Automatic filling machine for boxing sandbag and filling method

An automatic filling machine and sandbag technology, applied in the direction of sports accessories, etc., can solve the problems of uneven packing compactness, poor aesthetics of sandbags, and low efficiency of artificial packing, so as to reduce production labor costs, improve training effects, and compact The effect of hitting the hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples.

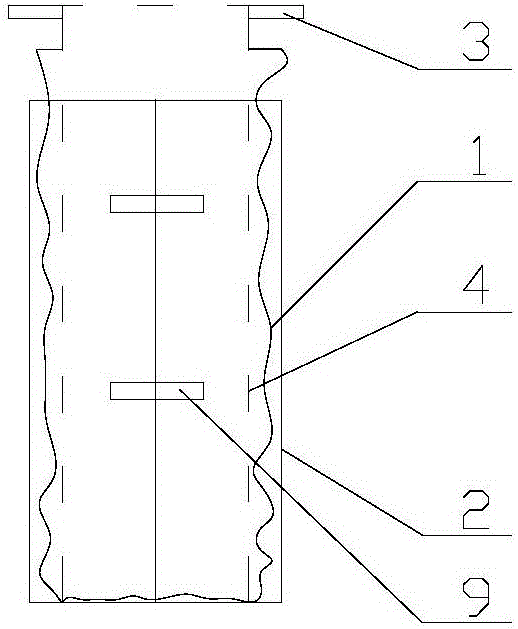

[0020] Such as figure 1 As shown, the boxing sandbag automatic filling machine includes a frame 5, a tamping hammer 6 positioned above the sandbag 1 to be filled, an inner sleeve 4 is arranged inside the sandbag 1, an outer sleeve 2 is placed on the outside, and an inner sleeve 2 is placed inside the sandbag 1. The end of the sleeve 4 is provided with lifting lugs 3 . The stamping hammer 6 has a vertical lifting degree of freedom by means of a hydraulic cylinder 10 fixed on the frame 5, and can compact the packing in the inner sleeve 4.

[0021] The boxing sandbag automatic filling machine is also provided with a bag holder pull-out mechanism, which includes a bracket 7 connected to the driving end of the hoist 11, that is, a hook, a pull-out rod 8 fixed on the bracket 7, and a bag holder pull-out mechanism. With regard to the hook at the end of the pulling rod 8, the pulling rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com