Automatic sleeving device for heat shrinkable sleeve

A heat-shrinkable sleeve and automatic fitting technology, applied in the field of heat-shrinkable sleeve processing, can solve the problems of unguaranteed processing quality, unstable sleeve position, and dependence on processing quality, etc., to achieve continuous batch processing and ensure stable quality Sexuality and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

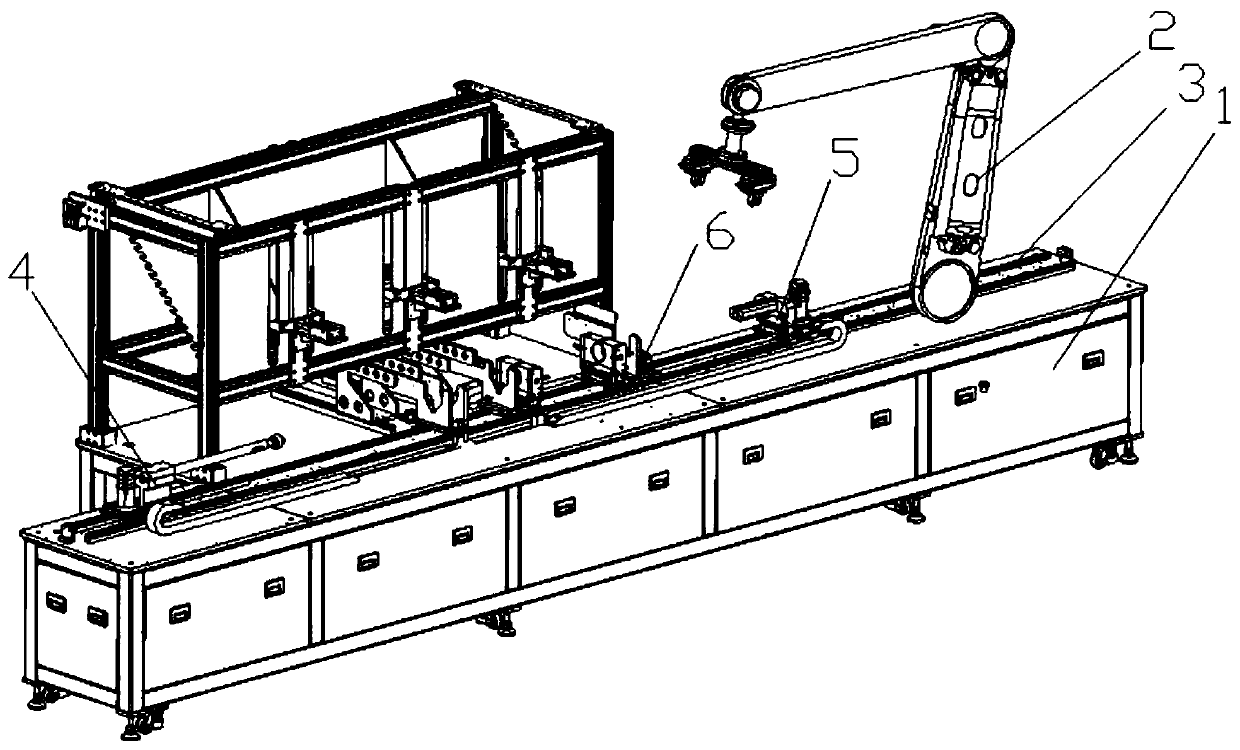

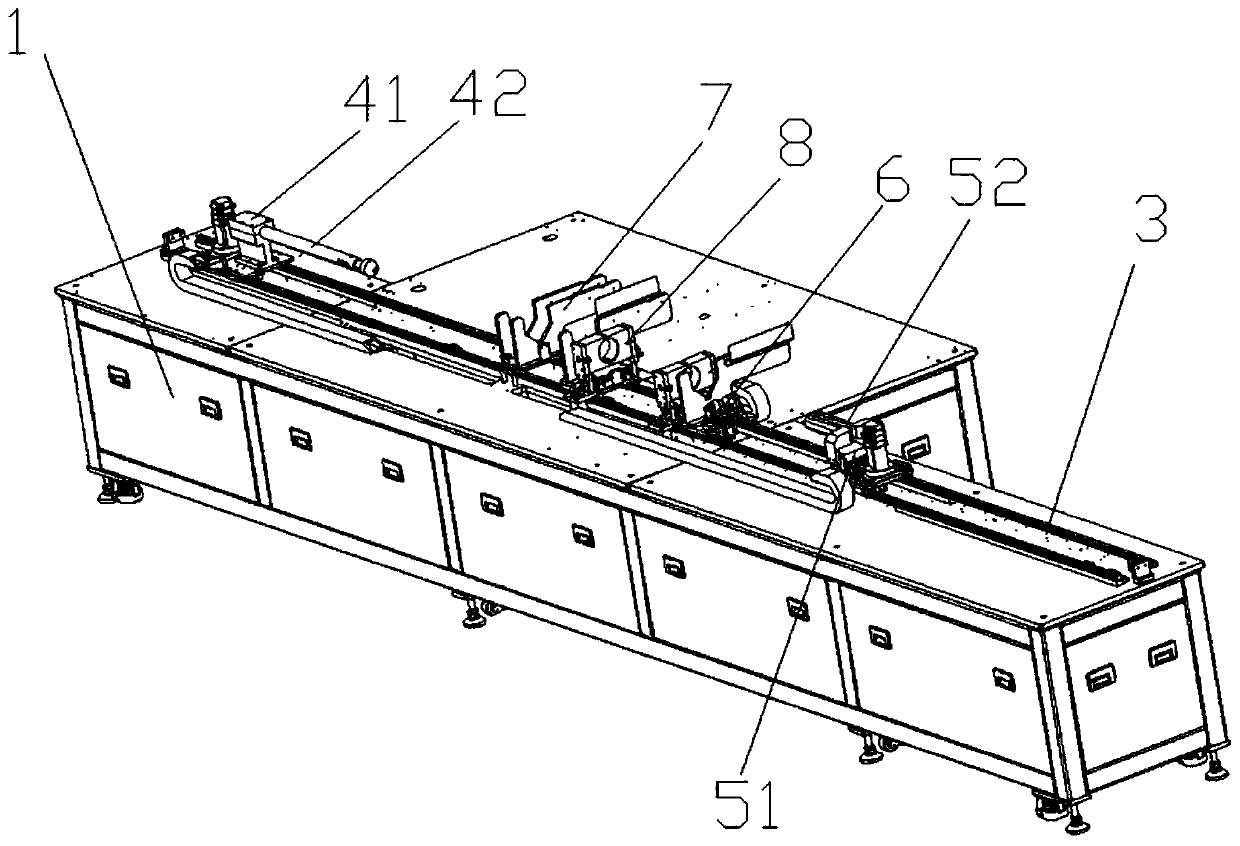

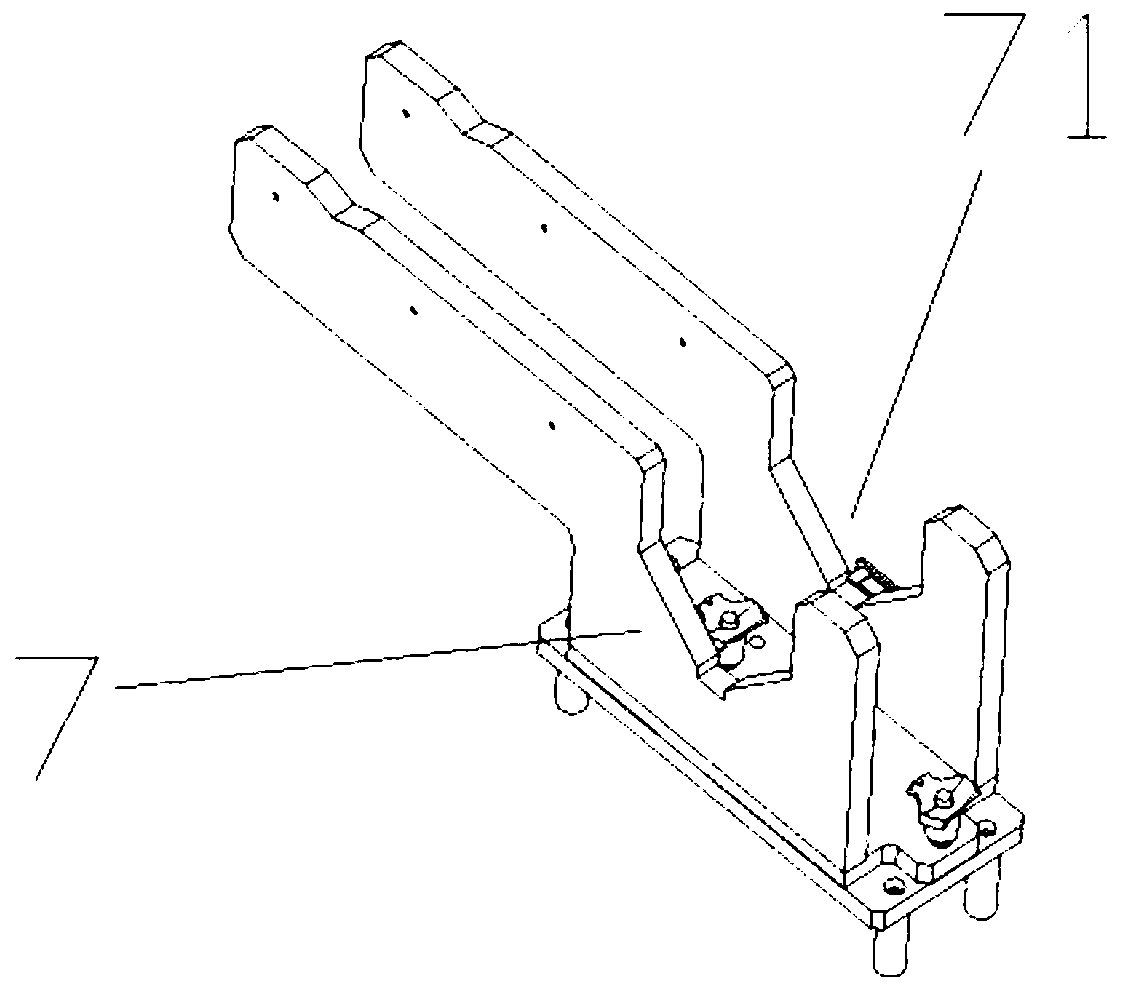

[0022] Example: Control Figure 1~5

[0023] An automatic fitting device for heat-shrinkable sleeves, comprising a transfer manipulator 2, a body 1, straight double rails 3 laid on the upper surface of the body 1, and pipes; starting from left to right, the double rails 3 are sequentially provided with positioning Device 4, a casing device and a feeding device 5 for placing the heat-shrinkable sleeve.

[0024] The transfer manipulator 2 is used to place the pipe to be sleeved on the feeding device 5, and is subsequently used to transfer the sleeved product to the heating furnace for heating. It is a prior art product. The feeding device 5 is used to place the pipe to be sleeved, and then push the pipe to be sleeved into the casing device to complete the sleeve with the heat-shrinkable sleeve, and set the heat-shrinkable sleeve on the outside of the pipe. The positioning device 4 is used to penetrate into the heat-shrinkable sleeve, so as to facilitate the top contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com