Electronic expansion valve small shaft and cover plate and forming method

An electronic expansion valve and molding method technology, applied in valve device, refrigeration and liquefaction, lighting and heating equipment and other directions, can solve the problem of the connection between the small shaft and the cover plate being difficult to ensure verticality, etc., and achieve strong connection strength and good processing. Quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

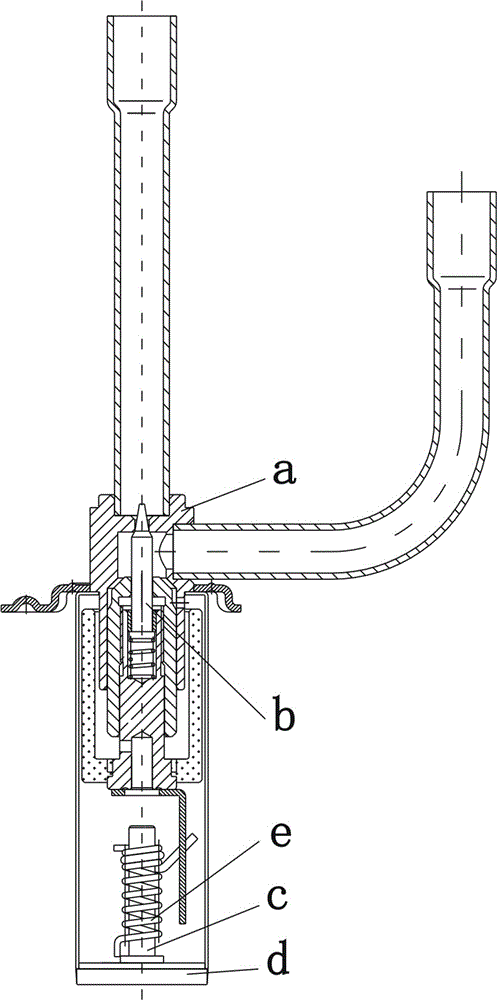

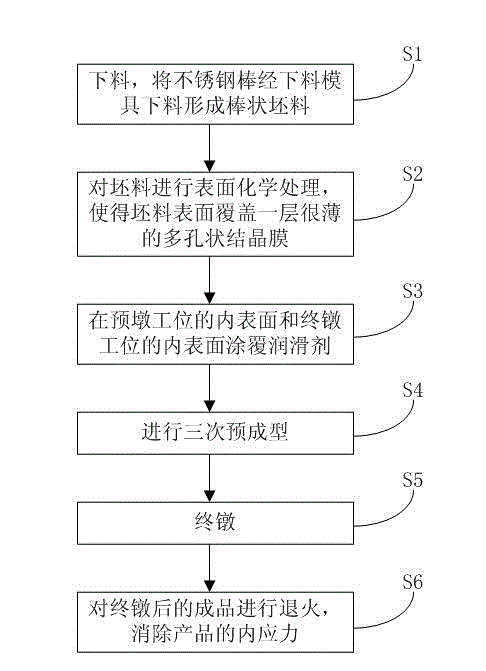

[0024] Such as figure 2 As shown, the forming method of the small shaft and the cover plate of the electronic expansion valve provided in this embodiment is integrated forming by cold heading, and the specific forming process includes:

[0025] Step S1, blanking, blanking the stainless steel rod through a blanking mold to form a rod-shaped blank.

[0026] Step S2, performing surface chemical treatment on the blank, so that the surface of the blank is covered with a thin layer of porous crystal film. In this embodiment, the surface of the billet is treated with phosphate, that is, after phosphating treatment. The crystalline film can be deformed together with the blank, but will not peel off from the blank.

[0027] Step S3, coating the lubricant on the inner surface of the pre-heading station and the inner surface of the final heading station. Commonly used lubricants are liquid and solid, which can be used alone or in combination. Liquid lubricants include animal oil, ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com