Floating cutter handle for reaming and using method of floating cutter handle

A tool handle and reaming technology, which is applied in the direction of reamers, reaming devices, metal processing equipment, etc., can solve the problems of large radial runout of reamers, low life of reamers, poor surface quality, etc., and achieve stable production efficiency, The effect of good processing quality and low tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0034] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

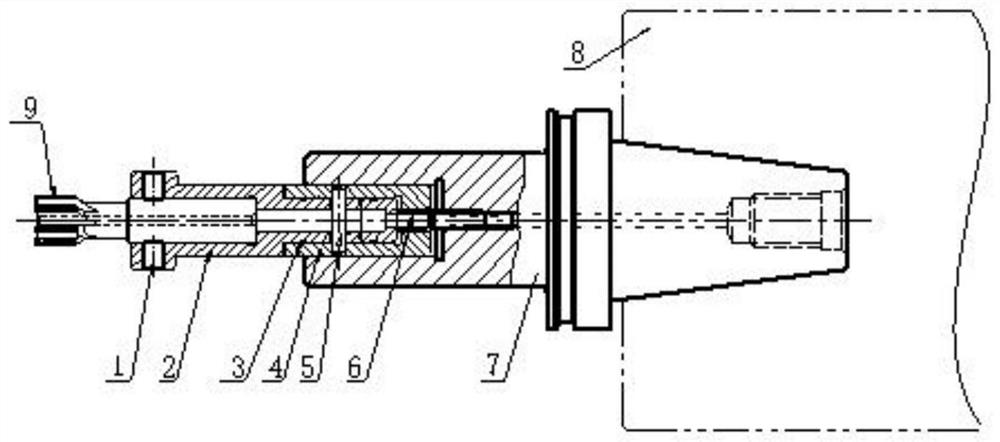

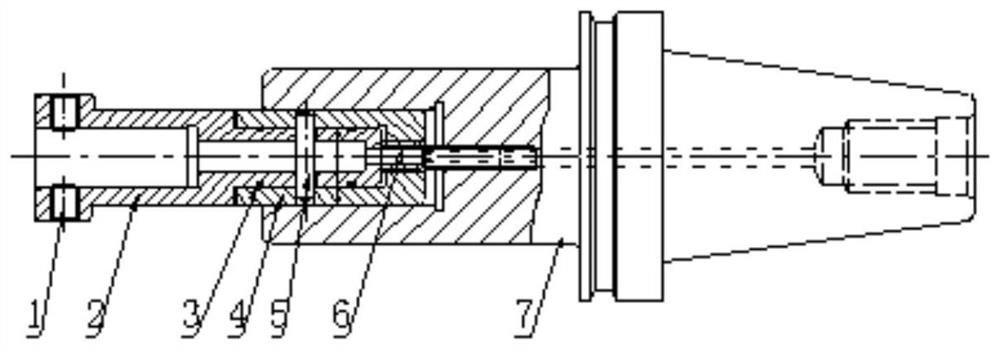

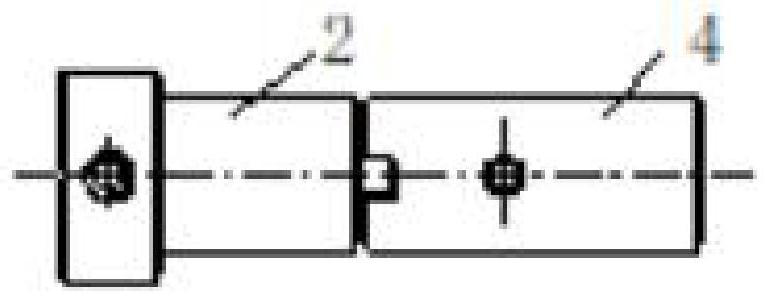

[0035] Such as figure 1 A floating tool holder for reaming shown in ~ includes a floating device and a tool handle 7. The tool handle 7 is a conventional standard tool holder, which can generally be a hydraulic tool holder, a side-fixed tool holder, a shrink-fit tool holder, etc. , the floating device is installed on the left part of the handle 7 and rotates synchronously with the handle 7. The floating device includes a tool socket 2, a handle socket 4, and a connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com