Multi-shaft linkage intelligent high-pressure water deburring device

A multi-axis linkage, high-pressure water technology, used in filtration and separation, metal processing, fixed filter element filters, etc., can solve problems such as low production efficiency, reduced workpiece surface quality, surface roughness, etc., to purify the production and processing environment, protect Good health, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

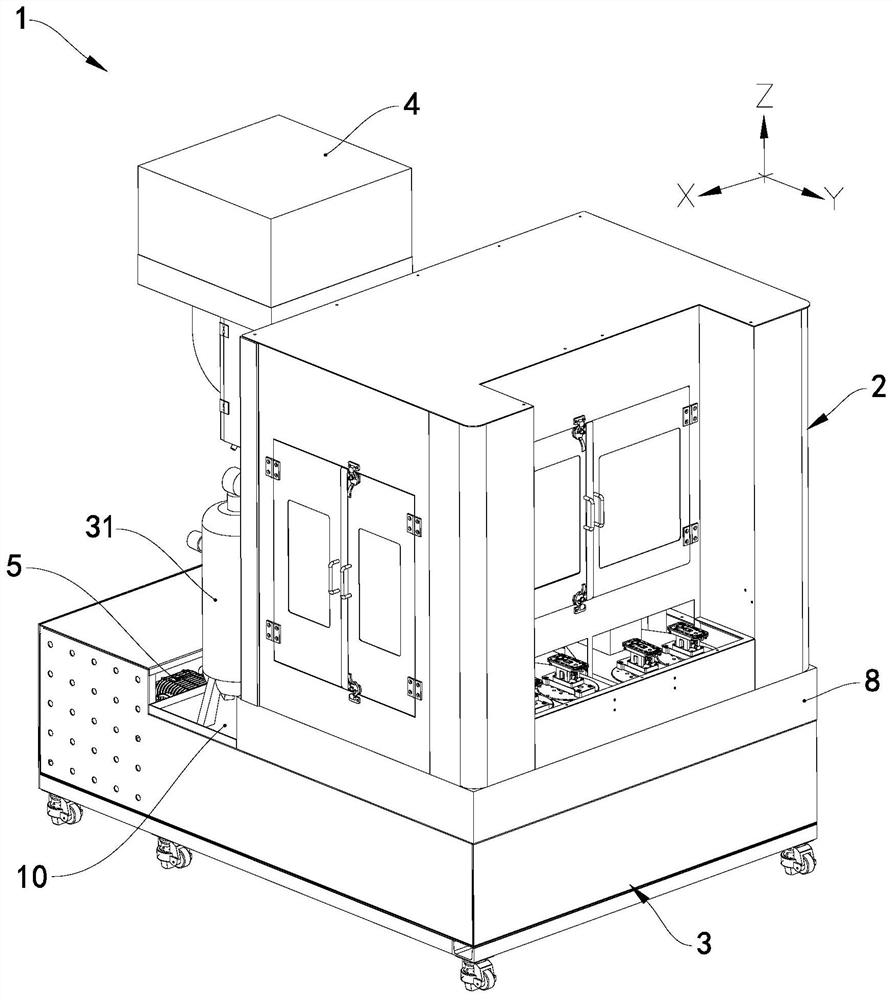

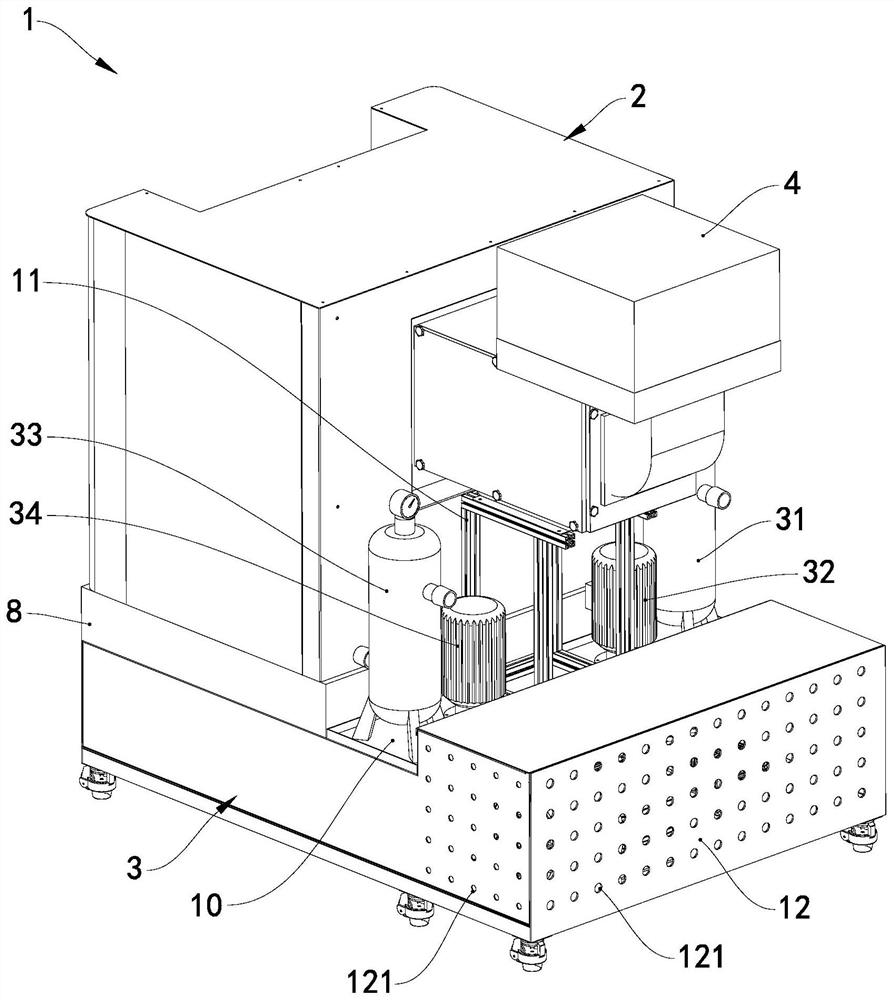

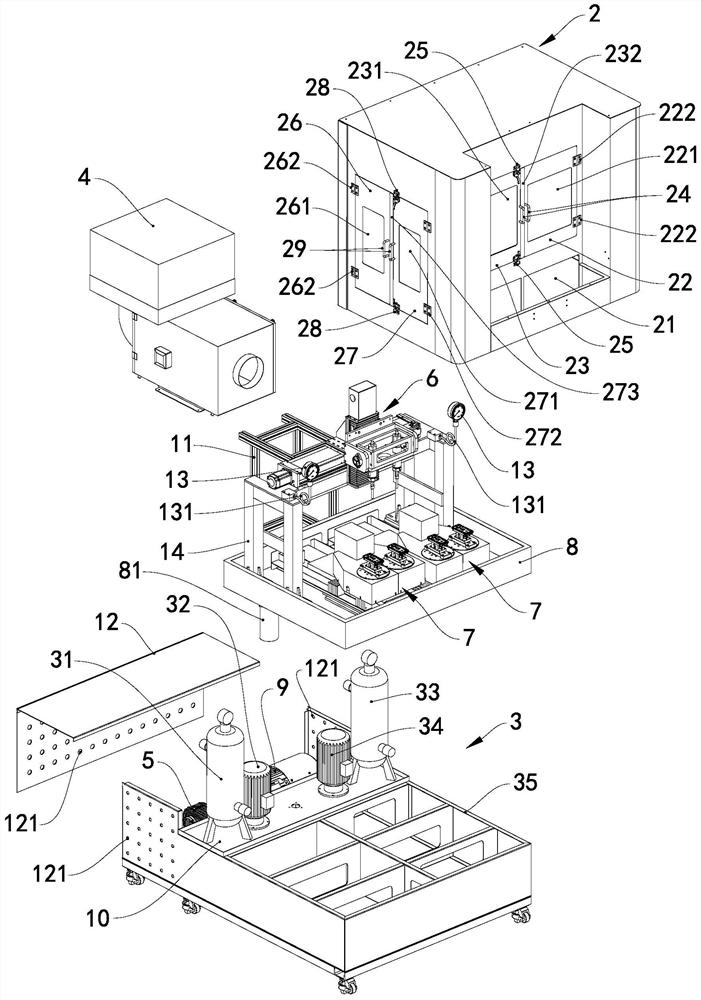

[0049] see Figure 1 to Figure 5 In this embodiment, the multi-axis linkage intelligent high-pressure water deburring equipment 1 includes a frame frame 2, a water collection platform 8, a water knife device 6, a workpiece control device 7, a high-pressure pump 5, a high-pressure pump motor 9, and an oil mist purifier 4 , pressure gauge 13 and filter system 3, the frame frame 2 is covered on the water collection platform 8, the pressure gauge 13, the water knife device 6 and the workpiece control device 7 are located inside the frame frame 2, the frame frame 2 The upper and lower troughs 21 are opened on the first side of the first side. The oil mist purifier 4 communicates with the inside of the frame outer frame 2 , and the oil mist purifier 4 is used to absorb the oil mist inside the frame outer frame 2 . In this embodiment, the third side of the frame frame 2 opposite to the first side in the Y-axis direction is provided with a discharge port 210 , and the oil mist purifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com