Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good temperature and weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High/low-temperature general-purpose hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN104031586AStable performanceGood weather resistanceMineral oil hydrocarbon copolymer adhesivesChemistryWeather resistance

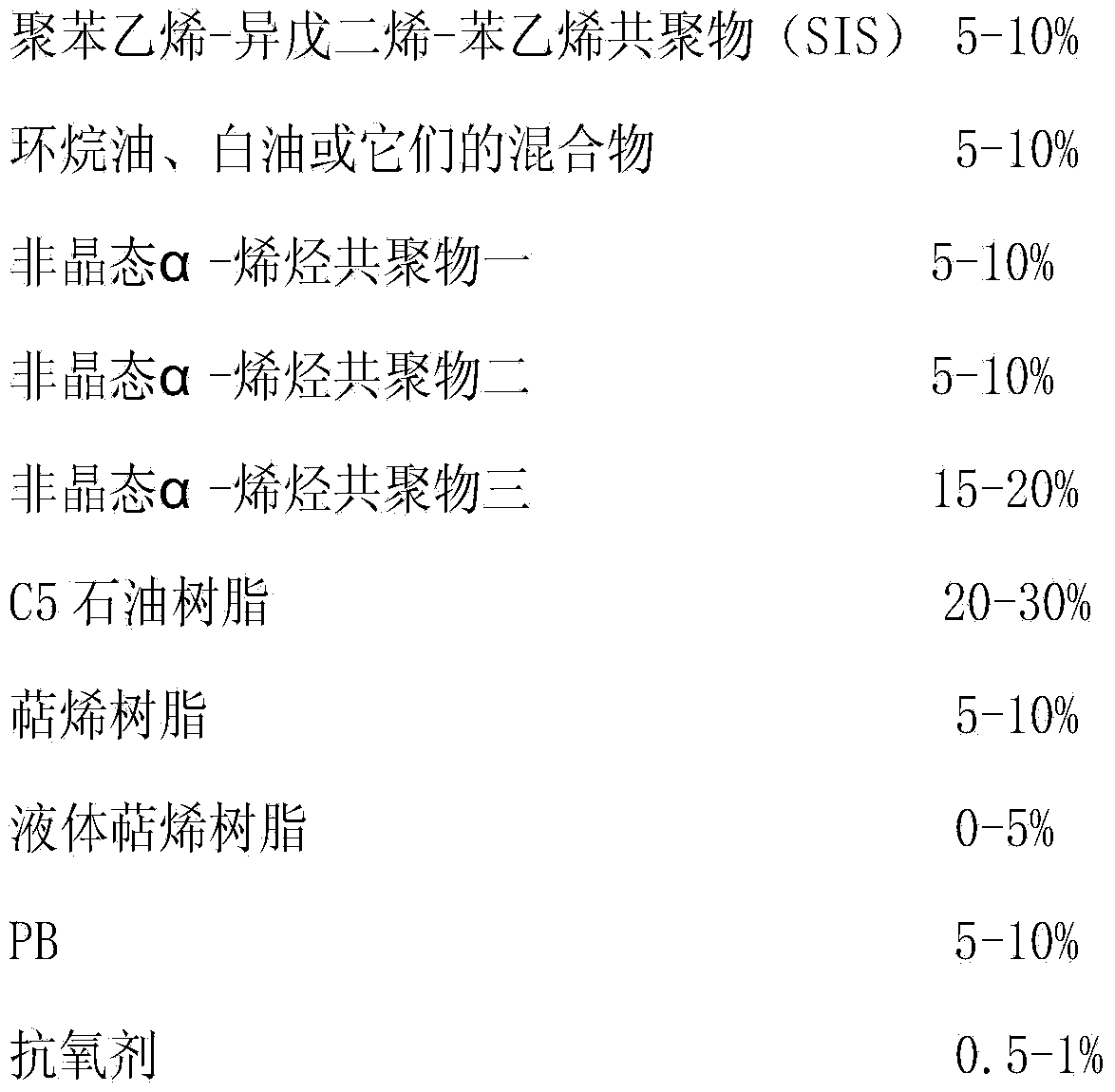

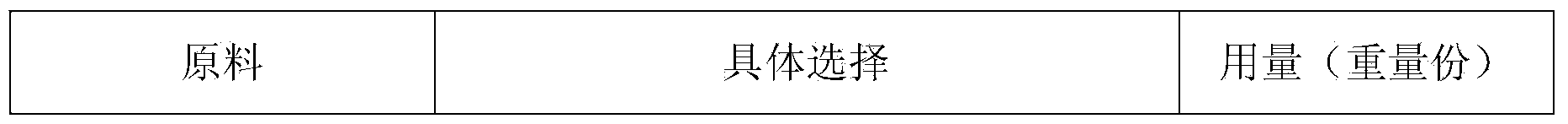

The invention discloses a high / low-temperature-resistant high / low-temperature general-purpose hot-melt pressure-sensitive adhesive and a preparation method thereof. In order to overcome the technical defects, the invention provides a high-viscosity-strength high / low-temperature-resistant high / low-temperature general-purpose hot-melt pressure-sensitive adhesive and a preparation method thereof. The general-purpose hot-melt pressure-sensitive adhesive comprises 5-10% of polystyrene-isoprene-styrene copolymer (SIS), 5-10% of naphthenic oil, white oil or mixture thereof, 5-10% of amorphous alpha-olefin copolymer 1, 5-10% of amorphous alpha-olefin copolymer 2, 15-20% of amorphous alpha-olefin copolymer 3, 20-30% of C5 petroleum resin, 5-10% of terpene resin, 0-5% of liquid terpene resin, 5-10% of PB (polybutadiene) and 0.5-1% of antioxidant. The high / low-temperature general-purpose hot-melt pressure-sensitive adhesive has the advantages of stable performance, favorable weather resistance, favorable viscosity strength, low cost, high viscosity, wide application range and the like, is free from the influence of the regional temperature, and is stable in all seasons.

Owner:浙江固特新材料科技股份有限公司

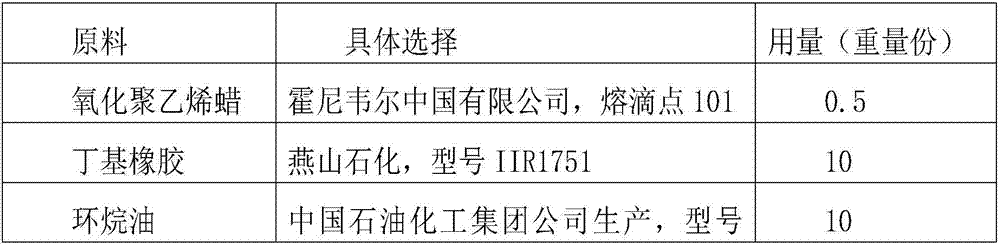

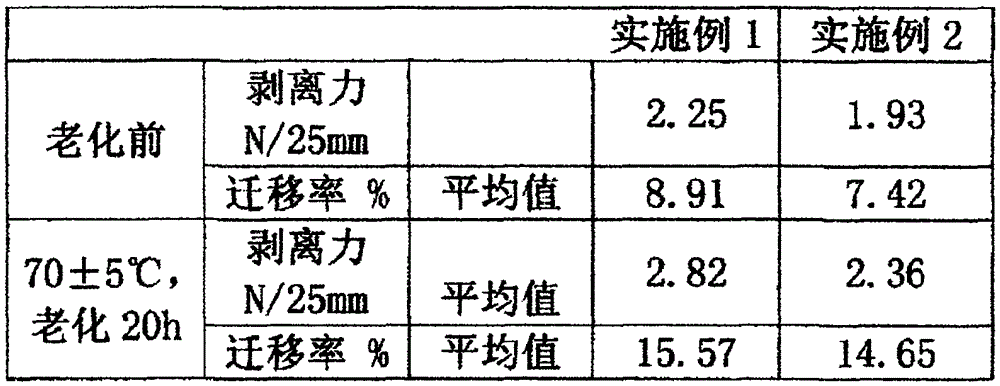

Mold release agent for masking tape, and preparation method thereof

ActiveCN103924478AIncrease productivityReduce foamingDefoamers additionFilm/foil adhesivesSodium bicarbonateWater based

The invention relates to a mold release agent for a masking tape, and a preparation method of the mold release agent. The mold release agent is prepared from the following raw materials in parts by weight: 150-270 parts of ethyl acrylate, 0-90 parts of butyl acrylate, 0-110 parts of methyl methacrylate, 0-105 parts of styrene, 5-10 parts of succinic acid, 0-7 parts of crosslinking monomer, 500-600 parts of deionized water, 0.1-0.4 part of sodium bicarbonate, 3-5 parts of lauryl sodium sulfate, 1.2-3.0 parts of ammonium persulfate, 0.5-2 parts of a defoaming agent, 30-55 parts of zinc glycinate, 5-15 parts of ammonia water, 20-100 parts of long-chain alkyl surface active agent and 0-10 parts of modified polysiloxane. The mold release agent is a water-based mold release agent, is convenient to use and can be directly coated or can be coated after being diluted by water; a catalyst is not fed into the mold release agent, and the mold release agent is capable of crosslinking at low temperature and does not contain an organic solvent, so that the mold release agent is free from environmental pollution and harmless to the human health; furthermore, the mold release agent has good heat resistance and weather resistance, is capable of providing proper mold release force for the masking tape, and is lower in migration rate; the tape prepared by the mold release agent is free from residual glue after being used, so that the protected surface is not polluted.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

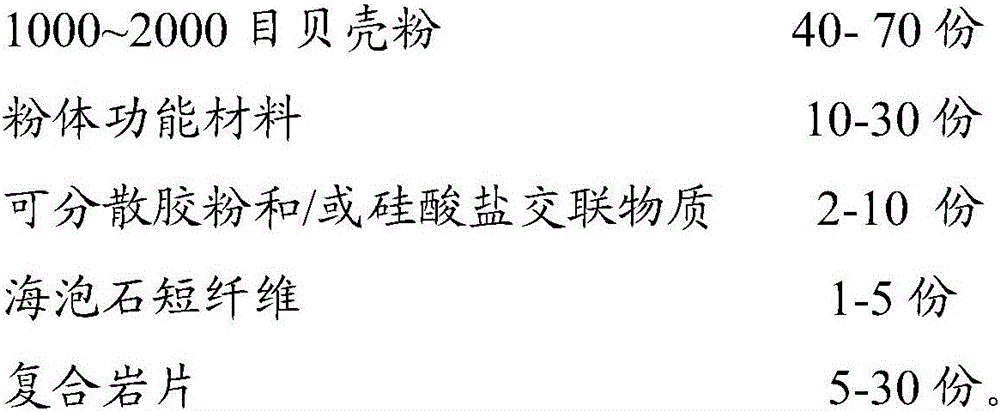

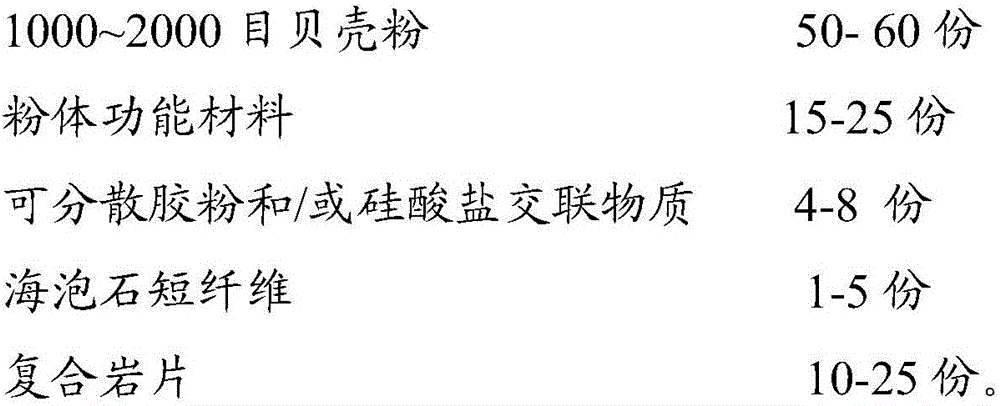

Powder decoration coating and preparation and construction methods thereof

ActiveCN106084927AImprove breathabilityGood scrub resistanceFireproof paintsCovering/liningsFiberCross-link

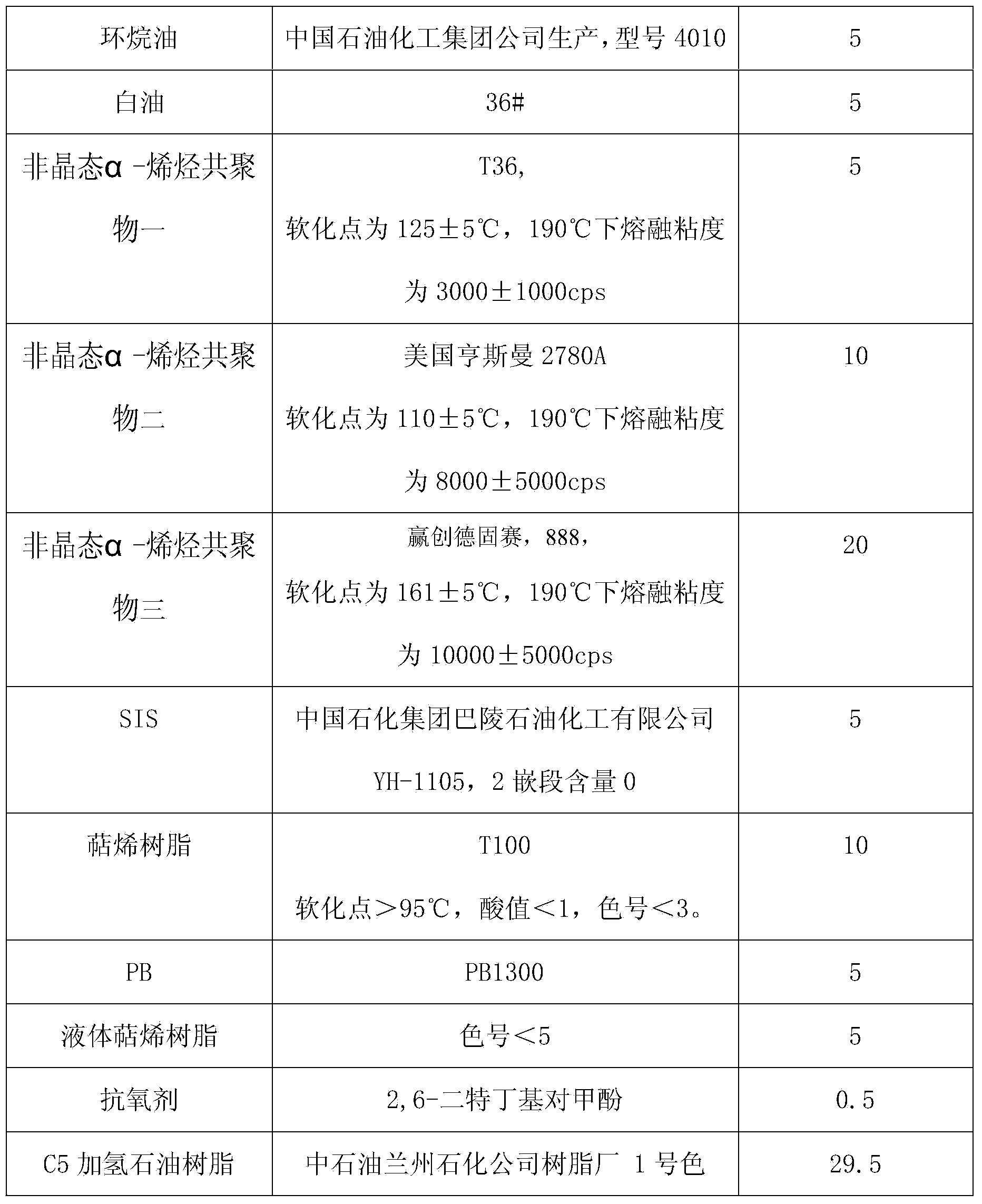

The invention discloses a powder decoration coating and preparation and construction methods thereof, and belongs to the technical field of coatings. The powder decoration coating comprises raw materials in parts by weight as follows: 40-70 parts of shell powder of 1,000-2,000 meshes, 10-30 parts of a powder functional material, 2-10 parts of dispersible gelatin powder and / or a silicate cross-linked substance, 1-5 parts of sepiolite short-fibers and 5-30 parts of colorful composite rock slices. The powder decoration coating is prepared from the shell powder calcinated at the temperature of 300 DEG C, the powder functional filler, the colorful composite rock slices, the powder cross-linked substance and functional additives through blending, the shell powder calcinated at the temperature of 300 DEG C is taken as a main material, and the powder decoration coating is good in breathability, anti-condensation, scrubbing-resistant, pollution-resistant, anti-bacterial, mould-proof and non-inflammable and has a green and environment-friendly inorganic system and a colorful decoration effect.

Owner:江苏海之屋新材料有限公司

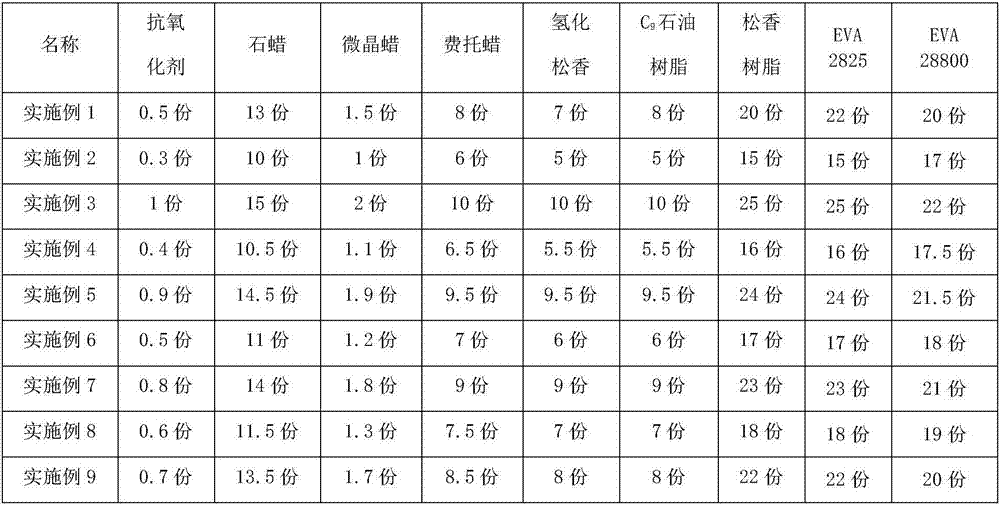

High-grammage coated paper bonding weather-proofing sealant

InactiveCN107474761AImprove adhesionGood flexibilityMineral oil hydrocarbon copolymer adhesivesWax adhesivesMicrocrystalline waxPetroleum resin

The invention relates to a high-grammage coated paper bonding weather-proofing sealant, belonging to the field of hot melt adhesive production. Existing paper bonding adhesives are low in initial adhesiveness. The high-grammage coated paper bonding weather-proofing sealant provided by the invention comprises the following components in parts by mass: 0.3-1 part of an antioxidant, 10-15 parts of paraffin, 1-2 parts of microcrystalline wax, 6-10 parts of Fischer-Tropsch wax, 5-10 parts of hydrogenated rosin, 5-10 parts of C9 petroleum resin, 15-25 parts of rosin resin, 15-25 parts of EVA 2825 and 17-22 parts of EVA 28800. The EVA 2825 with a melt index of 25 and a VA content of 28 and the EVA 28800 with a melt index of 800 and a VA content of 28 are taken as main materials, which are compatible with the tackifying resin and the antioxidant, and the microcrystalline wax, the C9 petroleum resin and the rosin resin are added simultaneously, so that the sealant has the advantages of high cohesive strength, strong adhesive force and stable performance.

Owner:浙江固特新材料科技股份有限公司

Graphene modified organic silicon coating as well as preparation method and application thereof

InactiveCN106634574AMake up for the defect of low strengthExcellent ozone resistanceCoatingsAlkylphenolTemperature resistance

The invention discloses a graphene modified organic silicon coating as well as a preparation method and application thereof. The coating is mainly prepared from the following materials in parts by mass: 0.1-5 parts of graphene, 15-50 parts of an organic silicon emulsion, 5-35 parts of kaolin, 0.1-0.2 part of defoaming agents, 1-3 parts of thickening agents, 0.5-3 parts of dispersants and 0.07-3.5 parts of alkylphenol polyoxyethylene ether. The invention also discloses the preparation method and application of the coating. According to the graphene modified organic silicon coating, high strength and flexibility of a graphene material are used for making up for the defect of low strength of organic silicon; meanwhile, the organic silicon also has high ozone resistance and electrical insulation; the advantages of the graphene and the organic silicon are complementary, so that the prepared graphene modified organic silicon coating can be used to coat the surface of a material and can achieve high strength, high temperature resistance and weather resistance, ozone resistance and high electric insulation; compared with ordinary high-silica glass fiber, the strength, abrasion resistance and heat resistance of graphene modified high-silica glass fiber prepared by coating glass fiber with the graphene modified organic silicon coating are all improved to some extent.

Owner:HOHAI UNIV

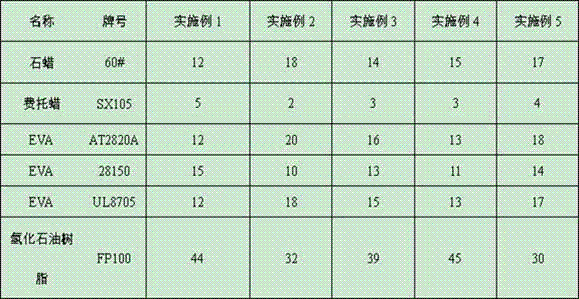

Image-text binding transparent glue

InactiveCN107201202AMeet universalMeet the needs of small batches of glueMineral oil hydrocarbon copolymer adhesivesWax adhesivesTO-18Wax

The invention relates to a transparent glue for picture-text binding, which is suitable for picture-text binding. The graphic and text binding transparent glue is characterized in that it is prepared from the following components according to the mass ratio: paraffin wax 60#, 12-18 parts; Fischer-Tropsch wax SX105, 2-5 parts; EVA AT2820A, 12-20 parts ; EVA 28150, 10‑15 parts; EVA UL8705, 12‑18 parts; hydrogenated petroleum resin FP100, 30‑45 parts. A variety of different performance indicators and low-odor polyolefin compounds are used to stabilize performance, improve high-temperature resistance, and strive to bond to various materials.

Owner:浙江固特新材料科技股份有限公司

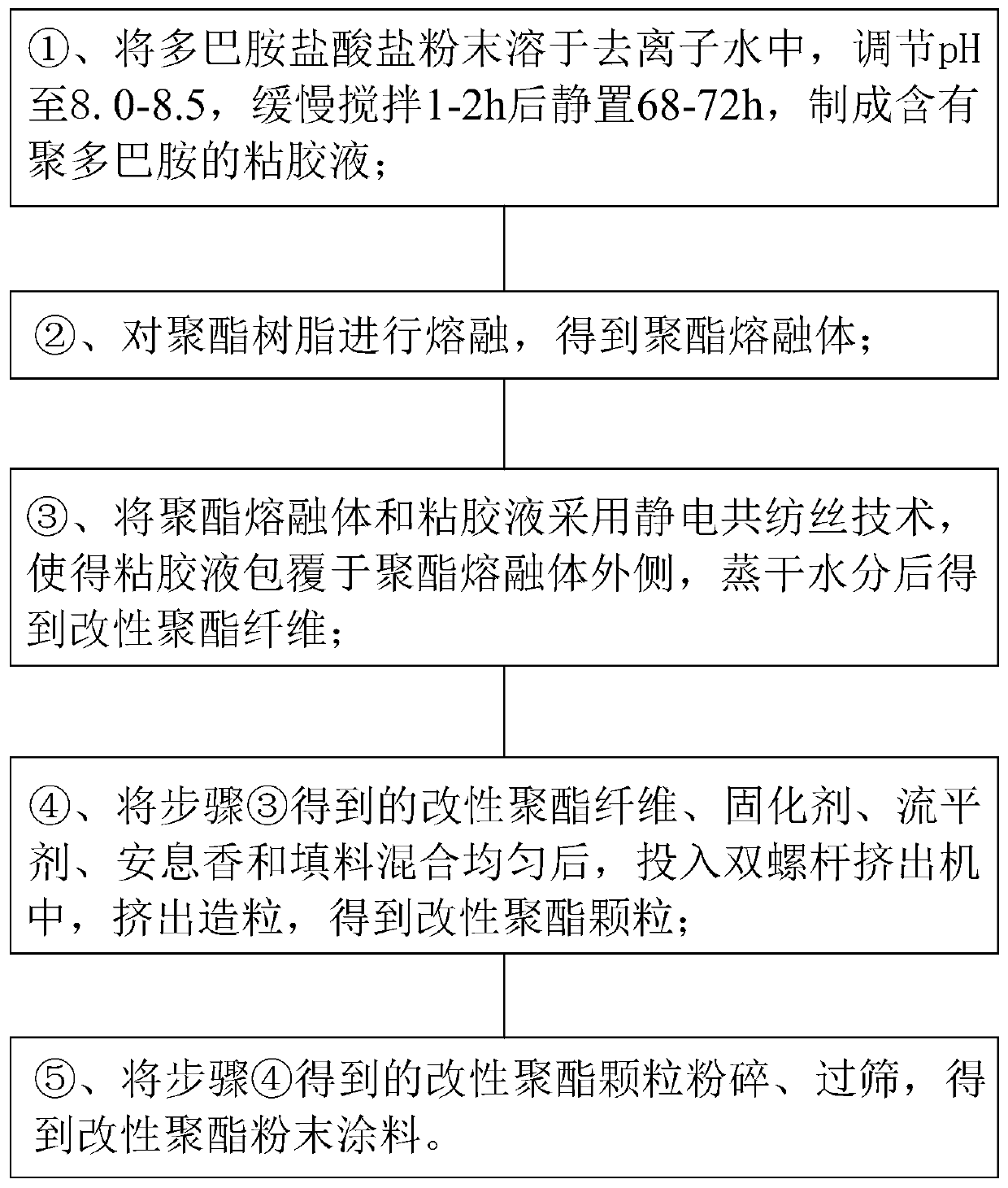

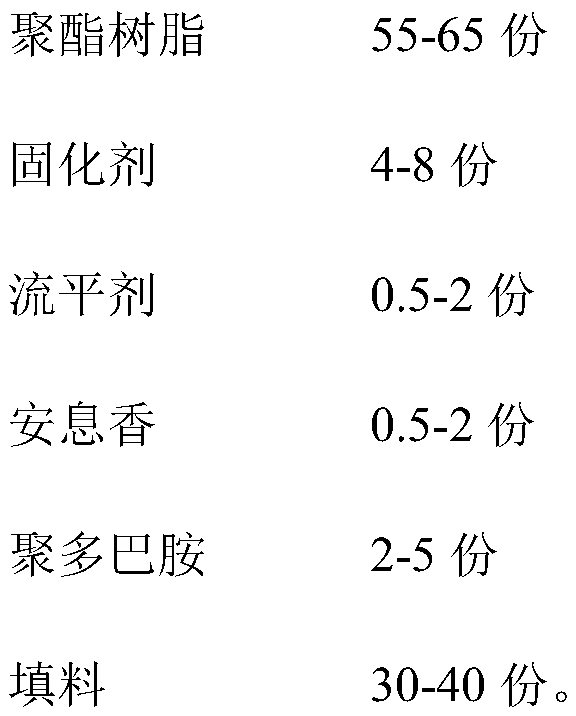

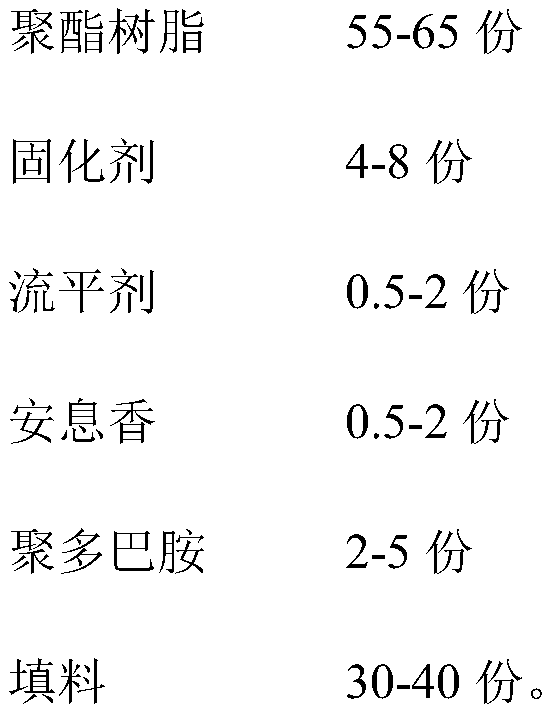

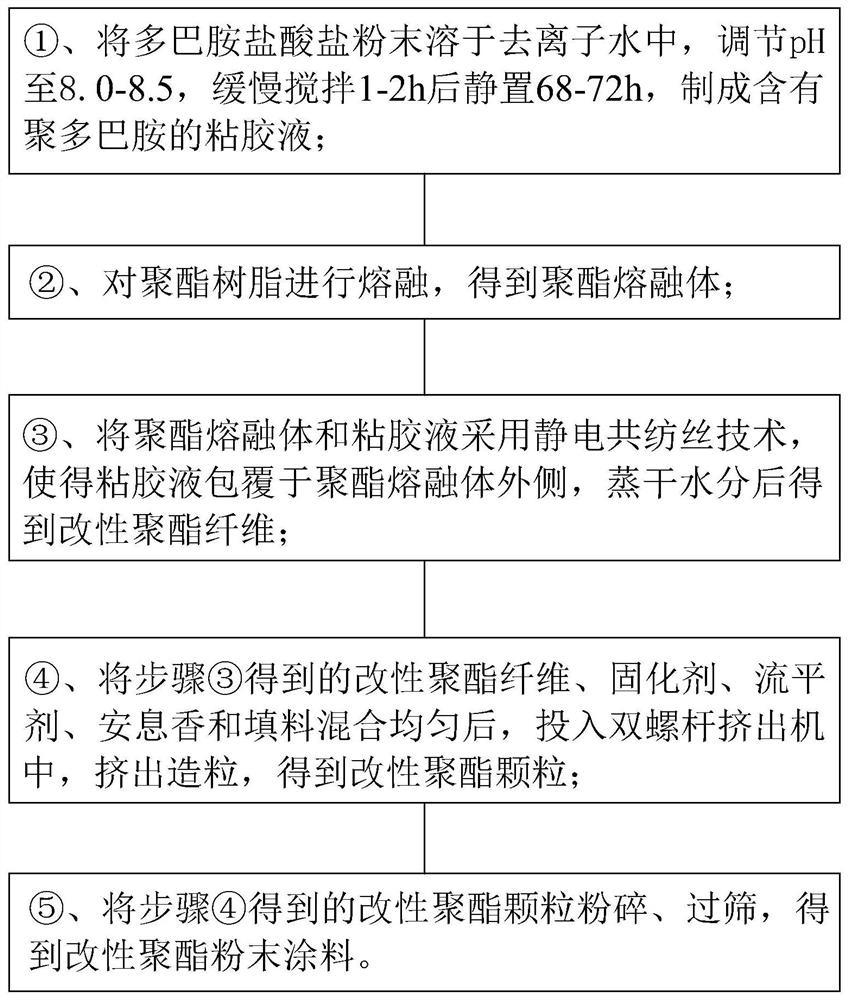

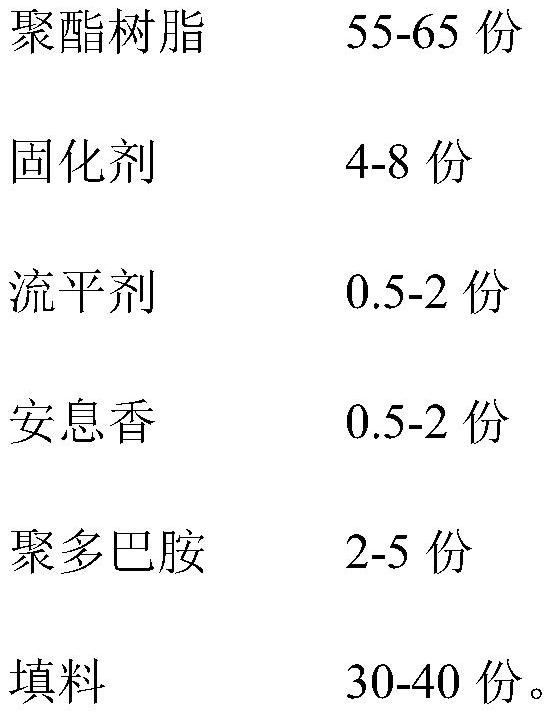

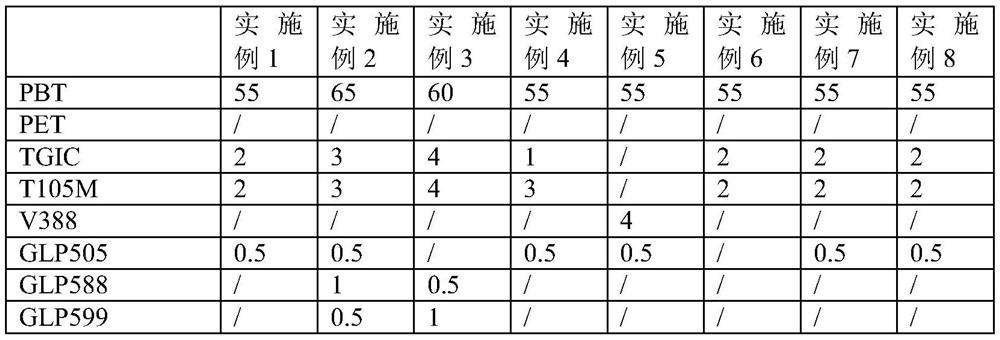

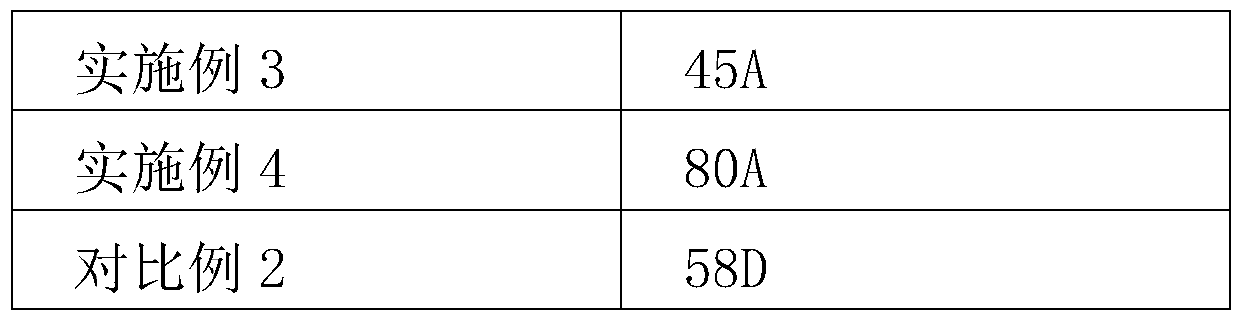

Modified polyester powder paint and preparation method thereof

ActiveCN109810618AGood dispersionImprove film formationPowdery paintsPolyester coatingsFilling materialsPolyester resin

The invention belongs to the technical field of paint, and particularly relates to modified polyester powder paint and a preparation method thereof. The modified polyester powder paint is prepared from the following ingredients in parts by weight: 55 to 65 parts of polyester resin, 4 to 8 parts of curing agents, 0.5 to 2 parts of leveling agents, 0.5 to 2 parts of benzoin, 2 to 5 parts of polydopamine and 30 to 40 parts of filling materials through viscose preparation, polyester resin melting, electrostatic cospinning, extrusion molding granulation and crushing sieving. Bubbles, shrinkage holes and particles on the coating can be effectively reduced; good film forming performance, weather resistant performance, luster degree and adhesion power are realized.

Owner:余姚市亚宇工贸有限公司

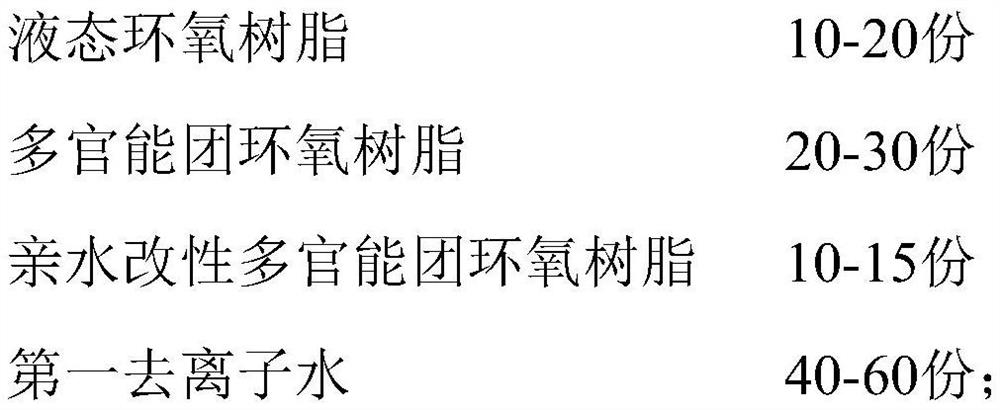

High-gloss high-hardness water-based epoxy floor coating and preparation method thereof

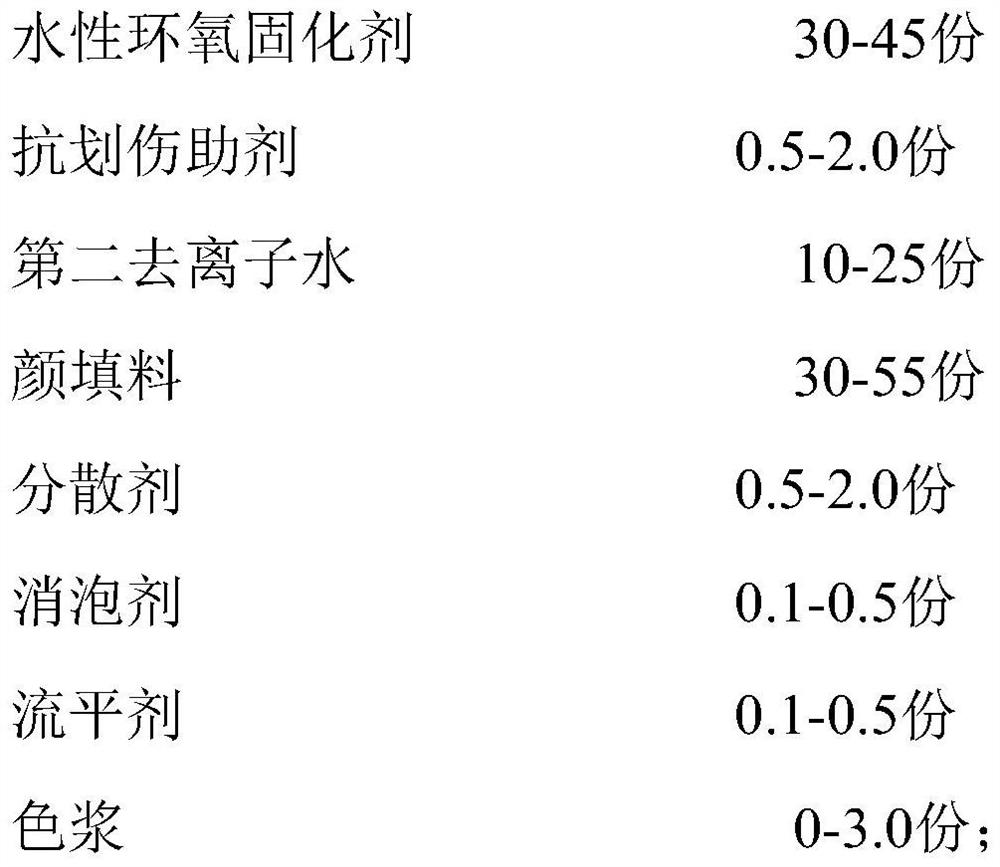

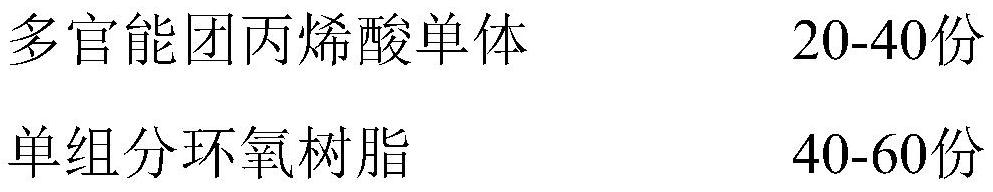

InactiveCN111763458AImprove the level ofReduce pollutionEpoxy resin coatingsPolymer scienceShrinkage rate

The invention belongs to the technical field of coatings and relates to a high-gloss high-hardness water-based epoxy floor coating and a preparation method thereof. The coating comprises a component Aand a component B. The component A is a water-based emulsion prepared from liquid epoxy resin, polyfunctional epoxy resin, hydrophilic modified polyfunctional epoxy resin and first deionized water; the component B is prepared from a water-based epoxy curing agent, second deionized water, a pigment filler, a dispersing agent, an antifoaming agent, a leveling agent, a scratch-resistant auxiliary agent and color paste. By compounding the modified polyfunctional epoxy resin, the scratch-resistant assistant and the pigment filler, the prepared floor coating has the advantages of favorable levelingproperty, high curing speed, high film crosslinking density, high bonding strength, low shrinkage rate during hardening and low tendency to flooding during construction. When coating film formation is performed, the hardness and gloss of a coating layer are high; the whole coating layer is seamless and flat, not prone to cracking and easy to clean; the probability of bubbles appearing on a water-resistant surface is low; and the environmental protection requirements are met.

Owner:英德市黑马涂料有限公司

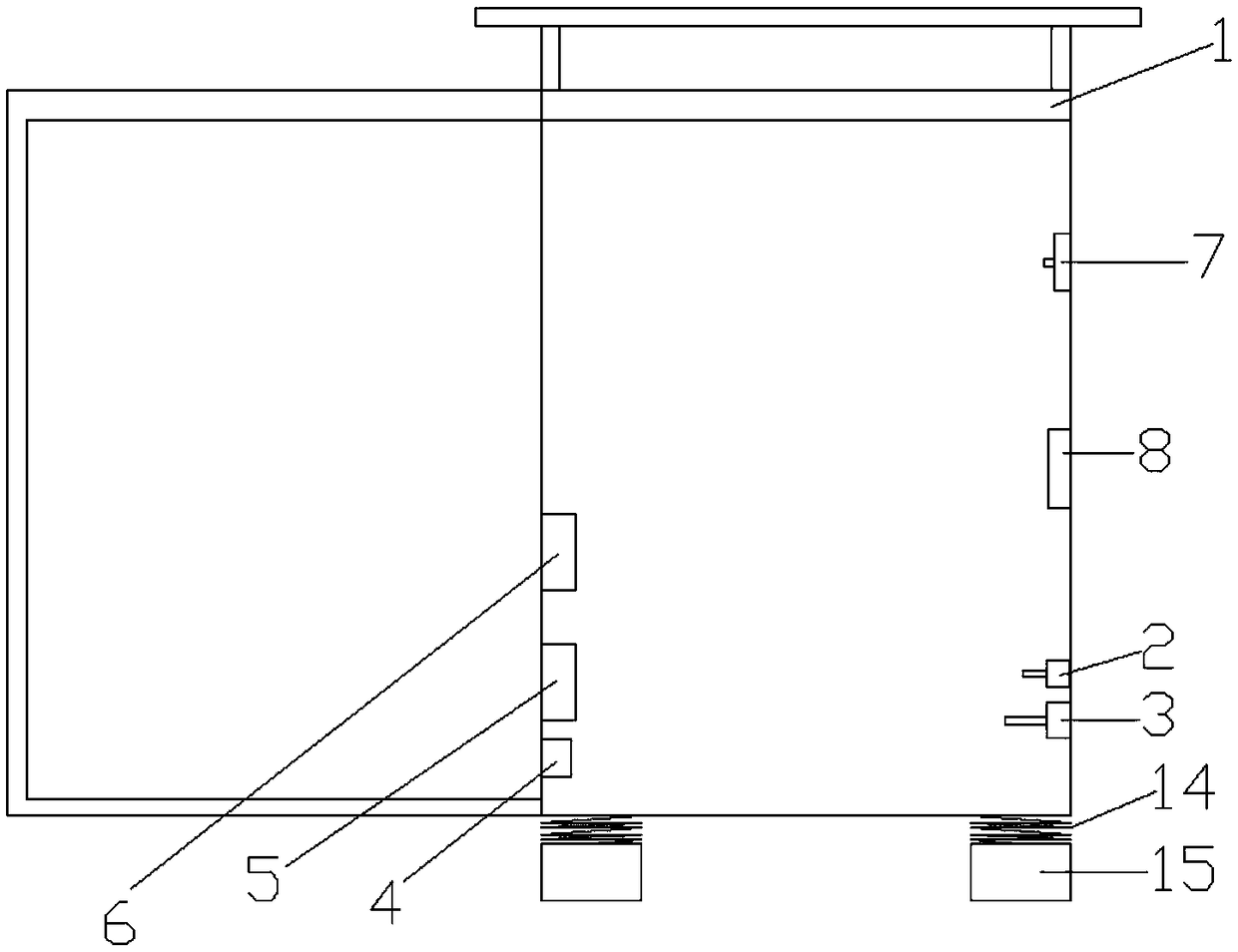

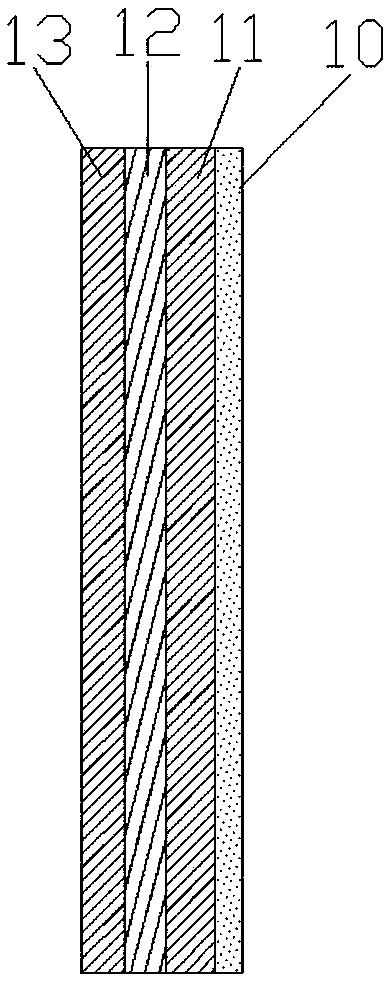

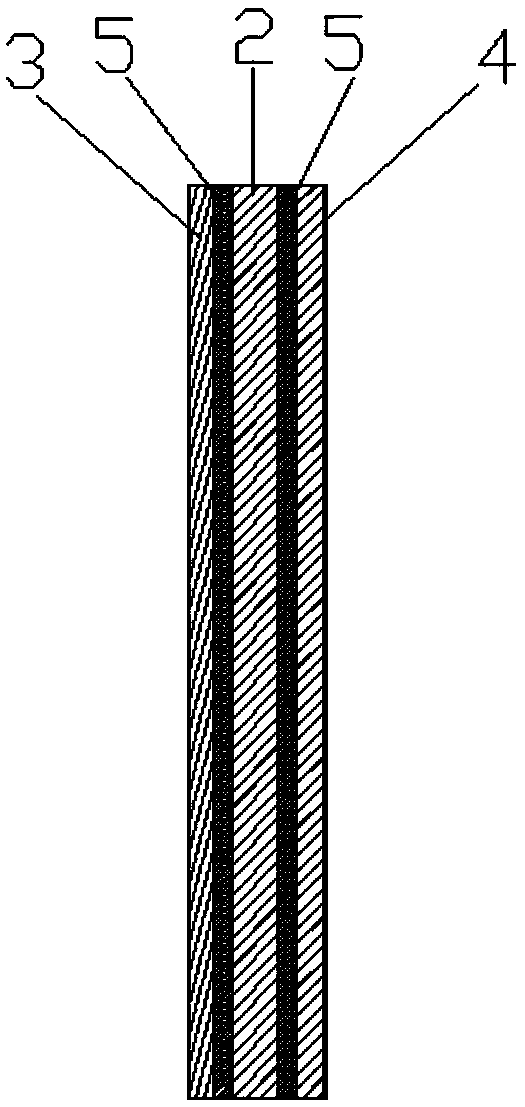

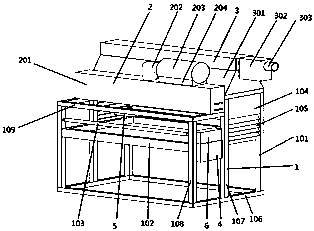

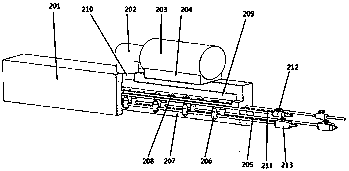

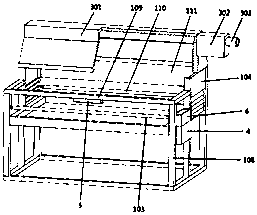

Flame-retardant switchgear

InactiveCN109135284AImprove flame retardant performanceImprove heat and weather resistanceSubstation/switching arrangement casingsAnti-seismic devicesSteel platesMetallurgy

The invention discloses a flame-retardant switchgear, comprising a switchgear body, and a temperature sensor, humidity sensor and alarm arranged in the switchgear body. The switchgear body includes anouter steel plate layer, an inner steel plate layer, a flame-retardant layer arranged between the outer steel plate layer and the inner steel plate layer, and a protective surface layer arranged on the outer wall of the outer steel plate layer. The flame-retardant switchgear has the advantages that the flame-retardant layer between the outer steel plate layer and the inner steel plate layer helpsgreatly improve flame retardancy of the switchgear body; the protective surface layer arranged on the outer wall of the outer steel plate layer helps improve heat resistance, weatherability, insulating property and mechanical strength of the switchgear body, provides effective protection for the switchgear body, and extends the service life of the switchgear. The flame-retardant switchgear can also provide real-time monitoring and controlling for temperature, humidity and current conditions in the switchgear body, so that safety of the switchgear can be further improved.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

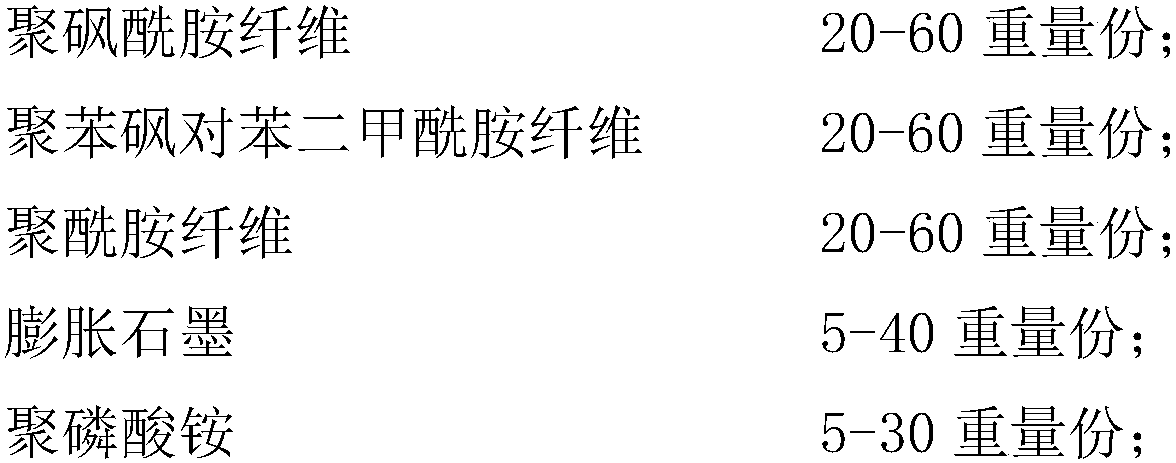

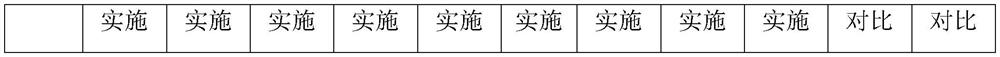

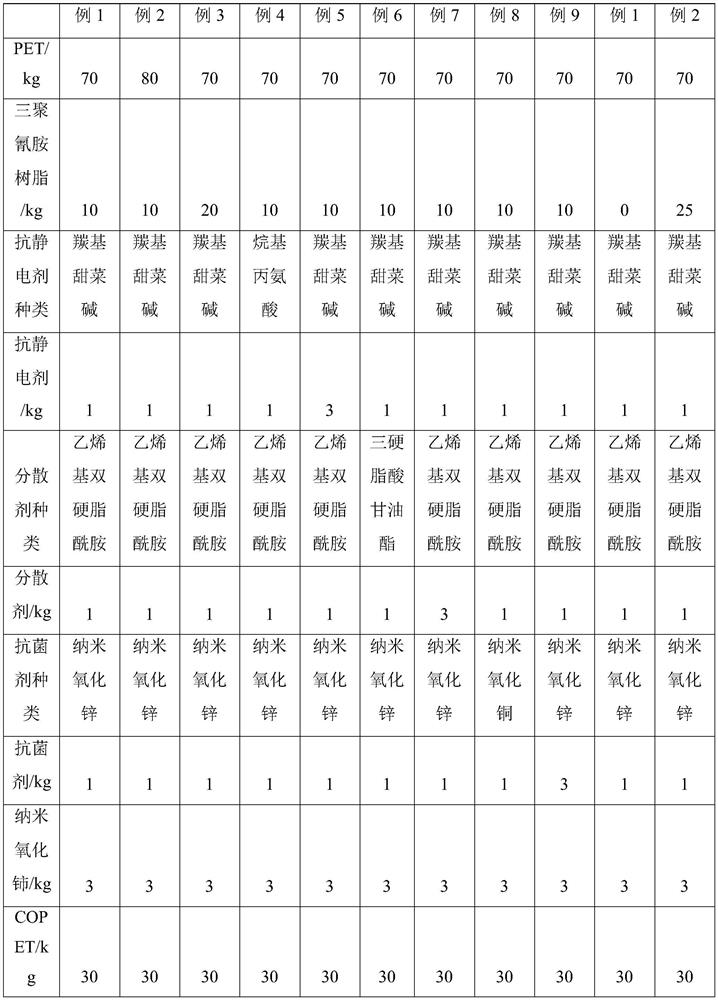

High-flame-retardant superfine sea-island filament and preparation process thereof

ActiveCN114318589ALow priceLow thermal conductivityElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberAcrylate ester

The invention relates to the field of sea-island filaments, and particularly discloses a high-flame-retardant superfine sea-island filament and a preparation method thereof. The high-flame-retardant superfine sea-island filament comprises a sea-island filament inner layer and a sea-island filament outer layer wrapping the sea-island filament inner layer, and the sea-island filament outer layer is made of flame-retardant fibers; the sea-island filament inner layer comprises the following raw materials in parts by weight: a PET solution and a COPET solution; the PET solution is prepared from the following raw materials in parts by weight: 70-80 parts of PET, 10-20 parts of melamine resin, 1-3 parts of an antistatic agent, 1-3 parts of a dispersing agent and 1-3 parts of an antibacterial agent; the COPET solution is prepared from 30 to 40 parts of COPET; the flame-retardant fiber is prepared from the following raw materials in parts by weight: 3 to 5 parts of polyacrylate, 10 to 15 parts of zirconium dioxide fiber, 3 to 5 parts of nano titanium dioxide, 3 to 8 parts of aluminum hydroxide and 2 to 3 parts of red phosphorus; the prepared sea-island filament has the advantage of high flame retardance.

Owner:杭州惠丰化纤有限公司

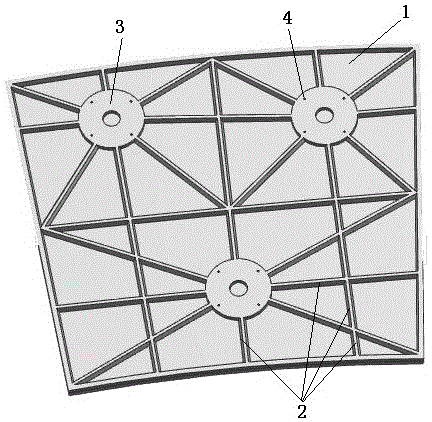

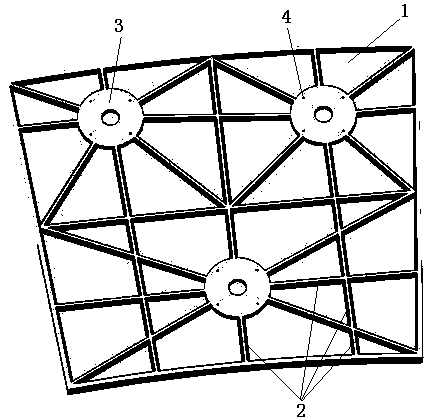

Solar thermal power generation composite backboard and preparation method

ActiveCN105116516AUniform structureHigh strengthSolar heating energySolar heat devicesEpoxyEngineering

The invention relates to a solar thermal power generation composite backboard and a preparation method thereof. The composite backboard comprises a backboard and a reflective mirror laid on the backboard, wherein reinforcing ribs and a plurality of connecting discs which are integrally formed with the backboard are arranged on the backboard, the connecting discs and the reinforcing ribs are closely jointed, the backboard and the connecting discs are made of epoxy resin, firstly, the connecting discs are prepared in a mold, then reinforcing layer auxiliary materials, the reinforcing ribs, the connecting discs, vacuum auxiliary materials and the like are laid in the backboard mold as required, vacuum pouring of the epoxy resin is performed, the backboard integrally formed with the reinforcing ribs and the connecting discs is prepared after cooling forming, then reflective glass is bond to the backboard, and the composite backboard is prepared. Compared with the prior art, the composite backboard is uniform in structure, high in strength, low in cost, long in service life, simple in preparation technology and convenient to install.

Owner:JIANGSU YUEKE NEW MATERIAL

A kind of modified polyester powder coating and preparation method thereof

ActiveCN109810618BGood dispersionImprove film formationPowdery paintsPolyester coatingsPolymer scienceSpinning

The invention belongs to the technical field of paint, and particularly relates to modified polyester powder paint and a preparation method thereof. The modified polyester powder paint is prepared from the following ingredients in parts by weight: 55 to 65 parts of polyester resin, 4 to 8 parts of curing agents, 0.5 to 2 parts of leveling agents, 0.5 to 2 parts of benzoin, 2 to 5 parts of polydopamine and 30 to 40 parts of filling materials through viscose preparation, polyester resin melting, electrostatic cospinning, extrusion molding granulation and crushing sieving. Bubbles, shrinkage holes and particles on the coating can be effectively reduced; good film forming performance, weather resistant performance, luster degree and adhesion power are realized.

Owner:余姚市亚宇工贸有限公司

High-performance organic silica gel

InactiveCN104479360AGood temperature and weather resistanceImprove insulation performanceEpoxyPolymer science

The invention discloses high-performance organic silica gel. The high-performance organic silica gel is prepared from 6-14 parts by weight of methyl vinyl silicone rubber, 5-9 parts by weight of silicon trioxide, 5-7 parts by weight of dimethylhydrosiloxy-terminated dimethylpolysiloxane, 2-6 parts by weight of DTBP, 3-8 parts by weight of epoxy resin, 4-7 parts by weight of chlorosulfonated polyethylene, 1-5 parts by weight of dodecyl phosphate, 5-8 parts by weight of polyethylene glycol, 2-9 parts by weight of stearic acid, 2-7 parts by weight of zinc oxide, 4-10 parts by weight of DOP, 1-3 parts by weight of a plasticizer and 7-11 parts by weight of a gel membrane reinforcing agent. The high-performance organic silica gel has good temperature resistance and weatherability, and excellent insulating properties, and can be widely used in the fields of electron and mechanical energy.

Owner:田琳琳

TPE coated silicane cross-linked polyethylene composite material and preparation method thereof

The invention relates to a TPE coated silicane cross-linked polyethylene composite material and a preparation method thereof.Technical problems of low heat resistance and low environmental cracking resistance of the polyethylene material are solved, the TPE coated silicane cross-linked polyethylene composite materialincludessilicane cross-linked polyethylene and a TPE material, the silicane cross-linked polyethylene includesa silicane grafted polyethylene material and a catalytic polyethylene material, and the weight ratio of the silicane grafted polyethylene material and the catalytic polyethylene material is (80-95) to (5-20); the silicane grafted polyethylene material is prepared from the following components in parts by weight: 80-120 parts of polyethylene, 1-5 parts ofsilicane and0.04-0.15 part of an initiator; the catalytic polyethylene material is prepared from the following components in parts by weight: 80-120 partsof polyethylene, 3-6 parts of an antioxidant and0.5-3 parts ofa catalyst; and the TPE material is prepared from the following components in parts by weight:15-45 parts of SEBS, 30-90 parts of white oil, 20-60 parts of polypropylene, 5-25 parts of acompatibilizer and 0.01-0.1 part of an auxiliary agent. The invention providesthe preparation method of theTPE coated silicane cross-linked polyethylene composite material at the same time. The TPE coated silicanecross-linked polyethylene composite material and the preparation method thereof can be widely applied to the field of high polymer material preparation.

Owner:威海联桥新材料科技股份有限公司

Polytrimethylene terephthalate toughening weather-proof master batch

The invention discloses a polytrimethylene terephthalate toughening weather-proof master batch. The master batch comprises the following ingredients, by weight, 20%-50% of carrier resins, 15%-40% of glass fibers, 20%-30% of elastomer graft, 10%-15% of ultraviolet ray stabilizing agents, 2%-6% of heat resistant agents, 0.1%-1% of anti-oxidants and 0.5%-3% of dispersants. The elastomer graft is one selected from ethylene-octylene copolymer grafting maleic anhydride, styrene-ethylene-butylene-styrene segmented copolymer grafting maleic anhydride, ethylene-octylene copolymer grafting glycidyl methacrylate. The beneficial effects are that the polytrimethylene terephthalate toughening weather-proof master batch has characteristics of environmental protection, no pollution, high dispersion, high impact resistance, high heat resistance, high weather resistance and the like; when the master batch is added in PTT production, excellent impact resistance and weather resistance are achieved, and the mechanical strength, the appearance quality, the chemical resistance and the like of a product can be raised obviously.

Owner:QINGDAO XINZHAN PLASTIC

Environment-friendly dust removal gel capable of being repeatedly cleaned and preparation method thereof

InactiveCN104031606AGood stability and aging resistanceStable performanceMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesRosinPlasticizer

The invention discloses an environment-friendly dust removal gel capable of being repeatedly cleaned and a preparation method thereof. The invention aims at providing an environment-friendly dust removal gel which is stable in property, and applicable to all seasons and environments, and can be repeatedly cleaned, and a preparation method thereof. The environment-friendly dust removal gel comprises the following raw materials in parts by weight: 30-50 parts of naphthenic oil, white oil or a mixture thereof, 2-6 parts of polystyrene-polyethylene-polybutylene-polystyrene copolymer (SEBS1), 13-20 parts of polystyrene-polyethylene-polybutylene-polystyrene copolymer (SEBS2), 20-30 parts of C5 hydrocarbon resin, 10-20 parts of pentaerythritol ester of rosin, 0.5-1 part of antioxidant and 0-2 parts of plasticizer. The dust removal gel has the advantages of being stable in performance, good in weather ability, long in adhesive holding time, ultraviolet resistant, free of oil impregnation at a high temperature, good in tenacity and elasticity, environment-friendly, free of a public hazard, low in cost and the like.

Owner:浙江固特新材料科技股份有限公司

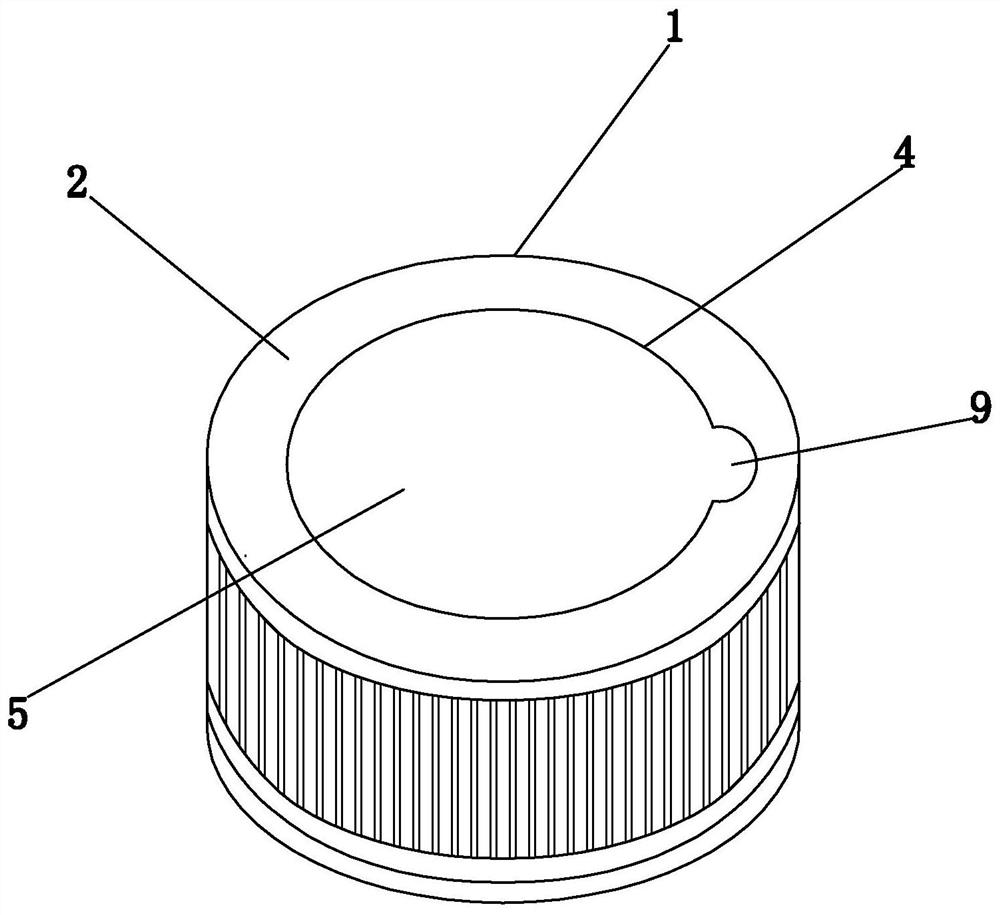

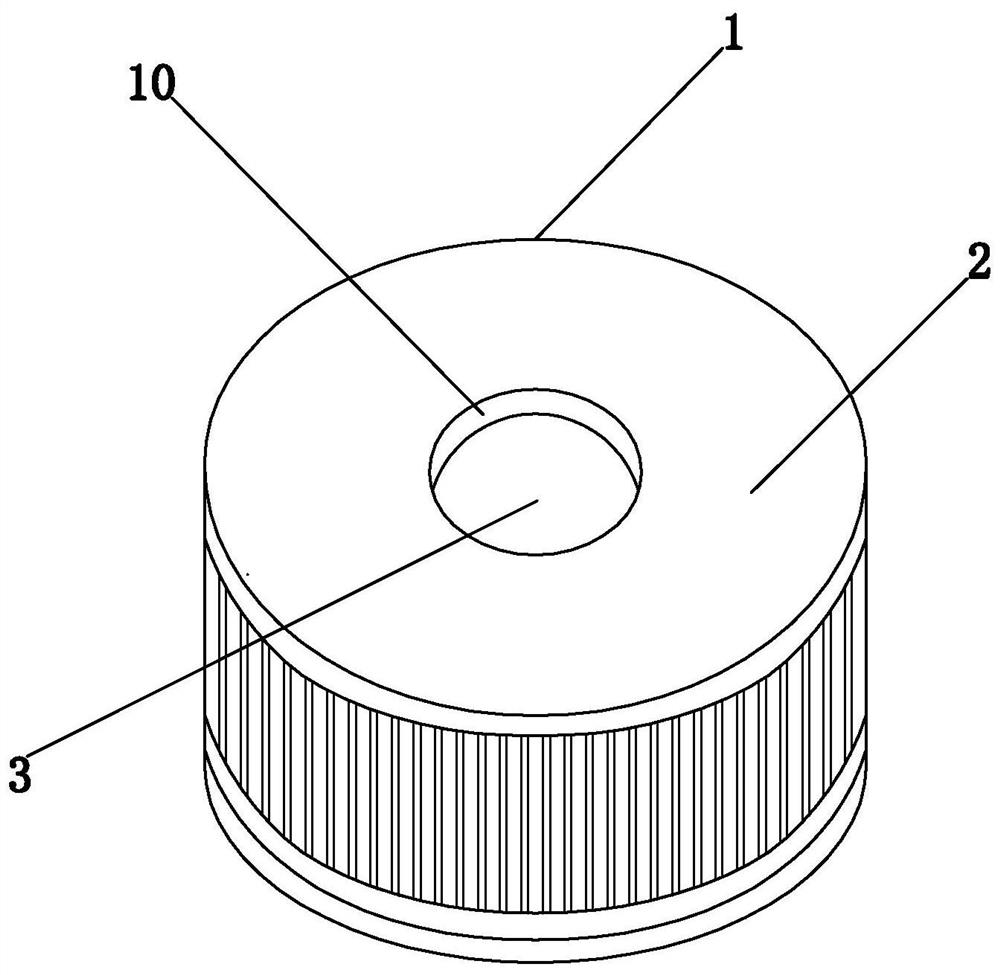

Novel barreled water smart cover and production process thereof

InactiveCN111873589AHigh mechanical strengthWide operating temperatureClosuresSynthetic resin layered productsBoPETEnvironmental engineering

The invention discloses a novel barreled water smart cover which comprises a cover body, wherein the cover body comprises a cover surface, a through hole is formed in the middle of the cover surface,a water sealing film is bonded to the cover surface in a hot pressing mode to block the through hole, and the edge of the water sealing film extends outwards to form a hand tearing part. The water sealing film is formed by compounding a BOPET layer, a first OPP layer, a second OPP layer and a modified PE layer which are sequentially arranged from top to bottom. According to the barreled water smart cover, the simple structure that the water sealing film blocks the penetrating hole replaces a combined structure of a cover piece, an open hole, a circular pipe and an inner plug or a top penetrating piece in a conventional barreled water smart cover; the barreled water smart cover solves the problem that an inner plug or a top penetrating piece in a conventional barreled water smart cover is difficult to open sometimes and is suddenly opened to damage drinking equipment, is safe and practical, completely replaces the conventional barreled water smart cover in function, and is also suitablefor transportation, storage and use. Compared with a conventional barreled water smart cover, the product has the advantages of convenience in use, simple process, low cost, high production efficiency, strong market competitiveness, wide commercial prospect and high popularization value.

Owner:贾作贵

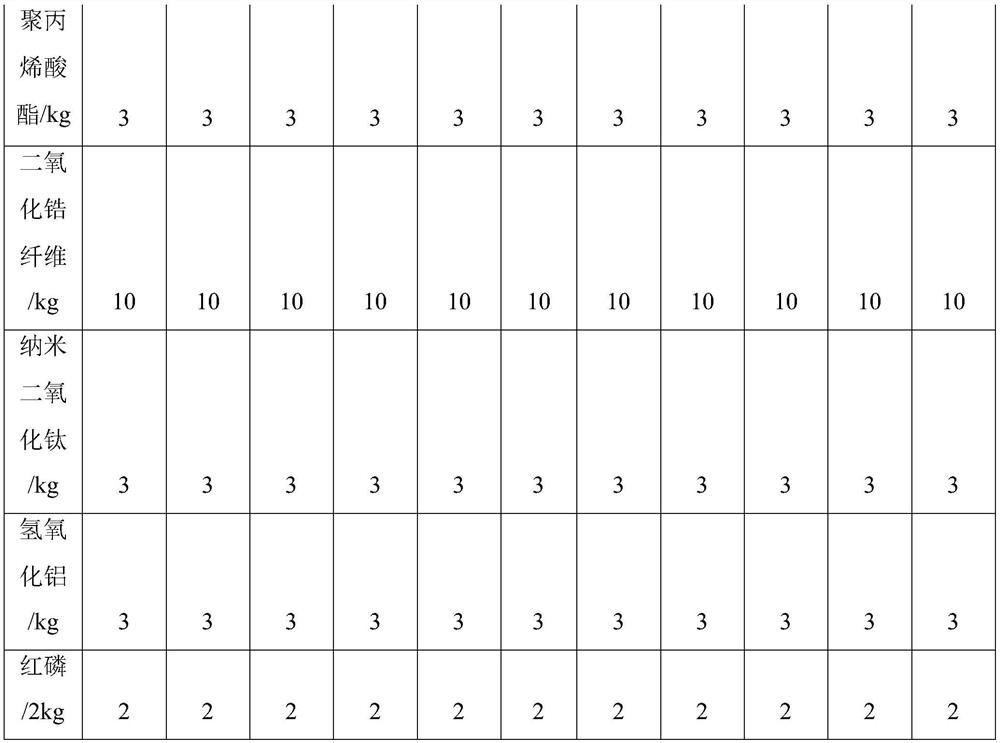

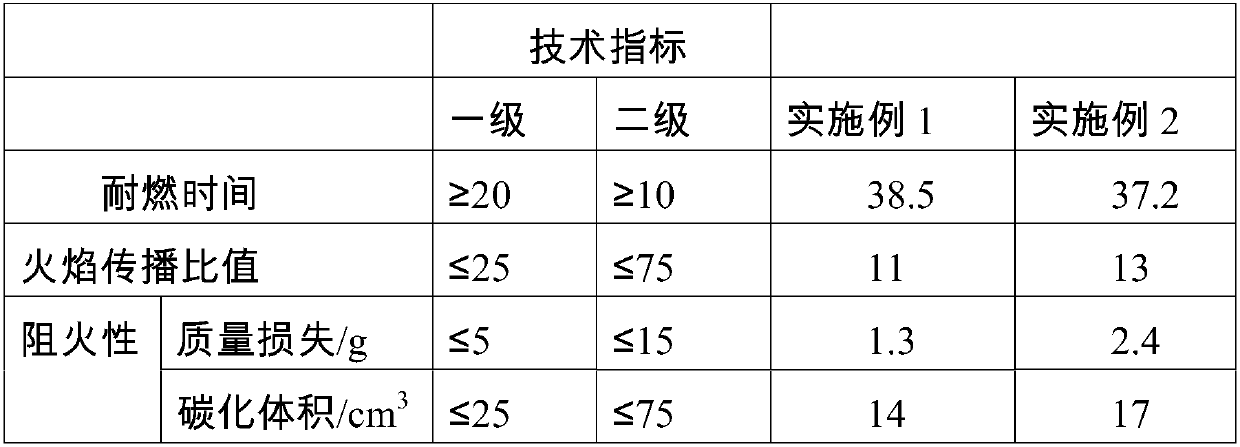

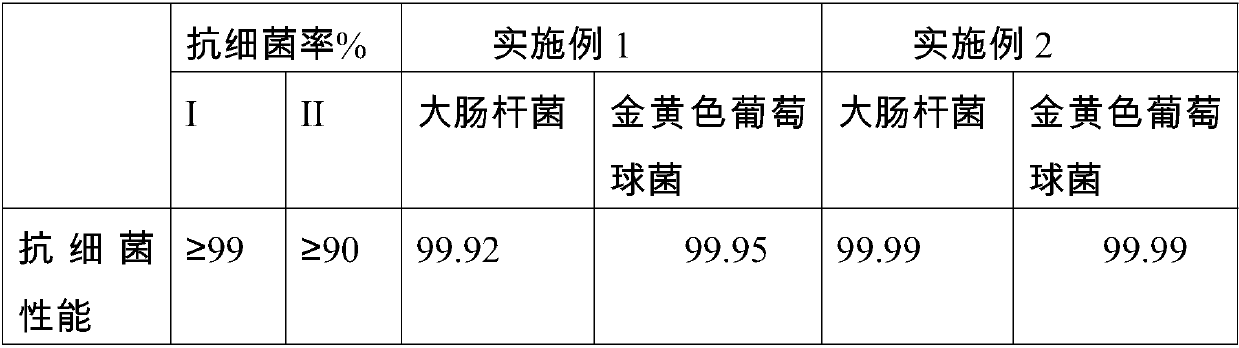

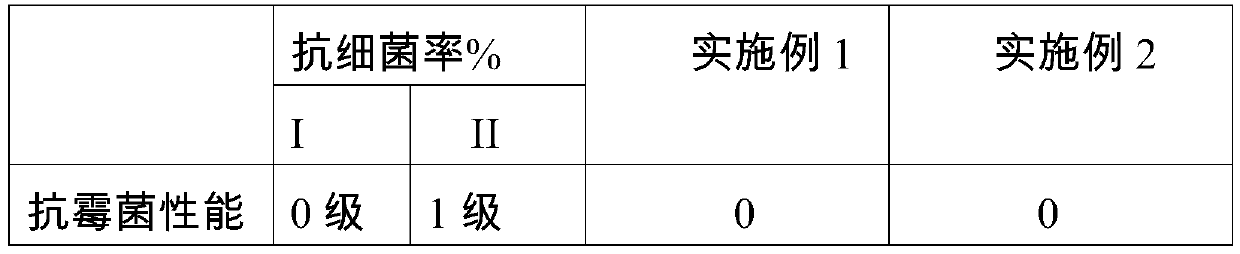

Fireproof, antibacterial and mildew-resistant interior wall coating

InactiveCN109777228AGood temperature and weather resistanceImprove processing performanceFireproof paintsAntifouling/underwater paintsPhosphoric acidWeather resistance

The invention provides a fireproof, antibacterial and mildew-resistant interior wall coating. The coating comprises, by weight, 10-30 parts of silicone acrylic resin, 5-15 parts of talcum powder, 5-10parts of titanium dioxide, 6-12 parts of light calcium carbonate powder, 4-10 parts of kaolin powder, 3-9 parts of a hydroxyethyl cellulose solution, 3-7 parts of polyvinyl alcohol, 0.3-0.5 part of an antifoaming agent, 0.2-0.6 part of an antifreeze agent, 0.4-0.8 part of a film forming aid, 0.5-1 part of a thickener, 0.2-2 parts of a dispersant, 15-20 parts of deionized water, 3-5 parts of zirconium phosphate-supported silver antibacterial powder and 2-10 parts of a phosphate flame retardant. The zirconium phosphate-supported silver antibacterial powder and the phosphate flame retardant areadded on the basis of ensuring basic functions of the coating, the synergistic effects between the raw materials and a phosphoric acid-containing compound are used to make the interior wall coating have the advantages of good heat and weather resistance, good antibacterial performance, good fireproof and flame-retardant performances and high processing performances, so the coating is good for public health.

Owner:晋大纳米科技(厦门)有限公司

Hot melt adhesive film, production method thereof, and automobile door sill

InactiveCN107652921AIncrease costLow costNon-macromolecular adhesive additivesFilm/foil adhesivesSolventHot-melt adhesive

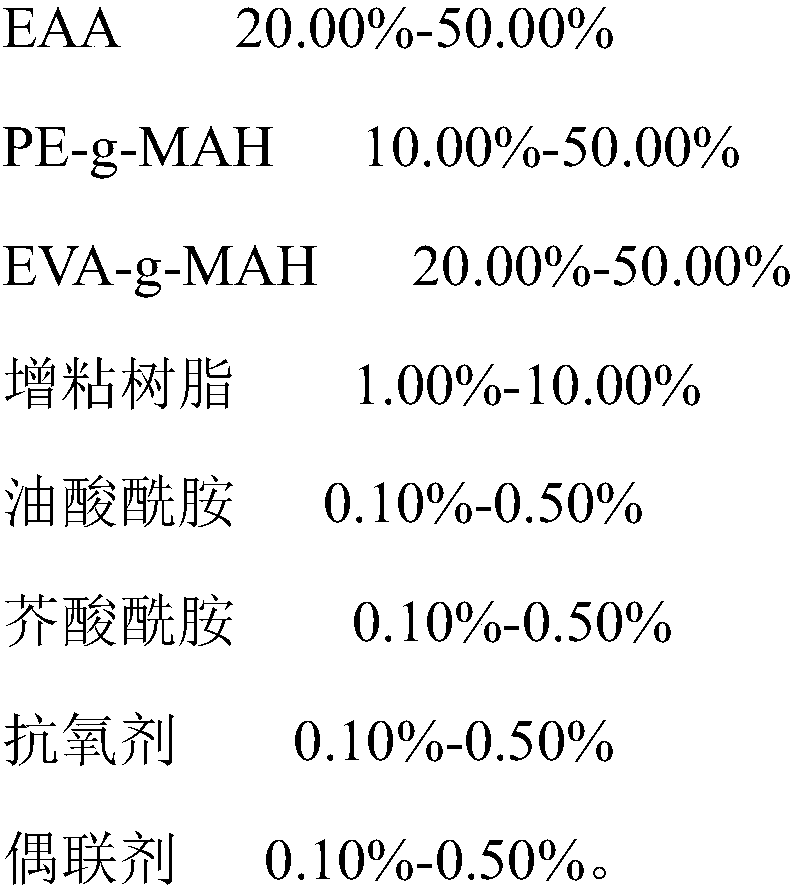

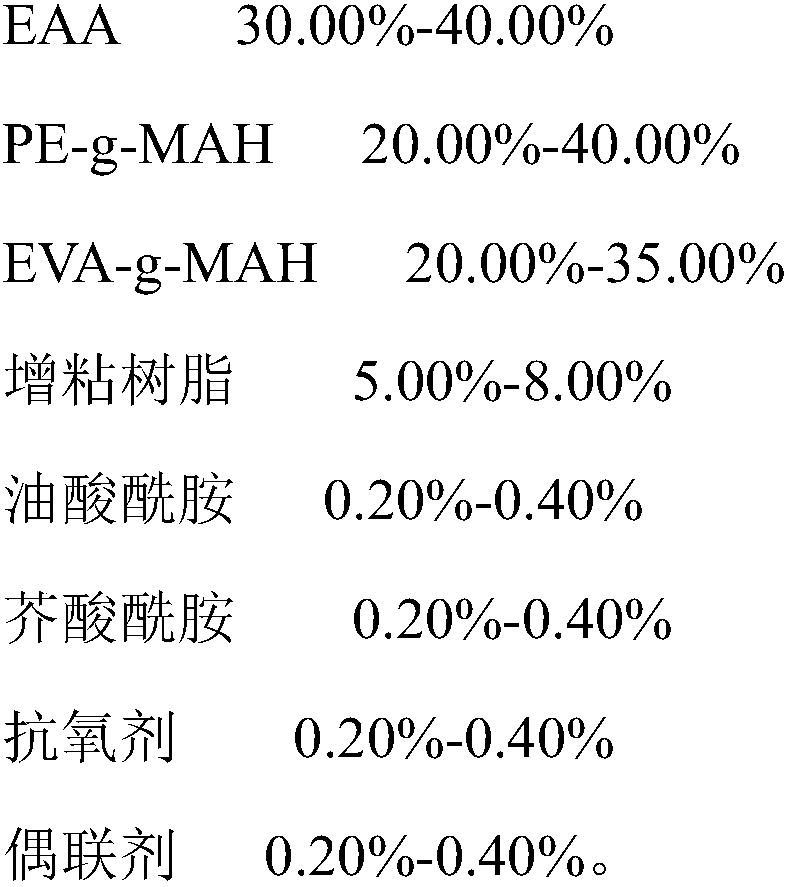

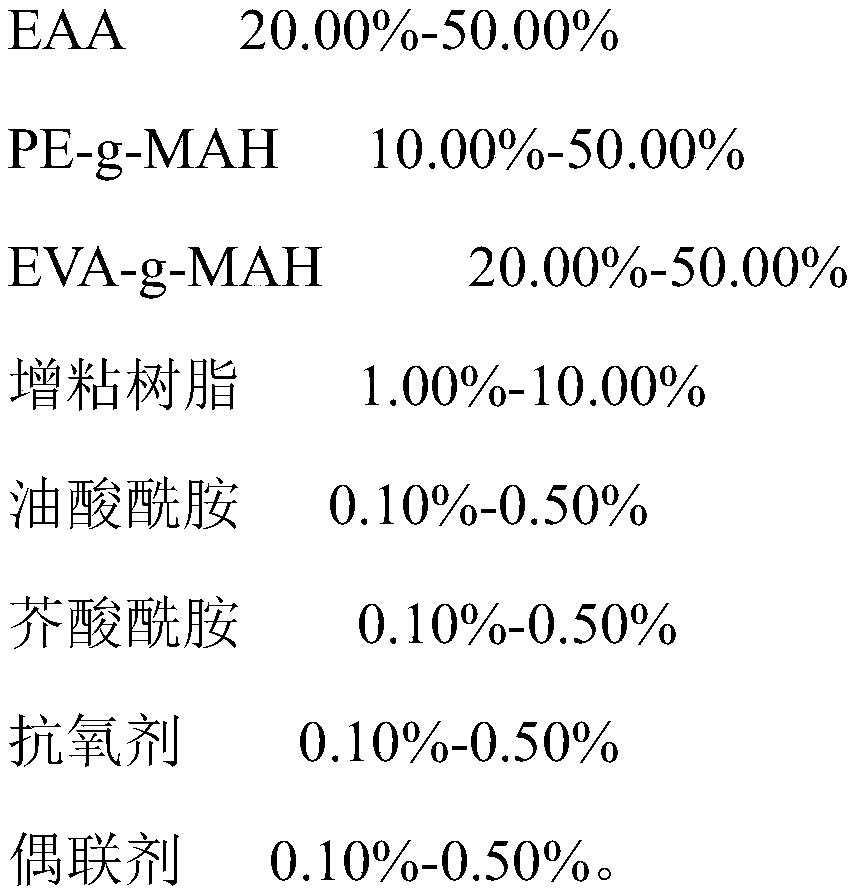

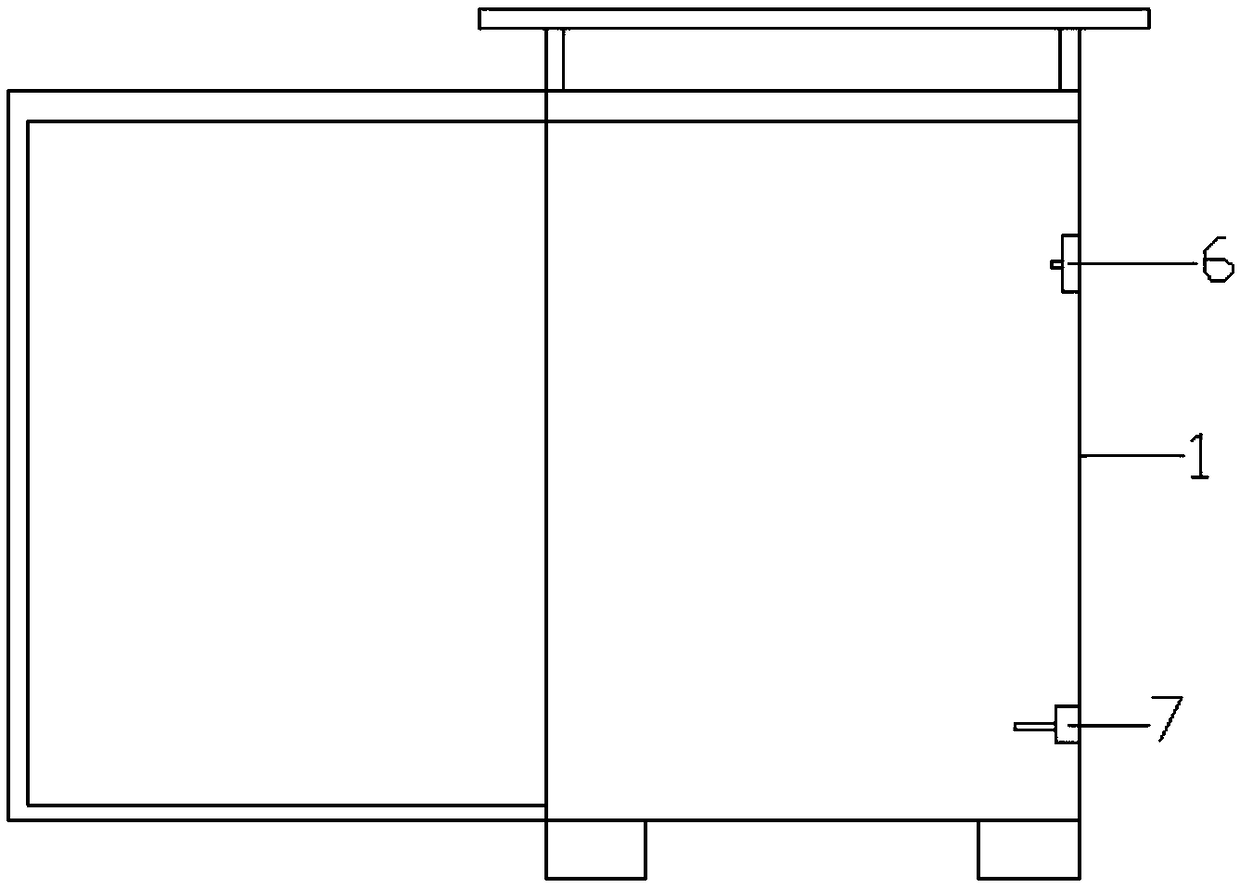

The invention discloses a hot melt adhesive film, a production method thereof, and an automobile door sill. The hot melt adhesive film for bonding a metal part and a plastic part comprises 20.00-50.00% of EAA, 10.00-50.00% of PE-g-MAH, 20.00-50.00% of EVA-g-MAH, 1.00-10.00% of tackifying resin, 0.10-0.50% of oleamide, 0.10-0.50% of erucamide, 0.10-0.50% of an antioxidant and 0.10-0.50% of a coupling agent. The hot melt adhesive film can be used for bonding the metal part and the plastic part, and has the advantages of no solvent volatilization, environmental protection, no pollution no healthrisks, high processing efficiency, device improvement, continuous production, increase of the yield, and high market acceptance.

Owner:江苏和和新材料股份有限公司

Insulating switch cabinet

InactiveCN109054304AExtended service lifeImprove insulation performancePlastic/resin/waxes insulatorsSubstation/switching arrangement casingsPower flowSurface layer

The invention discloses an insulating switch cabinet, which comprises a switch cabinet body, wherein the switch cabinet body comprises a steel plate layer, an insulating layer and a protection surfacelayer; the insulating layer is arranged on the inner wall of the steel plate layer, and the protection surface layer is arranged on the outer wall of the steel plate layer. According to the insulating switch cabinet disclosed by the invention, the inner wall of the steel plate is provided with the insulating layer, the insulating performance and the heat-proof and weather-proof performance of theswitch cabinet body can be greatly improved, and the use safety of the switch cabinet body is improved; the outer surface of the steel plate layer is provided with the protection surface layer, so that the mechanical strength, the weather fastness and the stability of the switch cabinet body can be improved, effective protection can be formed for the switch cabinet body, and the service life of the switch cabinet is prolonged. The invention also can carry out real-time monitoring on temperature and current situations in the switch cabinet body, and the safety performance of the switch cabinetcan be further improved.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

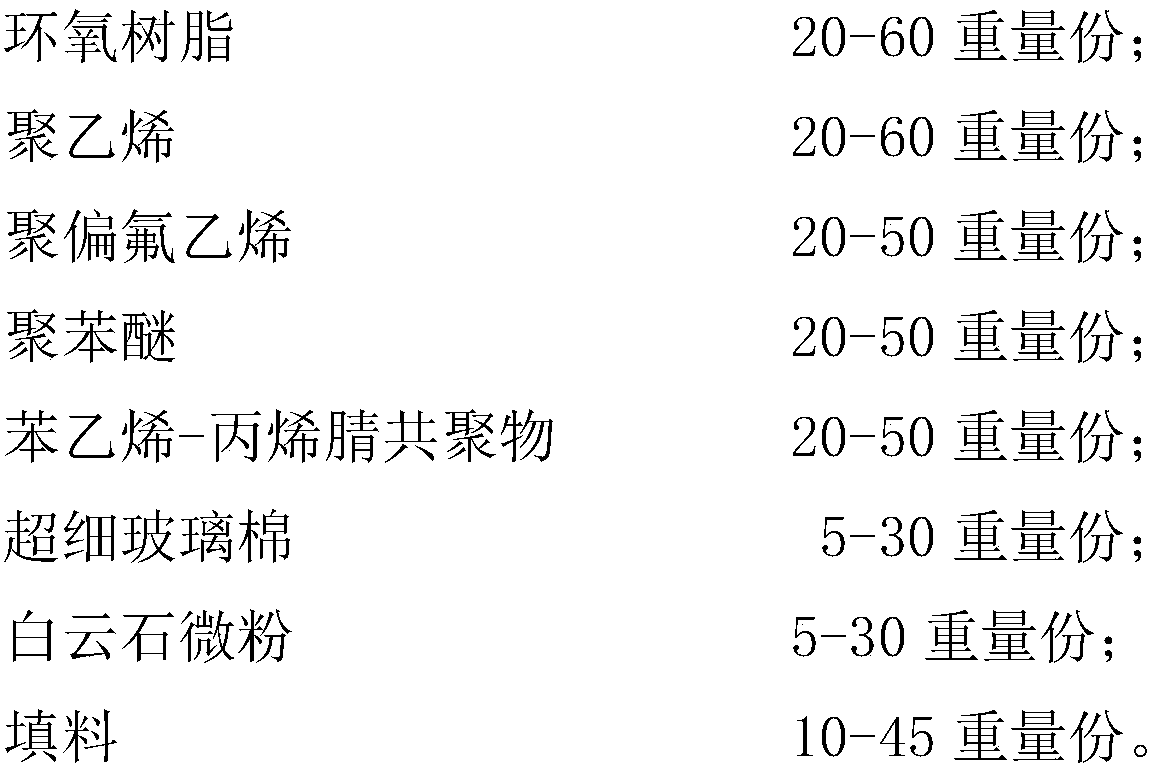

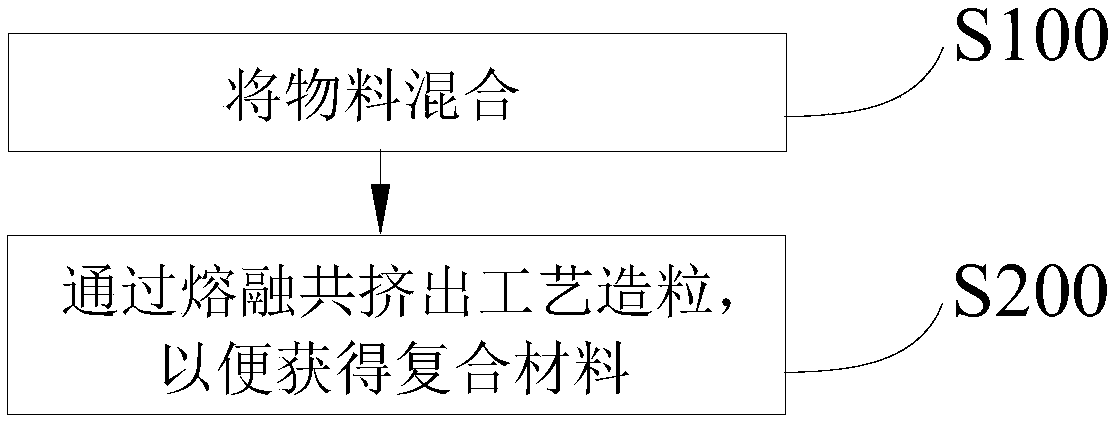

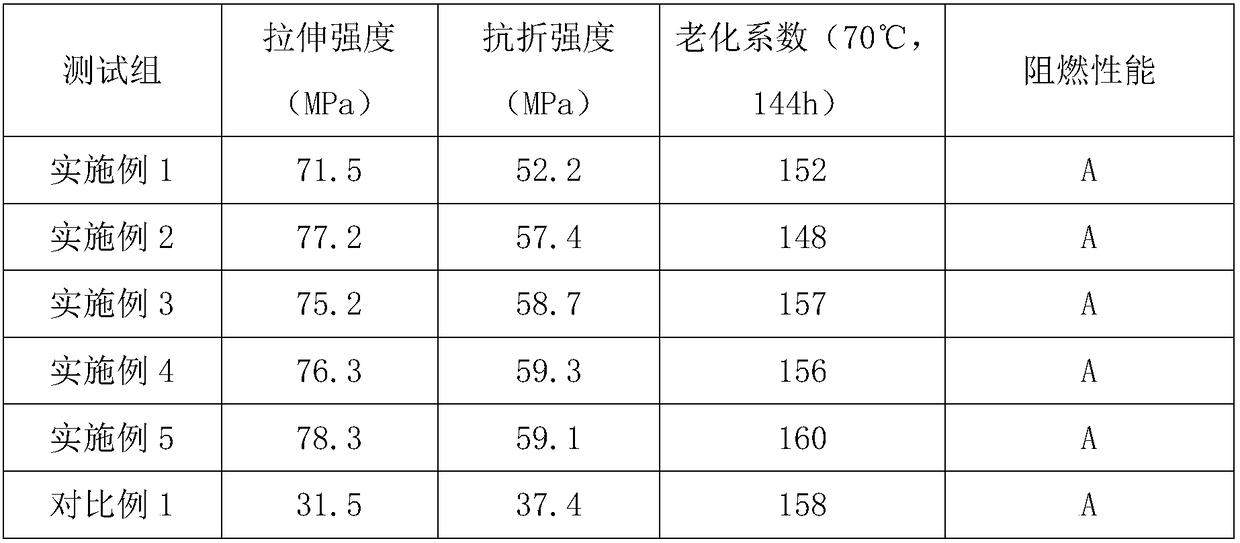

Composite material and preparation method thereof, air deflector and air conditioner

InactiveCN108641330AImprove liquidityEasy to processAir-flow control membersWeather resistanceHeat resistance

The invention discloses a composite material, a preparation method thereof, an air deflector and an air conditioner. Specifically, the invention provides a composite material, the composite material,based on the total weight of the composite material, comprises: 75-85 parts by weight of polycarbonate, 10-20 parts by weight of polyvinylidene fluoride, 0.5-1 part by weight of antioxidant, 1-3 partsby weight of light stabilizer, and 1 to 3 parts by weight of ultraviolet absorber.. Therefore, the composite material not only has good heat resistance and weather resistance, but also has good processing property and mechanical property; the air deflector prepared by the composite material has the advantages of good mechanical performance, light weight, difficult deformation and discoloration, simple production process and low production cost.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Wire and cable material for telecommunication engineering and preparation method thereof

InactiveCN108690284AHigh strengthGood temperature and weather resistancePlastic/resin/waxes insulatorsEpoxyBoron nitride

The invention discloses a wire and cable material for telecommunication engineering and relates to the field of cable materials. The wire and cable material for telecommunication engineering comprisesthe following raw materials (by weight): 50-60 parts of VC resin, 20-30 parts of EPDM rubber, 8-15 parts of epoxy resin, 12-18 parts of modified montmorillonite powder, 8-15 parts of diatomite, 10-16parts of glass fiber, 12-18 parts of polyacrylonitrile fiber, 14-20 parts of light calcium carbonate, 4-9 parts of nickel oxide, 5-10 of nano-zinc oxide, 4-9 parts of nano-boron nitride, 3-7 parts oftitanium dioxide, 3-7 parts of carbon black, etc. Through synergism of the raw materials, the cable material of the invention has advantages of high strength, heat and weather resistance, corrosion resistance and ageing resistance, and has excellent tensile strength and fracture resistance. The raw materials contain no halogen elements, and no smokeless or harmful gas is generated during combustion. The wire and cable material of the invention is green and environmentally friendly.

Owner:合肥市闵葵电力工程有限公司

Anti-cracking anti-corrosion cable material and preparation method thereof

InactiveCN108912457AImprove heat resistanceGood weather resistancePlastic/resin/waxes insulatorsMaterials scienceRaw material

The invention discloses an anti-cracking anti-corrosion cable material and a preparation method thereof, and relates to the field of a cable material. The cable material is prepared from the followingraw materials in parts by weight: 50 to 60 parts of high density polyethylene, 18 to 25 parts of ethylene-vinyl acetate copolymers, 3 to 8 parts of maleic anhydride grafted polyethylene, 5 to 10 parts of modified polytetrafluoroethylene particles, 5 to 10 parts of nanometer titanium dioxide, 22 to 27 parts of aluminum hydroxide, 3 to 8 parts of chitin, 1.8 to 4.2 parts of plasticizers and 1.6 to3.5 parts of antioxidizers. The cable material has the advantages that through the cooperated matching effect between the raw materials, good heat resistance, weather resistance and anti-corrosion performance can be realized; the mechanical toughness and the anti-stretching performance are excellent; the durability and the fireproof performance are high; the use safety is high; the preparation method is simple; the operation and the production are easy.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

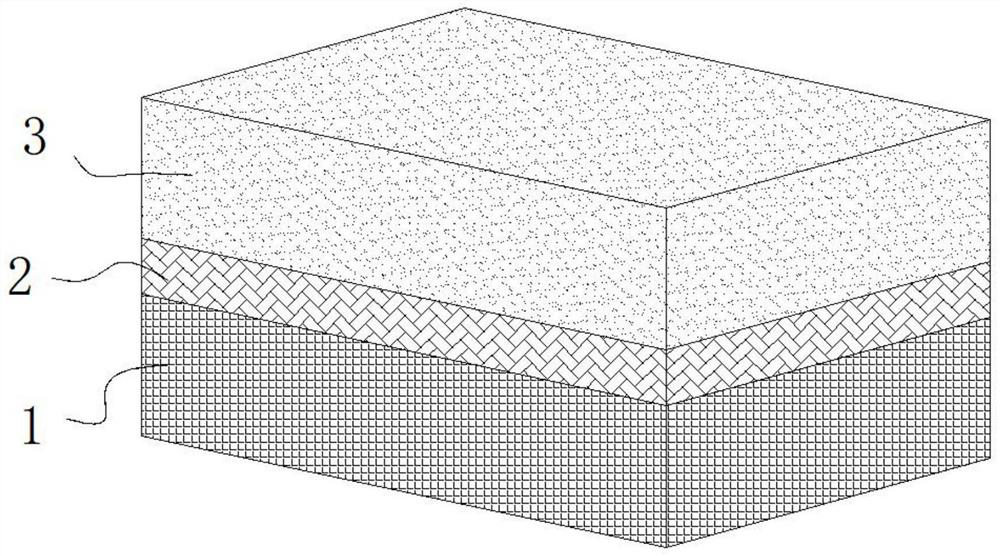

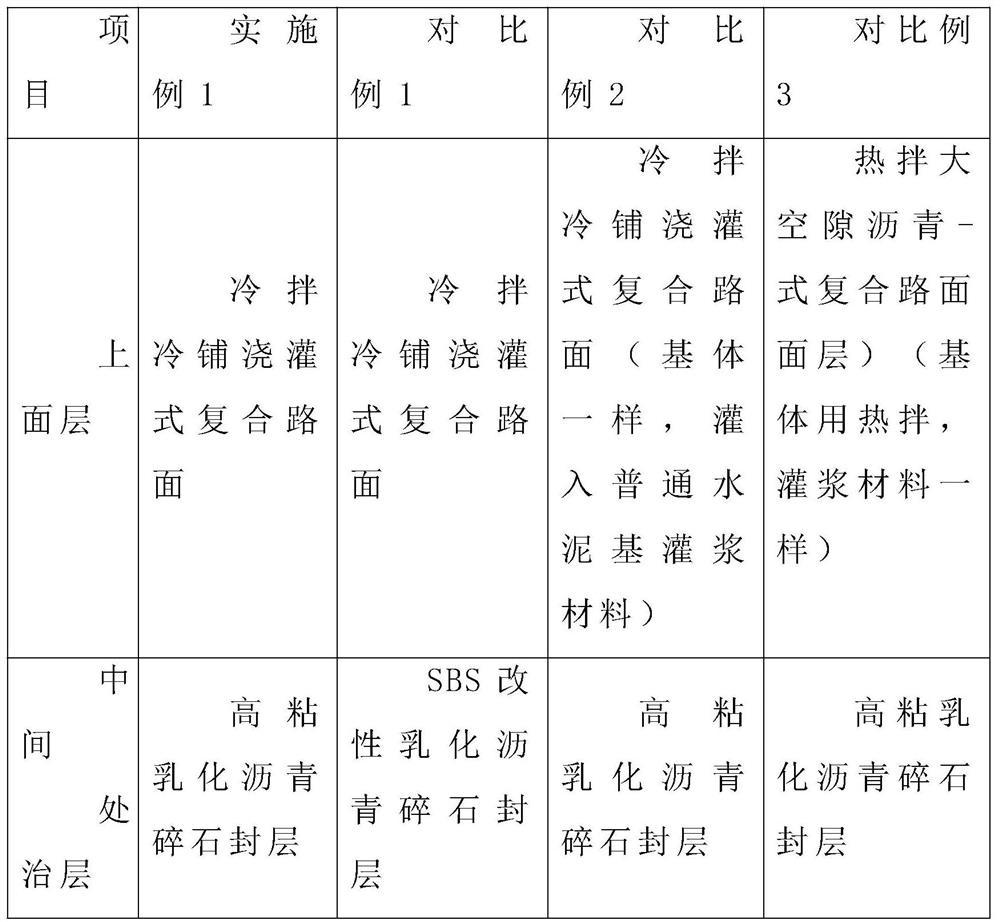

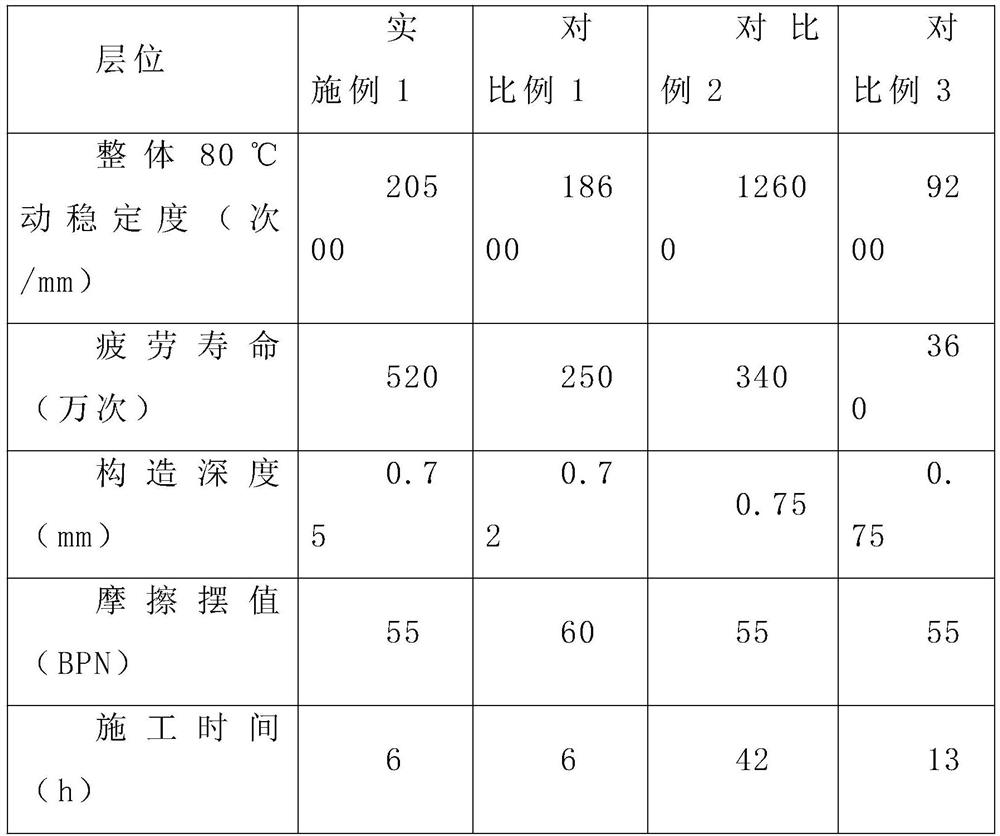

Low-carbon rapid maintenance and pavement method for asphalt pavement ruts

ActiveCN113622247AResistance to reflective cracking issuesImproves rutting resistanceIn situ pavingsRoads maintainenceBitumen emulsionStructural engineering

The invention discloses a low-carbon rapid maintenance and pavement method for asphalt pavement ruts. The method comprises the following steps: (1), milling an asphalt surface layer; (2), paving a super-viscous emulsified asphalt macadam sealing layer; and (3), paving the surface layer of the cold-mixing and cold-paving pouring type composite pavement. The combined pavement layer obtained by the method has the characteristics of excellent rut resistance, simple maintenance process and environmental protection, and the whole structure has the characteristics of high rut resistance, skid resistance, wear resistance, long service life and low carbon.

Owner:浙江固路交通科技有限公司

ABS heat-resisting weather-proof modified material and preparation method thereof

The invention discloses an ABS heat-resisting weather-proof modified material and a preparation method of the ABS heat-resisting weather-proof modified material. The ABS heat-resisting weather-proof modified material comprises the following main components by mass ratio: 80-85 parts of ABS resin, 4-5 parts of titanium dioxide R105, 0.7-0.9 part of ethylene bis stearamide EBS, 1-1.05 part of PE wax, 0.3-0.35 part of an ultraviolet absorbent UV-P, 0.3-0.4 part of a polyamide 1010, 0.25-0.3 part of a light stabilizer 770, 0.2-0.25 part of 168, and 8-10 parts of an MS-NB heat resisting agent. TheABS heat-resisting weather-proof modified material has the advantages that the ABS heat-resisting weather-proof modified material is prepared from various raw materials at the specific ratio, obviously improves the heat resistance and the weather fastness, and is convenient to popularize and apply.

Owner:合肥永健工贸有限公司

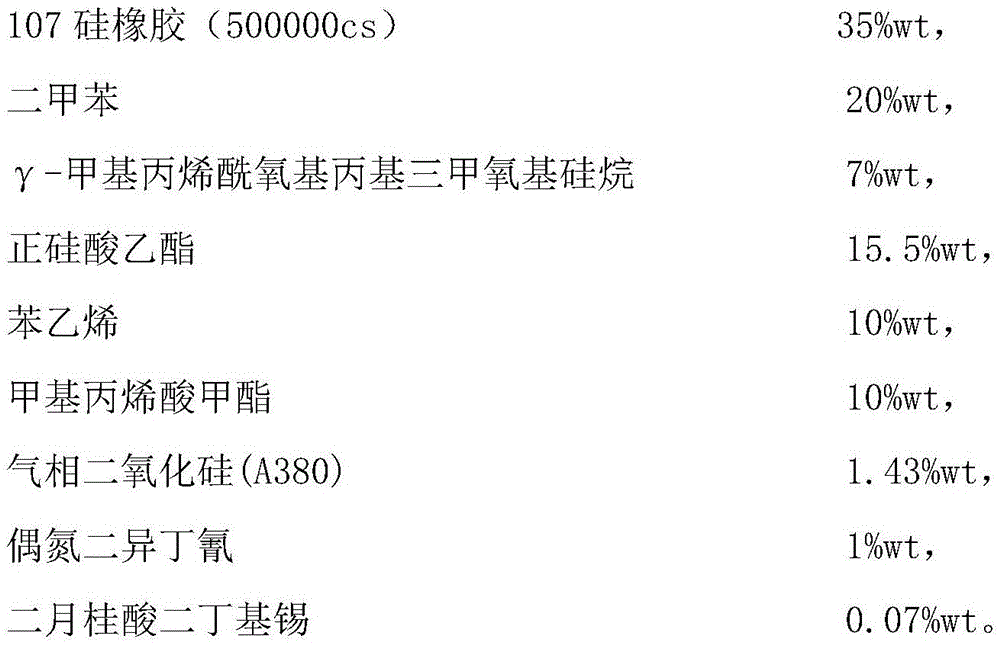

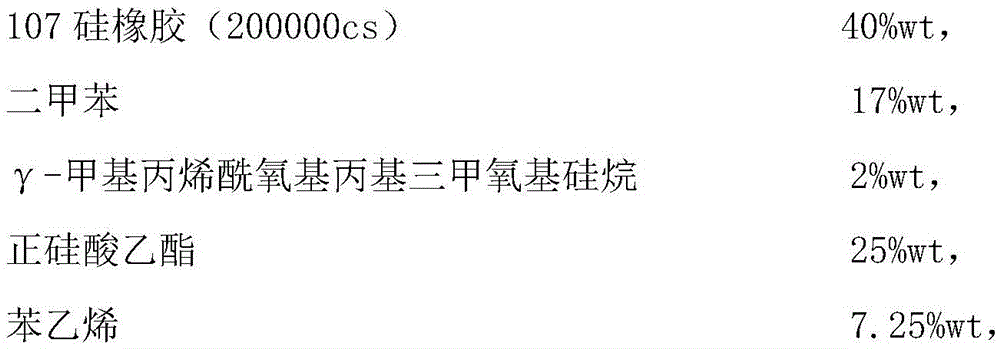

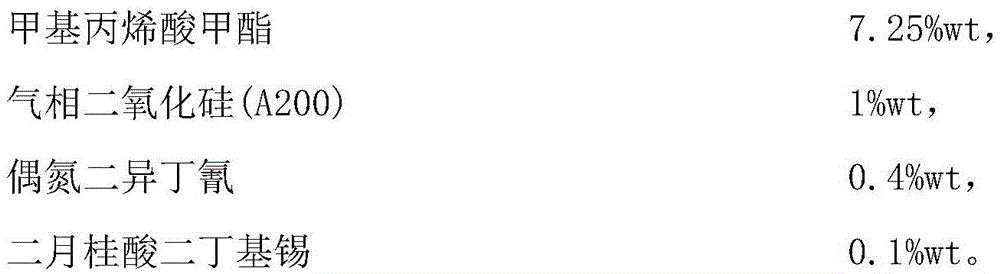

Room temperature curable composite coating based on modified 107 silicone rubber and preparation method thereof

ActiveCN104004429BReduce surface tensionGood temperature and weather resistanceCoatingsSilanesAcrylic resin

Owner:SHENZHEN JINLIAN TECH

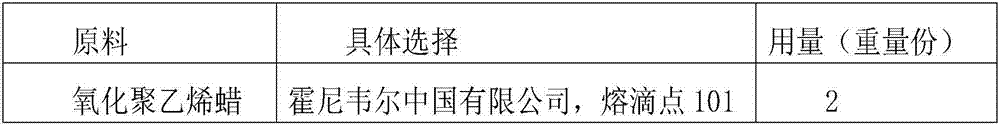

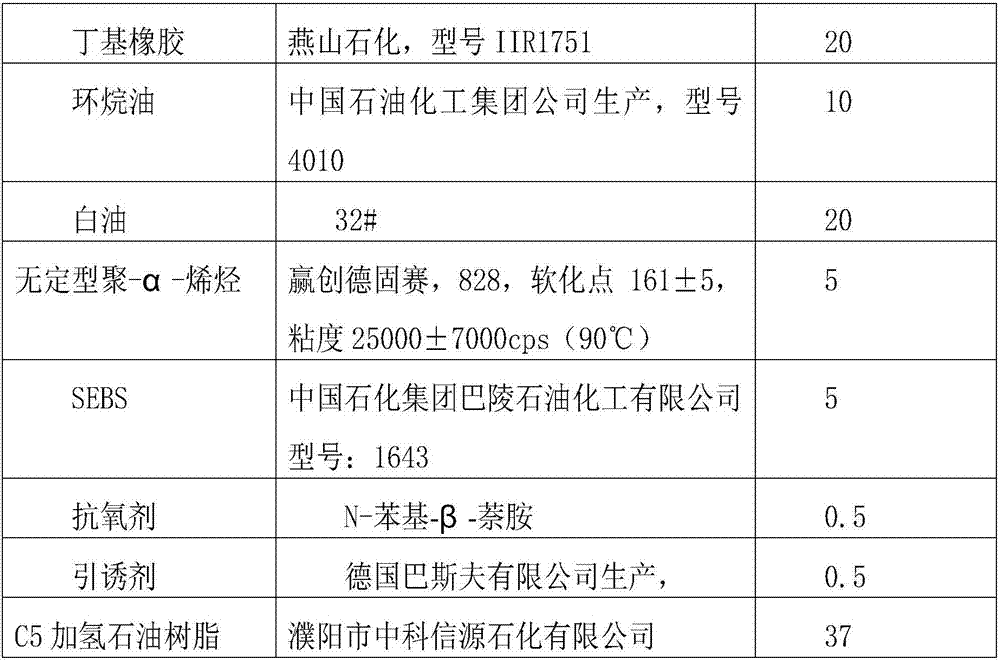

Environment-friendly, pollution-free, high-efficiency mouse glue and production method thereof

ActiveCN103709977BImprove performanceGood weather resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantPetroleum

The invention relates to the hot melt adhesive field, and especially discloses an environmentally friendly, nuisanceless and efficient rat adhesive with long viscidity holding time and a production method therefor. The rat adhesive is composed of 0.5-4 parts of oxidized polyethlene wax, 10-30 parts of butyl rubbers, 10-40 parts of one of naphthenic oil and white oil or a mixture thereof, 20-45 parts of C5 hydrogenated petroleum resins, 0.5-1 part of antioxidants, 0.5-1 part of attractants, and 4-15 parts of one of amorphous form poly-alpha-alkene, styrene-butadiene-styrene segmented copolymer hydride (SEPS) or a mixture thereof. The rat adhesive has advantages of good weather resistance, long viscidity holding time, good sagging resistance and the like.

Owner:浙江固特新材料科技股份有限公司

A kind of release agent for masking tape and preparation method thereof

ActiveCN103924478BIncrease productivityReduce foamingDefoamers additionFilm/foil adhesivesSodium bicarbonateWater based

The invention relates to a mold release agent for a masking tape, and a preparation method of the mold release agent. The mold release agent is prepared from the following raw materials in parts by weight: 150-270 parts of ethyl acrylate, 0-90 parts of butyl acrylate, 0-110 parts of methyl methacrylate, 0-105 parts of styrene, 5-10 parts of succinic acid, 0-7 parts of crosslinking monomer, 500-600 parts of deionized water, 0.1-0.4 part of sodium bicarbonate, 3-5 parts of lauryl sodium sulfate, 1.2-3.0 parts of ammonium persulfate, 0.5-2 parts of a defoaming agent, 30-55 parts of zinc glycinate, 5-15 parts of ammonia water, 20-100 parts of long-chain alkyl surface active agent and 0-10 parts of modified polysiloxane. The mold release agent is a water-based mold release agent, is convenient to use and can be directly coated or can be coated after being diluted by water; a catalyst is not fed into the mold release agent, and the mold release agent is capable of crosslinking at low temperature and does not contain an organic solvent, so that the mold release agent is free from environmental pollution and harmless to the human health; furthermore, the mold release agent has good heat resistance and weather resistance, is capable of providing proper mold release force for the masking tape, and is lower in migration rate; the tape prepared by the mold release agent is free from residual glue after being used, so that the protected surface is not polluted.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

PCT-based antibacterial flame-retardant simulation wig fiber and preparation method thereof

InactiveCN111575828AExcellent hydrolysis and chemical resistanceRollable and stable performanceElectroconductive/antistatic filament manufactureWigsMaleic anhydrideOligosaccharide

The invention provides a PCT-based antibacterial flame-retardant simulation wig fiber and a preparation method thereof. The PCT-based antibacterial flame-retardant simulation wig fiber comprises the following components in percentage by weight: 60%-95% of PCT, 0.1%-0.5% of maleic anhydride, 0.1%-1% of polyacrylate, 0.1%-0.5% of chlorinated paraffin, 0.4%-6% of barium metaborate, 0.3%-5% of pentabromobenzyl polyacrylate, 0.3%-5% of tris (tribromopentyl) phosphate, 0.2%-0.5% of ethylene bis stearamide, 0.1%-0.5% of nano calcium carbonate, 1%-3% of a nano silver antibacterial agent, 0.8%-4% of quaternary phosphonium salt, 0.6%-4.5% of alpha-ketonic acid, 0.8%-5.5% of chitosan oligosaccharide and 0.2%-4% of alum. The wig fiber provided by the invention has the characteristics of being antibacterial, flame-retardant, excellent in hydrolysis resistance and chemical resistance, stable in reelability, comfortable to wear, soft in touch, easy to comb and dye and the like, and has good market competitiveness.

Owner:XUCHANG HONGYANG BIOCHEM IND DEV

A kind of photothermal power generation composite material backplane and preparation method

The invention relates to a photothermal power generation composite material backplane and a preparation method thereof. The composite material backplane includes a backplane and a reflective mirror surface laid on the backplane, and the backplane is provided with a reinforcement integrally formed with it. Ribs and a plurality of connecting discs, the connecting discs are tightly connected with the reinforcing ribs, and the back plate and the connecting discs are both made of epoxy resin. Firstly, the connecting discs are prepared in the mold, and then on the back In the plate mold, the reinforcement layer auxiliary materials, reinforcement ribs, connecting discs and vacuum auxiliary materials are laid according to the requirements, epoxy resin is vacuum poured, and after cooling and forming, a back plate integrally formed with the reinforcing ribs and connecting discs is obtained, and then in the The reflective glass is glued on the back plate to obtain a composite material back plate. Compared with the prior art, the composite material backboard prepared by the invention has uniform structure, high strength, low cost, long service life, simple preparation process and convenient installation of the backboard.

Owner:JIANGSU YUEKE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com