Polylactic acid film blowing processing aid and preparation method and application thereof

A processing aid, polylactic acid technology, applied in the field of preparation of polylactic acid blown film processing aids, can solve the problems of migration of small molecular processing aids, difficulty in branching, poor compatibility of blends, etc. Good processability, good transparency, and improved blown film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After dispersing 2 parts of modified nano-silica particles in the solution, add and dissolve 70 parts of 4 mol / g polylactic acid solution, add 3 parts of catalyst stannous octoate, react at 160°C for 48 hours, then keep magnetic stirring under nitrogen atmosphere. After the reaction is completed, the reaction solution is centrifuged to obtain a white powder that is polylactic acid grafted silicon dioxide nanocomposite particles.

Embodiment 2

[0028] After dispersing 2 parts of modified nano-silica particles in the solution, add and dissolve 10 parts of 4 mol / g polylactic acid solution, add 3 parts of catalyst stannous octoate, react at 160°C for 48 hours, then keep magnetic stirring under nitrogen atmosphere. After the reaction is completed, the reaction solution is centrifuged to obtain a white powder that is polylactic acid grafted silicon dioxide nanocomposite particles. One part of the prepared polylactic acid-grafted silica nanoparticles was added into the polylactic acid matrix, melt-blended, and the blending temperature was 180°C for 15 minutes to obtain a composite material. The preferred number of parts of the polylactic acid matrix is 100-20 parts.

Embodiment 3

[0030] After dispersing 2 parts of modified nano-silica particles in the solution, add and dissolve 10 parts of 4 mol / g polylactic acid solution, add 3 parts of catalyst stannous octoate, react at 160°C for 48 hours, then keep magnetic stirring under nitrogen atmosphere. After the reaction is completed, the reaction solution is centrifuged to obtain a white powder that is polylactic acid grafted silicon dioxide nanocomposite particles.

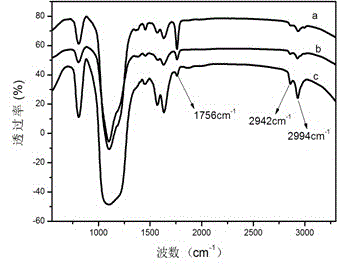

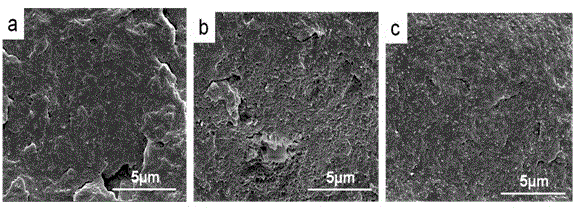

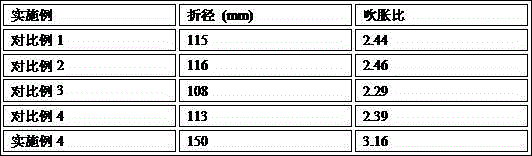

[0031] With the polylactic acid prepolymer of different molecular weight size as reactant, the product infrared spectrum of embodiment 1 is as follows figure 1 Shown in a curve in middle, the infrared spectrum of embodiment 2 product is as figure 1 Shown in the middle b curve, the infrared spectrum of embodiment 3 product is as figure 1 As shown in the curve of middle c, the experimental results show that the nano-silica particles with polylactic acid long-chain branches were successfully synthesized. The SEM photos of the product of Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com