Automatic dispensing device for nuts

An automatic batching and power device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of cumbersome positioning of barrels and trays, and achieve the effect of reducing production labor costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

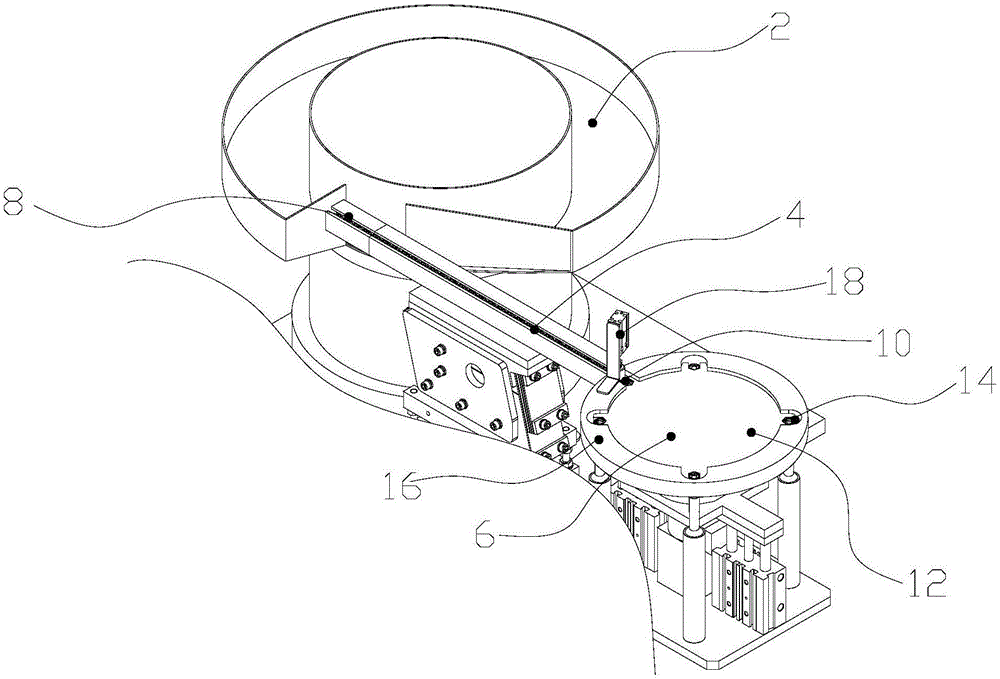

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] like figure 1 As shown, the present invention includes:

[0026] A nut accumulation mechanism 2 of the first discharge port 8 is provided, and the nut accumulation mechanism 2 is used to discharge a plurality of nuts along the first discharge port 8 sequentially, and ensure that they enter the first discharge port 8 The said nut is set with its prescribed end facing upwards;

[0027] The nut transport mechanism 4 connected to the first discharge port 8 is used to drive the nuts entering the nut transport mechanism 4 from the first discharge port 8 along the length of the nut transport mechanism 4 Direction movement to the second discharge port 10, the second discharge port 10 is arranged on the other end of the nut transport mechanism 4;

[0028] It is characterized in that it also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com