Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Reduce production labor costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

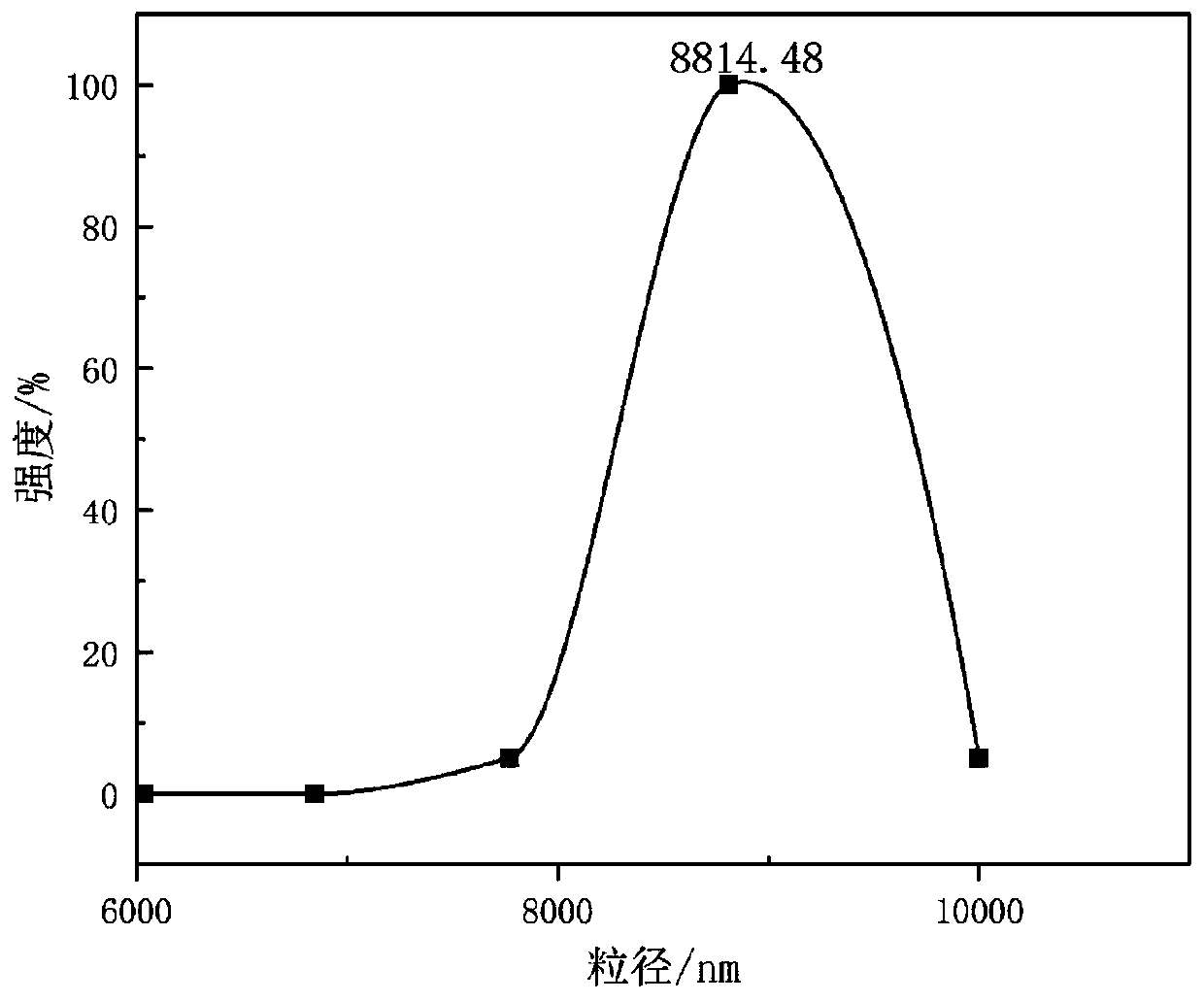

Preparation method of continuous high quality soldering powder

The invention discloses a method for preparing alloy powder, more particularly relates to a method for continuously preparing high-quality tin alloy welding powder. The invention is characterized in that an atomizing chamber is vacuumed, then inert protection gas is filled into the atomizing chamber; the tin alloy material is melted in a melting furnace, and then is controlled to be atomized in the atomizing chamber; after being cooled, the tin alloy material is solidified into tin alloy powder grain; by the sieving of the equipment, the needed product is obtained; products not meeting the requirements is melted and prepared again. The invention has the advantage that the quality of tin alloy powder is greatly improved by optimizing producing condition; the surface chemical property is improved; the productive labor cost can be greatly lowered; high priority is given to environmental protection in the process of realizing a circular production process. Products prepared by the method can be widely applied to encapsulation and circuit board welding material in electronic industry.

Owner:HUIJIN ATOMIZING SCI

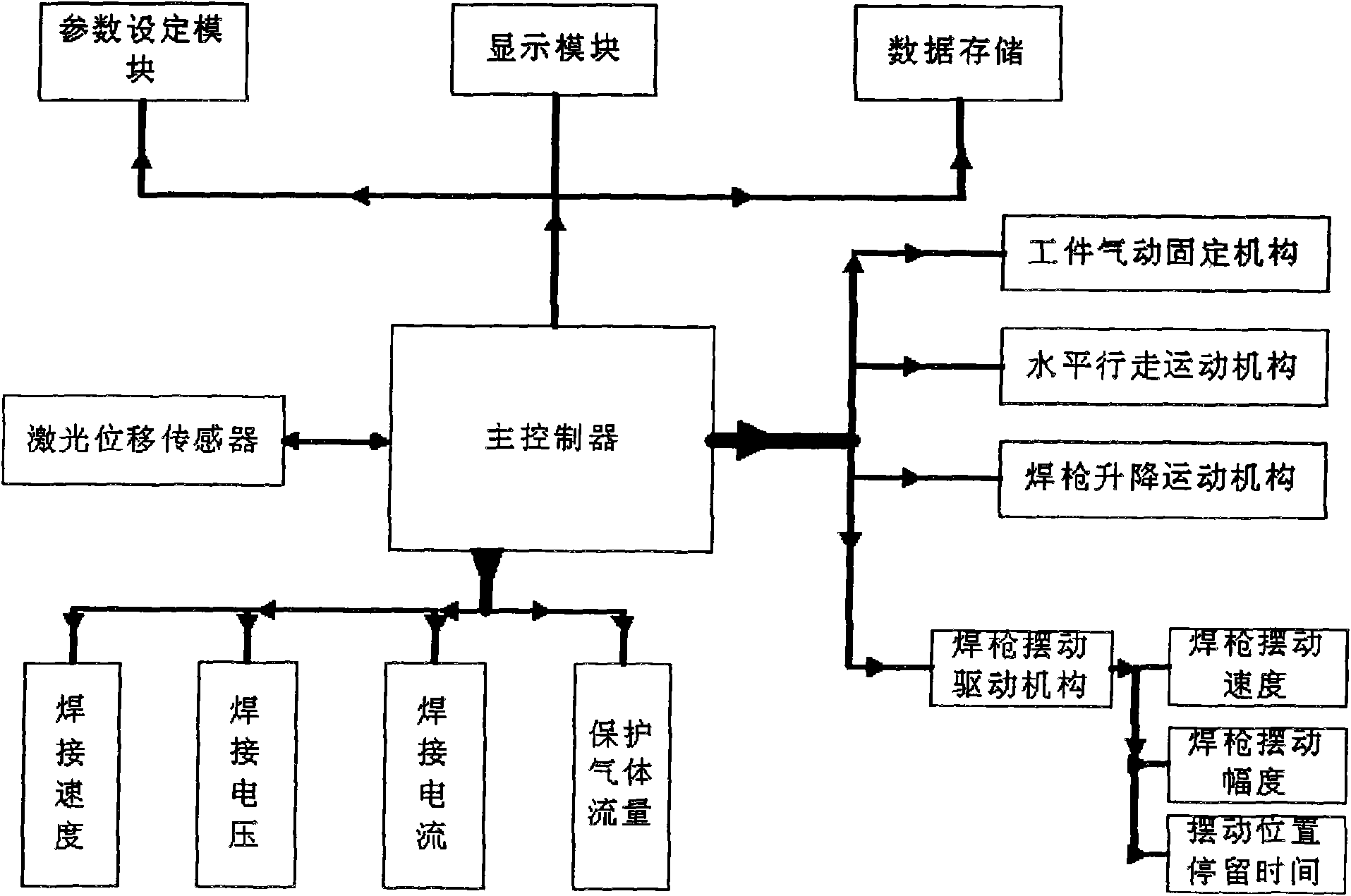

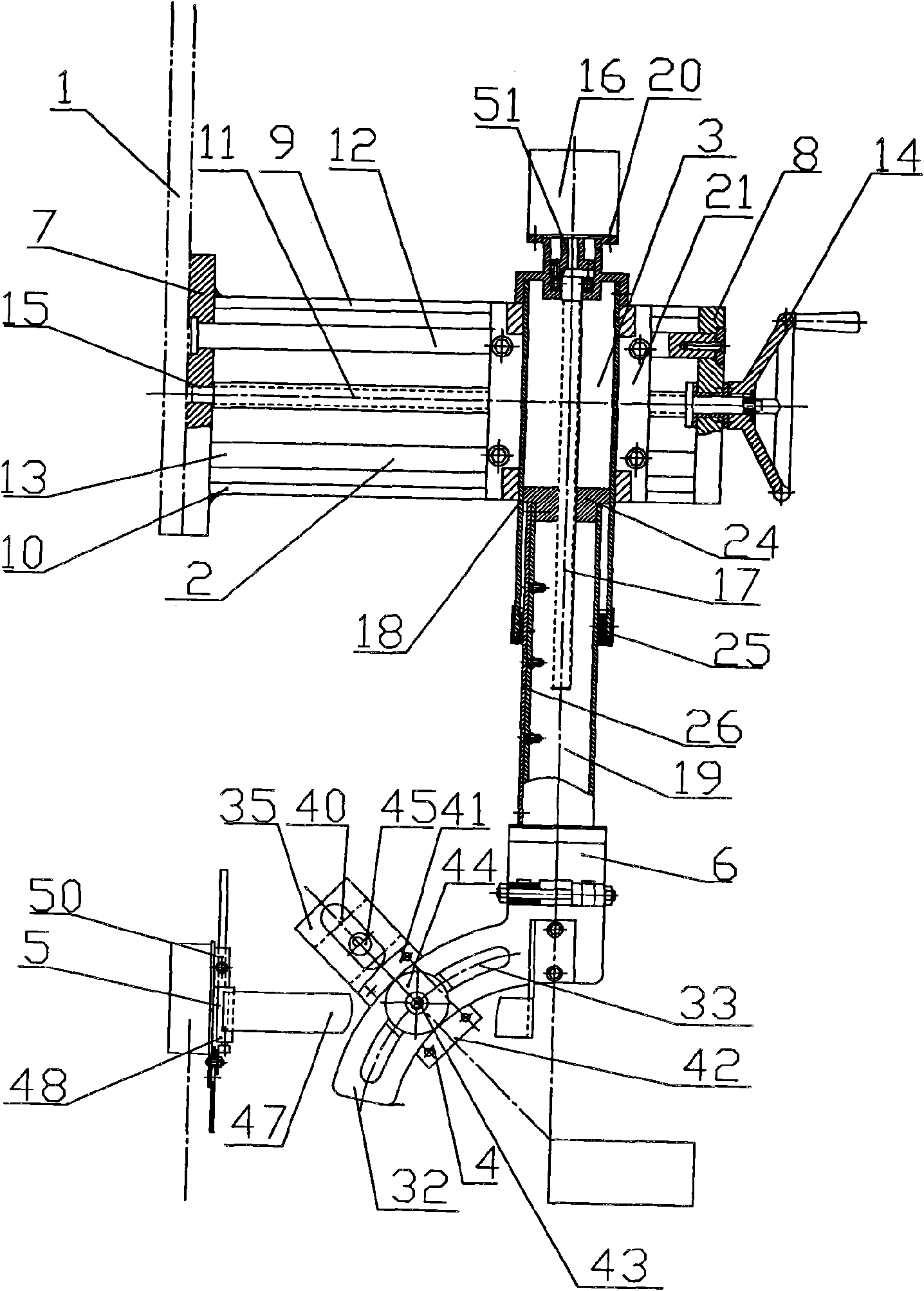

Detection and control system for container corrugated plate welding track based on laser ranging

InactiveCN101554672ARealize detectionImprove quality and efficiencyComputer controlArc welding apparatusLaser rangingAutomatic control

The invention relates to a detection and control system for a container corrugated plate welding track based on laser ranging, comprising a laser displacement sensor, a welding torch pose adjusting device and a circuit control device. The laser displacement sensor and the welding torch pose adjusting device are connected with the circuit control device through a circuit; one end of a welding torch space position and pose adjusting mechanism is fixed on a stand; and the laser displacement sensor is arranged at the lower end of the welding torch space position and pose adjusting mechanism. Through the diction of the corrugated plate welding line, the control of the welding torch pose and the automatic control of the welding process, the invention achieves the effect that the thickness of welding lines of a downslope welding section from a wave crest to a wave trough, a upslope welding section from a wave trough to a wave crest, a wave crest tangential path and a wave trough are consistent, remarkably improves the uniformity of welding lines of each welding section, greatly reduces the labor intensity of workers, reduces the manual expense of production and is fast and convenient to adjust parameters. The welding speed is more than three times of general manual welding or profile modeling welding, and automatic control is available in the whole process.

Owner:SHANDONG UNIV

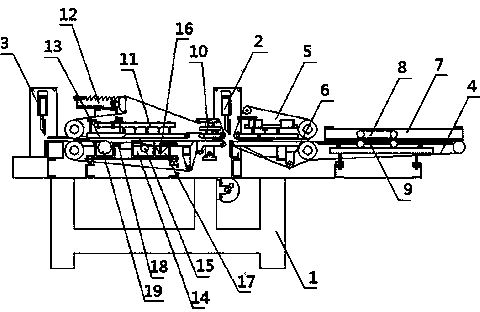

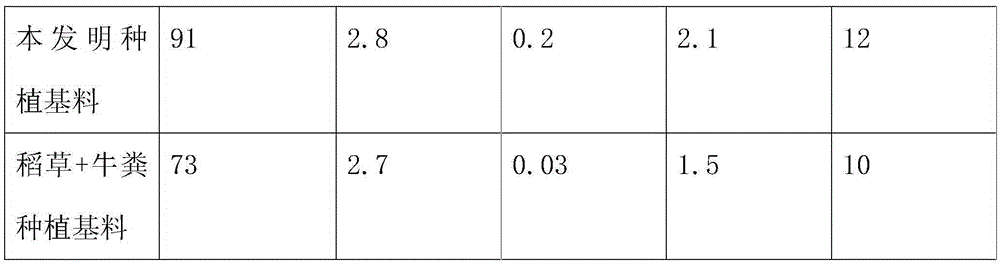

Medium plate splicing machine

ActiveCN103846985AFully automatedRealize fully automatic controlOther plywood/veneer working apparatusWood veneer joiningEngineeringMechanical engineering

The invention discloses a medium plate splicing machine. The medium plate splicing machine comprises a front rack, a feeding belt, a correction mechanism, an edge trimming cutter, a sawdust removing, material receiving and conveying mechanism, a sol tank, a finished product cutting mechanism, a transmission mechanism, a pneumatic mechanism, a coil table, a splicing mechanism and a plate collection device, wherein the splicing mechanism is arranged at a middle-to-rear position of the front rack, a feeding mechanism is arranged at the front end of the front rack, the edge trimming cutter is arranged at the tail end of the feeding mechanism, the correction mechanism is arranged on a conveying rack on one side of the feeding mechanism, and a line adding mechanism, a plate splicing mechanism and the finished product cutting mechanism are sequentially arranged at the middle-to-rear end of the front rack; the plate collection device comprises a rear rack, a lifting mechanism, a plate feeding mechanism, a plate collection device conveying mechanism, a plate receiving mechanism and a plate pressing mechanism. The medium plate splicing machine has the advantages that the design is reasonable, the medium plate splicing machine is integrated with functions of edge cutting, butting, line adding and plate collection, the process is finished in one step, the working efficiency is effectively improved, the labor cost is reduced, the waste small leftovers can be spliced together and the maximum utilization of resources is realized.

Owner:李东生

Coal additive and method for raising coke output and performance

InactiveCN101020831AFully carryFast and Efficient CarryCoke ovensSolid fuelsEngineeringProcess engineering

The present invention relates to coal additive and method for raising coke output and performance. The coal additive contains surface activating catalyst, co-solvent, permeation assistant and solvent. When the coal additive is used, the surface activating catalyst is dissolved in the solvent, added into coal through a specific mode, and distributed on the surface of coal and inside coal under the action of the permeation assistant. During producing coke, the coal additive is heated and the volatile component is separated out, to raise the output and performance of the produced coke. The high performance coke may be used in coal burning, dry distilling, gasifying, liquefying and other fields. The present invention can reach the aims of raising the utilization rate of coal, saving coal resource, reducing pollutant, etc.

Owner:北京金源化学集团有限公司

Environment-friendly type degradable slow release fertilizer envelope agent and preparing method thereof

InactiveCN101033160AIncrease profitThe effect of increasing production is obviousFertilizer mixturesLiquid productWater based

This invention relates to an envelope agent of an environment protection degradable slow released fertilizer and its preparation method composed of MMA, PVA, dodecyl alcohol ester, water-base resin, fat alcohol and a binder, in which, compositions are thermal-dissolved in a reaction kettle then cooled and mixed to get a liquid product, which can envelope mineral compositions(CaO, MgO and ZnO) outside of particle fertilizers by a special enveloping machine so as to release nutrition of fertilizer slowly.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

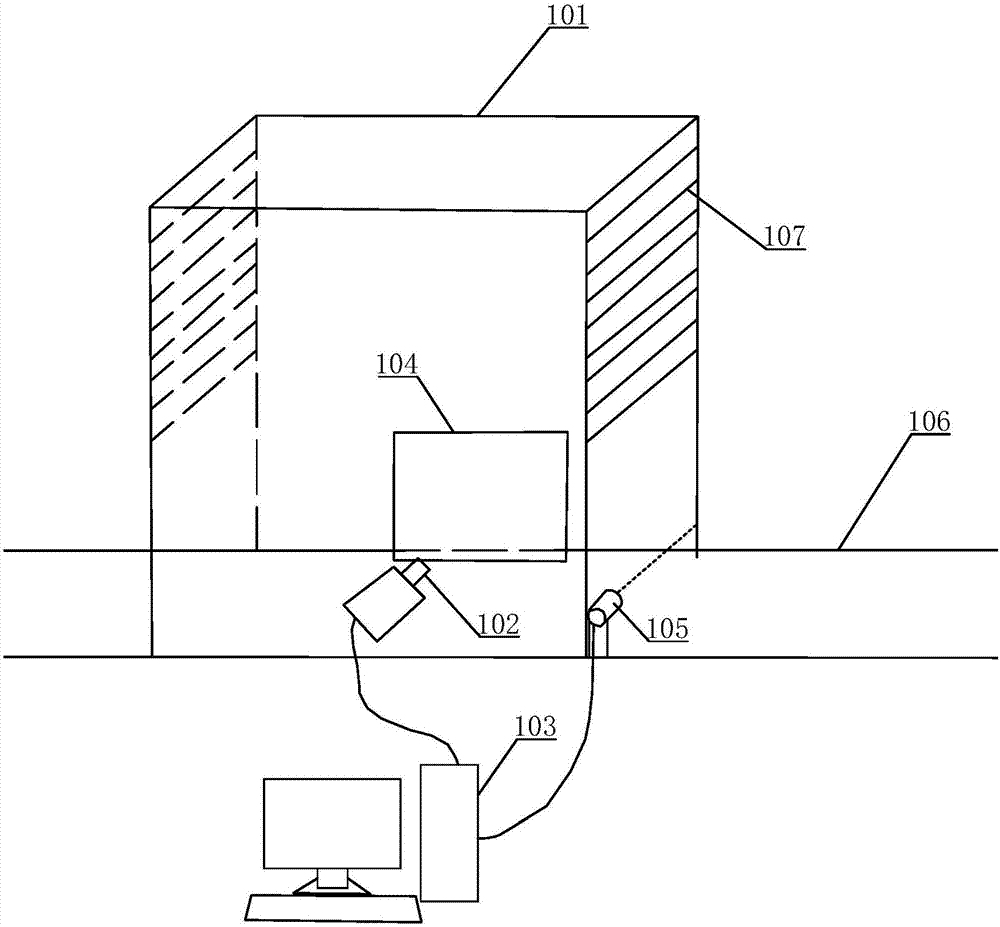

Automatic display screen defect detection system and method

InactiveCN107576663ADefect detectionDefect stableOptically investigating flaws/contaminationComputer graphics (images)Camera obscura

The invention discloses an automatic display screen defect detection system and method. The system comprises a camera obscura, a camera and an upper computer, wherein the camera is connected with theupper computer, and is used for shooting pictures of a display screen to be detected in the camera obscura under different color displays and outputting the pictures to the upper computer; the upper computer is used for processing the received pictures so as to judge whether the display screen to be detected has defects or not. Through the automatic display screen defect detection system and the automatic display screen defect detection method, defects of the display screen in different color interfaces can be rapidly and stably detected, so that the production speed is increased and the production labor cost is reduced.

Owner:无锡达蒙科技有限公司

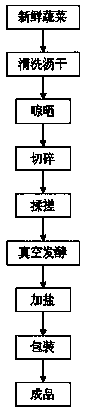

Preparation method for Chinese sauerkraut

The invention discloses a preparation method for Chinese sauerkraut. The method comprises the following steps: using fresh vegetables as raw materials, sorting, selecting, cleaning up, then drying to remove 60-70% of moisture, cutting the fresh vegetables into fragments, kneading and rubbing to remove a majority of residual moisture in vegetables, filling the vegetables into a vacuum enamel can while compressing to exhaust, sealing the can for fermentation, removing moisture in the can under the vacuum state periodically, stopping sealing the can after the fermentation for 7-15 days, adding salt, uniformly mixing the salt with the vegetables, so as to obtain the final product. The method is scientific and reasonable and facilitates large-scale production, besides, the preparation technology is excellent in stability, and the prepared Chinese sauerkraut is excellent in mouthfeeling and stable in quality; the Chinese sauerkraut prepared by adopting the method is nutrient-rich, delicious in taste, sour, appetizing and tasty, and promotes the secretion of saliva or body fluid, thereby being a green food suitable for people of all ages.

Owner:广西远邻集团食品有限责任公司 +1

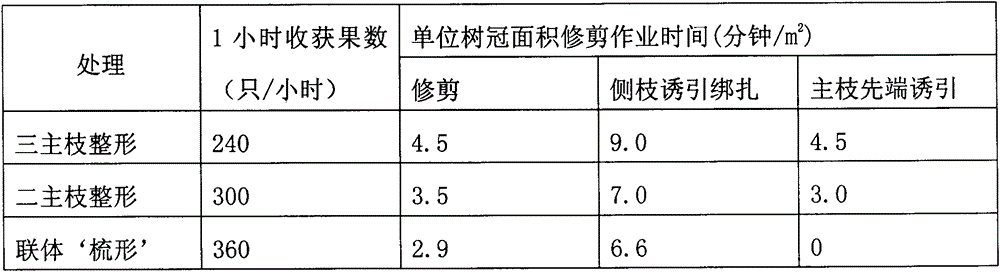

Chinese pear horizontal shed frame single main branch conjoined comb-shaped shaping cultivation method

ActiveCN105248211ALow technical requirementsEasy to masterCultivating equipmentsHorticulture methodsGraftingBasic block

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

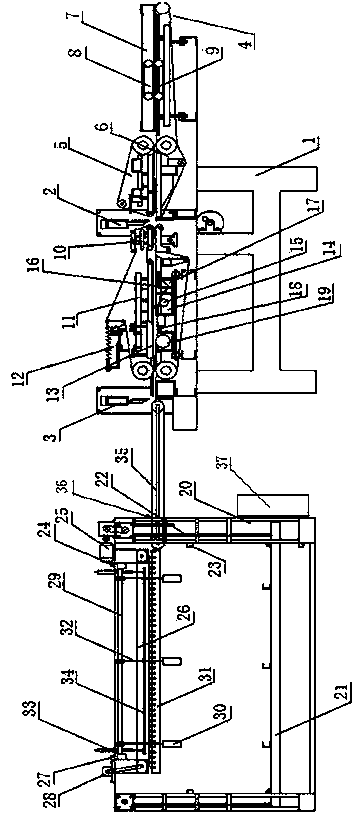

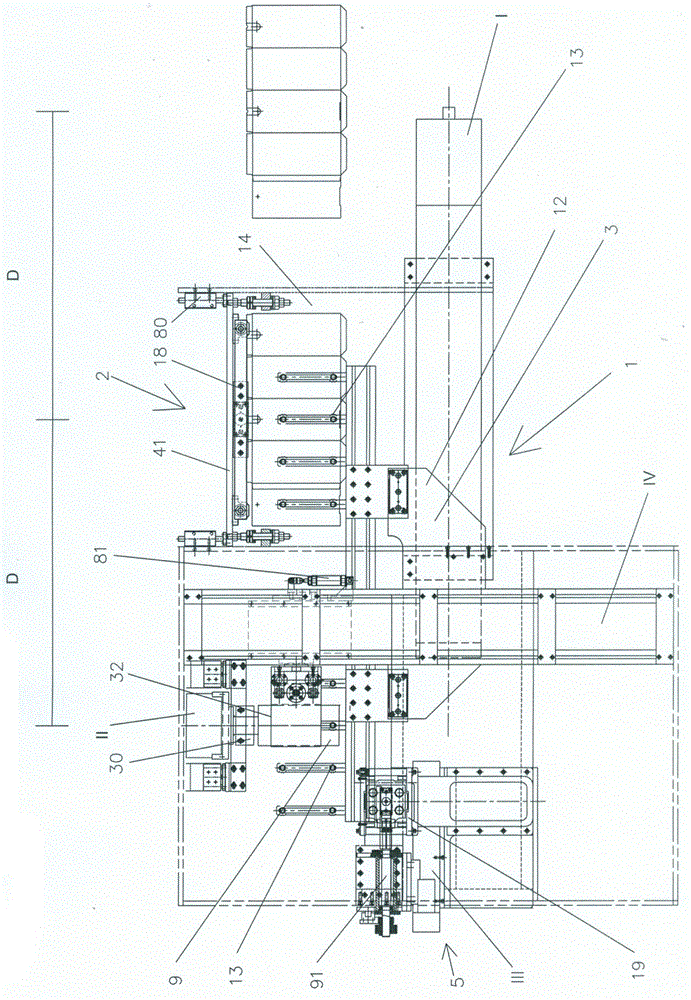

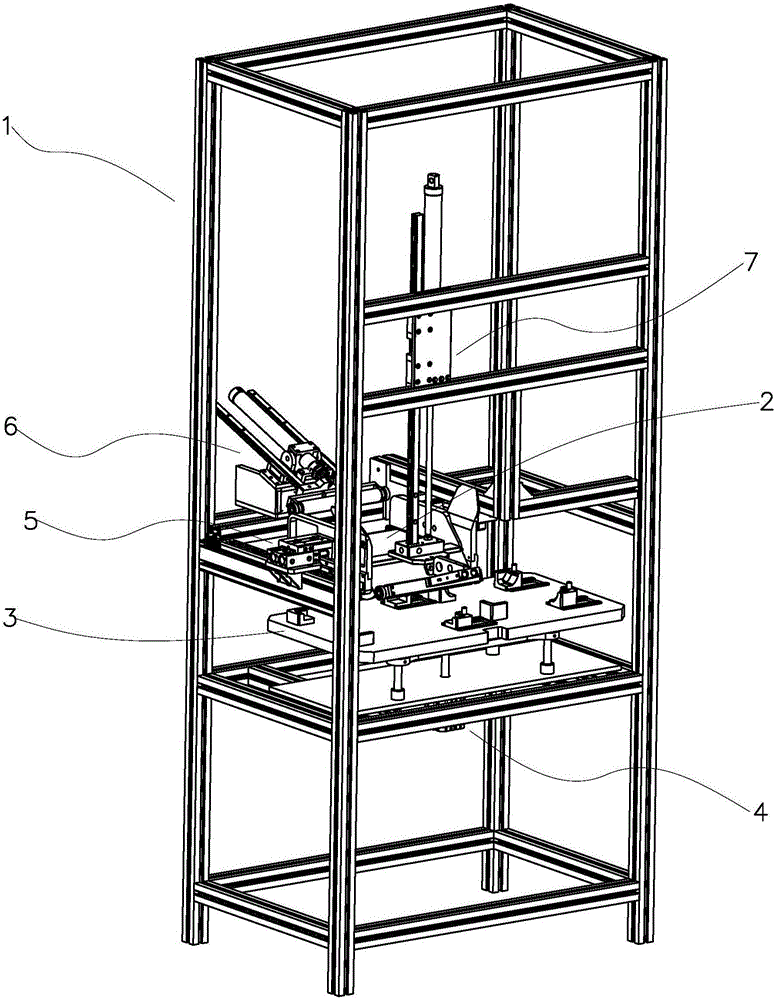

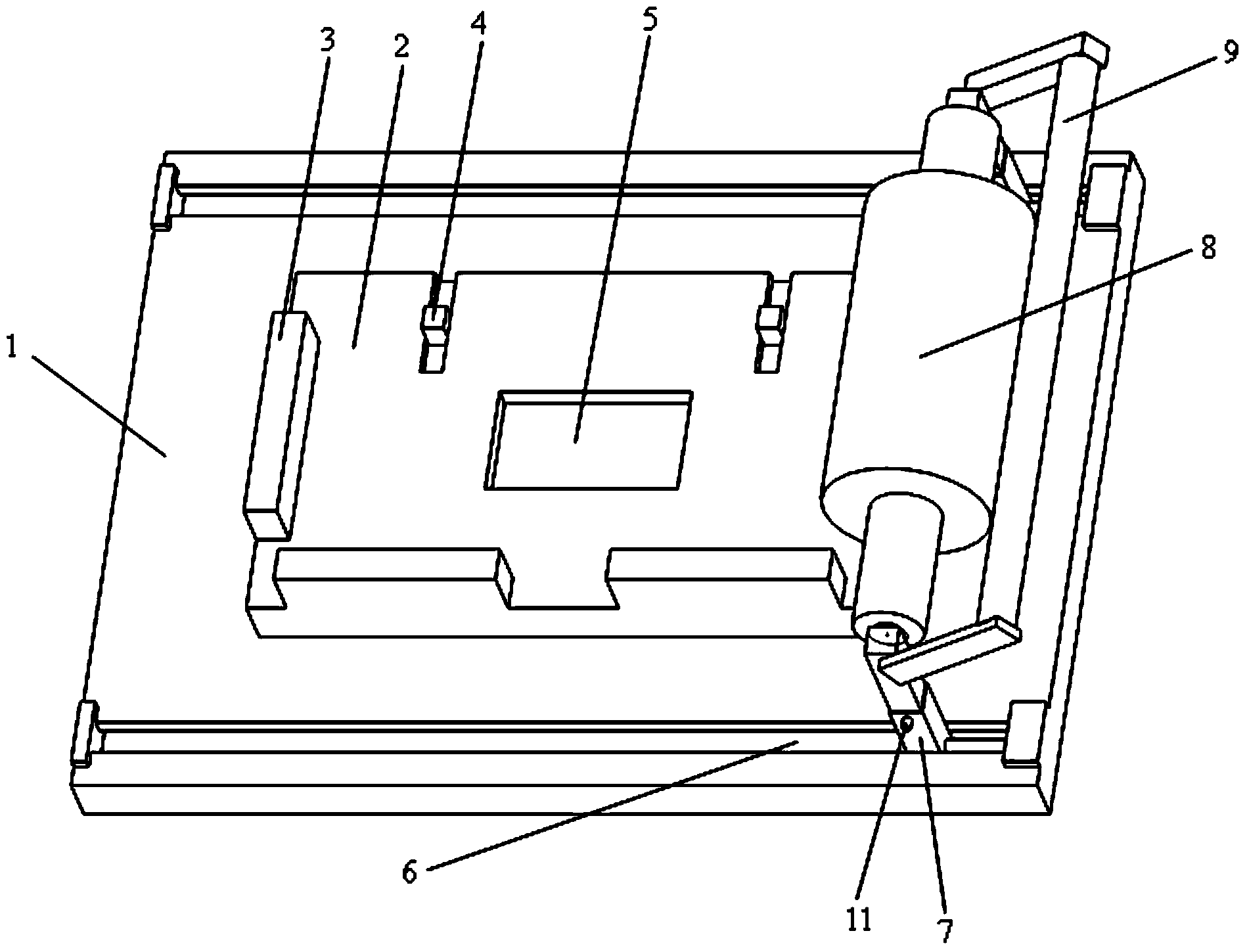

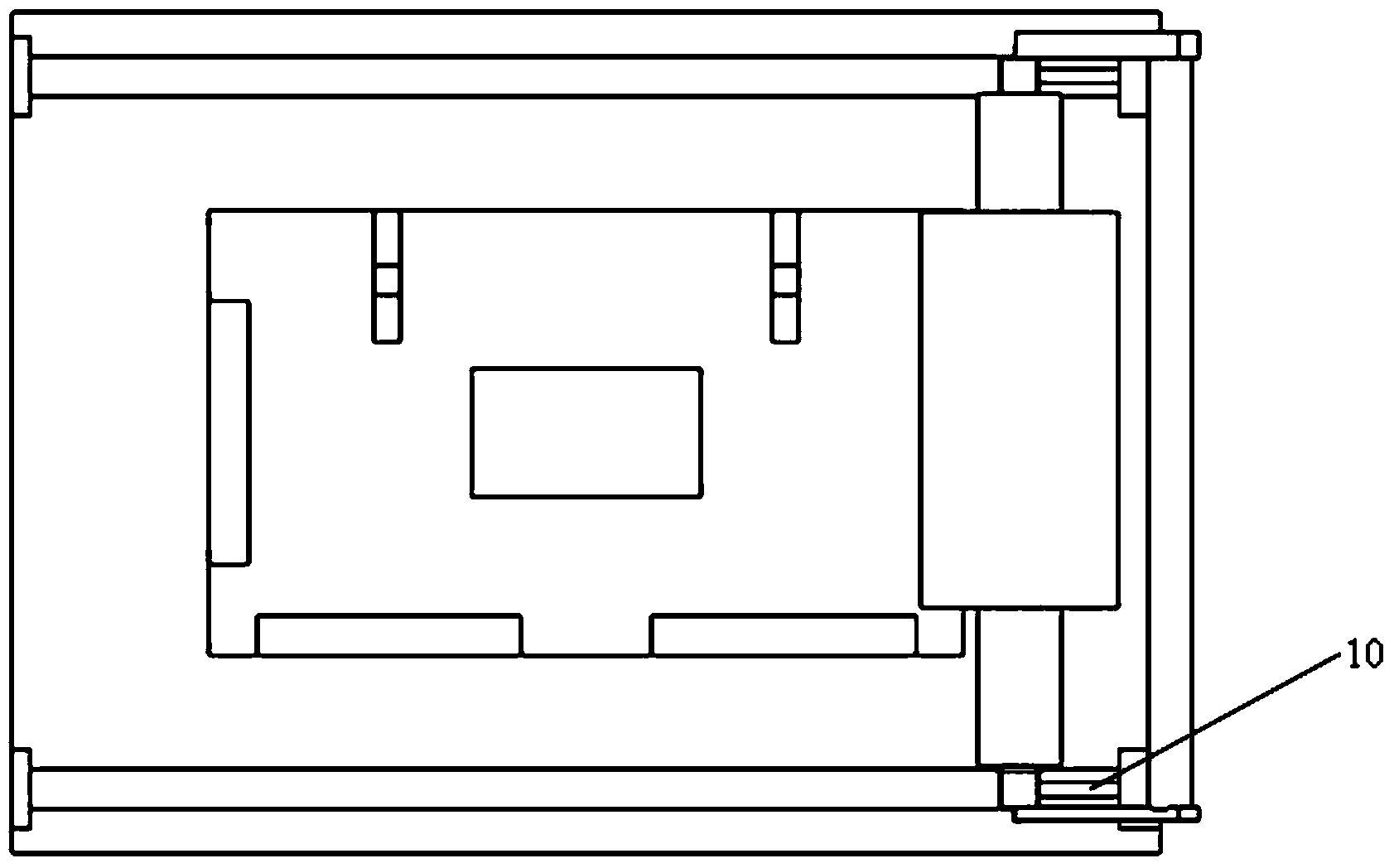

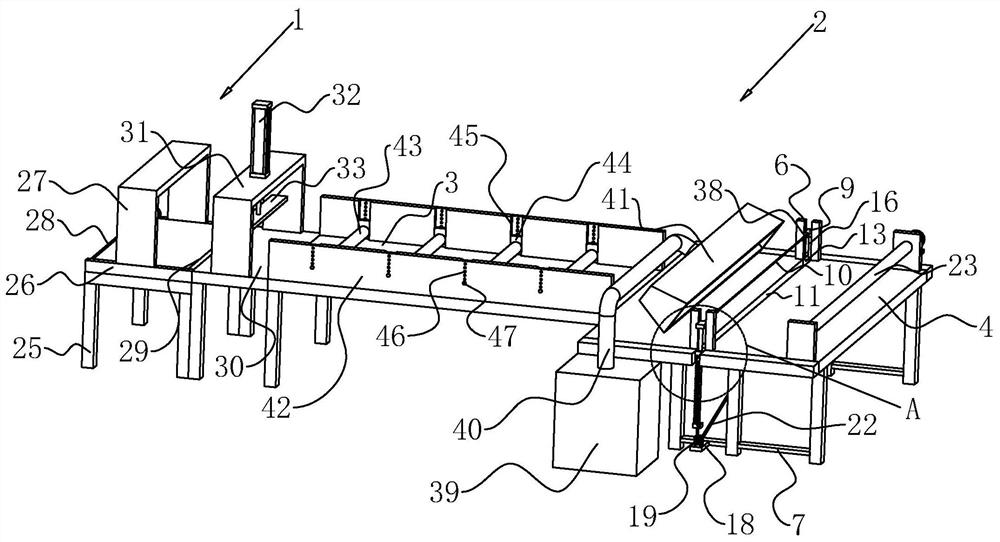

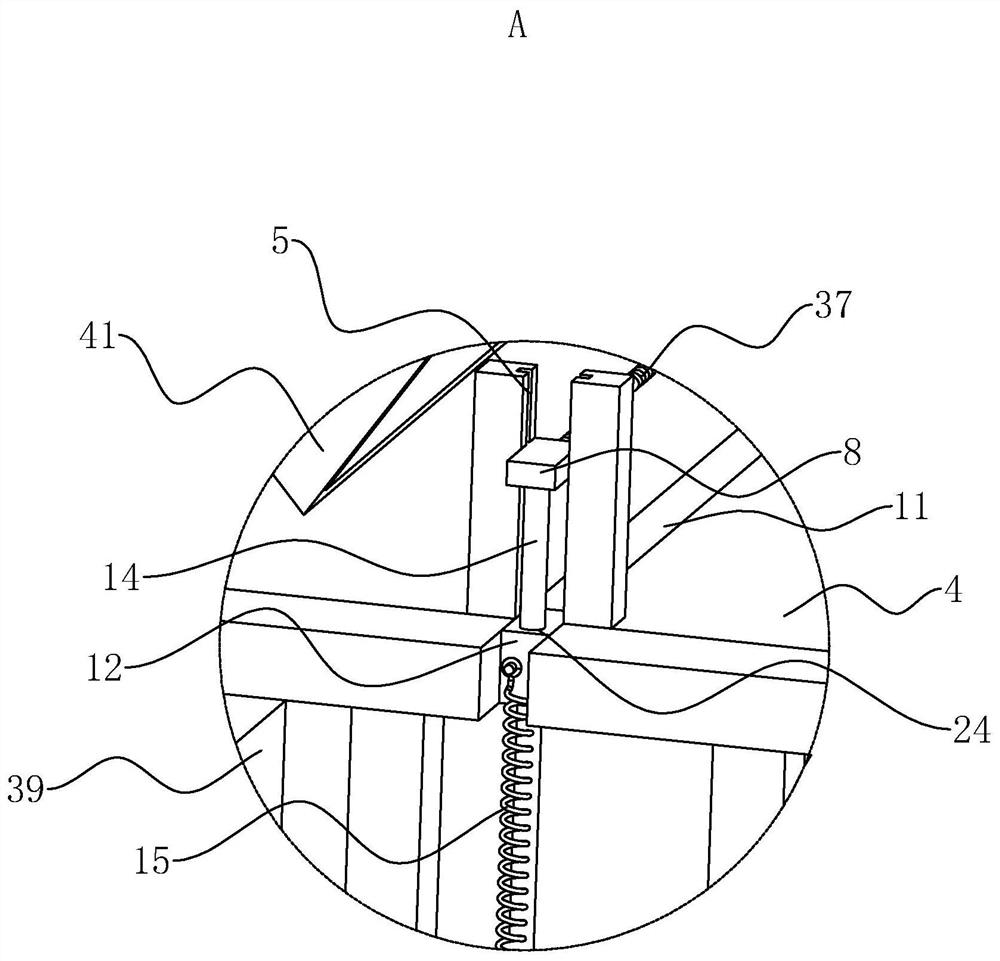

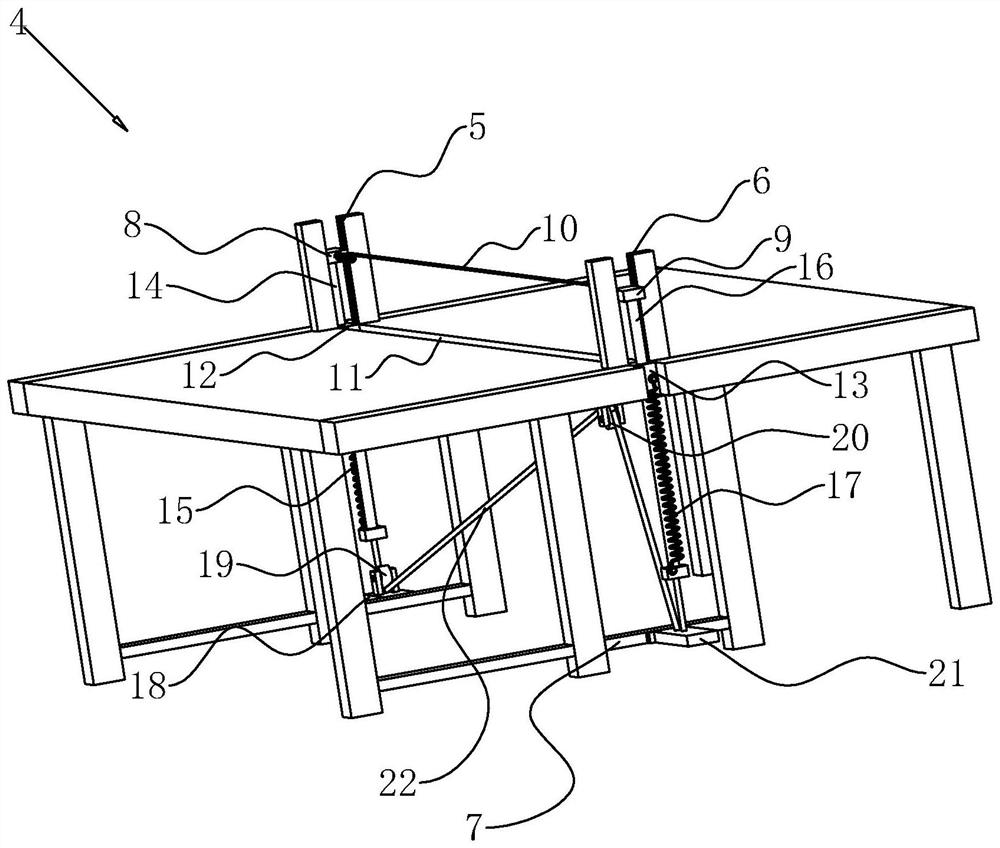

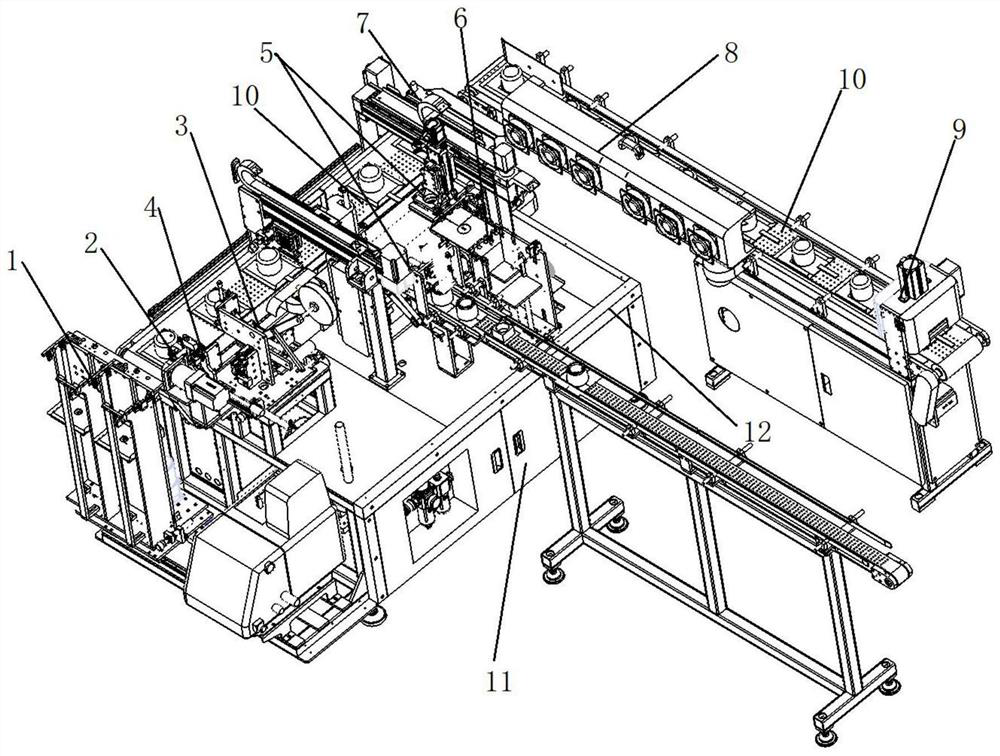

Full-automatic wine box forming machine

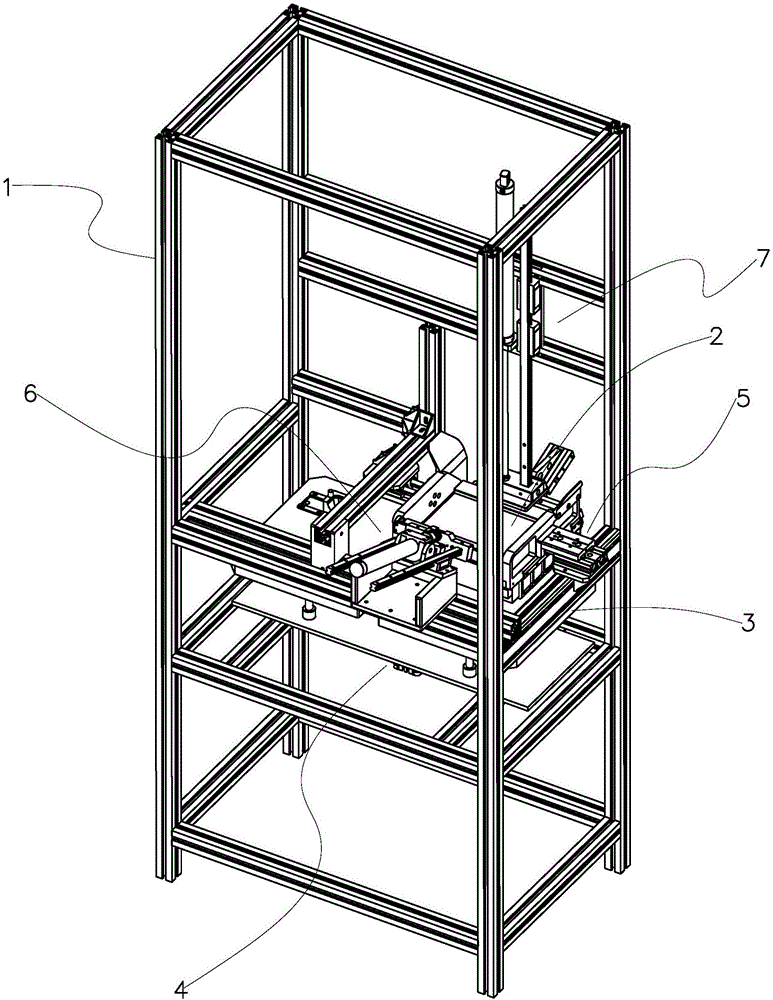

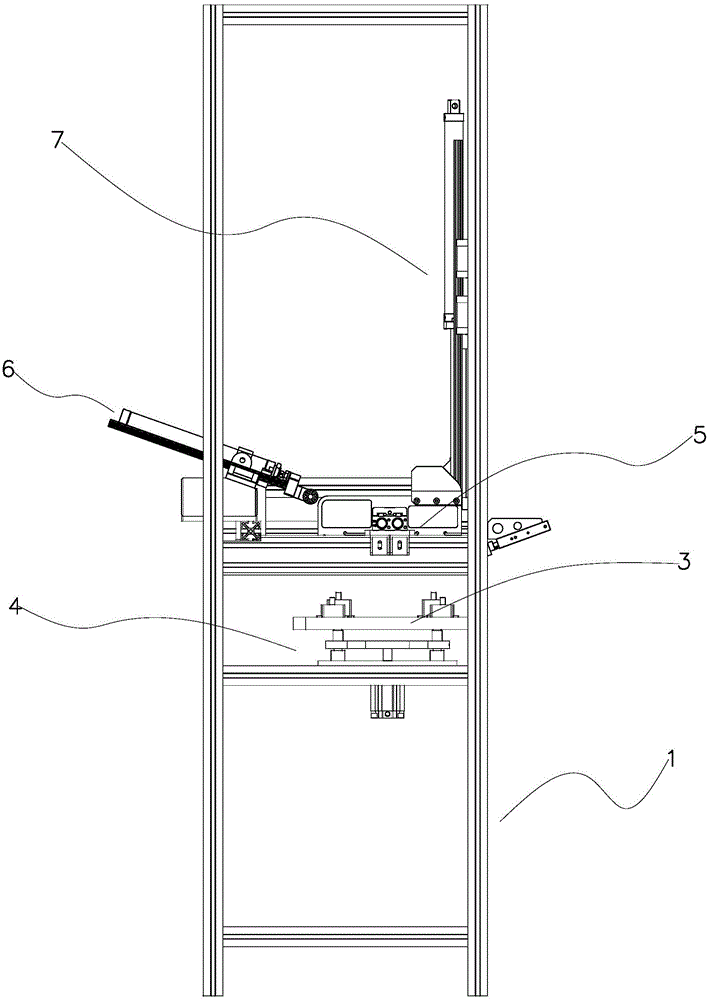

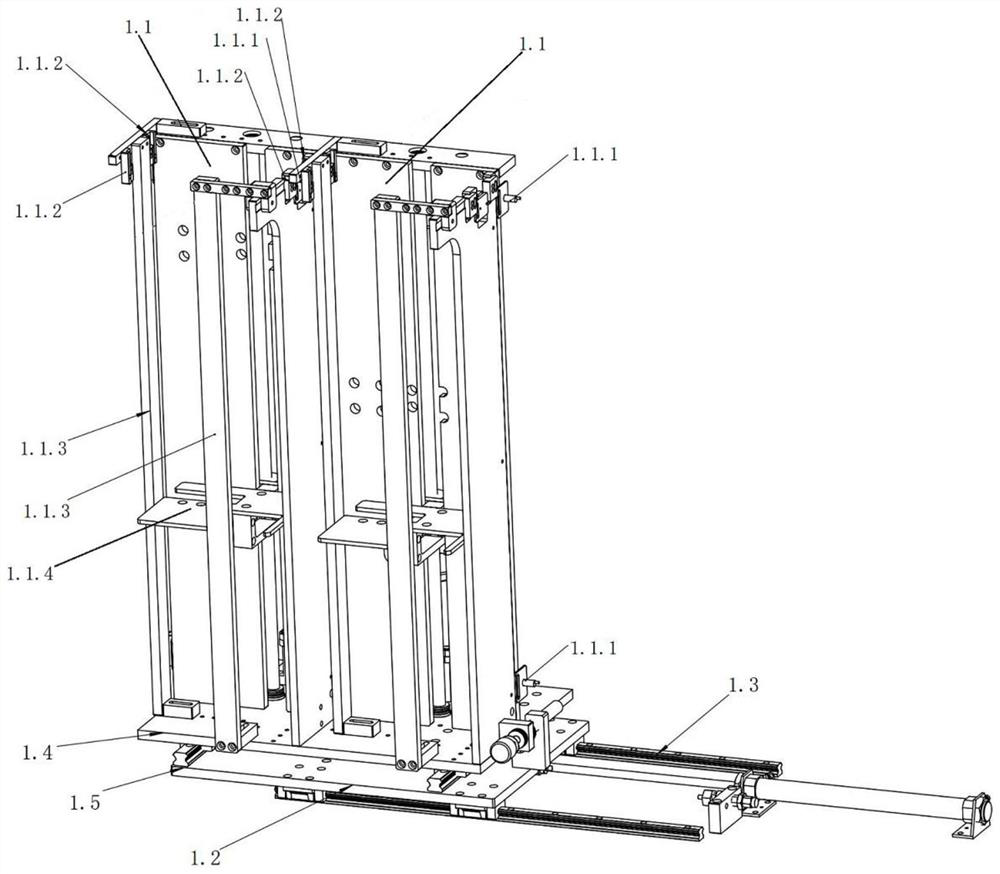

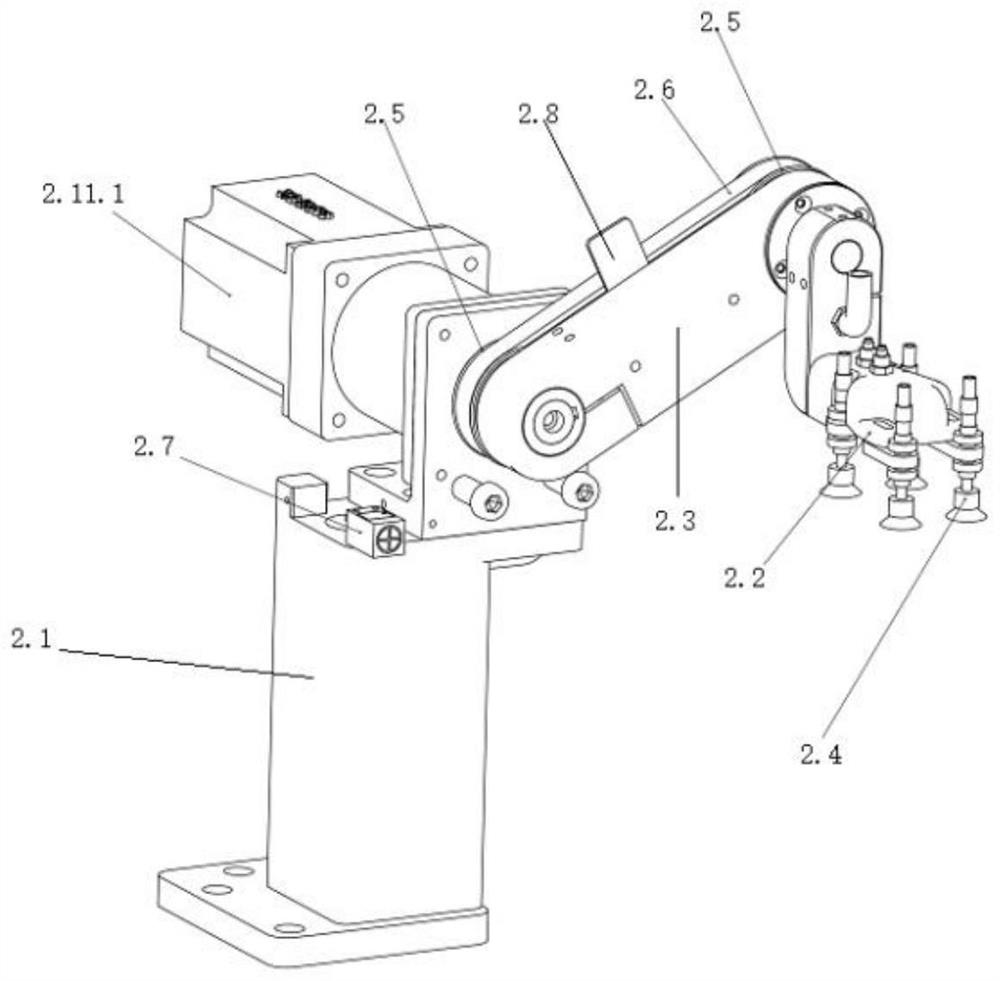

ActiveCN104553045AReduce production labor costsImprove labor productivityBox making operationsPaper-makingManipulatorPosition paper

The invention discloses a full-automatic wine box forming machine, which comprises a rack, and is characterized in that the rack is provided with three positions; the three positions are a wait position, a three-opening edge covering position and a forming position in sequence, and the three positions are arranged linearly; the rack is provided with a three-position paper stock transfer manipulator mechanism (1), a three-opening edge covering mechanism (2), a wine box mold lifting mechanism (4), a wine box bottom plate conveying mechanism (5), a wine box mold supporting mechanism (6), a forming mechanism (7) for four side faces of a wine box and an inward edge covering mechanism for the fourth of box openings. The wine box forming operation can be mechanically and automatically completed, so that the production efficiency is effectively increased, and the production cost is reduced.

Owner:ZHEJIANG XINWEI MACHINERY

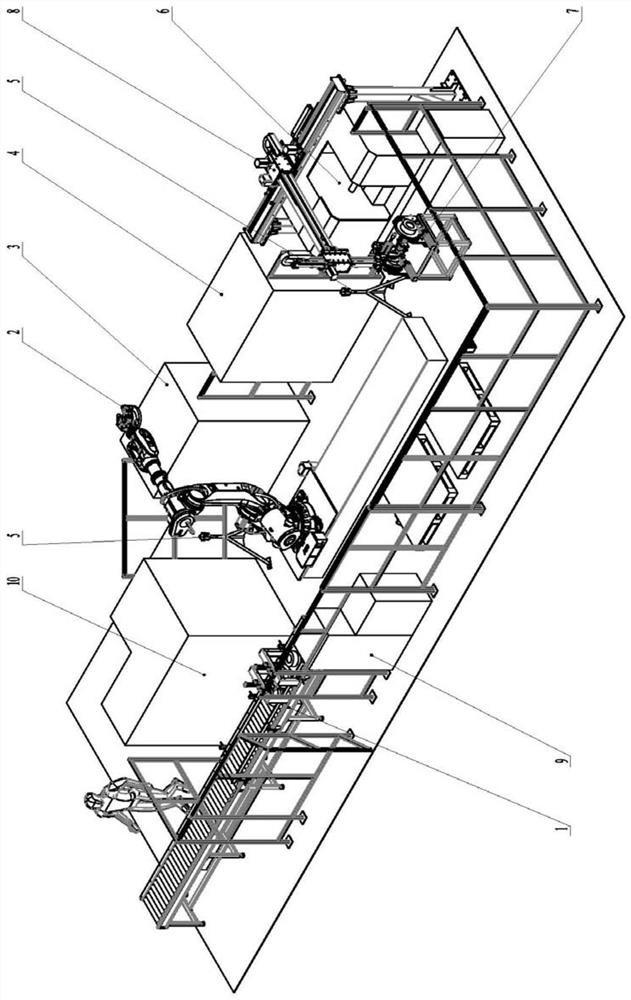

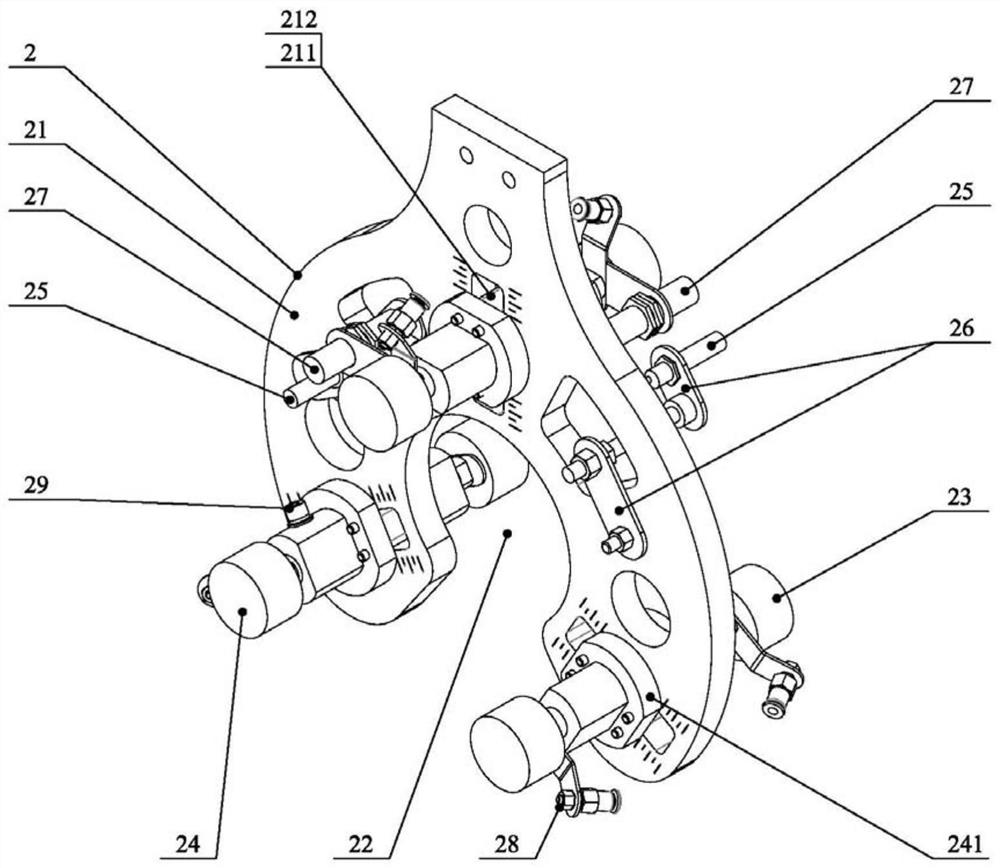

Brake disc machining robot feeding and discharging production line and production method

ActiveCN112296723AHigh degree of automationIncrease productivityMetal working apparatusPositioning apparatusNumerical controlProduction line

The invention discloses a brake disc machining robot feeding and discharging production line and a production method. The brake disc machining robot feeding and discharging production line comprises an auxiliary feeding system, a first numerical control machine tool, a second numerical control machine tool, a machining center, a grinding machine tool, an auxiliary turnover mechanism, an auxiliarytransfer mechanism, a truss manipulator, a mechanical clamping jaw, an industrial robot and a control cabinet, wherein the industrial robot comprises a ground rail, a robot body arranged on the groundrail, a robot arm connected to the robot body and a robot jig connected to the tail end of the robot arm; the control cabinet controls the robot body, the robot arm and the robot jig to act; and under the control of the control cabinet, a brake disc sequentially finishes the machining process on the first numerical control machine tool, the second numerical control machine tool, the machining center and the grinding machine tool. The production line has high automation degree, production efficiency and percent of pass of products. According to the production method, the brake disc machining efficiency can be further improved, and the enterprise production cost is reduced.

Owner:青岛智研自动化设备有限公司

Device for automatically buckling packaging box

ActiveCN106005519ARealize automatic fastening productionIncrease productivityPackagingBuckling - actionFront cover

The invention discloses a device for automatically buckling a packaging box. The device comprises a machine frame, a tool jig, a jacking mechanism, side clamping guide mechanisms, a buckling mechanism and a cover pressing mechanism. A lifting mechanism jacks up the packaging box through the tool jig; the side clamping guide mechanisms clamp the packaging box which is jacked up; then, the lifting mechanism resets; the buckling mechanism conducts rolling on a cover body so that side covers can be buckled on a box body; then, the buckling mechanism resets; finally, the cover body is pressed through the cover pressing mechanism; rolling is conducted on a front cover so that buckle lugs can be buckled on the box body; and therefore the buckling action of the packaging box is automatically completed. The above structure is adopted in the device, automatic production is achieved, the production efficiency is effectively improved, and the labor cost is reduced.

Owner:ZHONGSHAN XINHUI PRECISION TECH CO LTD

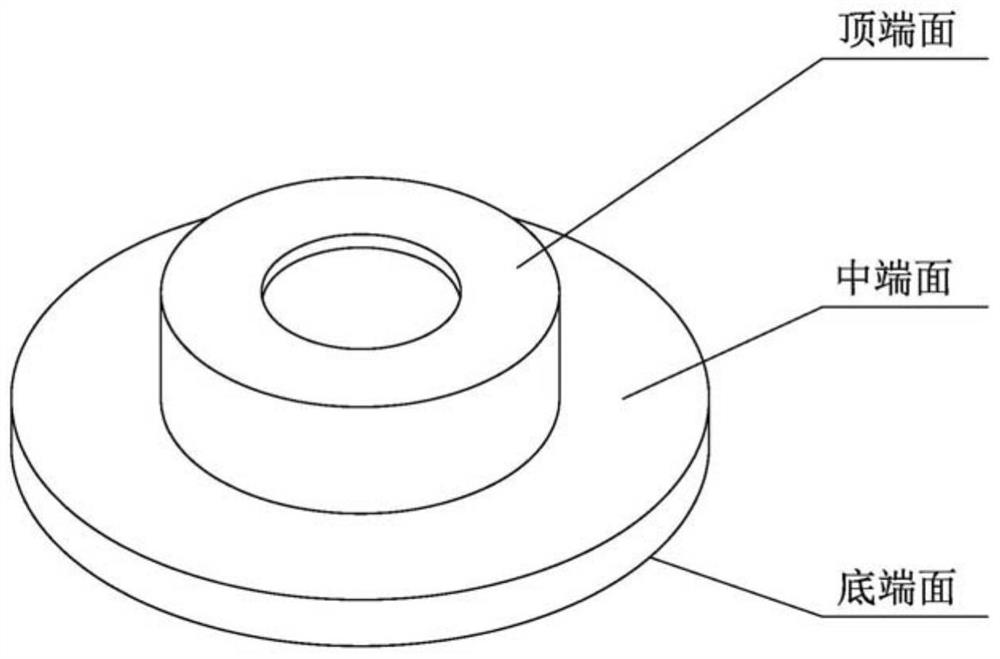

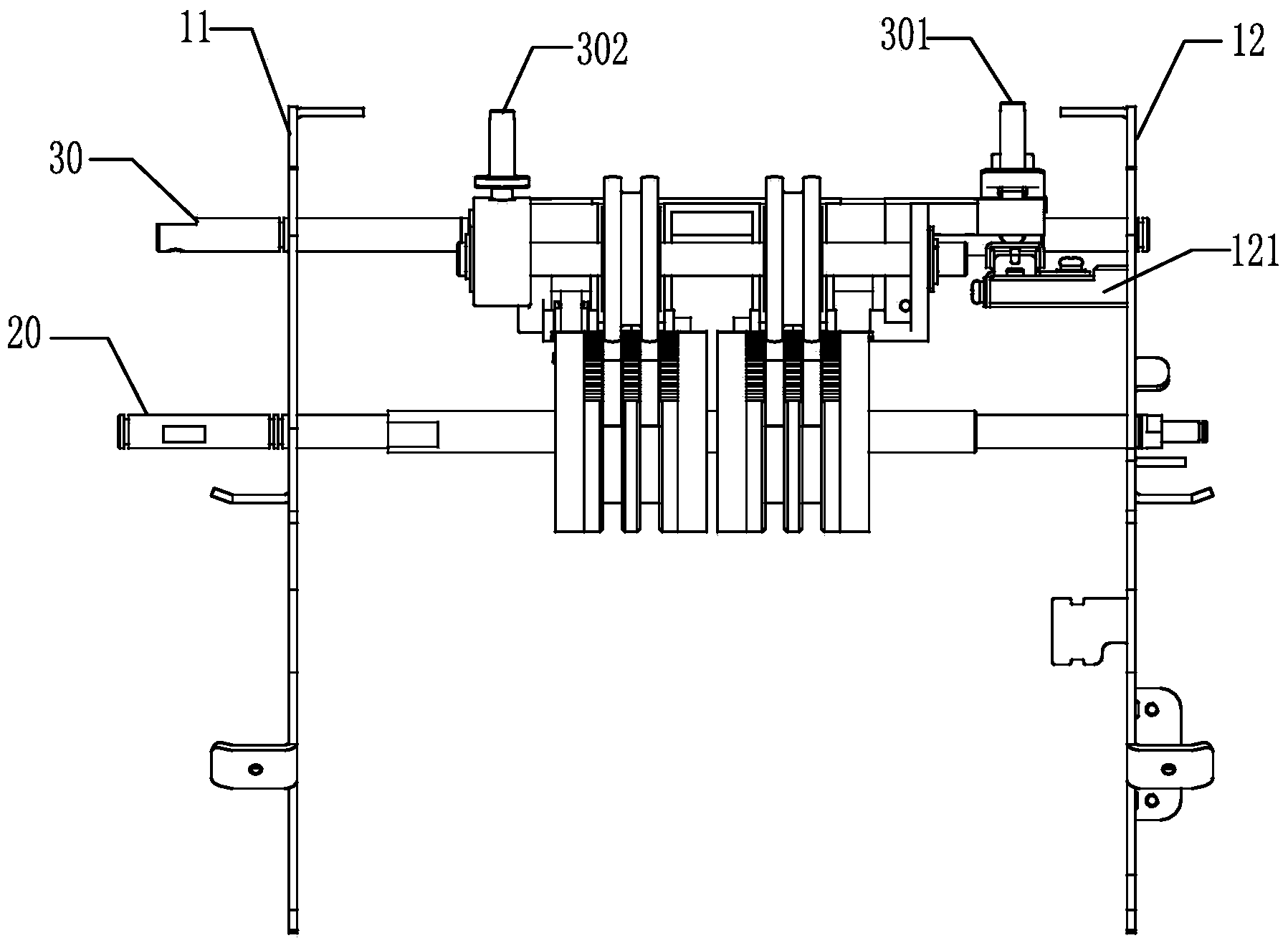

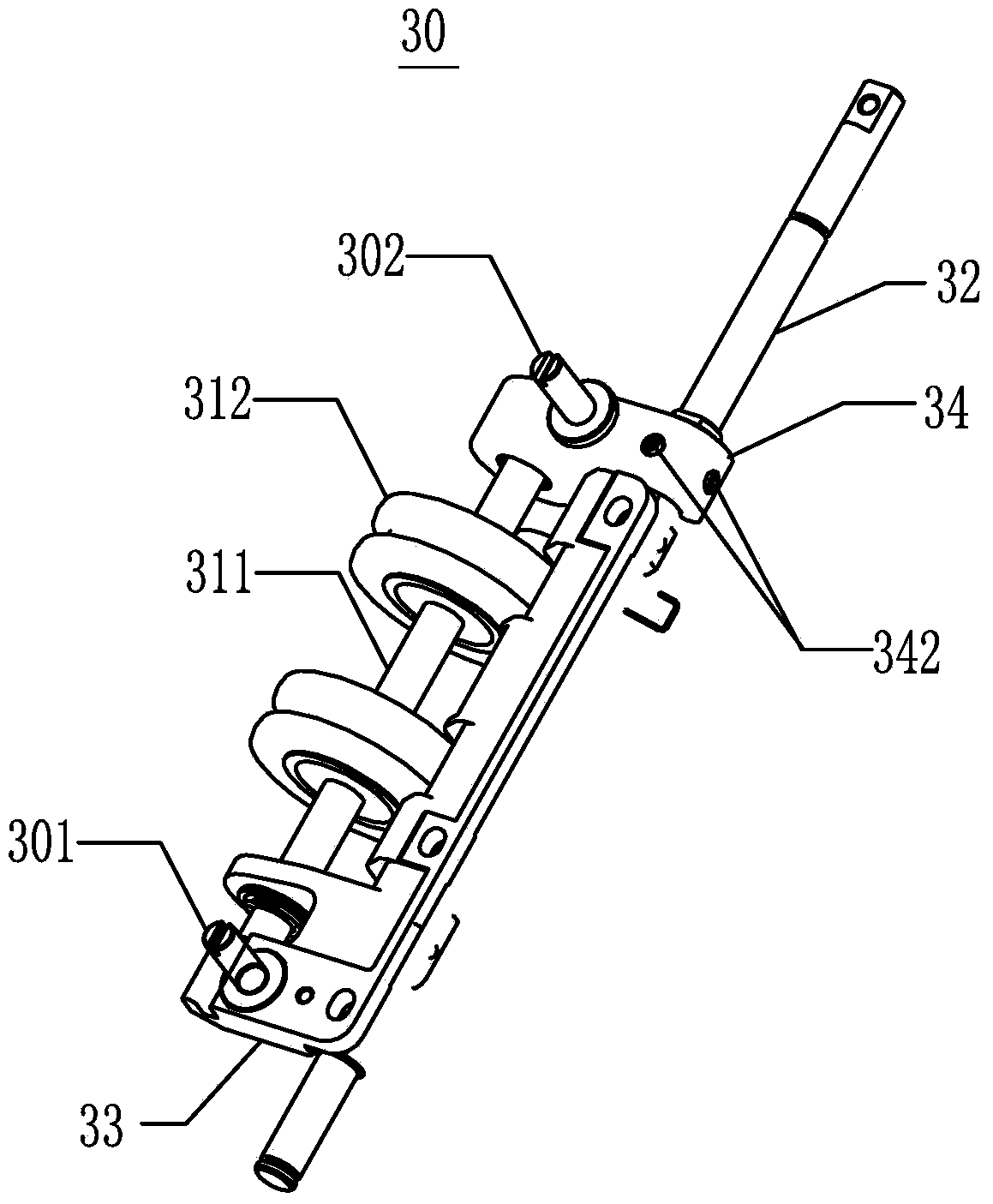

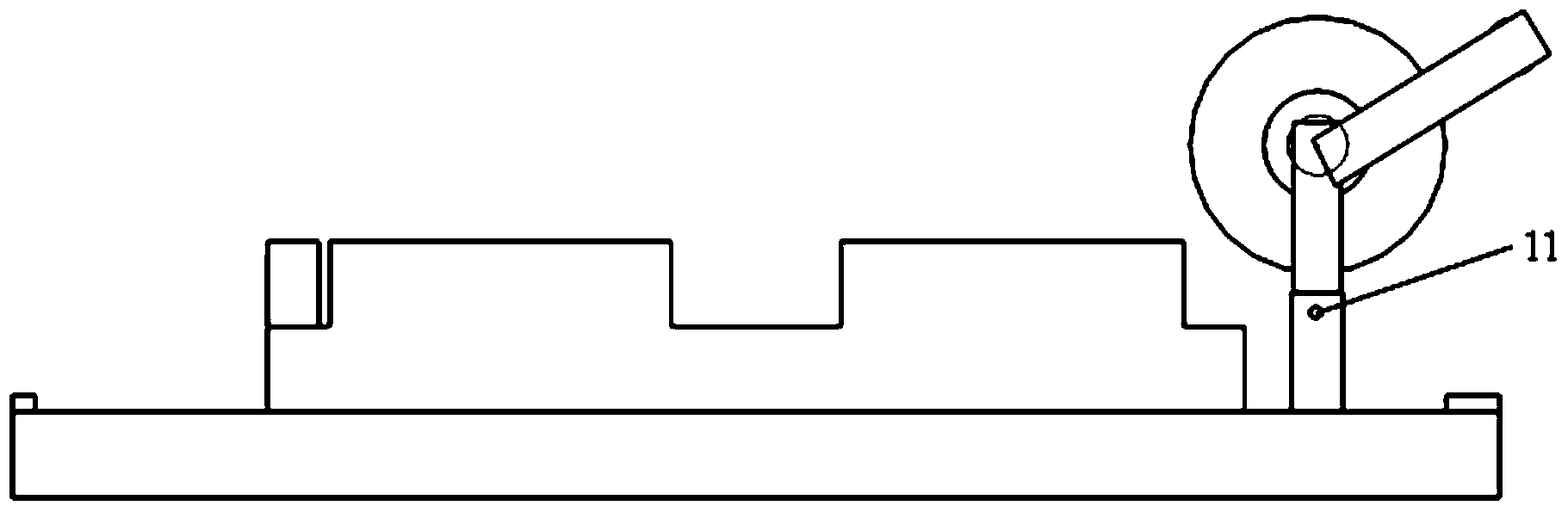

Banknote sorting device and radial clearance adjusting method thereof

ActiveCN104392541ALow unit priceReduced precision requirementsCoin/currency accepting devicesArticle separationEngineeringMechanical engineering

The invention relates to a banknote sorting device and a radial clearance adjusting method thereof. The banknote sorting device comprises a banknote sorting wheel group and a reversal rotating wheel group cooperating with the banknote sorting wheel group. The reversal rotating wheel group consists of a reversal rotating wheel assembly, a reversal rotating wheel rotating shaft, a first fixed rack, and a second fixed rack; the two ends of the reversal rotating wheel rotating shaft are respectively fixed at two mounting side plates in a financial self-service device; and the first fixed rack and the second fixed rack are respectively and fixedly connected to the two ends of the reversal rotating wheel assembly. A first clearance adjustment threaded hole is formed in the first fixed rack and a second clearance adjustment threaded hole is formed in the second fixed rack; a first clearance adjusting bolt is arranged in the first clearance adjustment threaded hole and a second clearance adjusting bolt is arranged in the second clearance adjustment threaded hole; and the radial clearances between the two ends of the reversal rotating wheel assembly and the banknote sorting wheel group are respectively adjusted by the first clearance adjusting bolt and the second clearance adjusting bolt.

Owner:GRG BAKING EQUIP CO LTD

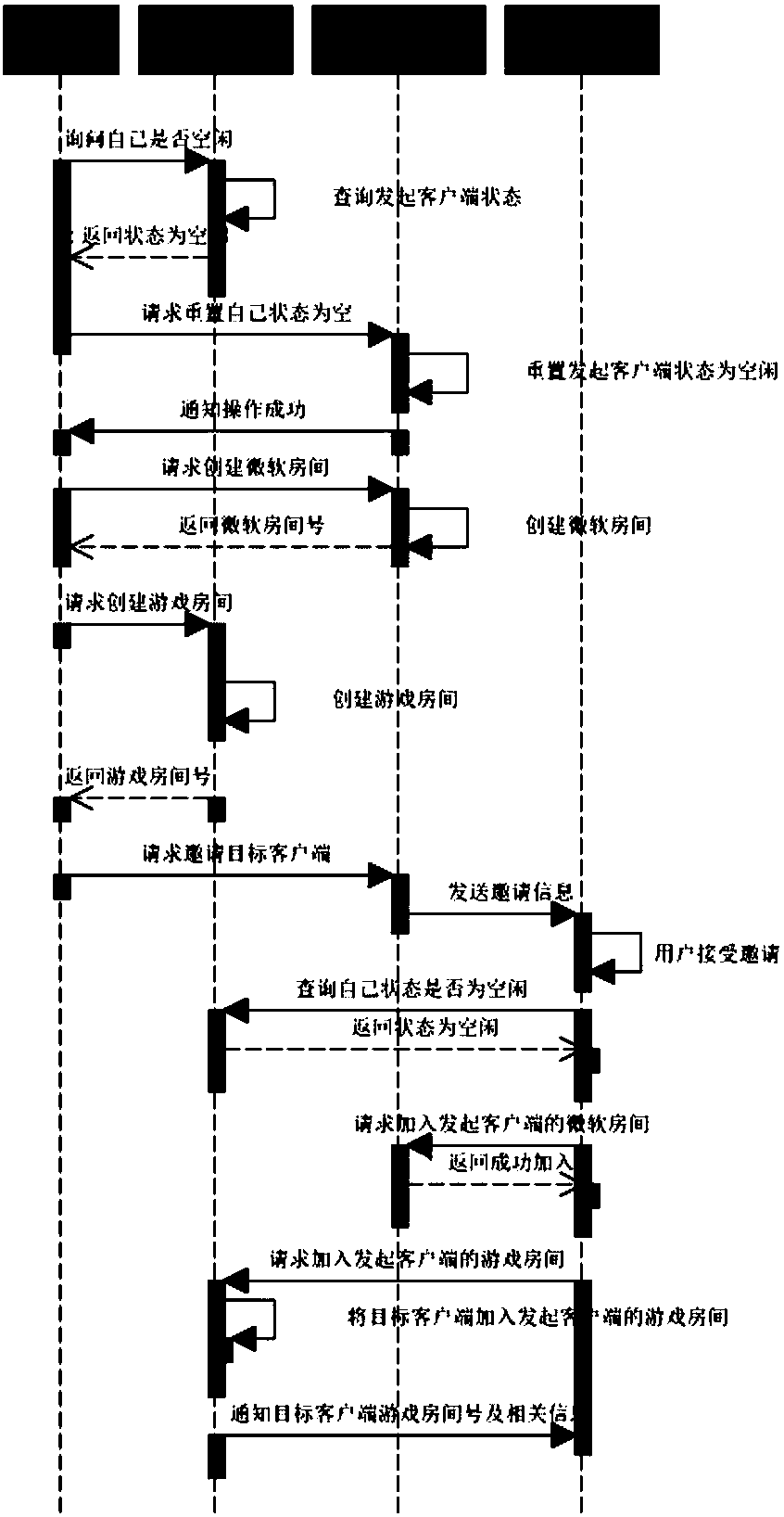

Xbox platform multiplayer game access control method based on client synchronization

ActiveCN107930113AAvoid disruptionComplies with mandatory requirementsVideo gamesMultiplayer gameGame server

The invention relates to an Xbox platform multiplayer game access control method based on client synchronization. A game outside invitation function of a multiplayer network war game on an Xbox seriesgame machine is implemented, the problem that player and room state data is not synchronized between a developer game server and an Xbox Live server, which leads to the interruption of original service processes is solved, and functions of 'game room' and 'Microsoft room' are integrated, and states are unified. The modification of a stable 'game room' function of a game server engine is avoided,and the disruption of original service processes by logic service developers for redevelopment is avoided. Multiplayer war network games on a traditional PC platform can be quickly transplanted to anXbox platform, so that game products conform to Microsoft mandatory requirements, and the products can be released on the line. The flexibility of an Xbox Live platform for the quick transplantation of the multiplayer war network games on the traditional PC platform is enhanced, the product development efficiency is improved, the development cycle is shortened, and the production labor cost is reduced.

Owner:SNAIL GAMES

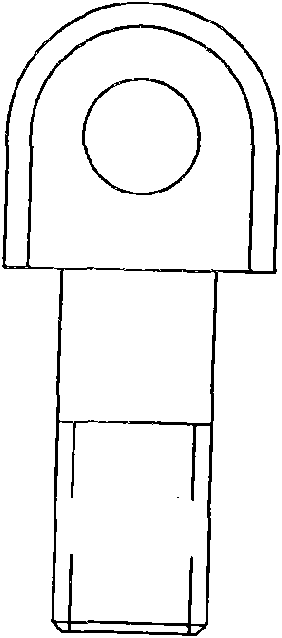

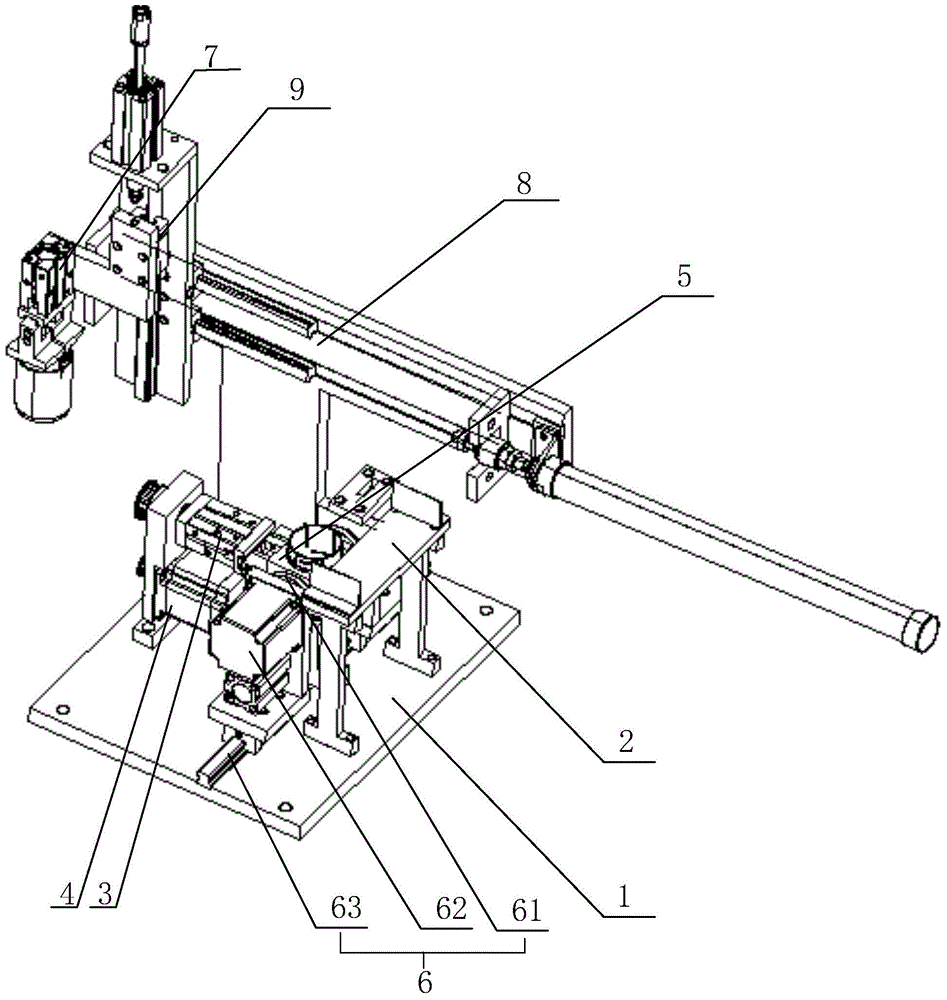

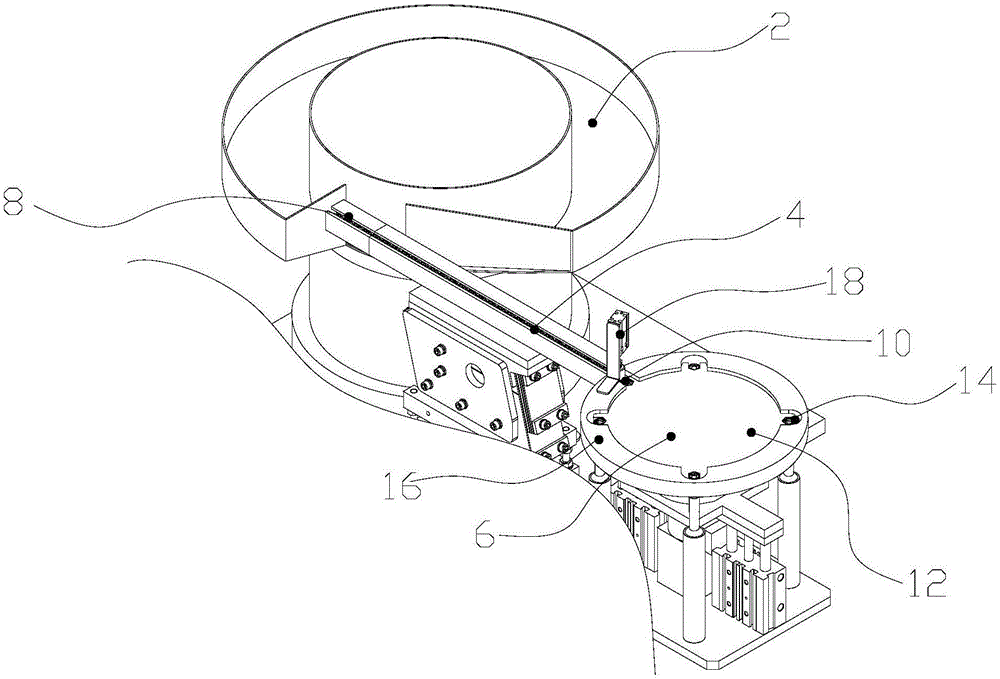

Device for positioning cylindrical component with holes

InactiveCN104985419AQuality improvementEfficient productionMetal working apparatusEngineeringManipulator

The invention discloses a device for positioning a cylindrical component with holes. One side of a feeding stage is provided with a clamping air cylinder with a clamp and a rotation motor which drives the clamping air cylinder to rotate; a position corresponding to the clamp is provided with a clamping device; the clamping device includes clamping components which are arranged at the left side and the right side of the clamp and thrust air cylinders which drive the clamping components to approach the clamp; the clamping components are provided with bosses; the diameter of the bosses is smaller than the diameter of the holes of the cylindrical component; the bosses are provided with infrared sensors; and a mechanical arm which clamps the cylindrical component is arranged just above the clamp. With the device of the invention adopted, the quality of produced products can be increased, and production labor cost can be reduced. The device has the advantages of automatic feeding and discharging, automatic assembly, fully-automated production operation, high practicability, high speed and accurate and reliable positioning.

Owner:WENZHOU RES INST OF BEIHANG UNIV

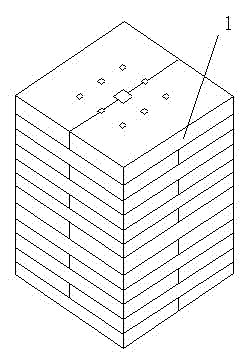

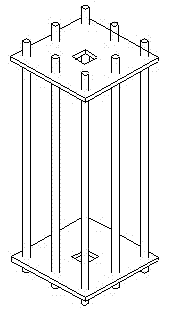

Method for constructing block base

ActiveCN102926545AHigh strengthLight in massFoundation engineeringBuilding material handlingSheet steelReusability

The invention discloses a method for constructing a block base, which comprises the steps that: flake concrete blocks are built and pressed, a reinforcing bar framework passes through holes which are arranged on the flake concrete blocks which are built and pressed, the all flake concrete blocks which are built and pressed together are connected, the two ends of the reinforcing bar framework are pressed fit by utilizing steel plates, the steel plates are closely fixed on the reinforcing bar framework to fix the flake concrete blocks which are built and pressed and the reinforcing bar framework to be fixed together, and the fixed flake concrete blocks are adhered through U-type concrete blocks. Because the flake concrete blocks are light in quality, the shapes of the flake concrete blocks can be designed according to actual requirement, the flake concrete blocks are simple to produce and process, are convenient to transport, can be produced in advance, can be reused, and are convenient to combine and construct and low in production and human cost. The method for constructing the block base achieves the purpose of simple construction, convenient transportation and reusability.

Owner:新疆美特智能安全工程股份有限公司

Glass laminating device

InactiveCN104230184AReasonable designSimple structureLamination ancillary operationsLaminationPlastic materialsEngineering

The invention discloses a glass laminating device, comprising a base, a positioning device and a laminating device, wherein the base is of a rectangular structure and is arranged at the bottom layer of the device; the positioning device is composed of a base plate, a positioning barrier strip, a positioning slide block and a positioning groove and is fixed on the base through bolts; and the laminating device is composed of a linear slide rail, a stretchable link, an idler wheel, a hand shank and a spring device. The idler wheel is made of a flexible plastic material, ensures a good laminating effect and avoids hard scratches in the rolling laminating process; and the laminating device has an automatic resetting function, so that the laminating efficiency is greatly improved. The glass laminating device is simple and reasonable in structure, low in manufacturing cost, and suitable for massive production and application of manufacturing enterprises of aluminum alloy doors and windows.

Owner:HEFEI JIAWEI DECORATION ENG

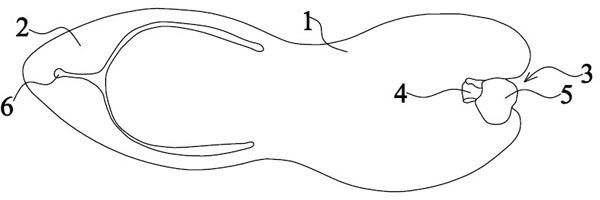

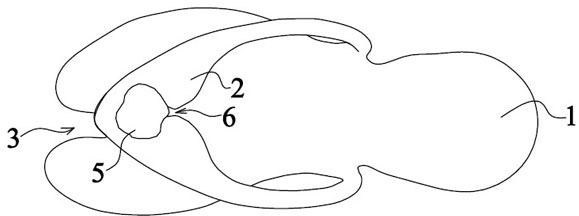

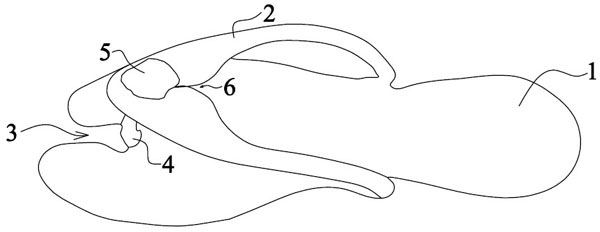

Slipper and machining method thereof

The invention discloses a slipper and a machining method thereof. The slipper comprises a sole and an upper, wherein a groove is formed between a big toe part and a second toe part of the sole; the root of the groove is provided with a front band; the other end of the front band is provided with a protruded cap; two sides of the rear part of the sole are connected with a rear band; the middle of the rear band is provided with a clamping groove, which is clamped with the protruded cap of the front band; and the shape of the rear band is matched with the external outline of the rear part of the sole. The machining method comprises the following steps of: performing hot press molding on materials by adopting an insole integrally-forming module; and trimming the formed materials to form an available product. The product can be unfolded, so that the space is saved; therefore, the product is convenient to carry, the sole and the upper do not need to be additionally adhered or fixed, and the machining efficiency is high.

Owner:张华荣

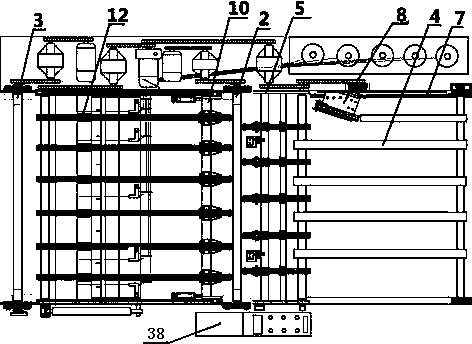

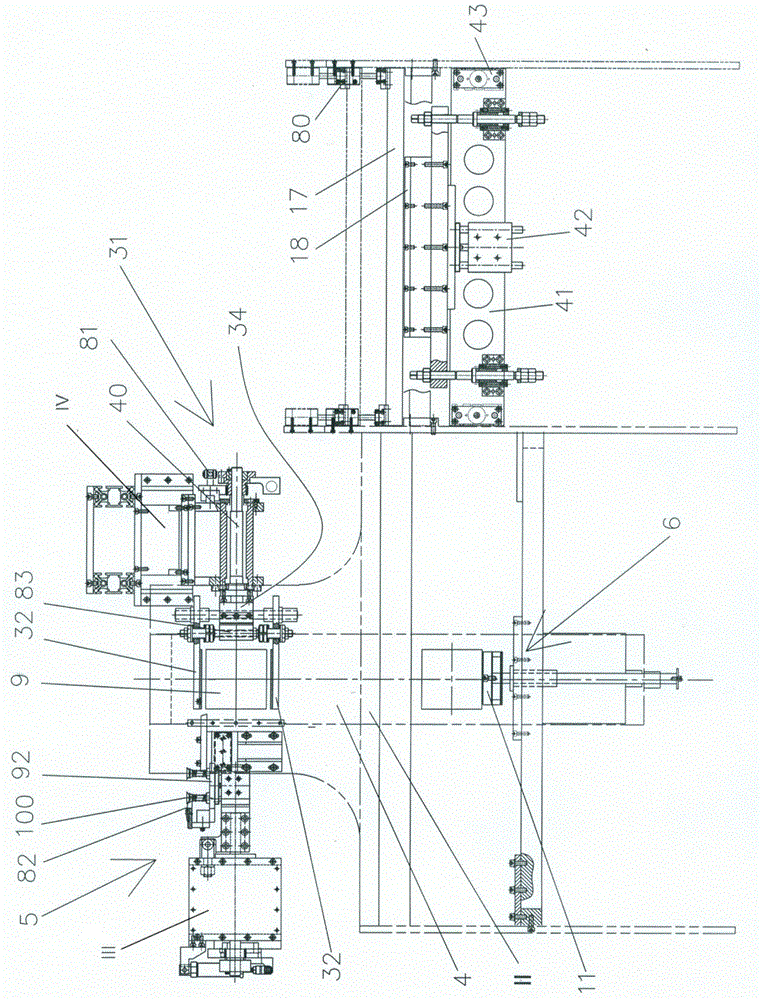

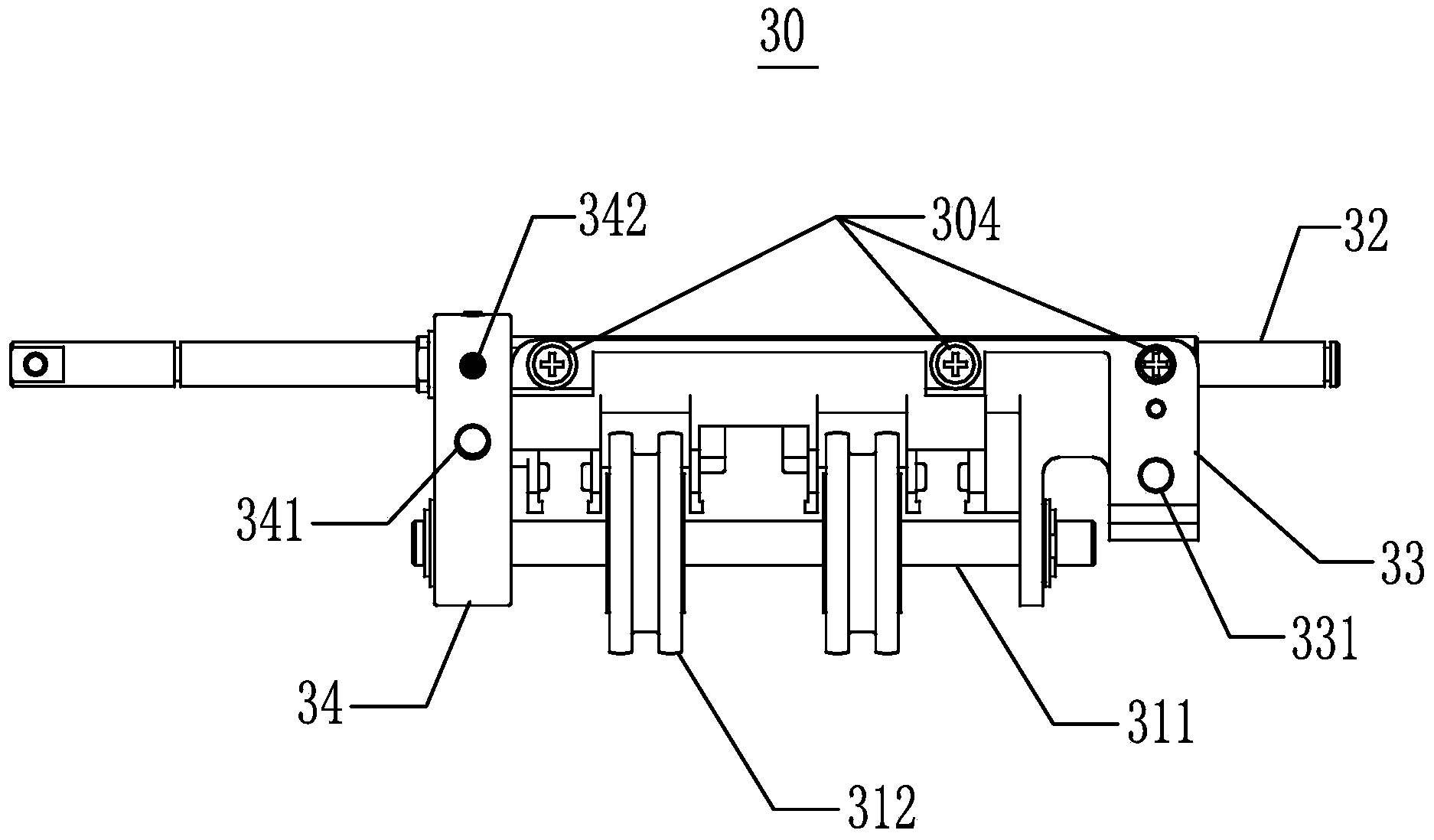

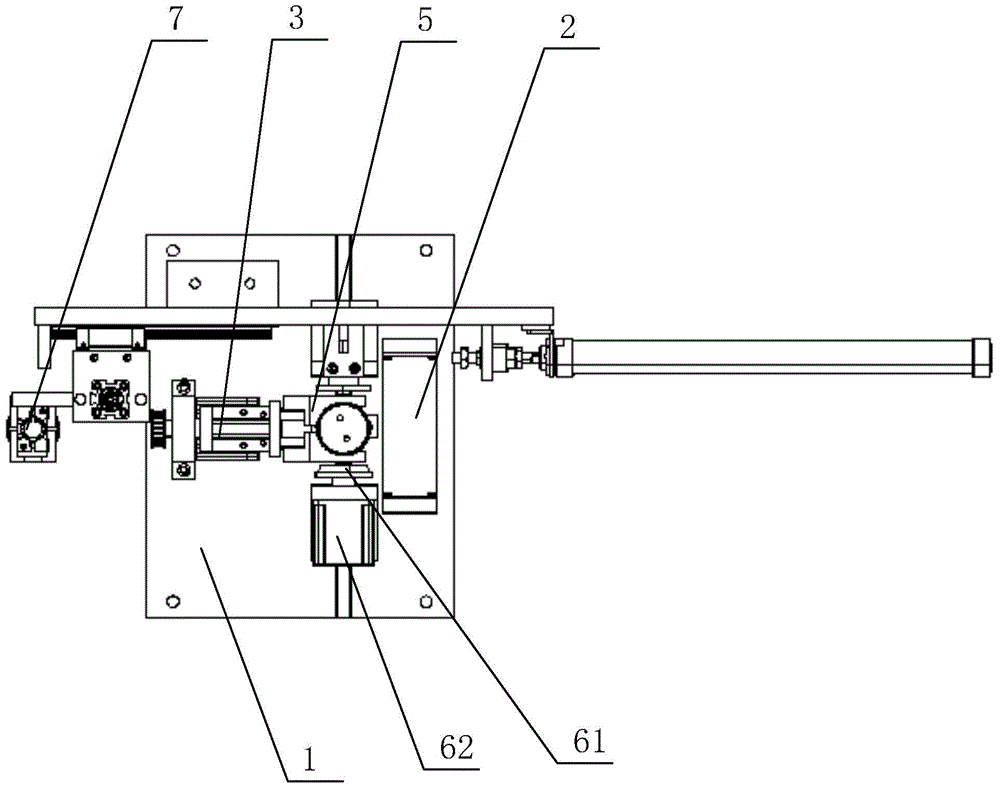

Automatic dispensing device for nuts

ActiveCN106392606AEasy to take awayReduce production labor costsMetal working apparatusPush outAutomatic Dispensing

The invention discloses an automatic dispensing device for nuts, which is used for arraying nuts in a manner same as an arraying manner of a plurality of nuts in a material tray. The automatic dispensing device for nuts comprises a nut accumulating mechanism (2), a nut conveying mechanism (4) and a nut dispensing mechanism (6), wherein the nut dispensing mechanism (6) comprises a cutting device (12) and a push-out mechanism (15). The nut accumulating mechanism (2), the nut conveying mechanism (4) and the nut dispensing mechanism (6) are arranged, and the nuts can be placed in the cutting device (12) in a specified form and be pushed out by the push-out mechanism (6), such that the material tray can be directly taken away without location, the process can be realized automatically, a manual cost of production is greatly reduced and production efficiency is improved.

Owner:江苏亨芯石英科技有限公司 +1

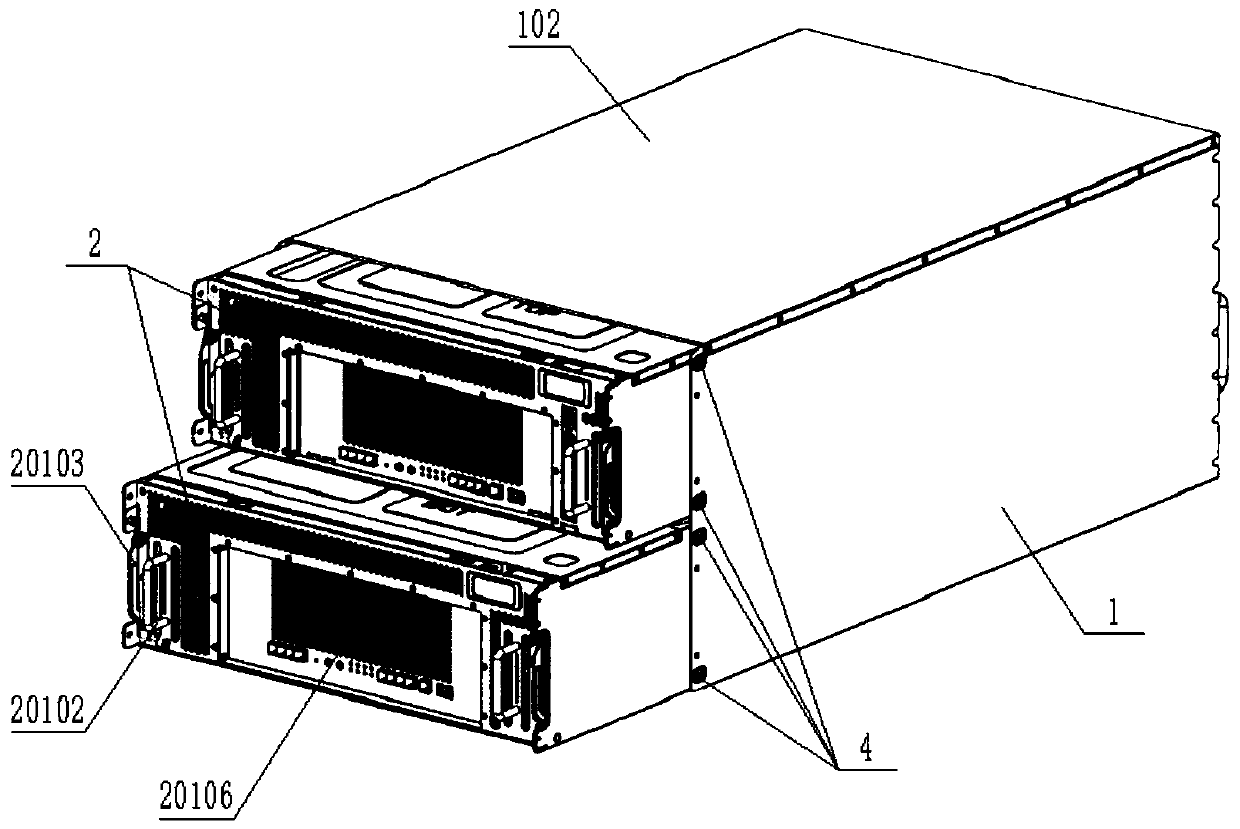

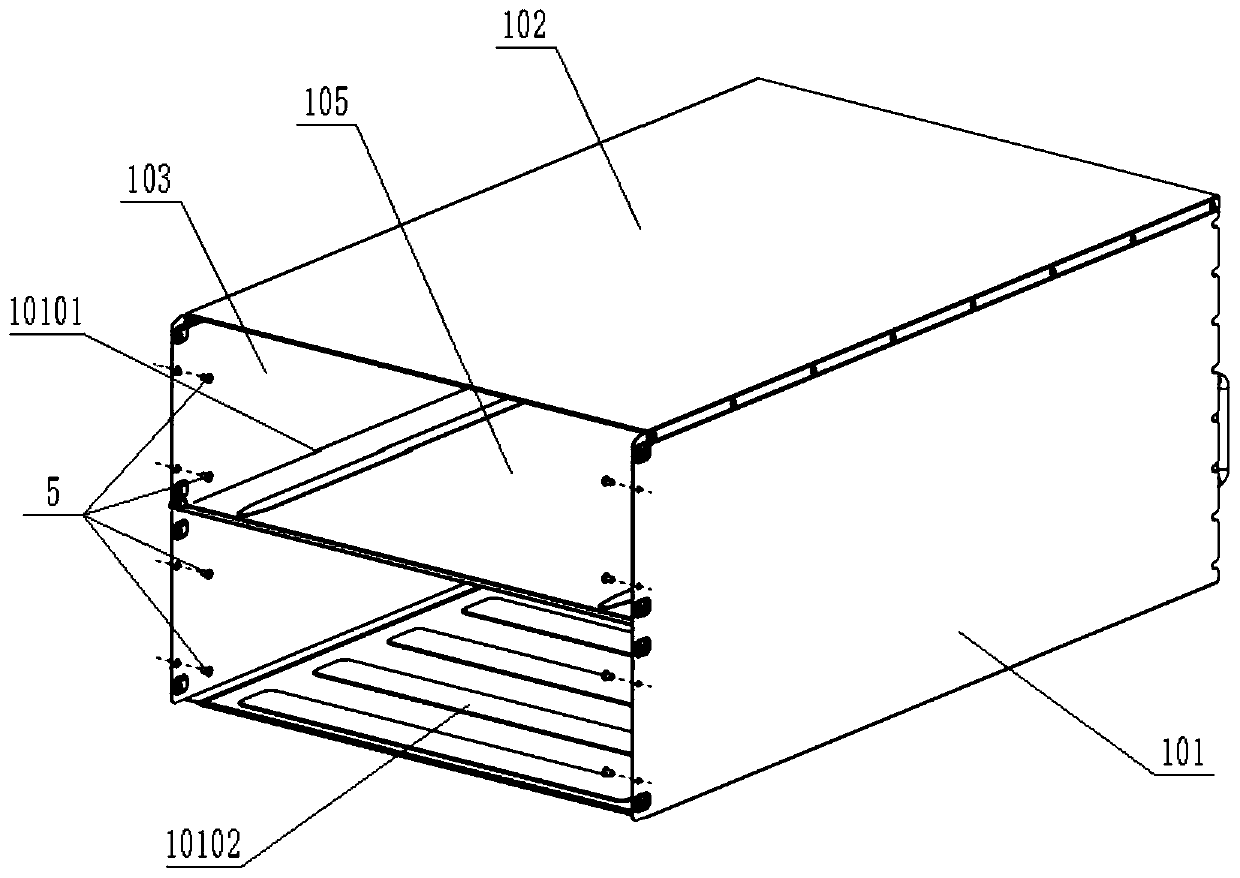

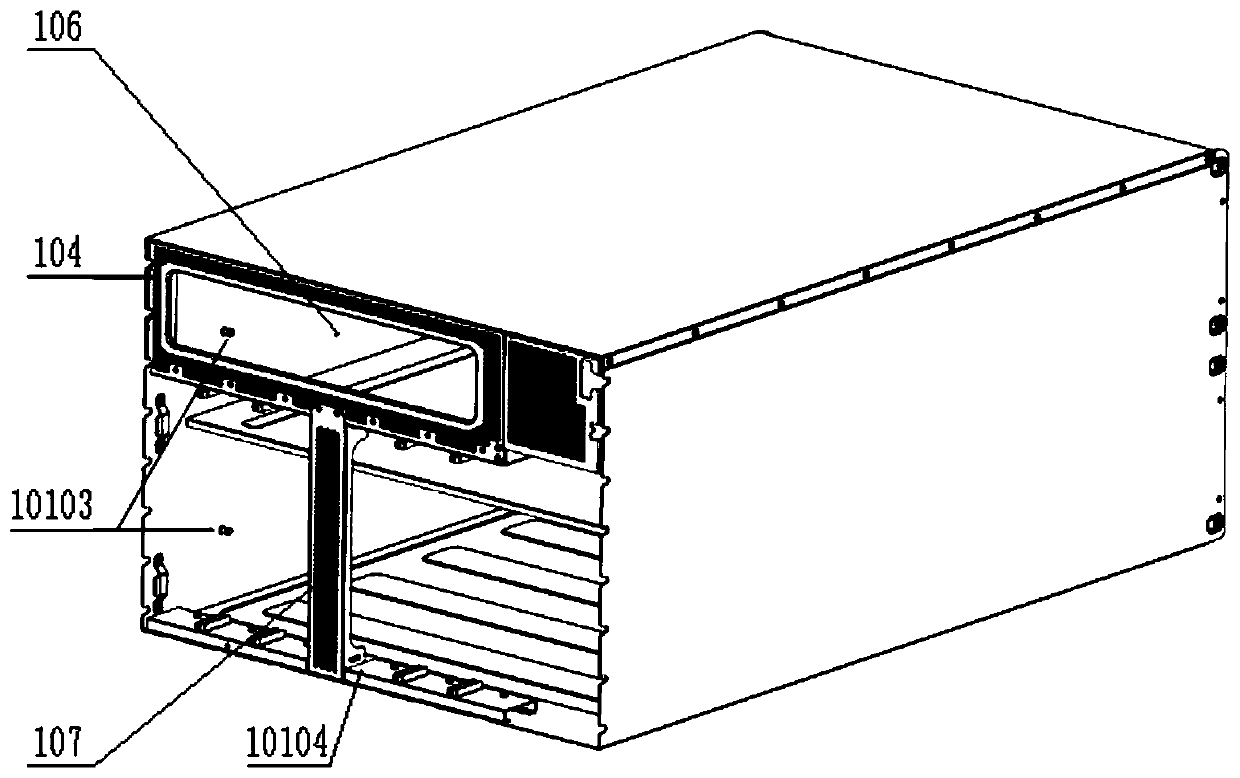

A server structure supporting a 16GPU

ActiveCN109710557AImprove cooling effectGuaranteed cooling effectMultiple digital computer combinationsDigital processing power distributionHigh densitySoftware engineering

The invention discloses a server structure supporting a 16GPU. The device comprises an 8U case, a 4U server, a bridging module, bolts and screws, The 8U case is provided with a front window structureand a rear window structure. The device comprises a base, Upper cover and middle partition plate, Rear window perforated plate, Rear window support, The invention designs a 4U server structure capableof accommodating eight GPUs. Meanwhile, an 8U case capable of storing two 4U servers is designed. The invention discloses a server structure supporting a 16GPU. GPU high-density ports of the two 4U servers are connected through the bridging module; the two 4U servers are arranged; Sixteen GPU cooperative work, the space requirement of the novel server is met; meanwhile, due to the special structural design of the wind scooper, the heat dissipation performance of the server is improved; the rear window opening plate is connected with the upper cover and the base through bolts at the rear window, so that connection between the upper cover and the base is reinforced, heat dissipation of the server can be guaranteed, and technicians can conveniently observe whether the server has abnormal conditions or not at the rear window.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Curtain production line and technological process thereof

ActiveCN112796088AReduce mistakesReduce resource requirementsInspecting textilesSevering textilesEngineeringManufacturing line

The curtain production line comprises a curtain production line and technological process thereof. The curtain production line comprises a metal detection device and a cutting device, the cutting device being provided with a cloth cutting table, wherein a material guide plate is arranged at one end of the cloth cutting table, a first sliding groove and a second sliding groove are fixedly arranged on two sides of the material guide plate correspondingly, a first sliding block is slidably connected into the first sliding groove, a second sliding block is slidably connected into the second sliding groove, a heat conduction wire is arranged between the first sliding block and the second sliding block, a strip-shaped groove is formed in the cloth cutting table, and the material guide plate is provided with a winding roller. Curtain cloth detected to be qualified by the metal detection device is conveyed to the cloth cutting table and conveyed to one end of the guide plate from the cloth cutting table under he traction of the winding roller, when the curtain cloth is conveyed to the position above a strip-shaped groove, the first sliding block and the second sliding block move downwards at the same time by treading a pedal, then the heat conduction wire moves into the strip-shaped groove, and the curtain cloth is cut off through the heat conduction wire by means of high temperature, so that the phenomena of errors and resource waste caused by manual cutting are reduced, the production labor cost is reduced, and the production efficiency of curtain cloth cutting is improved.

Owner:威海利能家纺有限公司

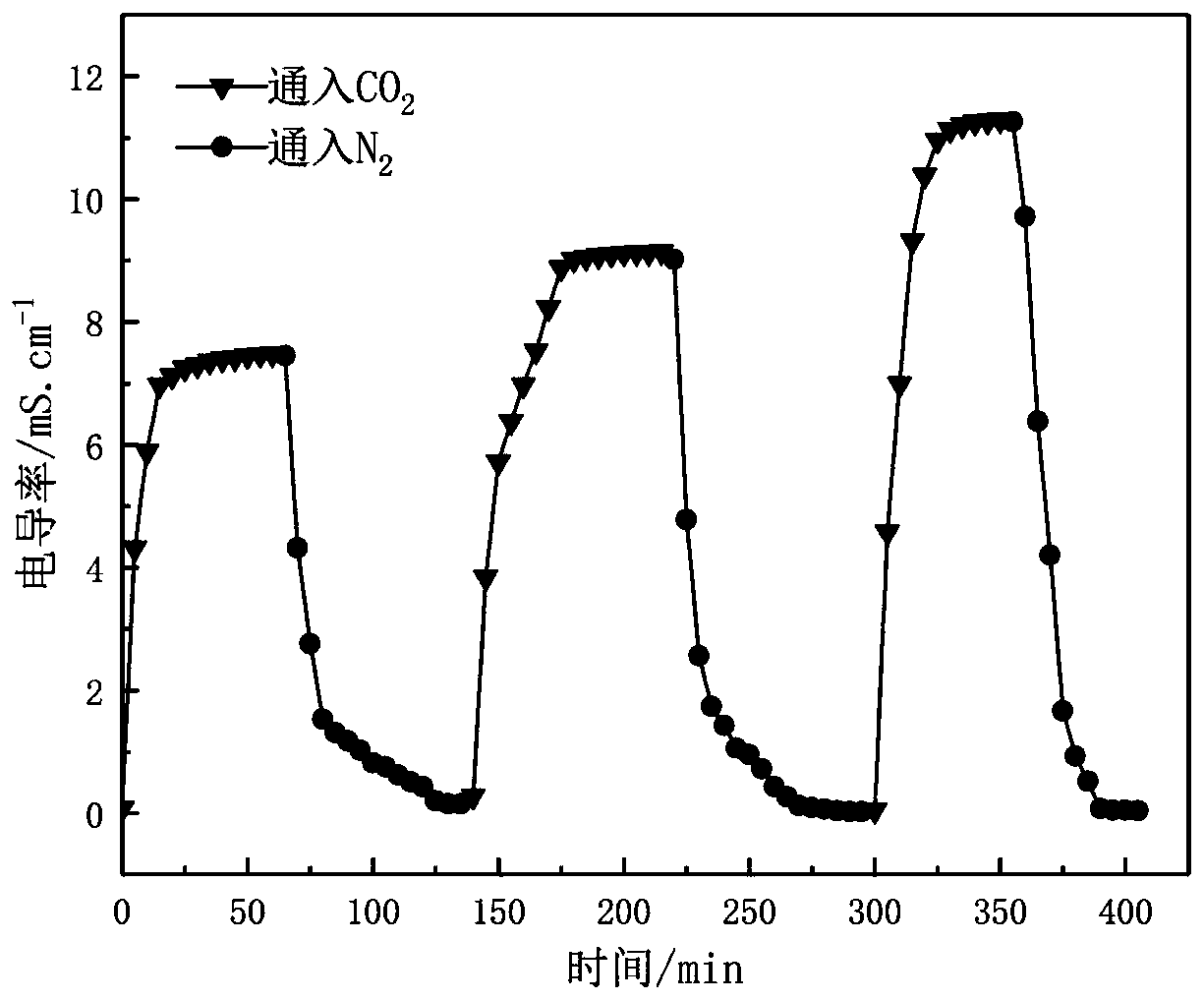

Preparation method of paraffin particles based on CO2/N2 switch emulsion and application of paraffin particles

ActiveCN111253970AReduce pollutionEasy to saveWax physical treatmentDrilling compositionParaffin waxCyclohexylamines

The invention relates to a preparation method of paraffin particles based on CO2 / N2 switch emulsion and an application of the paraffin particles, which relate to the technical field of paraffin particles. The preparation method specifically comprises the following steps: S1) preparing an oil phase; S2) preparing a water phase; S3) preparing an O / W emulsion: mixing the oil phase and the water phase, stirring and emulsifying to obtain the O / W emulsion; S4) preparing paraffin particles: introducing carbon dioxide into the O / W emulsion, separating out the paraffin particles, and centrifuging to obtain the paraffin particles and a protonated solvent; S5) performing cyclic utilization: introducing nitrogen into the protonated solvent to obtain N, N-dimethylcyclohexylamine and an emulsifier aqueous solution, and respectively recycling. The invention also discloses the application of the paraffin particles. The invention discloses the preparation method of paraffin particles with recyclable solvent and emulsifier aqueous solution, which saves raw materials, lowers the cost and reduces the environmental pollution. Meanwhile, the invention further discloses the application of the product indrilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

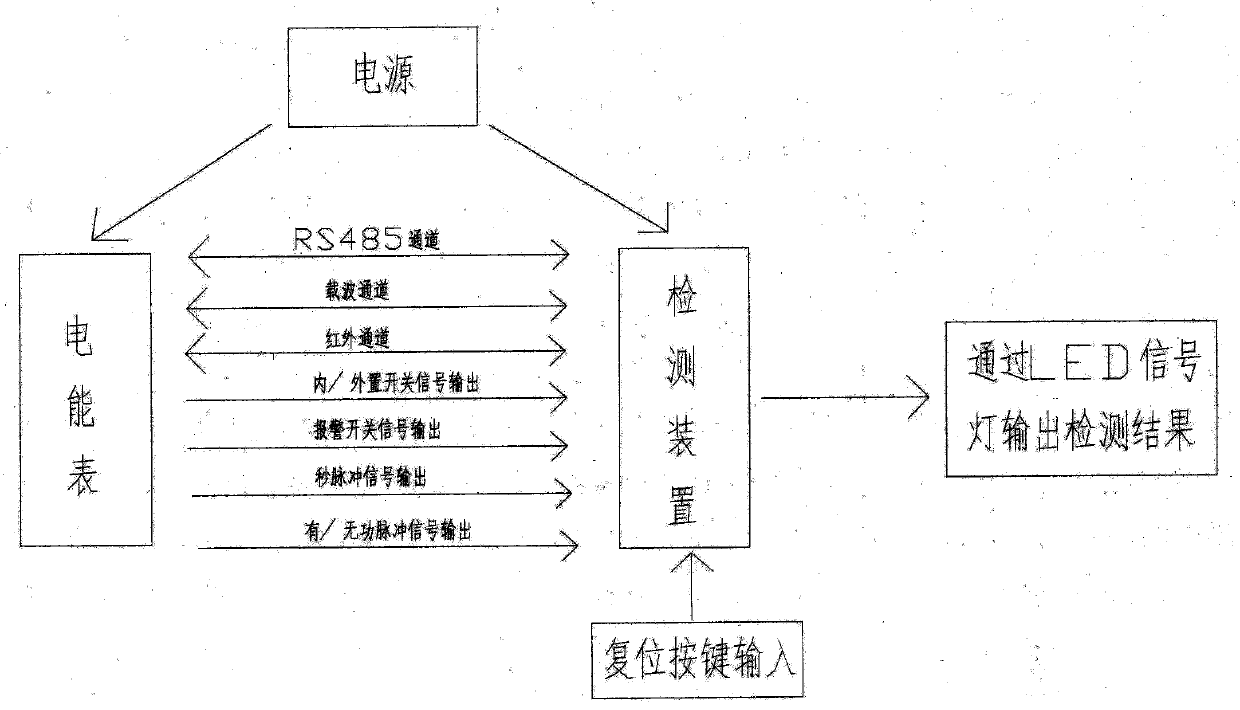

Automatic detection device of hardware fault of whole electric energy meter and detection method thereof

InactiveCN107561478AReduce inflowTake up debugging timeElectrical measurementsEngineeringRepeatability

The invention discloses an automatic detection device of a hardware fault of a whole electric energy meter and a detection method thereof. The device comprises a power supply module, a CPU signal processing chip, a signal prompting LED lamp, a reset button, a signal detection port and a power supply port. According to the invention, before the whole electric energy meter is debugged, problems arefound in advance so that maintenance is performed, so occupation of a debugging bench body when fault products enter the next step is reduced; the bottleneck that the production device limits the yield is reduced; production efficiency is improved; before the whole electric energy meter is detected, hardware problems are detected in advance, so some repeated detection work of fault products lateris reduced and production and labor cost is reduced; and after the electric energy meter is assembled, the detection device carries out comprehensive hardware detection on the electric energy meter, so entering to the next production step of fault products is reduced; and production quality is improved.

Owner:HUNAN DONGRUI INTELLIGENT INSTR

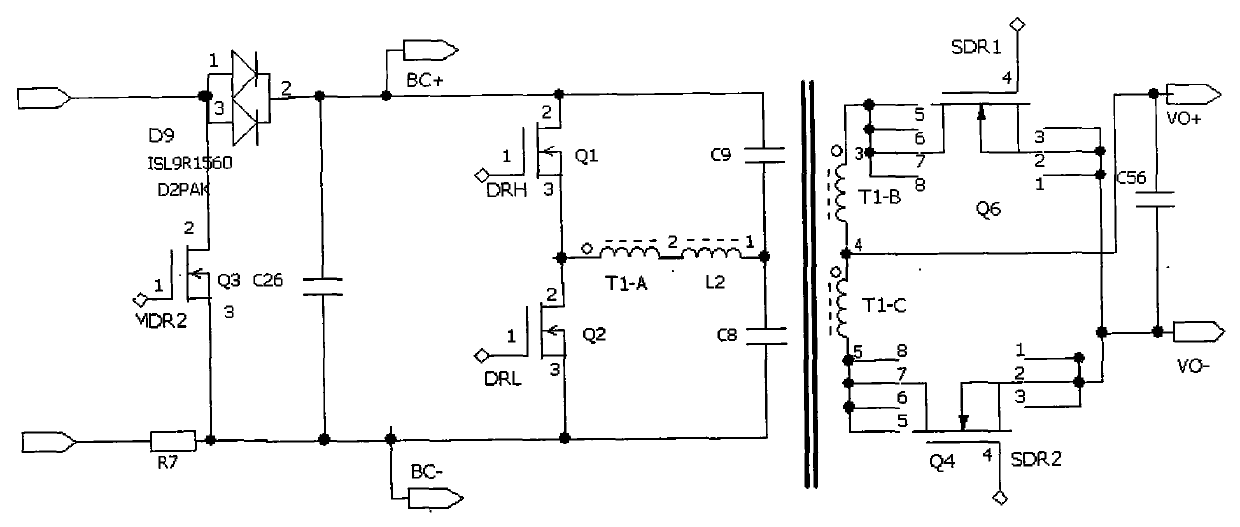

Power supply framework integrating AC/DC and wide-input DC/DC designs

ActiveCN104184342AWide range of applicationsReduce heat dissipationAc-dc conversion without reversalEnergy industryInductorCapacitance

The invention discloses a power supply framework integrating AC / DC and wide-input DC / DC designs. The framework includes a power module and external elements. The power module includes an aluminum substrate which has a size of a whole brick and a control panel. Power devices which are heating in a circuit are welded on the aluminum substrate. Control devices are installed on the control panel. The control panel and the aluminum substrate are connected into an up-down structure through a pin structure and can also be connected into a plane structure through a wire. The external elements include a rectifying bridge, an input PFC inductor and a PFC output capacitor. The inductor is capable of being installed on the aluminum substrate according to difference of conditions. When a power supply is of wide voltage DC input, the PFC inductor can be saved. The power supply frame work integrating all heating power devices onto the aluminum substrate so that heat radiation is convenient and a power supply circuit is simplified sufficiently and different power supplies can be designed through addition of simple external elements so that labor cost is reduced and the framework is capable of significantly shortening a research and development cycle.

Owner:SHENZHEN VAPEL POWER SUPPLY TECH

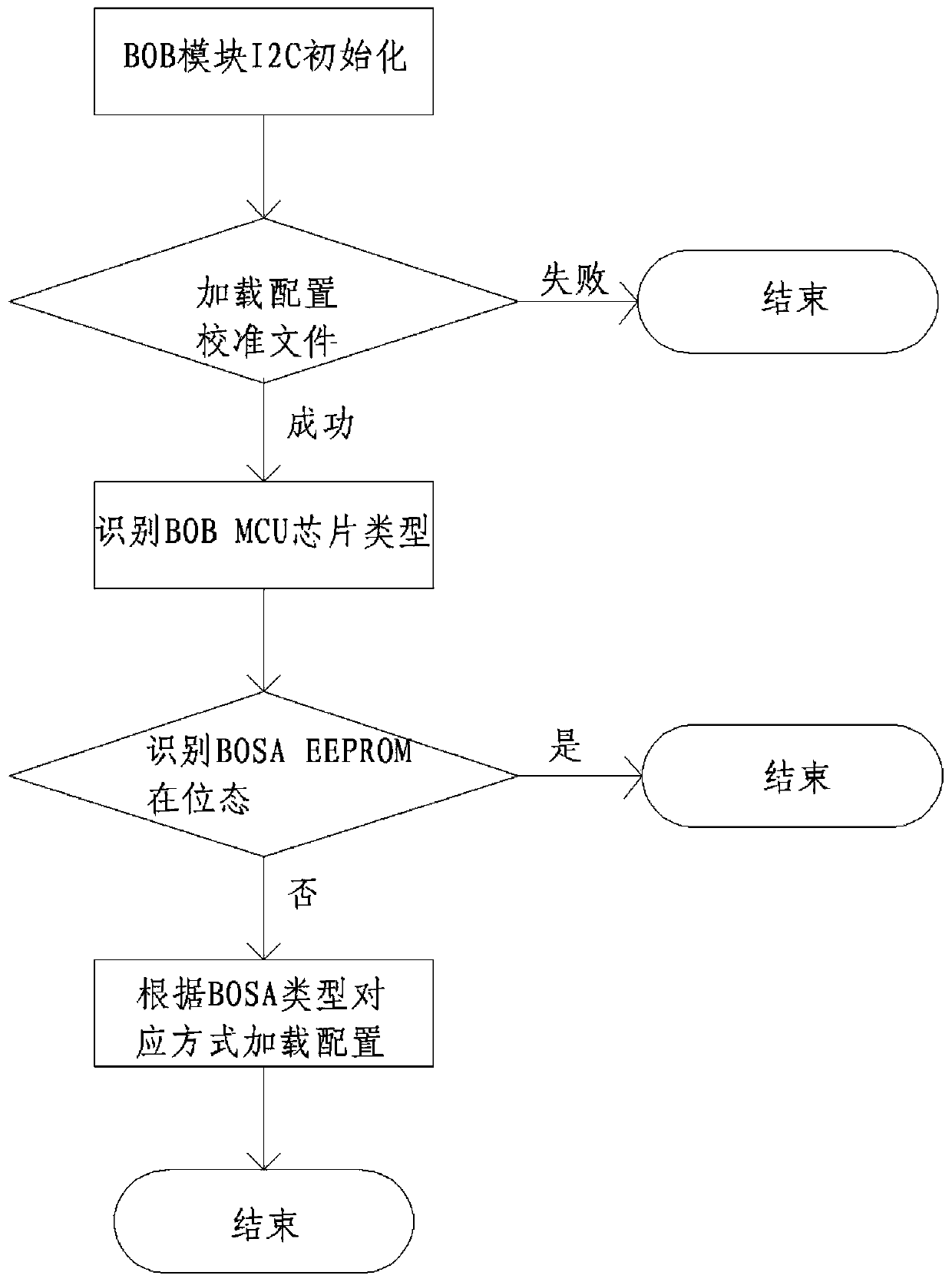

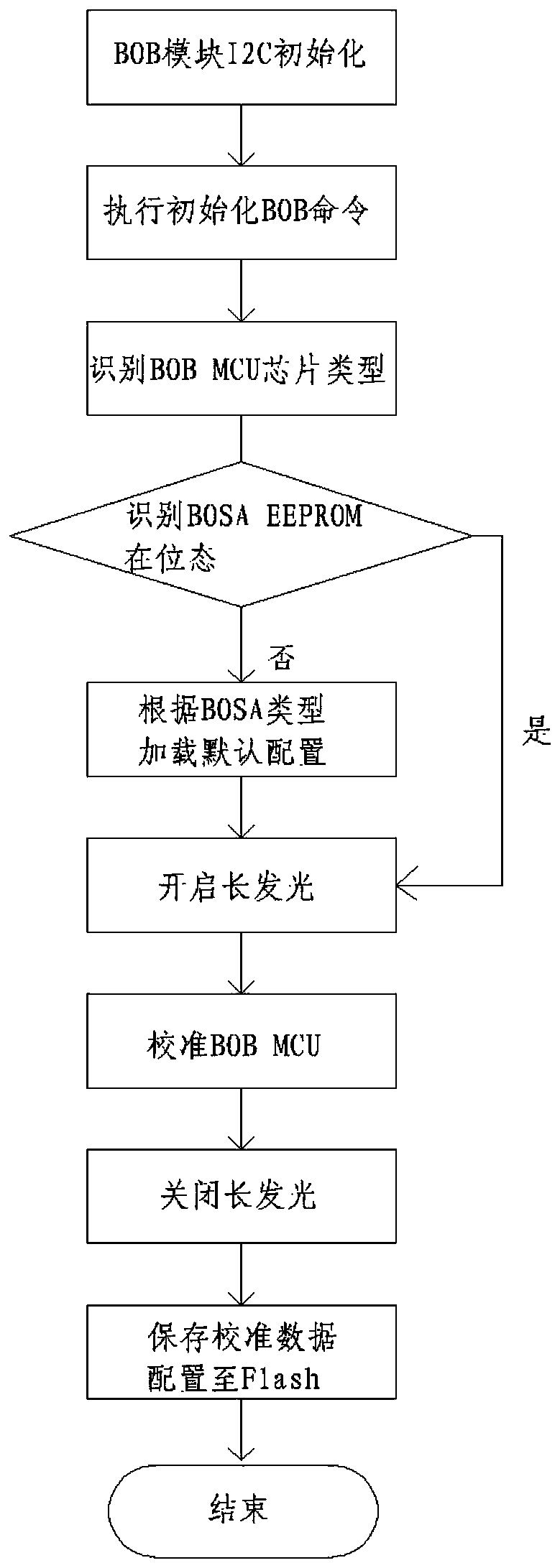

Calibration and configuration management method based on 10G PON BOB equipment

ActiveCN111399945AIndependent portability is goodReduce production calibration proceduresMultiplex system selection arrangementsProgram loading/initiatingSpecific modelLogisim

The invention discloses a calibration and configuration management method based on 10G PON BOB equipment. The calibration and configuration management method comprises the following steps that a loading module is started on the 10G PON equipment; the module identifies a corresponding manufacturer and a specific model; an upper computer reads the corresponding status bit of a BOB chip to judge whether the BOB chip has EEPROM / Flash or not; if the external EEPROM / Flash is detected, the following steps are ended; if the configuration information of the BOB in the Flash is not detected, the upper computer needs to load the configuration information of the BOB in the Flash to the BOB driver and perform configuration according to the configuration logic of the corresponding BOB type. According tothe invention, the BOB configuration storage and management are completely controlled by the PON main chip, so an EEPROM / Flash memory of BOB hardware is saved, and the hardware cost is reduced; BOB chips of different models can be automatically identified and correspondingly configured and loaded in an adaptive manner; BOB factory production calibration programs are reduced, and the production labor cost is saved.

Owner:TAICANG T&W ELECTRONICS CO LTD

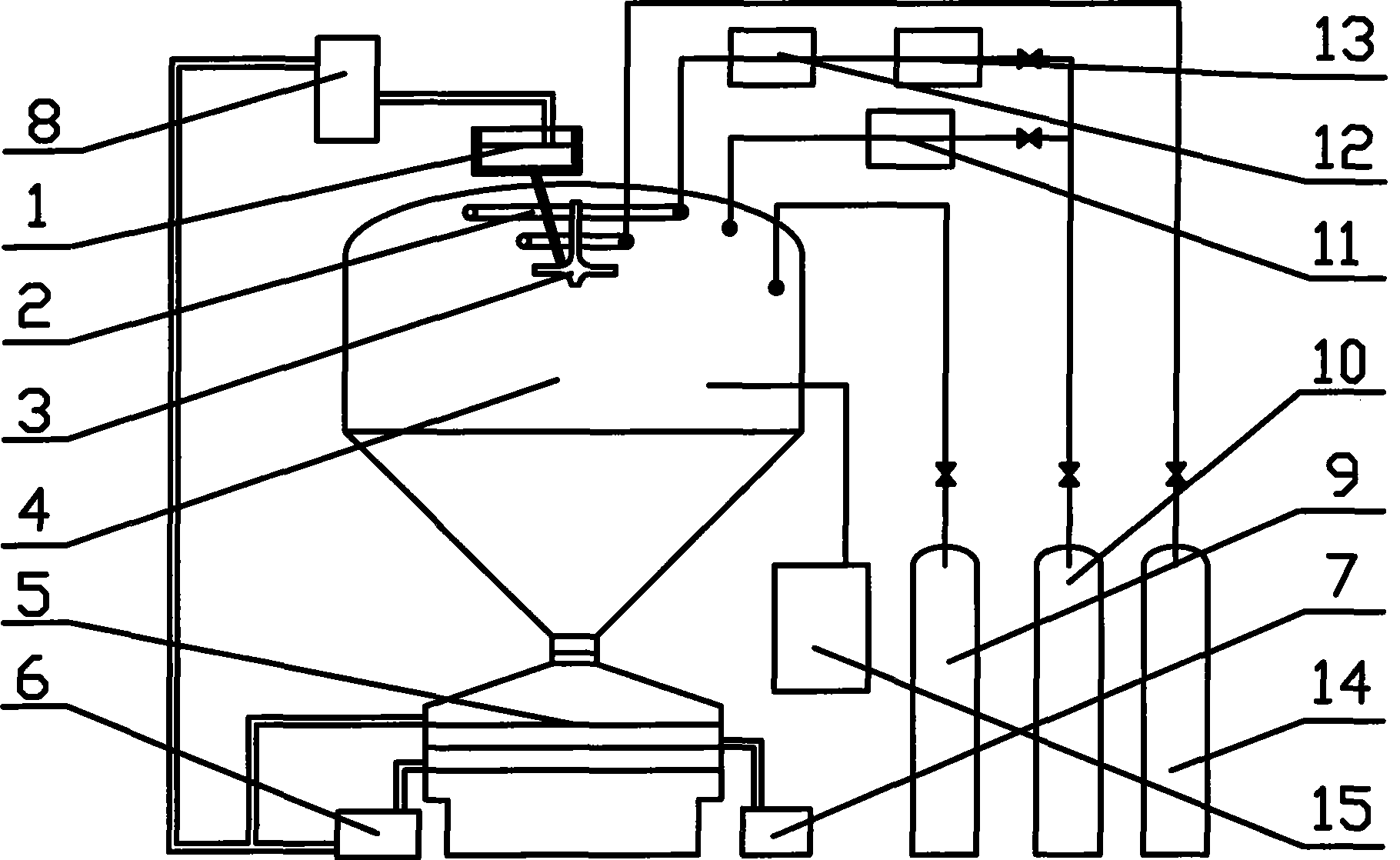

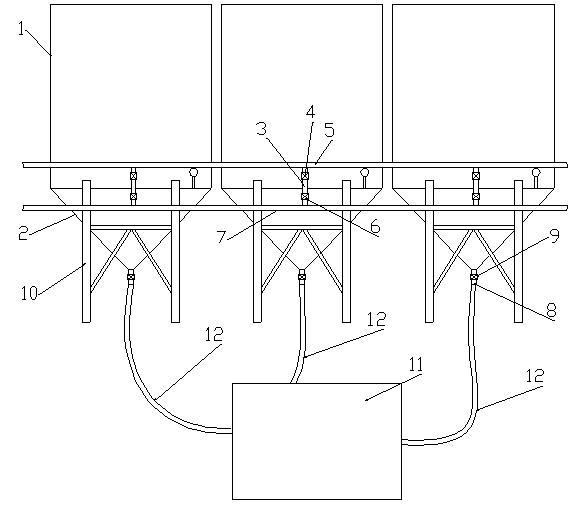

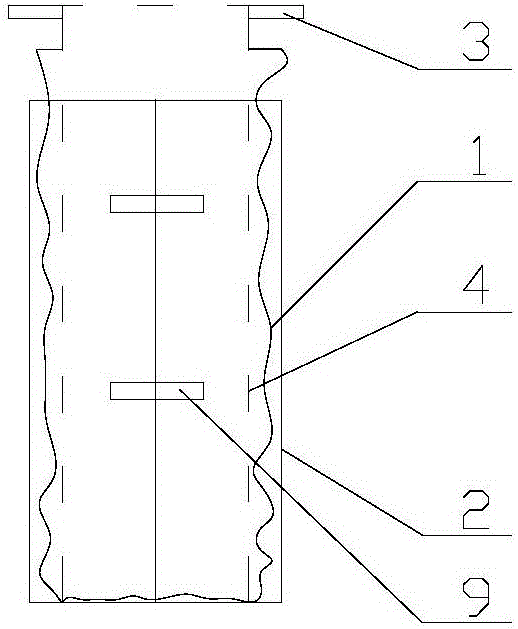

Rapeseed oil refining precipitation system

InactiveCN103571618AEasy to handleImprove high-volume processing capabilitiesSettling tanks feed/dischargeFatty-oils/fats refiningRapeseedEngineering

The invention discloses a rapeseed oil refining precipitation system which comprises a plurality of precipitation tanks arranged together, an oil inlet pipe and an oil outlet pipe communicated with the precipitation tanks, and an oil residue recovery pool disposed on the ground; the lower end of each precipitation tank is provided with a residue discharging port and a control valve; the residue discharging port is communicated with the oil residue recovery pool through a flexible pipe. According to the rapeseed oil refining precipitation system of the invention, the plurality of precipitation tanks are arranged together, and are parallelly connected on the same oil inlet pipe and the oil outlet pipe, so unified oil charging, oil discharging, and oil residue discharging control is realized, which not only improves the mass processing capability of the rapeseed oil precipitation procedure, but also improves working efficiency, reduces operation labor intensity, and decreases production manpower cost; oil residues from each precipitation tank are collected and stored through the oil residue recovery pool, which is simple in operation and facilitates subsequent oil residue processing.

Owner:SICHUAN DEYANG NIANFENG FOOD

Automatic filling machine for boxing sandbag and filling method

ActiveCN106267771AReduce production labor costsFirm blow feelSport apparatusEngineeringSports equipment

The invention discloses an automatic filling machine for a boxing sandbag and a filling method, and belongs to the technical field of the manufacturing of sports equipment. The automatic filling machine is used to fill the sandbag with filler. The key point is that: the automatic filling machine comprises a machine frame, a sandbag opening device, a stamp hammer and a sandbag opening device pulling-out mechanism, wherein the stamp hammer and the sandbag opening device pulling-out mechanism are arranged above the sandbag opening device by means of the machine frame, the stamp hammer has a degree of freedom of elevation in a vertical direction by means of the driving of a first driving mechanism fixed on the machine frame, and the sandbag opening device pulling-out mechanism has a degree of freedom of movement in the vertical direction by means of the driving of a second driving mechanism, and is matched with the sandbag opening device to form the pulling-out mechanism. According to the automatic filling machine disclosed by the invention, the problem of low efficiency of the conventional manual filling of the filler in the boxing sandbag is solved, the filling of the boxing sandbag is automated, and the filled sandbag is more attractive, solid and uniform, and has a good handfeel for beating.

Owner:石家庄市五龙体育器材有限公司

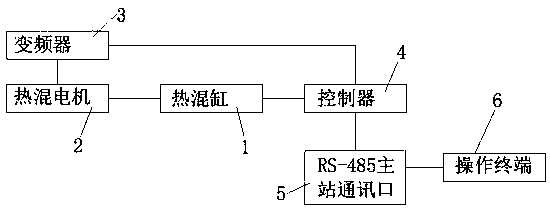

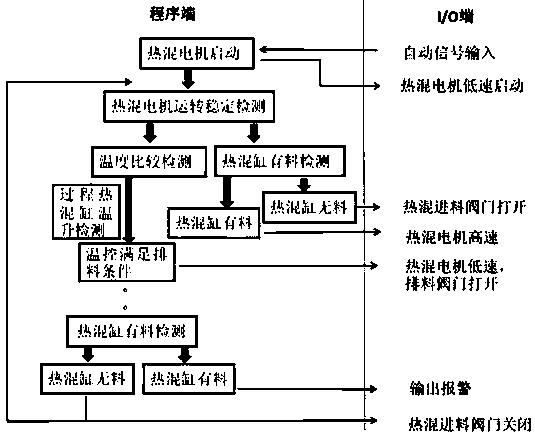

Temperature-current intelligent control method

ActiveCN108628361ASmooth runningStrict control methodTemperatue controlTemperature controlLoop control

The invention provides a temperature-current intelligent control method, and the method comprises the steps: monitoring the process parameters, such as hot mixing temperature and hot mixing motor current; establishing a control model by the sampled hot mixing temperature and hot mixing motor current, establishing a temperature model for a key mixing process, and establishing a hot mixing temperature-hot mixing motor frequency closed-loop control; taking the temperature control as the core, combining with a current value of a hot mixing variable frequency motor, and detecting the mixing state;building a hot mixing discharge interlocking and unlocking process, so as provide a reliable basis for motor control and valve opening, and to guarantee the smooth operation of the hot mixing process.The hot mixing temperature-hot mixing time is within a control range in the entire mixing process.

Owner:茂名联塑建材有限公司

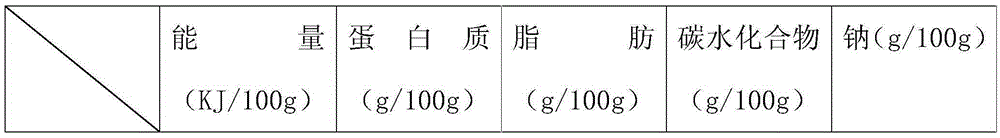

Rice-husk plantation base material for agaricus bisporus, preparation method thereof and method for planting agaricus bisporus by using rice husk

InactiveCN105347929AReduce ammonia removal timeShorten fermentation timeCalcareous fertilisersBio-organic fraction processingBiotechnologyAgaricus

A disclosed rice-husk plantation base material for agaricus bisporus comprises the following compositions in parts by weight: 15-25 parts of rice husk, 65-75 parts of cow dung, 2-4 parts of lime, 0.5-1.5 parts of a phosphate fertilizer, 0.5-1.5 parts of gypsum, 2-4 parts of a vegetable cake, and 0.5-1.5 parts of calcium carbonate. The preparation method for the plantation base material for agaricus bisporus comprises uniformly mixing rice husk, cow dung, lime, the phosphorus fertilizer, gypsum, vegetable cake and calcium carbonate, and piling in a room and fermenting to obtain the plantation base material, and performing turning during piling fermentation. The plantation base material can be momentarily prepared and stored and is not influenced by time and climate, also the raw materials are easy to obtain, price is low, and fermentation time is short, indoor fermentation is employed, fermentation temperature is easy to control, mechanical turning and industrialized production are easy to realize, and production labor cost is substantially reduced. The plantation base material is good in quality, nutrition ratio is scientific and reasonable, agaricus bisporus is fruited ahead of about 10 days compared with a traditional plantation base material, the yield of fresh agaricus bisporus in per one mu farmland is increased by 200 Kg, and the quality of fresh agaricus bisporus is relatively good.

Owner:CHONGQING XUNYE EDIBLE FUNGI PLANTATION DEV CO LTD

Impact-resistant toughened PVC pipe fitting and preparation method thereof

The invention discloses an impact-resistant toughened PVC pipe fitting and a preparation method thereof, the impact-resistant toughened PVC pipe fitting comprises the following raw materials by weight: 100 parts of SG-7 type PVC resin; 4.2 to 4.9 parts of an HL-60 type processing aid; 2-5 parts of an MBS-66 type impact modifier; 6.1-6.9 parts of a calcium-zinc heat stabilizer; 11.5 to 13.8 parts of PCC-P type ultrafine calcium carbonate; 2.1 to 2.8 parts of SR-240 type titanium dioxide powder; 4.2 to 4.9 parts of DS (Diethylhexyl Sulfate)-65 type dioctyl ester; and 0.6 to 0.8 part of an LA-W95type lubricant. The prepared impact-resistant toughened PVC pipe fitting solves the technical problems that a PVC pipe fitting produced in the prior art is low in impact resistance and toughness.

Owner:GUANGDONG LIANSU TECH INDAL

Wine box top cover forming machine

PendingCN112549632APrecise BondingExcellent adhesionPaper-makingBox making operationsProcess engineeringManipulator

The invention provides a wine box top cover forming machine. The wine box top cover forming machine is characterized by comprising a feeding device, a material taking manipulator, a dispensing device,a wine box top cover belt forming, shaping and conveying integrated device, a lining object feeding and positioning device, a lining object or wine bottle positioning piece synchronous obtaining, gluing and positioning manipulator, a primary defoaming device, a drying device, a secondary defoaming device, a conveying device, a control device and a machine base, wherein the material taking manipulator is located on one side or the upper portion of the feeding device, and the feeding device, the material taking manipulator, the dispensing device, the wine box top cover belt forming, shaping andconveying integrated device, the lining object or wine bottle positioning piece synchronous obtaining, gluing and positioning manipulator, the first defoaming device, the drying device and the seconddefoaming device are sequentially arranged along the conveying device. According to the wine box top cover forming machine, wine box top cover belt forming, shaping and conveying integration can be achieved, the defoaming effect is good, the automation degree is high, the production time is shortened, and the labor production efficiency is improved.

Owner:深圳市国润自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com