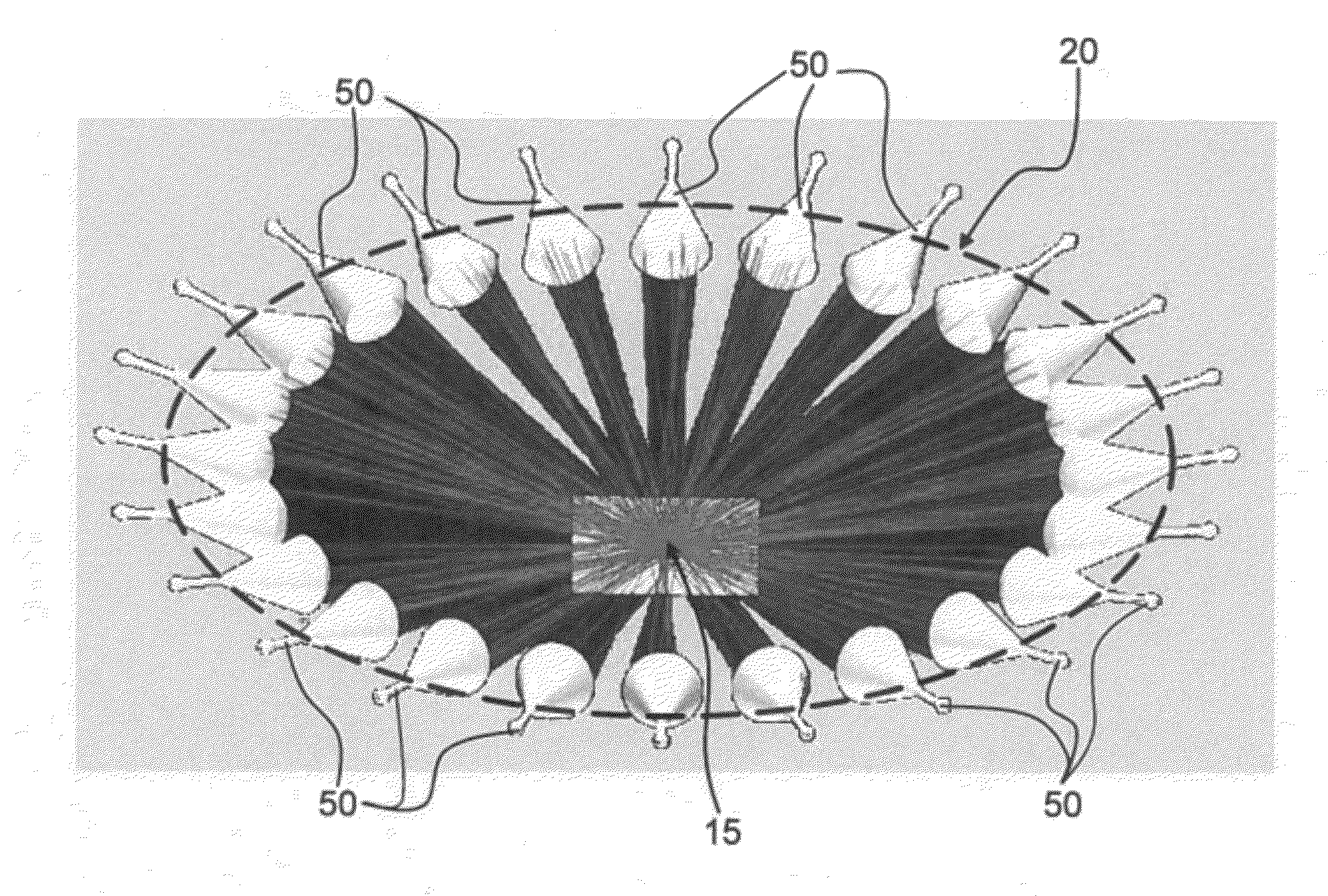

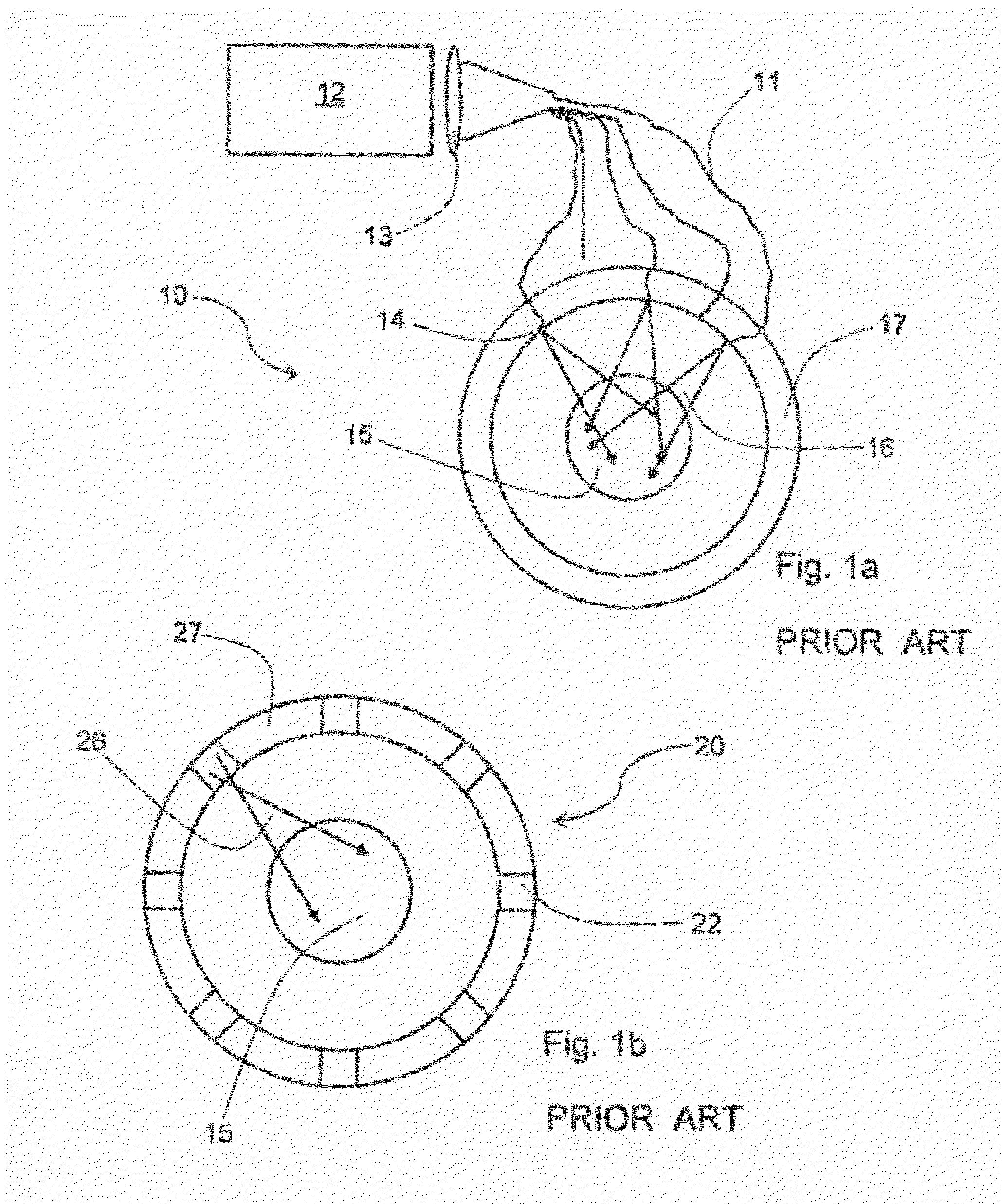

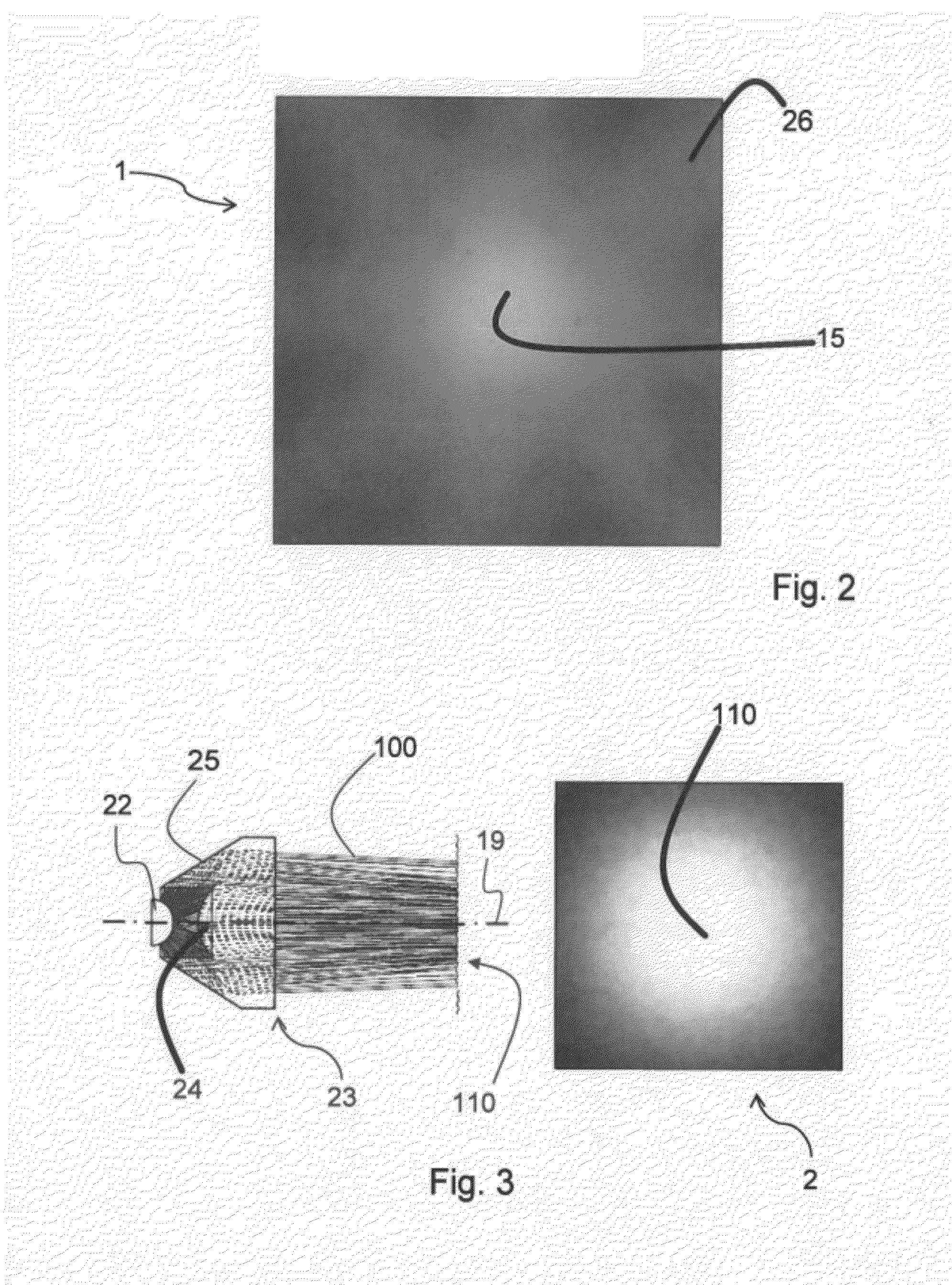

Ring light illuminator, beam shaper and method for illumination

ActiveUS20120188786A1Efficient collectionClear processMechanical apparatusLighting support devicesLight beamOptoelectronics

A ring light illuminator with annularly arranged light sources is disclosed. To each light source there corresponds a light collector, a homogenizing means for light from the light source, and an anamorphic system for imaging an output of the homogenizing means into an area to be illuminated. The anamorphic system compensates deformations of a cross-sectional area of a light beam in a surface to be illuminated due to an oblique angle of incidence of the light beam onto the surface. The homogenizing means in embodiments is a rod, into which light from the light collector is directed. The end of the rod opposite the light collector is imaged by the anamorphic system into the area to be illuminated on the surface. Also disclosed is a method for illumination.

Owner:KLA TENCOR TECH CORP

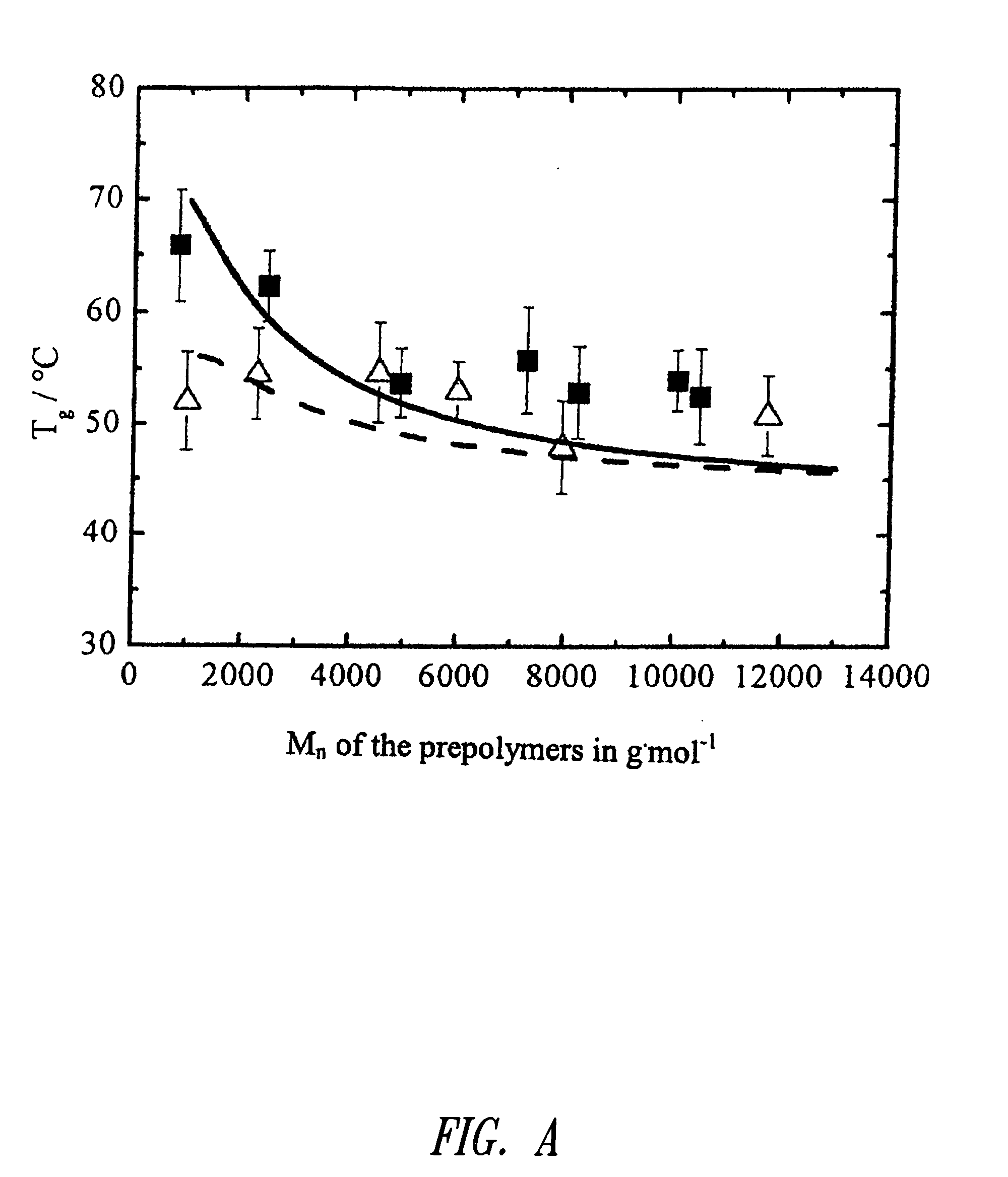

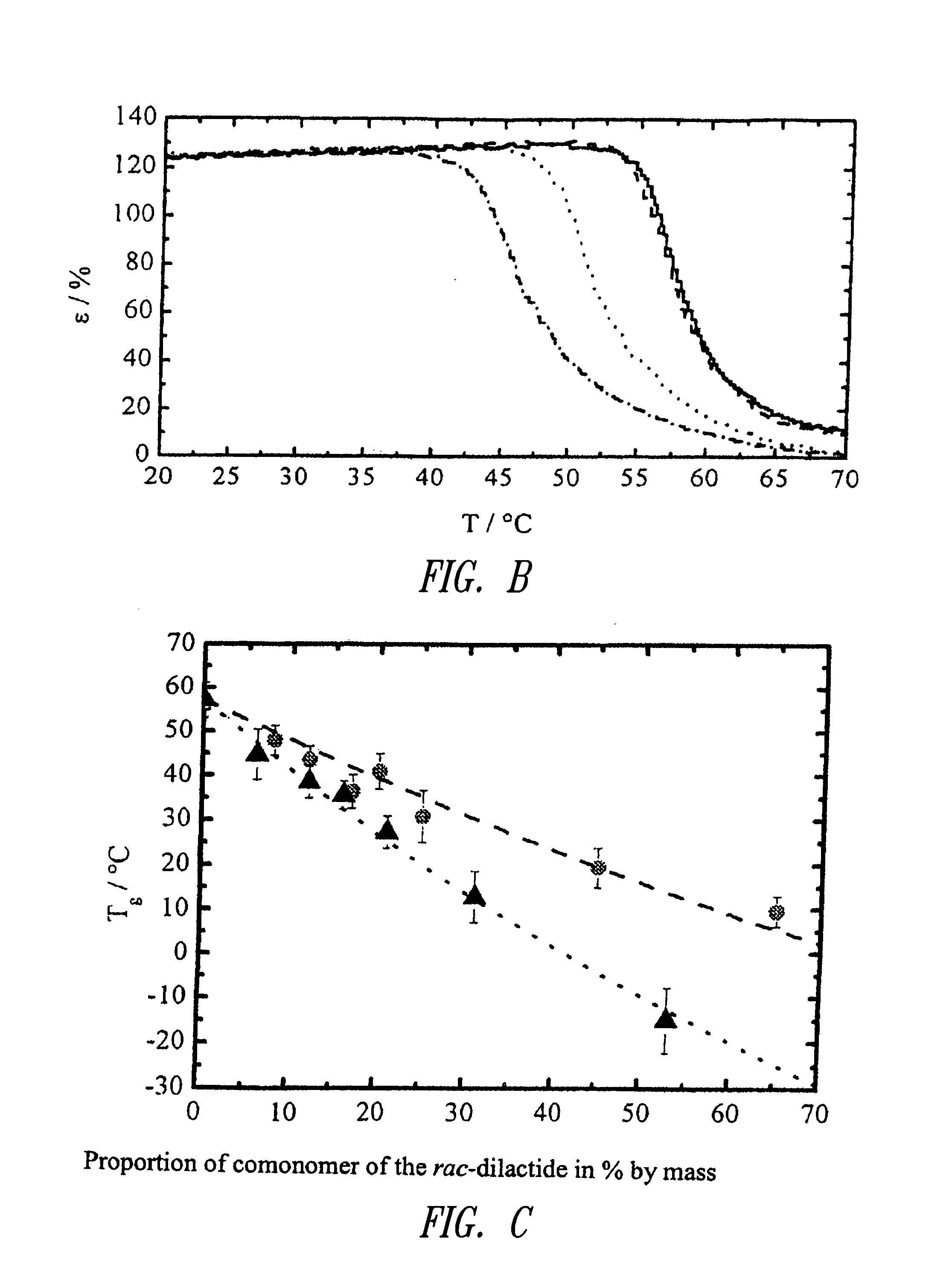

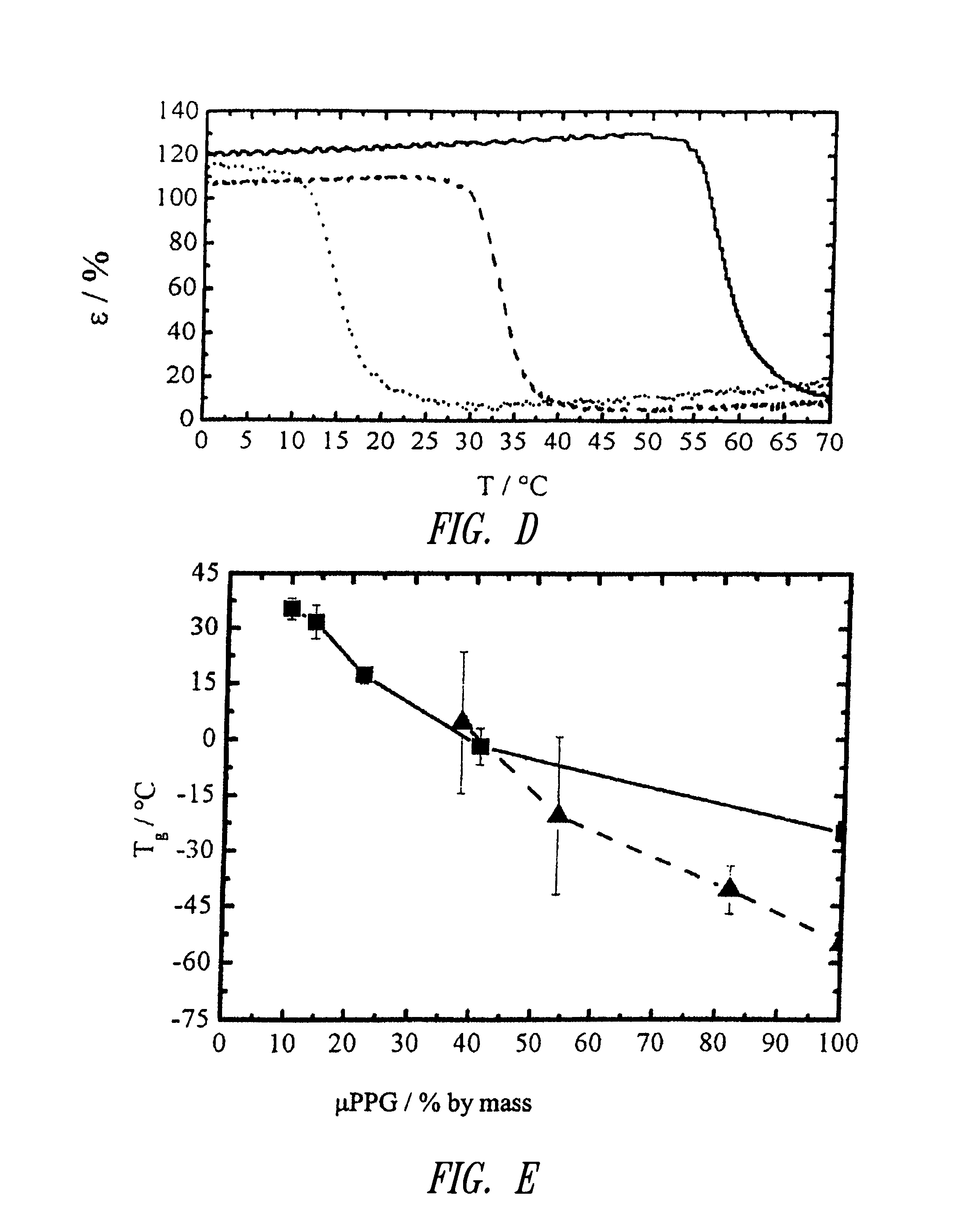

Amorphous Polyester Urethane Networks Having Shape Memory Properties

In order to avoid structural heterogeneities in the networks, in accordance with the invention under consideration, a novel system of amorphous polymer networks comprising one or several segments with shape memory properties is provided. The networks are preferably composed of biodegradable and biocompatible components and open up the possibility for use in the medical domain. The systemic character of the materials allows the thermal and mechanical properties as well as the decomposition behavior to be adjusted in a specific manner. The invention under consideration particularly makes it possible to produce polyphase amorphous networks.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

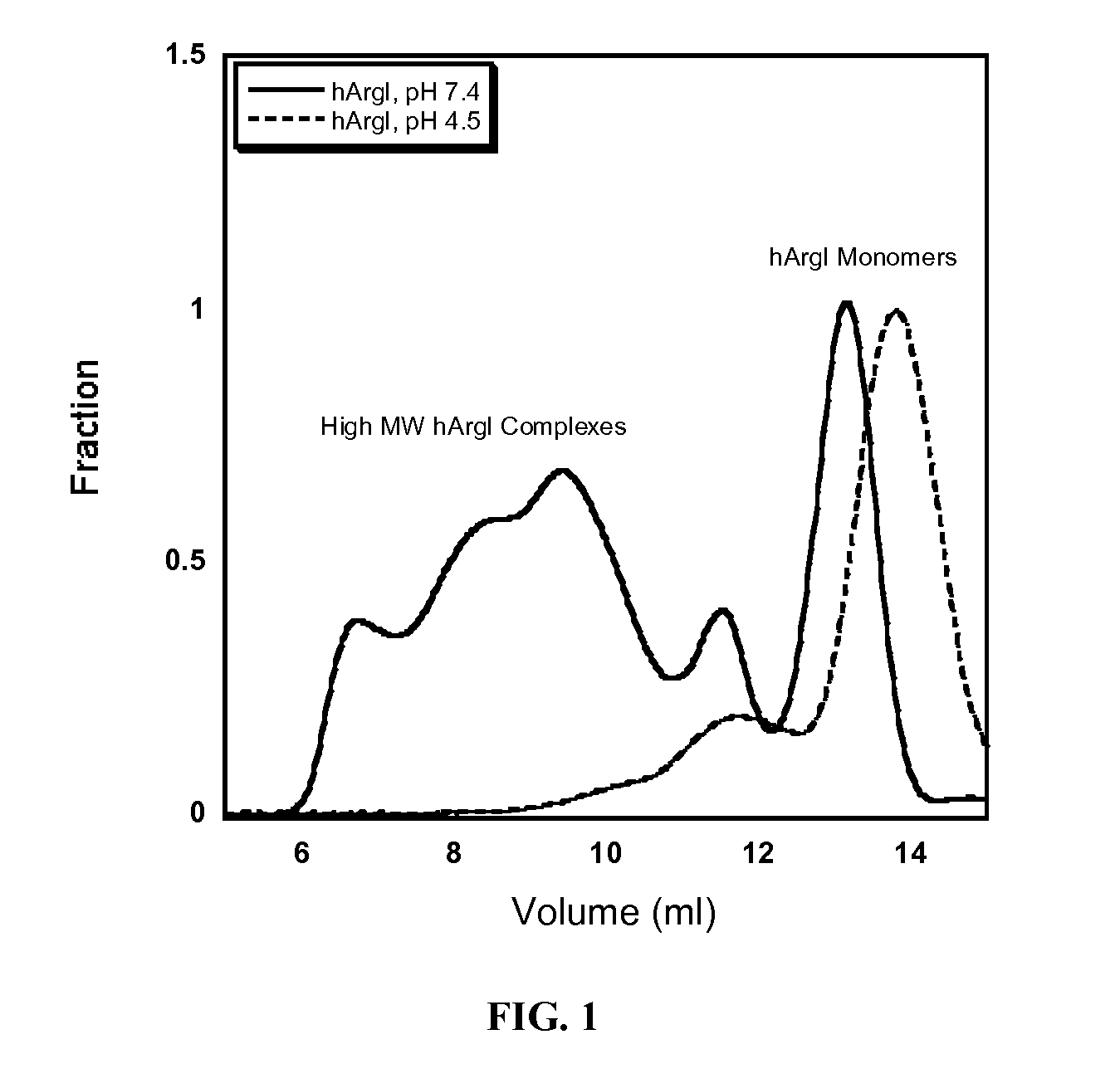

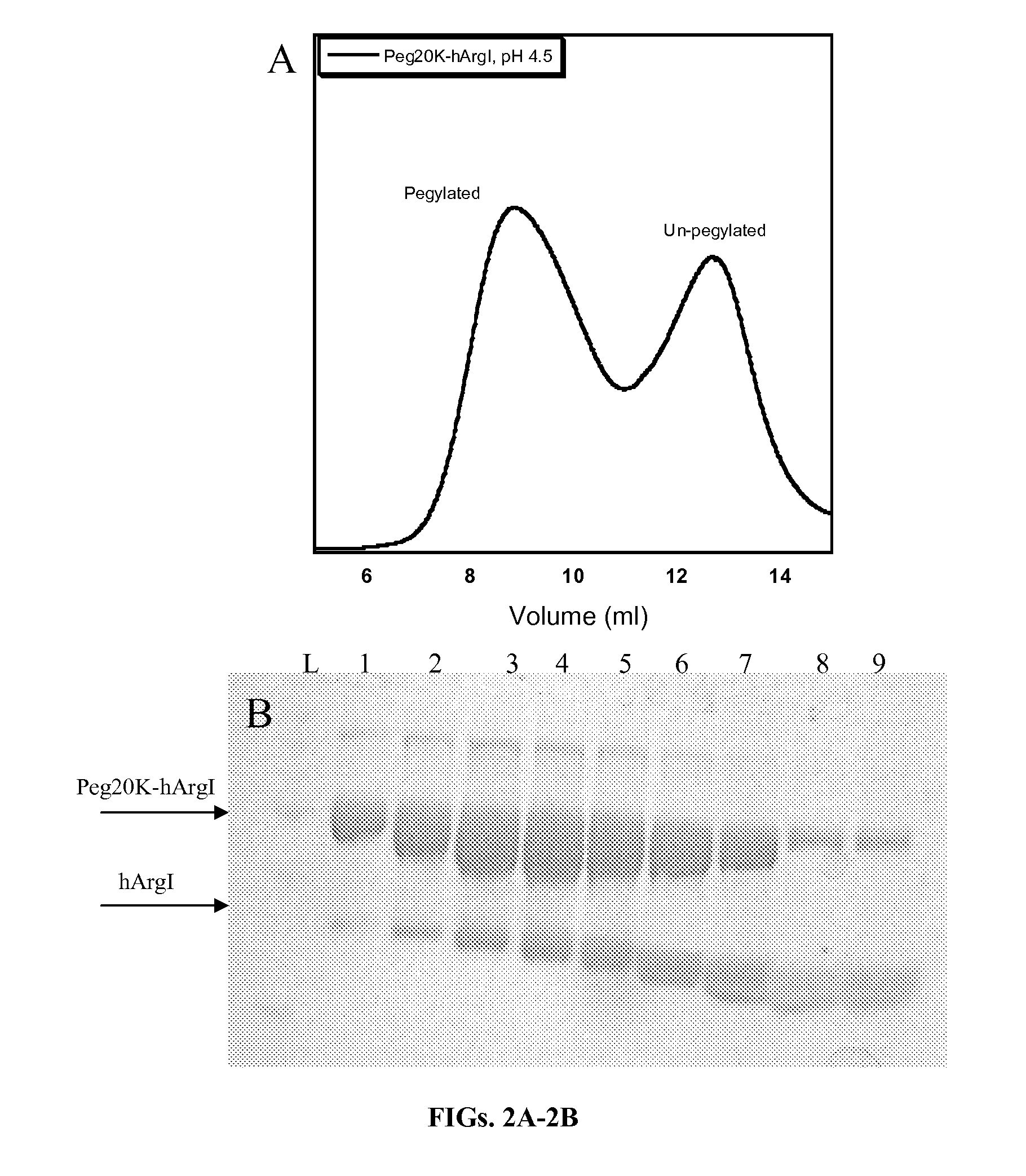

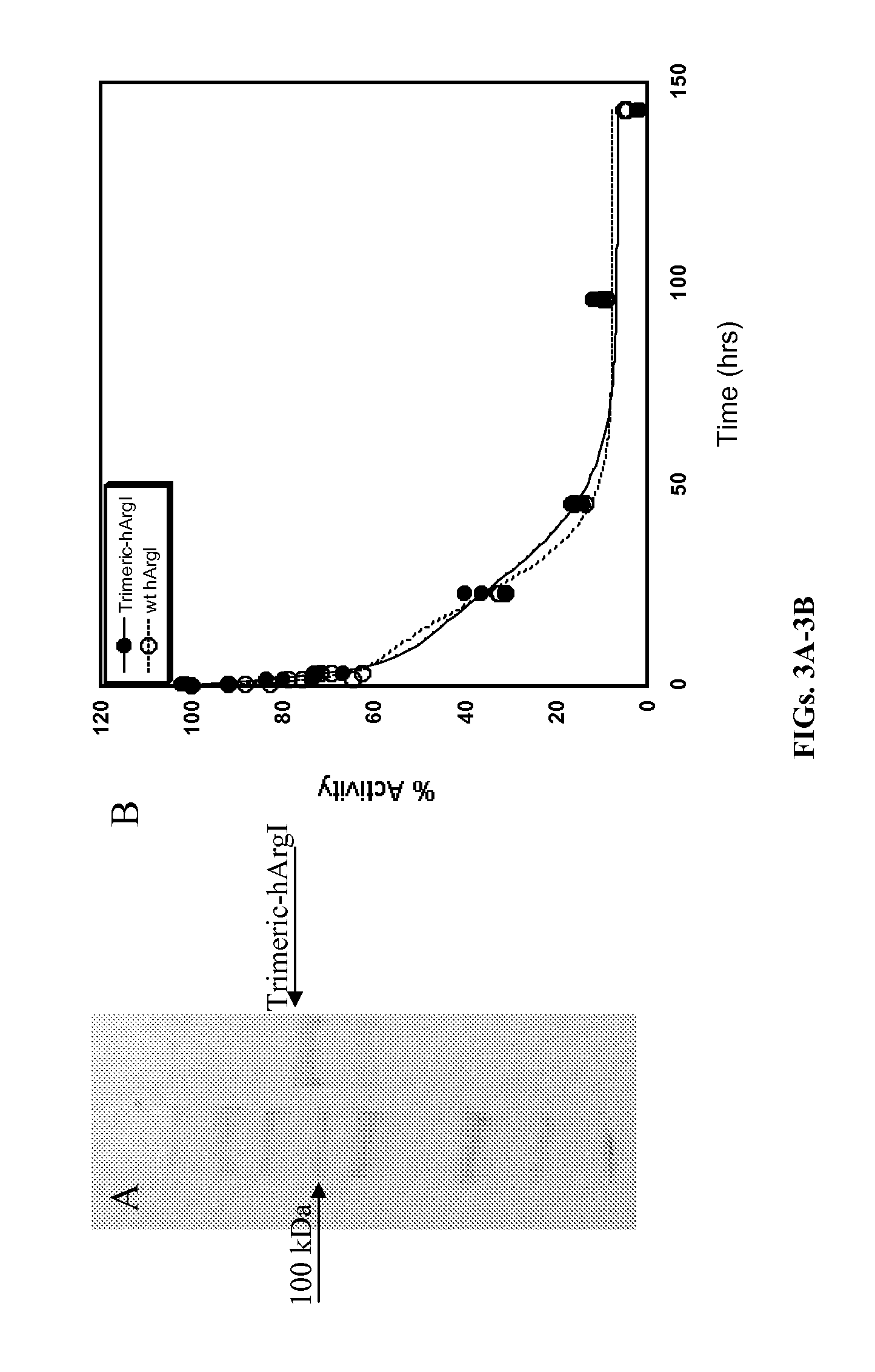

Methods for purifying pegylated arginase

ActiveUS8679479B2High degree of homogeneityHigh molecular weightHydrolasesPeptide/protein ingredientsArginasePEGylation

Owner:AERASE

Lithium nickel manganese oxide positive electrode material and preparation method thereof

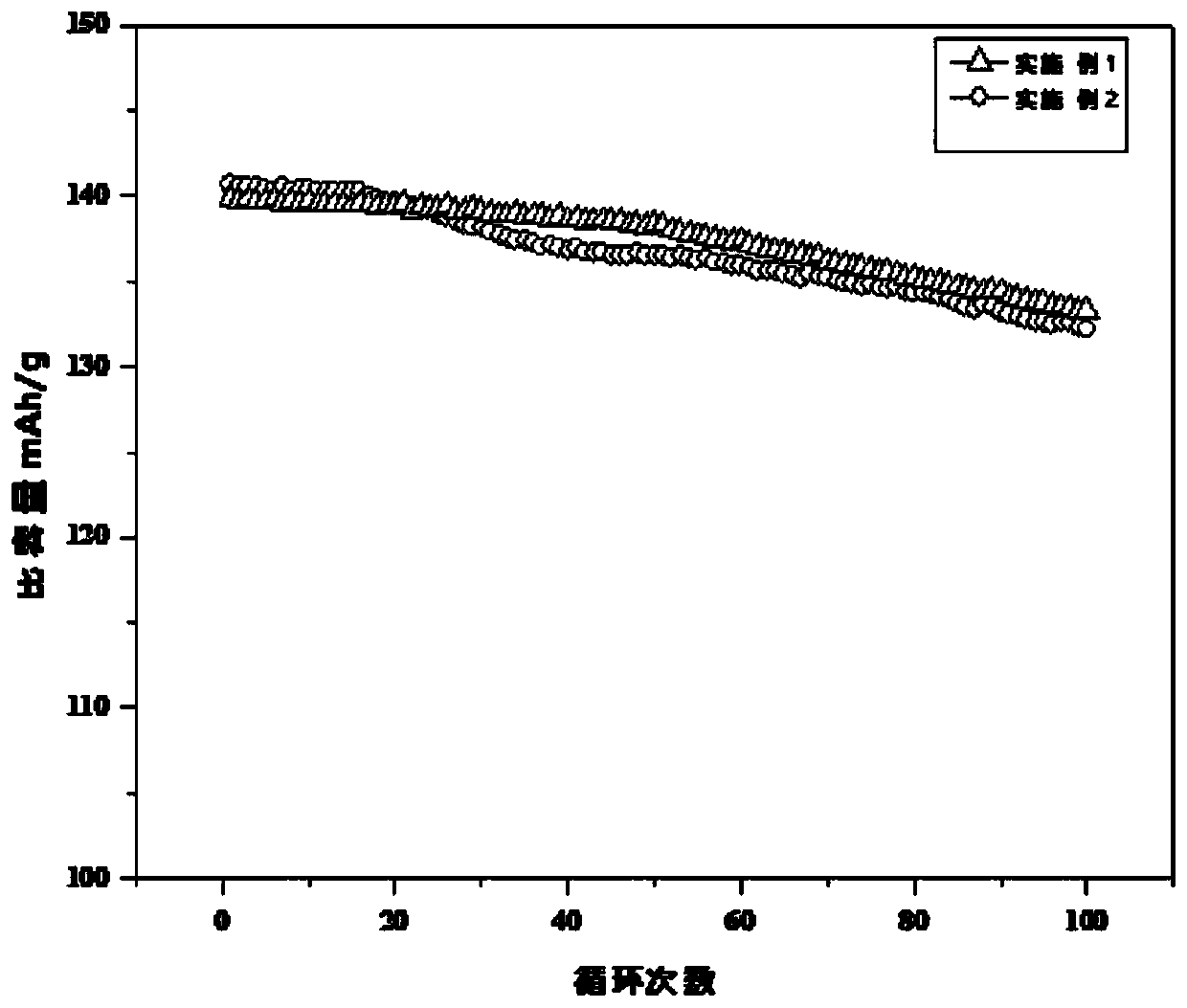

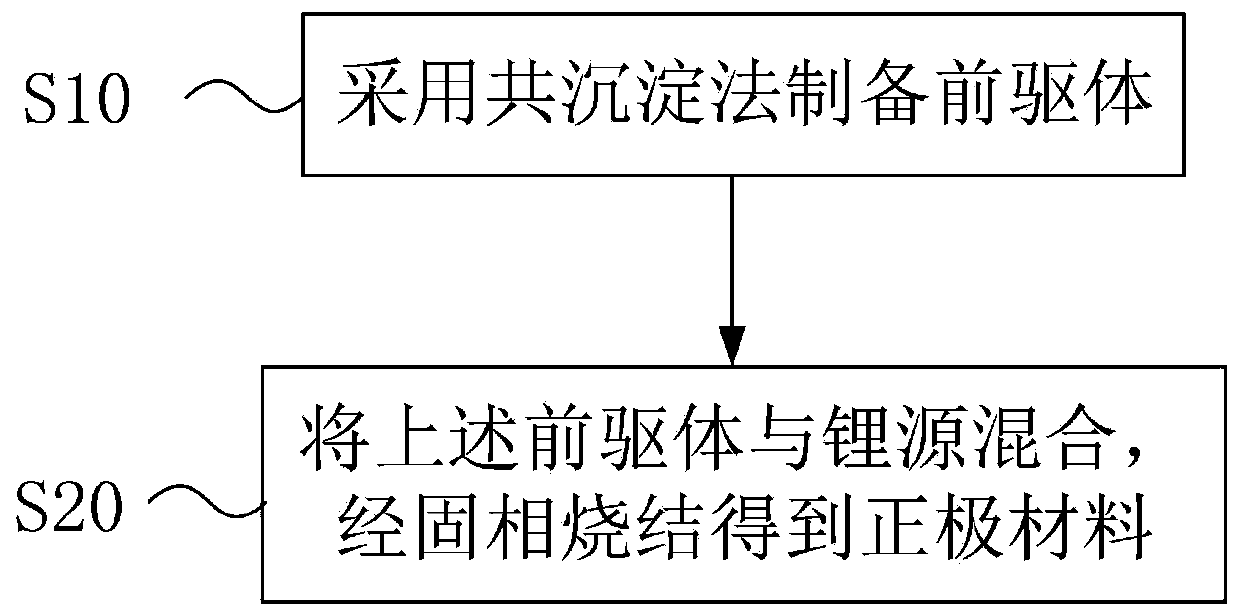

ActiveCN109704411AShape is easy to controlImprove electrochemical performanceCell electrodesSecondary cellsManganateCoprecipitation

The invention discloses a preparation method of a lithium nickel manganese oxide positive electrode material, and relates to the technical field of battery materials. The preparation method comprisesthe following steps: preparing a precursor by adopting a coprecipitation method, mixing the precursor with a lithium source, and carrying out solid-phase sintering to obtain the lithium nickel manganese oxide positive electrode material. The nickel lithium manganate positive electrode material provided by the invention has a high material uniformity degree, controllable morphology and particle size and good electrochemical performance, and performance of a battery made of the lithium nickel manganese oxide positive electrode material can be improved. Meanwhile, a chelating agent in the preparation method is environmentally friendly and is free of pollution, the process flow is simple, operation is easy, cost is low, the synthesis period is short, the product composition is uniform, and uniformity of product batches is good, so that the preparation method is very suitable for industrial production and is an efficient and energy-saving method for preparing the high-voltage lithium nickelmanganese oxide positive electrode material.

Owner:YINLONG ENERGY CO LTD

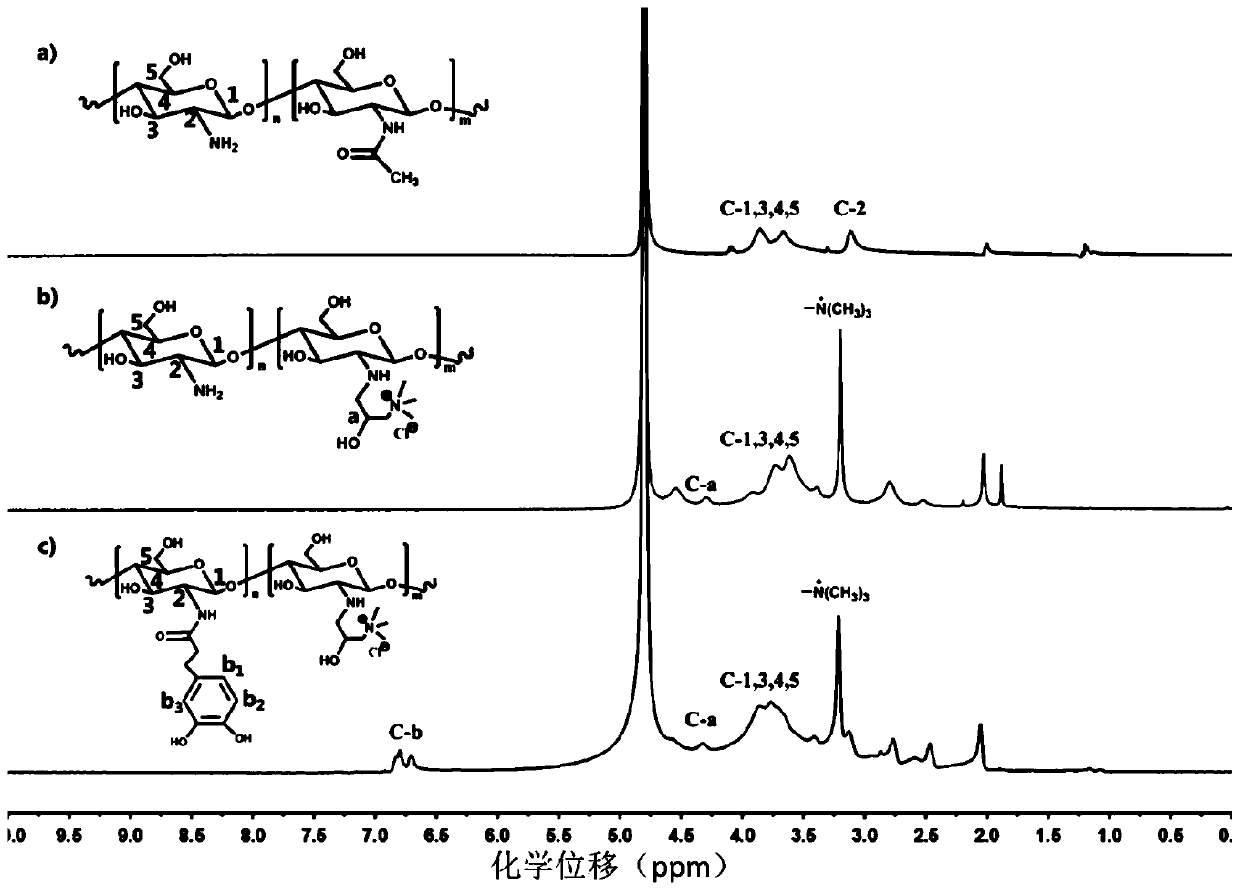

Adhesion thermo-sensitive hydrogel of composite bioglass and preparation method and application of adhesion thermo-sensitive hydrogel

ActiveCN110420350AImprove biological activityGood water solubilityAerosol deliveryInorganic non-active ingredientsBiocompatibility TestingDopamine

The embodiment of the invention provides an adhesion thermo-sensitive hydrogel of composite bioglass. The adhesion thermo-sensitive hydrogel is prepared from the following components in percentage byweight: 25-40% of PDLLA-PEG-PDLLA triblock polymer, 1-1.25% of dopamine modified quaternized chitosan, 1-5% of bio-glass and the balance of deionized water. The adhesion thermo-sensitive hydrogel of the composite bioglass has good adhesion, antibacterial property and biocompatibility. The adhesion thermo-sensitive hydrogel of the composite bioglass can self-adhere to the surface of the skin wound,and is beneficial for promoting skin regeneration and wound repair. The invention further provides a preparation method and application of the adhesion thermo-sensitive hydrogel of the composite bioglass. The preparation method is simple in process and high in yield, and is suitable for large-scale industrial production. The adhesion thermo-sensitive hydrogel of the composite bioglass prepared bythe preparation method has good adhesion, antibacterial property and biocompatibility, and has broad application prospects in the preparation of drugs for skin wound healing.

Owner:SHENZHEN INST OF ADVANCED TECH

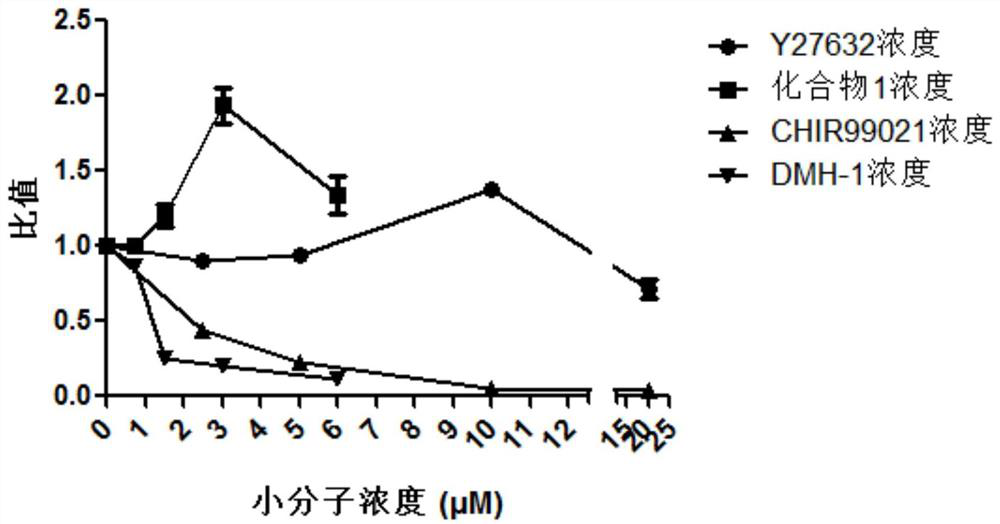

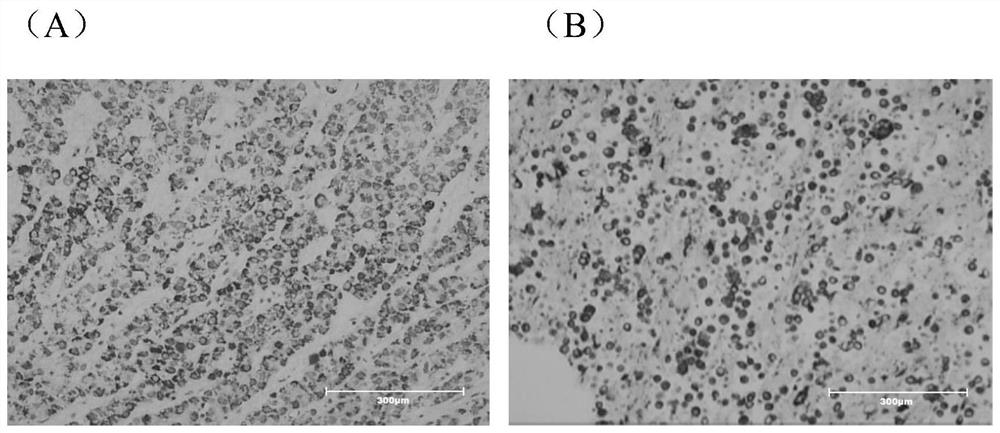

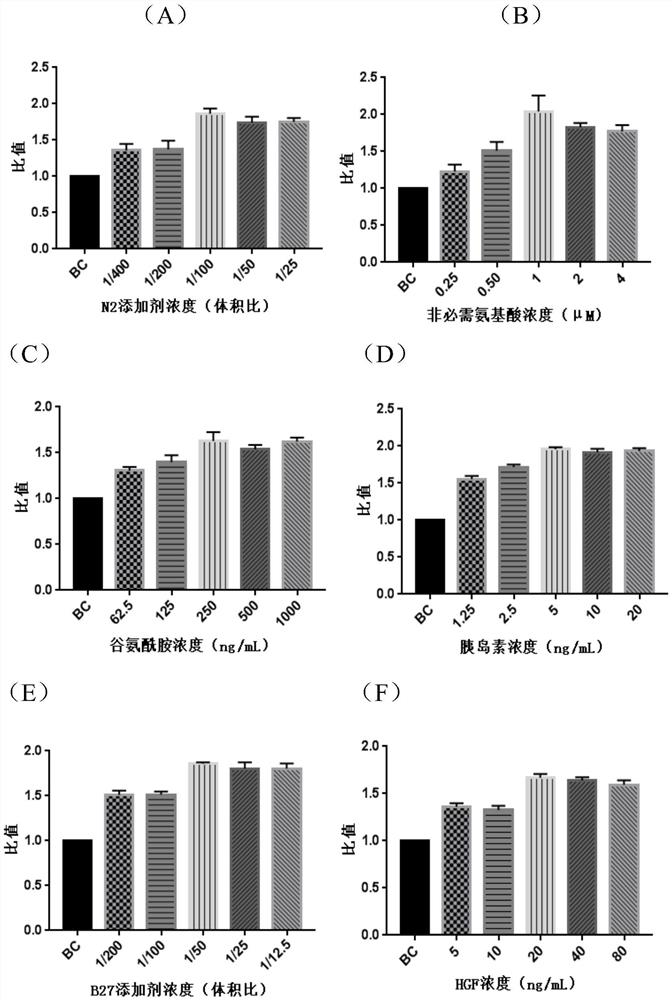

Primary hepatoma carcinoma cell culture medium, primary hepatoma carcinoma cell culture method and application

ActiveCN113373116AImprove efficiencyControllable training costsMicrobiological testing/measurementCulture processPenicillinHydrocortisone

The invention provides a primary hepatoma carcinoma cell culture medium and a primary hepatoma carcinoma cell culture method which are used for rapidly and stably culturing primary hepatoma carcinoma cells. The primary hepatoma carcinoma cell culture medium contains glutamine, non-essential amino acid, a basic fibroblast growth factor, a hepatocyte growth factor, IL-6, an epidermal growth factor, insulin, Y27632, an N2 additive, a B27 additive, Primocin, penicillin, streptomycin, fetal calf serum, optional hydrocortisone and optional R-spondin1. A cell model obtained by the primary hepatoma carcinoma cell culture medium and the primary hepatoma carcinoma cell culture method can be used for evaluating and screening curative effects of medicines.

Owner:PRECEDO PHARMA CO LTD

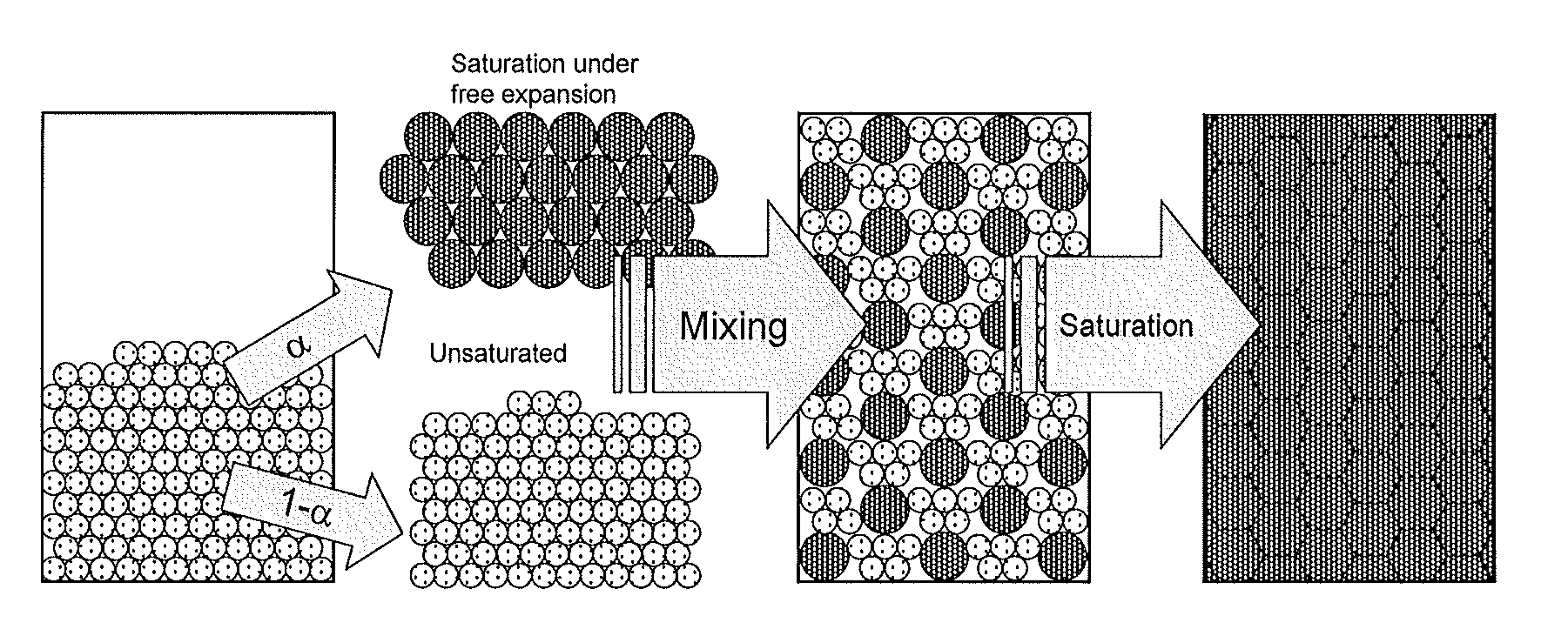

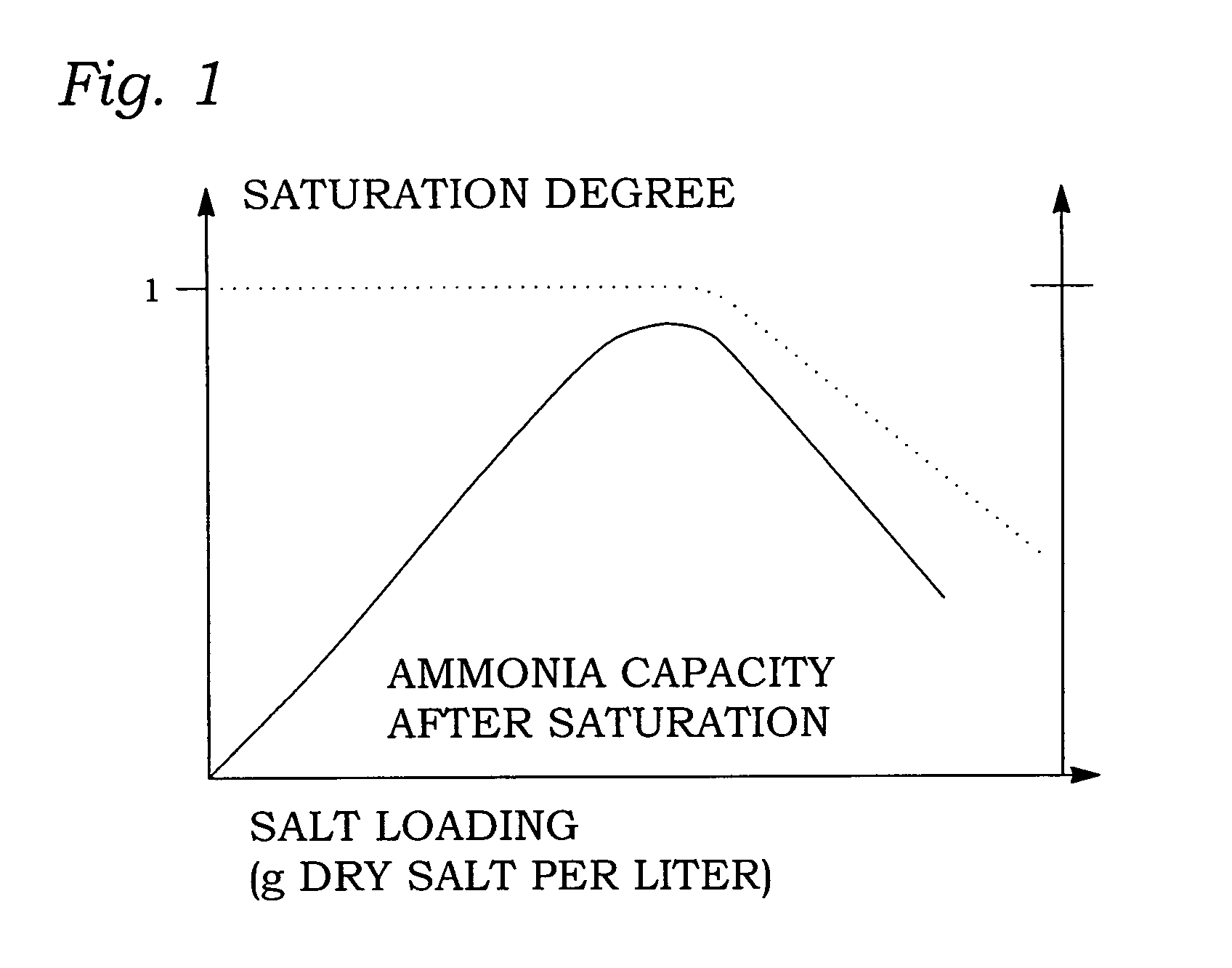

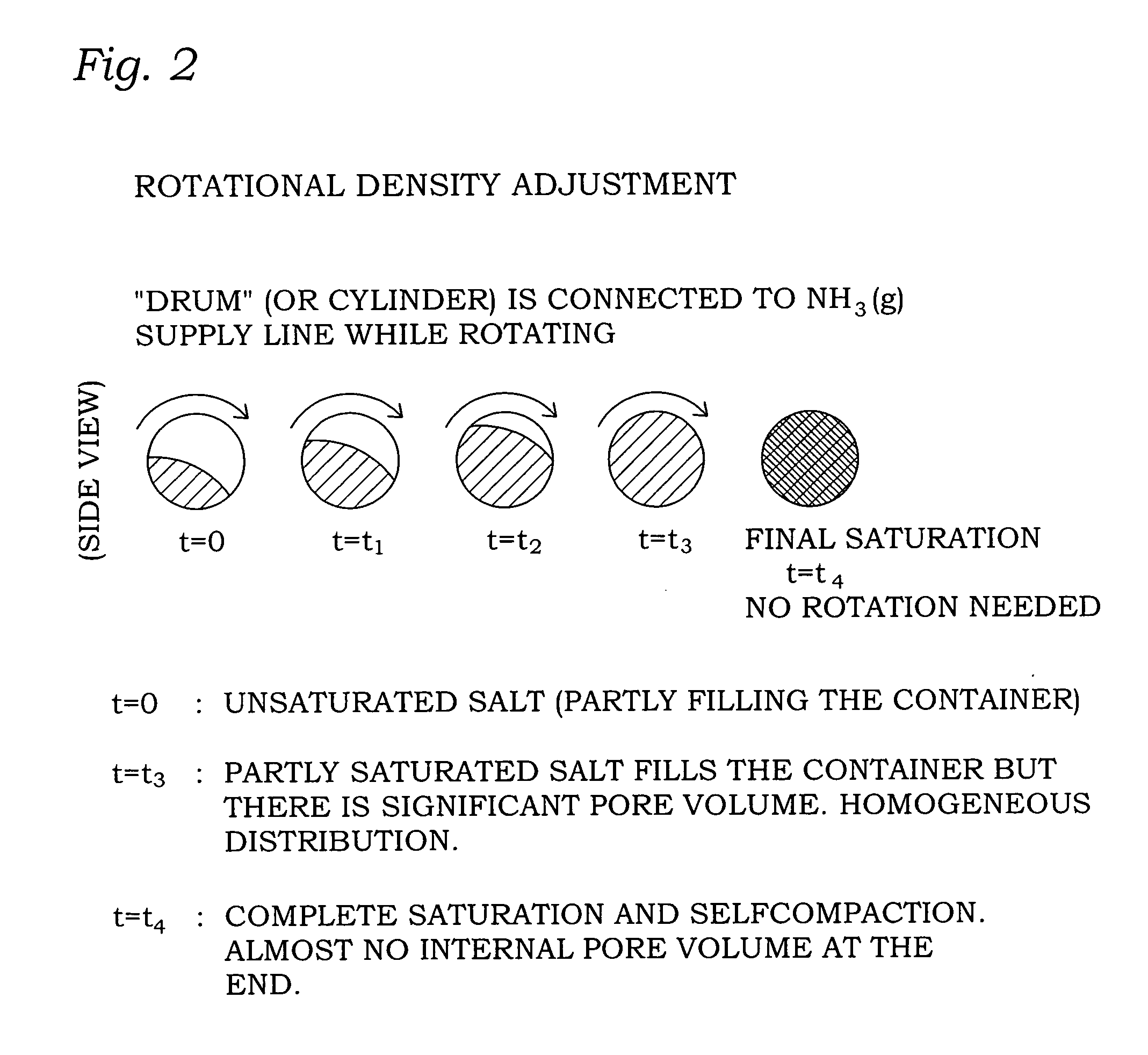

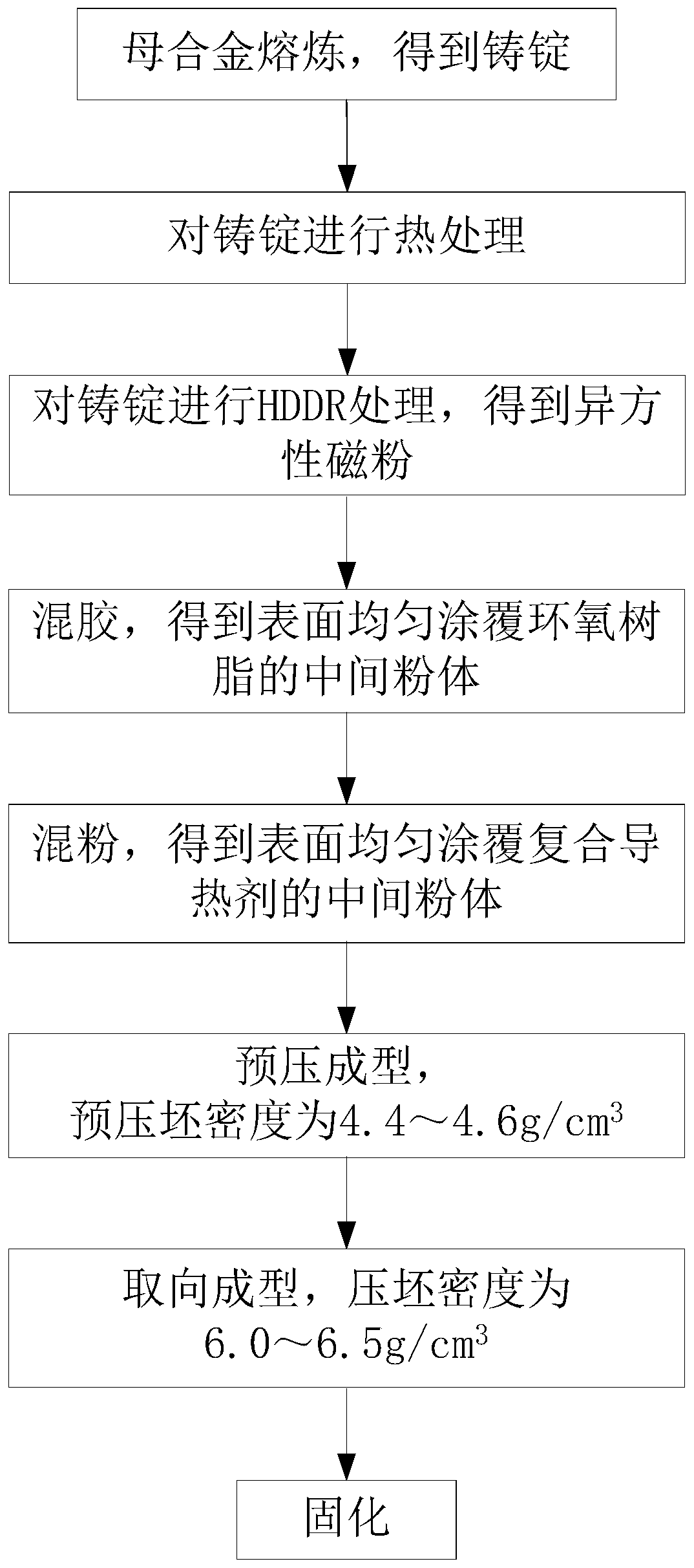

Saturation of Ammonia Storage Materials in Containers

InactiveUS20110236294A1High saturationAvoid mechanical damageCalcium/strontium/barium chloridesPackaging corrosive chemicalsAmmonia storageStorage material

Owner:AMMINEX EMISSIONS TECH

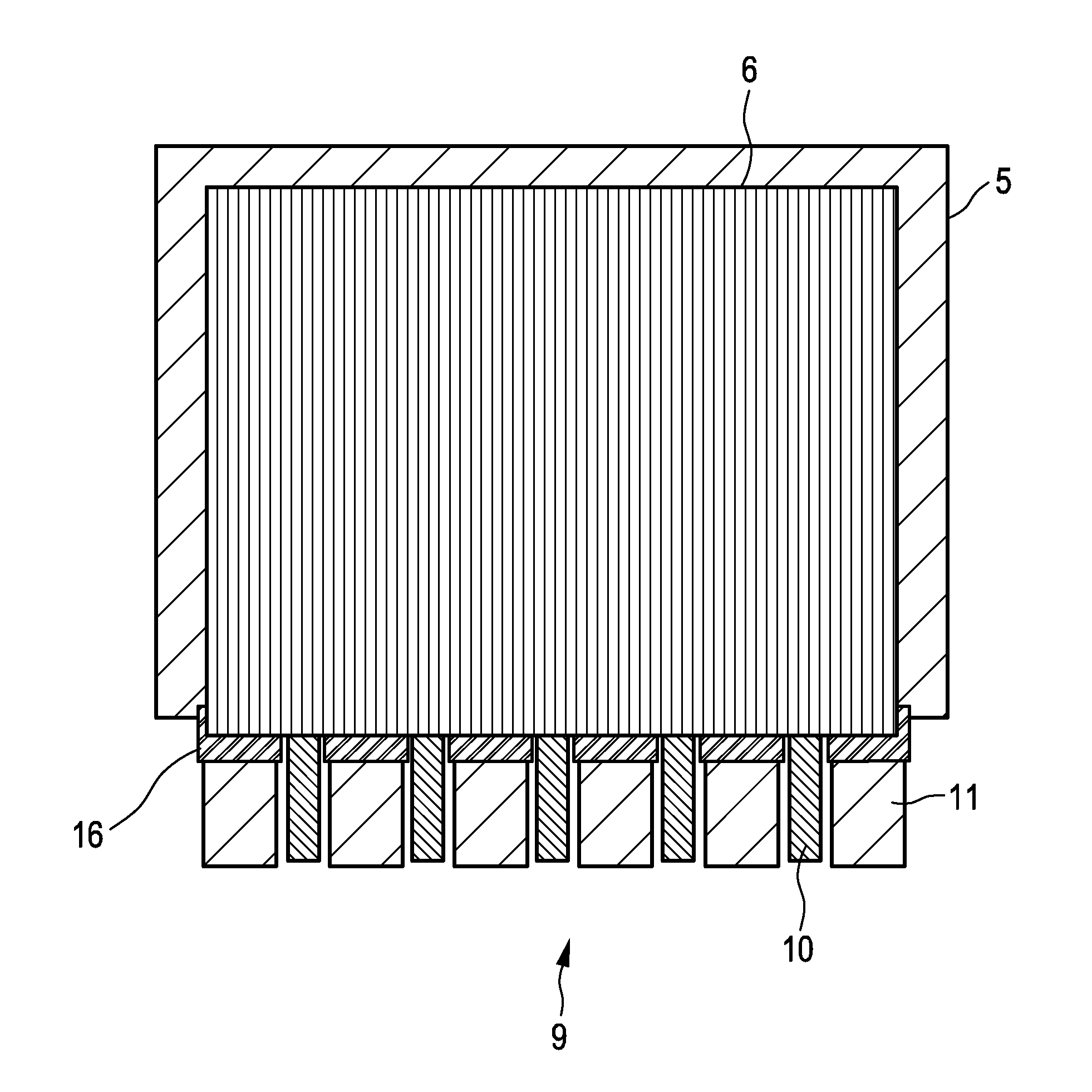

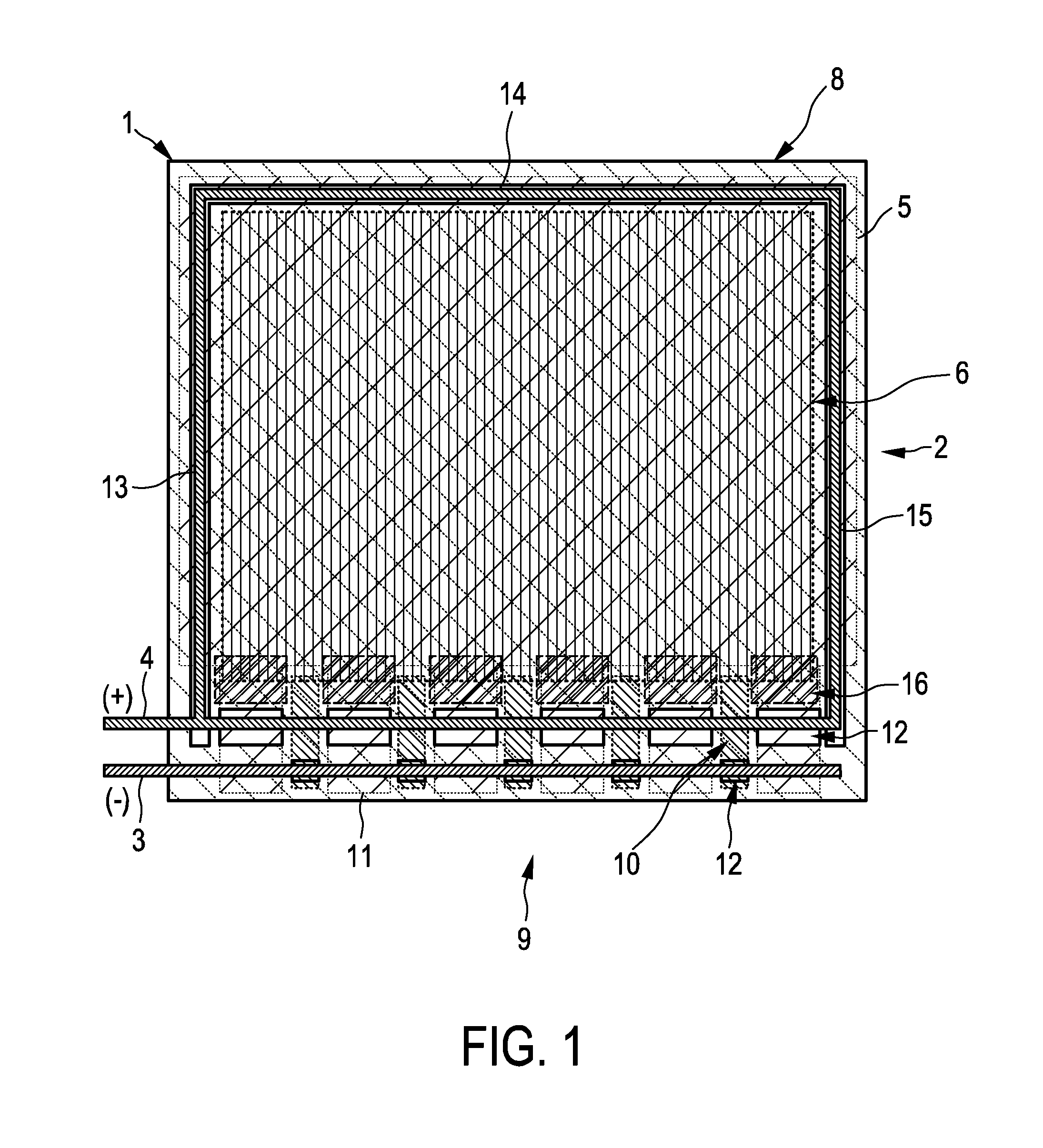

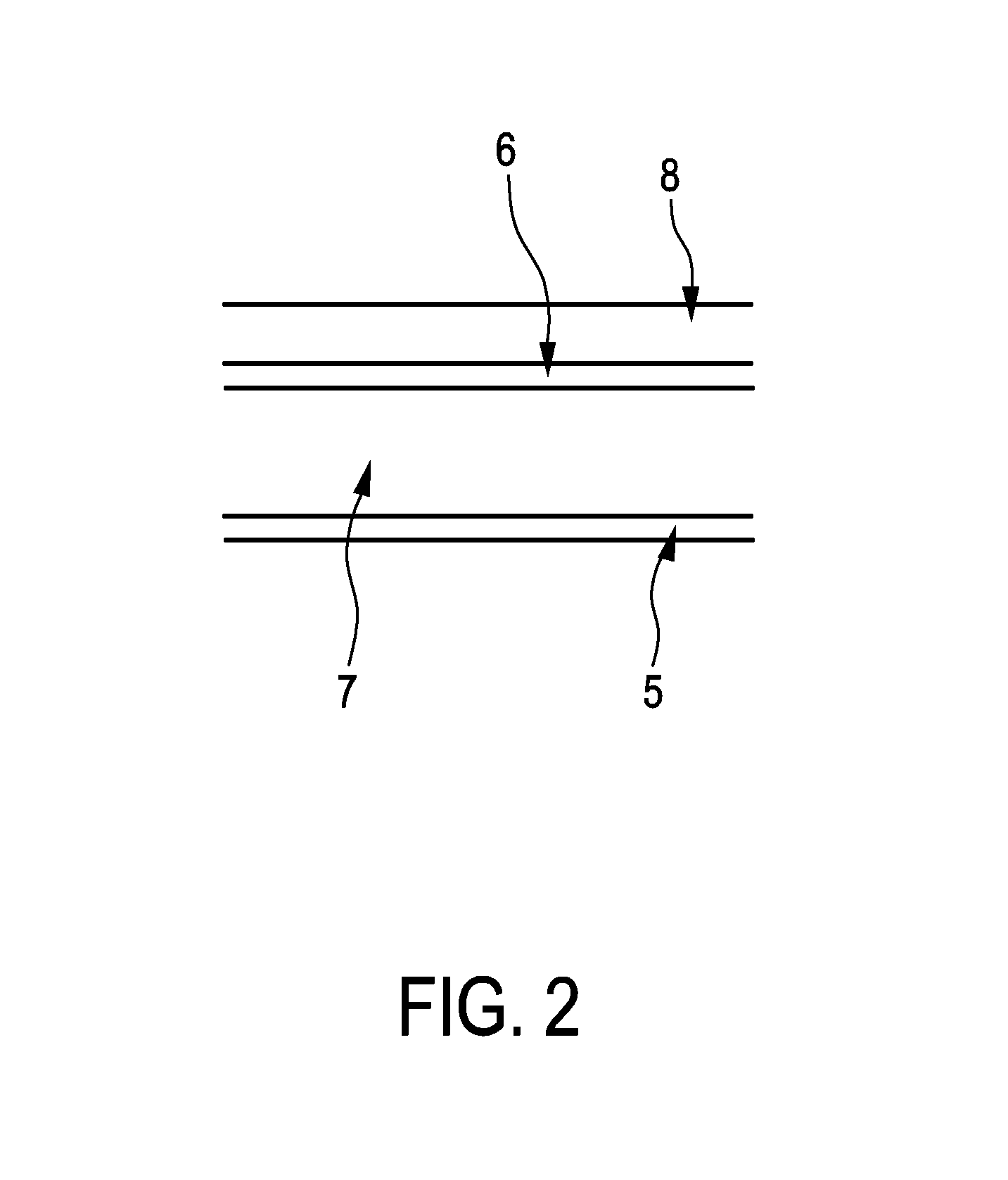

Light-emitting device with alternating arrangement of anode pads and cathode pads

ActiveUS20160133868A1Improve homogeneityReduce effortSolid-state devicesSemiconductor/solid-state device manufacturingElectricityElectrical connector

The invention relates to a light-emitting device like an OLED comprising a light emission region between an anode (5) and a cathode (6). An alternating arrangement (9) of anode pads (11) for electrically connecting the anode and cathode pads (10) for electrically connecting the cathode and an encapsulation (8) are configured such that the anode and cathode pads are electrically connectable by straight anode and cathode electrical connectors (3, 4) through openings (12) of the encapsulation. The alternating arrangement of the anode and cathode pads can lead to a more homogenous electrical field between the anode and the cathode and therefore allows for an improved degree of homogeneity of light emission. More, since the alternating arrangement of the anode and cathode pads is connectable by corresponding straight connectors, the contacting of the pads can be performed technically relatively easily.

Owner:OLEDWORKS GMBH

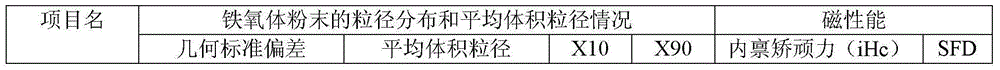

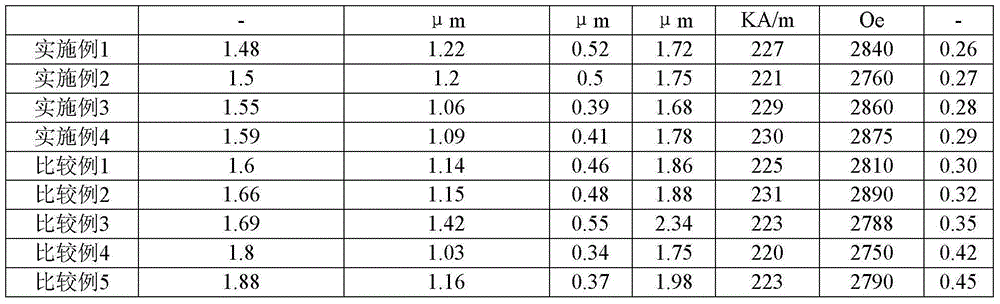

Ferrite powder and formed body prepared by same

The invention discloses ferrite powder and a formed body prepared by same. In the granularity distribution determination of a laser diffraction granularity distribution instrument, the geometric standard deviation of the granularity distribution is 1.4 to 1.59, the average volumetric particle size is 0.9 to 1.5 micrometers, the particle size X10 of screen underflow with an accumulated ratio of 10 percent is 0.35 to 0.55 micrometers, and the particle size X90 of the screen underflow with accumulated ratio of 90 percent is 1.5 to 2.5 micrometers. By adopting the ferrite powder, the SFD can be effectively controlled to be less than or equal to 0.30, so that the homogenization degree of the coercivity is higher, the magnetic uniformity is better, the magnetic performance is higher, when a magnetic recording medium is formed, a transitional area between two recording sites is smaller, the recording density is higher, the signal sensitivity is better, the print-through effect of the magnetic recording medium is smaller, and the rewriting performance is better.

Owner:BGRIMM TECH CO LTD

Breeding medium of potato stem segment and application method thereof

ActiveCN108401900ASimple ingredientsEasy to preparePlant tissue cultureHorticulture methodsIndole acetic acidAgricultural science

The invention relates to a breeding medium of a potato stem segment and an application method thereof. The propagation medium of the potato stem segment comprises a MS medium, indole acetic acid, vegetable gel, polyvinylpyrrolidone and sucrose. The medium has simple composition, is easy to prepare, has high homogenization degree, and is suitable for industrialization operation. By a suitable ratioof the MS, the indole acetic acid, G3251, the PVP (polyvinylpyrrolidone) and the sucrose, the potato stem segment can obtain a good rooting and seedling strengthening effect on the medium, and is suitable for a subsequent one-step culture breeding method. At the same time, the present invention also provides a preparation method and a specific application method of the propagation medium of the potato stem segment.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

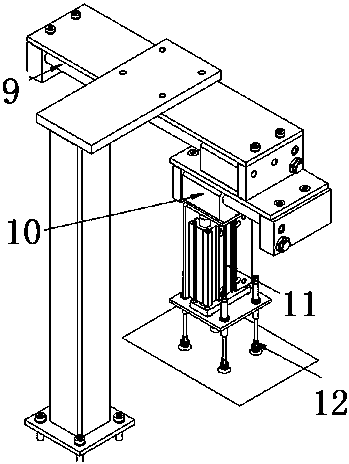

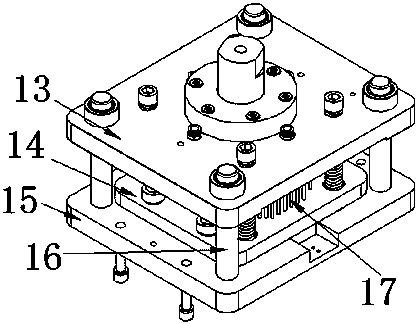

Automatic paper circle blanking device and method

PendingCN108190568AHigh degree of automationHigh degree of homogeneityMetal working apparatusArticle feedersPunchingPulp and paper industry

The invention relates to the field of machinery, in particular to an automatic paper circle blanking device and method. The method comprises the following steps that paper is manually placed into a paper box, an automatic paper taking mechanism lifting air cylinder drives a vacuum sucker to move downwards, a first translation cylinder works to make the paper move forwards by one position, the lifting air cylinder moves downwards to enable the paper to be tightly attached to a paper conveying platform, a second translation cylinder works to make the paper continuously move forwards, the paper can be fed into the bottom of a paper feeding mechanism at the moment, the vacuum sucker is closed, and the paper taking mechanism is returned; a pressing wheel of the paper feeding mechanism, namely adriven friction wheel moves downwards, the driven friction wheel tightly presses the paper, a pneumatic motor drives the driven friction wheel to rotate, and the paper is conveyed into a blanking diethrough friction force; after the paper feeding mechanism finish feeding the paper, the front end of the paper enters the bottom of a paper discharging mechanism pressing wheel; after a blanking mechanism detects that the paper is fed, the blanking die drives a hollow punching needle to press downwards for paper circle blanking, the blanked paper circle is sent into a transfer die in a transfer mechanism, and the paper circle is clamped in the hole of the transfer die; and the transfer mechanism swings by 180 degrees to send out the transfer die with the paper circle. According to the deviceand the method, the automation degree is high, the production efficiency can be greatly improved, and the product uniformity degree is high.

Owner:XIAN HEFA ELECTRICAL SYST ENG

High porosity vitrified superabrasive products and method of preparation

ActiveUS8216326B2High porositySmall sizePigmenting treatmentOther chemical processesPorosityVitrification

A vitrified superabrasive product includes a superabrasive component and a vitrified bond component in which the superabrasive component is dispersed, wherein the vitrified bond component defines pores occupying greater than about 50% of the total volume of the vitrified superabrasive product. The vitrified superabrasive product can be in the form of a grinding tool, such as a grinding wheel. A superabrasive mixture includes a glass powder, a superabrasive grit, a binder and a silicon carbide. The mixture can be in the form of a green body, which is fired under an atmosphere and pressure, and at a temperature sufficient to form a porous vitrified superabrasive product.

Owner:SAINT GOBAIN ABRASIVES INC +1

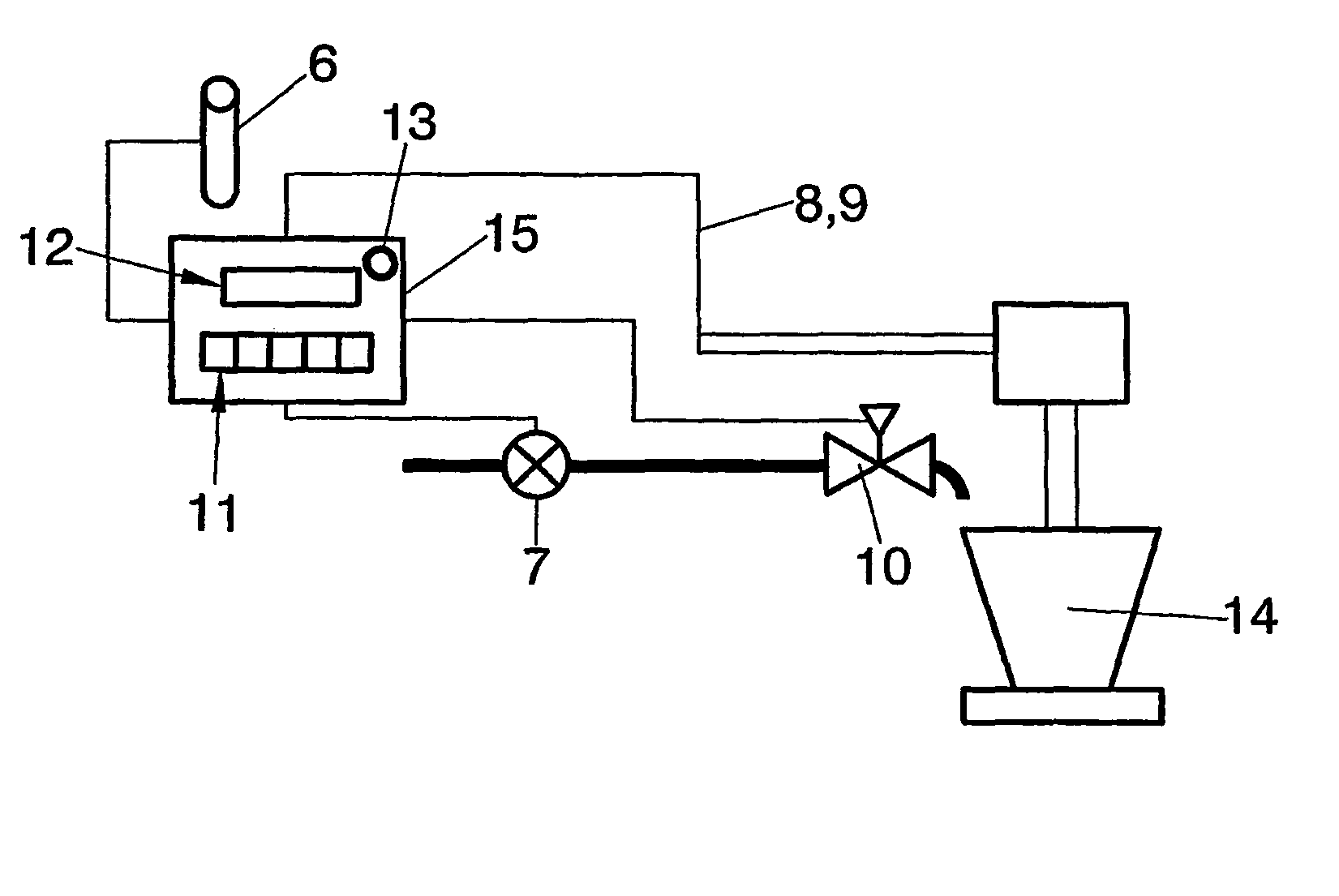

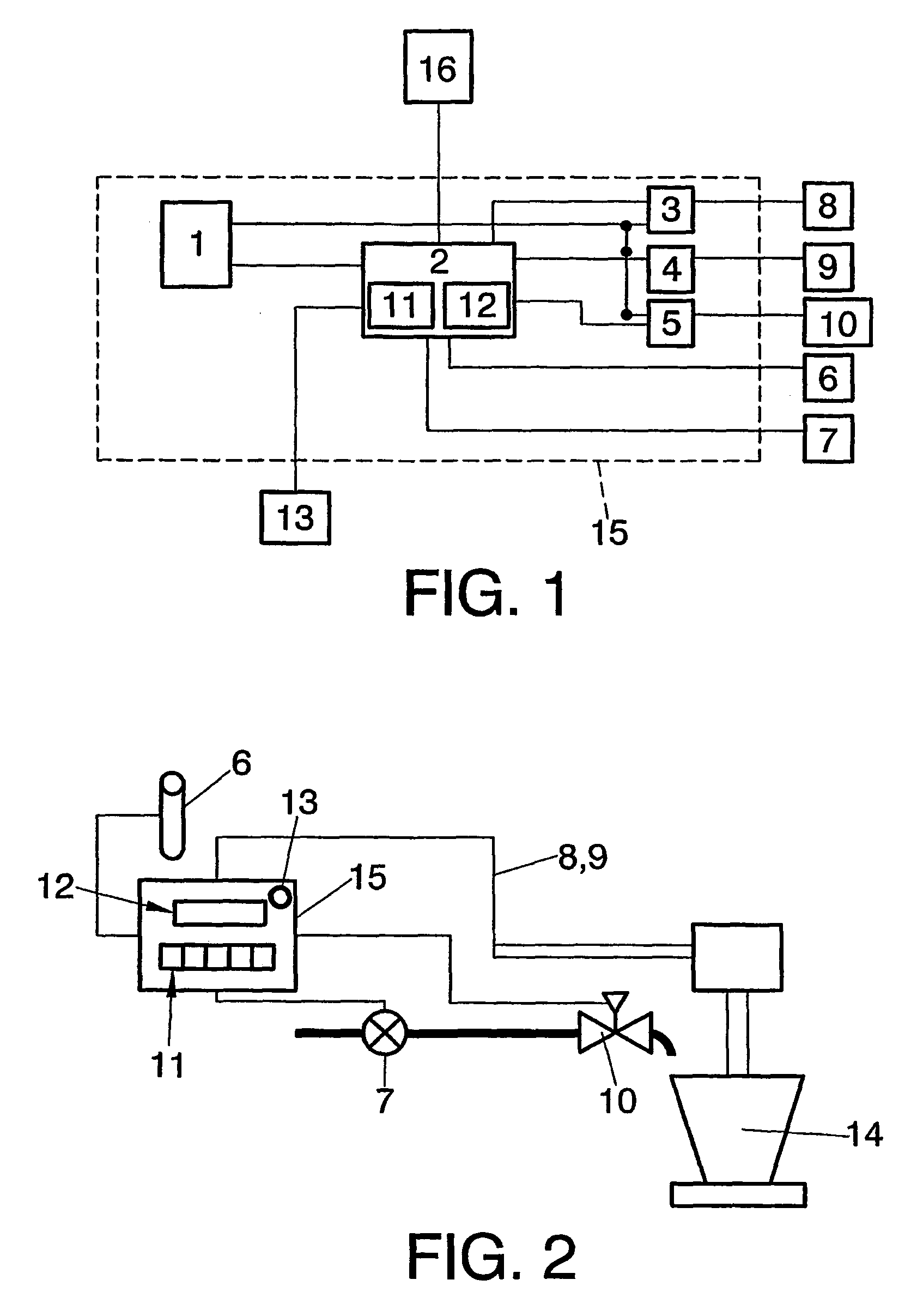

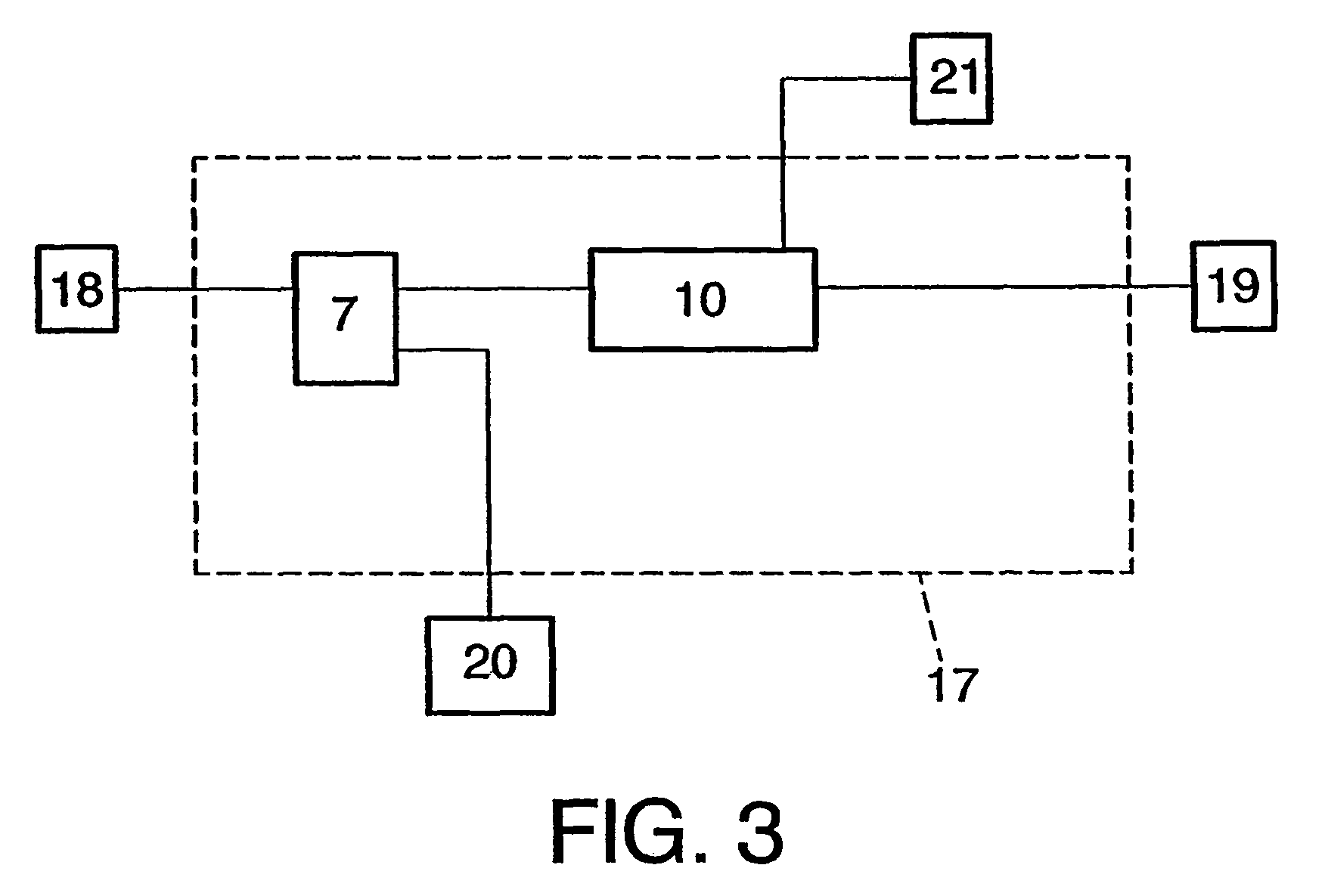

Electronic manager for bread dough mixers and operating method

InactiveUS8348493B2Improve plastic and viscosity characteristicHigh degree of homogeneityTransportation and packagingMixer accessoriesLow speedRelay

The invention relates to an electronic manager for bread dough mixers and to an operating method. The invention consists of an integral module (15) comprising a PLC (2) which, by means of relays (3, 4 and 5), controls a low-speed contact (8), a high-speed contact (9) and an electrovalve (10, 10′) in order to operate a mixer (14). In addition, the PLC (2) controls a temperature sensor (6), a flowmeter (7, 7′) and a visual and audible indicator (13). The corresponding method comprises a parameter definition step, a start confirmation step, an oxygenation step, a liquid metering step, a mixing step and a return-to-rest step.

Owner:BRISCIANI ROBERTO

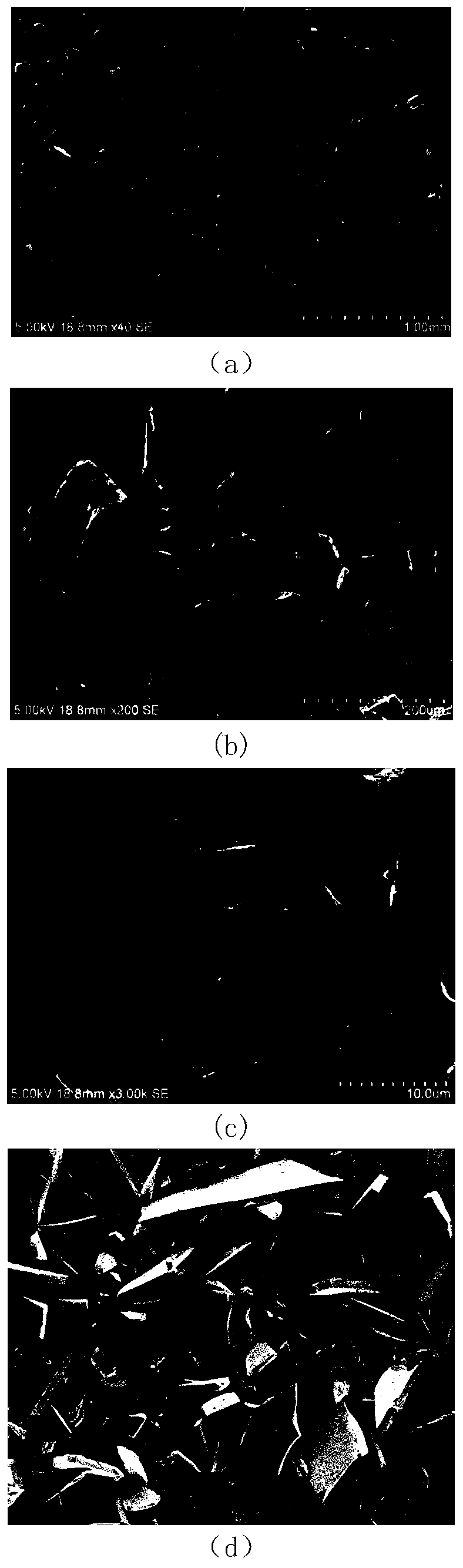

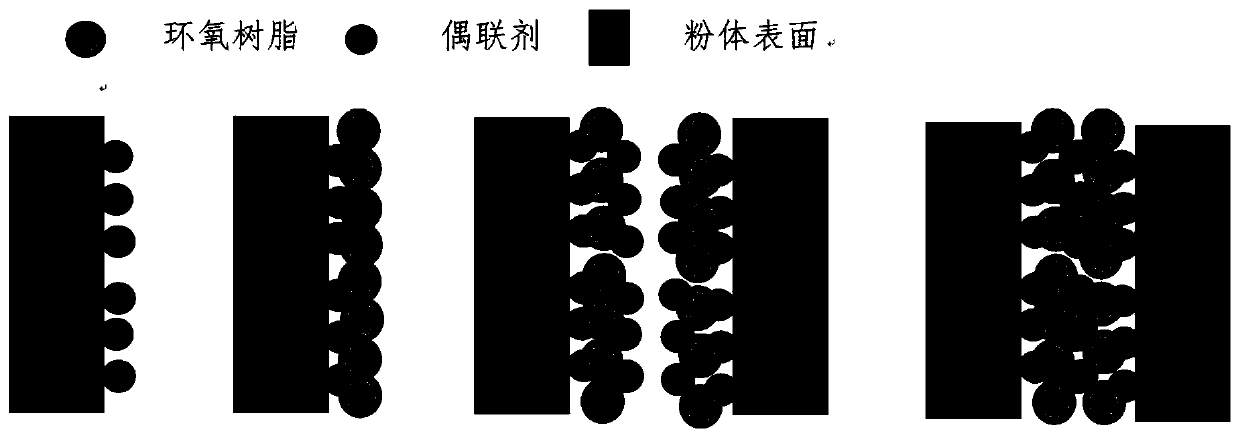

Warm-press molded bonded magnet and preparation method thereof

ActiveCN110767403AImprove compactnessImprove uniformityInductances/transformers/magnets manufactureMagnetic materialsEpoxyPhysical chemistry

The invention discloses a warm-press molded bonded magnet and a preparation method thereof. The warm-press molded bonded magnet comprises anisotropic neodymium iron boron magnetic powder, an adhesiveand a composite heat conduction agent. The preparation method comprises the steps of: master alloy smelting, heat treatment, HDDR treatment, glue mixing, powder mixing, pre-pressing forming, orientation forming, curing and the like. By adding a composite heat conduction agent, the heat conduction capability of a pre-pressed blank is enhanced to reach the Tf conversion temperature of added epoxy resin in an extremely short time, so that the powder is positioned in the uniform viscous epoxy resin, powder particles are conveniently arranged in order during orientation, the orientation is more complete, the effect is more remarkable, the density and the overall uniformity of the magnetic ring are improved during pressing, the conditions of layering, incomplete cementation and the like during orientation pressing are avoided, and the homogenization degree of the oriented magnetic ring is higher; and moreover, the composite heat conduction agent can replace traditional lubricants such as zinc stearate and magnesium stearate, so that the flowability of the magnetic powder is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

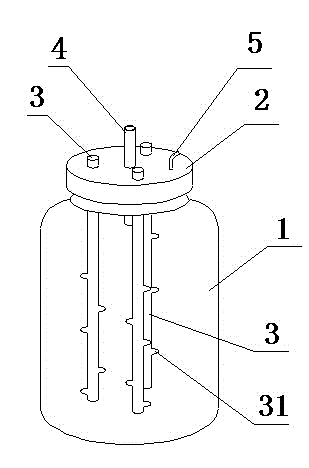

Method for producing fibrous protein-removed original blood from newborn calf blood

ActiveCN104546913AAchieve the purpose of mixingImprove stabilityAerosol deliveryOintment deliveryFiberFiltration

The invention discloses a method for producing fibrous protein-removed original blood from newborn calf blood. The method comprises the following steps: (1) receiving the blood of a newborn calf by a blood bottle and starting to stir the blood by a glass rod with a bulge at the stirring end at a speed of 110-140 rpm when the blood flows to 1 / 6 to 1 / 4 of the holding volume of the blood bottle; (2) stopping the stirring when the blood achieves the holding volume of the blood bottle and sealing the blood bottle; (3) stirring at a speed of 160-200 rpm for 2-4 min, stopping the stirring, standing for 3-4 min, stirring at 110-140 rpm for 5-8 min, stopping the stirring, and taking out the glass rod and the fibrous protein wound on the stirring end. The method provided by the invention has the advantages that the stability is high and the homogenization degree is high; the automatic stirring is realized so as to avoid the interferences of human factors; the standard operation and industrial production can be realized; the fibrous protein can be removed to a relatively complete extent without filtration, so that the time and the labor are saved; the bottle does not need to change and the blood bottle is a storage bottle for the non-solidified original blood; the recovery rate of the original blood is high and has an average of 93%.

Owner:内蒙古维克生生物技术股份有限公司

Superconducting magnet system for nuclear magnetic resonance with high magnetic field and high degree of homogeneity of magnetic field

ActiveUS8934950B2High magnetic fieldCompact structureMagnetic field measurement using superconductive devicesSuperconductor devicesNMR - Nuclear magnetic resonanceReverse current

A superconducting magnet system for nuclear magnetic resonance with a high magnetic field and a high degree of homogeneity of magnetic field is provided. The system comprises a main coil and a magnetic field homogeneity compensating coil having a combination of a forward current and a reverse current, and is composed of 24 superconducting coils formed by winding NbTi / Cu low-temperature superconducting wires. The system can produce a magnetic field of 9.4 T within a room-temperature space of 800 mm and can obtain a degree of non-homogeneity of magnetic field less than 0.1 ppm within a spherical volume of 300 mm. The system is equipped with a superconducting magnet inside, and a low-temperature vessel for liquid helium provides a low-temperature environment of 4K which is required for the normal operation of the superconducting magnet. A ferro-magnetic shielding system enables the system to have a good electromagnetic compatibility.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

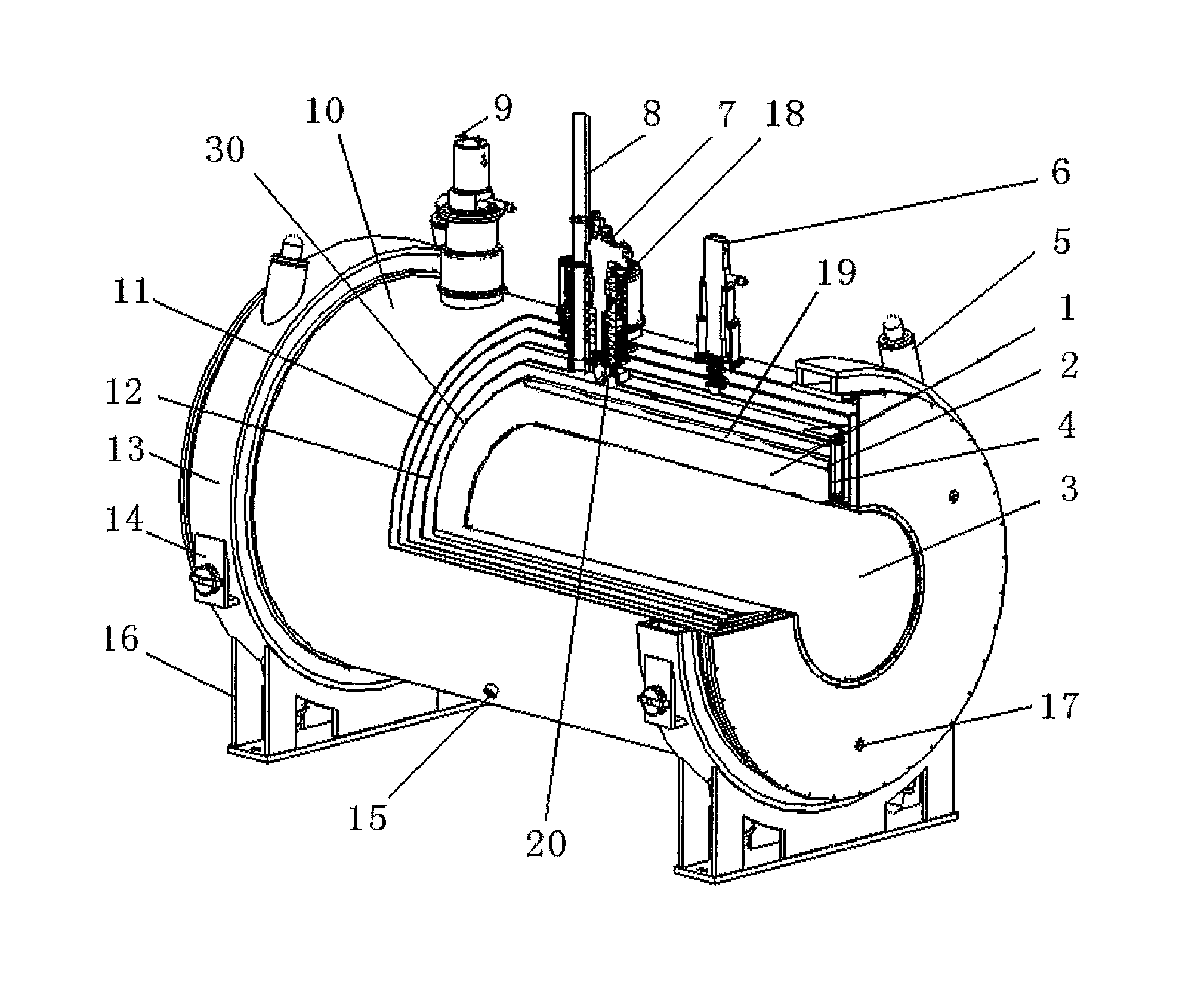

Method for producing a homogenous particulate material composition

ActiveUS20180076446A1Improve adhesionPlasticization is avoidedElectrolytic capacitorsHybrid capacitor electrodesMaterials scienceParticulate material

A method is provided for producing a homogenous particulate material composition, including at least one particulate material M, at least one additive Z, and at least one binding agent B, the method including providing at least one particulate material M, at least one additive Z, and at least one binding agent B; producing a homogenous mixture G1 from the at least one particulate material M and the at least one additive Z in a gravity mixer; producing a mixture G2 from the mixture G1 and the at least one binding agent B, with the introduction of shear forces; and removing dispersed gases from the mixture G2.

Owner:ROBERT BOSCH GMBH

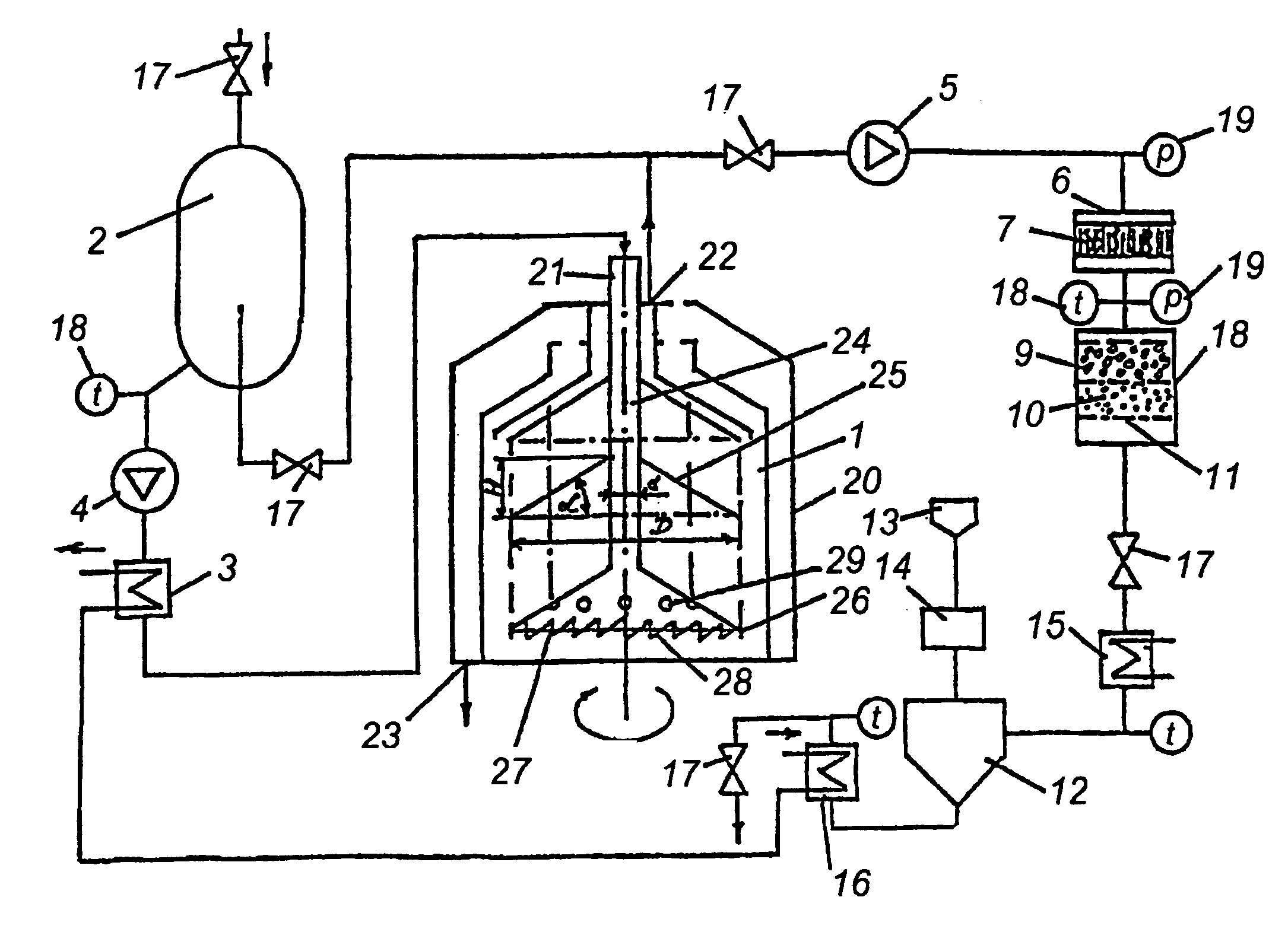

Method for combined processing of diesel fuel

InactiveUS7247234B1Improve operationImprove ecology propertyInternal combustion piston enginesRotary centrifugesFiltrationEngineering

The essence of the method is that diesel fuel is heated in the process of periodical circulation in a closed circuit including a heat exchanger and a rotor-disc apparatus of open type in centrifugal force field of which processes of mechanical destruction and dispersion run in environment of sucked air with oxygen saturation, simultaneously with processes of separation and homogenization fine filtration is carried out at a filtering porous partition of hydrophobic material with purification fineness 3÷8 micron as well as filtration at a multilayer filter-reactor at temperature 25÷45° C. which comprises granules of multifunctional catalyst alkylating aromatic compounds and a layer of fill of powder of transitional metals or their oxides. Then the treated fuel is stabilized by adding additives on the basis of surface-active substances. At that conical trays of the rotor-disc apparatus of open type are made with destruction edge in form of flanging with slots and bends at the following correlation of geometric parameters:D=(2,0÷2,5)d; H=(0,75÷0,85)d; α=45÷55°where:D=diameter of the large (lower) base of the conical tray;d=diameter of the small (upper) base of the conical tray;H=height of the conical tray;α=angle between the generator and the large (lower) base of the conical tray.

Owner:OOO FIRMA DITO

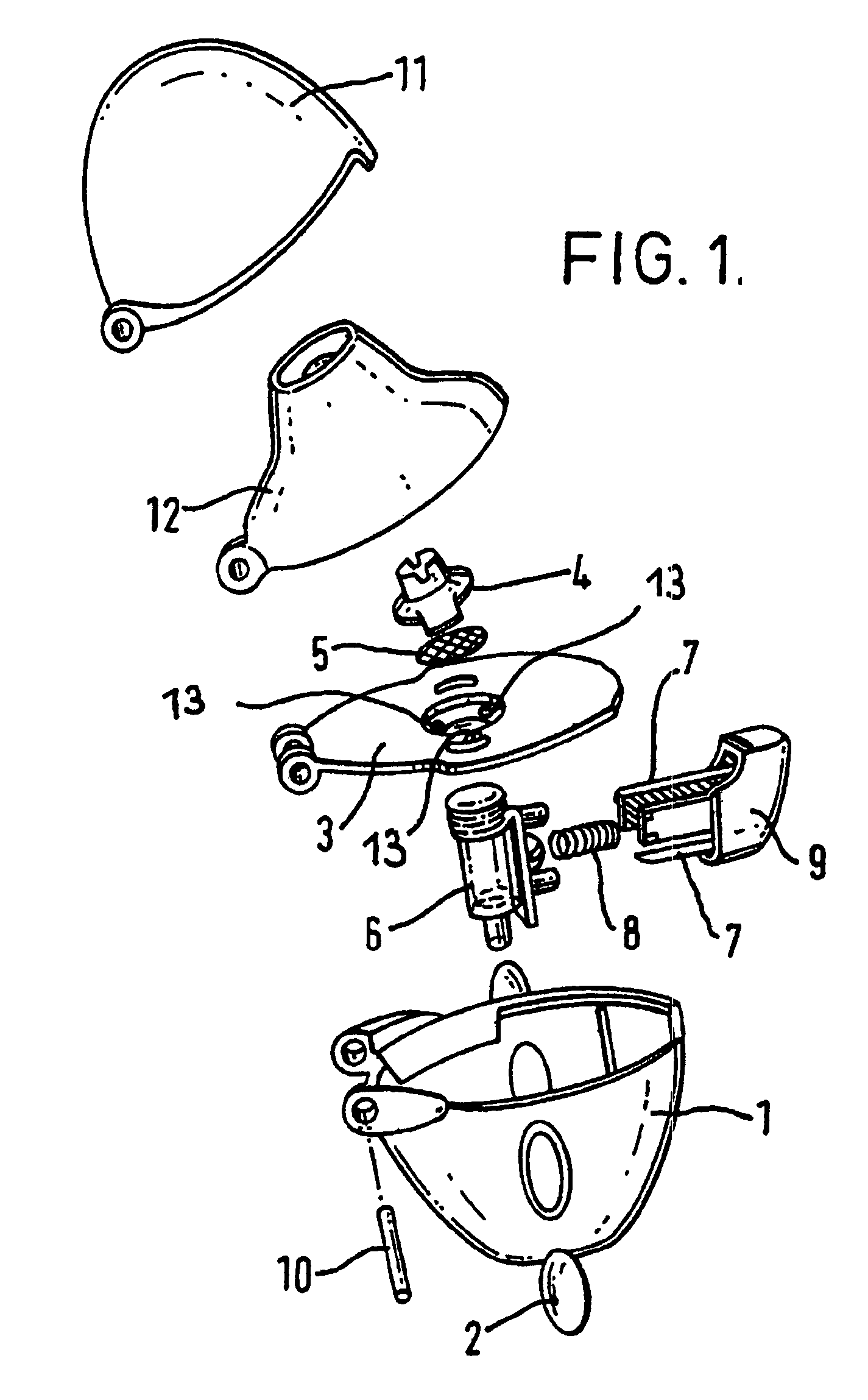

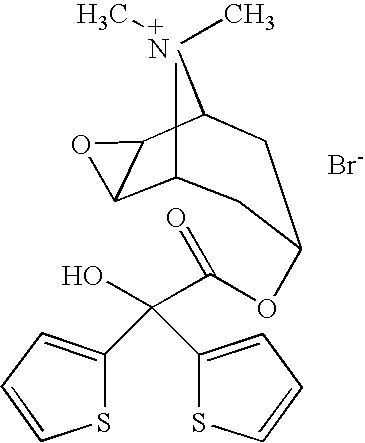

Tiotropium containing powder formulation for inhalation

ActiveUS7763280B2High degree of homogeneityLow variabilityPowder deliveryMedical devicesDiseaseTiotropium bromide

The invention relates to powdered preparations containing tiotropium for inhalation, processes for preparing them as well as their use in preparing a pharmaceutical composition for the treatment of respiratory complaints, particularly for the treatment of COPD (chronic obstructive pulmonary disease) and asthma.

Owner:BOEHRINGER INGELHEIM PHARMA GMBH & CO KG

Preparation method for small-particle-size magnetic agarose microspheres

ActiveCN103483602BLarge particle sizeLarge specific surface areaOther chemical processesOrganic/organic-metallic materials magnetismMicrosphereOil phase

The invention discloses a preparation method for small-particle-size magnetic agarose microspheres. According to the preparation method, emulgator and hydrophobic organic solvent serve as an oil phase, mixed liquor of agarose and superparamagnetic Fe3O4 aqueous solutions serves as an aqueous phase, the aqueous phase is added into the oil phase under mechanical stirring to carry out pre-dispersion, then ultrasonication is carried out on pre-dispersion emulsion, and cooling, magnetic separation and purification are carried out on the crushed emulsion to obtain the small-particle-size magnetic agarose microspheres. The magnetic agarose microspheres prepared according to the preparation method have high magnetic response and superparamagnetism, and compared with commercially available products, the magnetic agarose microspheres have smaller particle sizes, larger specific surface areas, more active sites, and broad application prospects. Due to the fact that hydrophilic magnetic cores are adopted, through the modes of vortex vibration, ultrasonic dispersion, microwave heating, mechanical stirring pre-dispersion, ultrasonication carried out by a cell disruption instrument and the like, not only can the fact that the magnetic cores can be uniformly dispersed in the agarose solutions be guaranteed, but also the fact that the obtained magnetic agarose is small in particle size is guaranteed, and distribution is narrow.

Owner:BEAVERNANO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com