Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about How to "Formula stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

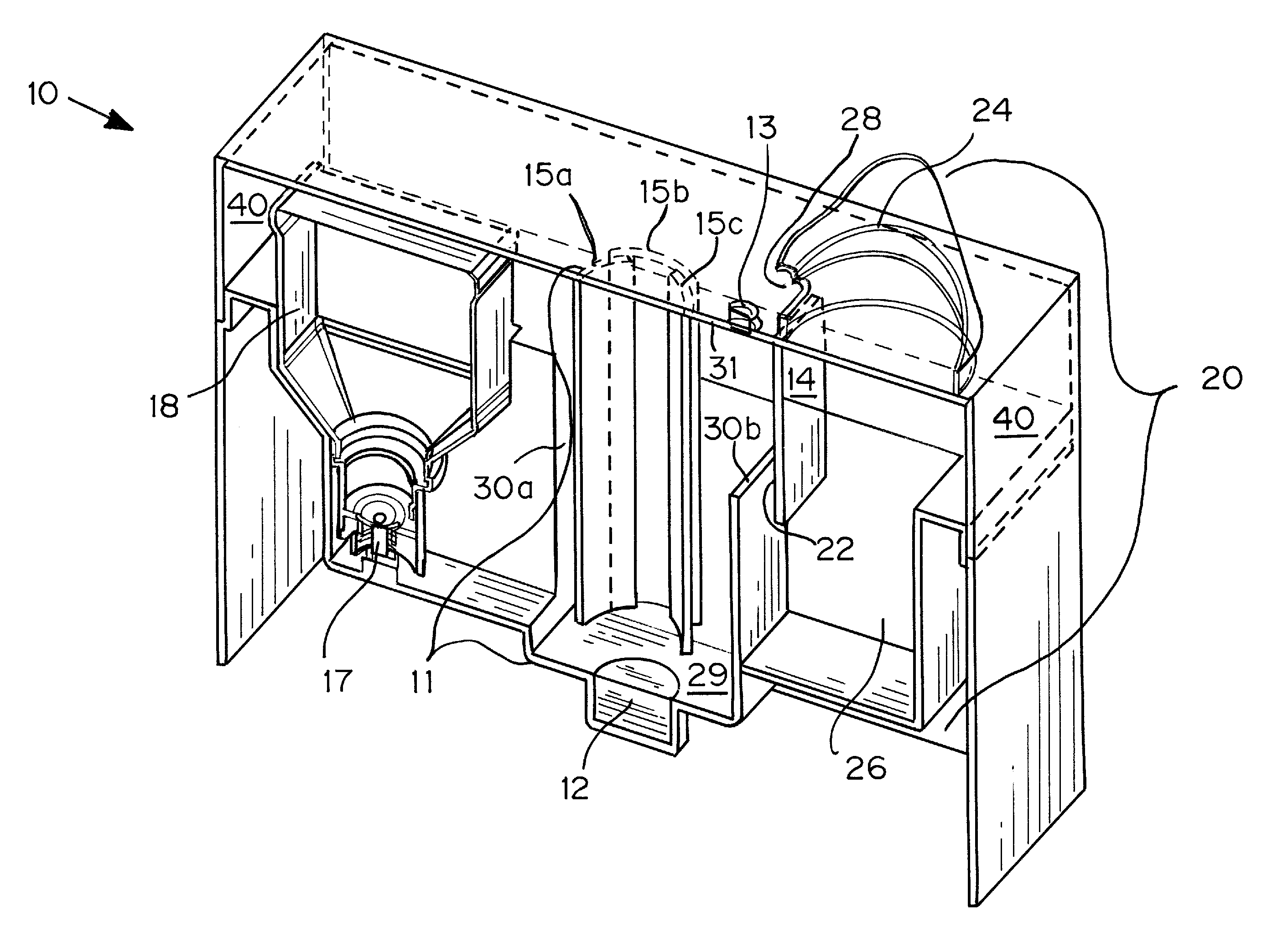

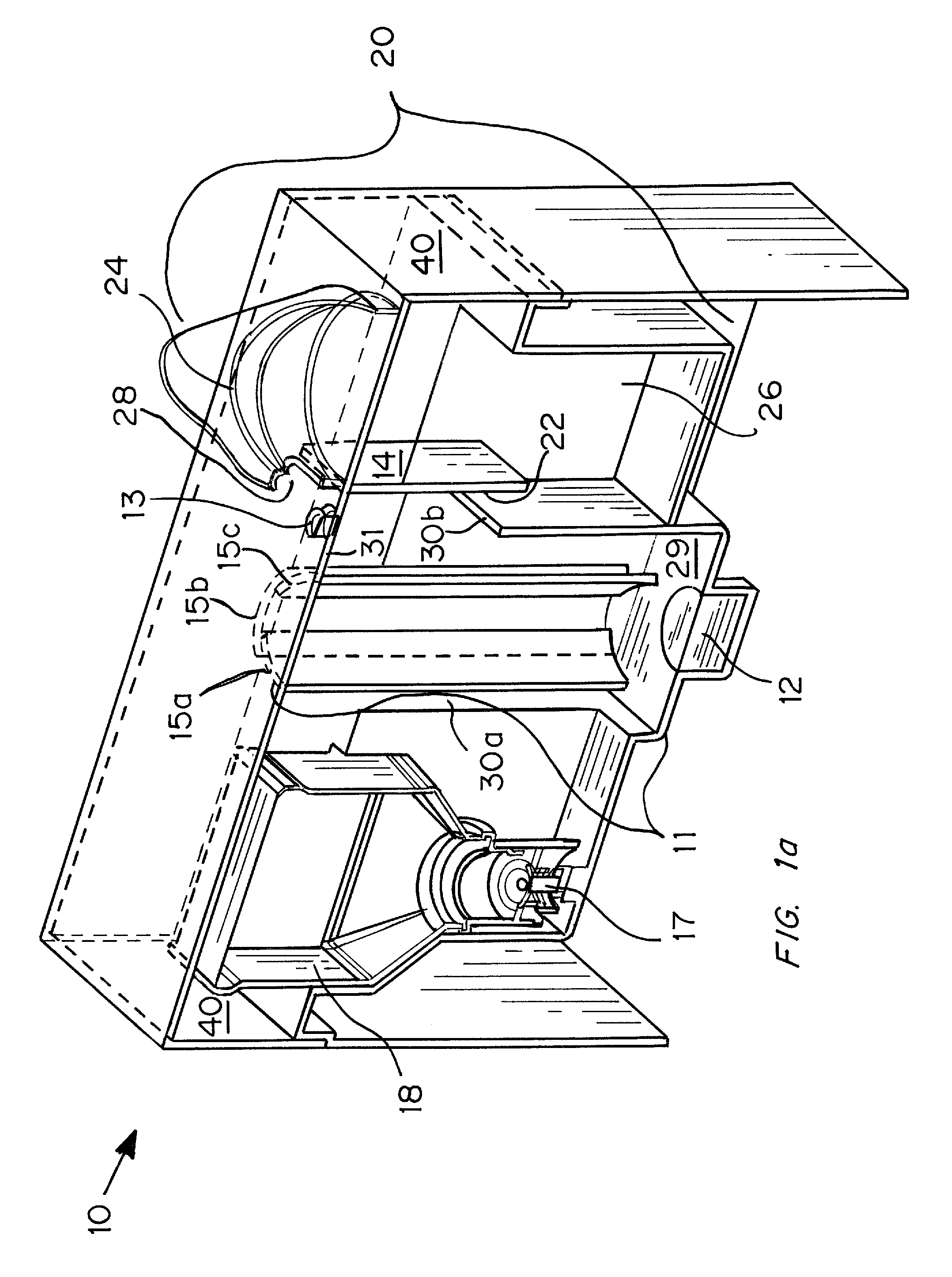

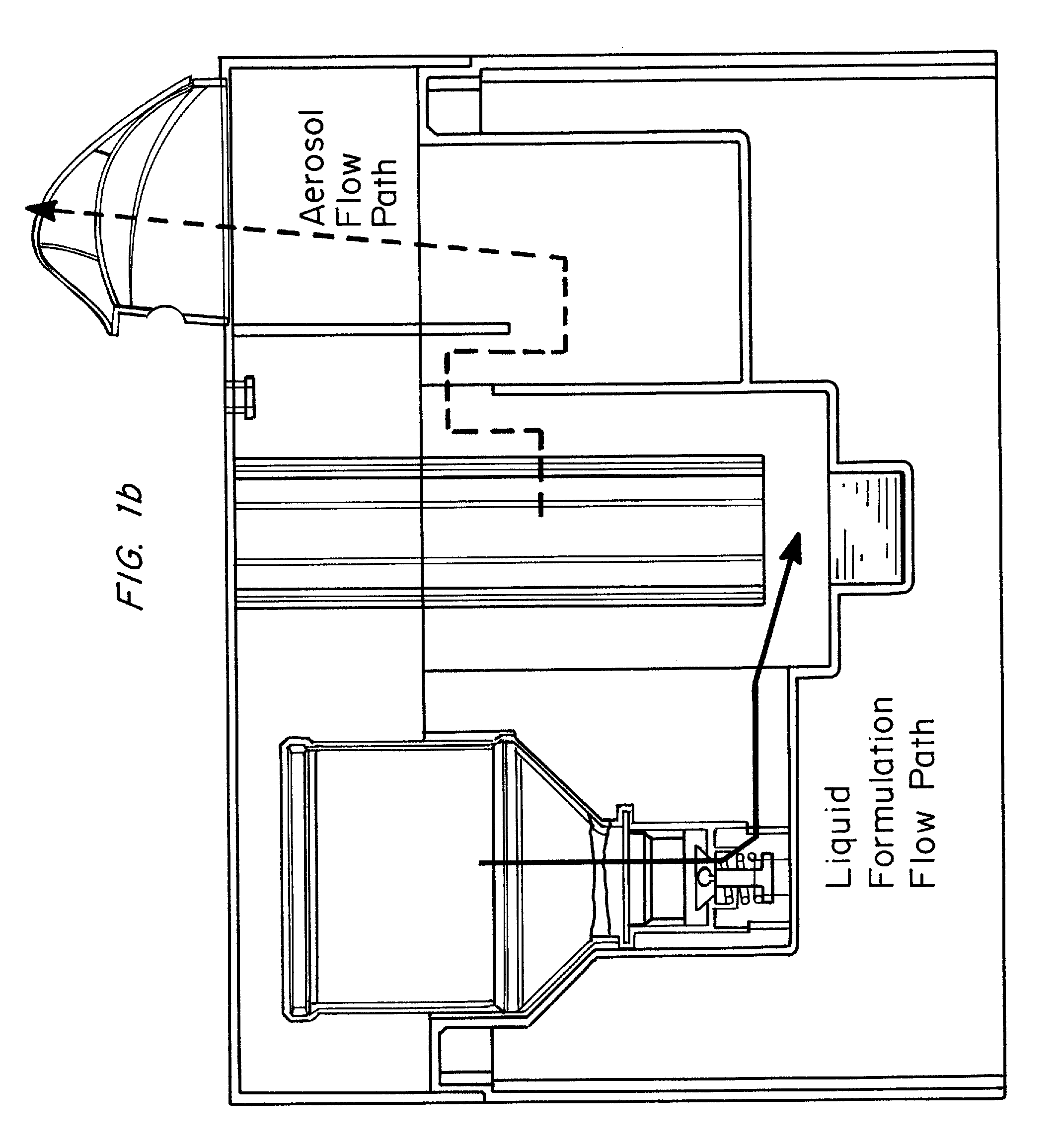

Ultrasonic Aerosol Generator

InactiveUS20060249144A1Low costFormula stableLiquid spraying apparatusMedical atomisersElectricityHand held

An ultrasonic aerosol generator for delivering a liquid formulation in an aerosolized form at a high output rate of greater than 0.5 mL / minute, preferably greater than 1.0 mL / minute, and with diameters in a respirable size range, methods of using this device and kits including the device are described herein. The ultrasonic aerosol generator (10) contains at least (a) a liquid reservoir / aerosolization chamber (11), (b) a piezoelectric engine (12), (c) a relief aperture (13), and (d) an aerosol delivery element (20). Preferably the aerosolized particles that are delivered to the user through the aerosol delivery element have an average aerodynamic diameter of between 1 and 20 μm, more preferably between 1 and 10 μm, and most preferably between 1 and 5 μm. Optionally, the ultrasonic aerosol generator is designed to deliver more than one formulation simultaneously, preferably a low cost and / or stable formulation is administered simultaneously with a more expensive and / or labile formulation. In the preferred embodiment, the ultrasonic aerosol generator is a hand-held device designed for a single user.

Owner:PULMATRIX

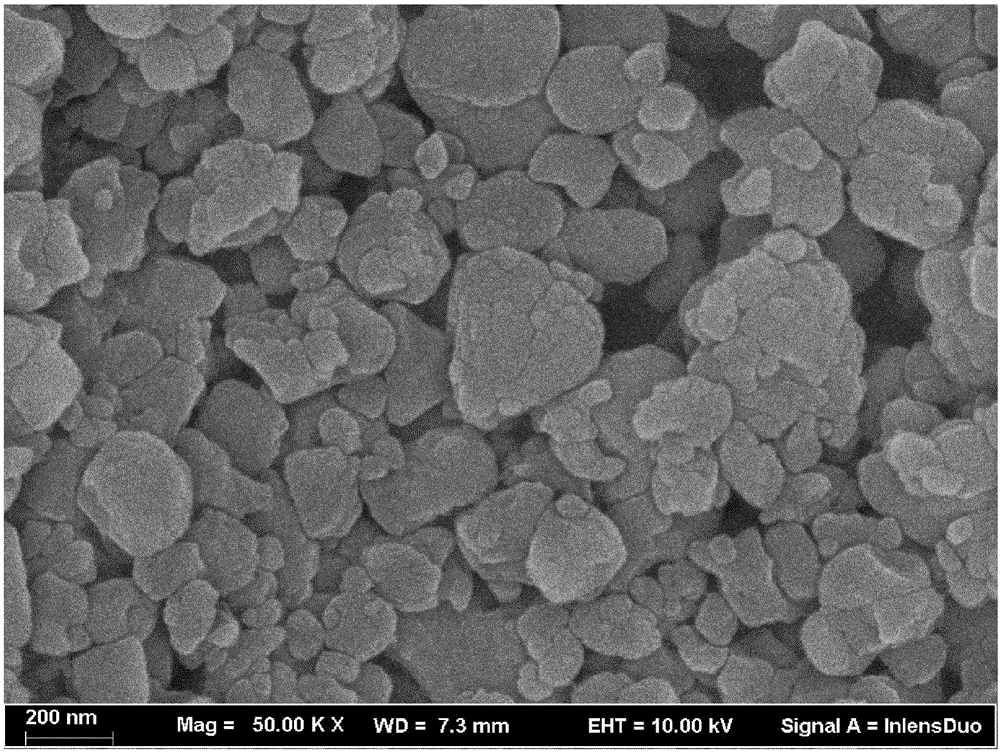

Microsphere type embolic agent and preparation technology thereof

The invention provides a microsphere embolic agent, which is an elastic microsphere formed by the crosslink polymer of the functionalized macromolecules with the biocompatibility, and the particle size of the microsphere ranges from 1 Mum to 1500 Mum. The preparing technology includes the steps as follows: in a covalent link, linking a crosslinkable micromolecules with an acrylic acid structure on the polyvinyl alcohol, polyethylene glycol or polysaccharide macromolecules, forming the functionalized macromolecules; after that, the functionalized macromolecules and the monomer of the 2- acrylamide-2-methyl propanesulfonic acid undertakes opposite suspension polymerization, obtaining the crosslink polymeric microsphere embolic agent. The embolic agent has comparatively large retractility and elasticity, whose particle size is controllable and has perfect dispersiveness; moreover, the raw material is non-toxic and at the same time has good biocompatibility and stability. The preparing technology is a real chemosynthesis technology, whose material and preparing process does not produce any virus pollution, according with various requirements of the international embolic agent, which can replace various import and domestic expensive embolic agent products and is extensively applicable to various surgeries in the interventional radiology field.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

Anti stress immunity enhancing agent for pig

InactiveCN101053370AIncrease feed intakeImprove immunityAnimal feeding stuffAccessory food factorsAnti stressWeaning

An anti stress immunity enhancing agent for pig, the weight ratio range of its component and dry matter is: citric acid 13 to 21 percent; oligomerization Fructose 15 to 25 percent; vitamin C 2 to 3percent; vitamin E 0.5 to 1 percent, vitamin B1 0.4 to 1.0 percent; vitamin B12 0.1to 0.6 percent; garlicin 1 to 4 percent; astragalus polyase 1 to 6 percent; bacitracin zinc 3 to 5 percent; the rest is carrier. The said anti stress immunity enhancing agent has reasonable compound, stable material resource, lower cost, simple producing technology, its merit is: increasing feed intake for pig, promoting growth; enhancing immunity of pig, preventing and curing diarrhea, tail-biting, anorexia etc stress symptom during the weaning, transforming, and transfer to group.

Owner:刘定发 +1

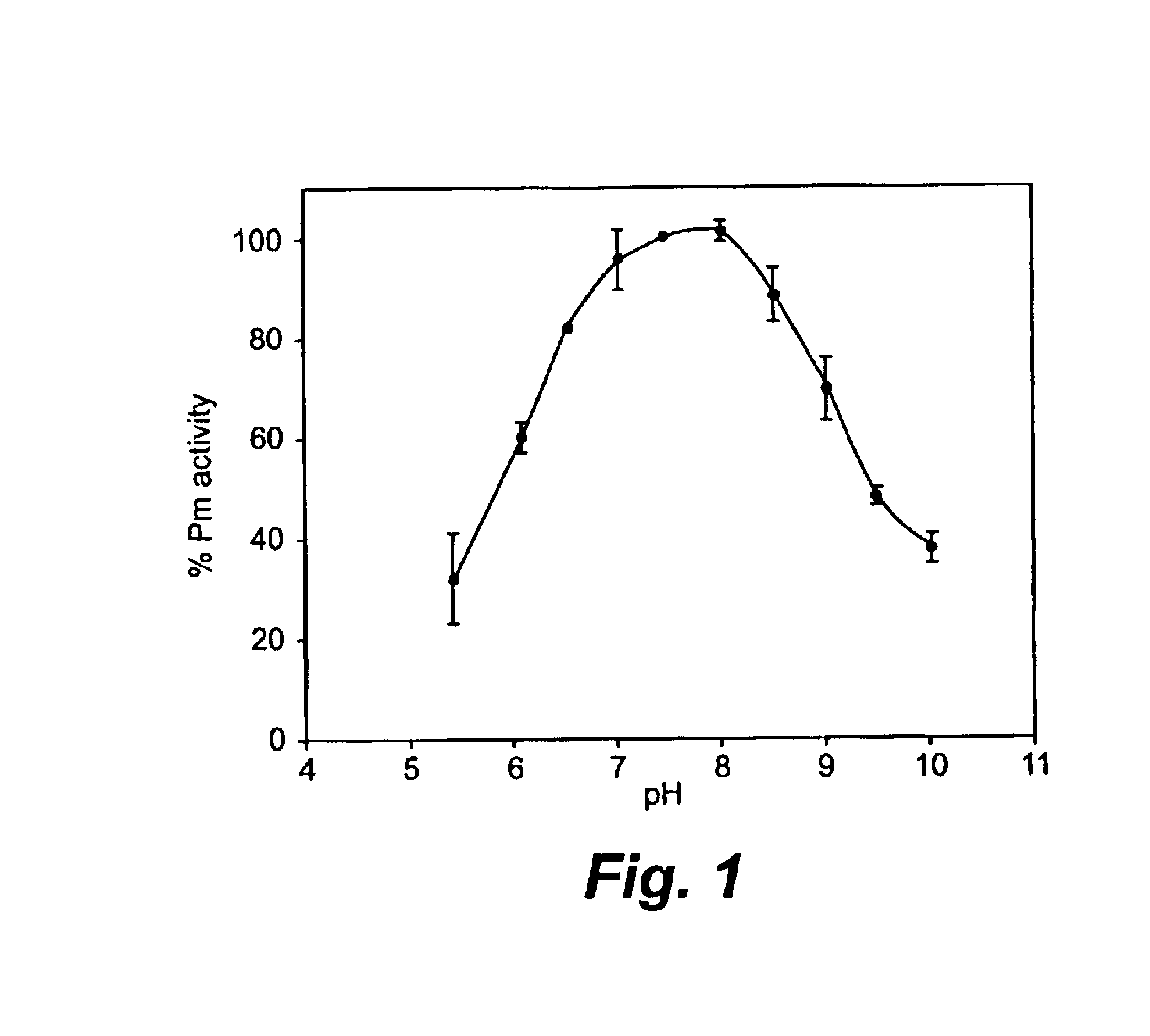

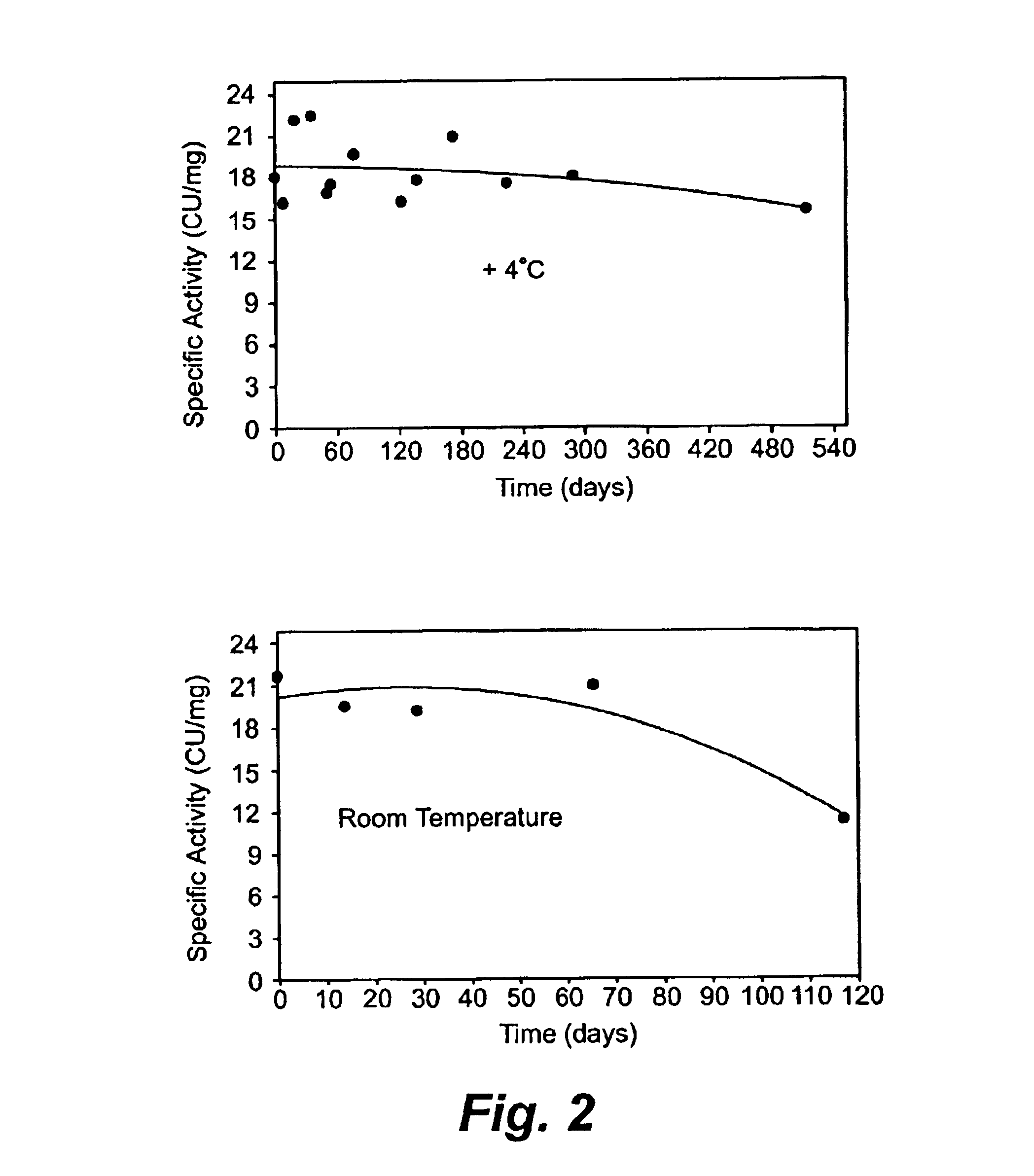

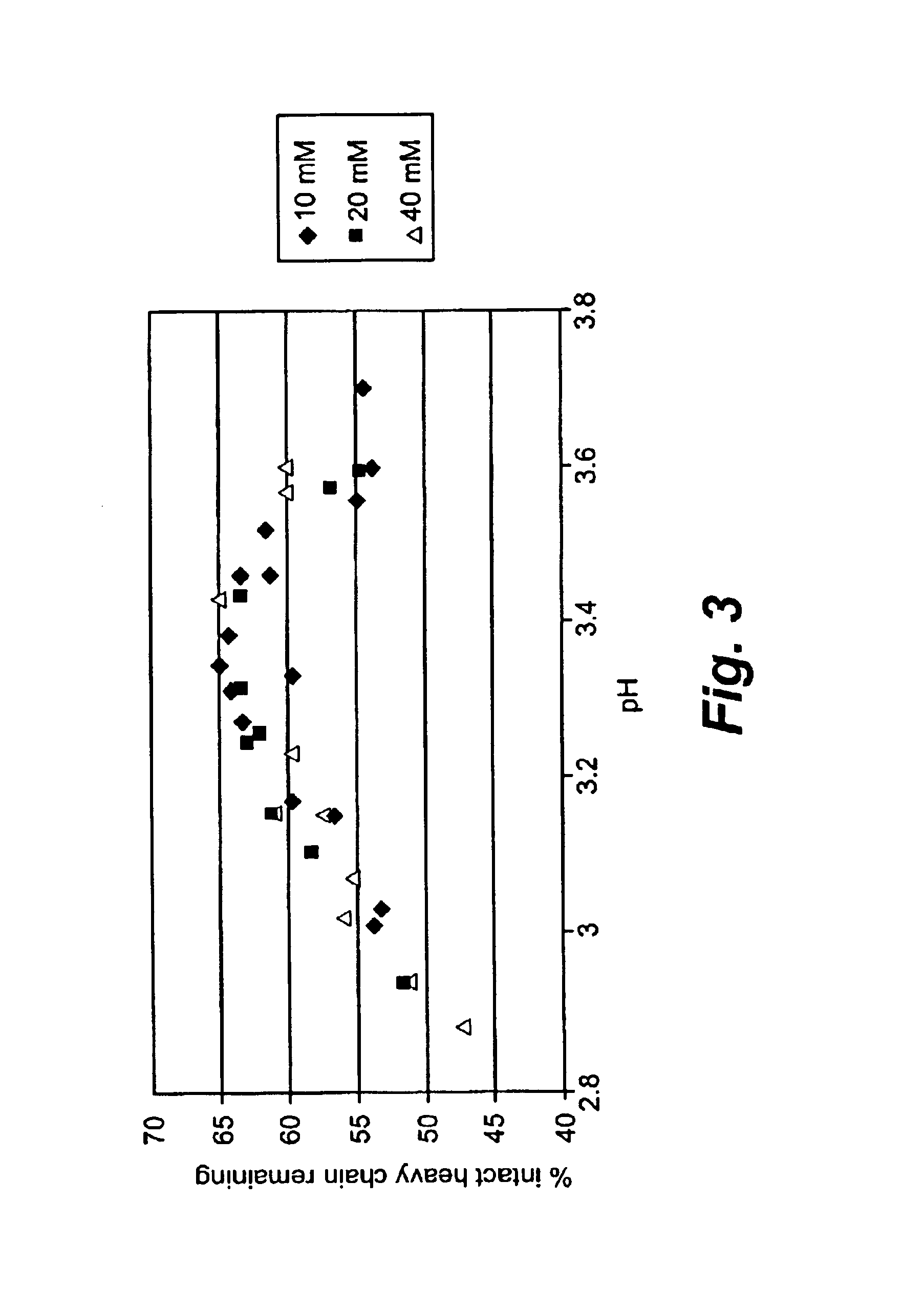

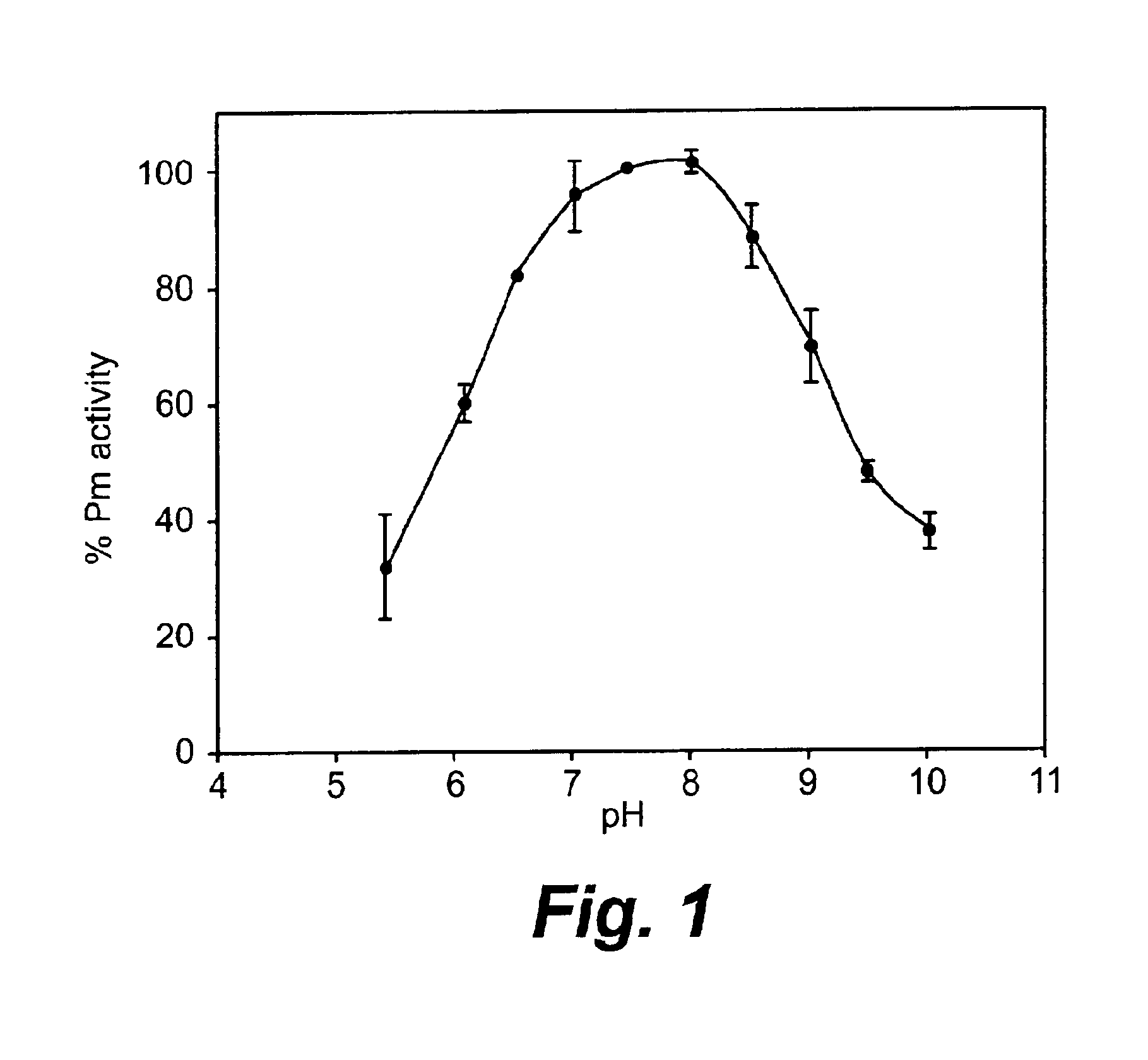

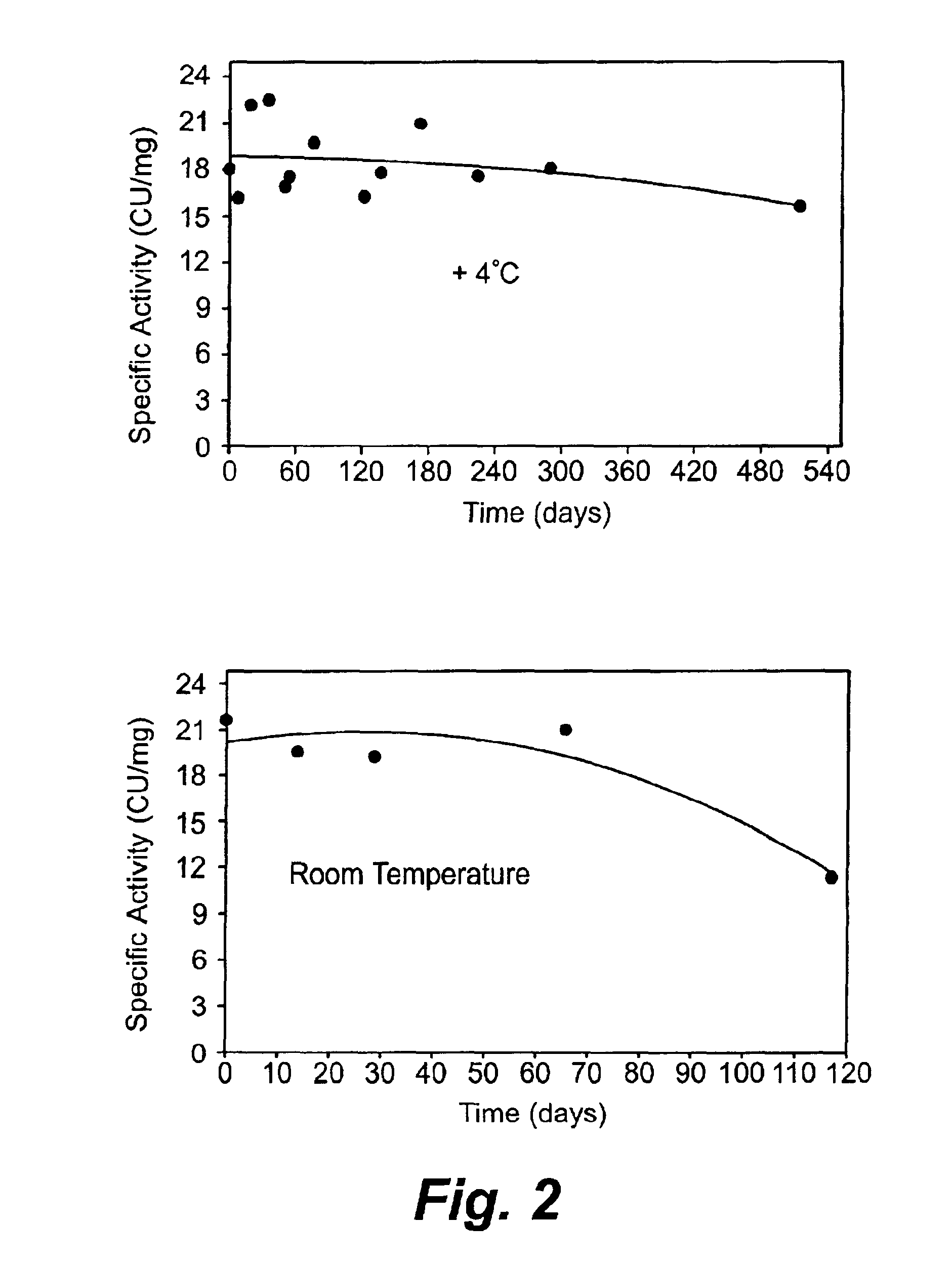

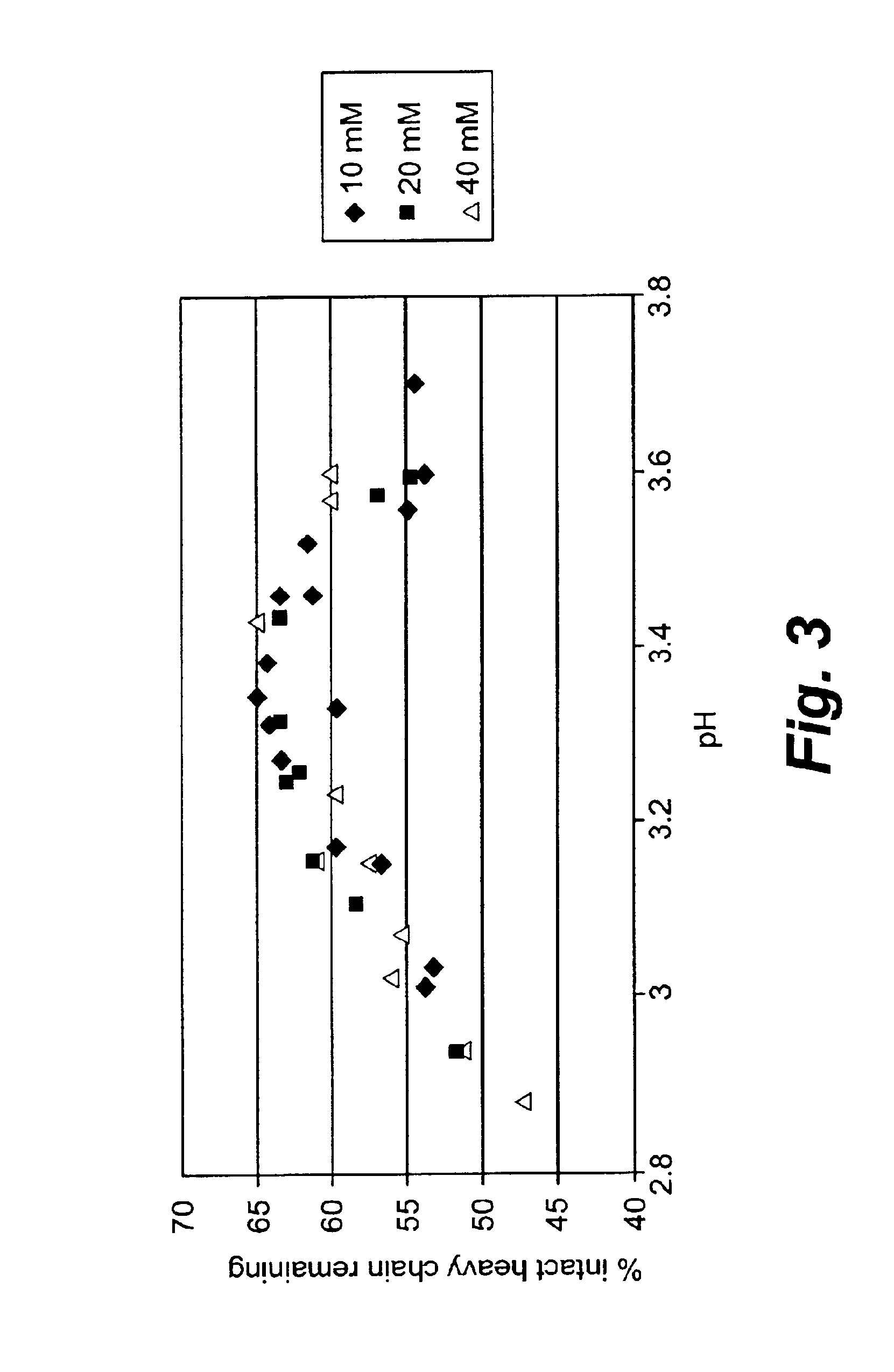

Method of thrombolysis by local delivery of reversibly inactivated acidified plasmin

InactiveUS6969515B2Optimize lytic activityOptimize applicationPeptide/protein ingredientsInorganic non-active ingredientsThrombolysisThrombotic occlusion

Methods of thrombolysis that allow the use of a fibrinolytic composition comprising reversibly inactivated acidified plasmin and the localized delivery of the plasmin to a vascular thrombotic occlusion are disclosed. Further disclosed is a method for administering a therapeutic dose of a fibrinolytic composition substantially free of plasminogen activator to a human or animal having a vascular thrombotic occlusion. The fibrinolytic composition includes a reversibly inactivated acidified plasmin substantially free of plasminogen activator. Intravascular catheter delivery of the fibrinolytic composition directly into or in the immediate vicinity of the thrombus is disclosed to minimize the systemic degradation of fibrin while retaining the maximum plasmin activity against the thrombus. The method is applicable to the dissolution of thrombi in artificial devices, e.g., hemodialysis grafts.

Owner:GRIFOLS THERAPEUTICS LLC

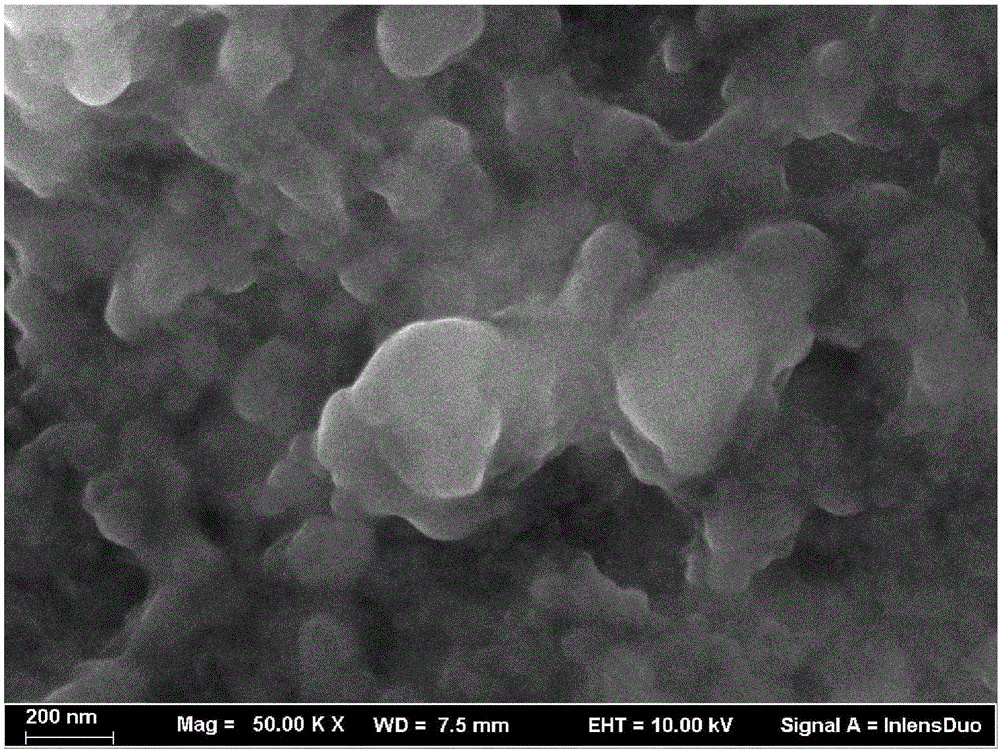

Preparation technology for microspheric embolization agent

ActiveCN101810587AUniform particle sizeGood dispersionPharmaceutical non-active ingredientsGranular deliveryChemical synthesisCross-link

The invention relates to a preparation technology for a microspheric embolization agent. The preparation technology is used for preparing elastic microspheres cross-linked and polymerized by functionalized macromolecules with biocompatibility, wherein the grain range of the microspheres is 1-1500mu m. The preparation technology comprises the following steps that: a cross-linkable micromolecule with a crylic acid structure is connected on a polyvinyl alcohol, polyethylene glycol or polyose macromolecule in form of a covalent bond to form a functionalized macromolecule; and reversed phase suspension polymerization is conducted to the functionalized macromolecule and a 2-acrylamide-2-methylpropanesulfonic acid monomer to prepare cross-linked and polymerized microspheric embolization agent. The embolization agent has the advantages that the flexibility and the elasticity are high, the grain is even and is controllable, the dispersity is good, the raw materials are nontoxic and the biocompatibility and the stability are good. The preparation technology is a pure chemical synthesis technology, no virus pollution is caused to the raw materials and the preparation process, the requirements on international embolization agents are satisfied, and the embolization agent can substitute for all kinds of imported or domestic expensive embolization agent products and can be widely used in surgeries in the field of interventional therapy.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

High Alcohol Content Sanitizer

ActiveUS20120214878A1Prevent dry skinImprove antibacterial propertiesCosmetic preparationsBiocideIrritationPhospholipid

This invention relates to an antimicrobial sanitizing composition in the form of a gel or cream that contains an alcohol in an amount of at least 55% by weight. The sanitizer is capable of disinfecting and providing prolonged antimicrobial property to a variety of surfaces, including the skin, without causing, drying, cracking, redness or irritation. In addition to alcohol, the sanitizer contains an anionic phospholipid in a controlled concentration as well as components conventionally found in skin creams and gels such as emulsifiers, emollients, moisturizers, rheology modifiers, and neutralizers. The anionic phospholipid enables use of the composition without the user experiencing dryness or irritation and the feeling of a greasy and unpleasant residue on the skin following use.

Owner:KORB DONALD R

Method of thrombolysis by local delivery of reversibly inactivated acidified plasmin

InactiveUS6964764B2Formula stableReduce capacityPeptide/protein ingredientsInorganic non-active ingredientsWhole bodyThrombus

Methods of thrombolysis that allow the use of a fibrinolytic composition comprising reversibly inactivated acidified plasmin and the localized delivery of the plasmin to a vascular thrombotic occlusion are disclosed. Further disclosed is a method for administering a therapeutic dose of a fibrinolytic composition substantially free of plasminogen activator to a human or animal having a vascular thrombotic occlusion. The fibrinolytic composition includes a reversibly inactivated acidified plasmin substantially free of plasminogen activator. Intravascular catheter delivery of the fibrinolytic composition directly into or in the immediate vicinity of the thrombus is disclosed to minimize the systemic degradation of fibrin while retaining the maximum plasmin activity against the thrombus.

Owner:GRIFOLS THERAPEUTICS LLC

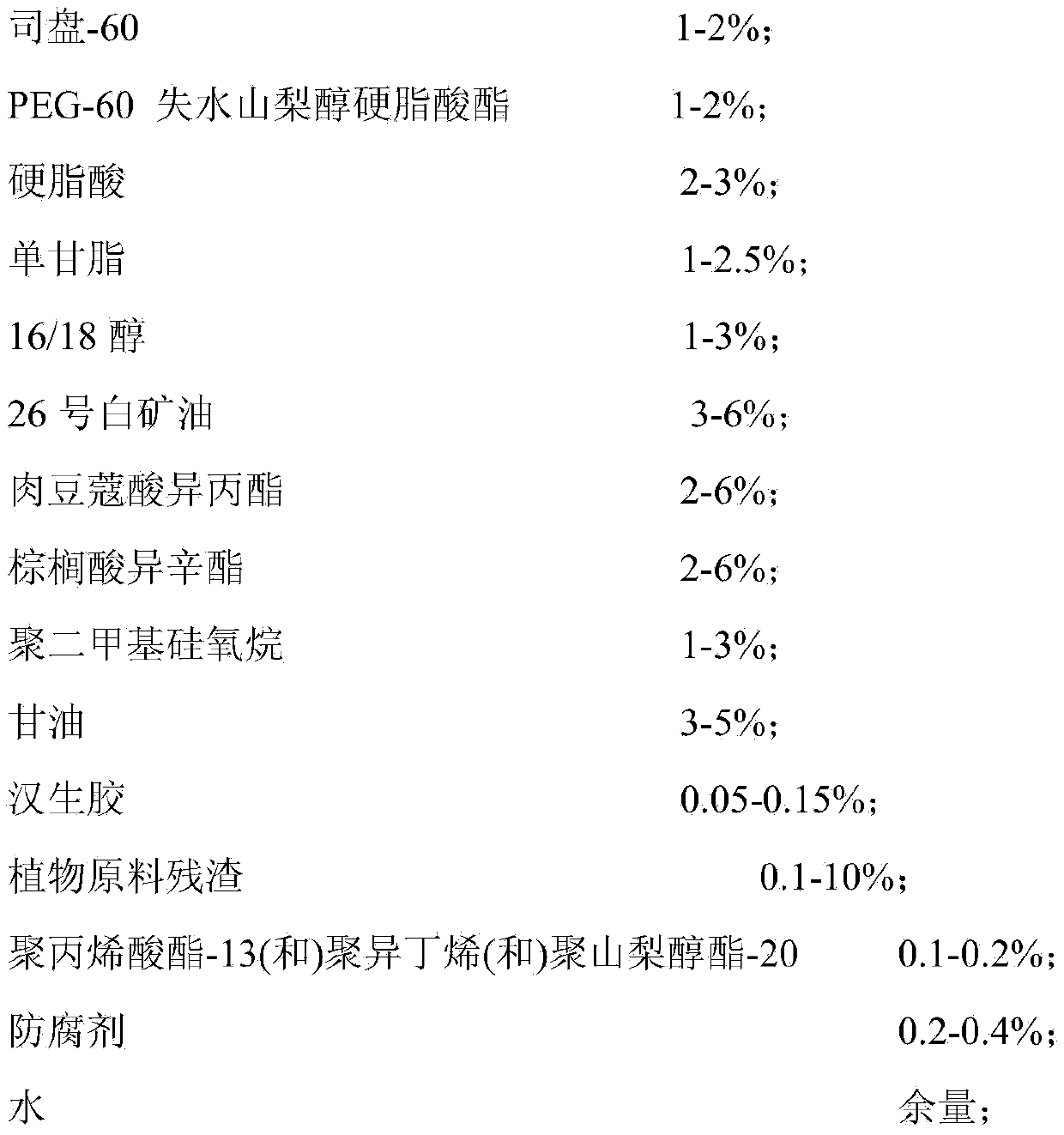

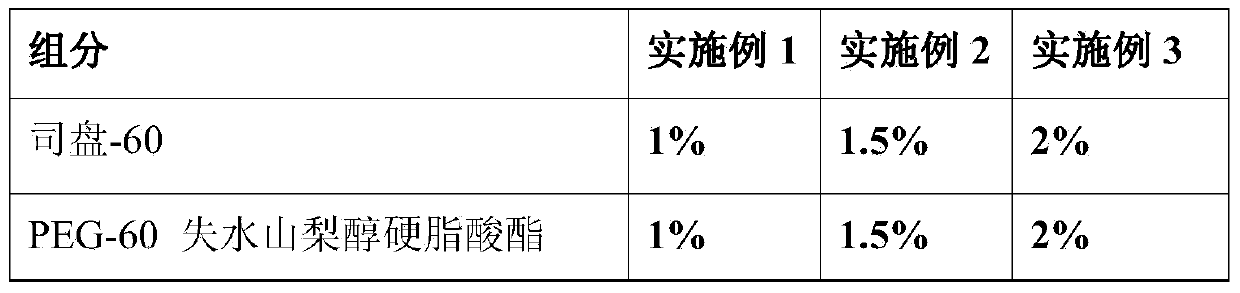

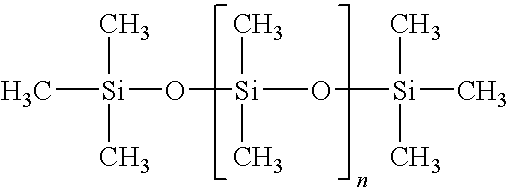

Face mask containing plant material residues

ActiveCN103432043ATake advantage ofIncrease profitCosmetic preparationsToilet preparationsMonoglyceridePolyethylene glycol

The invention provides a face mask containing plant material residues. A formula of the face mask comprises the following components in percentage by weight: 1%-2% of span 60, 1%-2% of PEG-60 (polyethylene glycol-60) sorbitan stearate, 2%-3% of stearic acid, 1%-2.5% of monoglyceride, 1%-3% of 16 / 18 alcohol, 3%-6% of 26# white mineral oil, 2%-6% of isopropyl myristate, 2%-6% of isooctyl palmitate, 1%-3% of polydimethylsiloxane, 3%-5% of glycerinum, 0.05-0.15% of xanthan gum, 0.1-10% of the plant material residues, 0.1%-0.2% of polyacrylate-13 (and) polyisobutene (and) polysorbate-20, 0.2%-0.4% of preservative and the balance of water. According to the face mask provided by the invention, the material residues after plant materials are extracted and utilized are turned into wealth, the production cost is reduced, and the utilization rate of the plant materials is increased.

Owner:广州市千纤草化妆品有限公司

Method for utilizing molecular sieve systhesis mother liquor

InactiveCN102225772AAchieving zero emissionsFormula stableMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMother liquor

The invention provides a method for complete cyclic utilization of ITQ-2 molecular sieve mother liquor with zero discharge. The key points of the invention are as follows: ITQ-2 molecular sieve mother liquor undergoes separation at first, then a cetyl trimethyl ammonium bromide surfactant and alkali lye obtained from the separation are analyzed and determined, and finally the surfactant and alkali lye are reused as raw materials to reprepare ITQ-2 molecular sieves with a high degree of crystallization. According to the invention, a method of recycling mother liquor is formulated by ingeniously utilizing the rule of temperatures for a cetyl trimethyl ammonium bromide surfactant to crystallize and precipitate in the mother liquor. In the invention, ITQ-2 molecular sieve mother liquor is recycled, thereby reducing cost, protecting environment and enabling mother liquor recycle formula and the quality of the obtained products to be stabilized.

Owner:DALIAN UNIV OF TECH

Antique matte glaze with delicate texture and using method thereof

The invention discloses an antique matte glaze with delicate texture. The antique matte glaze with the delicate texture consists of a frit and raw materials, wherein the mass ratio of the frit to the raw materials is 1-1.5: 1. The invention also discloses a preparation method of the antique matte glaze with the delicate texture. The preparation method comprises the following steps of: applying a layer of base glaze on the surface of a brick blank, and applying a layer of the matte glaze; and sintering the brick blank at the temperature of 1150-1250 degrees centigrade to obtain a final product. The matte glaze provided by the invention consists of the frit with good high temperature fluidity and part of the raw materials, so that the glaze surface can flow levelly at high temperature quickly; through matching of different materials, the matte, smooth and delicate effects of the glaze surface are ensured; through the composition design of half raw material and half frit, the compositionis more stable and is applicable to different technical conditions and furnace temperatures; and the sintering temperature and the matte degree of the matte glaze are regulated by regulating the adding amount of aluminum oxide.

Owner:广东道氏陶瓷材料有限公司

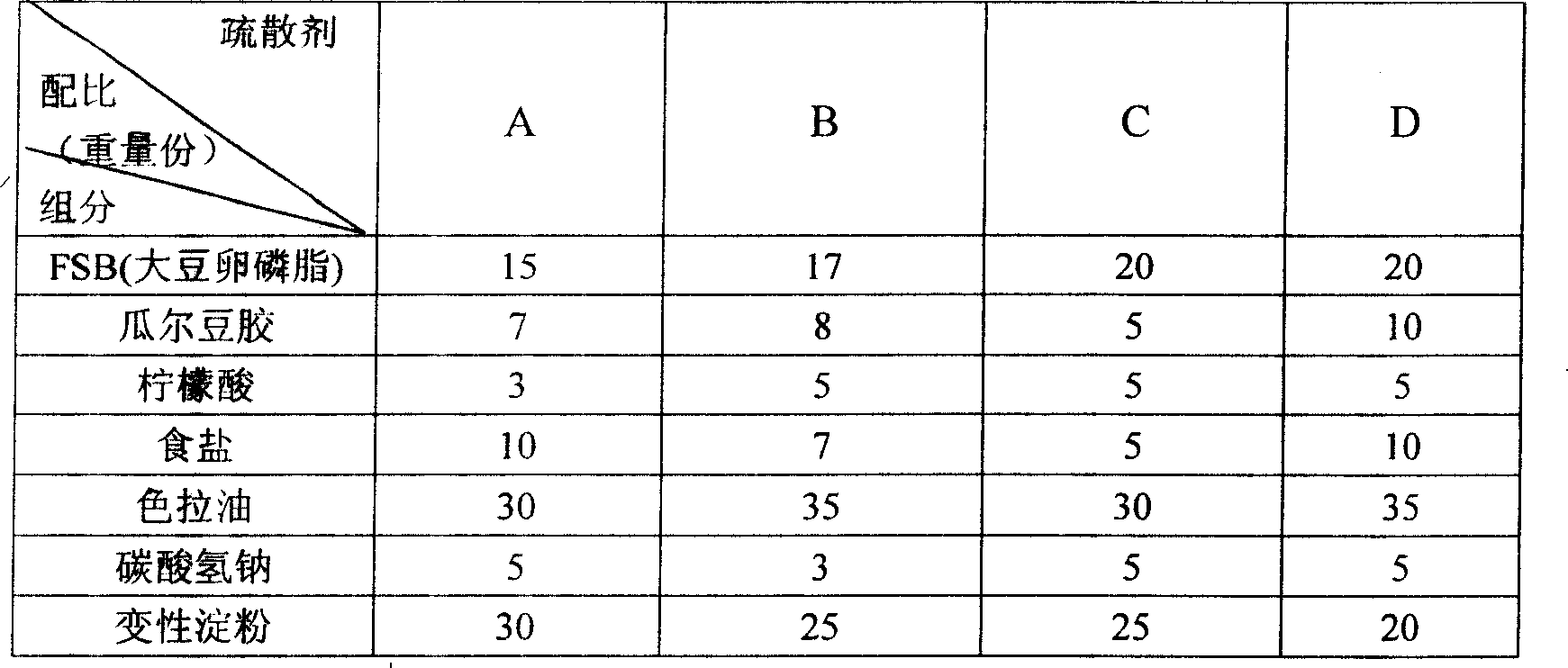

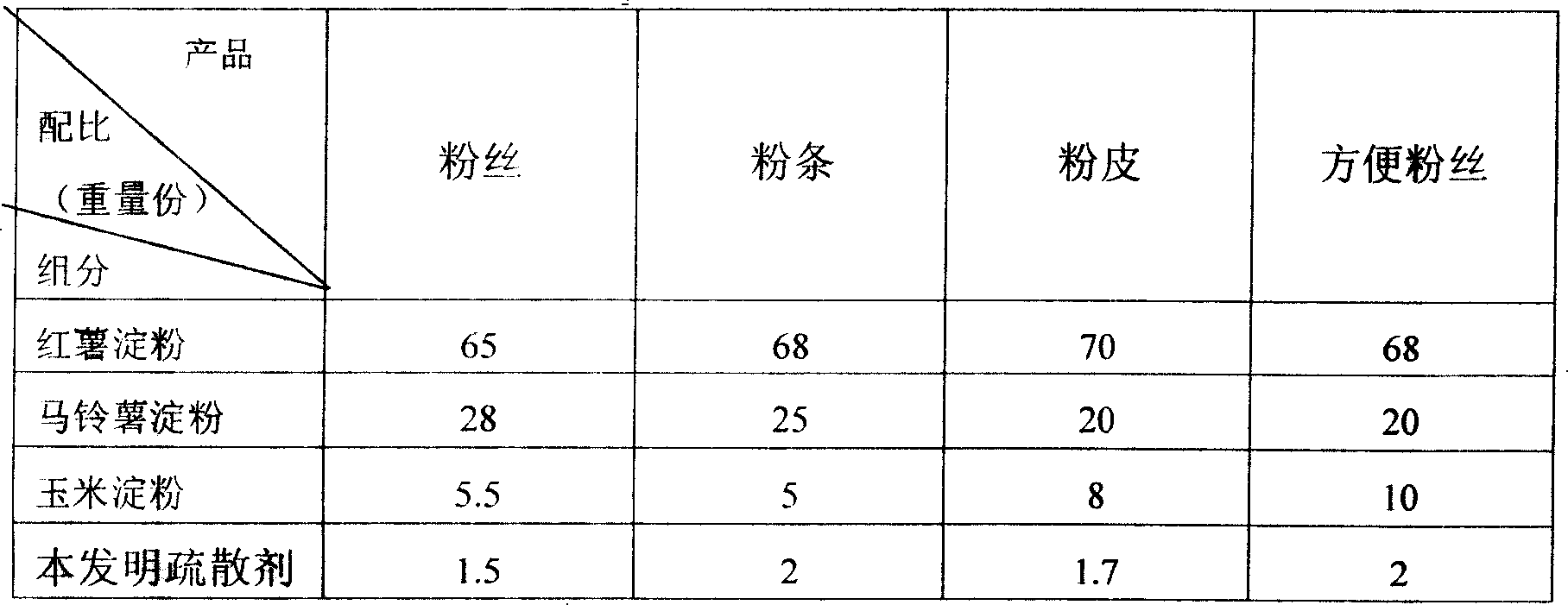

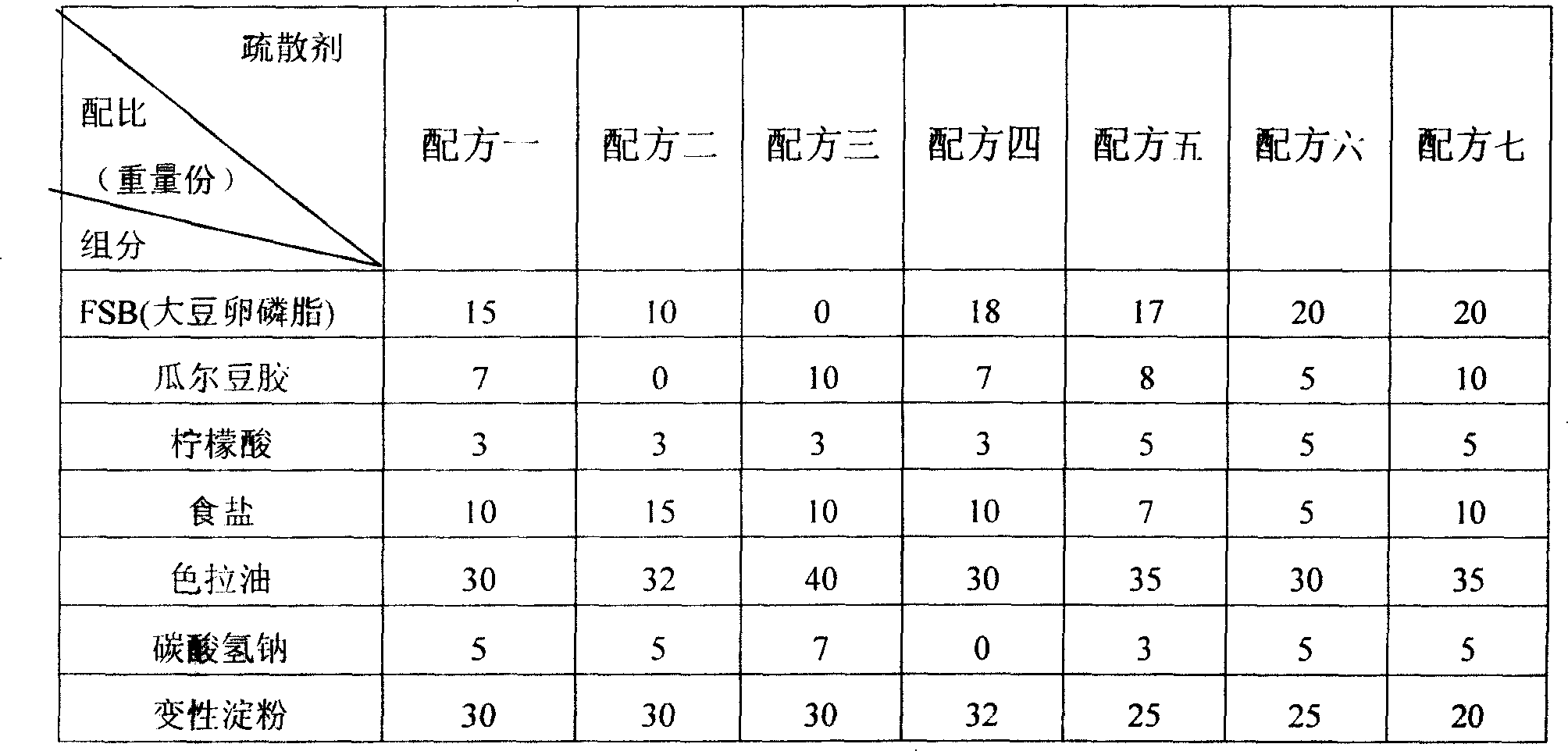

Evacuating agent of vermicelli foodstuff and the vermicelli foodstuff thereof

ActiveCN101081065AEvenly distributedDraw downFood preservationFood preparationSodium bicarbonateAdditive ingredient

The present invention belongs to the field of food producing technology, and is especially one kind of dispersant for vermicelli. The dispersant for vermicelli consists mainly of soybean lecithin 15-25 weight portions, salad oil 20-40 weight portions, sodium bicarbonate 3-8 weight portions, guar gum 5-15 weight portions, citric acid 3-8 weight portions, table salt 5-15 weight portions, and modified starch 15-30 weight portions. The present invention also provides corresponding vermicelli, which consists of the dispersant 1.5-2 weight portions and plant starch 80-120 weight portions. Experiment shows that the dispersant for vermicelli has no harmful matter contained and effect similar to traditional dispersant. The vermicelli with the dispersant is one kind of health food possessing high safety, good look, good taste, physical, chemical and hygienic indexes meeting relevant requirements, balanced and rich nutrients and high marketability.

Owner:四川白家阿宽食品产业股份有限公司

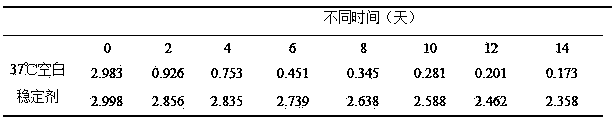

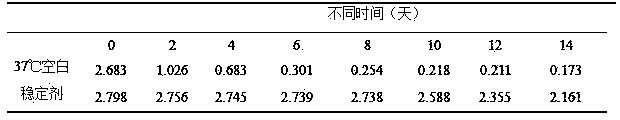

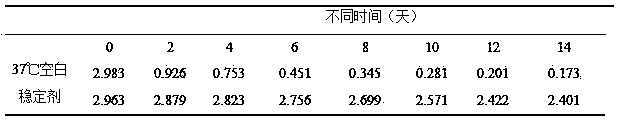

Long-acting ELISA plate stabilizing agent

ActiveCN103472222AGuaranteed continuous stabilityLow costMaterial analysisProtein activityBULK ACTIVE INGREDIENT

The invention relates to a long-acting ELISA (Enzyme-linked Immunosorbent Assay) plate stabilizing agent for keeping protein activity in an ELISA plate. The agent comprises 0.1-5g protein, 1-15g sugar, 0.1-10g organic matter, 0.01-0.1%(V / V) of preservative, and 10-200mmol buffer solution salt per 100ml water, and a pH (Potential of Hydrogen) value is 7.2-7.4. The stabilizing agent adopts a technical route integrating a closing process and a stabilization process, and can effectively close excessive sites in the ELISA plate, and some active ingredients in the stabilizing agent can ensure continuous stabilization of the ELISA plate. The agent is simple in formula, can stabilize the ELISA plate, and does not produce any influence on a result simultaneously. The ingredients of the agent are easy to obtain, and the formula is simple, so that the cost of the stabilizing agent is lowered.

Owner:河北渤腾医药技术有限公司

Pharmaceutical composition for parenteral administration of idebenone

InactiveUS20100130619A1Formula stableHigh shear mixingBiocideNervous disorderParenteral nutritionIdebenone

Owner:ALPHARX

Nonformaldehyde nonpoisonous adhesive and preparation method thereof

ActiveCN101709211AShorten the preload timeShorten the hot pressing timePolyureas/polyurethane adhesivesChemistryAqueous solution

The invention discloses a nonformaldehyde nonpoisonous adhesive and a preparation method thereof. The method comprises the following steps: firstly, adding proper water in a reactor which is provided with a stirring device; secondly, slowly adding polyvinyl alcohol into the reactor when the water is heated to 40 DEG C, heating the mixture to over 90 DEG C to ensure that the polyvinyl alcohol is completed dissolved, and preserving the heat for 1 hour; thirdly, cooling the materials to 70 DEG C, and adding polyalcohol, dispersant, emulsifier and aqueous solution of plasticizer into the reactor respectively, adding filler into the reactor, keeping stirring for 15 to 20 minutes to ensure that the raw materials are uniformly mixed, and filtering and discharging; and finally, uniformly mixing the raw materials with isocyanate in the proportion when the adhesive is used. The adhesive has simple production technology, can be subjected to both cold pressing and hot pressing, has low cost, and can completely realize non toxicity, harmlessness, greenness and environmental protection.

Owner:东营市盛基环保工程有限公司

Melt-Coated Dosage Forms

InactiveUS20110217289A1High active ingredient loadingGood stabilityBiocidePretreated surfacesSolventFoam Dosage Form

Formulations of sparingly water-soluble active ingredientscomprising carrier particles provided with active ingredient-containing coatings, the sparingly soluble active ingredients being embedded in coatings composed of amphiphilic copolymers, and the coatings being applied in the form of a solvent-free melt.

Owner:BASF SE

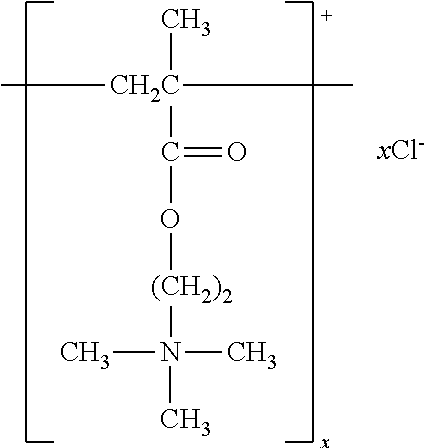

Formula and preparation method for high gloss color ink-jet printing paper coating

InactiveCN104099807AHigh glossGood ink absorptionDefoamers additionCoatings with pigmentsEmulsionPolymer science

The invention relates to a formula and a preparation method for a high gloss color ink-jet printing paper coating. According to the method, 100 parts of pure water, 50-60 parts of nano-silica, 5-10 parts of a cationic color fixing agent, 3-6 parts of a 10% polyvinyl alcohol aqueous solution, 1-3 parts of an acrylic emulsion, and 0.5-1 part of a defoamer are subjected to preparation processing and coating. The color ink-jet printing paper prepared according to the formula and the preparation process provided by the invention not only has high gloss, high ink absorbency high color reducibility, high color density, high resolution, high pull-out capacity and other characteristics, but also has stable formula, the product qualification rate reaches over 95%, 24h uninterrupted coating production can be realized, and the production efficiency and product qualified rate are improved. Thus, the formula and the preparation method are suitable for wide popularization and use.

Owner:南京泛太克文化产业发展有限公司

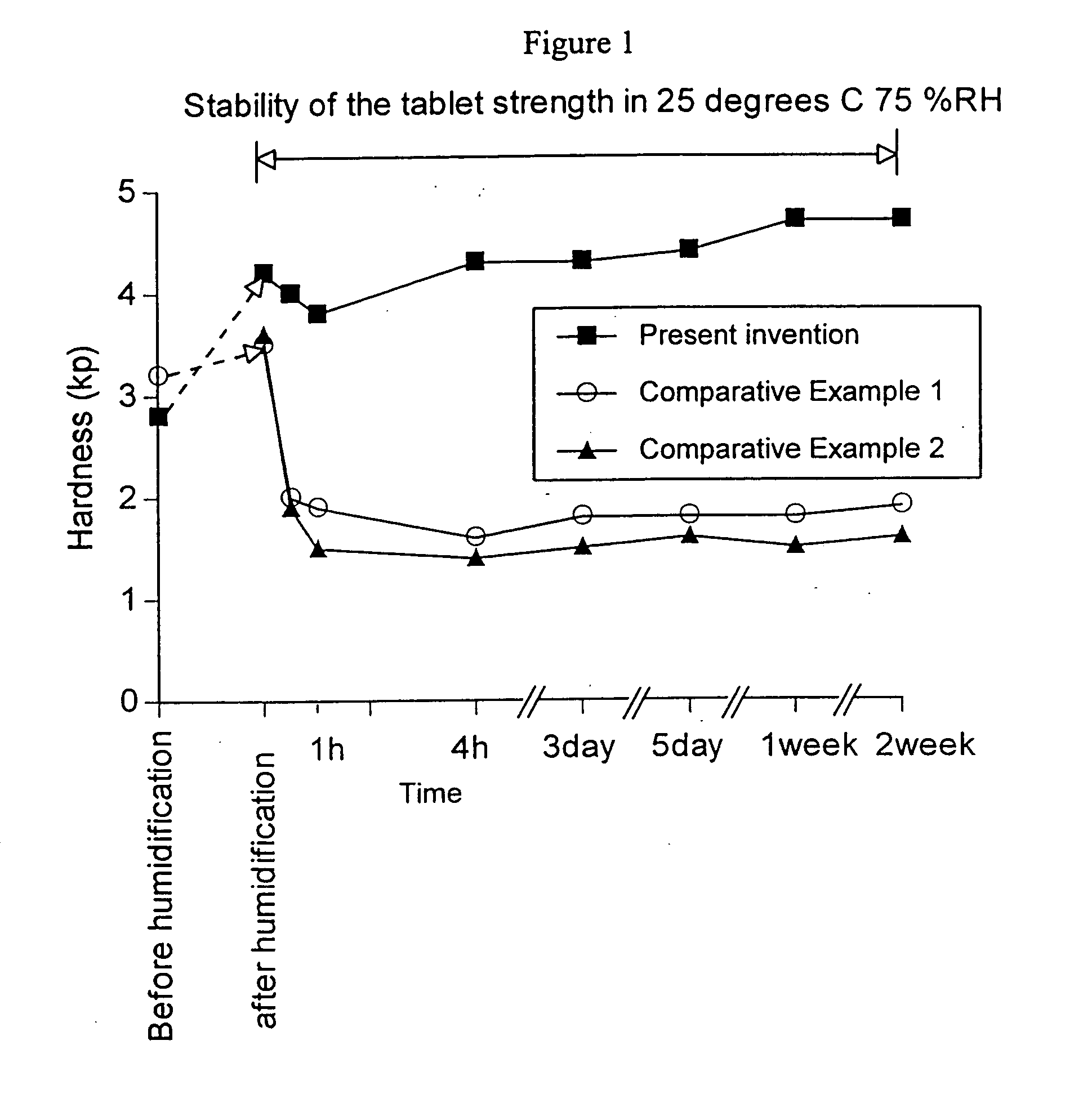

Quick disintegrating tablet in buccal cavity and production process thereof

InactiveUS20050100598A1High strengthFormula stablePill deliveryPharmaceutical non-active ingredientsSugarSolvent

The present invention relates to a quick disintegrating tablet in buccal cavity, comprising: a mixture, comprising a drug, a sugar (A), and an amorphous sugar (B), and after it is forming a tablet, it is humidified and dried. In particularly, the present invention relates to a quick disintegrating tablet in buccal cavity comprising: a mixture; comprising a drug, a sugar (A), and an amorphous sugar (B) which an amorphous-forming sugar in crystalline state is dissolved in a medicinally permitted solvent, the amorphous sugar is obtained from this solution by removing the solvent, and after it is forming a tablet, and it is humidified and dried. The tablet in the present invention is to provide stability against moisture at preserved, because the amorphous sugar changed to the crystalline state in a nonreversible reaction after it is humidified and dried in a manufacturing process. The tablet in the present invention is to further provide a design for the pharmaceutical preparation with respect to the stability of a drug, because the tablet is manufactured by one kind of a sugar and an amorphous sugar. Furthermore, the tablet in the present invention is to provide a production process by utilizing a common granulating machine and by utilizing a common tablet machine.

Owner:ASTELLAS PHARMA INC

Stuffing cookies and production method thereof

ActiveCN101331892AIncrease total fiberMake up for the shortcomings of high oil and high fatBakery productsFlavorChemistry

The invention discloses a cookie with fillings and a making method thereof, wherein, the cookie with fillings consists of two parts, that is, a skin part and a filling part; and the making method includes the following steps: A. mixing the skin and the fillings; B. incrusting the mixed skin and the fillings into small balls by using a pastry machine; C. and baking the small balls at the top temperature of 180 - 200 DEG C and the bottom temperature of 160 - 180 DEG C for 10 - 16 minutes. The cookie and the method of the invention have the advantages of novel style, good flavor and taste, and being capable of effectively utilizing the pastry machine, etc.

Owner:珠海元朗食品有限公司

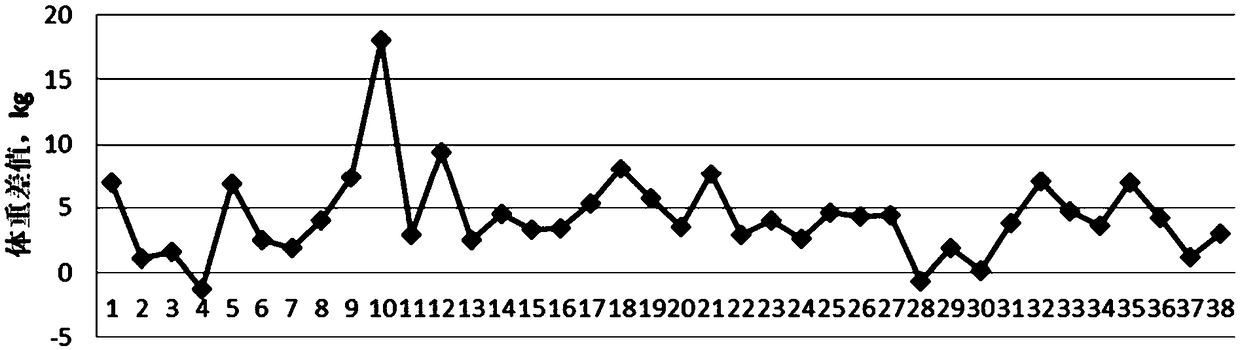

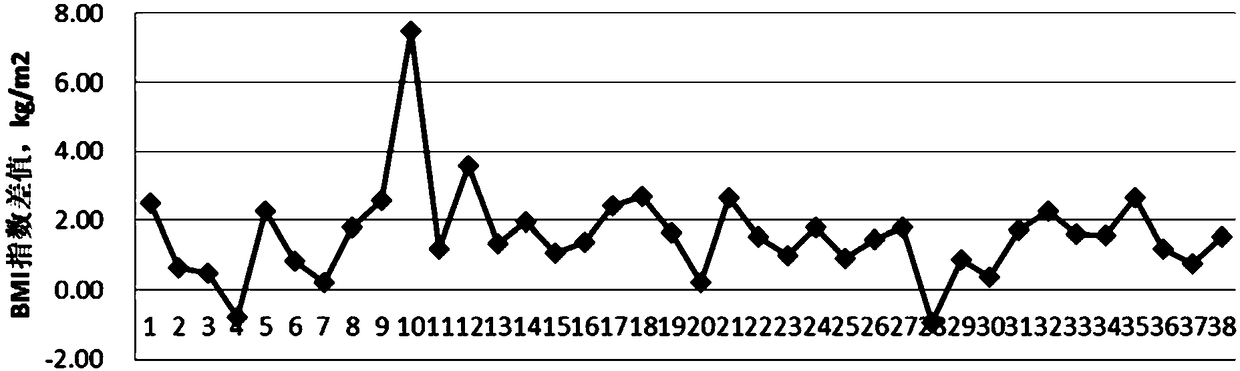

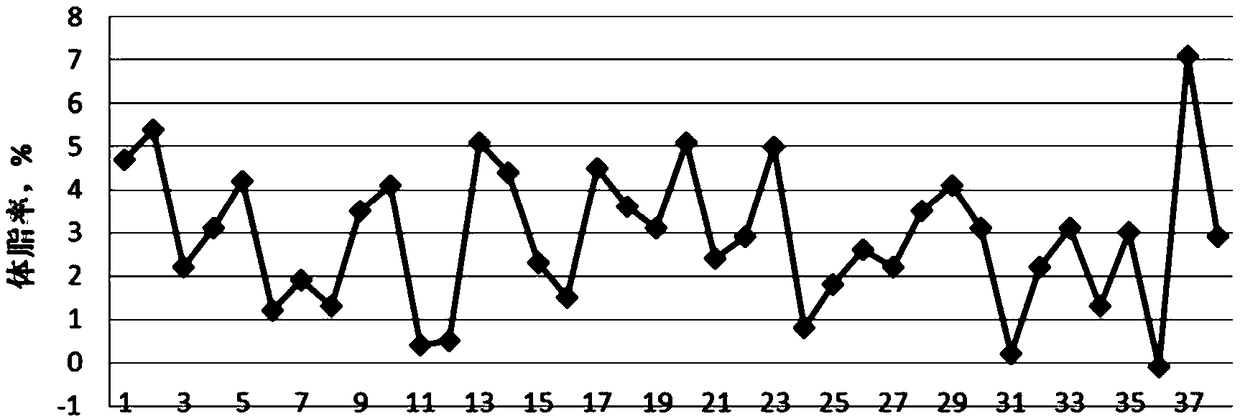

Weight-losing functional food containing conjugated linoleic acid

InactiveCN108703375AFormulation ScienceFormula stableLipidic food ingredientsFood ingredient functionsPerilla oilWhey protein powder

A weight-losing functional food containing conjugated linoleic acid comprises, by mass, the following components: 1-10 parts of conjugated linoleic acid glyceride microcapsule powder, 1-5 parts of flaxseed oil microcapsule powder, 1-5 parts of perilla oil microcapsule powder and 1-10 parts of protein powder; the protein powder is selected from wheat protein powder, whey protein powder, soybean protein powder, casein powder or a mixture thereof. According to the invention, a weigh-losing functional nutritional product which is scientific in formula, stable in product, and good in taste and is easily accepted by consumers is provided. The product uses the formula of high-fat and low-carbon, and utilizes functional grease to replace common meat and fat. The energy supply ratio of fat is morethan or equal to 45%, the energy supply ratio of carbohydrate is more than or equal to 35%, and is beneficial to human body absorption; the carbohydrate is replaced by dietary fiber and low GI carbohydrate, thereby avoiding the problem of fat conversion caused by common carbohydrate and improving the blood sugar control of a diabetic population. The food brings more benefits to the body while ensuring the effect of losing weight.

Owner:INNOBIO CORP LTD

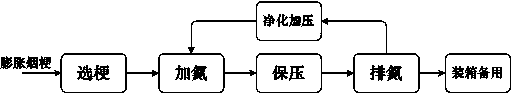

Treatment process for expanded tobacco stems

The invention relates to a treatment process for expanded tobacco stems, and belongs to the technical field of main material and auxiliary material processing in the tobacco industry. The microwave expanded tobacco stems are classified according to the thickness and / or the length, the expanded tobacco stems are placed into a pressure vessel, nitrogen with the purity being larger than 78% is connected into the pressure vessel, the tobacco stems and the nitrogen are evenly mixed, the pressure in the vessel is normal pressure to 8 MPa, the pressure is kept for 10 seconds to 40 minutes, the nitrogen in the pressure vessel is exhausted, the nitrogen can be recycled after purification and compressing treatment, the expanded tobacco stems after treatment are taken out, and the expanded tobacco stems are boxed or bagged in a classified mode for standby application; or moisture regain is conducted directly, so that products such as stem shreds, stem strip shreds and stem particles are manufactured. The microwave expanded tobacco stems treated through the process do not need to be stored any more, wooden odors and offensive odors in the tobacco stems are reduced, the tobacco stems cannot retract after moisture regain, and good elasticity and processing resistance are achieved. By means of the treatment process for the expanded tobacco stems, the requirement for the conditions such as warehouse space, manpower and logistics in the storage link is met, and therefore enterprise cost is greatly lowered.

Owner:姚波

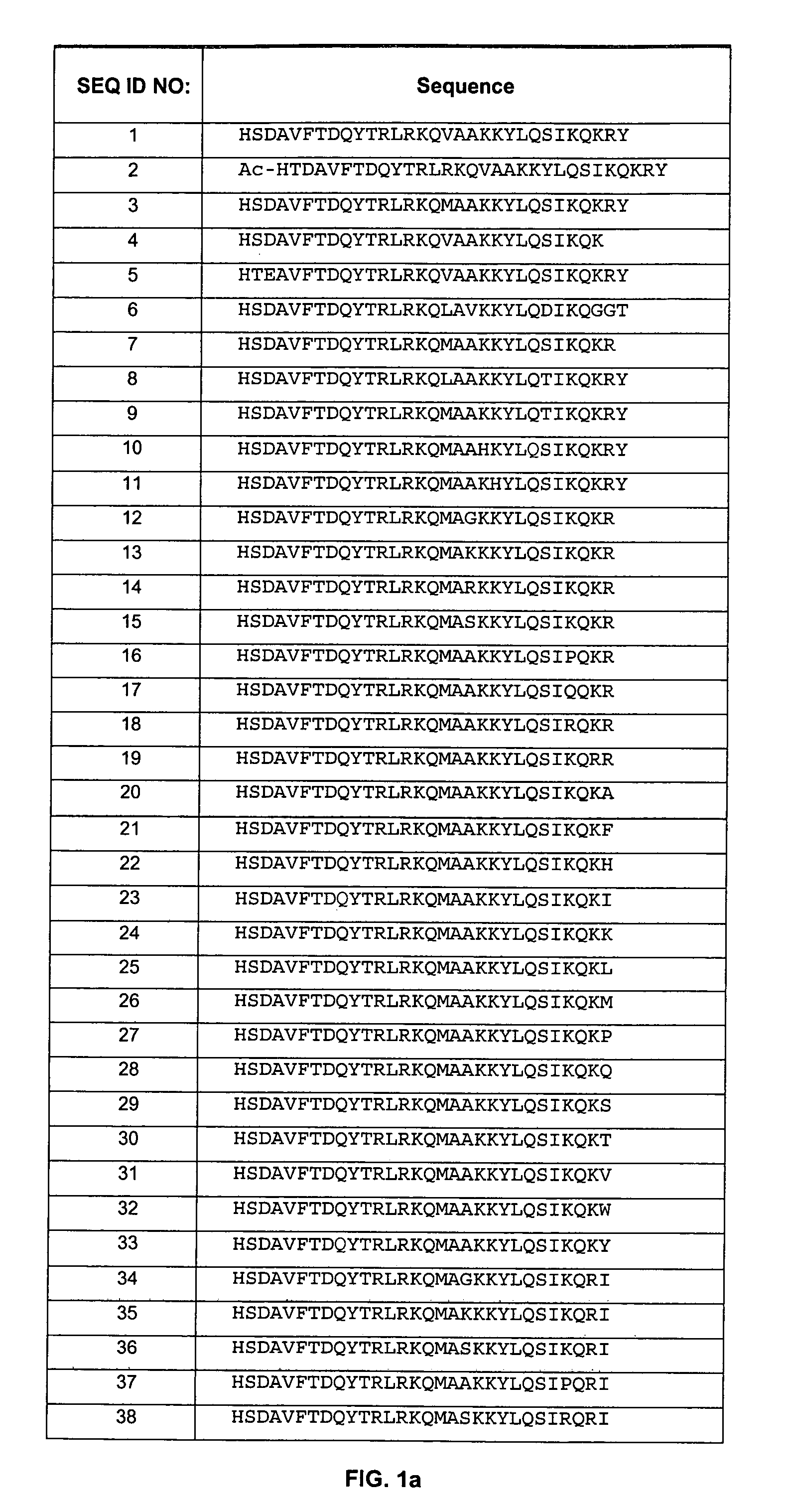

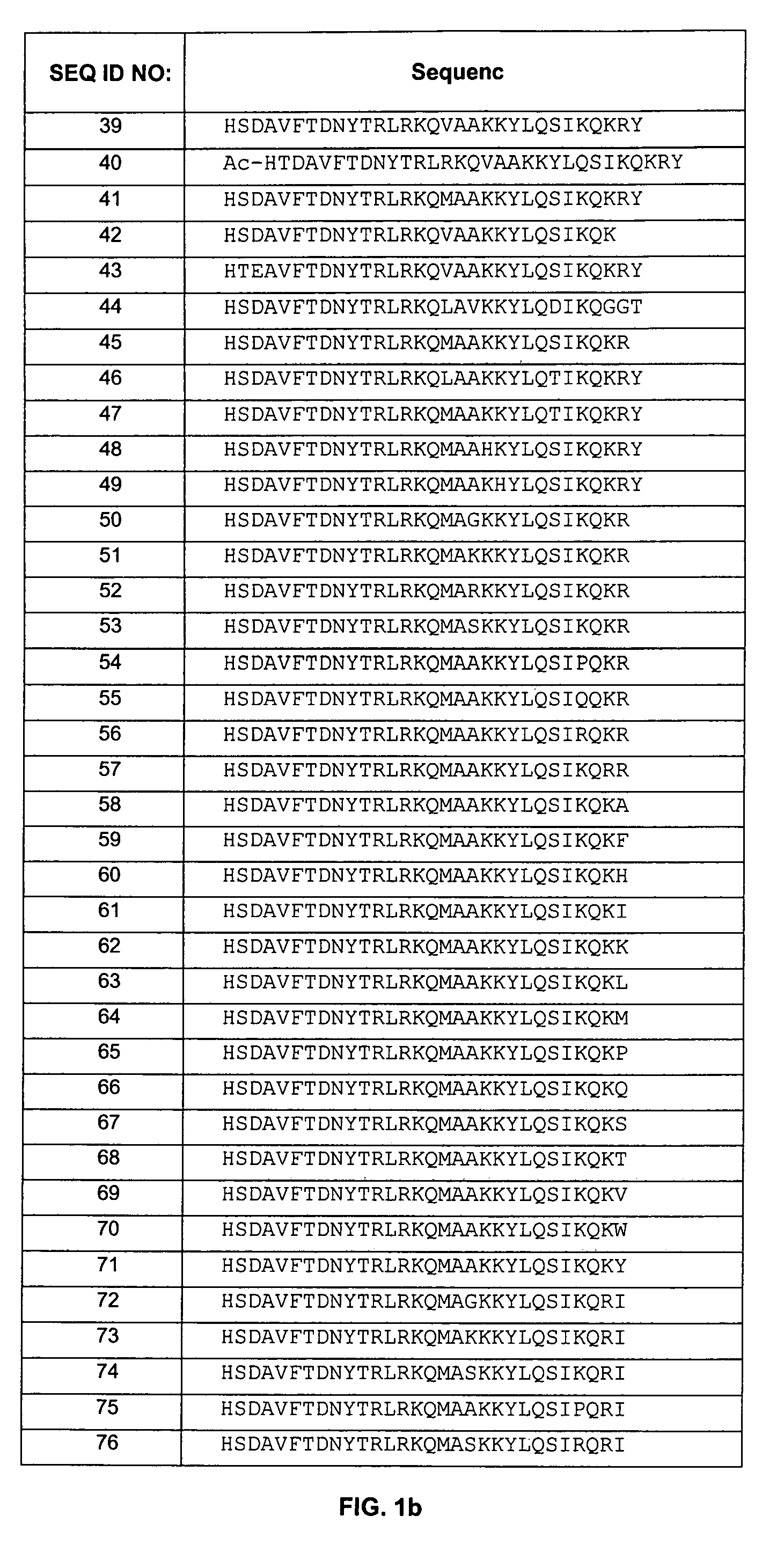

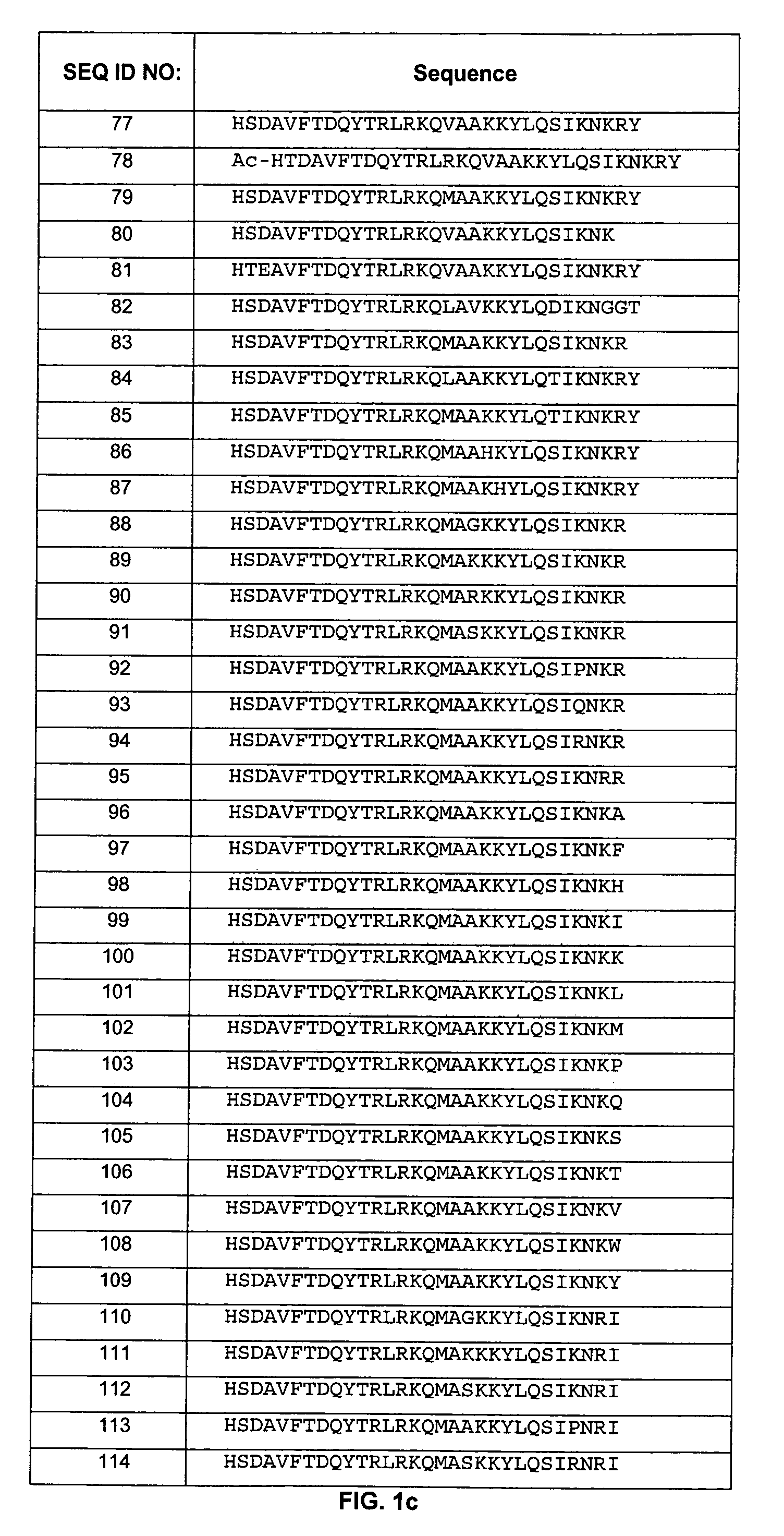

Pituitary adenylate cyclase activating peptide (PACAP) receptor (VPAC2) agonist peptide

InactiveUS7378494B2Good potencyFormula stableAntibacterial agentsPeptide/protein ingredientsDiseaseHalf-life

This invention provides novel peptides that function in vivo as agonists of the VPAC2 receptor. These insulin secretagogue polypeptides are shown to lower blood glucose in vivo more than controls upon glucose challenge. The polypeptides of this invention are also stable in formulation and have long half-lives. The peptides of the present invention provide a new therapy for patients with decreased endogenous insulin secretion, in particular type 2 diabetics. In particular, the invention is a polypeptide selected from a specific group of VPAC2-related polypeptides, or functional equivalents thereof. The invention is also directed to a method of treating a metabolic disease in a mammal comprising administering a therapeutically effective amount of the insulin secretagogue peptides to said mammal. Also disclosed are methods of making the peptides, both recombinant and synthetic.

Owner:BAYER HEALTHCARE LLC

Broad?bean?paste?with?chili?oil and production process thereof

InactiveCN104146236AStable flavorThe production process is easy to controlFood preparationUniform - qualityFood flavor

The invention discloses a broad?bean?paste?with?chili?oil and a production process thereof, and belongs to the technical field of broad?bean?pastes. The broad?bean?paste?with?chili?oil comprises the following components in parts by weight: chili 100-120, broad?bean?paste?20-25, and a flavoring 1. The preparation method comprises the following steps: (1) producing salty fermented and crushed chili pieces, (2) processing the broad bean paste; (3) making starter; (4) fermenting; (5) packaging. The raw materials and the production process are standardized, and the produced broad?bean?paste?with?chili?oil has uniform quality; the production process is controllable, the formula is stable, the flavor of the finished products of the broad?bean?paste?with?chili?oil is stable, so that the population can eat the authentic broad?bean?paste?with?chili?oil at any time.

Owner:MIANYANG LEIZU BREWING FOOD CO LTD

Core-shell structure cellular material for removing methanal and preparation method of core-shell structure cellular material

The invention discloses a core-shell structure cellular material for removing methanal and a preparation method of the core-shell structure cellular material. The core-shell structure cellular material for removing the methanal is prepared from the following components according to a weight ratio: 50 to 70 percent of clay, 10 to 15 percent of inorganic salt, 1 to 5 percent of aerogel, 5 to 9 percent of sepiolite fiber, 1 to 15 percent of molecular sieve and 1 to 8 percent of glue. The core-shell structure cellular material for removing the methanal is prepared by four production links including material mixing, solution dipping, dry granulation and finishing activation. The new core-shell structure material with coexisting multi-stage pore canals consists of an inner core formed by a composite strong oxidant and a shell layer formed by inorganic fiber, and the new material has the advantages of the performance of efficiently and thoroughly oxidating to remove indoor methanal pollutants, simple production links, lower preparation cost and wide popularization and application prospect.

Owner:广东格仑帝环保材料科技有限公司

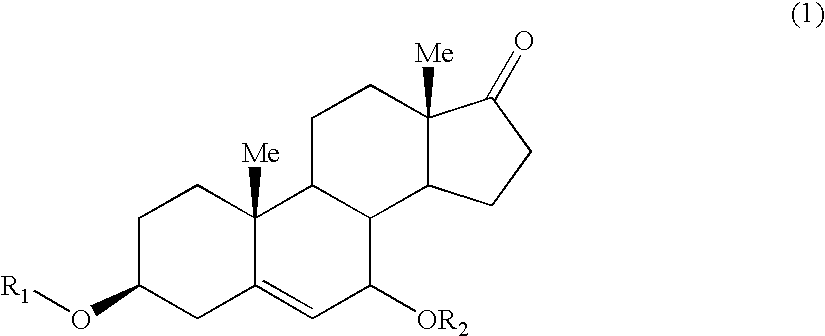

Invert emulsions containing dhea

InactiveUS20090069279A1Good stabilityHigh dispersed volume fractionOrganic active ingredientsCosmetic preparationsEmulsionChemistry

Stable, recrystallization-resistant invert emulsions, suited, e.g., for preventing / treating the signs of chronological or actinic skin aging and for preventing / treating atrophy of the skin or mucous membranes, comprise a cosmetically / therapeutically effective amount of DHEA and / or chemical and / or biological precursor or derivative thereof, such invert emulsions also comprising a glycolic or hydroglycolic dispersed hydrophilic phase, a lipophilic continuous phase and an emulsifier having an HLB ranging from 2 to 7.

Owner:GALDERMA RES & DEV SNC

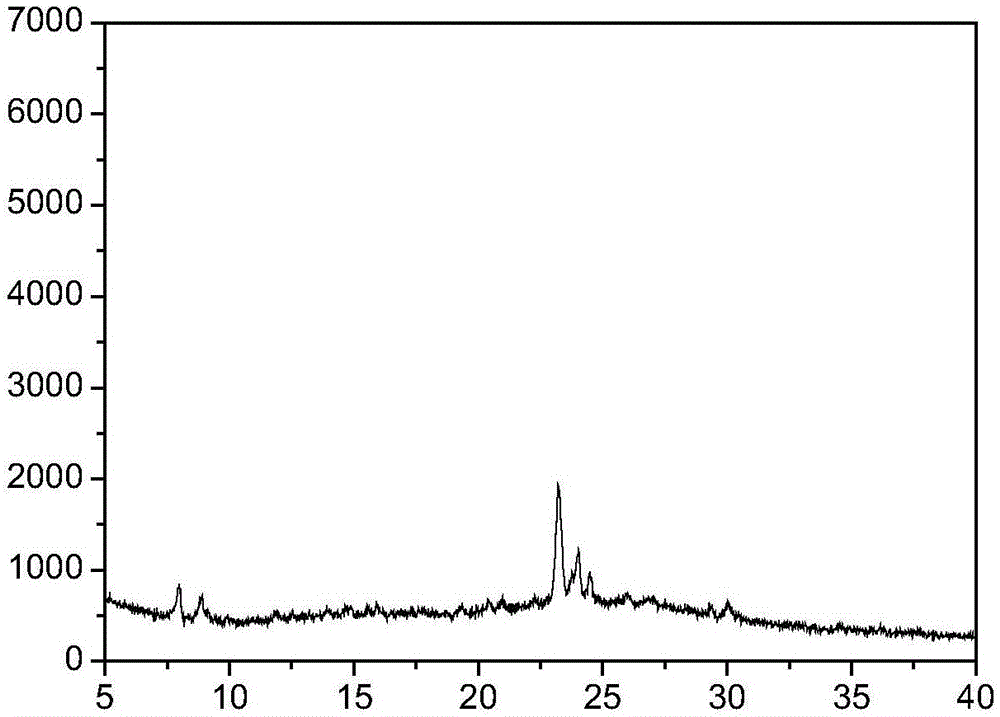

Method for synthesis of nanometer ZSM-5 molecular sieve from mother liquor flocculate

InactiveCN106044793AShort synthesis timeReduced nucleation activation energyMaterial nanotechnologyPentasil aluminosilicate zeoliteFlocculationAdditive ingredient

The invention relates to a method for synthesis of a nanometer ZSM-5 molecular sieve from mother liquor flocculate and belongs to the field of chemical engineering. The method comprises carrying out flocculation on a ZSM-5 molecular sieve crystallization mother liquor, separating the flocculate, drying the flocculate and recycling the flocculate as a ZSM-5 molecular sieve synthesis raw material. The method flocculates unreacted effective ingredients in the ZSM-5 molecular sieve crystallization mother liquor, recycles the flocculate, prevents synthesis waste liquid discharge, reduces environment pollution, recovers and recycles the mother liquor, saves raw materials and reduces a molecular sieve synthesis cost. Microcrystallines are formed in the mother liquor flocculate after the reaction so that a nucleation rate and quantity of crystal nucleuses in an induction period of crystallization are greatly improved, molecular sieve nucleation activation energy is reduced, crystallization time is shortened, the molecular sieve crystal grain size is reduced and a molecular sieve crystallization degree is improved.

Owner:JIANGSU TIANNUO NEW MATERIAL TECH

Hydrocarbon mixture and use thereof

ActiveUS8309065B2Formula stableGood dispersionBiocideCosmetic preparationsHydrocarbon mixturesPolymer chemistry

The invention relates to hydrocarbon mixtures containing linear C11 and linear C13 hydrocarbons, wherein the sum of the linear C11 and linear C13 hydrocarbons is greater than or equal to 60 wt. % with relation to the sum of the hydrocarbons, and to the use of said mixtures in cosmetic and / or pharmaceutical preparations.

Owner:COGNIS IP MANAGEMENT GMBH

Engine coolant

InactiveCN106916574AFormula stableGood corrosion inhibitionHeat-exchange elementsChemistryCarboxylate

The invention belongs to the technical field of chemical composition and particularly relates to an engine coolant. The engine coolant is prepared from the following substances in parts by weight: 45-55 parts of water, 25-35 parts of ethylene glycol, 5-8 parts of carboxylate, 5-12 parts of silicate stabilizer, 1-3 parts of nano oxide, 15-25 parts of propylene glycol, 1-5 parts of cesium formate, 3-5 parts of trimethylglycine, 5-8 parts of citric acid, 5-10 parts of ammonium citrate, 15-25 parts of molybdate, 8-12 parts of fatty acid, 0.5-0.8 part of antifoamer, 15-25 parts of potassium aminopropylsilicate, 5-10 parts of sodium octylsilicate, 5-8 parts of sodium benzoate, 3-5 parts of benzotriazole and 5-8 parts of methylbenzotriazole. The engine coolant provided by the invention is stable in formula, has long-acting bacteriostasis and anti-corrosion capability, is free of high-pollutional substances, cannot cause pollution to environments, has a very good corrosion inhibition action and can be used for effectively protecting engines.

Owner:青岛城轨交通装备科技有限公司

Slow-release preservative for fruits and vegetables and preparation method thereof

ActiveCN102422880APrevent agingDelay agingFruit and vegetables preservationBiotechnologyPreservative

The invention relates to a slow-release preservative for fruits and vegetables. Adsorbing carrier adsorbing ethanol solution is loaded into a slow-release bag made of a polyethylene slow-release film, and the slow-release bag is then packaged by an air-permeable paper bag; the adsorbing carrier is powder or a shaped block, and the components of the adsorbing carrier include silica gel, diatomite and polydivinylbenzene porous adsorbent. The invention adopts the method of slowly releasing ethanol to inhibit the yellowing and rotting of fruits and vegetables, and the slow-release preservative has a remarkable effect in reducing the loss of the moisture of fruits and vegetables and inhibiting the growth of pathogenic bacteria and the aging of fruits and vegetables, and is a pollution-free, non-toxic and recyclable preservative product for fruits and vegetables. Compared with conventional products, the slow-release preservative can decrease the weight loss rate of different fruits and vegetables in the storage period by 10 to 30 percent and the rotting rate by 15 to 40 percent and prolong the shelf life by 30 to 50 percent, thus having a good preservation effect, and is applicable to the preservation of various fruits and vegetables. The formulation of a preparation method is simple, material resources are rich, the slow-release preservative is easy to prepare, the cost is low, and moreover, the slow-release preservative is convenient to use.

Owner:MICROBIOLOGY INST OF SHAANXI

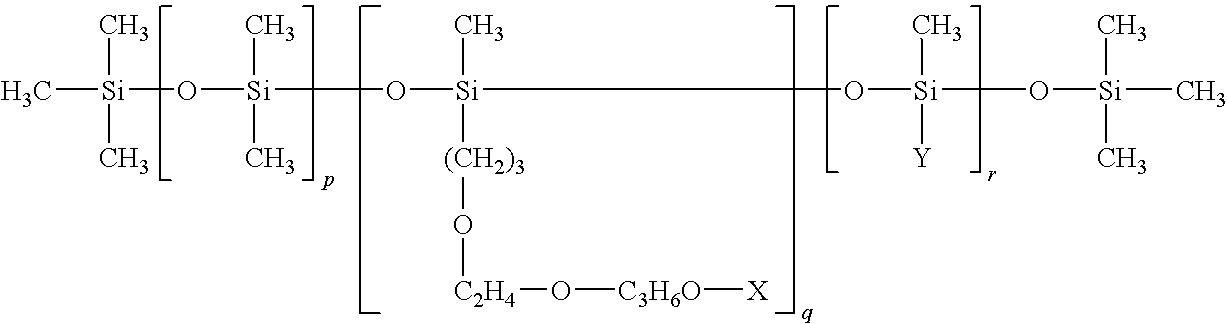

Polylactic acid film blowing processing aid and preparation method and application thereof

InactiveCN103602048AImprove blown film processabilitySimple production processSilicon dioxideSurface modification

The invention discloses a preparation method of a polylactic acid film blowing processing aid, which comprises the following steps of (1) performing surface modification on nano silicon dioxide by use of a silane coupling agent, adding 0.01-6 weight parts of isocyanate substrate, and reacting at over 25 DEG C for more than 4 hours for secondary modification on the silicon dioxide; (2) taking the silicon dioxide after the secondary modification and a polylactic acid prepolymer as raw materials, preferably adding 50-200 parts of polylactic acid prepolymer into each part of silicon dioxide, introducing nitrogen into the reaction kettle, adding a metal lithium or tin catalyst, magnetically stirring at 25-140 DEG C, and heating and reacting for 1-24 hours to finally obtain solid powder; drying in a vacuum oven for 24 hours to obtain the polylactic acid film blowing processing aid. The invention also discloses an application of the polylactic acid film blowing processing aid. In the method disclosed by the invention, polylactic acid is directly grafted to the surface of the silicon dioxide to obtain polylactic acid-grafted silicon dioxide modified particles which are used as a polylactic acid processing aid, and the film blowing processability of polylactic acid is effectively improved.

Owner:SICHUAN UNIV

Face-cleansing skin-moisturizing tea oil soap

ActiveCN105419991AFormula stableImprove fitSoap detergents with organic compounding agentsSkin careCocoyl glutamateAdditive ingredient

The invention provides face-cleansing skin-moisturizing tea oil soap. The face-cleansing skin-moisturizing tea oil soap comprises, by weight, 1.5-3 parts of tea-seed oil, 1.5-3 parts of tea polyphenol, 1.5-3 parts of tea saponin, 26-30 parts of sodium lauroyl glutamate, 2-5 parts of sodium myristoyl glutamate, 2-4 parts of disodium cocoyl glutamate and 0.3-0.6 part of tocopherol. The face-cleansing skin-moisturizing tea oil soap containing woody plant oil is rich in antioxidant ingredients such as the tea saponin, squalene and vitamin E, strong in saponification and capable of deep moisturizing, gently cleansing and moisturizing the skin and keeping face elasticity.

Owner:CHONGQING HUPO TEA OIL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com