Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Good processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

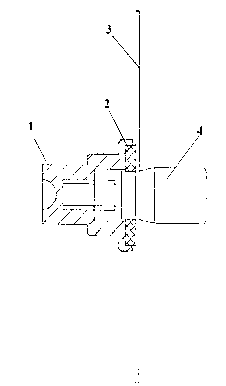

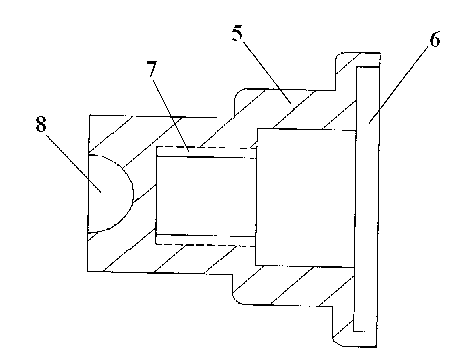

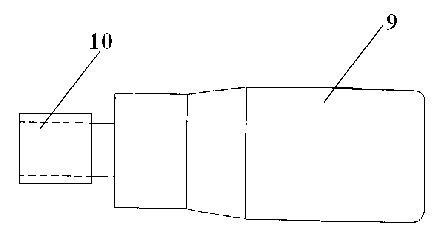

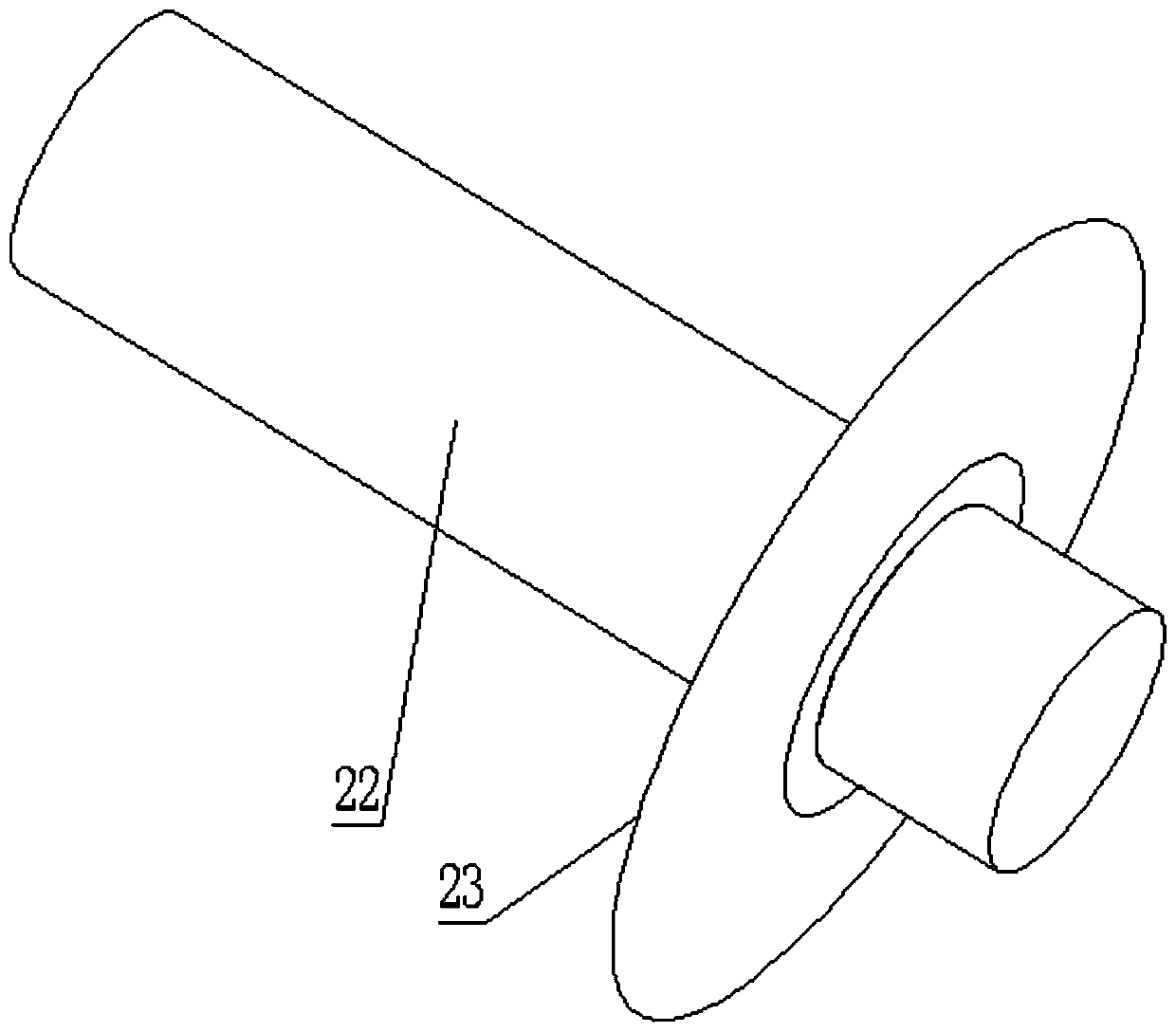

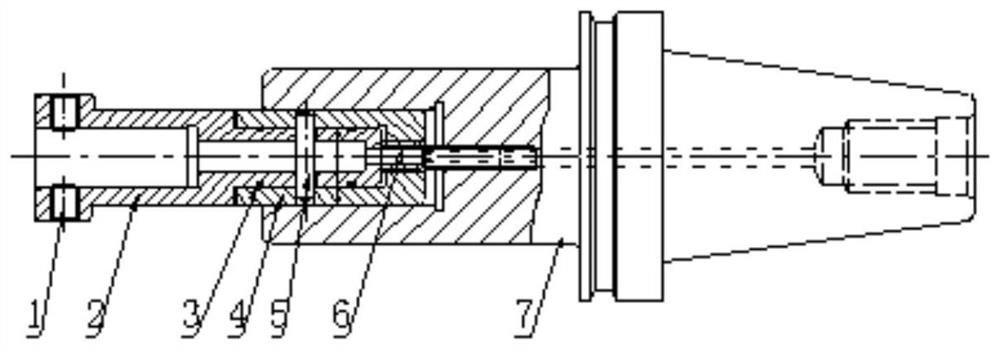

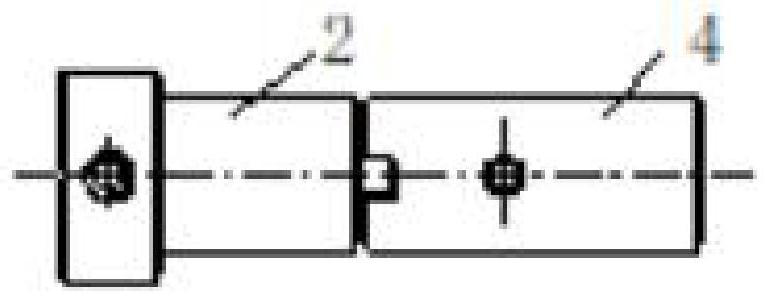

Spring steel sheet mark-free electrophoresis apparatus

ActiveCN103074663AGood processing qualityImprove efficiencyElectrophoretic coatingsSpring steelPolytetrafluoroethylene

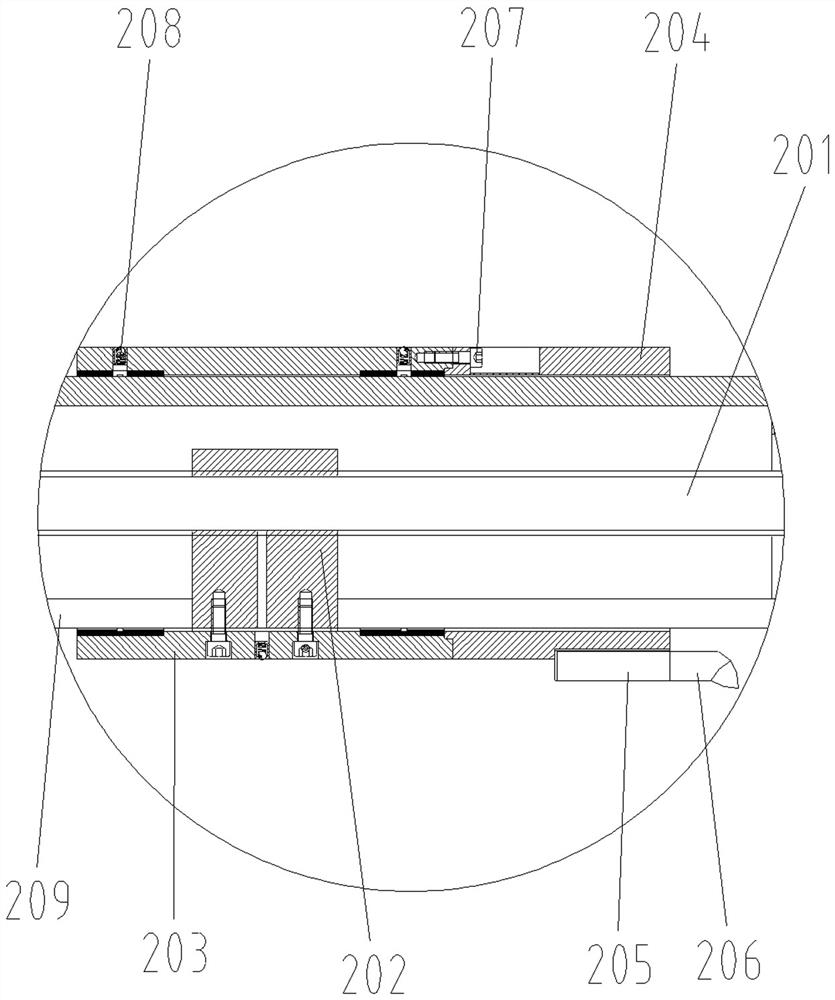

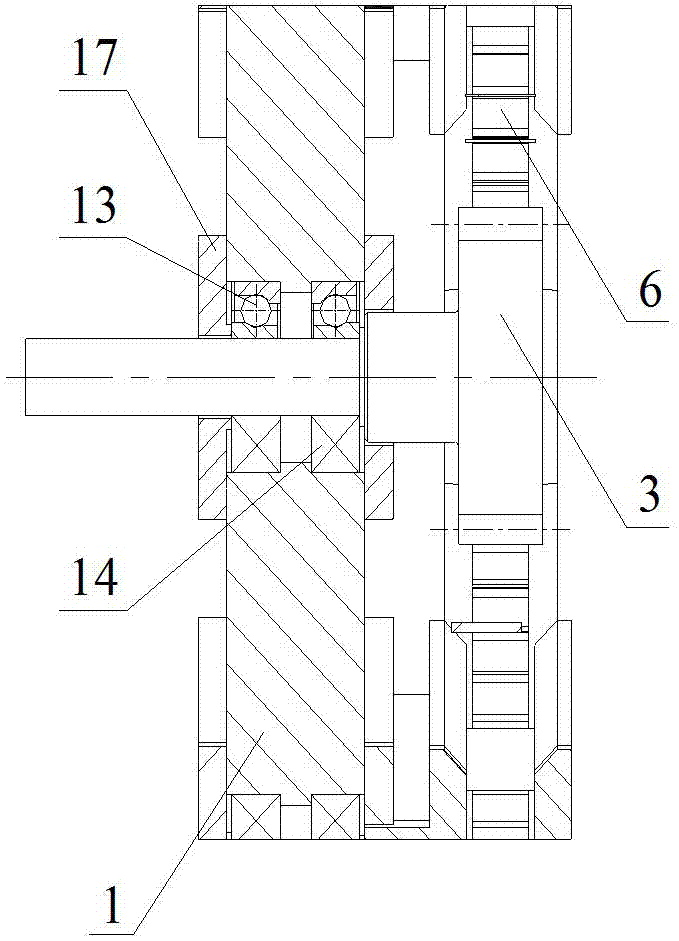

The invention discloses a spring steel sheet mark-free electrophoresis apparatus, which comprises a positioning sleeve, a screening sleeve and a positioning mandrel. The positioning sleeve comprises a step-shaped positioning sleeve body. A step blind hole is formed in the right end of the positioning sleeve body. A circular groove is arranged at the right end of the step blind hole. The screening sleeve is arranged in the circular groove. A female thread is arranged at the left end of the step blind hole. A semicircular groove is formed at the left end of the positioning sleeve body. The positioning mandrel comprises a positioning mandrel body. The positioning mandrel body is a reducing cylinder. A male thread is formed at the left end part of the positioning mandrel body. The spring steel sheet mark-free electrophoresis apparatus has the advantages of good processing quality, high efficiency and low cost. Applicable materials of the screening sleeve are high-temperature-resistant, anticorrosive and nonconductive materials with certain elasticity, such as silicon rubber and polytetrafluoroethylene.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

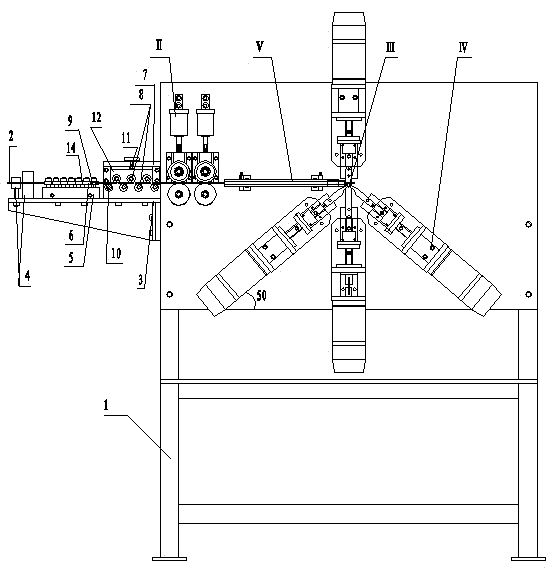

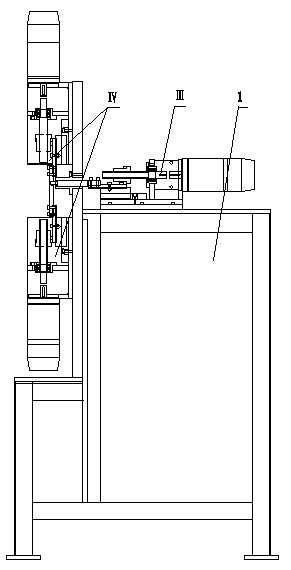

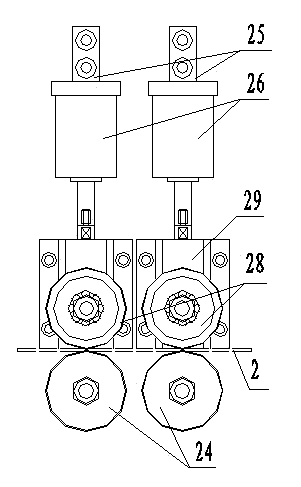

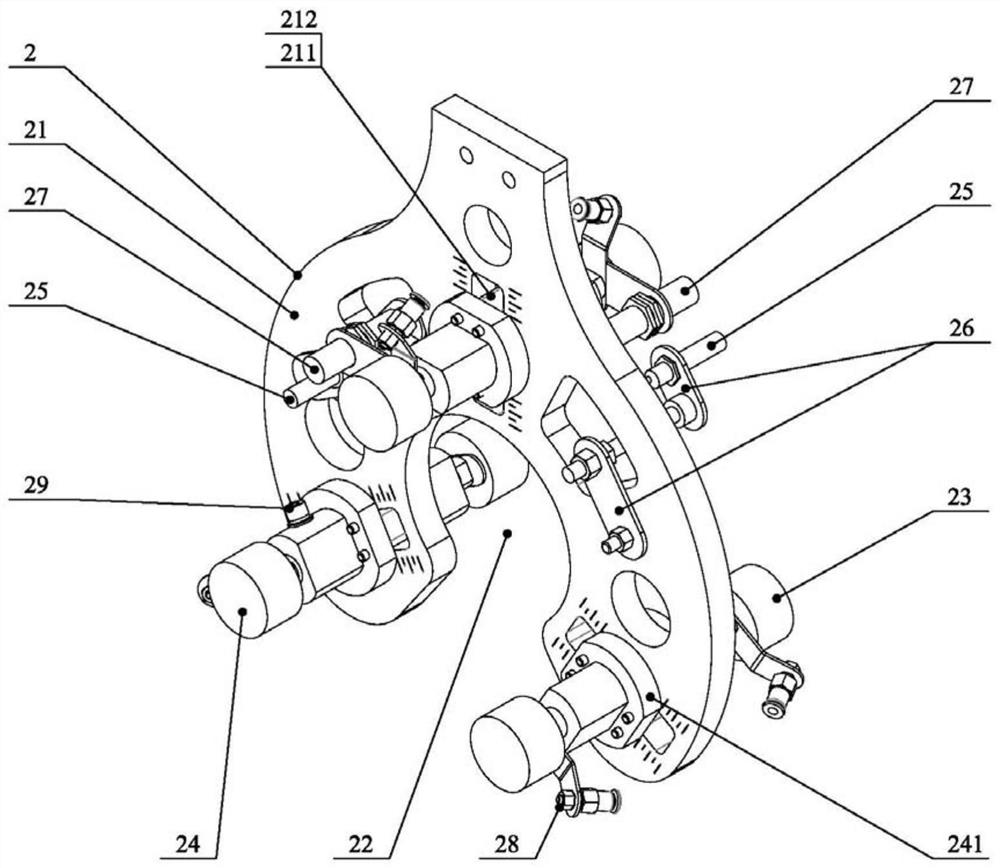

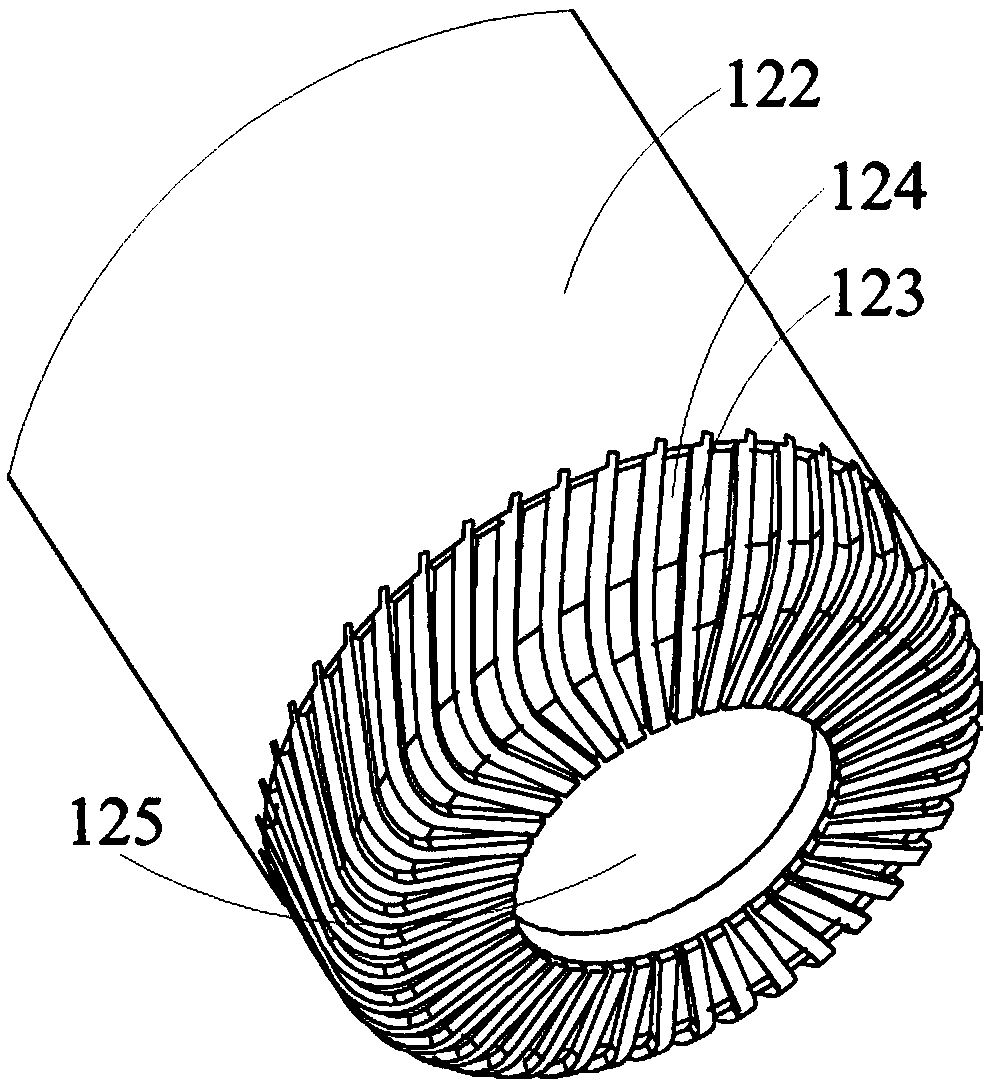

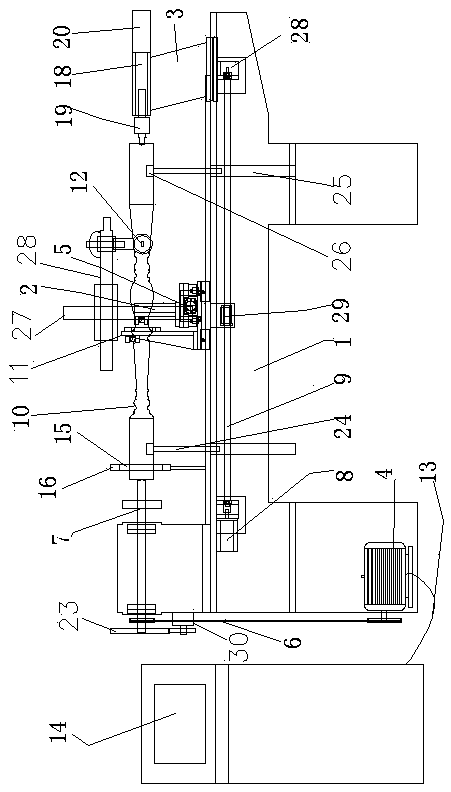

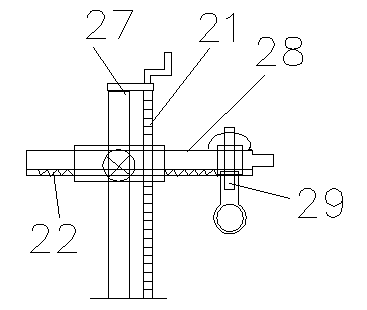

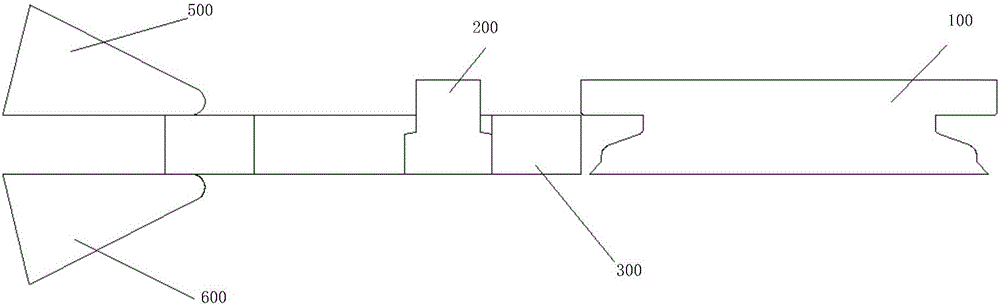

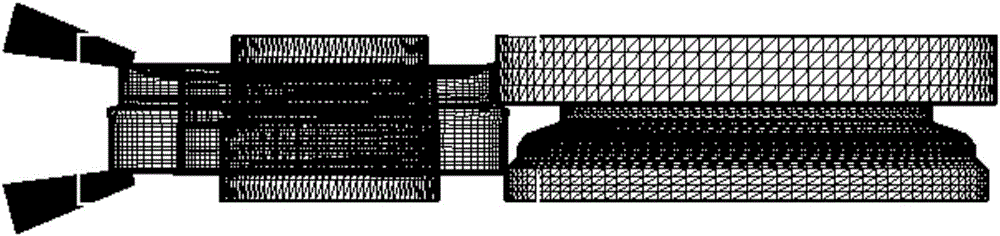

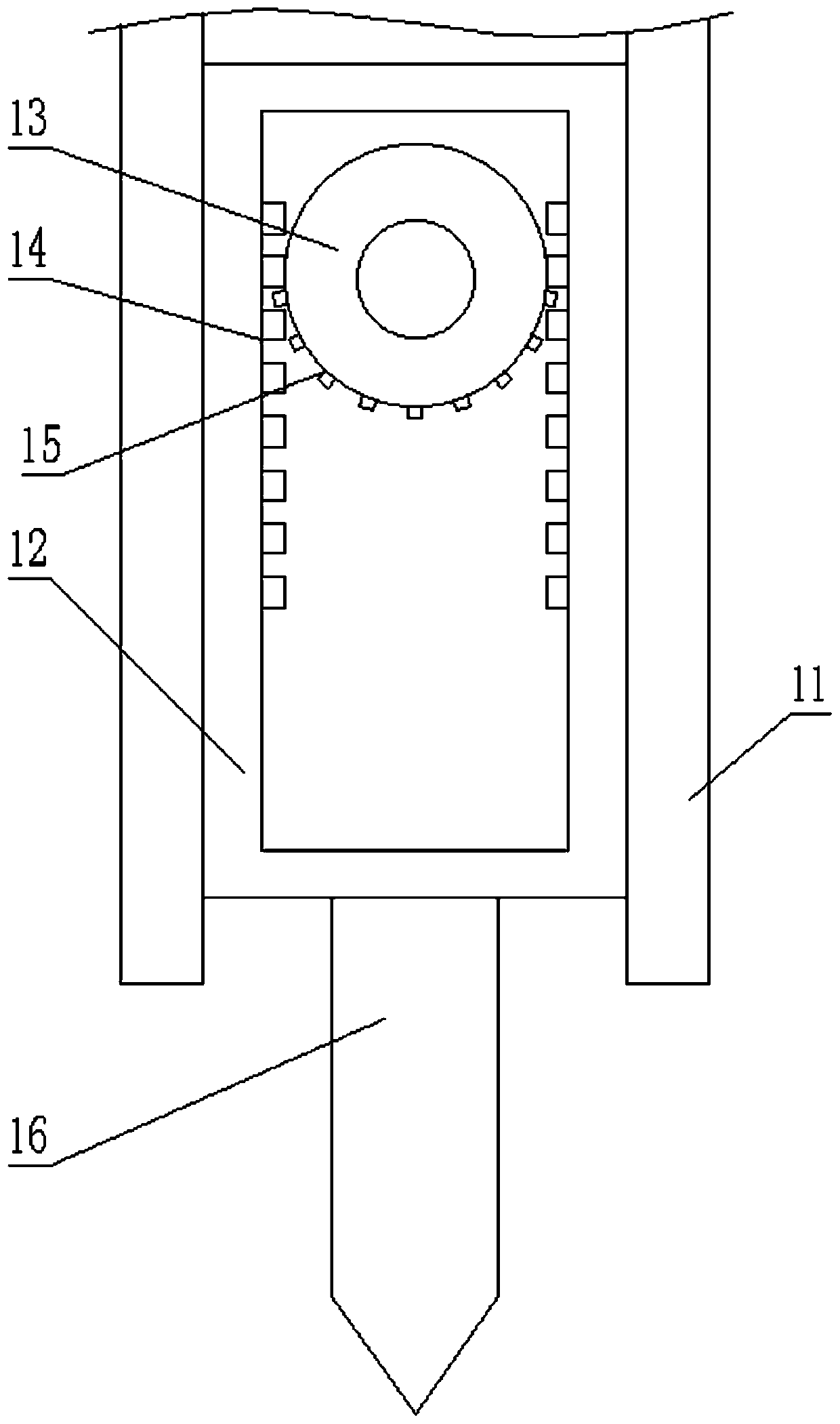

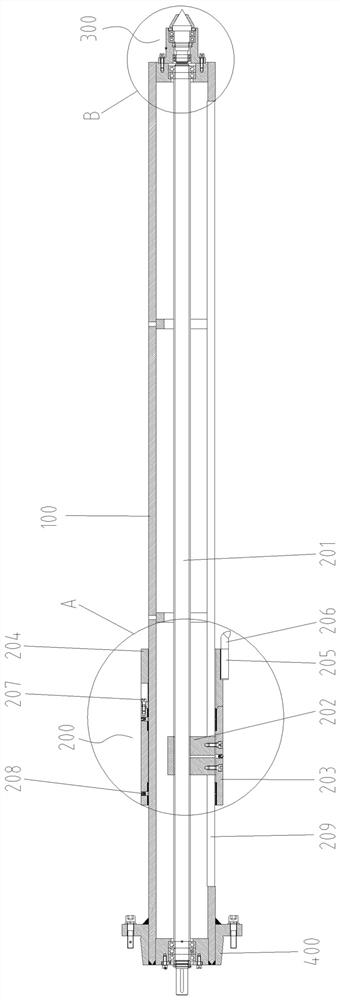

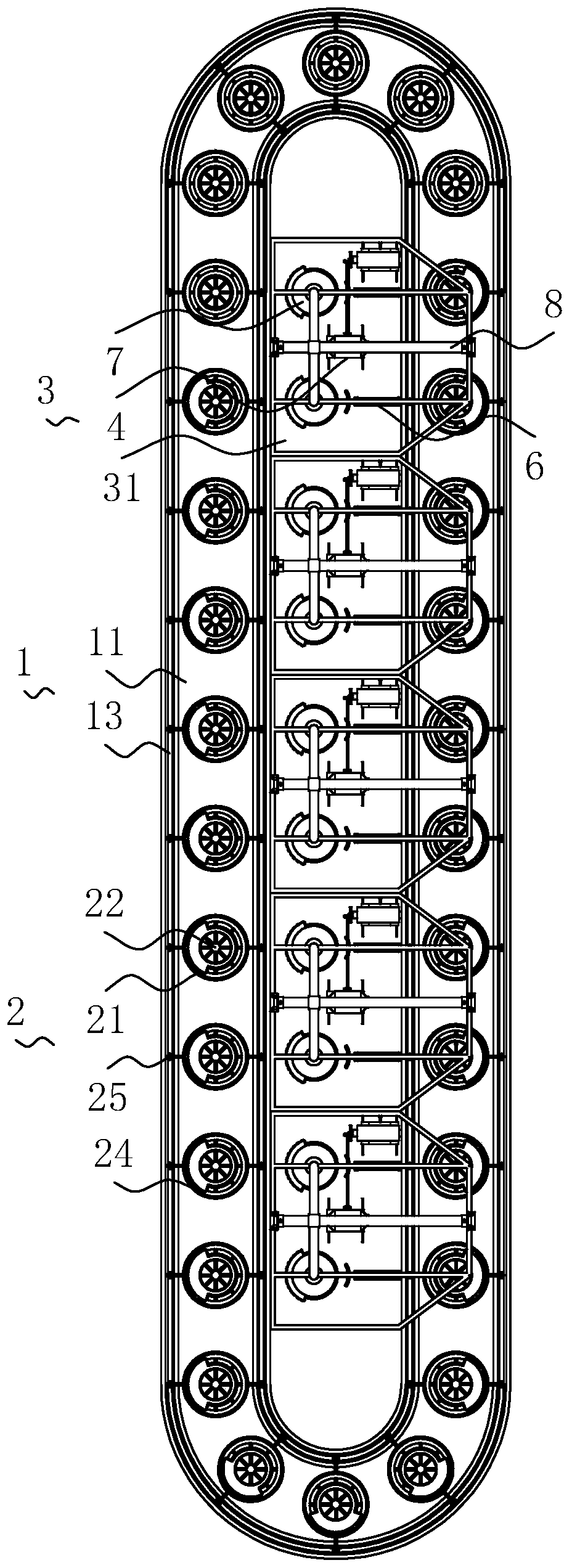

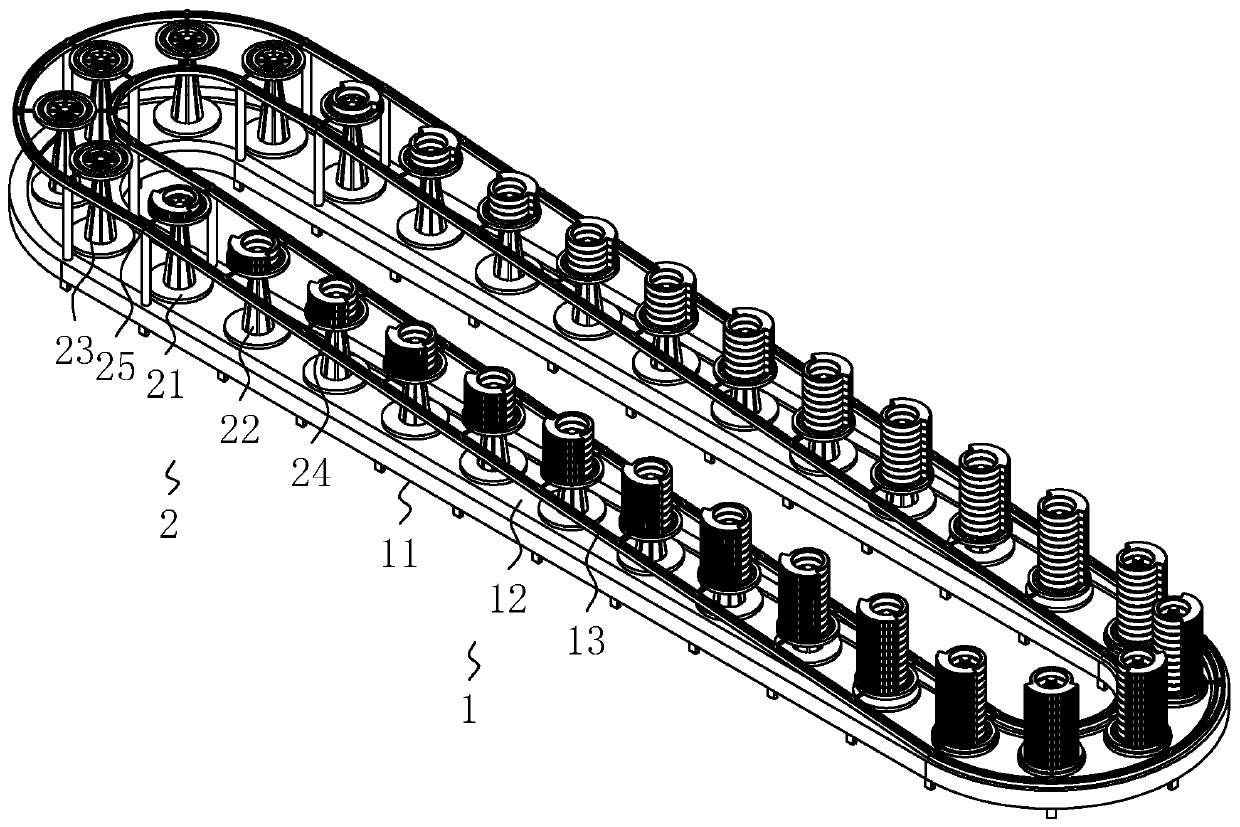

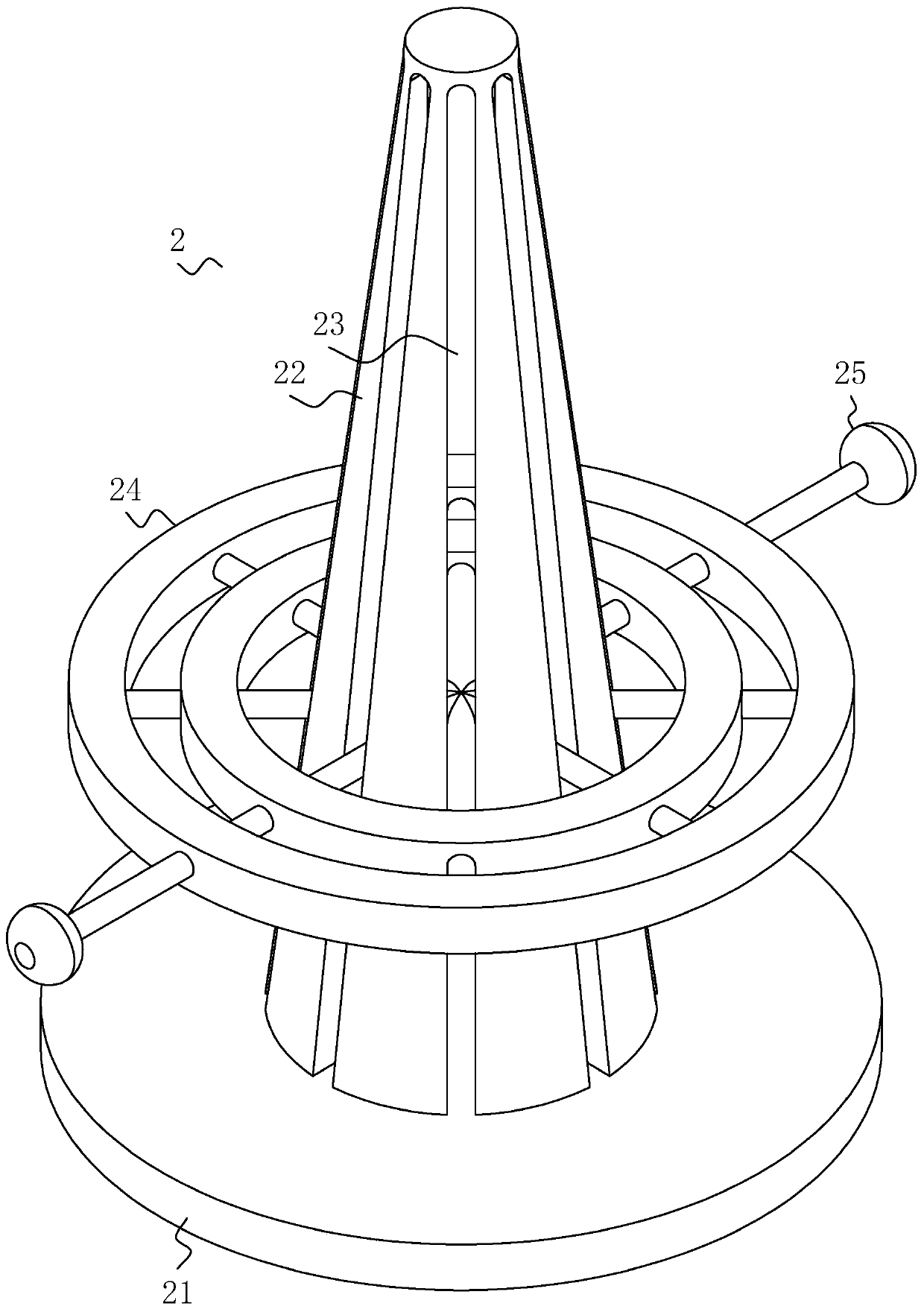

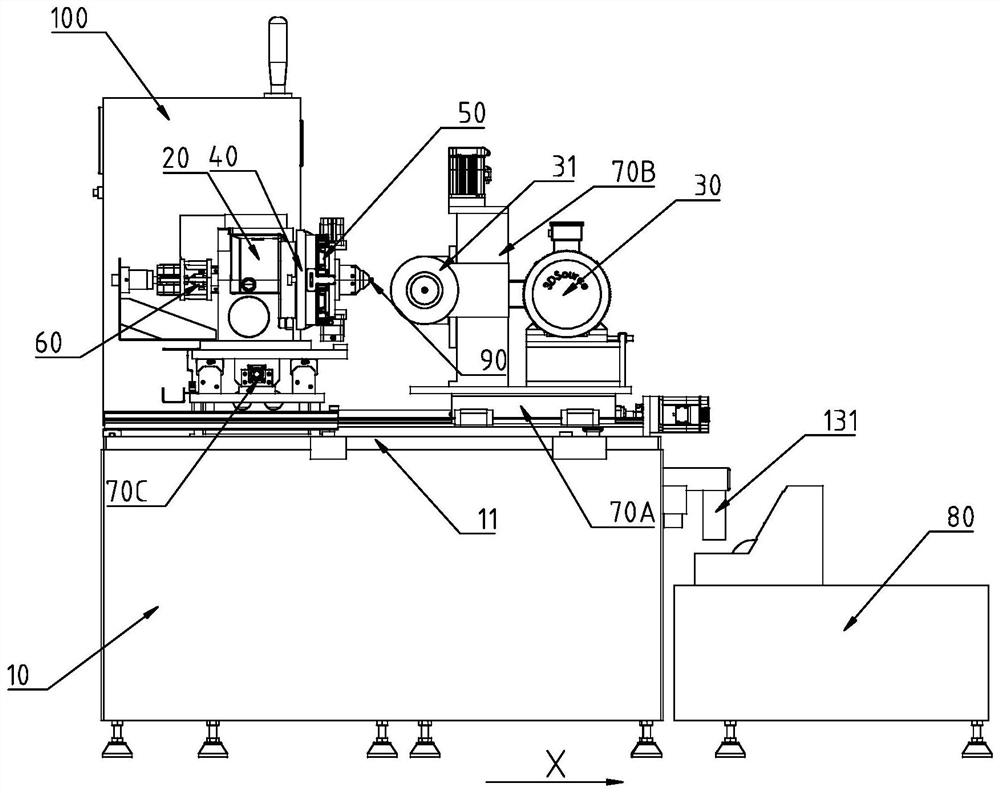

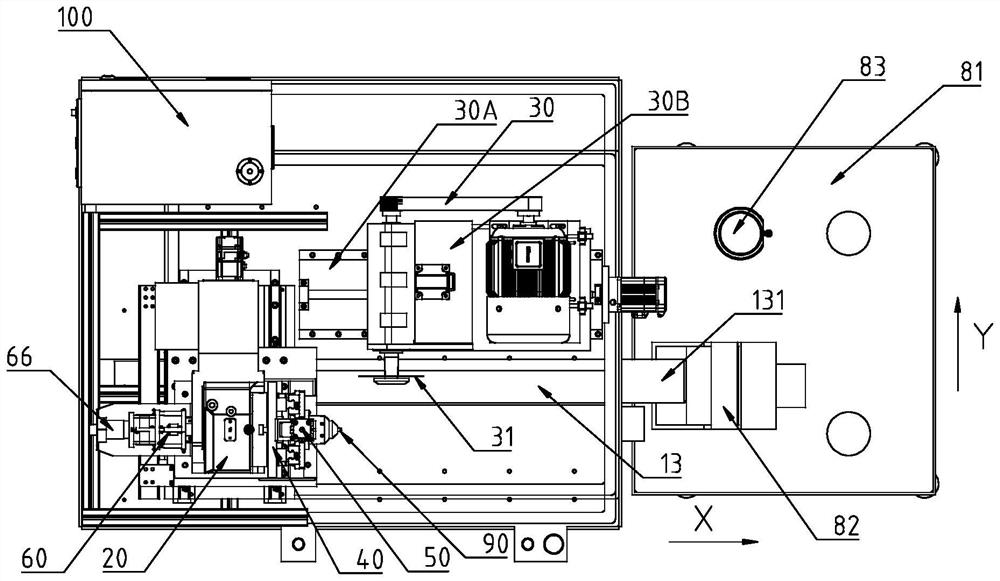

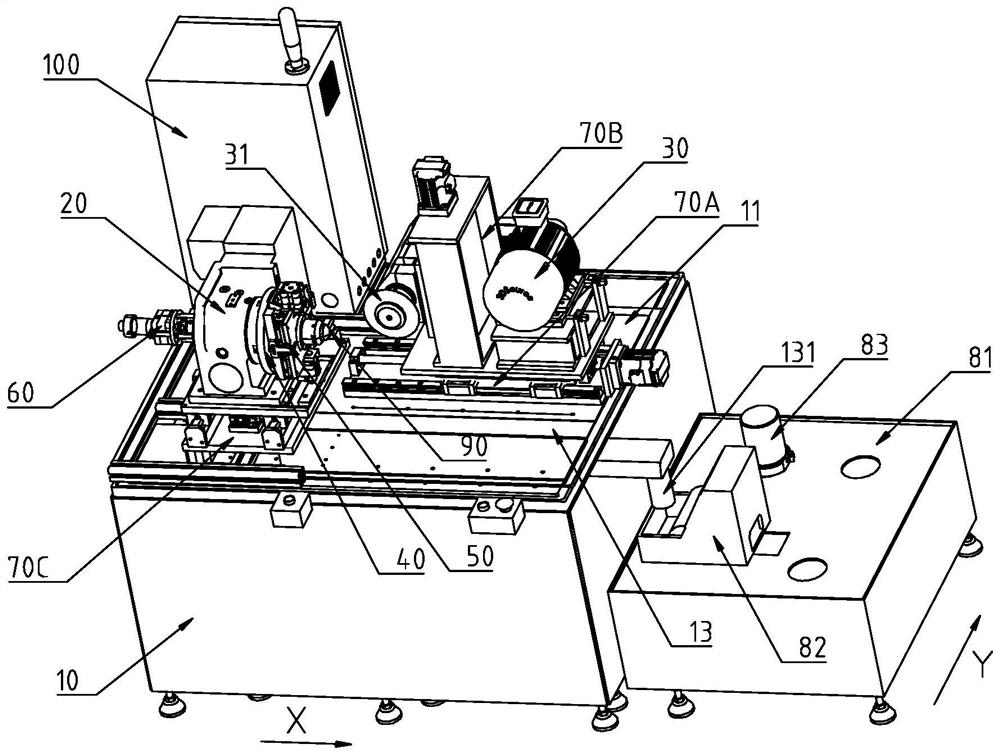

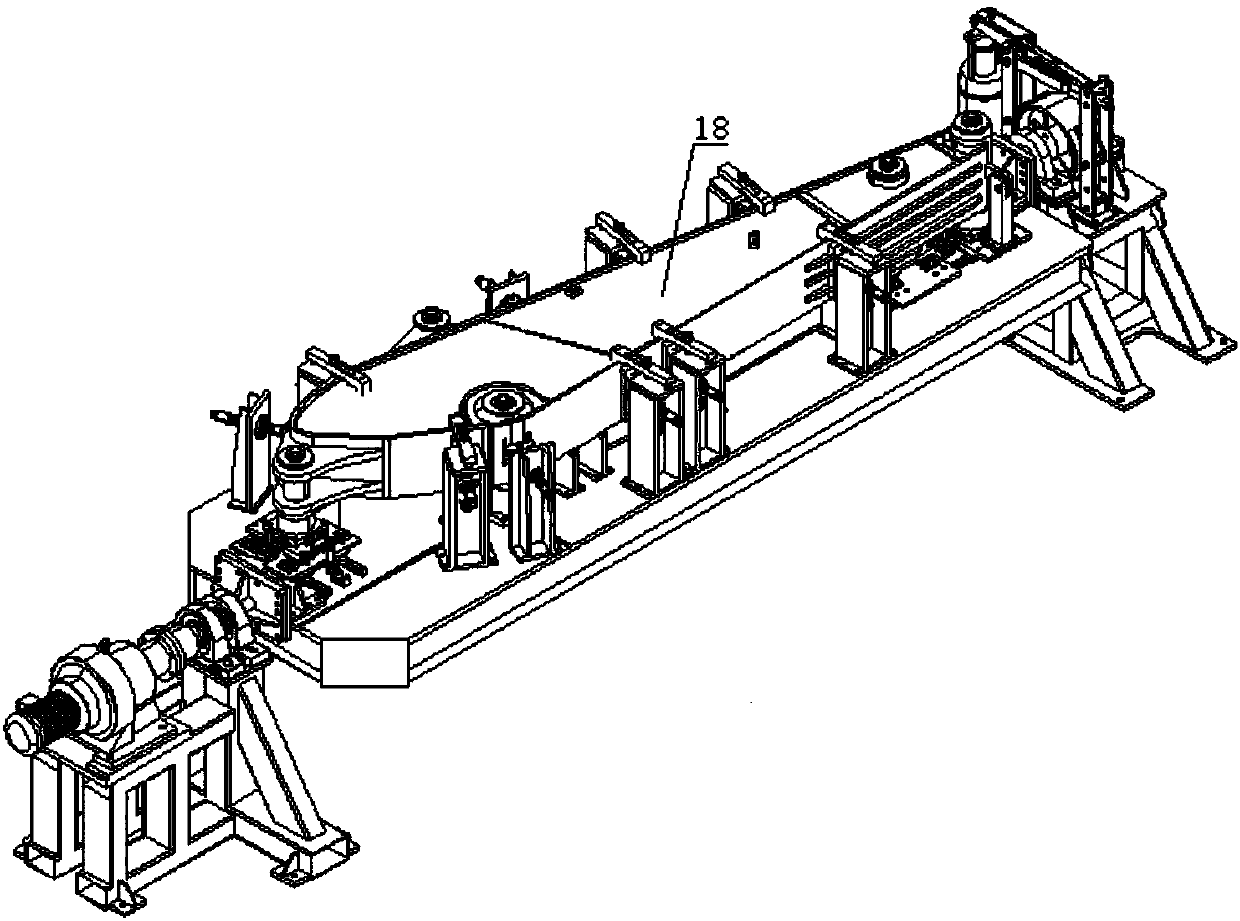

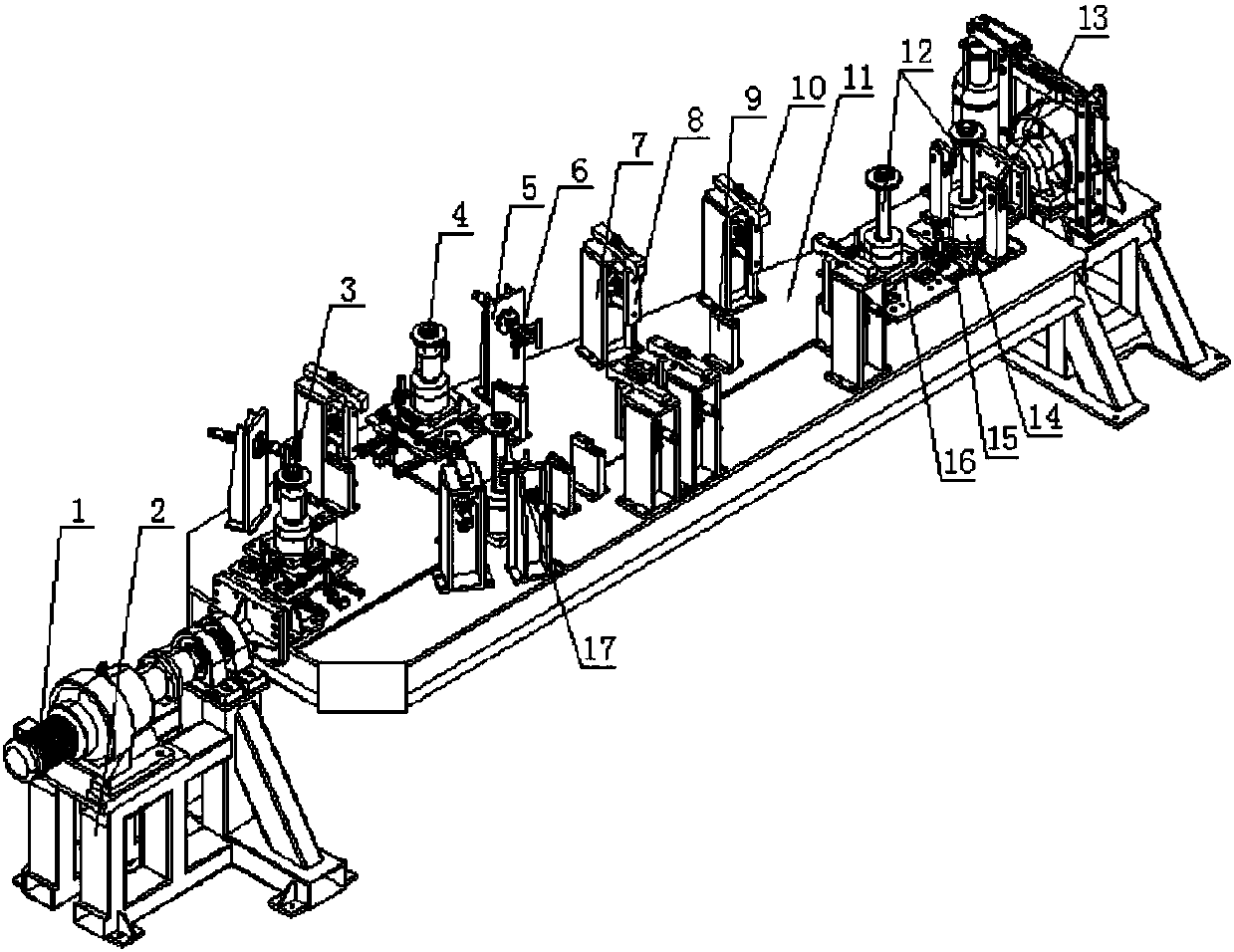

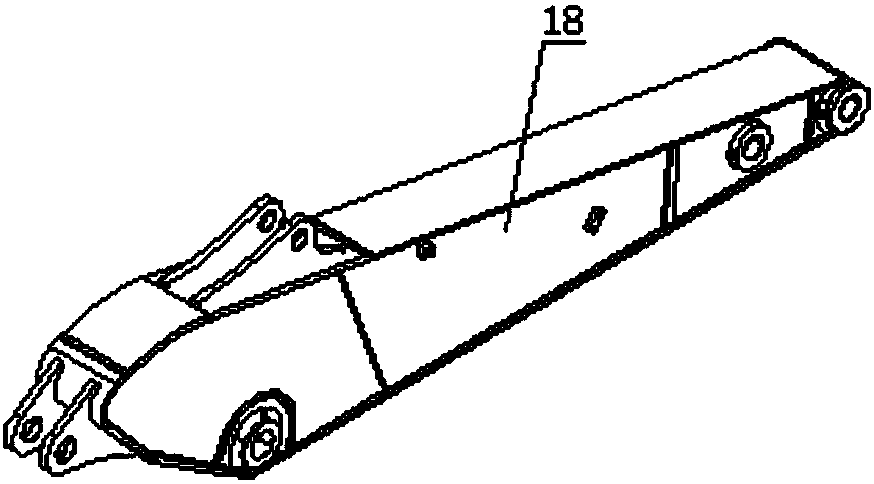

Fully-automatic ring making machine special for processing brazing alloy material and processing method thereof

ActiveCN103028680AReasonable structural designGood processing qualityWire ringsProgrammable logic controllerFully automatic

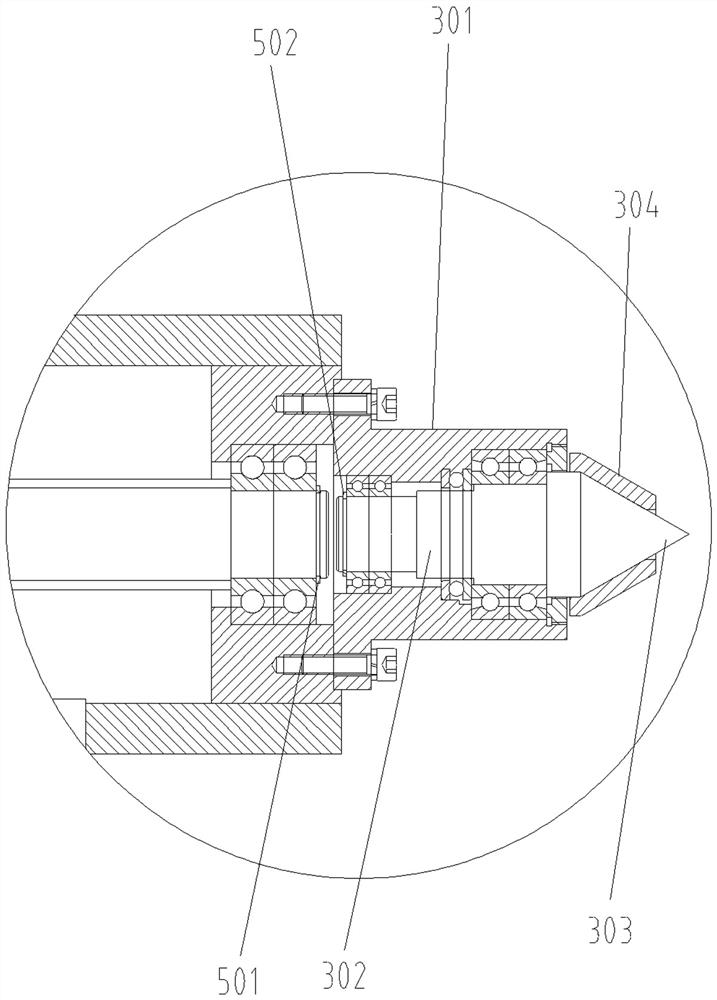

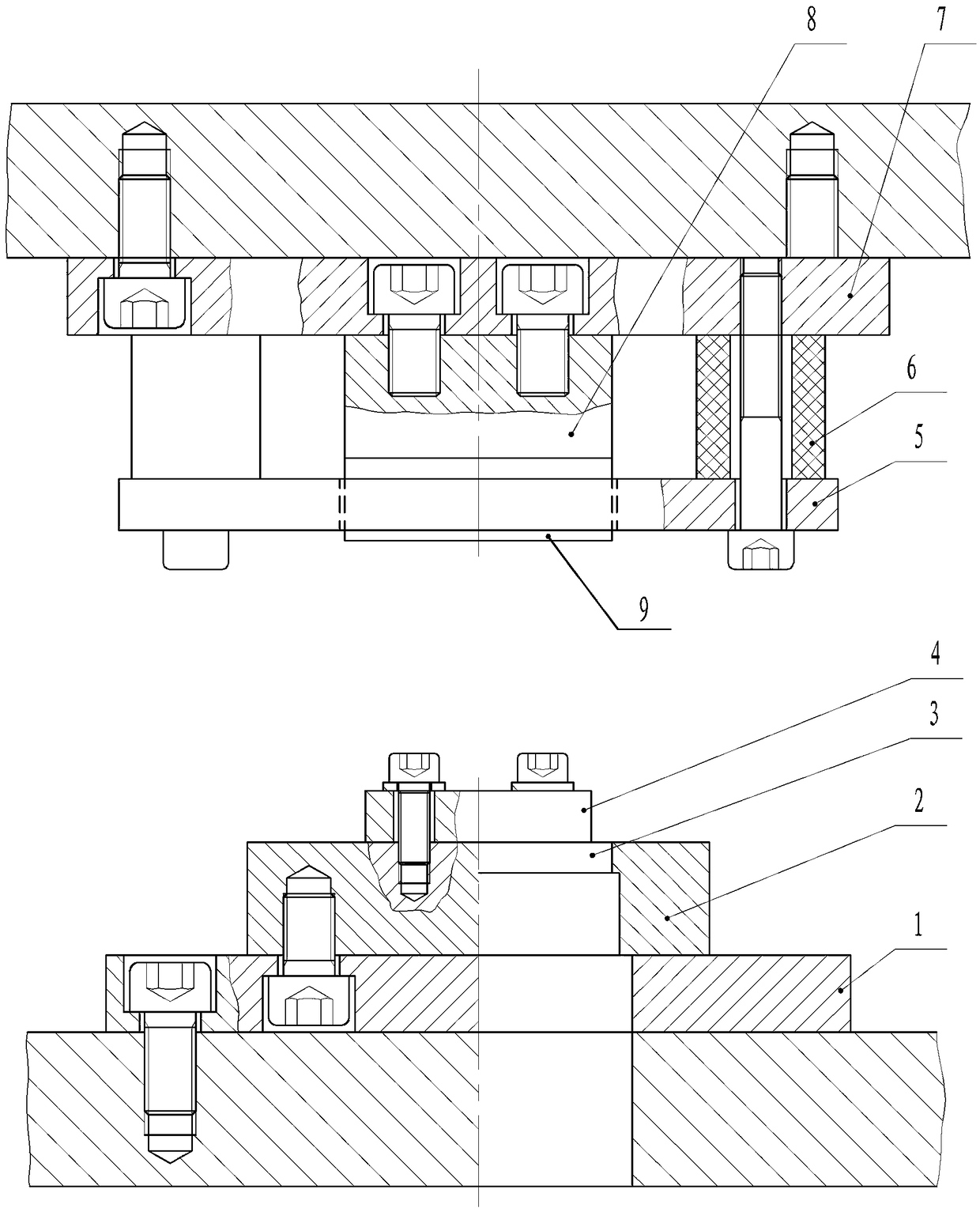

The invention discloses a fully-automatic ring making machine special for processing a brazing alloy material and a processing method thereof. The fully-automatic ring making machine is provided with a straightening device, a traction device, a core die device, a multi-angle forming device, a heater and a PLC (Programmable Logic Controller), wherein the PLC controller is used for controlling the traction device, the core die device, the multi-angle forming device and the heater to work in a matching manner; after a continuously-processed raw material is treated by the straightening device and the heater, the traction device is used for conveying the raw material to the core die device and the multi-angle forming device; the core die device and the multi-angle forming device are used for cutting off, molding and demolding the processed raw material in a mutual-matching manner; the straightening device is positioned at the feeding end of the processed raw material; the traction device is positioned between the straightening device and the heater; the core die device is positioned at an outlet of the heater; and the core die device is mutually matched with the multi-angle forming device. The invention also comprises a processing method of the fully-automatic ring making machine. The fully-automatic ring making machine and the processing method thereof have the advantages of reasonable design, good processing quality, high efficiency and low cost.

Owner:HANGZHOU JIUGU MACHINERY TECH

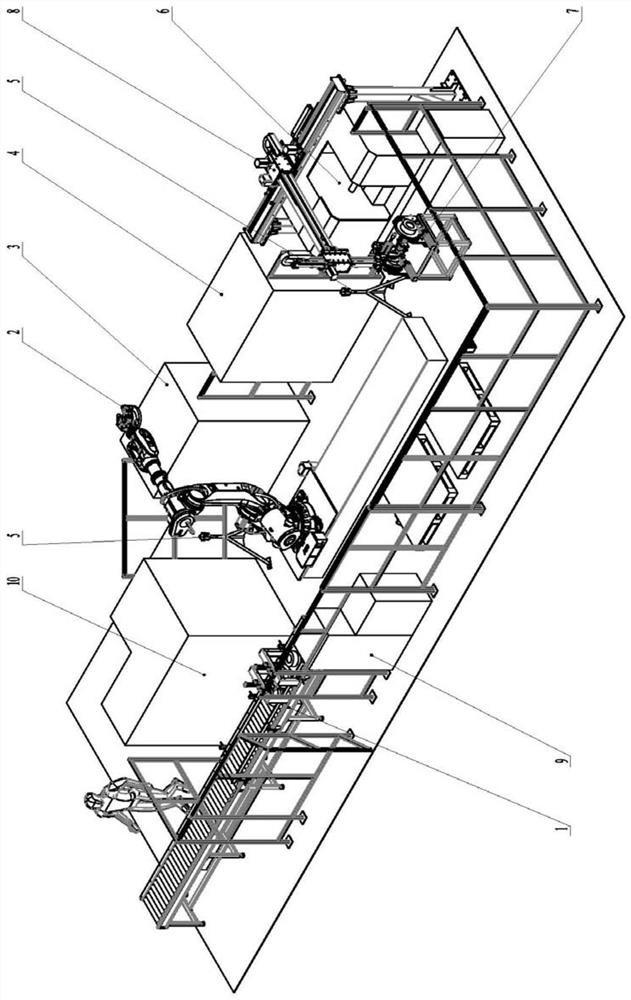

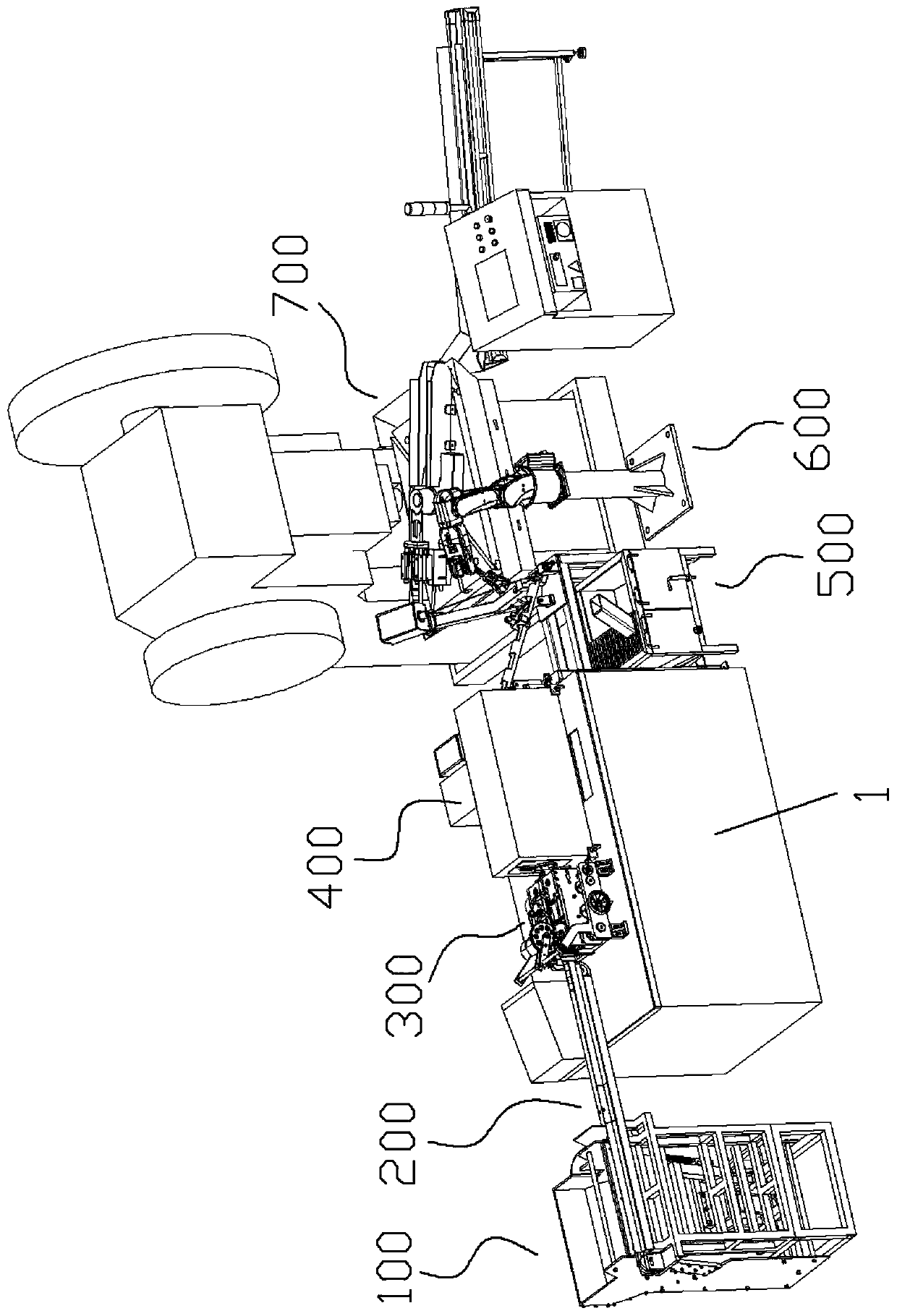

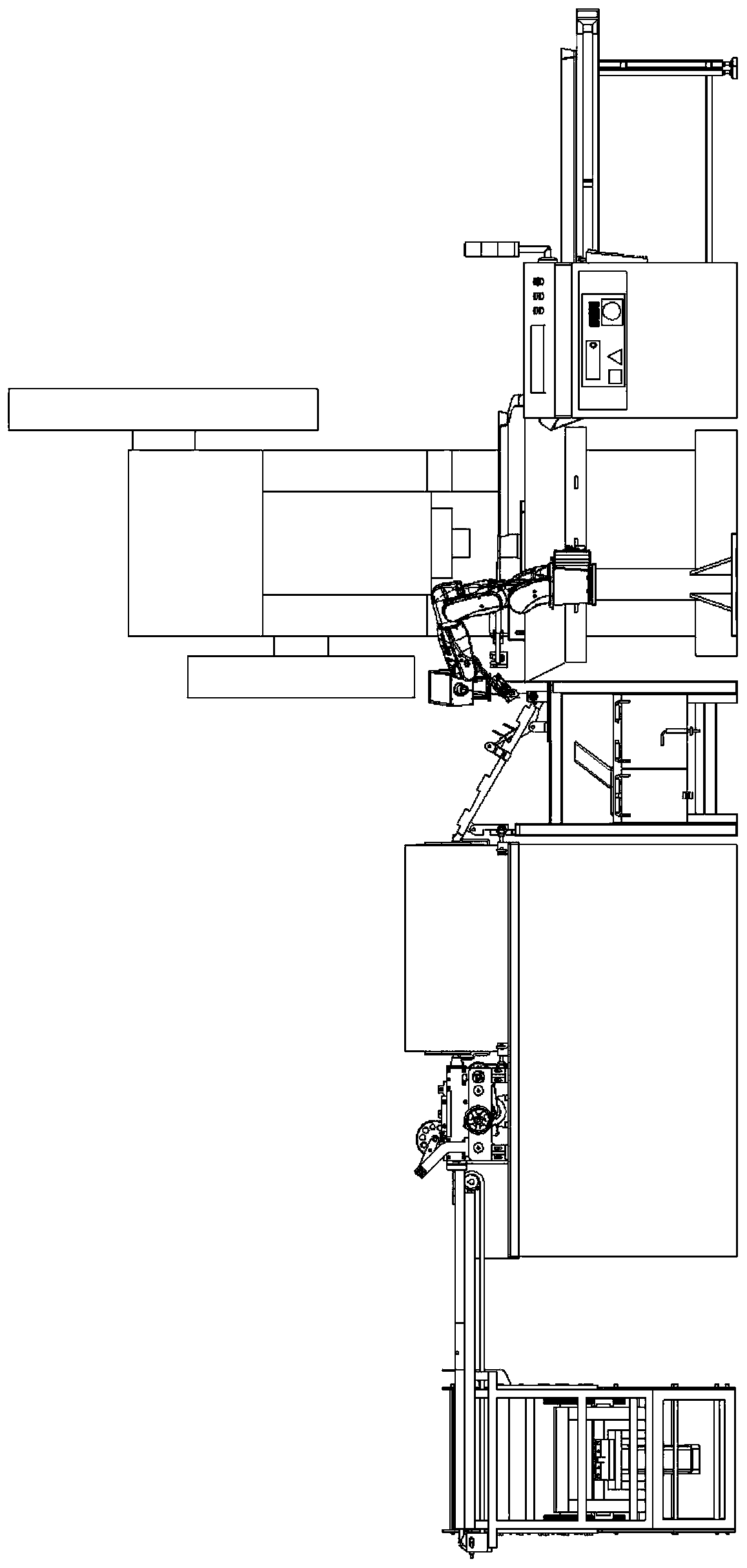

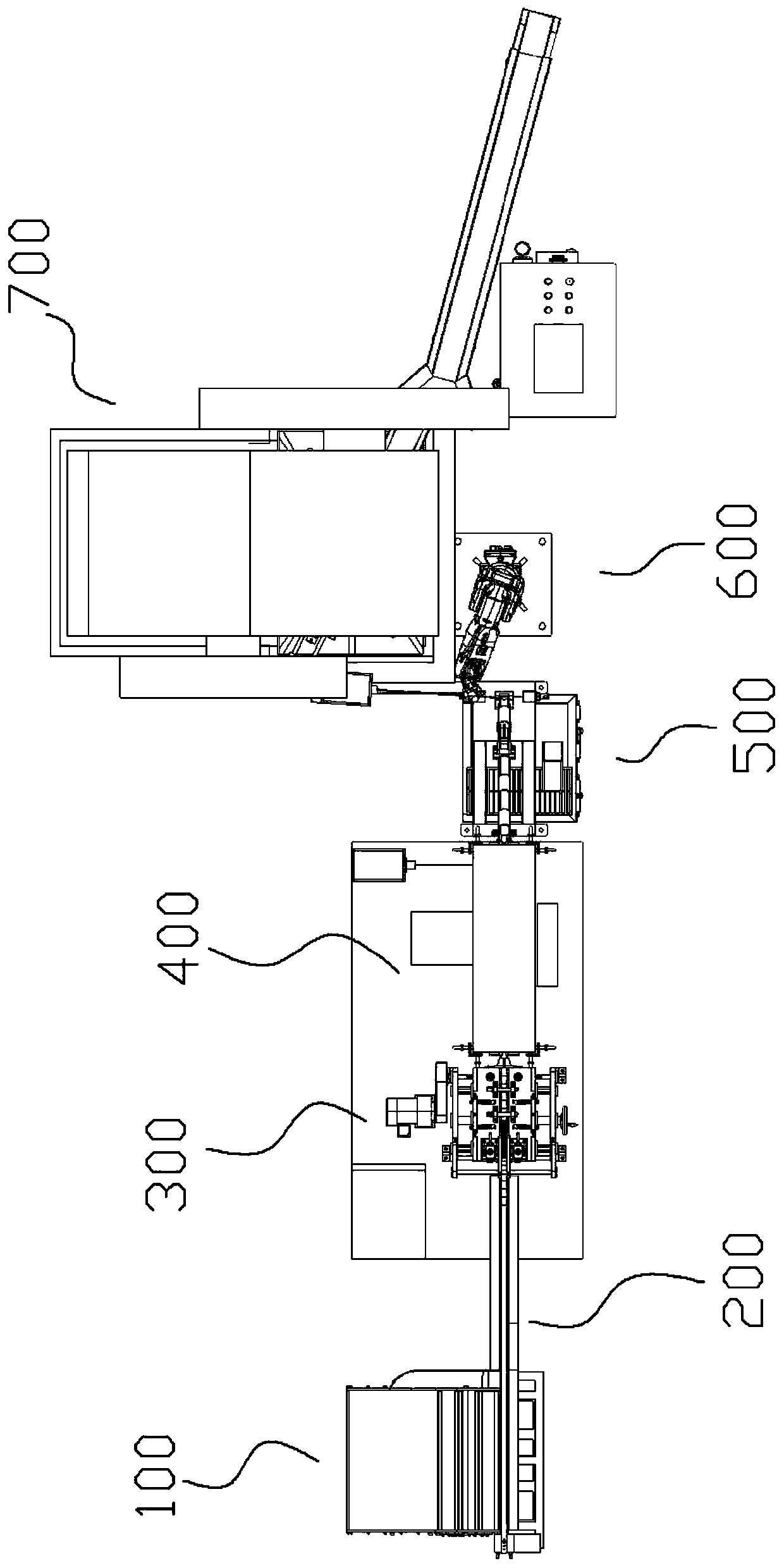

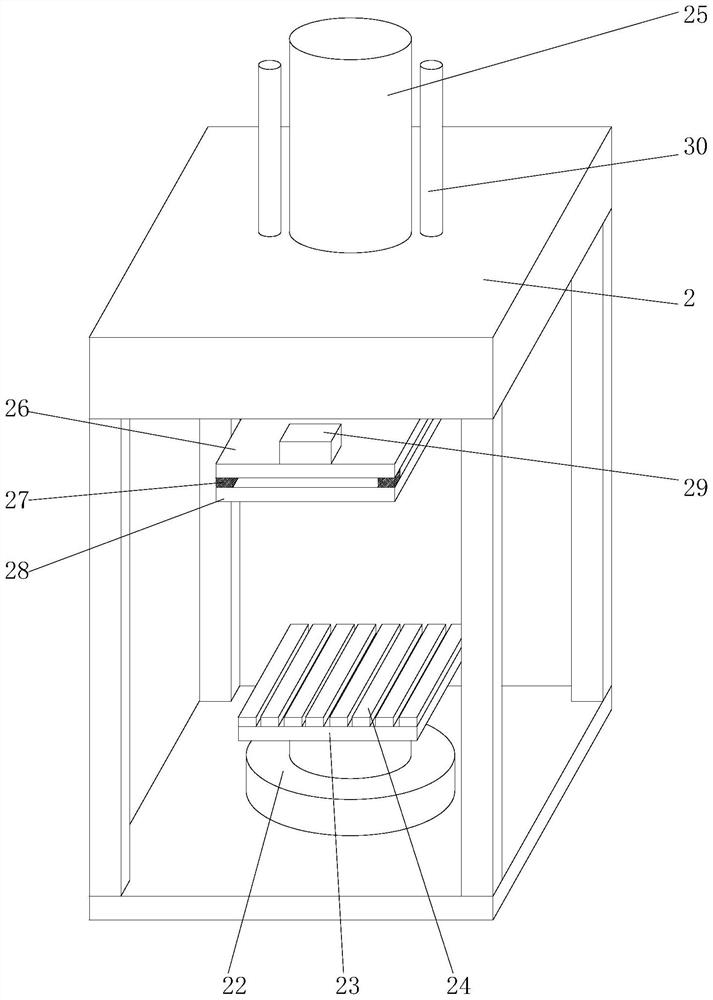

Brake disc machining robot feeding and discharging production line and production method

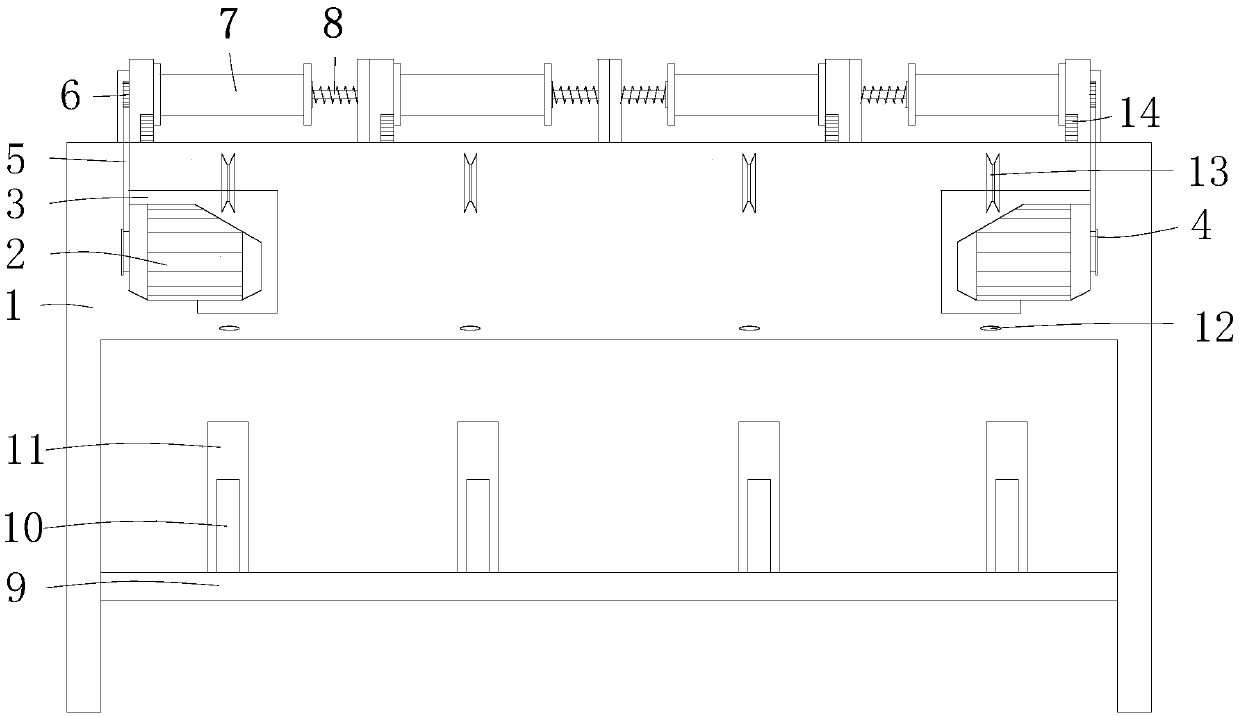

ActiveCN112296723AHigh degree of automationIncrease productivityMetal working apparatusPositioning apparatusNumerical controlProduction line

The invention discloses a brake disc machining robot feeding and discharging production line and a production method. The brake disc machining robot feeding and discharging production line comprises an auxiliary feeding system, a first numerical control machine tool, a second numerical control machine tool, a machining center, a grinding machine tool, an auxiliary turnover mechanism, an auxiliarytransfer mechanism, a truss manipulator, a mechanical clamping jaw, an industrial robot and a control cabinet, wherein the industrial robot comprises a ground rail, a robot body arranged on the groundrail, a robot arm connected to the robot body and a robot jig connected to the tail end of the robot arm; the control cabinet controls the robot body, the robot arm and the robot jig to act; and under the control of the control cabinet, a brake disc sequentially finishes the machining process on the first numerical control machine tool, the second numerical control machine tool, the machining center and the grinding machine tool. The production line has high automation degree, production efficiency and percent of pass of products. According to the production method, the brake disc machining efficiency can be further improved, and the enterprise production cost is reduced.

Owner:青岛智研自动化设备有限公司

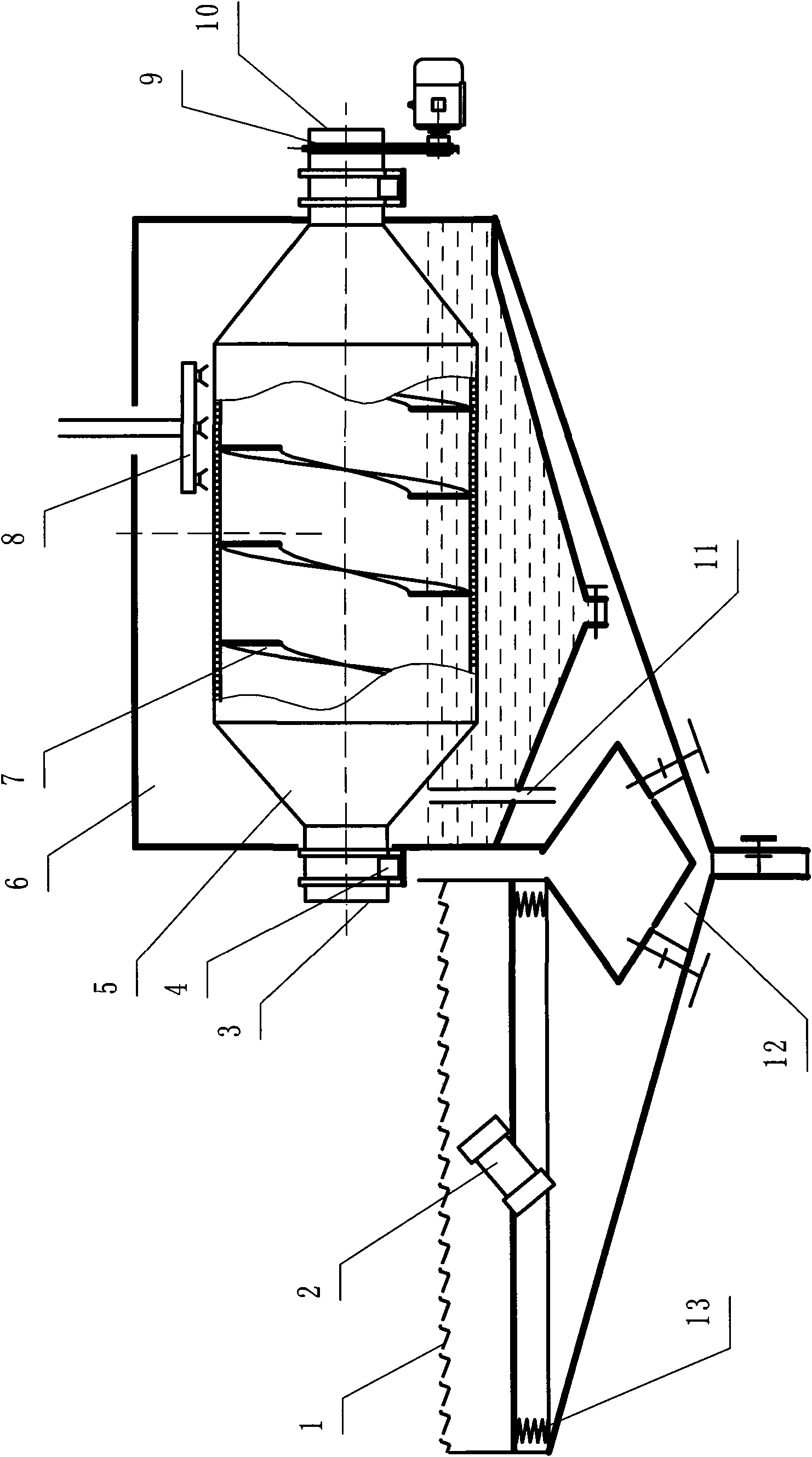

Device for precessing acid solution used in corron seed manufacture

InactiveCN101584271AGood processing qualityReduce damageSeed and root treatmentPropellerSolution processed

The invention discloses a device for precessing acid solution used in corron seed manufacture, includes a machine frame, a revolving screen containing a feed port and a discharge port is provided on the machine frame, inner wall of the revolving screen is provided with a propeller blade, lower of the revolving screen is provided with a acid solution pool, and lower of the revolving screen is immersed into acid solution in the acid solition pool. Comparing with prior art, the invention has advantages of better processing quality, lower damage to seeds.

Owner:石河子市华农种子机械制造有限公司

Automatic forging production line

PendingCN111014562AIncrease productivityGood processing qualityWheelsHandling devicesManufacturing engineeringHeating furnace

The invention relates to a forging production line, in particular to an automatic forging production line. The production line comprises a feeding machine, a conveyor, a clamping and feeding mechanism, an intermediate-frequency heating furnace, a discharging guiding mechanism, a joint robot and a punching machine which are arranged in sequence. The clamping and feeding mechanism comprises a guideplate, two feeding clamping modules symmetrically arranged on the two sides of the guide plate, and a driving wheel; a driven wheel and a tensioning wheel are provided with chains, and the two clamping modules are detachably and fixedly connected; and the upper plate surface of the guide plate is clamped between the chains of the two clamping modules. The automatic forging production line adoptingthe scheme has the advantages of being high in automation degree, high in production efficiency and high in adaptability.

Owner:CHONGQING FUCHUAN GUSHENG ELECTROMECHANICAL CO LTD

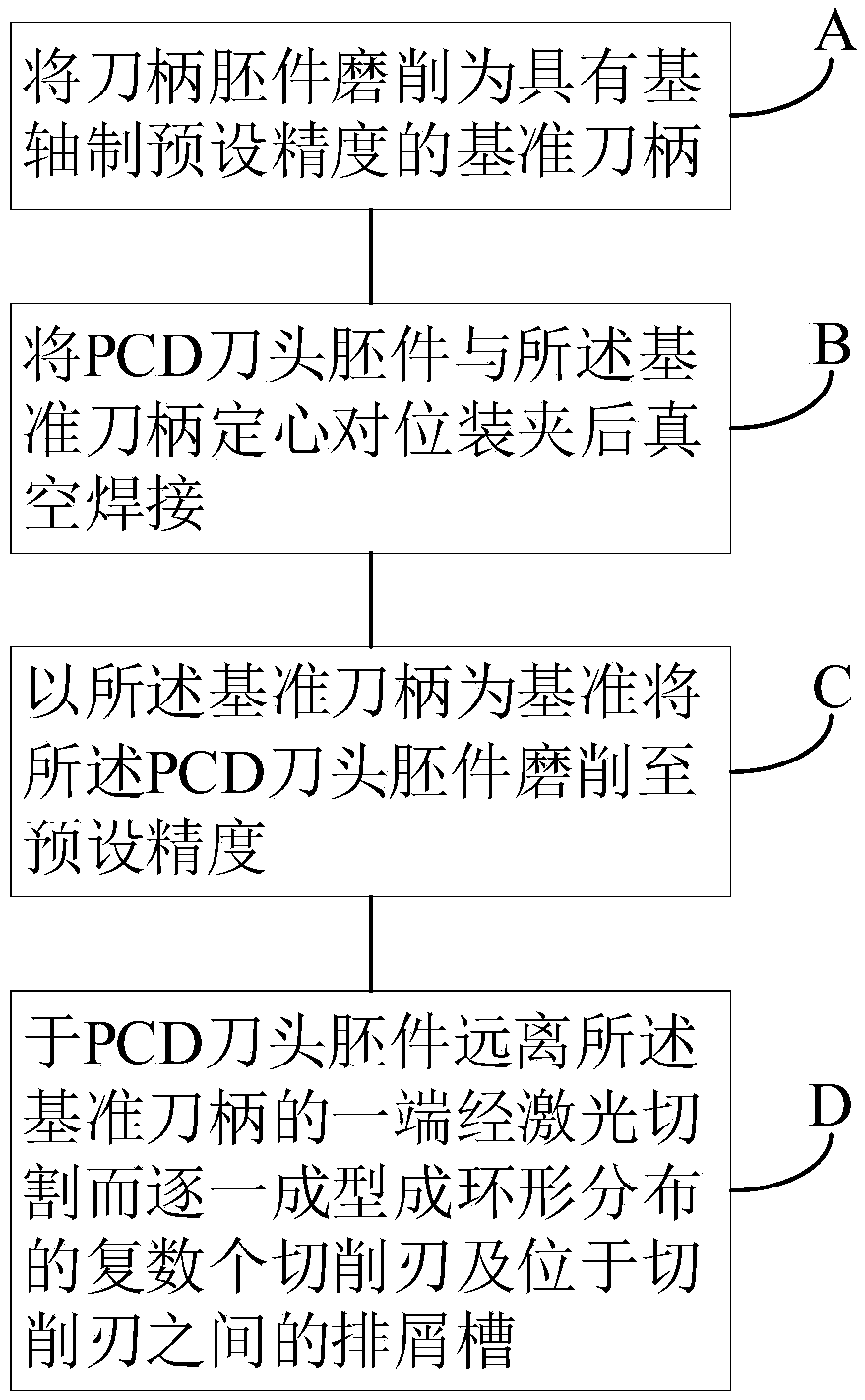

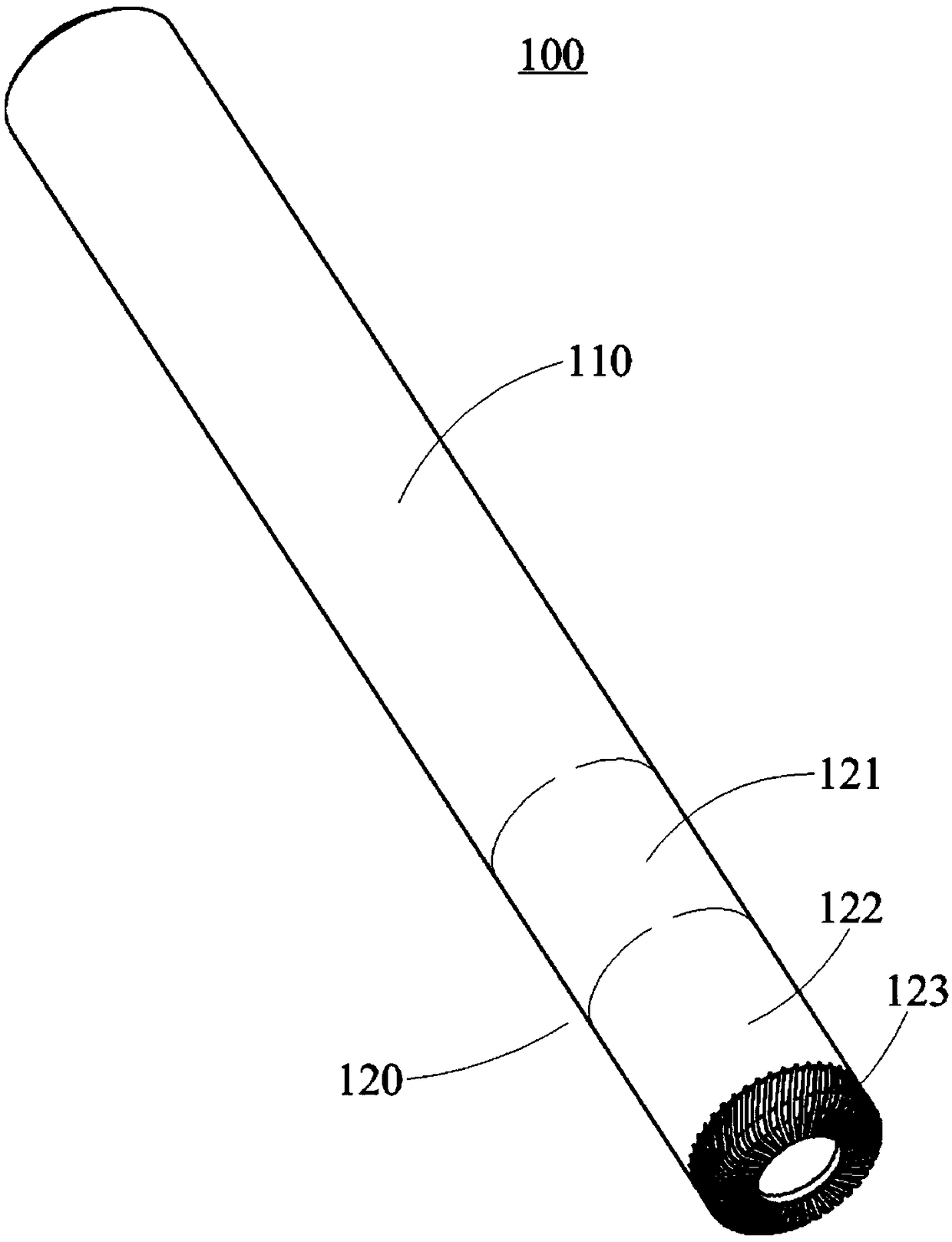

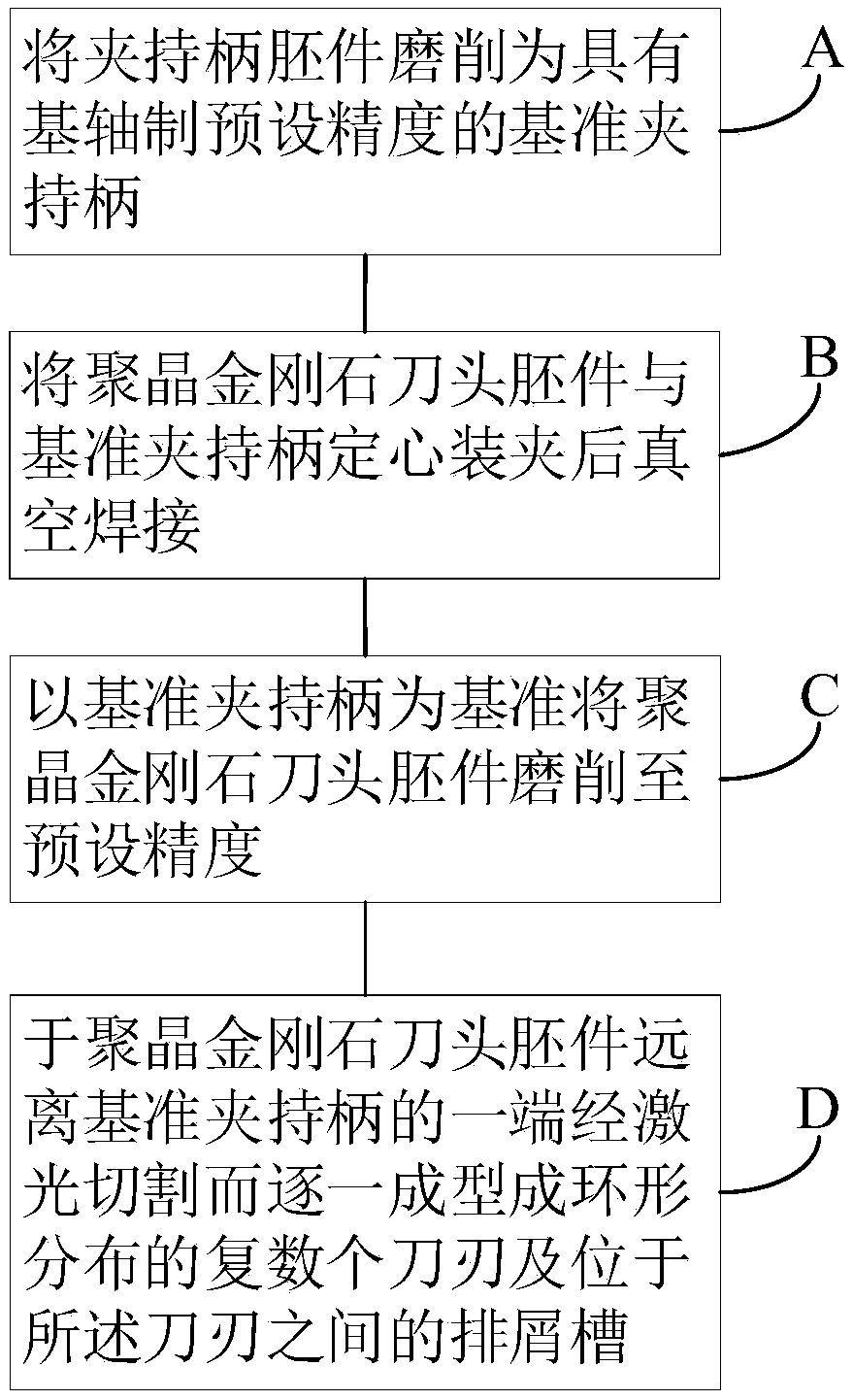

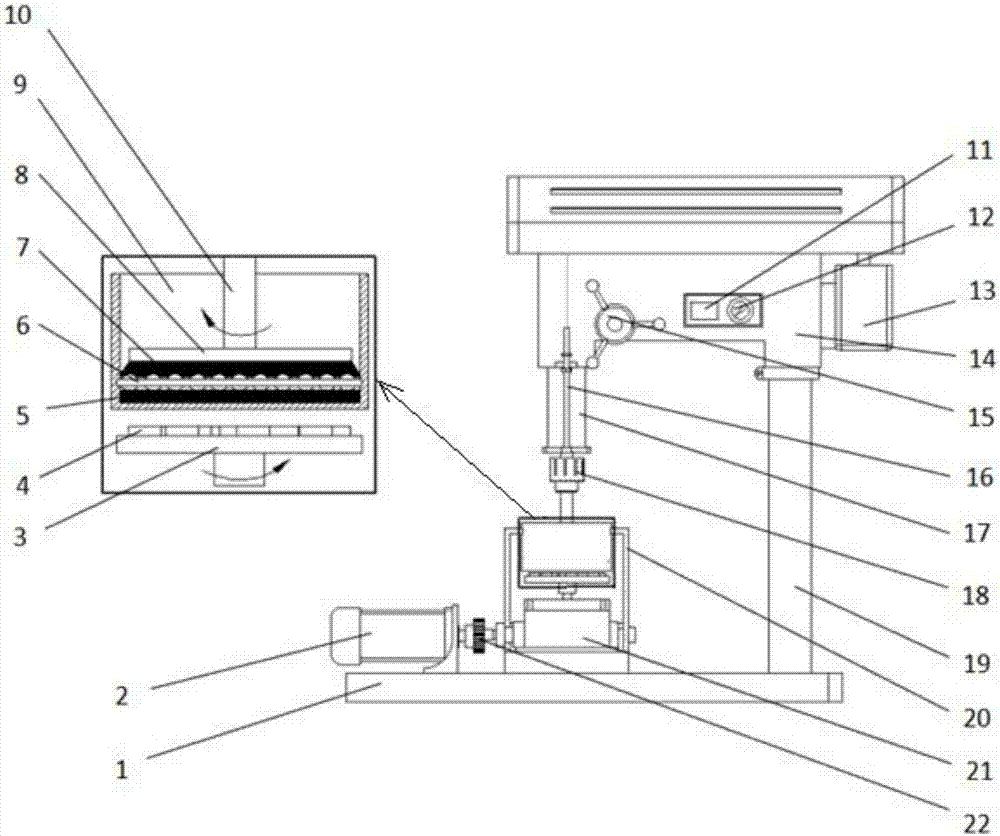

Integral multi-edge contour knife processing method

InactiveCN108994556AIdeal Multi-Flute Contour Knife FeaturesImprove processing efficiencyMilling cuttersWorkpiecesEdge surfaceMicrometer

An integral multi-edge contour knife processing method comprises the following steps: a knife handle blank is grinded into a benchmark knife handle with the preset precision in a basic shaft system; aPCD knife head blank and the benchmark knife handle are clamped in a centering and aligning manner, and then vacuum welding is performed; and the PCD knife head blank is grinded to reach the preset precision with the benchmark knife handle as a benchmark; and a plurality of cutting edges distributed in a ring-shaped manner and a plurality of chip removing grooves positioned among the cutting edges are formed one by one through laser cutting at the end, far away from the benchmark knife handle, of the PCD knife head blank, and then an integral multi-edge contour knife is obtained, wherein theedge width of each cutting edge is 0.04-0.2 millimeters, the edge surface roughness Ra of each cutting edge is 0.1-0.4 micrometers, and the depth of each chip removing groove is 0.1-0.2 millimeters. The integral multi-edge contour knife obtained through the integral multi-edge contour knife processing method provided by the invention has an integrated multi-edge structure, thereby facilitating theimprovement of the processing efficiency and the prolonging of the service life, and guaranteeing the ideal processing quality; the economic benefit is great, thereby facilitating the promotion and the application; and the integral multi-edge contour knife processing method is especially suitable for glass or ceramic processing.

Owner:CONPROFE TECH GRP CO LTD +1

Numerically controlled wood engraving and milling machine with universal regulating function

ActiveCN103448104AImprove machining accuracyGood processing qualityMulti-purpose machinesModel makingEngineeringClutch control

The invention discloses a numerically controlled wood engraving and milling machine with a universal regulating function. The numerically controlled wood engraving and milling machine comprises a machine body, a controller, a power shaft, a power shaft driving motor, a tailstock and a tool apron, wherein the power shaft is arranged on the machine body; the power shaft driving motor comprises a high-speed motor and a low-speed motor; the low-speed motor is matched with the power shaft through a gear; the high-speed motor is matched with the power shaft through a belt wheel and a belt; one side of the low-speed motor is hinged at the front part of the machine body, and the other side of the low-speed motor is connected with an air cylinder clutch at the front part of the machine body; the air cylinder clutch controls a gear which is connected with the low-speed motor to be disengaged from and engaged with a gear on the power shaft; a turning tool is arranged on one side of the tool apron, and an engraving tool is arranged on the other side of the tool apron through a universal regulating frame; a central sleeve which is sleeved outside a wood rod material is arranged at the front part of the machine body; a patterned inner hole is formed in the central sleeve; the exterior of the central sleeve is arranged on the machine body through a bearing. The numerically controlled wood engraving and milling machine can regulate a cutter conveniently with labor saving, is high in machining accuracy, good in machining quality, and easy and convenient to operate; skin turning and engraving can be completed by clamping at one time.

Owner:BINZHOU COSEN CNC EQUIP TECH

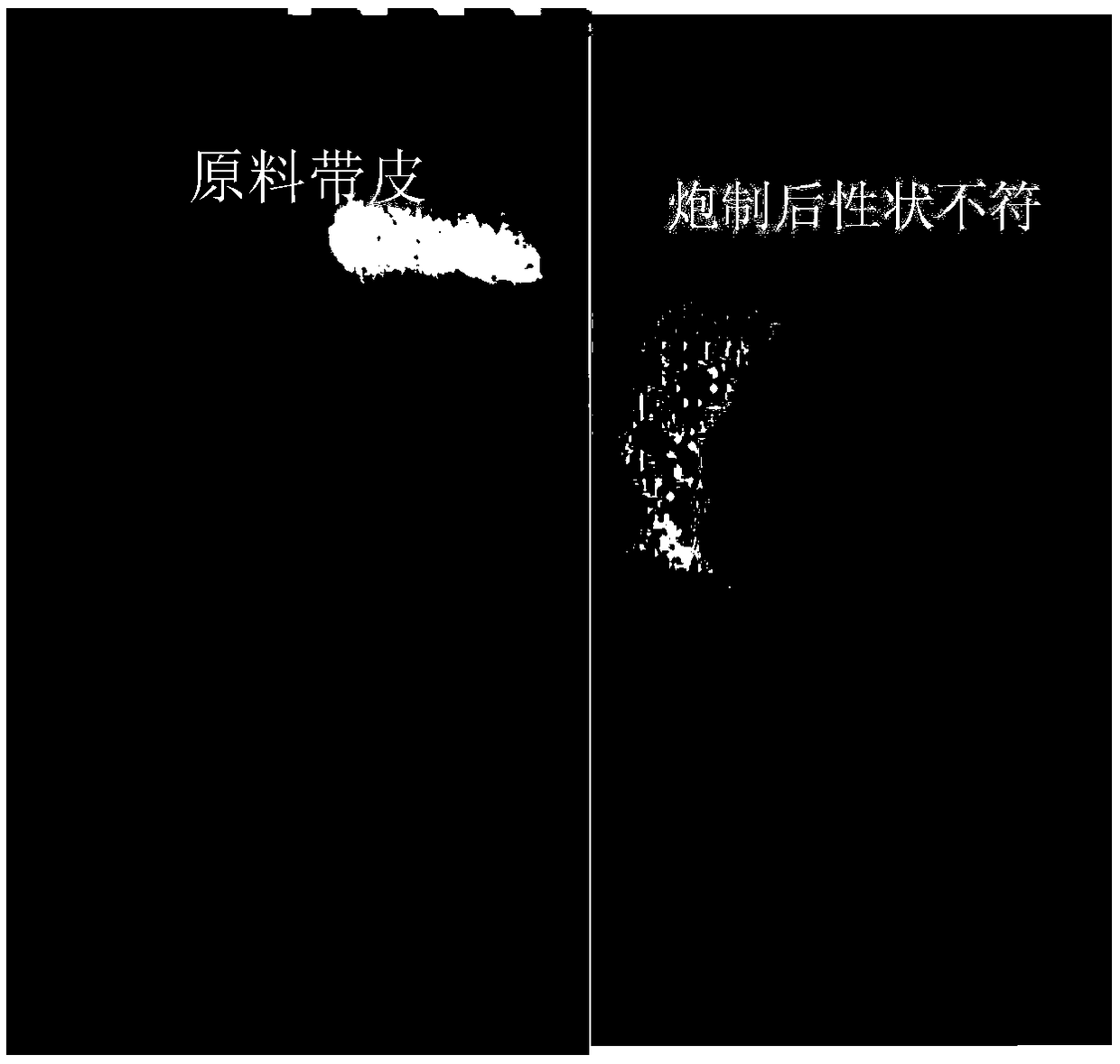

Processing method of medicinal material processed ginger slices and product

InactiveCN109224044AReduce total content lossReflect rationalityAntipyreticAnalgesicsComputer scienceRiver sand

The invention discloses a processing method of medicinal material processed ginger slices and a product. The processing method comprises the following steps: a step of hitting the skin, a step of frying the river sand, a step of sanding, a step of sieving, that is, a ginger piece. The invention adopts the step of smashing the skin before being processed, which is a key step for the trait of the product to reach the Pharmacopoeia standard. By adjusting the grain size of the processed sand and processing the parameters of the scalding, the process effectively reduces the total content loss of the leaching material and the 6-saponin, reflecting the rationality of the process.

Owner:KANGMEI PHARMA

A processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product

InactiveCN109172648ASimple production processGuaranteed stabilityNervous disorderMetabolism disorderMedicinal herbsBULK ACTIVE INGREDIENT

The invention discloses a processing method for radix Polygoni Multiflori decoction pieces from medicinal materials and a product . The processing method comprises the following steps: a washing step,a moistening step, a step of preparing black soybean juice, a step of steaming medicine and a step of baking medicine, namely, the radix Polygoni Multiflori decoction pieces are obtained. On the onehand, under the guidance of pharmacopoeia, the processing technology of Radix Polygoni Multiflori Preparata is optimized, and the best effect of wetting and swelling is obtained by the method of decompressing and moistening drugs, so as to ensure the content of active ingredients to meet the legal standard; on the other hand, the processing technology of radix Polygoni Multiflori is optimized. Product appearance and internal quality are improved, and the stability and reproducibility of varieties and processes are guaranteed.

Owner:KANGMEI PHARMA

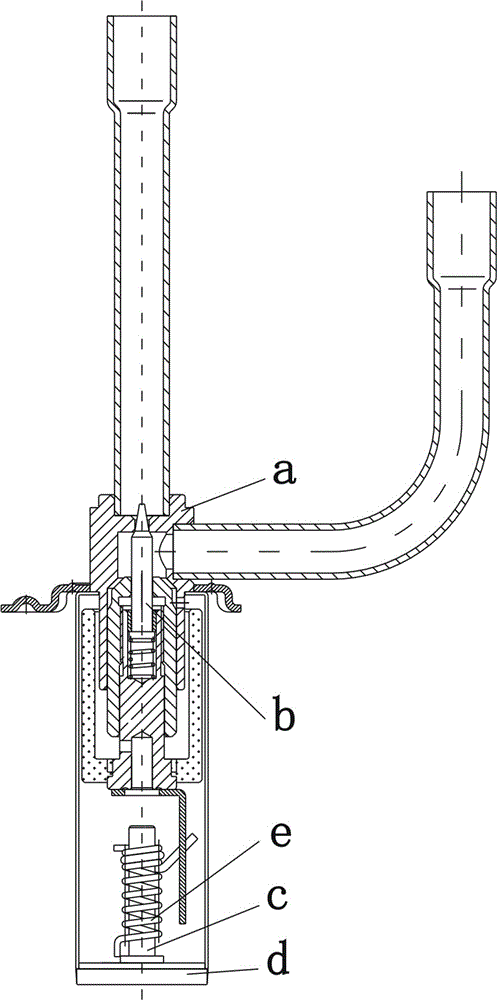

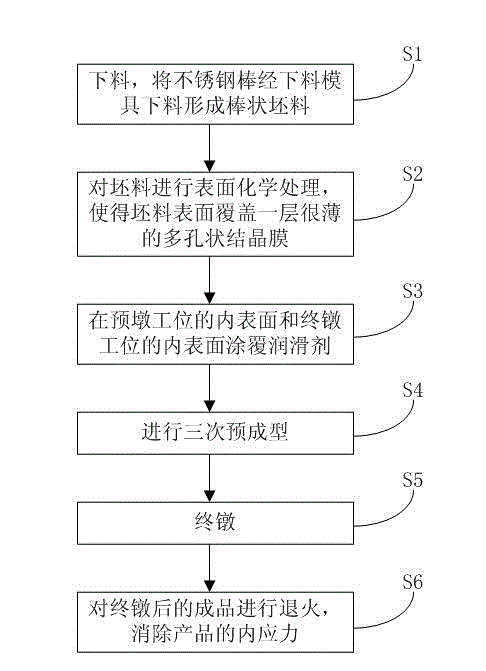

Electronic expansion valve small shaft and cover plate and forming method

InactiveCN104624891AGood consistencyGood processing qualityValve arrangementsMetal-working apparatusWork in processEngineering

The invention provides an electronic expansion valve small shaft and cover plate and a forming method. A small shaft and a cover plate are integrally formed in a cold heading mode. The forming method includes the steps that blanking is conducted, blanking is conducted on a stainless steel rod through a blanking die to form a rod-shaped blank; multi-preforming is conducted, each performing includes the steps that the blank is fixed into a corresponding pre-heading station, a punch is pressed downwards to extrude metal on the blank, the metal on the blank moves and fills up the whole pre-heating station, and a semi-finished product of a small shaft and cover plate is formed after multi-preforming is conducted on the blank; final heading is conducted, the semi-finished product obtained after multi-preforming is conducted is fixed in a final heading station, and the punch is pressed downwards to extrude the semi-finished product; finally, a finished product is formed in a stamping mode, wherein the cover plate and the small shaft are vertically connected with each other, and the thickness of the cover plate obtained after final heading is conducted is the final thickness. By means of the electronic expansion valve small shaft and cover plate forming method, the perpendicularity of the formed small shaft and cover plate can be guaranteed, and the electronic expansion valve small shaft and cover plate and the forming method have the advantages of being good in finished product consistency, high in production efficiency, low in production cost and the like.

Owner:福鼎市金闽辉机车部件有限公司

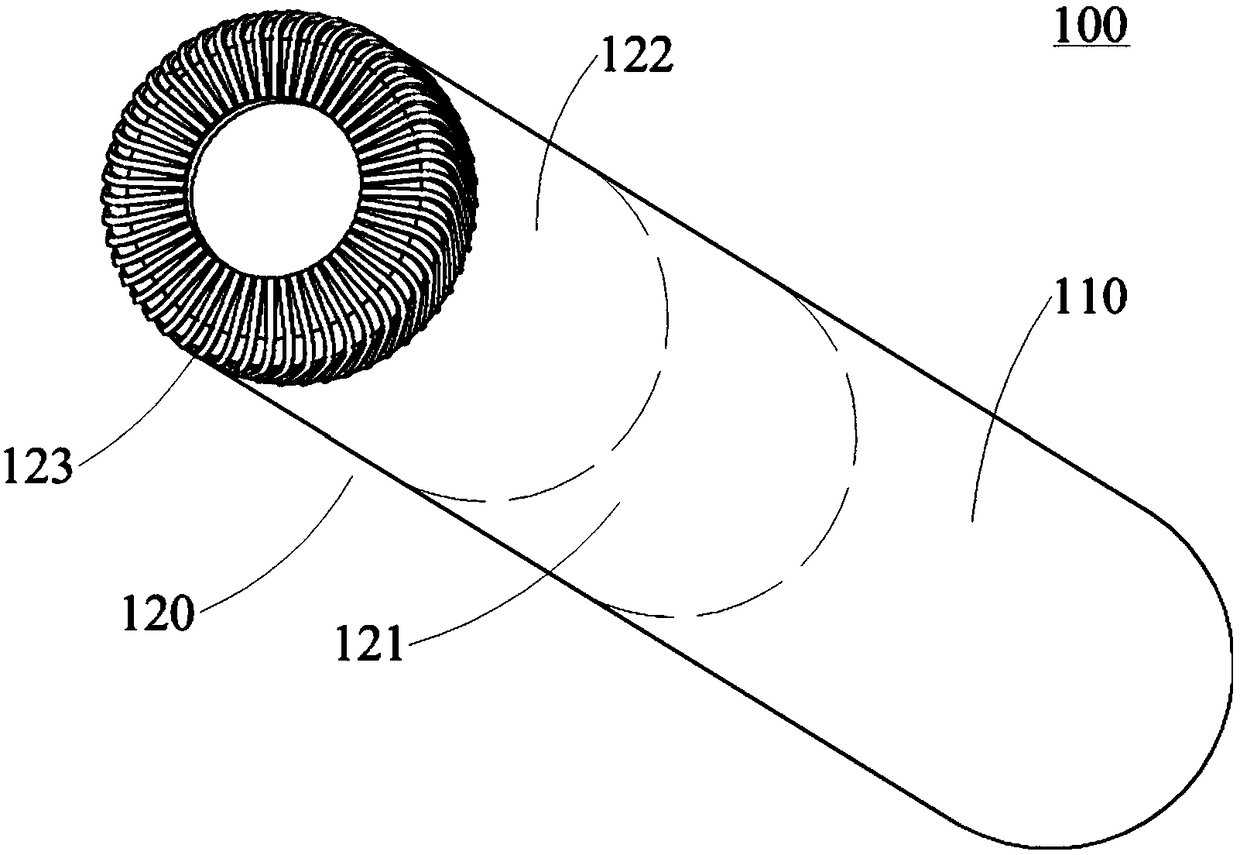

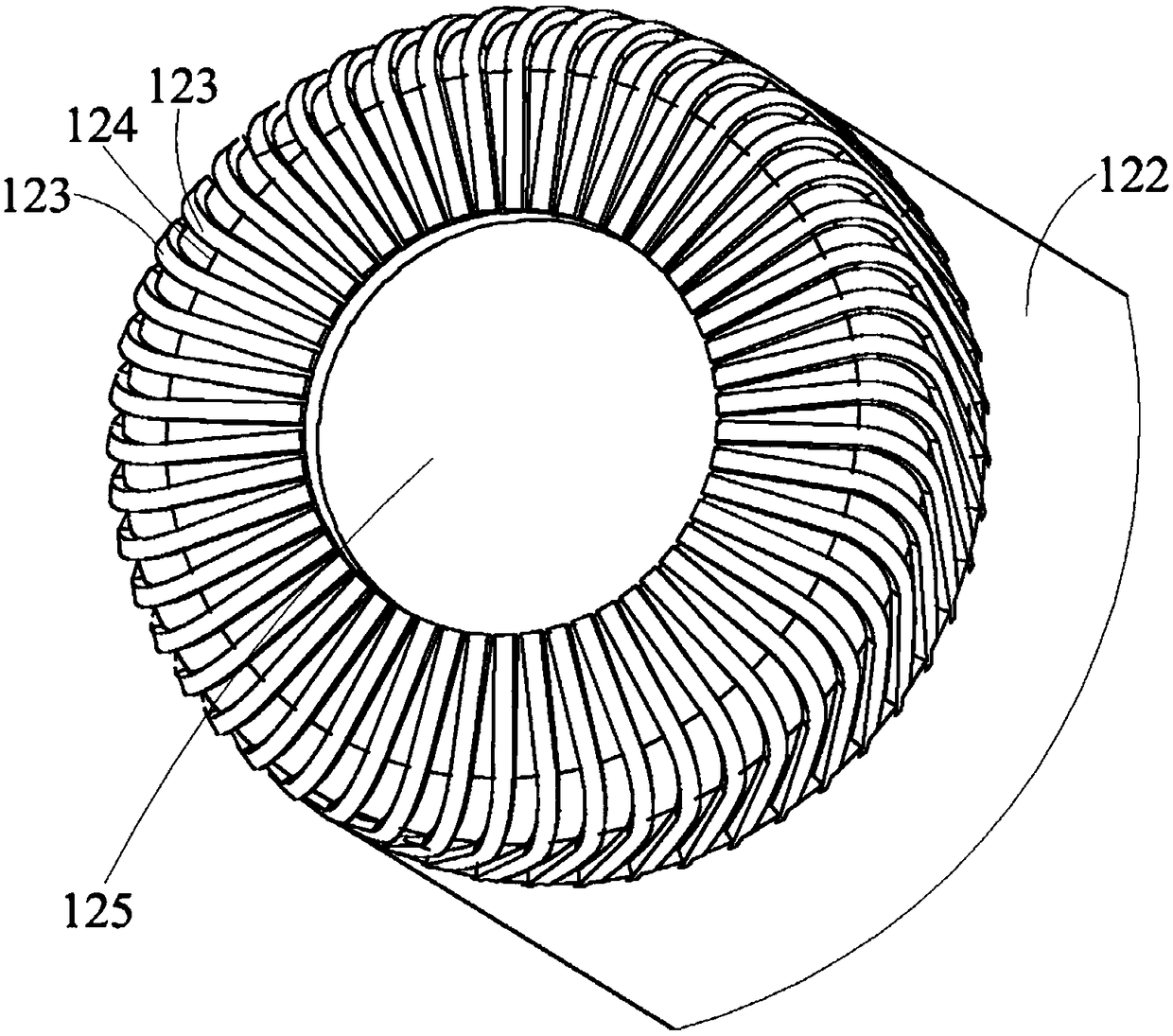

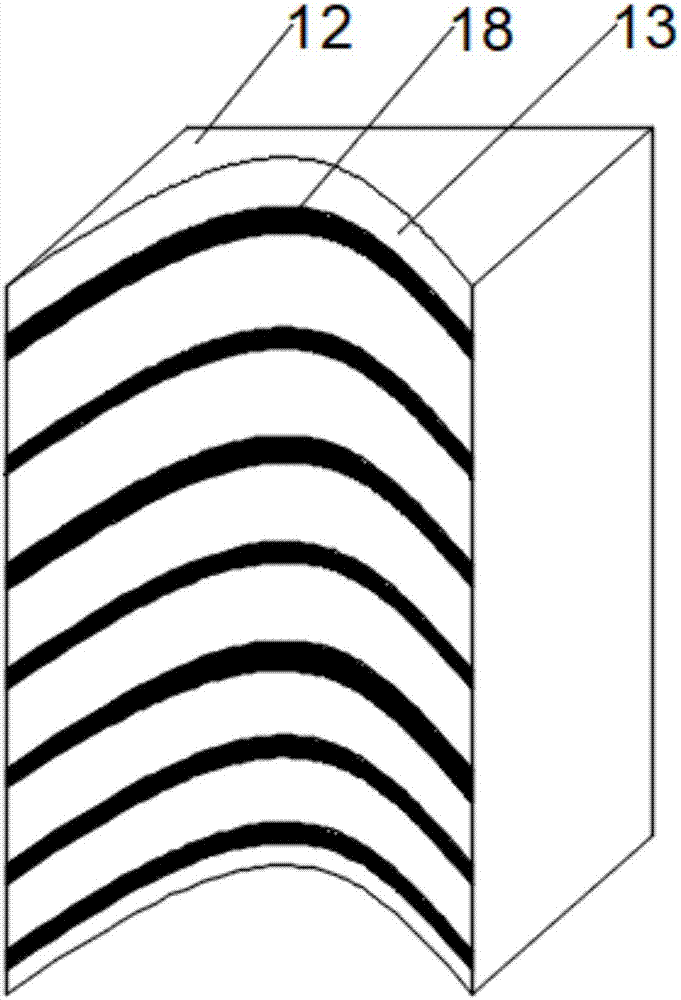

Manufacturing method of polycrystalline diamond integral cutter

InactiveCN108994363AFunctionalImprove processing efficiencyMilling cuttersBonded abrasive wheelsSurface roughnessPolycrystalline diamond

The invention relates to a manufacturing method of a polycrystalline diamond integral cutter. The manufacturing method comprises the steps of grinding a clamping handle blank into a reference clampinghandle; centering, aligning and clamping a polycrystalline diamond cutter head blank and the reference clamping handle, and then performing vacuum welding; grinding the polycrystalline diamond cutterhead blank to preset precision by using the reference clamping handle as the reference; and forming a plurality of cutting edges which are annularly distributed one by one and chip grooves which arelocated among the cutting edges in one end, which is far from the reference clamping handle, of the polycrystalline diamond cutter head blank through laser cutting so as to obtain the polycrystallinediamond integral cutter, wherein the width of the cutting edges is 0.04 to 0.1 mm, the surface roughness Ra of the cutting edges is 0.1 to 0.4 mum, and the depth of the chip grooves is 0.08 to 0.15 mm. The polycrystalline diamond integral cutter prepared by adopting the manufacturing method of the polycrystalline diamond integral cutter is of an integrated multiple-cutting-edge structure, is favorable for improving the machining efficiency and prolonging the service life and guaranteeing the ideal machining quality, has good economic benefits, is favorable for popularization and application and is especially suitable for glass or ceramic machining.

Owner:CONPROFE TECH GRP CO LTD +1

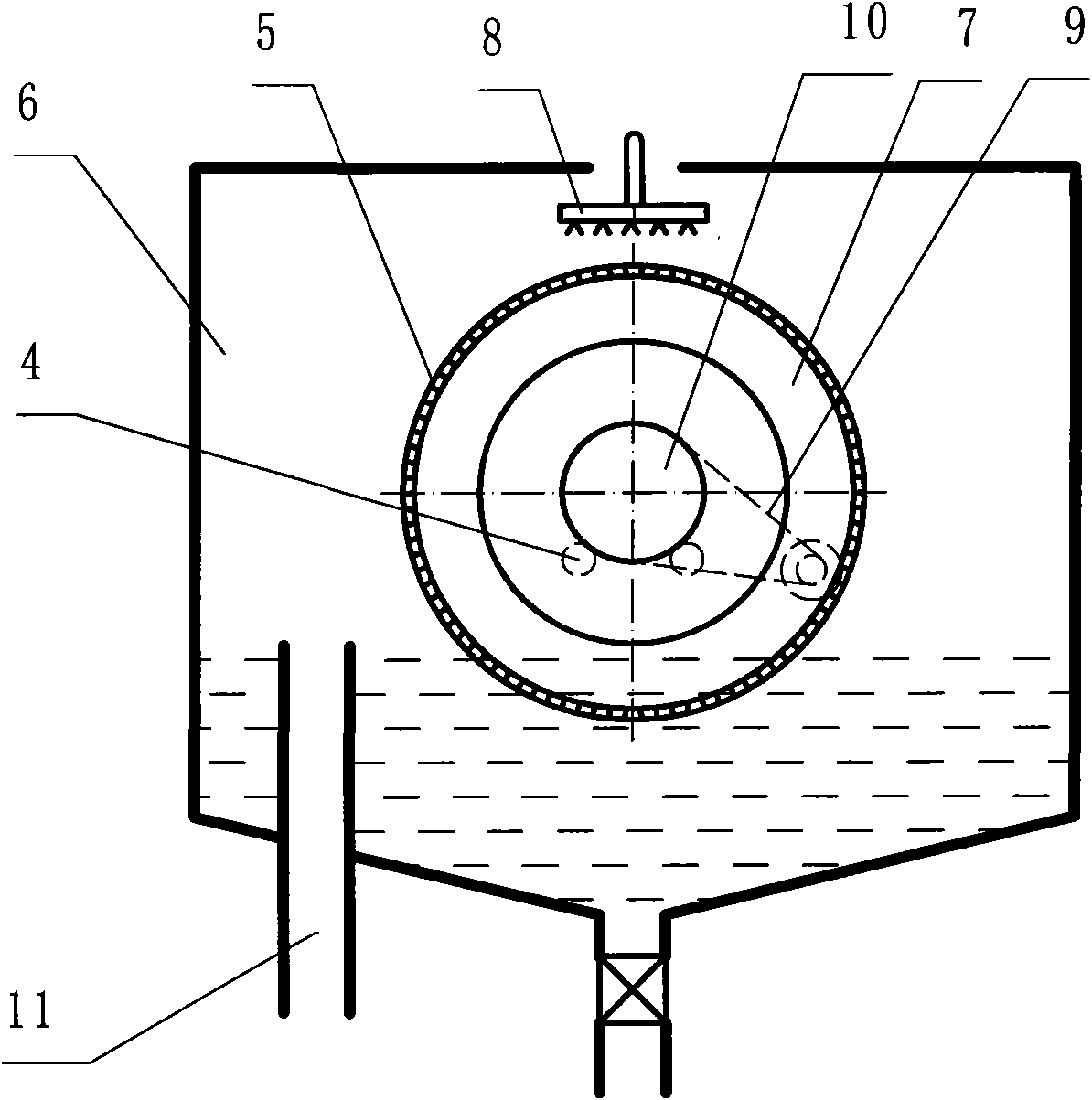

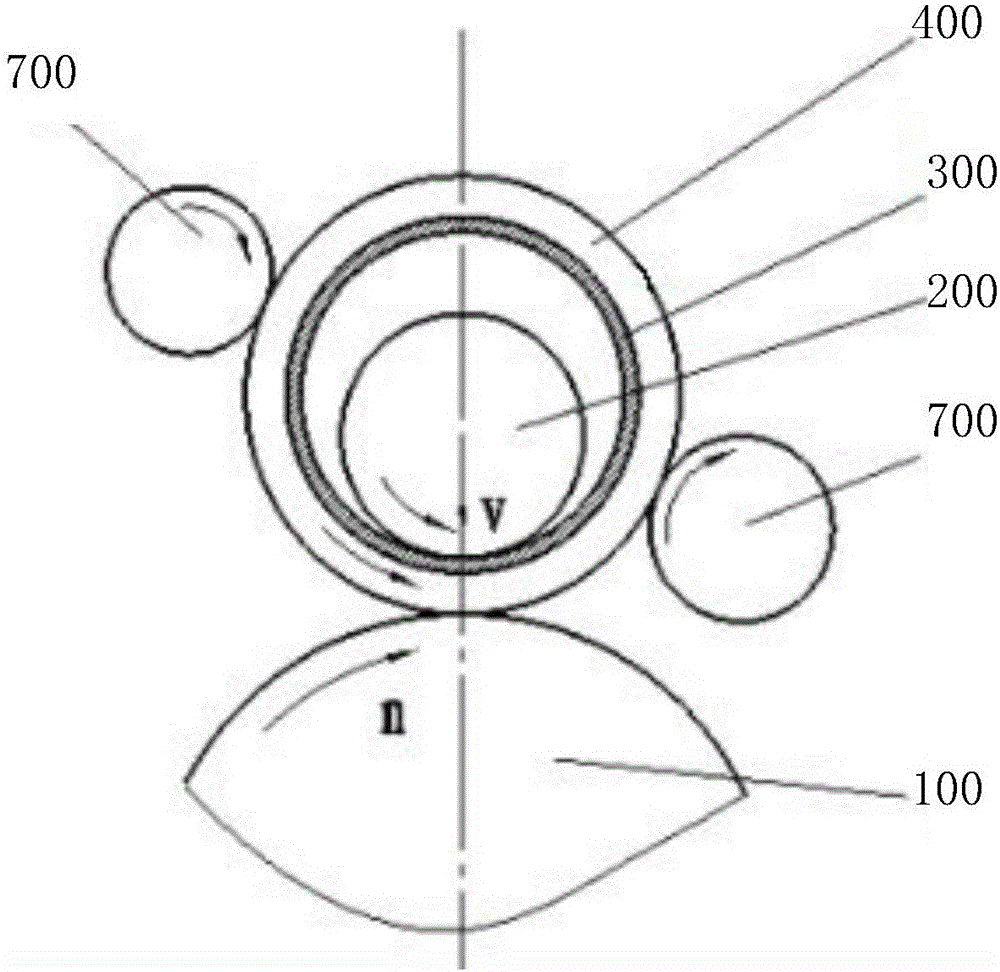

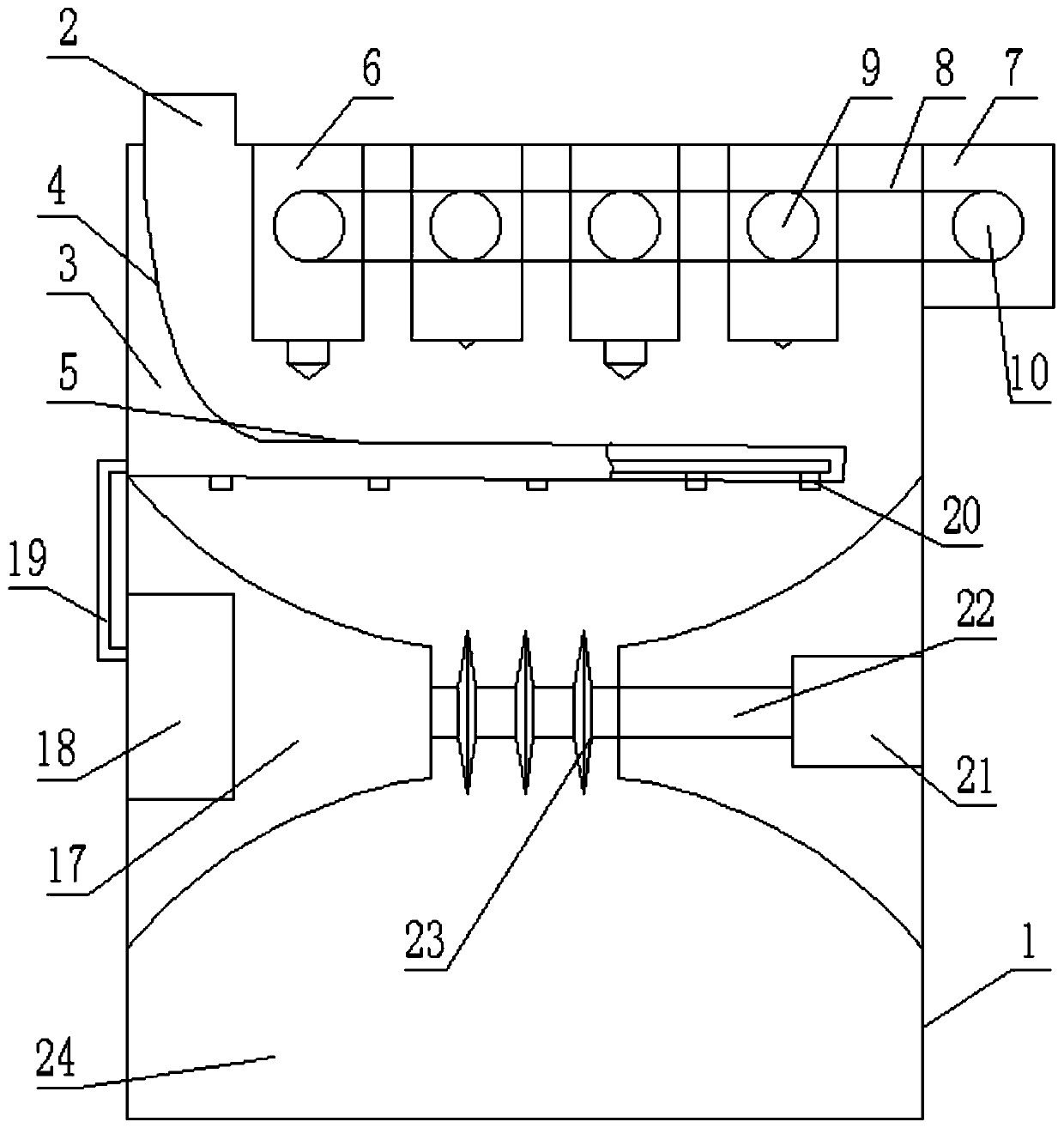

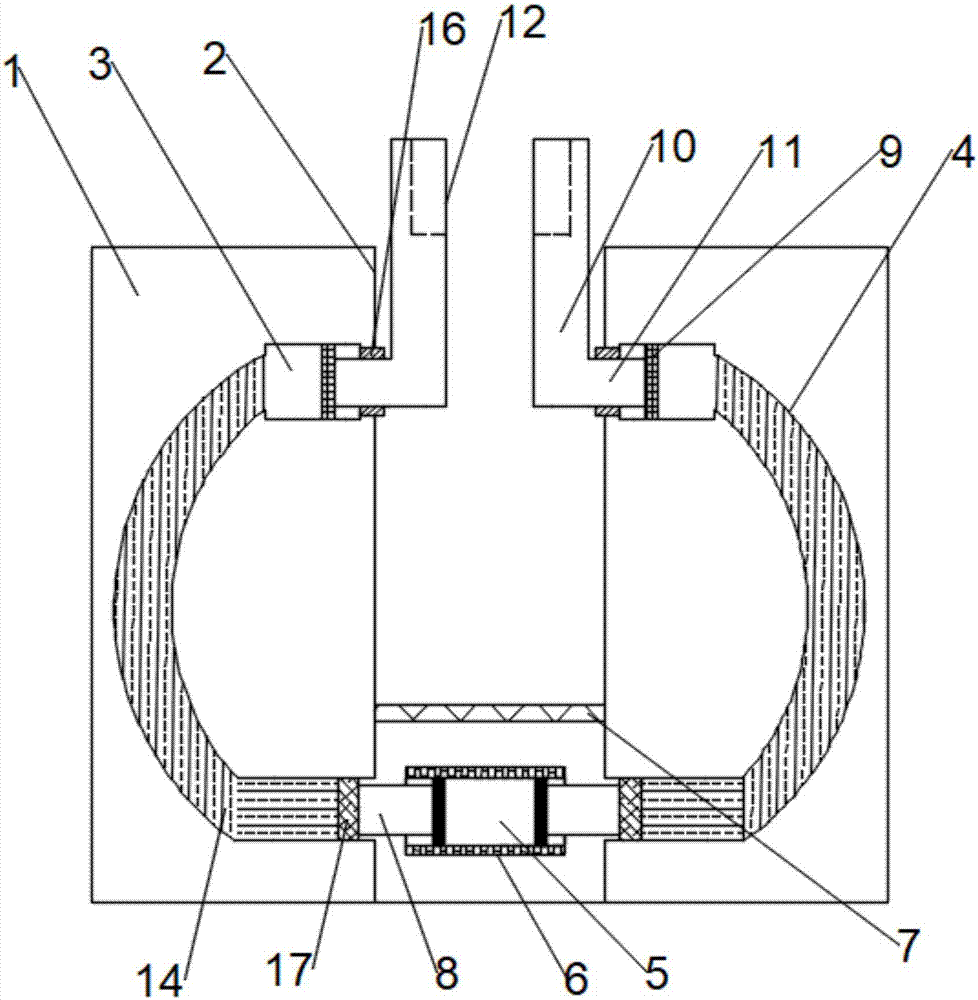

Device and method for automatically grinding spheroidal gem jade

ActiveCN106926059AGood processing qualityImprove processing efficiencySpherical surface grinding machinesSurface grindingEngineering

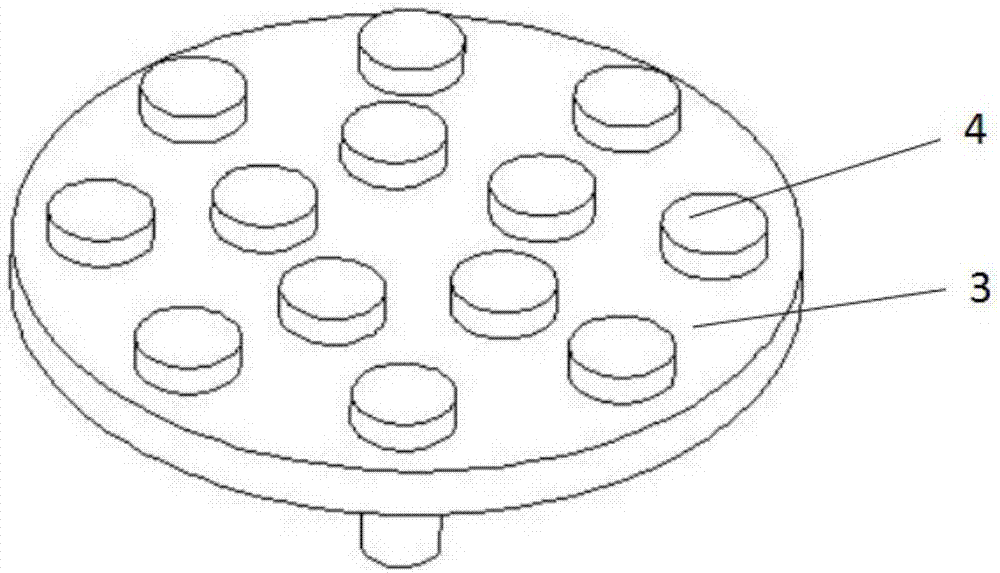

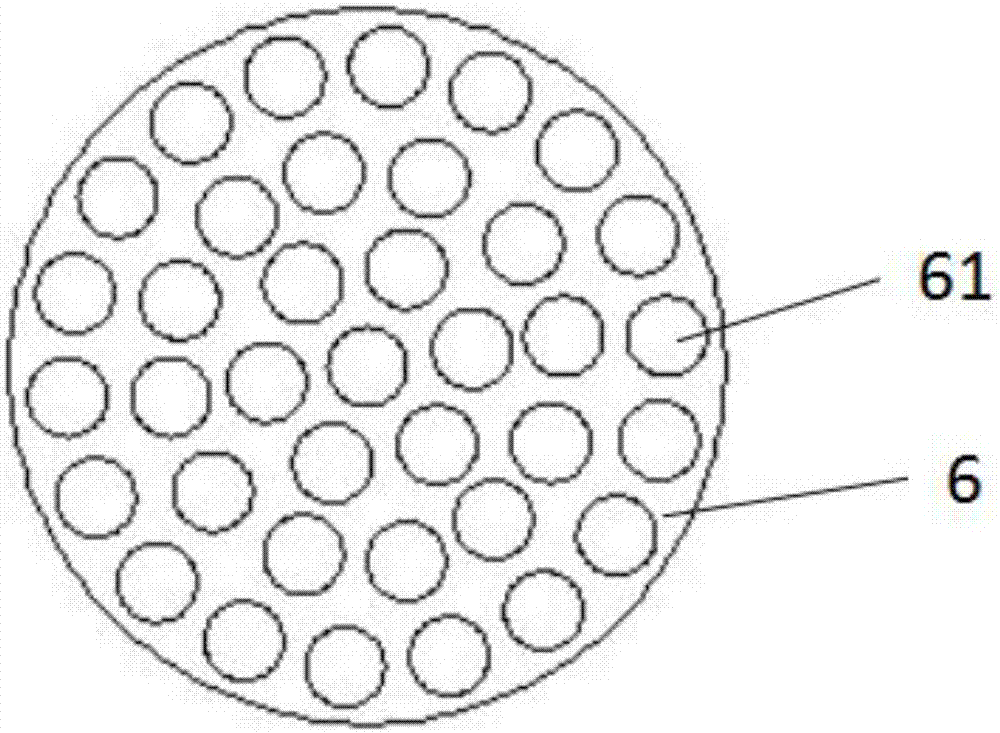

The invention relates to a device and a method for automatically grinding spheroidal gem jade. The device comprises a vertical transmission mechanism, a magnetic grinding mechanism and a rotating mechanism, wherein a permanent magnetic pole and an auxiliary magnetic pole are parallelly and oppositely arranged in the magnetic grinding mechanism to form a magnetic loop; the permanent magnetic pole is driven by the vertical transmission mechanism to rotate, the auxiliary magnetic pole is driven by the rotating mechanism to rotate, and the rotating directions of the permanent magnetic pole and the auxiliary magnetic pole are opposite; a retainer allowing the spheroidal gem jade to be placed thereon is fixedly arranged between the permanent magnetic pole and the auxiliary magnetic pole; and the upper side and the lower side of the retainer are filled with a magnetic abrasive to wrap the spheroidal gem jade therein. Through the synergistic effect between the auxiliary magnetic pole and the permanent magnetic pole, the surface of the spheroidal gem jade is ground and processed by the magnetic abrasive; and magnetic surface grinding and polishing of the spheroidal gem jade are realized, the processing efficiency is high, the processing quality is good, and shortcomings of a manual grinding method are made up.

Owner:HIGH END EQUIP & RAIL TRANSIT TECH R & D CENT OF HAIAN TAIYUAN UNIV OF SCI

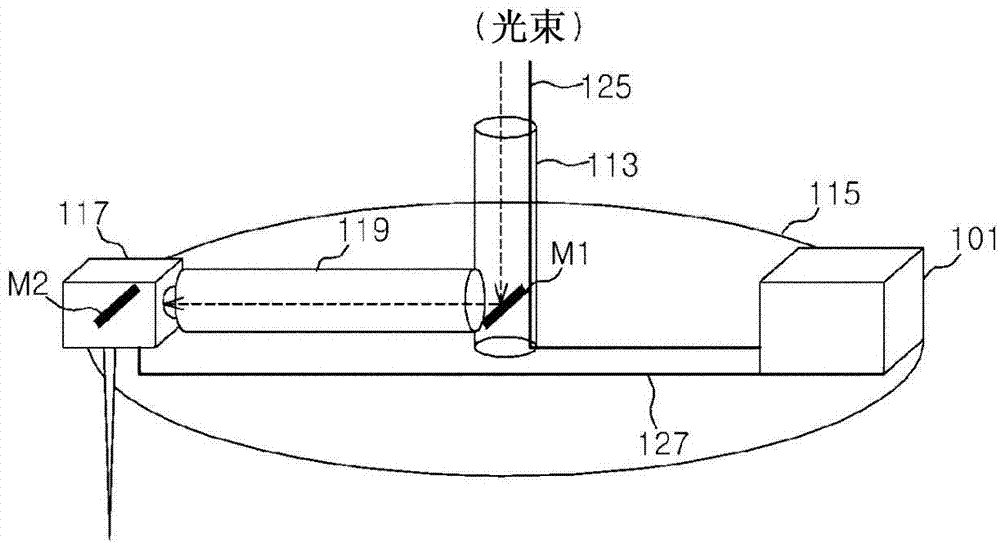

Apparatus and method for cutting electrode foils

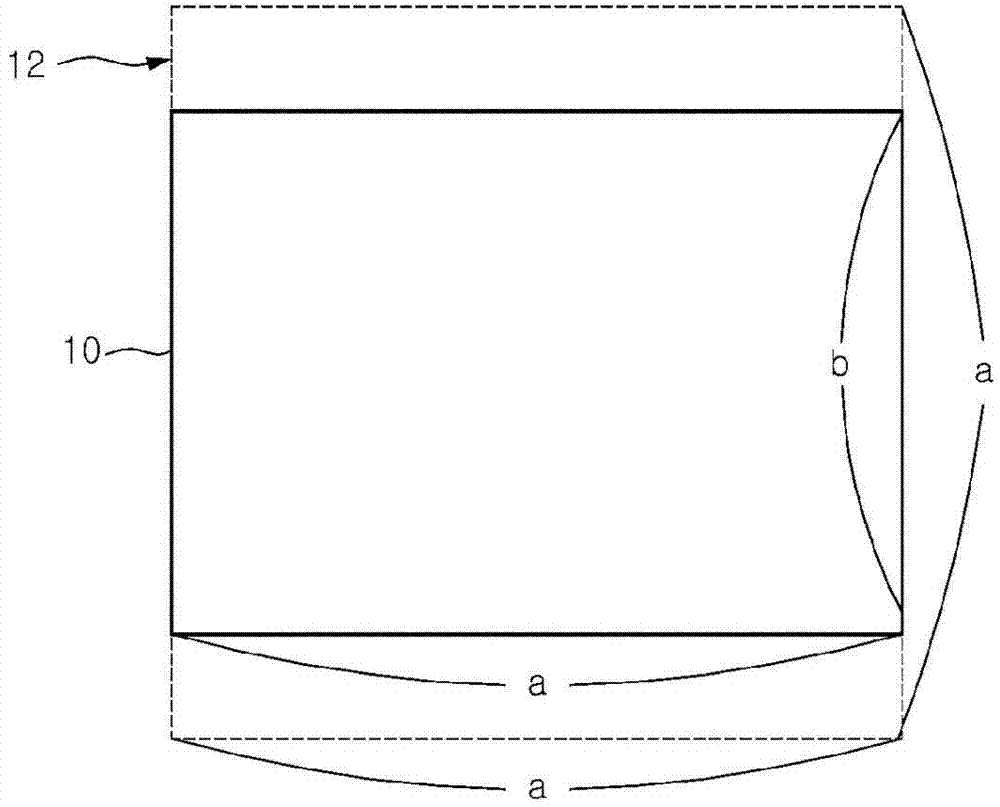

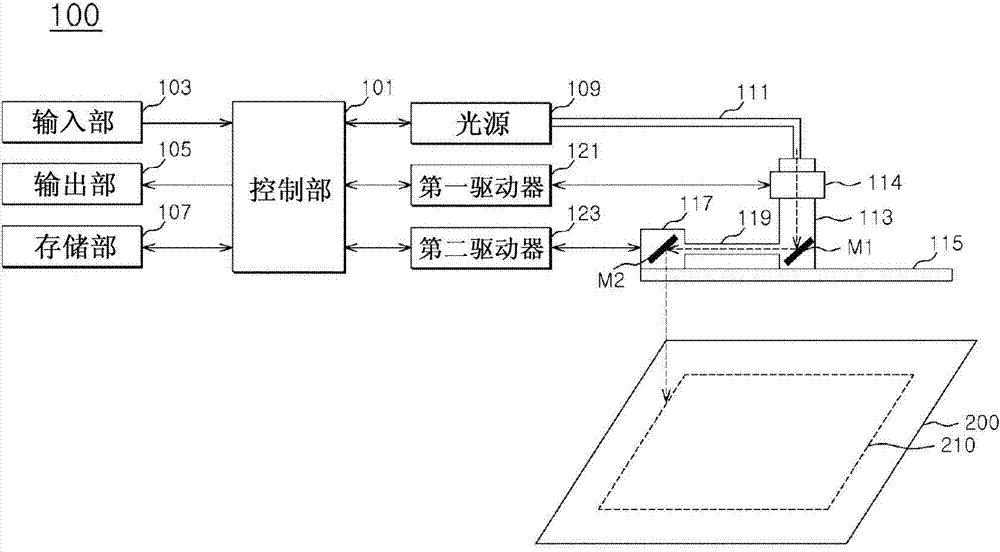

ActiveCN103947014AGood processing qualityImprove reliability and mass productionElectrode manufacturing processesFinal product manufactureMoving speedEngineering

The present invention relates to an apparatus and method for cutting electrode foils. The apparatus and method for cutting electrode foils includes: a rotating body disposed vertically spaced by a predetermined distance so as to be parallel to a working table; a rotating shaft disposed at the center of the rotating body and driven by a first driver to rotate the rotating body at a predetermined speed; and a scanner disposed at the end of one side of the rotating body to emit a laser beam onto an object to be processed according to the rate of change in speed based on the rotation angle and rotating speed of the rotating body and the processing size of the object to be processed.

Owner:有限公司 K 实验室

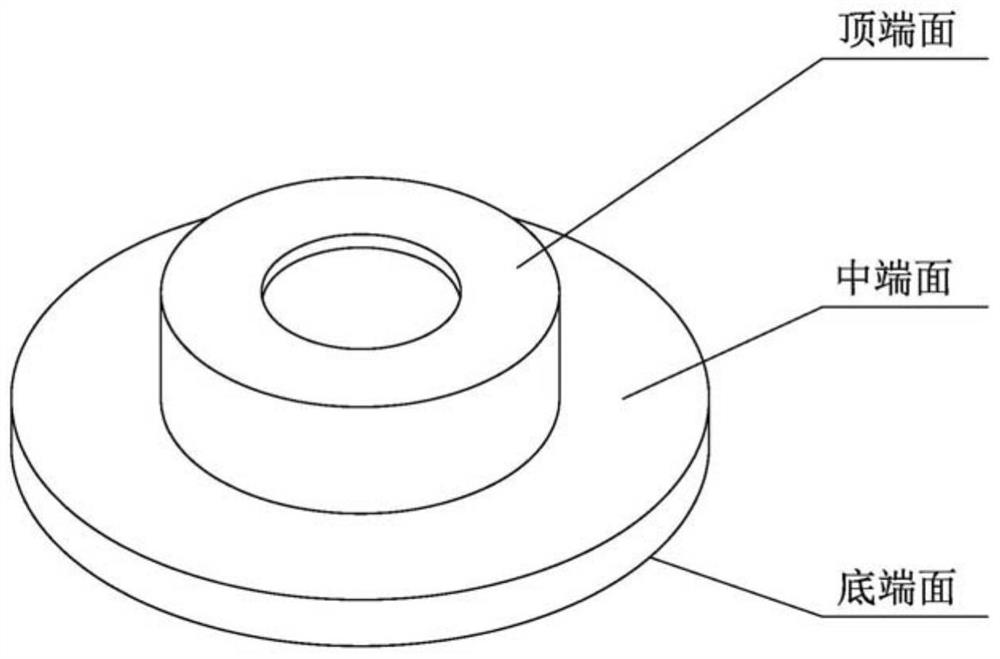

Automobile exhaust pipe flange manufacturing device and method

InactiveCN106021812AGood processing qualityIncrease productivityGeometric CADSustainable transportationEngineeringFlange

The invention provides an automobile exhaust pipe flange manufacturing device and method. The automobile exhaust pipe flange manufacturing device comprise a main roller serving as a driving roller to continuously rotate in the circumferential direction at a set angular speed, and a core roller peripherally provided with a flange ring blank and a die, serving as an impression roller, performing continuous feeding towards the main roller at a set speed and rotating under the driving of a friction force produced with the contact face of the flange ring blank, wherein the die changes an outer outline shape of the flange ring blank in the process, and the flange ring blank between the main roller and the core roller is stressed in the thickness direction and extends in the circumferential direction to make wall thickness decreased and make inner and outer diameters increased simultaneously. The automobile exhaust pipe flange manufacturing device adopts the annular roll-forming method, namely extrudes out a flange through thick-plate spinning, the method adopts a plate to replace a rod, and the material cost can be reduced by one third. In addition, follow-up machining allowance is small, and meanwhile the annular roll-forming method has the advantages of being good in machining quality, high in production efficiency, low in production cost, high in material utilization rate and the like.

Owner:SHANGHAI DIANJI UNIV

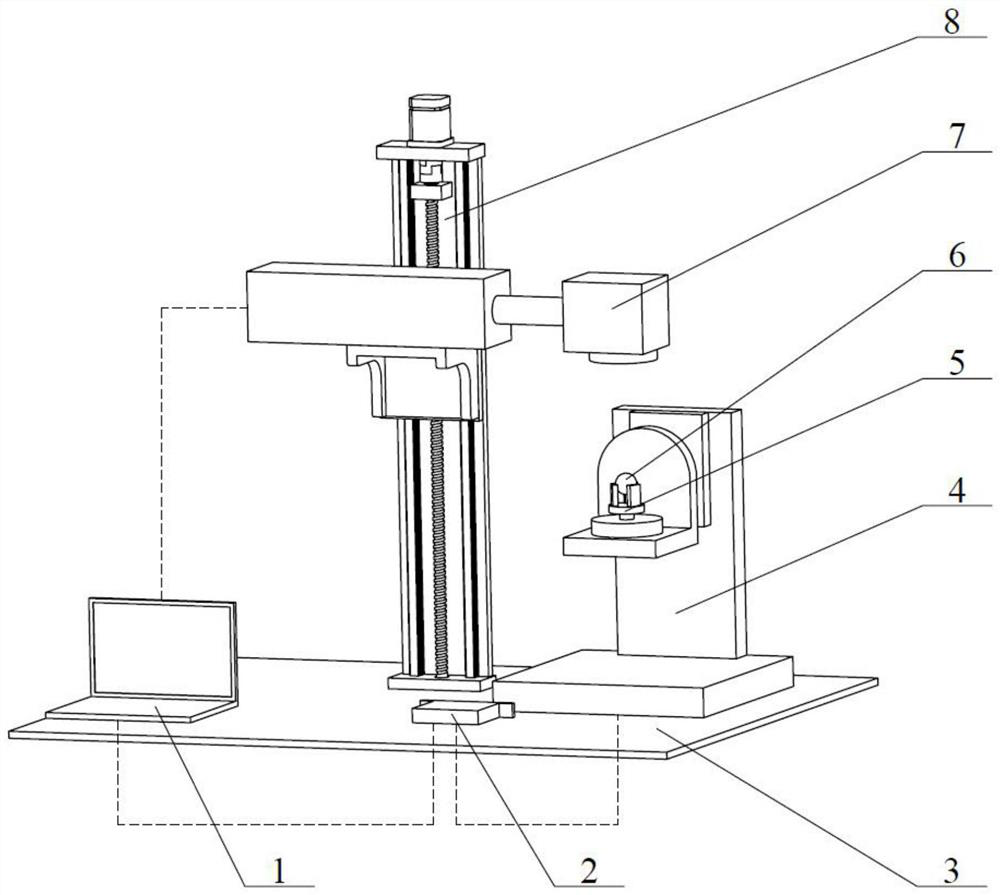

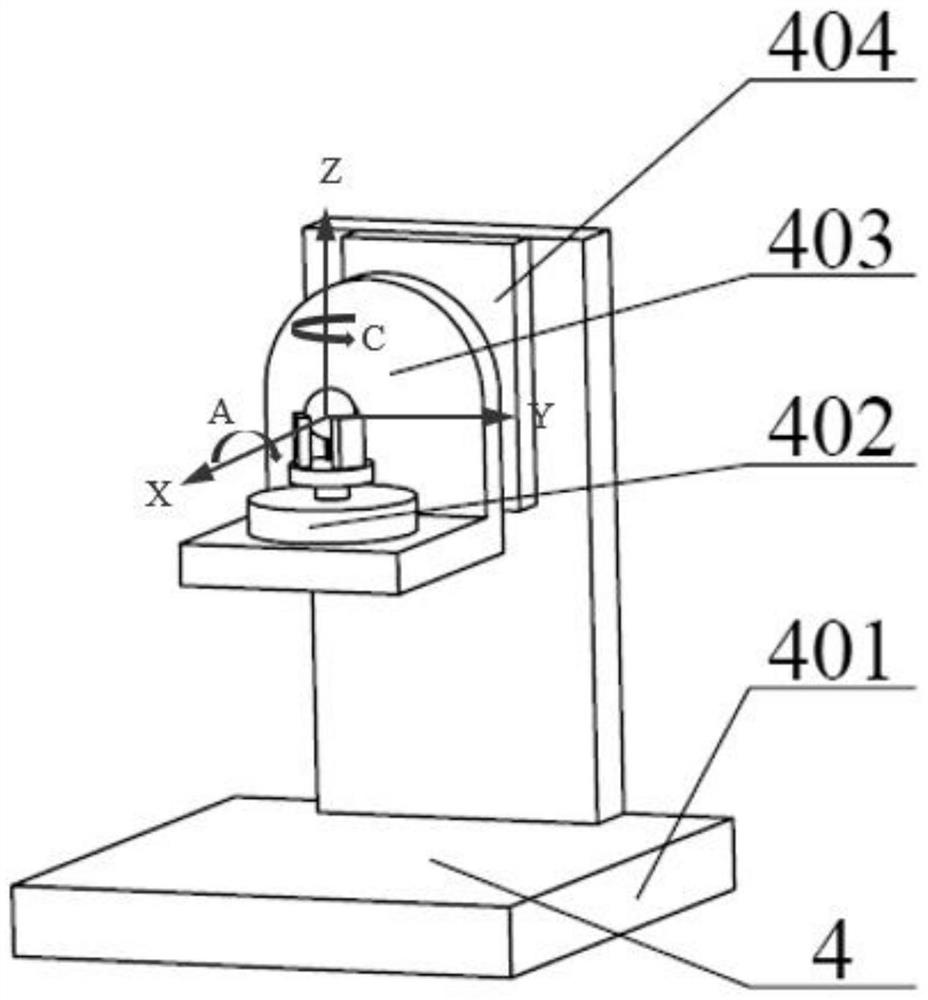

Laser ablation processing device and method for surface microstructure of curved-surface workpiece

ActiveCN113500298AHigh precisionGood processing qualityWelding/cutting auxillary devicesAuxillary welding devicesPhysicsErbium lasers

The invention discloses a laser ablation processing device and method for a surface microstructure of a curved-surface workpiece, and belongs to the technical field of laser machining. The device comprises a fixed seat; a linear module and a laser mounted on the linear module, wherein the linear module drives the laser to move up and down in the Z-axis direction; a five-axis linkage mechanical motion platform which is arranged on the fixed seat, wherein a clamp is mounted on the five-axis linkage mechanical motion platform; and the five-axis linkage mechanical motion platform drives the to-be-machined curved surface part to be in five-axis linkage, so that pose regulation and control of the machined curved surface part are achieved; a multi-axis motion controller which is arranged on the fixed seat and is electrically connected with the five-axis linkage mechanical motion platform; and a computer which is electrically connected with the multi-axis motion controller, the linear module and the laser. Accurate control over the laser machining position and the curved surface workpiece posture can be achieved through five-axis linkage, it is guaranteed that the laser focus is always located on the surface of the workpiece in the machining process, it is guaranteed that the laser beam is always perpendicular to the workpiece, and the machining quality can be effectively guaranteed.

Owner:HARBIN INST OF TECH +1

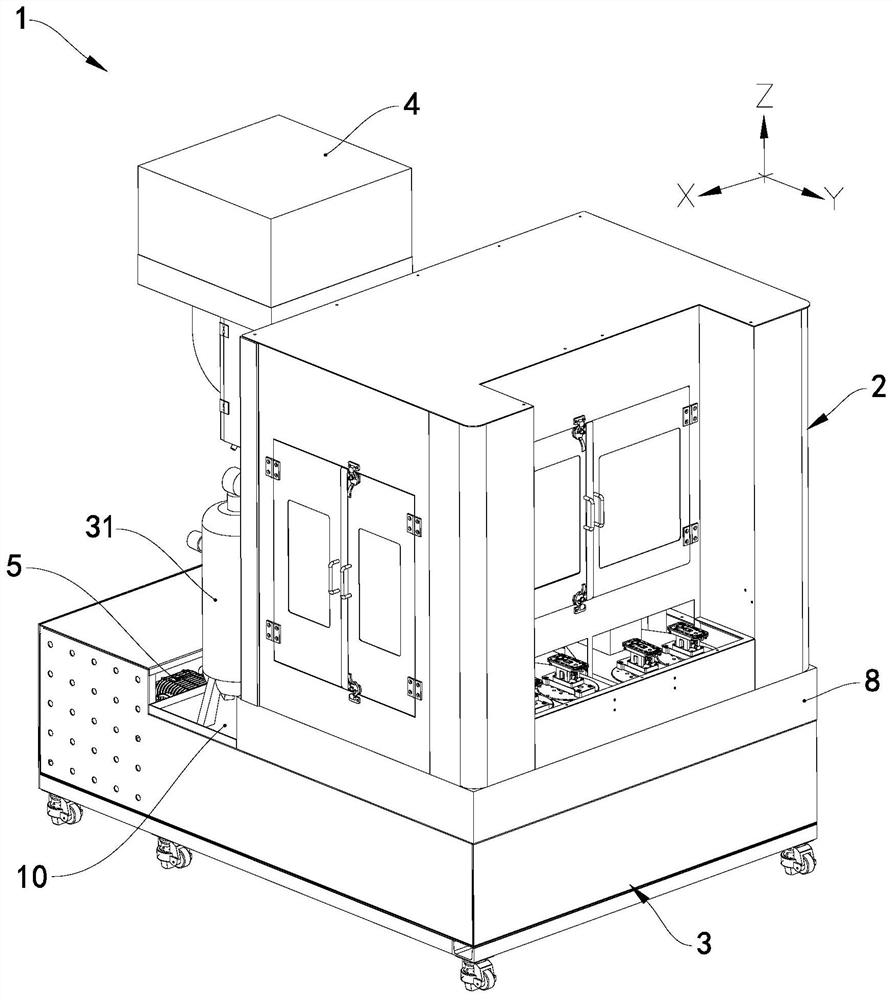

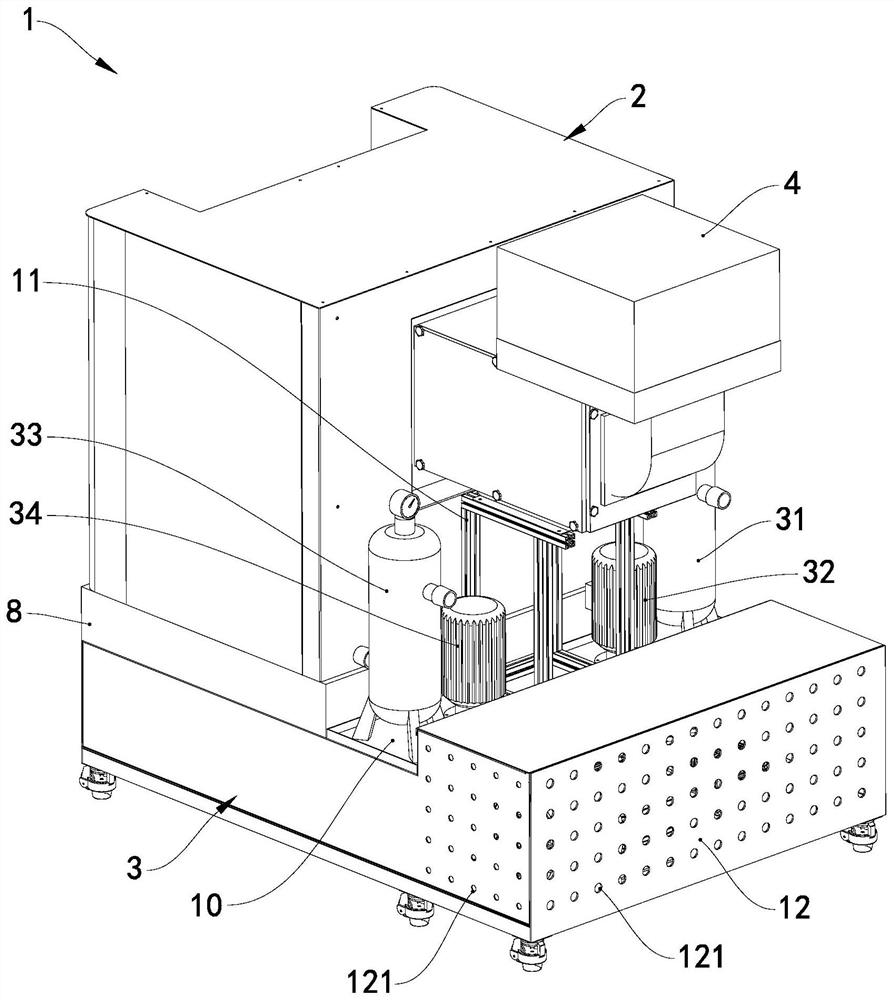

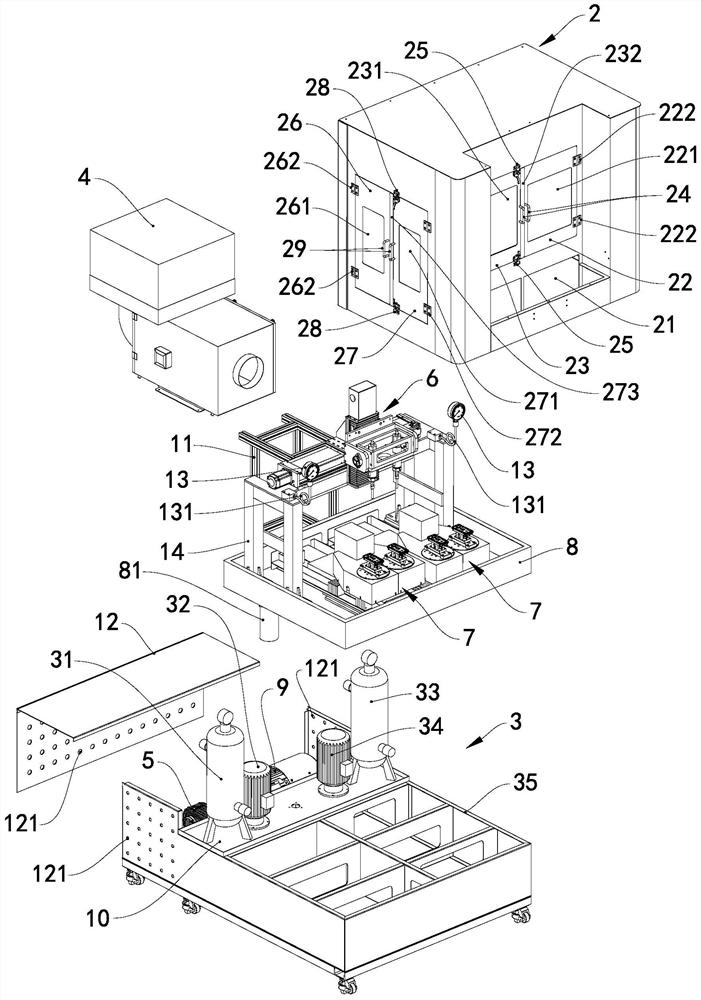

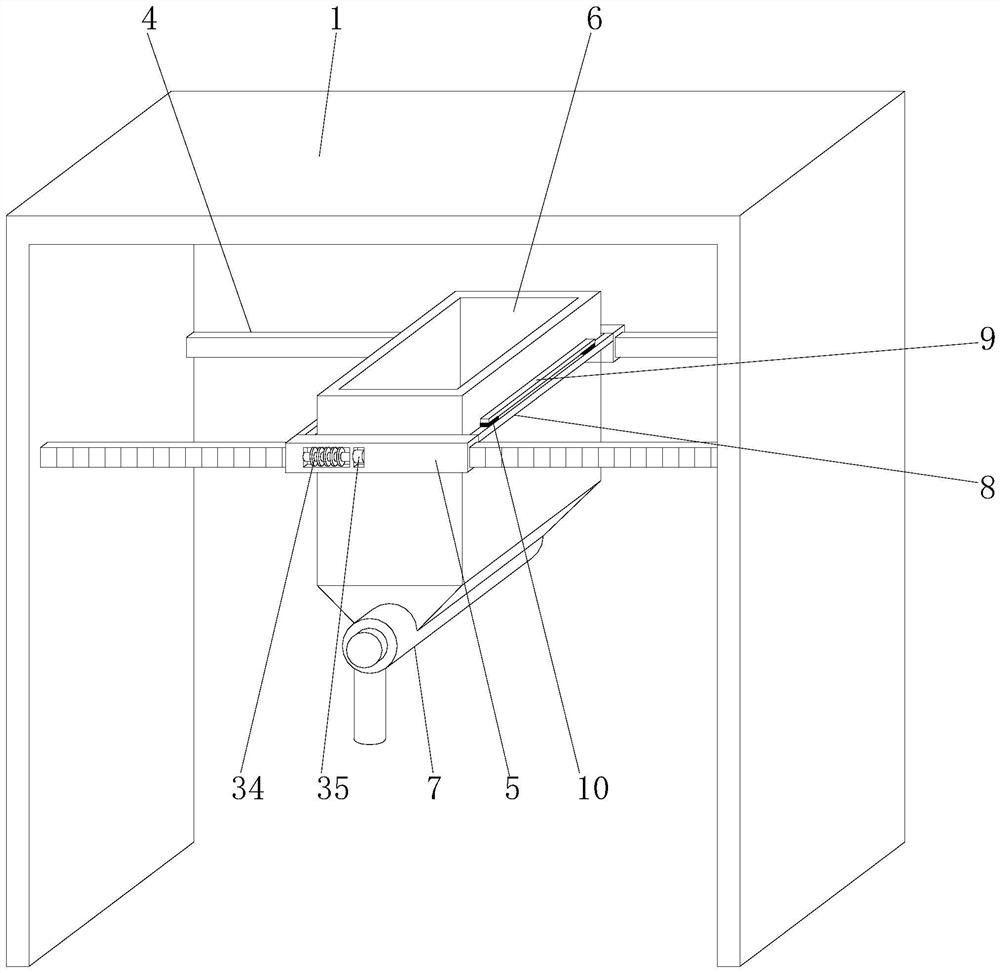

Multi-shaft linkage intelligent high-pressure water deburring device

ActiveCN112976160AGood processing qualityStrong automation performanceMetal working apparatusStationary filtering element filtersElectric machineryWater jet cutter

The invention provides a multi-shaft linkage intelligent high-pressure water deburring device. The multi-shaft linkage intelligent high-pressure water deburring device comprises a rack outer frame, a water collecting table, a water jet cutter device, a workpiece control device, a high-pressure pump, a high-pressure pump motor and an oil mist purifier; the water jet cutter device comprises a first control mechanism, a second control mechanism, a swing control mechanism and a water jet cutter assembly; the water jet cutter assembly comprises a water jet cutter head; the workpiece control device is installed on the water collecting table and comprises a third control mechanism, a movable plate, a rotation control mechanism and a clamp; a nozzle communicating with a high-pressure water channel is formed in the circumferential wall of the first end, close to the clamp, of the water jet cutter head; a water inlet in the second end of the water jet cutter head communicates with a water outlet of the high-pressure pump through a water pipe; the high-pressure pump motor is used for driving the high-pressure pump to operate; and the oil mist purifier communicates with the interior of the rack outer frame. The high-pressure water deburring device can thoroughly remove workpiece burrs and is good in machining quality, high in automation performance, compact in structure, wide in machining range and high in production efficiency, and the labor cost is saved.

Owner:GUANGDONG HESHI AUTOMATION TECH CO LTD

Primary processing device of silage

InactiveCN110150702AImprove processing efficiencyGood processing qualityFeeding-stuffCuttersEngineeringButt joint

The invention discloses a primary processing device of silage. The primary processing device comprises a processing box, wherein a storage chamber is arranged at the bottom in the processing box; a feeding opening is formed in the edge part of the top of the processing box; the top in the processing box is provided with a top plate in butt joint with the feeding opening; the top plate comprises aninclined plate and an arc-shaped rail in butt joint with the inclined plate; a plurality of rough cutting devices at equal intervals are arranged above the inclined plate; a gap is left between the tail end of the inclined plate and the inner wall of the processing box; two guide tables in symmetrical arrangement are arranged under the inclined plate; a material falling passage is arranged between the two guide tables; a rotary cutting shaft in the horizontal direction is arranged in the material falling passage. The primary processing device has the advantages that silage raw materials can be cut, crushed and processed in different modes; the processing efficiency is high; the processing quality is high; through the arrangement of a booster fan, the occurrence of blocking phenomenon canbe avoided; the processing continuity is ensured; meanwhile, the structure of a plurality of rough cutting devices is ingenious, so that the crushing effect is ensured; meanwhile, the continuous processing efficiency is also ensured.

Owner:郭丽

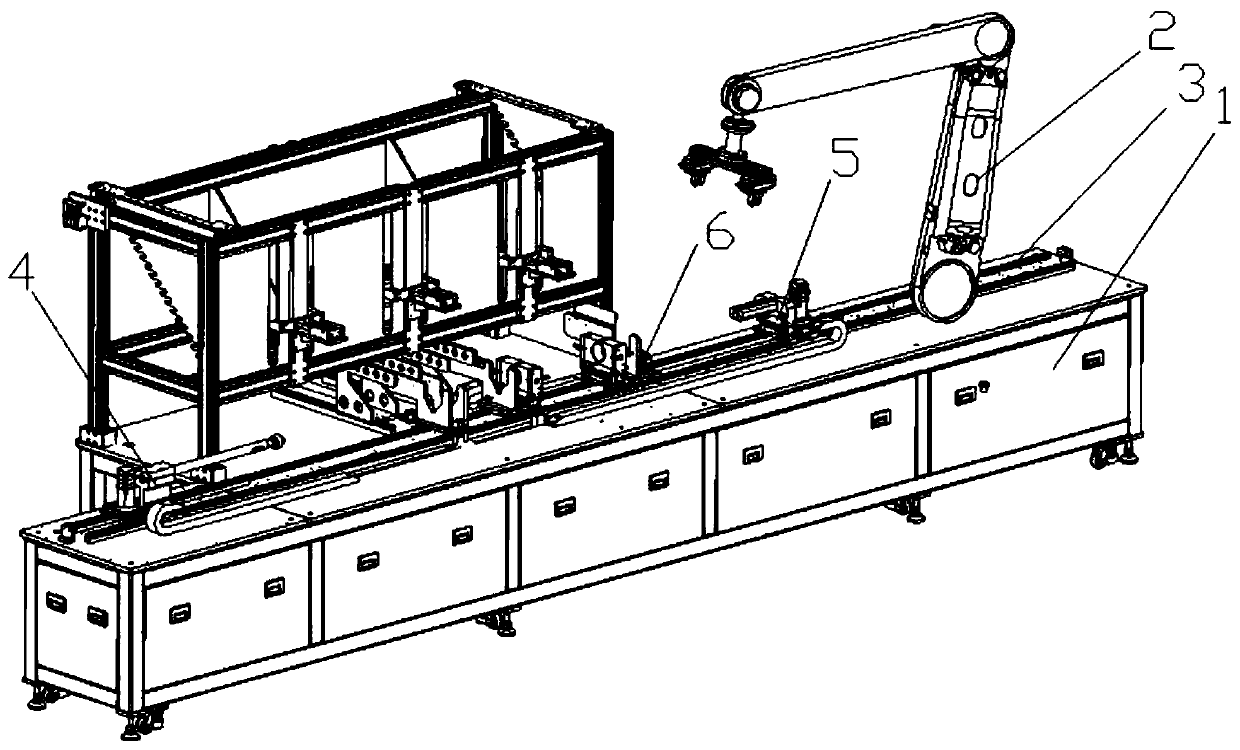

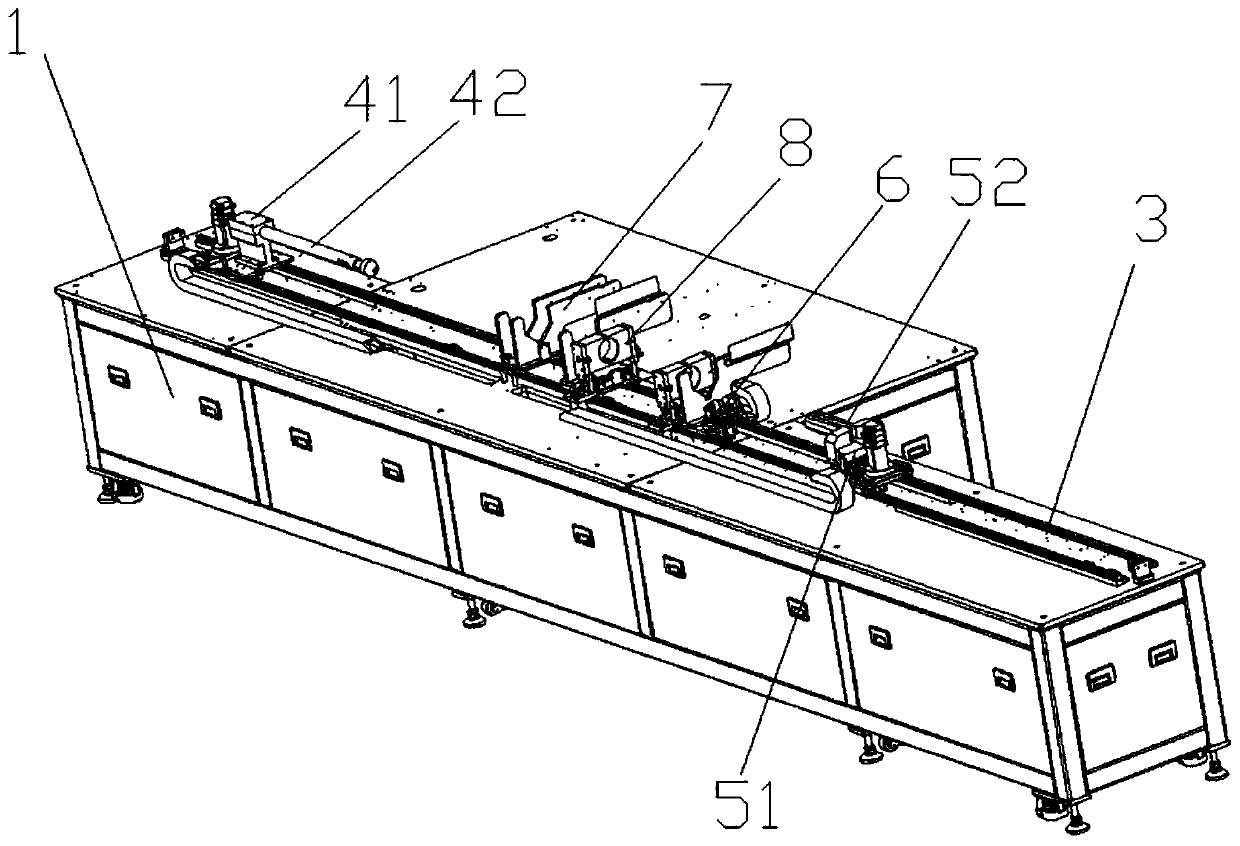

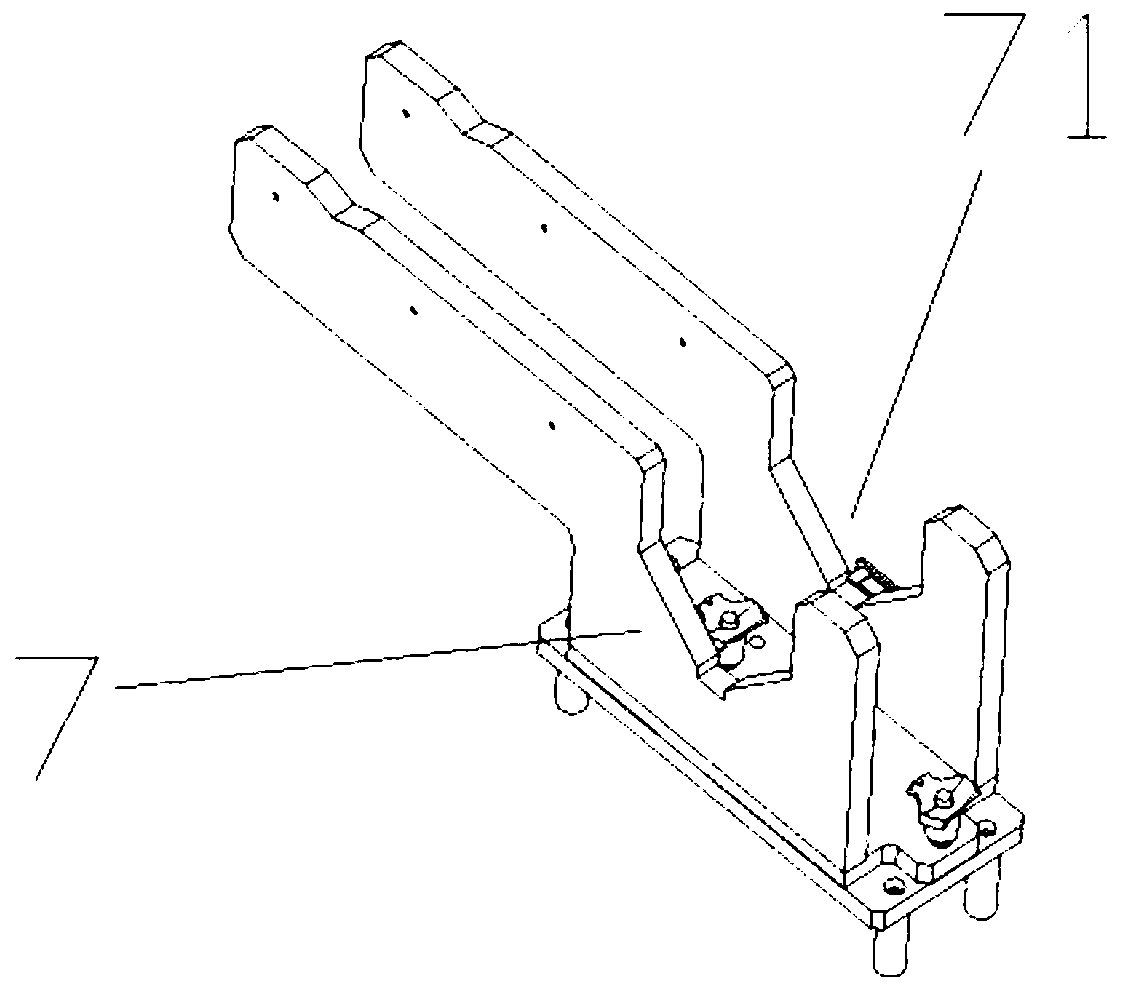

Automatic sleeving device for heat shrinkable sleeve

The invention discloses an automatic sleeving device for a heat shrinkable sleeve. The automatic sleeving device comprises a transferring mechanical arm, a machine body, a double rails and pipes whichare laid on the machine body; a positioning device, a sleeve device and a feeding device are sequentially arranged on the double rails at intervals, the positioning device and the feeding device areboth in sliding connection with the double rails, a heat shrinkable sleeve is arranged on the sleeve device, a pipe clamp component is arranged on the feeding device, a positioning ejector pin is arranged on the positioning device, the positioning ejector pin, the heat shrinkable sleeve and the pipe clamp component are positioned on the same horizontal line, the transferring mechanical arm is usedfor placing the pipes on the pipe clamp component of the feeding device, the feeding device and the positioning device move linearly towards the sleeve device at the same time, the positioning ejector pin is matched with the feeding device, the heat-shrinkable sleeve is arranged on the pipes in a sleeved mode, the feeding device and the positioning device are reset to an initial position, the transferring mechanical arm is used for taking away the pipes which are arranged in a sleeved mode, and automatic sleeving of the pipes is completed. According to the automatic sleeving device for the heat shrinkable sleeve, the traditional manual operation is avoided by automatically sleeving the heat-shrinkable sleeve, so that the automatic production of the product on line is facilitated.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Single crystalline silicon solar cell piece surface texture solution containing pomegranate bark extract and preparation method thereof

InactiveCN106012029AGood processing qualityGood process quality and stabilityAfter-treatment detailsFinal product manufacturePolyphenolSodium hydroxide

The invention discloses a single crystalline silicon solar cell piece surface texture solution containing a pomegranate bark extract. The single crystalline silicon solar cell piece surface texture solution is prepared from, by weight, 0.1-0.2 part of xylitol, 1.5-2.5 parts of styrene, 1-2 parts of a 5-10% ammonium persulfate solution, 3-5 parts of pomegranate bark powder, 0.1-0.15 part of cocoanut fatty acid diethanolamide, 0.1-0.2 part of sodium lauryl sulfate, 0.1-0.15 part of dodecafluoroheptyl-propyl-trimethoxysilane, 3-5 parts of sodium hydroxide, 0.3-0.5 part of citric acid, 0.05-0.1 part of tea polyphenol and 100-120 parts of water. The silicon slice texture solution is high in reaction speed, moderate in corrosion, small in thickness reduction and high in repeated utilization factor, the obtained texture pyramid is uniform in size, granules are small, the repeatability is good, and the single crystalline silicon solar cell piece surface texture solution is good in technological processing quality stability, high repeatability, low in cost and environmentally friendly.

Owner:CHINALAND SOLAR ENERGY

Deep hole machining boring bar

PendingCN114850518AGood processing qualityImprove processing efficiencyBoring barsDeep holeIndustrial engineering

The invention provides a deep hole machining boring bar which comprises a cylinder, a boring cutter mechanism is movably arranged on the cylinder, the boring cutter mechanism comprises a sliding sleeve and a turning tool, the sliding sleeve is movably arranged on the cylinder in a sleeving mode and slides in the length direction of the cylinder, and the turning tool is arranged on the sliding sleeve; the boring cutter mechanism further comprises a lead screw rotationally arranged in the cylinder in the length direction of the cylinder, the central axis of the lead screw coincides with the central axis of the cylinder, the lead screw rotates with the central axis of the cylinder as the center, the lead screw is sleeved with a threaded sleeve in a threaded mode, and a sliding groove is formed in the cylinder in the length direction of the cylinder in a penetrating mode. The threaded sleeve is connected with the sliding sleeve through a connecting plate, and the connecting plate slides in the sliding groove. The cylinder rotates to drive the sliding sleeve and the lead screw to rotate, and the sliding sleeve can be driven to slide in the length direction of the cylinder, so that the turning tool arranged on the sliding sleeve can be attached to the inner side wall of the cylinder arranged outside the cylinder in a sleeving mode to conduct rotary boring and can also conduct movable boring in the length direction of the cylinder, the machining quality is good, and the machining efficiency is high.

Owner:郑州凯博焊割设备有限公司

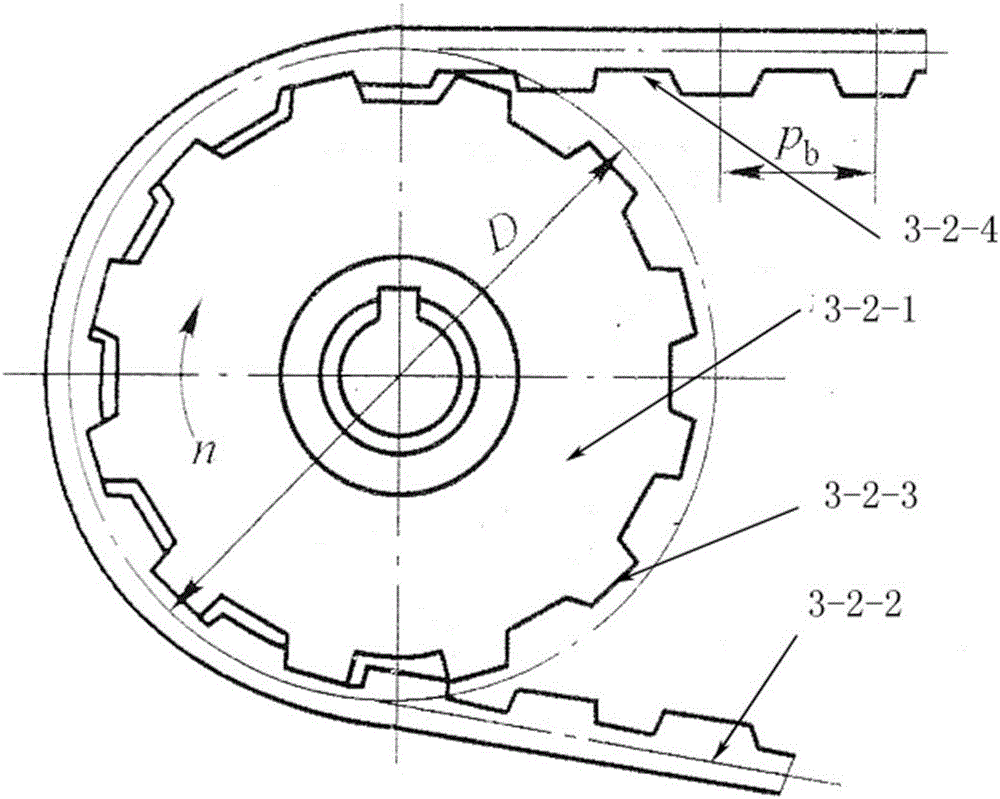

Dual-conical-surface supporting rotary tool device

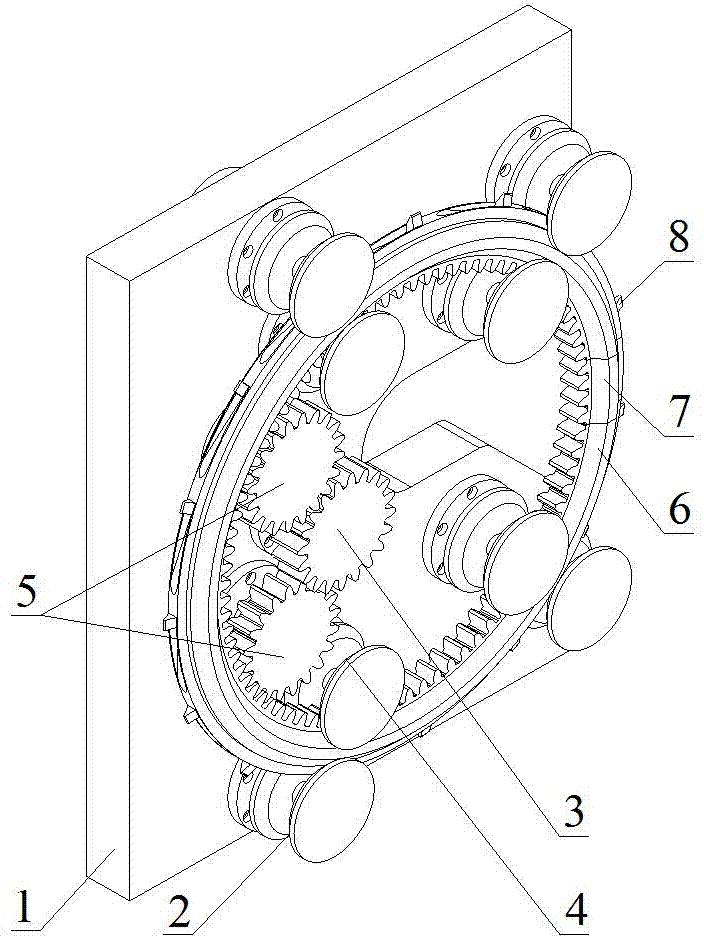

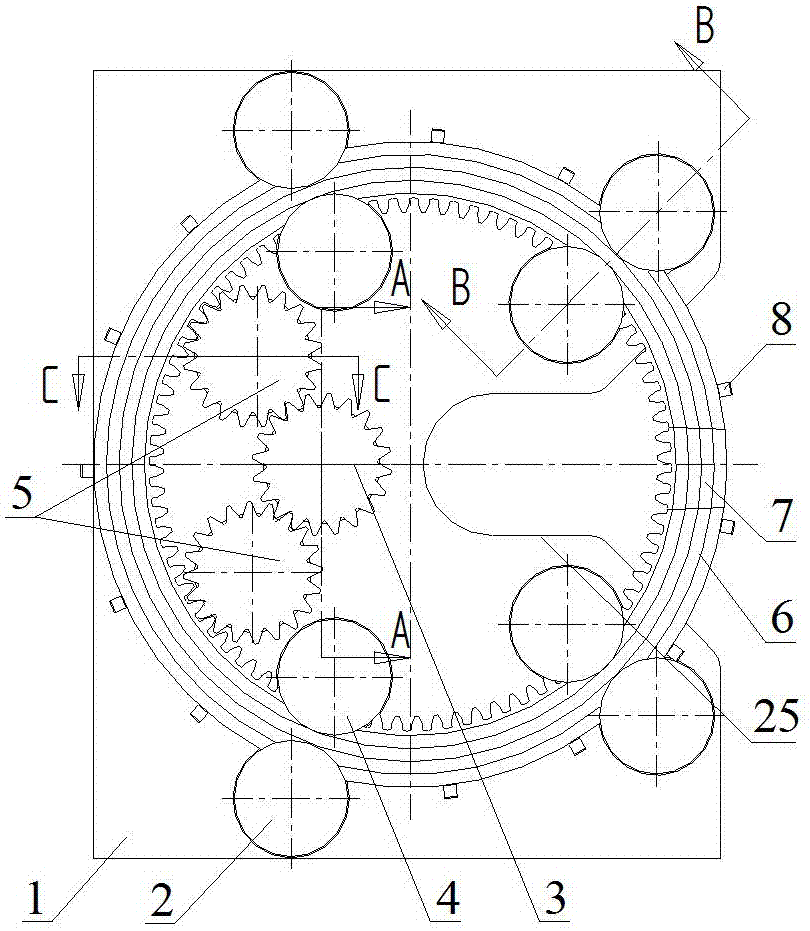

ActiveCN106903378AGood processing qualityIncreased processing speedToothed gearingsGear-cutting machinesThe chokesWheel and axle

The invention relates to a dual-conical-surface supporting rotary tool device. The dual-conical-surface supporting rotary tool device comprises a bracket, outer rotary supporting wheel shafts, a rotary drive gear shaft, inner rotary supporting wheel shafts, idle gear shafts, an inner gear rack, a choke plug, a tool head and the like, wherein the outer rotary supporting wheel shafts and the inner rotary supporting wheel shafts appear in pairs, and number of the outer rotary supporting wheel shafts or the inner rotary supporting wheel shafts is greater than or equal to 3; the inner gear rack and the choke plug are fixedly assembled together, and the inner gear rack and the choke plug have a superposed rotary center line; the inner gear rack is supported on roller paths of the outer rotary supporting wheel shafts and the inner rotary supporting wheel shafts; a gear on the rotary drive gear shaft is engaged with gears on the two idle wheel shafts; the gears on the two idle gear shafts are engaged with an inner gear on the inner gear rack; and the tool head is fixedly mounted on the inner gear rack. With the adoption of the dual-conical-surface supporting rotary tool device, a rotary tool obtains relatively high processing linear speed with relatively low rotation speed, breaks through the limit that a part must adopt a tool of the same size or a smaller size to process as a result of the small-size geometrical characteristic, and obtains better processing quality and a longer tool service life.

Owner:SHANDONG UNIV OF TECH

Shifting fork bush plate material slicing die

The invention discloses a shifting fork bush plate material slicing die. The die comprises a lower punching die and an upper punching die, wherein the lower punching die comprises a lower lining plate, a blanking female die and a positioning block, and the upper punching die comprises an upper lining plate, a blanking male die and a reset plate. According to the die, the problem that the plate material of the shifting fork bush is not provided with a special slicing die so that integral slicing machining can not be carried out is solved, through the corresponding arrangement of the blanking female die and the blanking male die, the shifting fork bush plate material can be fixed and positioned during punching, hole punching positioning is accurate, the machining quality is good, the machining procedures are reduced by adopting one-time integral stamping, loading and unloading are convenient, and the machining efficiency is improved.

Owner:江西赣东北轴瓦有限责任公司

Rewinding machine for underwear spinning

The invention discloses a rewinding machine for underwear spinning. The rewinding machine comprises a machine table, small-sized power motors, small-sized power motor fixing devices, motor gears, transmission belts, a power gear, finished product wire barrels, telescopic springs, a protruding supporting rod, barrel pipe fixing rods, small circular rings, small pulleys and automatic sensors; the small-sized power motors are arranged in the inner cavity of the machine table, the outer walls of the barrel pipe fixing rods are provided with the wire barrels, and the lower part of the front surfaceof the outer wall of the machine table is provided with the small circular rings, so that the wire can flow according to the fixed route, and therefore it is guaranteed that wires are not disordered;the small pulleys are arranged on the upper part of the front surface of the outer wall of the machine table, so that yarns can be kept at a constant line speed all the time, the constant tension andthe fixed length are constant, and the processing quality is good; and the automatic sensors are installed on the right side of the finished product wire barrels, so that the length of each bobbin winding wire can be well strictly kept consistent, and the trouble that the length of the winding wire of each pipe is not more than one for the follow-up work is avoided.

Owner:张锦

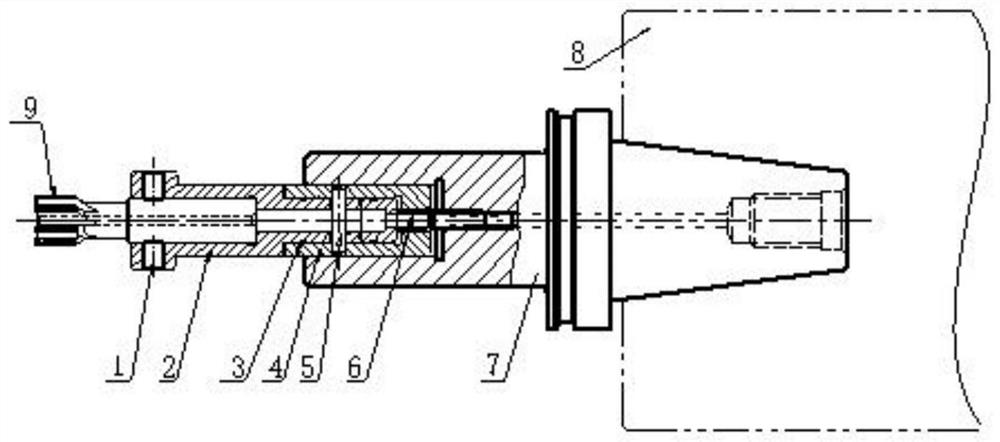

Floating cutter handle for reaming and using method of floating cutter handle

The floating cutter handle for reaming comprises a floating device and a cutter handle, the floating cutter handle comprises a cutter connecting sleeve, a cutter handle connecting sleeve and a connecting pin, the right portion of the cutter handle connecting sleeve is installed on the left portion of the cutter handle and rotates synchronously with a handle, and the left portion of the cutter handle connecting sleeve is further provided with an axial connecting hole; the right portion of the cutter connecting sleeve is assembled in the connecting hole in a clearance fit mode and connected with the clamping position through a connecting pin arranged in the radial direction, so that the cutter handle connecting sleeve and the cutter connecting sleeve rotate synchronously. The connecting pin is in clearance fit with the cutter connecting sleeve and is in interference fit with the cutter handle connecting sleeve; a gap is formed between the right end of the cutter connecting sleeve and the bottom of the connecting hole, and an axial mounting hole connected with a reamer is formed in the left end of the cutter connecting sleeve. The reamer has the advantages of simple structure, accurate processing, prolonged service life and the like.

Owner:GUANGXI YUCHAI MASCH CO LTD

Worm wheel polishing machine and polishing system

ActiveCN111546212AGood processing qualityImprove work efficiencyGrinding carriagesPolishing machinesPolishingEngineering

The invention relates to a worm wheel polishing machine and a polishing system. The worm wheel polishing machine comprises a workbench and a polishing device arranged on the workbench, wherein turntables, a feeding mechanism, electromagnetic discs and a discharging mechanism are arranged on the workbench; and the turntables are driven by a driving mechanism arranged on the workbench to lift or rotate, so that workpieces and the turntables are sequentially adsorbed on the electromagnetic discs. The polishing system comprises the plurality of worm wheel polishing machines arranged in a line, a circulating conveyor and a plurality of material frames, wherein the workpieces on the uppermost layers of the material frames sequentially pass through the feeding points of the worm wheel polishing machines and then sequentially passes through the discharging points of the worm wheel polishing machines. According to the worm wheel polishing machine, the machining and feeding and discharging operations of the workpieces are controlled mechanically, and good machining quality is guaranteed while automatic and continuous polishing is considered; and in addition, the polishing system eliminates the defects of an original single-machine manual auxiliary mode, and it is beneficial to improving the working efficiency of the polishing system.

Owner:浙江臻鑫智能传动科技有限公司

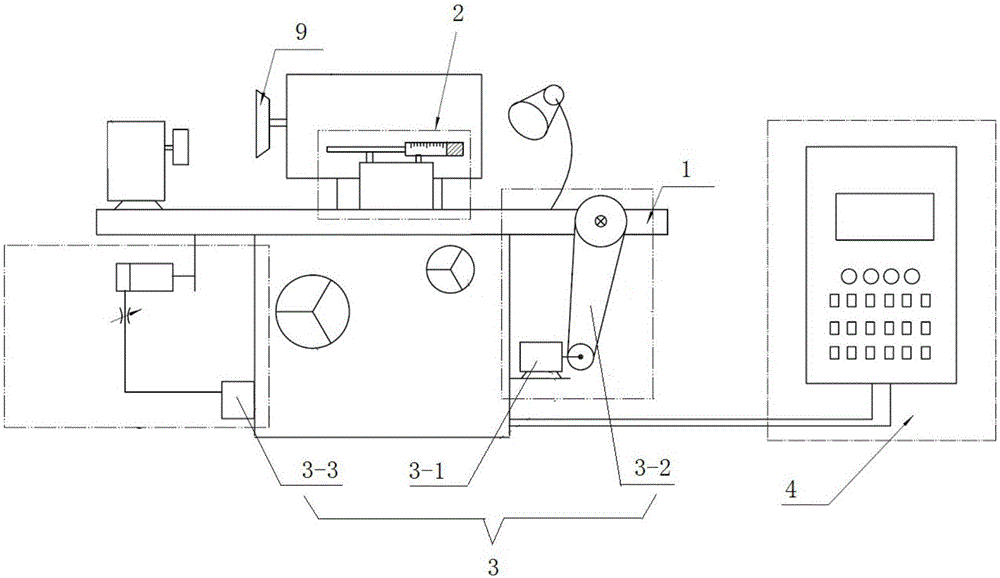

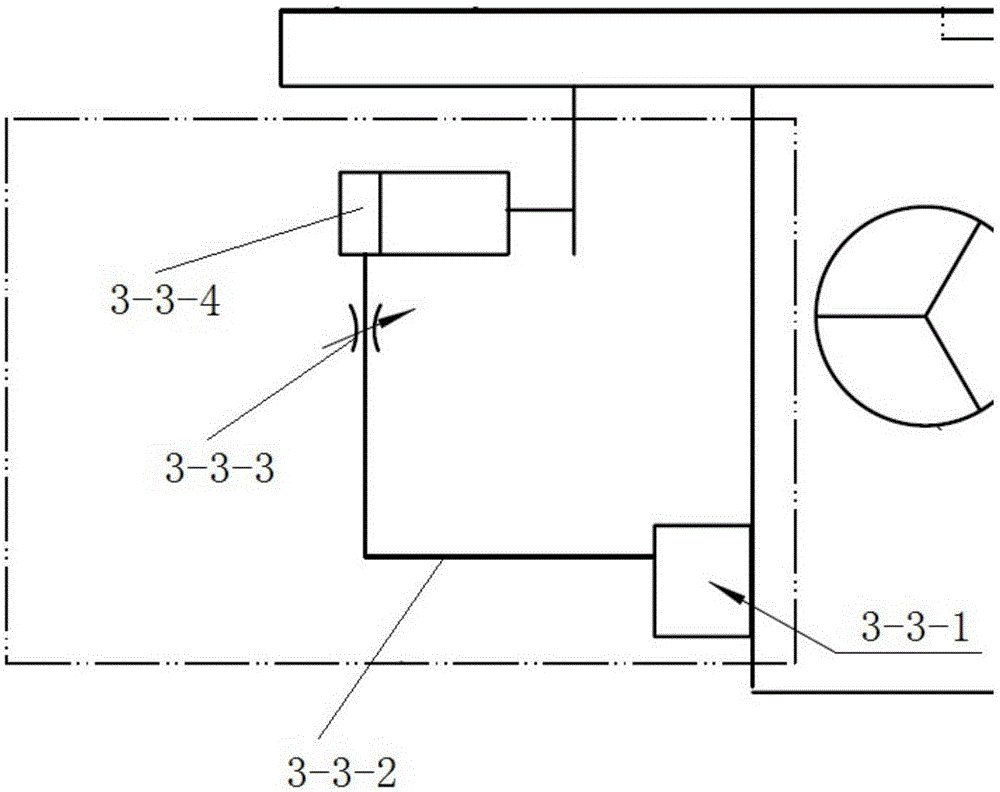

Constant-force grinding system integrating detection with grinding

ActiveCN106078515AExpand the grinding rangeGood processing qualityGrinding drivesGrinding feed controlThrough transmissionConstant torque

The invention discloses a constant-force grinding system integrating detection with grinding. The constant-force grinding system is characterized by comprising a working table, as well as an on-line detecting system, a constant-force grinding system and a controller mounted on the working table; the controller controls operation of the constant-force grinding system according to the information fed back by the on-line detecting system; the constant-force grinding system comprises a servo motor, a synchronous transmission mechanism and a working table return device; the servo motor serves as a constant-torque servo motor; the constant-torque servo motor is converted into the constant feed force of the working table through transmission of the synchronous transmission mechanism; and the working table return device is used for realizing returning of horizontal operation of the working table. Aiming at a machine tool transmission chain deformation phenomenon caused by unstable grinding feed force during ground finish and the constant-displacement forceful feeding mode adopted in numerically controlled grinder design, the design concept of constant-force grinding is adopted, and the grinding feed force is set into a constant quantity from an unstable variable, so that deformation of a machine tool transmission chain is in a stale state.

Owner:FOSHAN POLYTECHNIC

Outer knife groove cutting machine of vibrissa trimmer

ActiveCN114453634AIncrease productivityGood processing qualityFeeding apparatusMilling equipment detailsNasal hairStructural engineering

The invention discloses an outer cutter groove cutting machine of a vibrissa trimmer, which comprises a rack, a numerical control dividing head, a pneumatic clamp, a cutter, a cutter rotating mechanism, a feeding mechanism and a control circuit, and is characterized in that the control circuit comprises a controller, and the pneumatic clamp is arranged on the numerical control dividing head; the control end of the pneumatic clamp, the control end of the numerical control dividing head and the control end of the feeding mechanism are respectively connected with the controller. The outer cutter workpiece of the nose hair trimmer is clamped by the pneumatic clamp controlled by the controller, indexing of the outer cutter workpiece and feeding of the cutter are controlled by the controller in the groove cutting process, the production efficiency is high, and the machining quality is good.

Owner:深圳市弗莱博自动化设备有限公司

Rotary pairing spot welding equipment

InactiveCN109967849AImprove installation accuracyGood processing qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to rotary pairing spot welding equipment. The rotary pairing spot welding equipment comprises a workbench, a driving device, a bottom plate cushion block, a head double-hole positioning shaft, a straight lug plate positioning shaft, a bent lug plate positioning shaft, a sector piece positioning shaft and a side jacking device; a mounting frame is arranged on each of the leftside and the right side of the workbench; the driving device is mounted on one of the mounting frames; an output shaft of the driving device is connected to one side of the workbench; the other mounting frame is connected with the workbench through a rotating shaft; and the bottom plate cushion block, the head double-hole positioning shaft, the straight lug plate positioning shaft, the bent lug plate positioning shaft, the sector piece positioning shaft and the side jacking device are all mounted on the upper surface of the workbench. The rotary pairing spot welding equipment is novel in conception, reasonable in structure, high in matching degree with workpieces, good in fastening effect and high in practicability, and has the advantages of being capable of quickly and accurately clamping, positioning and pairing the workpieces, improving the machining precision and the machining quality, increasing the production speed and the like.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

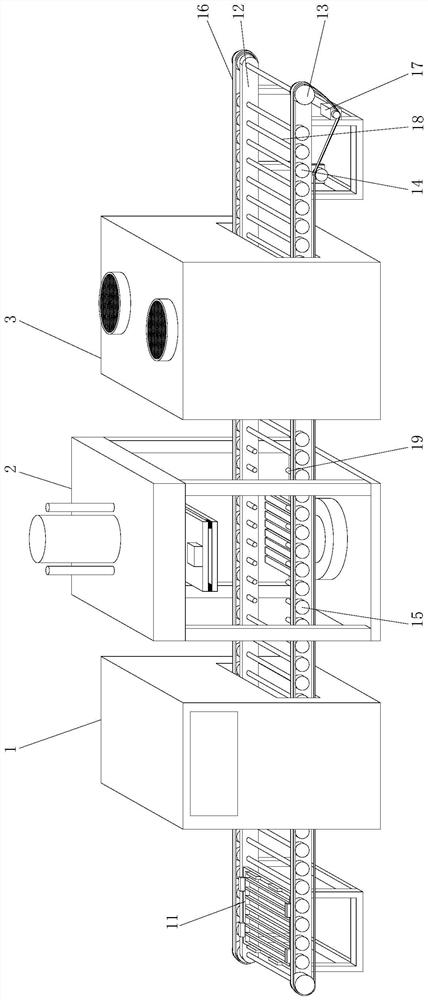

Processing production system for elevator composite counterweight filler

PendingCN114393687AGood processing qualityGood processing effectCeramic shaping plantsFeeding arrangmentsStructural engineeringManufacturing engineering

The invention provides a processing production system for elevator composite counterweight blocks, and relates to the technical field of counterweight block processing, the processing production system comprises a conveying part, a filling bin, a compaction frame and a drying bin, the conveying part passes through the filling bin, the compaction frame and the drying bin, and the filling bin, the compaction frame and the drying bin are internally provided with a filling assembly, a compaction assembly and a drying assembly respectively; the material filling assembly comprises guide rails, a sliding sleeve and an aggregate hopper, the two guide rails are arranged, and the two guide rails are arranged at the two ends of the upper portion of the interior of the material filling bin correspondingly; the counterweight block frame is placed through the tray frame, the tray frame is conveyed through the conveying part, the counterweight block frame is filled with aggregate through the filling assembly, the filled aggregate is compacted through the compacting assembly, in the filling process, the counterweight block frame moves rightwards along with the conveying part, and the aggregate hopper moves forwards and backwards on the guide rail through the sliding sleeve; and the discharging pipe is used for discharging, so that the aggregate can be conveniently filled into the counterweight block frame body in a snakelike manner and is more uniform.

Owner:湖北灿凯科技有限公司

Special clamp for milling head of numerically controlled machine tool

The invention discloses a special clamp for a milling head of a numerically controlled machine tool. The clamp comprises the milling head. A cylindrical hole is excavated in the milling head along the axial direction, a hydraulic oil cylinder is mounted in the bottom of the cylindrical hole, a cooling jacket sleeves the peripheral wall of the hydraulic oil cylinder, a round baffle plate is mounted on the top of the hydraulic oil cylinder, piston rods are mounted on two ends of the hydraulic oil cylinder, square holes and oil holes are formed between the upper outer wall of the milling head and the side wall of the cylindrical hole, the square holes communicate with the oil holes, rectangular blocks are inserted into the square holes, one ends of the rectangular blocks are fixedly connected to fixing clips, an oil body in the hydraulic oil cylinder is kept in a cooled state all the way by means of the cooling jacket, the hydraulic oil cylinder is not affected by dust and workpiece chippings by means of the round baffle plate, the hydraulic oil cylinder keeps a good working state all the way, the hydraulic oil cylinder pushes the pistons at two ends to squeeze hydraulic oil to push the clamp to tightly clamp a milling cutter by means of a liquid pressure of the hydraulic oil, and the clamping vigor of the milling cutter clamp is ensured by joint squeezing of the two piston rods, and the machining quality is better.

Owner:河南赫斯特威自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com