Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Shorten the hot pressing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

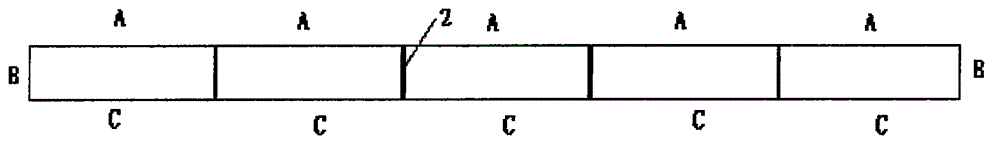

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

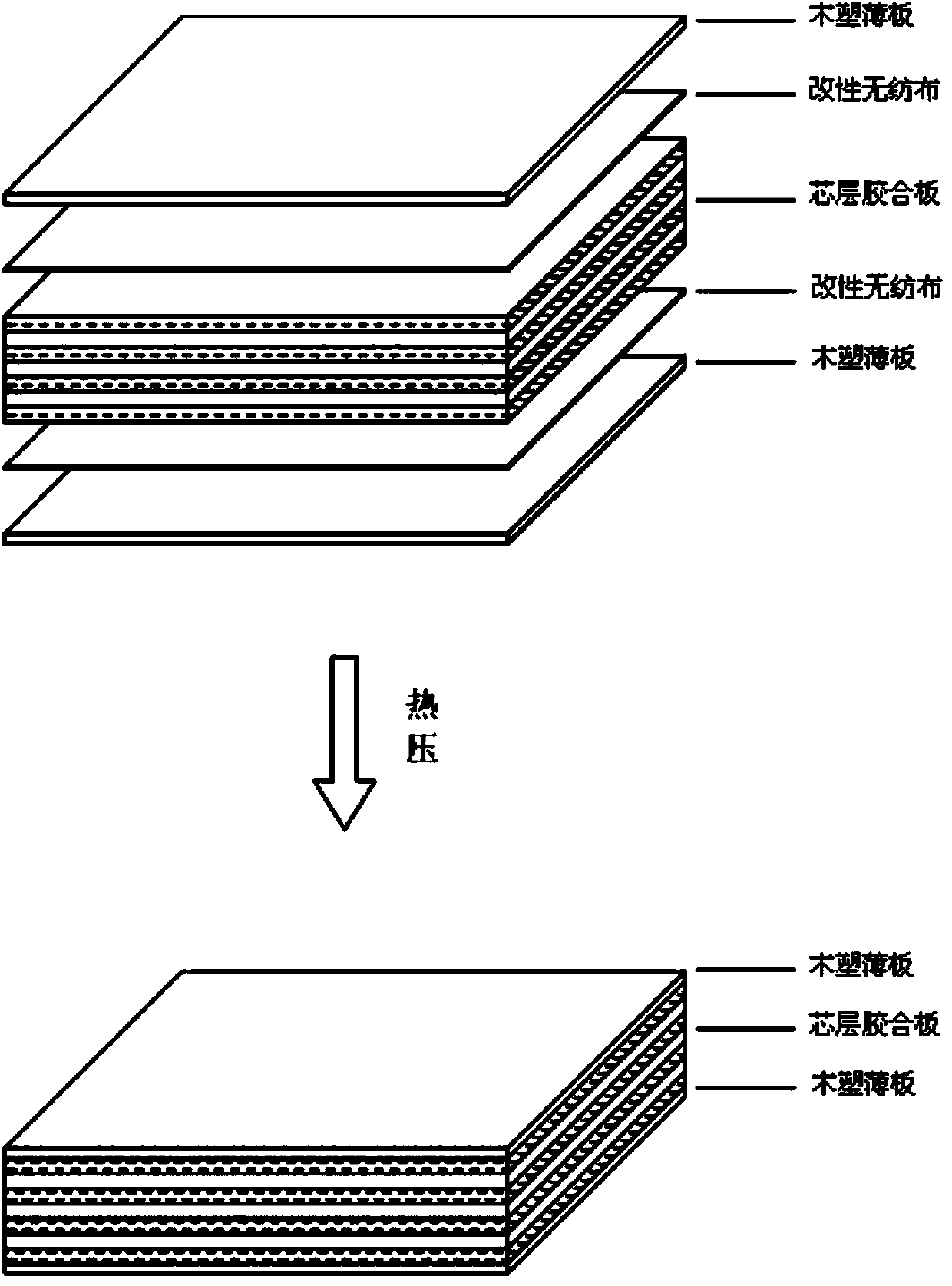

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

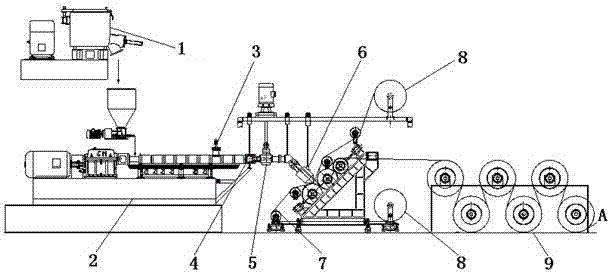

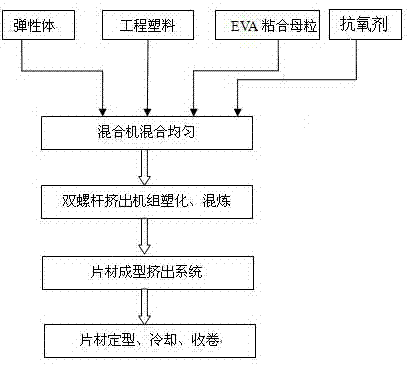

Shoe material hot-melt adhesive sheet and production process and equipment thereof

ActiveCN103613919AImprove physical performanceGood resilienceInsolesFlat articlesAntioxidantHot pressing

The invention discloses a shoe material hot-melt adhesive sheet. The shoe material hot-melt adhesive sheet comprises the following raw material components: 35-40% of elastomer, 45-50% of engineering plastic, 10-15% of EVA (ethylene vinyl acetate) binding masterbatch and 0.5-1.5% of antioxidant. A production process of the shoe material hot-melt adhesive sheet provided by the invention comprises the steps of mixing the elastomer, the EVA binder masterbatch, the engineering plastic and the antioxidant in a twin-screw extruder, pressurizing a melt by a melt pump, then enabling the melt to flow out of a T-shaped die head, hot-bonding double surfaces of polyester non-woven mesh fabric on the upper surface and lower surface of the melt of the sheet in a three-roller calendering machine, further calendering and shaping, cooling and shaping the sheet by a cooling roller cylinder after shaping, cutting edges, and then rolling or cutting according to a fixed size. The elastomer hot-melt adhesive sheet can be used for manufacturing finished products of shoe heads and back liners after being stamped by a mold, the shaped adhesive sheet finished products are placed into shoe inner liners and interlayers of shoe vamps for hot-pressing, binding and solidifying, and the production process flow is simplified and is suitable for mass production of an assembly line.

Owner:江苏诚盟装备股份有限公司

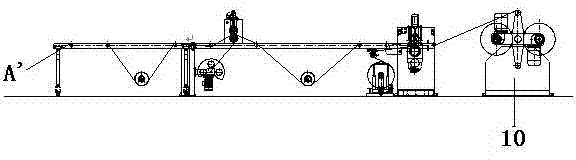

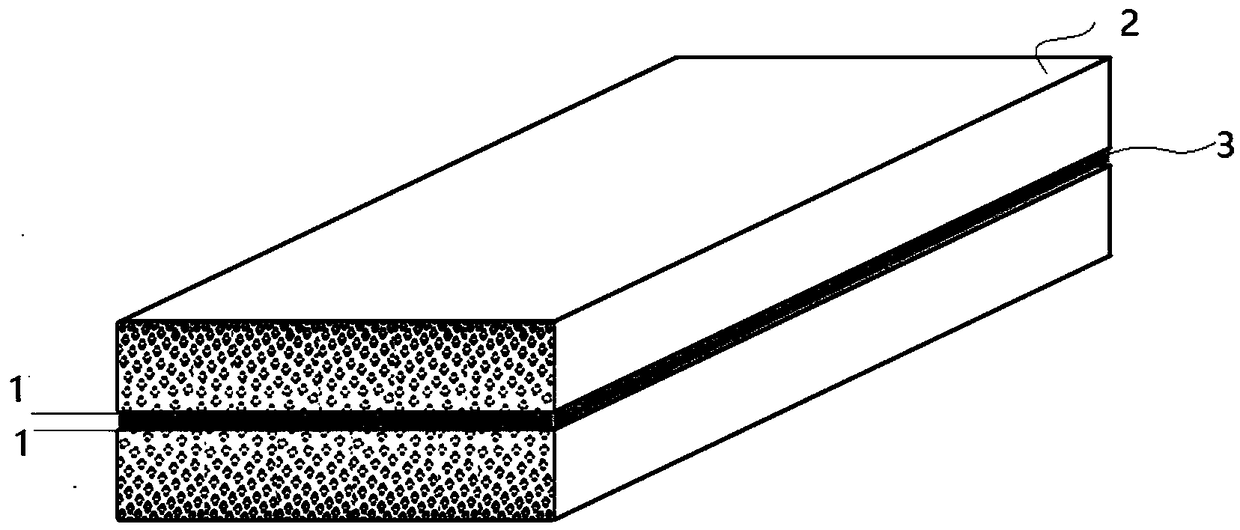

Carbon fiber cloth reinforced type wood-plastic composite material and preparation method thereof

InactiveCN103832042AImprove mechanical propertiesImprove toughnessSynthetic resin layered productsLaminationFiberCarbon fibers

The invention relates to a carbon fiber cloth reinforced type wood-plastic composite material and a preparation method thereof, and aims to solve the problems of low comprehensive mechanical property, particularly low impact toughness, of an existing wood-plastic composite material. The carbon fiber cloth reinforced type wood-plastic composite material consists of two surface wood-plastic layers, two carbon cloth reinforcement layers and a core wood-plastic layer. The preparation method comprises the following steps: (1) preparing a single wood-plastic composite plate; (2) treating carbon cloth, namely passivating the surface of the carbon cloth; (3) preparing the carbon fiber cloth reinforced type wood-plastic composite material, namely sequentially stacking and assembling a surface wood-plastic plate, the reinforced carbon cloth, a core wood-plastic plate, another reinforced carbon cloth and a surface wood-plastic plate with the corresponding thicknesses according to the performance requirements of the carbon fiber cloth reinforced type wood-plastic composite material, hot-pressing for 3-15min, cooling and finishing. According to the method, the toughness of the wood-plastic composite material is remarkably improved. The carbon fiber cloth reinforced type wood-plastic composite material can be applied to the field of high-performance structures and engineering materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

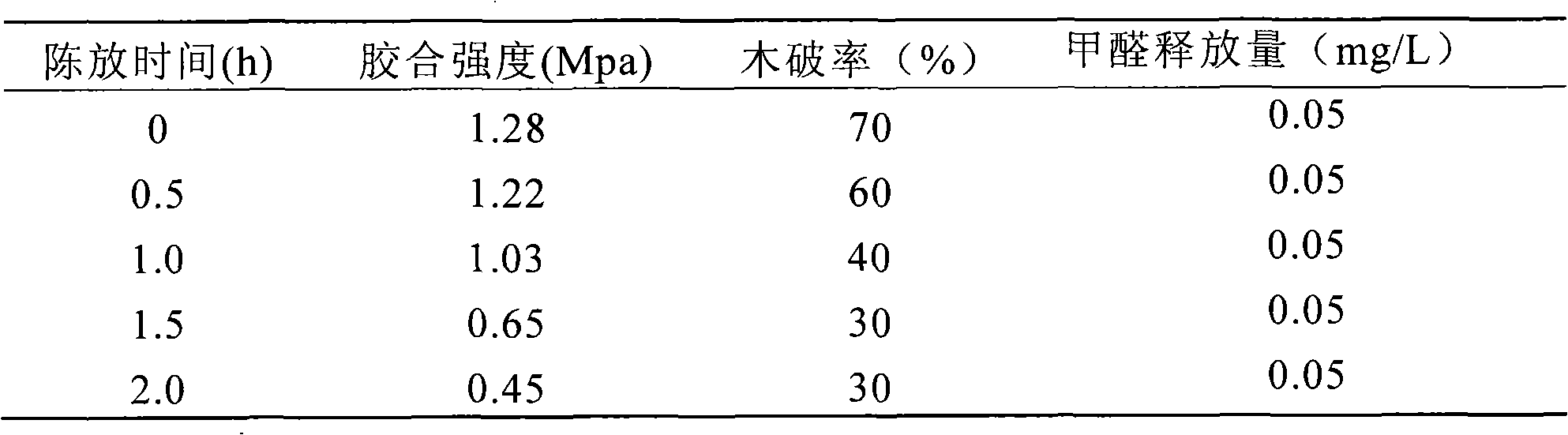

Protein-based wood adhesive and preparation method thereof

InactiveCN103740326ALow priceShort reaction timeNon-macromolecular adhesive additivesProtein adhesivesPhenolUltimate tensile strength

The invention relates to a protein-based wood adhesive and a preparation method thereof, and particularly relates to a protein-based wood adhesive prepared from vegetable protein and non-toxic epoxy resin and a preparation method thereof. The protein-based wood adhesive is prepared from natural vegetable protein, a formaldehyde-free epoxy resin curing agent, a filler and the like. The protein-based wood adhesive disclosed by the invention is a non-toxic and environment-friendly adhesive, and no formaldehyde or a toxic organic substance is released in production, transportation and application processes or use of the product. Meanwhile, the adhesive is high in bonding strength, and good in water tolerance, the strength of the adhesive after being boiled by boiling water can be comparable to the performance of phenol glue, and the use standard of secondary glue is completely achieved. The protein-based wood adhesive provided by the invention is simple in preparation technology, the hot-press time is much smaller than that of a formaldehyde-type adhesive, and an energy source is greatly saved.

Owner:阎肖华

Formaldehyde-free wood adhesive and preparation method thereof

InactiveCN101928546AReduce dosageImprove protectionProtein adhesivesGlue/gelatin preparationMeal powderPolyamide

The invention discloses a formaldehyde-free wood adhesive. The formaldehyde-free wood adhesive consists of the following components in percentage by weight: 0 to 94.8 percent of water, 5 to 99.8 percent of mixed vegetable protein powder, 0.1 to 94.9 percent of PPE-N, 0.05 to 5 percent of preservative, 0 to 15 percent of pH regulator, 0 to 10 percent of thickening agent, 0.05 to 15 percent of antifreeze and 0 to 20 percent of filler, wherein the mixed vegetable protein powder is a mixture formed from defatted soybean powder and defatted pea protein powder or defatted cottonseed meal powder or defatted castor meal powder in a weight ratio of (1-5):1; and the PPE-N is prepared from polyamide epichlorohydrin and urea. The wood adhesive of the invention adopts formaldehyde-free raw materials, so no formaldehyde is released in the production processes of the adhesive and an artificial sheet material; and an E0-level (GB / T9846.3-2004) artificial sheet material of which the formaldehyde release amount is far less than 0.5mg / L can be produced; and all trance formaldehyde in an artificial sheet material product is from a wood raw material per se, so that the problem of the release of the formaldehyde is solved fundamentally.

Owner:郑州宜康木业科技有限公司

Preparing method for dampproof mould-proof low-formaldehyde medium and high density fiberboard

The invention discloses a preparing method for a dampproof mould-proof low-formaldehyde medium and high density fiberboard. In the hot grinding process, 200 kg / m<3>-230 kg / m<3> of a urea resin adhesion agent, 6 kg / m<3>-8 kg / m<3> of refined paraffin wax, 1.5 kg / m<3>-2 kg / m<3> of a curing agent and an acid particle deep black solution accounting for 1% to 2% of absolutely-dried fibers are added into a slurry spraying pipe; and in the drying process, 100-200-mesh activated carbon powder is added. Through the special process, the effects that the product quality is improved, the dampproof and mould-proof effects are improved, and the formaldehyde emission amount is reduced are achieved; and in the board heating process, a preheating system heats fibers in advance, the fiber temperature is improved, the fibers are softened, the hot press time is shortened, the hot pressing efficiency is improved, the product quality is improved, the working cost is reduced, and the working efficiency is improved.

Owner:JINAN CAIMING IND CO LTD

Nonformaldehyde nonpoisonous adhesive and preparation method thereof

ActiveCN101709211AShorten the preload timeShorten the hot pressing timePolyureas/polyurethane adhesivesChemistryAqueous solution

The invention discloses a nonformaldehyde nonpoisonous adhesive and a preparation method thereof. The method comprises the following steps: firstly, adding proper water in a reactor which is provided with a stirring device; secondly, slowly adding polyvinyl alcohol into the reactor when the water is heated to 40 DEG C, heating the mixture to over 90 DEG C to ensure that the polyvinyl alcohol is completed dissolved, and preserving the heat for 1 hour; thirdly, cooling the materials to 70 DEG C, and adding polyalcohol, dispersant, emulsifier and aqueous solution of plasticizer into the reactor respectively, adding filler into the reactor, keeping stirring for 15 to 20 minutes to ensure that the raw materials are uniformly mixed, and filtering and discharging; and finally, uniformly mixing the raw materials with isocyanate in the proportion when the adhesive is used. The adhesive has simple production technology, can be subjected to both cold pressing and hot pressing, has low cost, and can completely realize non toxicity, harmlessness, greenness and environmental protection.

Owner:东营市盛基环保工程有限公司

Method for establishing moisture content gradient of shaving board

ActiveCN103950085AReduce drying energy consumptionGuaranteed drying qualityWood working apparatusFlat articlesWood shavingsSurface layer

The invention discloses a method for establishing a moisture content gradient of a shaving board. The method consists of three technological links, namely drying in levels, respective glue mixing and respective paving. The drying in levels is characterized in that two levels of drying systems are established and a shaving sorting procedure is set up between the first-level drying system and the second-level drying system; the shavings subjected to drying in levels are respectively stored, metered and mixed with glue, and the moisture content difference between shavings in a core layer and shavings on a surface layer are stabilized; after the shavings are metered, the shavings are respectively paved, and the moisture content gradient is finally established on a cross section of a blank of the shaving board. By the moisture content gradient, the moisture on the surface of the blank is quickly vaporized in the heating process, a steam impact effect is generated, the heat transfer speed is improved, the temperature rise speed of the core layer is improved and the aims of shortening hot-pressing time and improving hot-pressing efficiency are finally fulfilled; in addition, by establishing the moisture content gradient of the blank, the performance and the surface quality of the finished shaving board can be obviously improved, the static bending intensity of the board is improved, the made shaving board is more smooth in surface, and the sanding loss of the shaving board is reduced.

Owner:SOUTHWEST FORESTRY UNIVERSITY

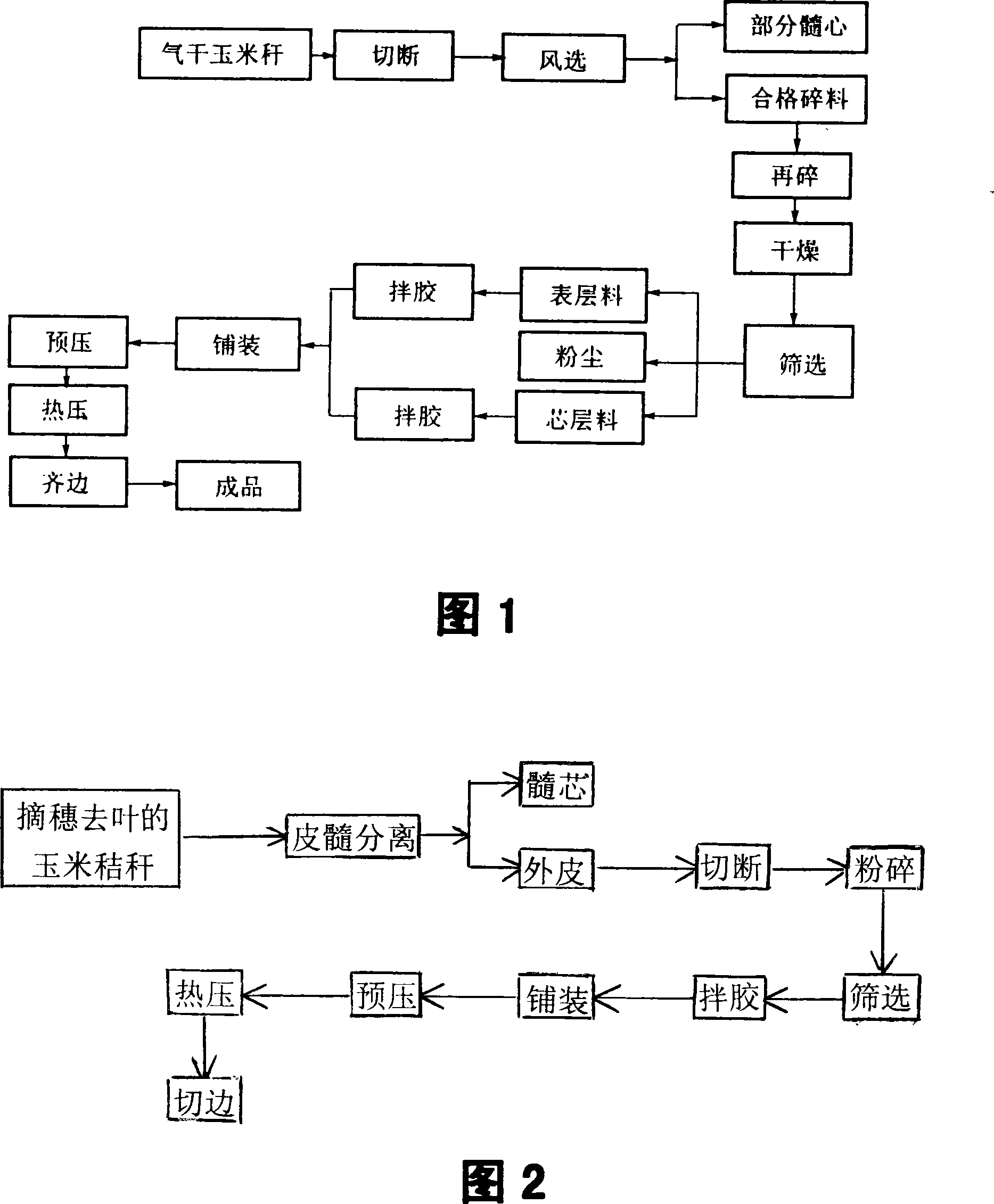

Corn straw particle board and manufacturing method thereof

The invention belongs to the category of cropper straw wood based panel. A maize straw grain plate comprises maize straw broken material and isocyanate adhesive. The invention is characterized in that the maize straw broken material is the grain of the skin of the marrow-removed maize straw; the weight percentage of the grain composition can be seen in the table; the content of the isocyanate is 3.2% to 3.7% times of the weight of the maize straw broken material. The manufacturing method of the maize straw grain plate is that the skin and marrow of the maize straw are removed; the peeled skin of the maize straw is cut off, crushed, screened, glued, paved, pre-pressed, hot pressed under the temperature ranging from 170 DEG C to 175 DEG C and edge cut. The invention solves the technical problems of improving the strength of maize straw crushed grain plate, simplifying gluing and glue mixing process, raising hot pressing temperature and shortening hot pressing time.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

High-speed hot press and its application method

InactiveCN102275038ALow costReduce the burden onNon-electric welding apparatusEngineeringConveyor belt

The invention aims to provide a high-speed hot press which can be matched with a movable pulse hot-pressing module to improve the process operation mode and enhance the productivity per unit time, and the application method of the high-speed hot press as well. The high-speed hot press comprises a machine station, a conveyor belt mechanism, a hot-pressing module, a moving mechanism and an operation system. The high-speed hot press is characterized in that the hot-pressing module is composed of a pulse hot-pressing electrode, a heat-dissipating module, a horizontal adjusting module, an actuating module and a transformer module which are orderly stacked from bottom to top; and the moving mechanism consists of two parallel opposite longitudinal bearing rails, a plurality of horizontal moving rails, a plurality of horizontal moving apparatuses and a plurality of longitudinal moving apparatuses, wherein the longitudinal bearing rails are respectively arranged at one side of the top end of the machine station, the horizontal moving rails are respectively corresponding to the hot-pressing modules and are arranged between the longitudinal bearing rails, the horizontal moving apparatuses are respectively disposed at positions where the horizontal moving rails and the longitudinal bearing rails are connected, and the longitudinal moving apparatuses are respectively disposed at positions where the hot-pressing modules and the horizontal moving rails are connected and enable the hot-pressing modules to be suspended below the horizontal moving rails.

Owner:PROGRESS Y&Y

Production method and production device for formaldehyde-free type medium-density fiberboard

ActiveCN106738184AReduce distortionSave storage spaceFlat articlesDomestic articlesFiberStack machine

The invention discloses a production method and a production device for a formaldehyde-free type medium-density fiberboard. The production device comprises a spreading machine, a pre-pressing machine, a hot press, a cold-pressing rolling machine, a diagonal saw, a first roller conveyor, a jitter conveyor, a plate cooler, a sanding machine, a plate cutter and a stacking machine which are sequentially arranged from front to rear in a base material motion direction, and further comprises a belt conveyor, a heating room, an air-inducing fan, a first fan and a second fan; and the spreading machine, the pre-pressing machine and the belt conveyor are positioned in the heating room. The production method comprises the following steps of: wood stripping and chipping, fiber preparing, waterproof agent and adhesive applying through fibers, fiber drying, fiber paving, fiber raw slab pre-heating, pre-pressing, hot-pressing, plain plate rolling, plain plate jittering and plain plate processing, wherein the adhesive applied by the fibers is formaldehyde-free polyisocyanate adhesive. According to the production method and the production device disclosed by the invention, hot-pressing time can be shortened by 10%, a plain plate curing process is cancelled, the production period is quickened, and production cost is reduced.

Owner:福建省永安林业(集团)股份有限公司永林蓝豹分公司

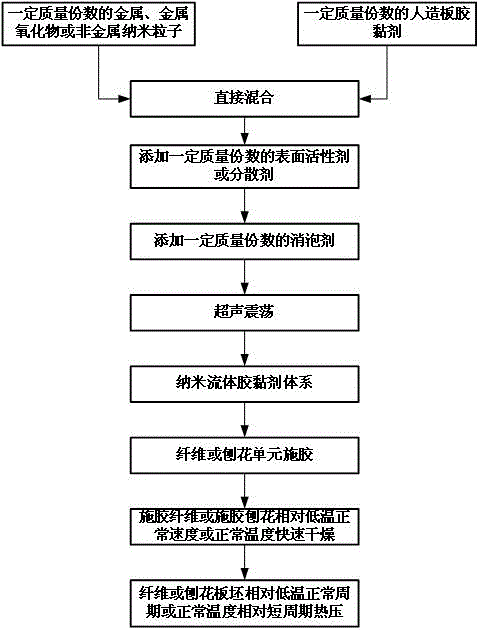

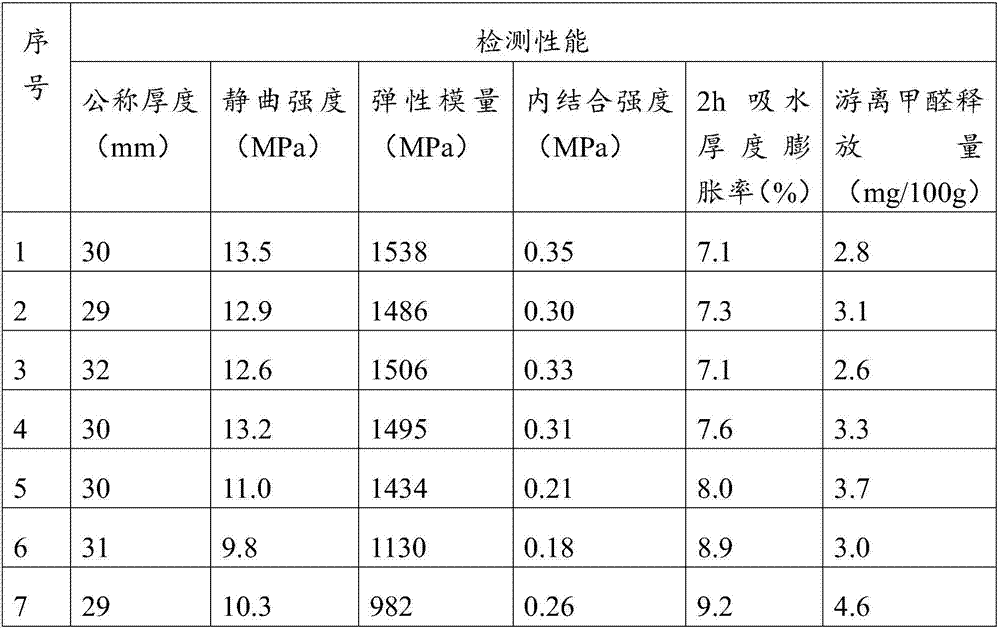

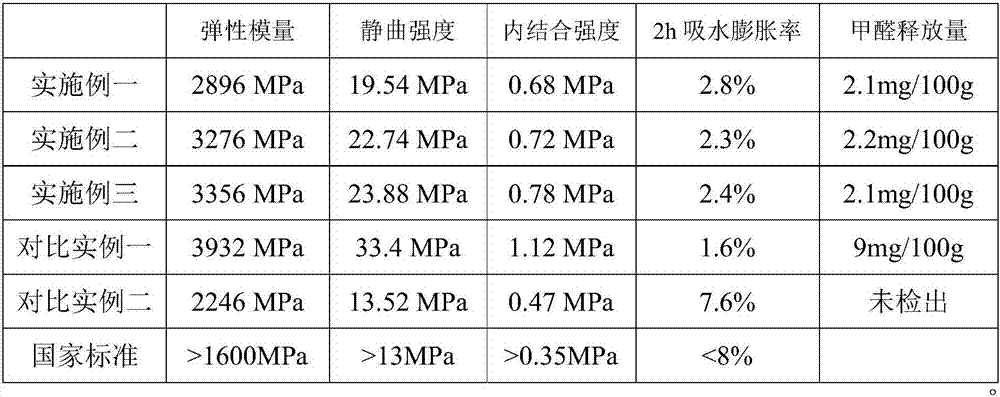

High-heat-conductive nano fluid adhesive, preparation method of same, and application thereof in production of artificial boards

ActiveCN106497468AImprove thermal conductivityLow drying temperatureNon-macromolecular adhesive additivesProtein adhesivesFiberMetal oxide nanoparticles

The invention discloses preparation of a high-heat-conductive nano fluid adhesive and an application thereof in production of artificial boards. The adhesive includes, by mass, 1-15% of high-heat conductivity metal nano particles, metal oxide nano particles or non-metal nano particles, 83-98.8% of an adhesive for production of a fiber board or a particle board, 0.1-1% of a surfactant or a dispersant, and 0.1-1% of a defoamer, all the components are mixed and are subjected to supersonic vibration to form the adhesive. The invention also discloses a preparation method of the adhesive and an application thereof in production of the artificial boards. The high-heat-conductive nano fluid adhesive has the character that the heat conductivity is significantly increased, so that the adhesive can significantly increase drying speed of the fibers and wood particles after application of the adhesive during production of the fiber board or the particle board, and meanwhile, can significantly reduce hot-pressing time or reduce the hot-pressing temperature of the fiber board or the particle board.

Owner:NANJING FORESTRY UNIV

Production method of particleboard

InactiveCN107379205AIncrease profitAdd channelFlat articlesDomestic articlesWood shavingsEngineering

The invention discloses a production method of a particleboard. The production method comprises the following steps of (1) wood shaving preparation; (2), drying and screening; (3) glue application; (4) laying and precompression; (5) hot press molding; and (6) edge sawing and sanding. According to the production method provided by invention, rough core layer wood shavings subjected to glue application are pretreated, and then procedures including laying, precompression and hot press molding are carried out, so that the hot pressing time can be effectively reduced, the hot press molding ratio is increased, and the production efficiency is improved; the particleboard prepared by the production method is low in cost and free formaldehyde releasing quantity and high in strength at the same time; and the production method provided by the invention is capable of effectively improving the quality of a particleboard product and increasing the benefit of an enterprise and is worthy of popularization.

Owner:广西祥盛家居材料科技股份有限公司

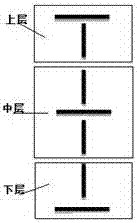

Formaldehyde-free solid wood composite floor and manufacturing method thereof

InactiveCN107310006AImprove filling abilityDoes not see throughLaminationLamination apparatusSolid woodSurface layer

The invention discloses a formaldehyde-free solid wood composite floor and a manufacturing method thereof. The formaldehyde-free solid wood composite floor comprises a surface layer, a base material layer and a bottom layer which are arranged from top to bottom. The base material layer is formed by sequentially bonding an upper layer body, a middle layer body and a lower layer body from top to bottom. The upper layer body and the lower layer body are both a two-layer board, and the middle layer body is a three-layer board. The two-layer board is composed of two layers of veneers with perpendicular texture, and the three-layer board is composed of three layers of veneers with perpendicular texture from top to bottom. All the veneers are bonded through YSD851 glue. The invention further provides the manufacturing method of the formaldehyde-free solid wood composite floor. The composite floor is free of formaldehyde and has no harm to human health; the glue is good in filling property, few in applied quantity, high in production efficiency and low in requirement for the hot-press time, temperature and pressure compared with other glue and saves cost; and the glue is long in active period and capable of being used for a long time.

Owner:兰州科天水性科技有限公司

Special composite ingredients for wood-based panel adhesive and method for making same

InactiveCN101113307AReduced stabilityHigh bonding strengthWood veneer joiningInorganic adhesivesSodium BentoniteAdditive ingredient

The invention aims at providing a special composite burden for adhesive used for a wood-based panel and a preparation method thereof. Mixture of ca-bentonite and na-bentonite according to a certain ratio is chosen to replace pure ca-bentonite or na-bentonite and certain amount of flour, strong water absorbent, reinforcing agent and curing agent are added into the mixture. The invention effectively makes up the disadvantages of pure ca-bentonite of poor water absorption and suspension property, small expansion multiple and poor tackifying effect, etc, and the disadvantages of pure na-bentonite of too strong water absorption, too fast water loss speed of prepared adhesive liquid and impossibility of adhesion, etc, in spite of the advantages of na-bentonite of good suspension property, large expansion multiple and comparatively ideal tackifying effect. The invention also reduces hardness of adhesive mode and water loss speed, improves initial adhesion and adhesive strength and enhances bonding strength and adsorption capacity towards formaldehyde and adhesive liquid can be fully solidified during the process of hot pressing.

Owner:伊梅生

Low-formaldehyde chipboard and preparation method thereof

InactiveCN106985257ASolve the problem of hot pressing sticky boardOvercoming the problem of high formaldehyde emissionFlat articlesDomestic articlesWood shavingsSurface layer

The invention discloses low-formaldehyde chipboard and a preparation method thereof. The low-formaldehyde chipboard comprises a surface layer and a core layer, wherein the surface layer adopts formaldehyde-free soybean glue as an adhesive; the dosage of the formaldehyde-free soybean glue is 15-40% of weight of wood shavings on the surface layer; the core layer adopts urea-formaldehyde glue as an adhesive; and the dosage of the urea-formaldehyde glue is 8-20% of weight of wood shavings on the core layer. The low-formaldehyde chipboard reduces the formaldehyde release amount of full-urea-formaldehyde glue chipboard and ensures the production efficiency of the chipboard; and the mechanical property and various indexes of the chipboard can reach the national standard requirements, and the low-formaldehyde chipboard is low in formaldehyde release amount and reaches the grade of F four solid pentalphas (the supreme grade of four grades in F series standard in Japan).

Owner:宁波中科朝露新材料有限公司 +1

Sound insulation and noise reduction type composite bamboo fiberboard

ActiveCN107877624AImprove sound insulation and noise reductionGuaranteed physical and mechanical performanceLaminationLamination apparatusFiberNoise reduction

The invention discloses a sound insulation and noise reduction type composite bamboo fiberboard, and relates to the technical field of bamboo fiberboard processing. The sound insulation and noise reduction type composite bamboo fiberboard is composed of three layer structures of a bamboo fiber bottom board, a sound insulation and noise reduction layer and a bamboo fiber panel, and the sound insulation and noise reduction layer is arranged between the bamboo fiber bottom board and the bamboo fiber panel and is made of an asbestos wool-foamed aluminum-magnesium composite. According to the soundinsulation and noise reduction type composite bamboo fiberboard, the asbestos wool-foamed aluminum-magnesium composite serves as the sound insulation and noise reduction layer, so that the manufactured composite bamboo fiberboard has excellent sound insulation and noise reduction performance; and the sound insulation and noise reduction performance of the manufactured composite bamboo fiberboard is further enhanced by using the self-made bamboo fiber bottom board or bamboo fiber panel, meanwhile, physical and mechanical using performance of the composite bamboo fiberboard is ensured, and construction requirements of building decoration are met accordingly.

Owner:广西平乐爱森新材料有限公司

Non-formaldehyde waterproof plastic film reinforced flexible decorative veneer and preparation method thereof

ActiveCN106272804AReduce heat stressLower bonding temperatureElectric wood treatmentSynthetic resin layered productsEngineeringPlastic film

The invention discloses a non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. Composting faces of a rotary cut or sliced decorative veneer and a plastic film are subjected to low-temperature plasma modification treatment, the treated composite faces of the decorative veneer and the plastic film are stacked to form composite blanks, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer is obtained through hot-press gluing. The invention further discloses a preparation method of the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. The product prepared by adopting the method releases no formaldehyde, no adhesive or gluing procedure is omitted, the production cost is lowered, the product suppleness is good, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer has the enough transverse tensile strength, will not cause glue penetration, is good in water resistance, saves energy, and is environmentally friendly, easy and convenient to operate and high in efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

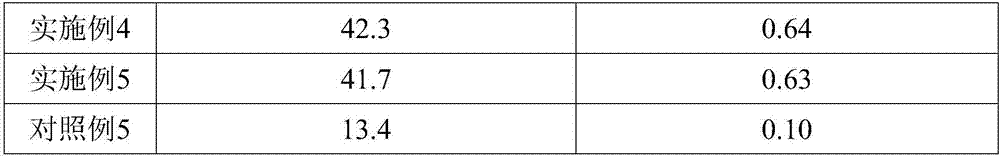

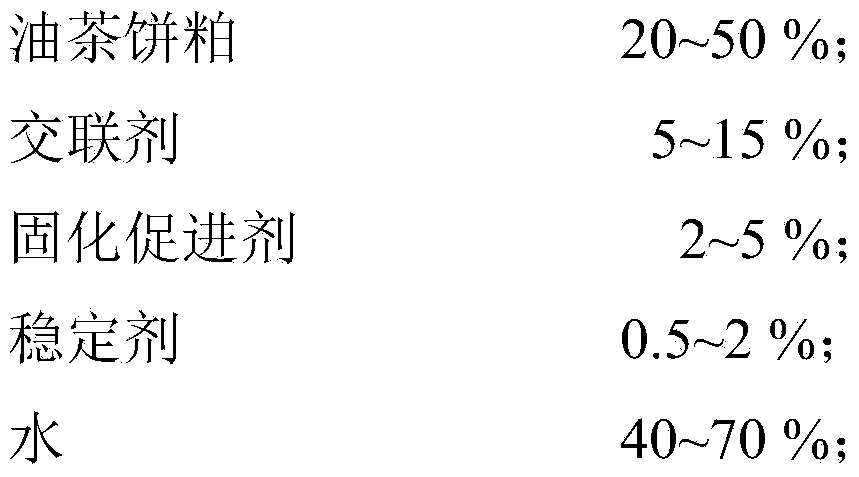

Additive of phenolic resin as well as preparation method and application of additive

ActiveCN104212122ALow costReduce dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveEnergy consumption

The invention discloses an additive of phenolic resin as well as a preparation method and an application of the additive, and belongs to the field of wood adhesives. The additive mainly comprises oil-tea-cake, a crosslinking agent, a curing accelerator, a stabilizer and water. The preparation method comprises the following steps: evenly dispersing oil-tea-cake powder into water; adding the crosslinking agent and evenly stirring; carrying out thermal reaction at 50-70 DEG C for 2-3 hours, and cooling to 30 DEG C; and adding the curing accelerator and the stabilizer, evenly stirring and carrying out thermal reaction for 0.5-1 hour, so as to obtain the additive of the phenolic resin, wherein the additive is applied to an adhesive of the phenolic resin. The curing speed and the bonding strength of the adhesive of the phenolic resin can be effectively improved, the hot-pressing time of plywood is shortened, and the hydrolytic resistance of the plywood can be significantly improved, and thus the production efficiency is improved, and the energy consumption and the manufacturing cost are reduced. The additive of the phenolic resin has social significances of energy conservation and emission reduction, and the preparation method is simple, and convenient to operate.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

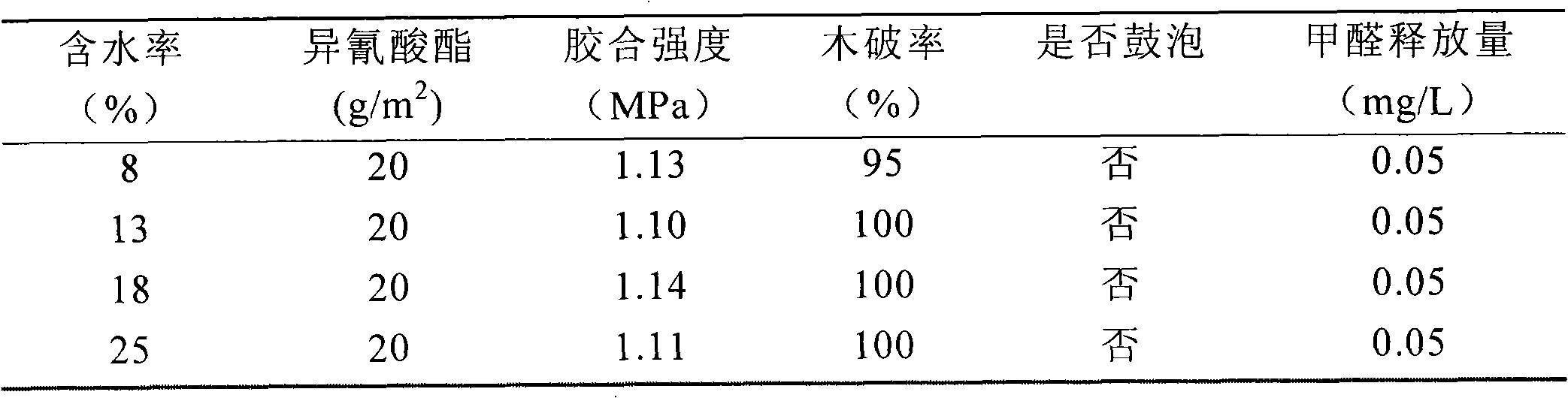

Aldehyde-free veneer and producing method thereof

ActiveCN101524857BLow costReduce drying energy consumptionWood veneer joiningWood layered productsAdhesiveSingle plate

The invention provides an aldehyde-free veneer which comprises a plurality of combined single plates, the contiguous layers of the single plates are in a crossed structure or a parallel structure, a glue layer is arranged between contiguous single plates, and the adhesive of the glue layer is isocyanate. The invention also includes the producing method of the aldehyde-free veneer. In the normal producing method of veneer, isocyanate adhesive is used, the hot pressing time in the work procedures is shortened, the hot pressing temperature is lowered, and the requirement of the water content of the single plate is lowered. Spraying glue application method is used in the work procedure of applying glue to the veneer to greatly reduce the applied glue amount of the veneer, thus besides the formol release amount is greatly lower than that of the relevant standard, and the aldehyde-free veneer also has more reasonable technology.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

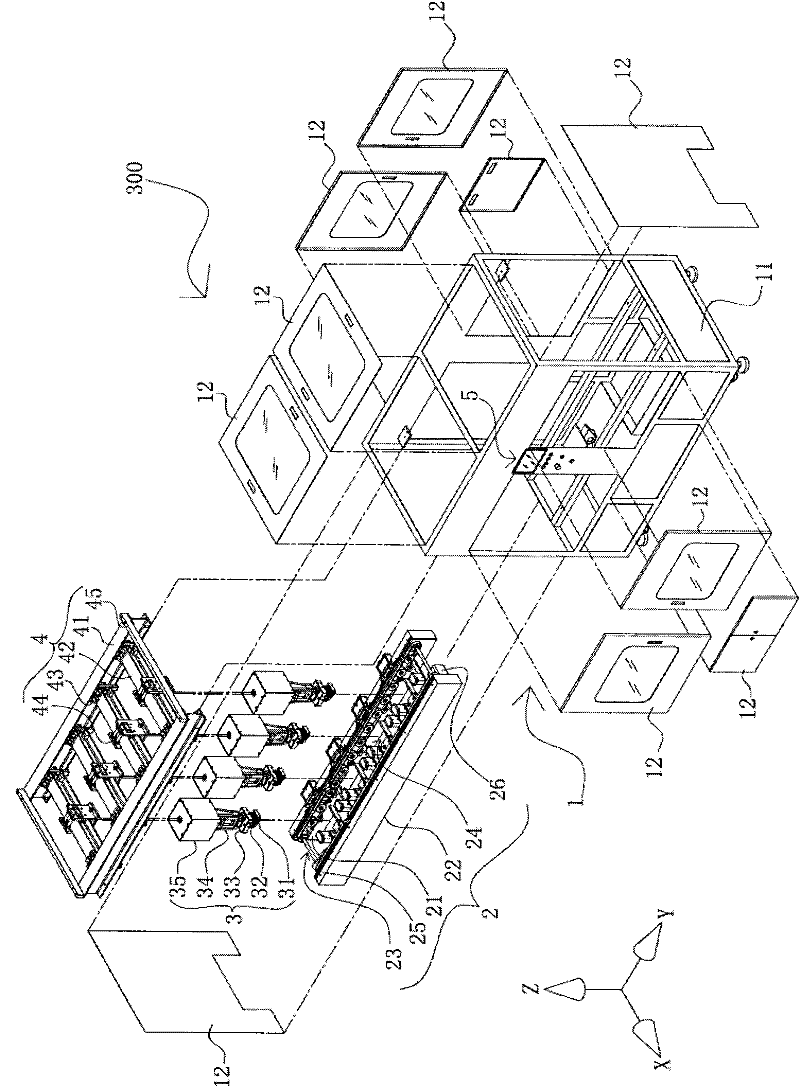

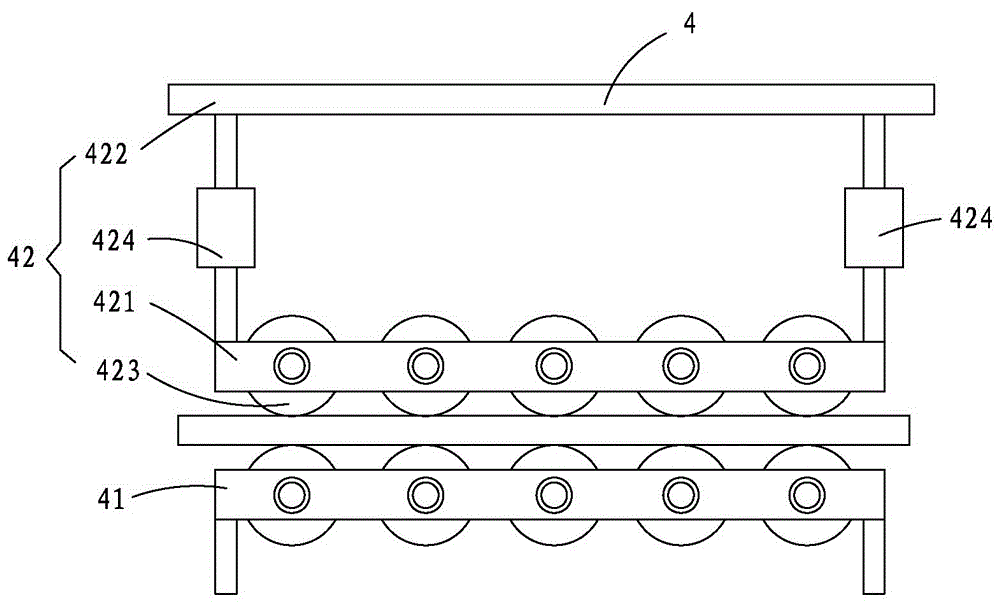

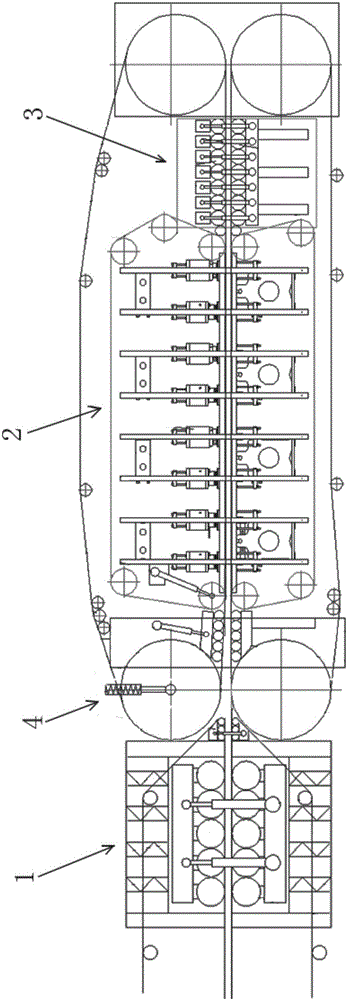

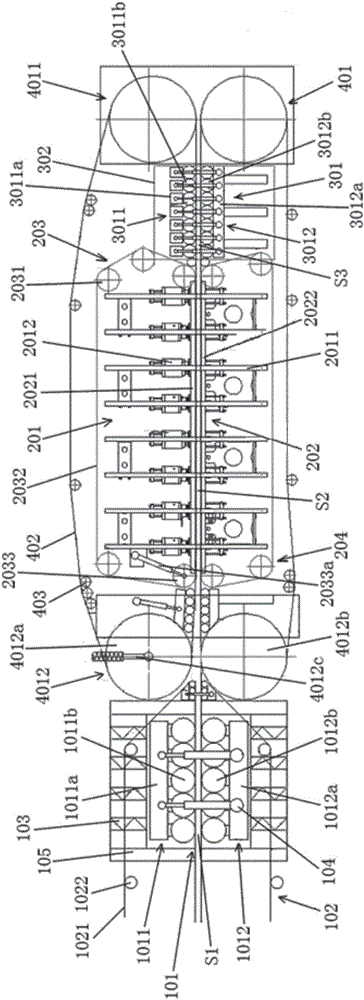

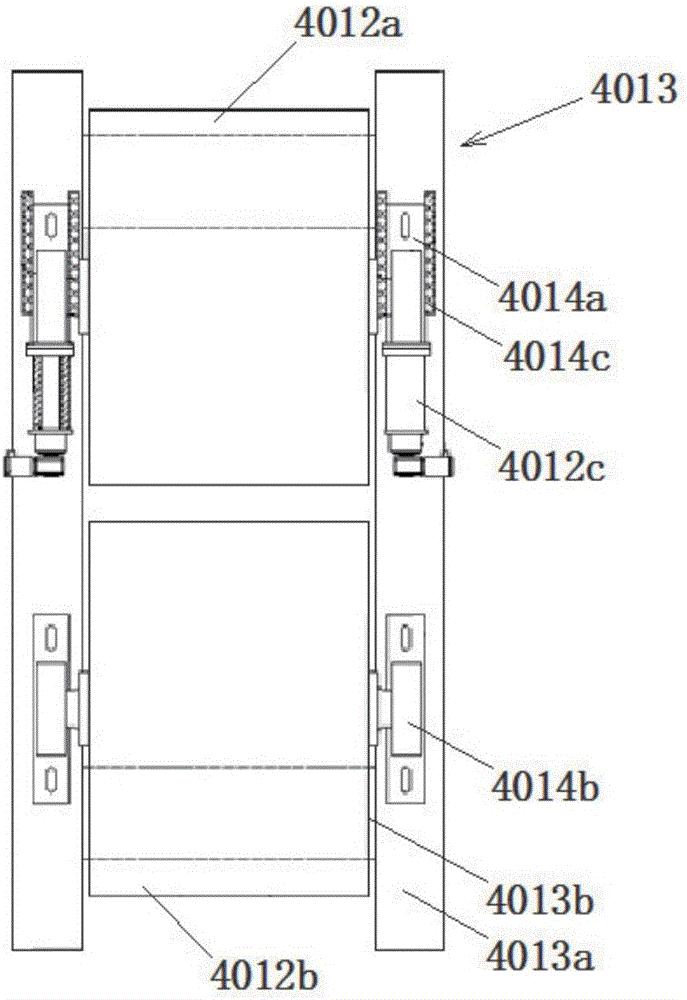

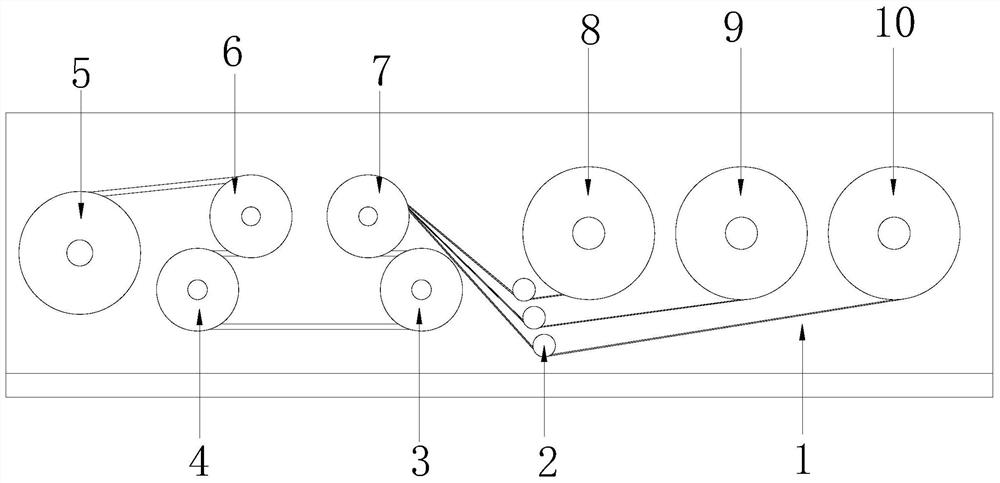

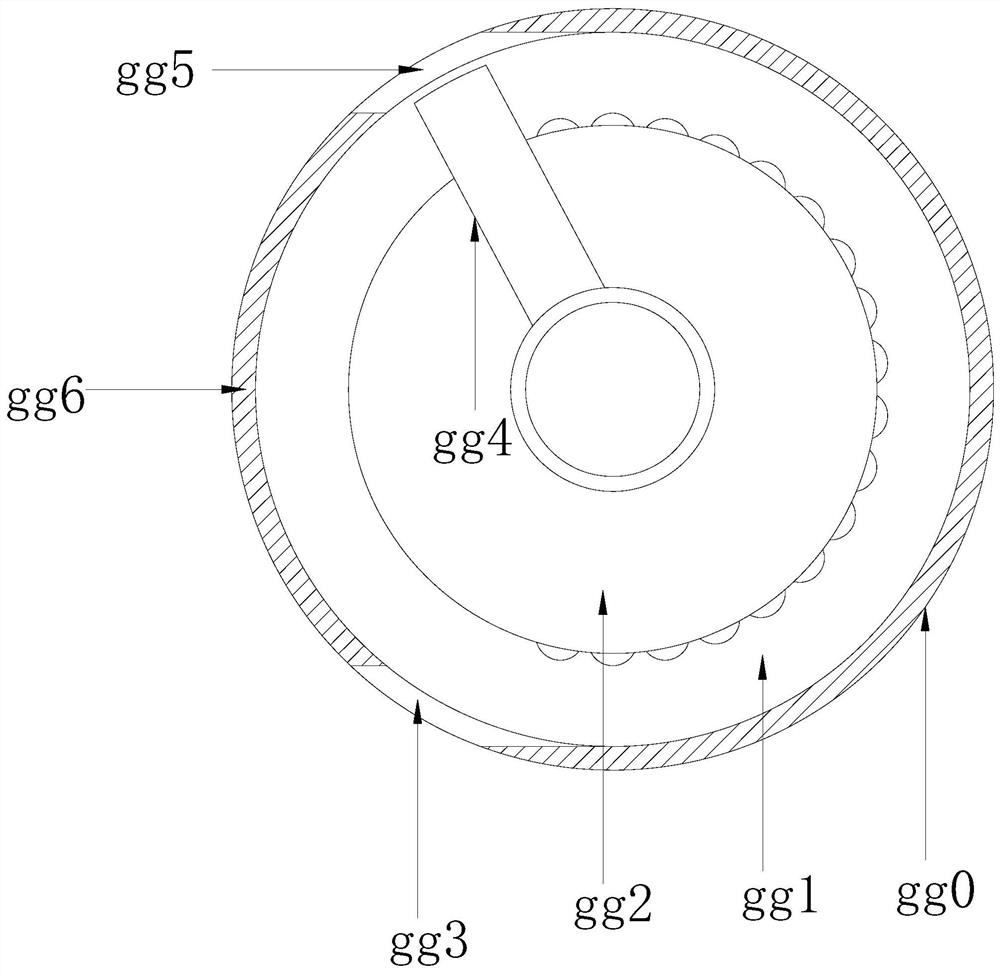

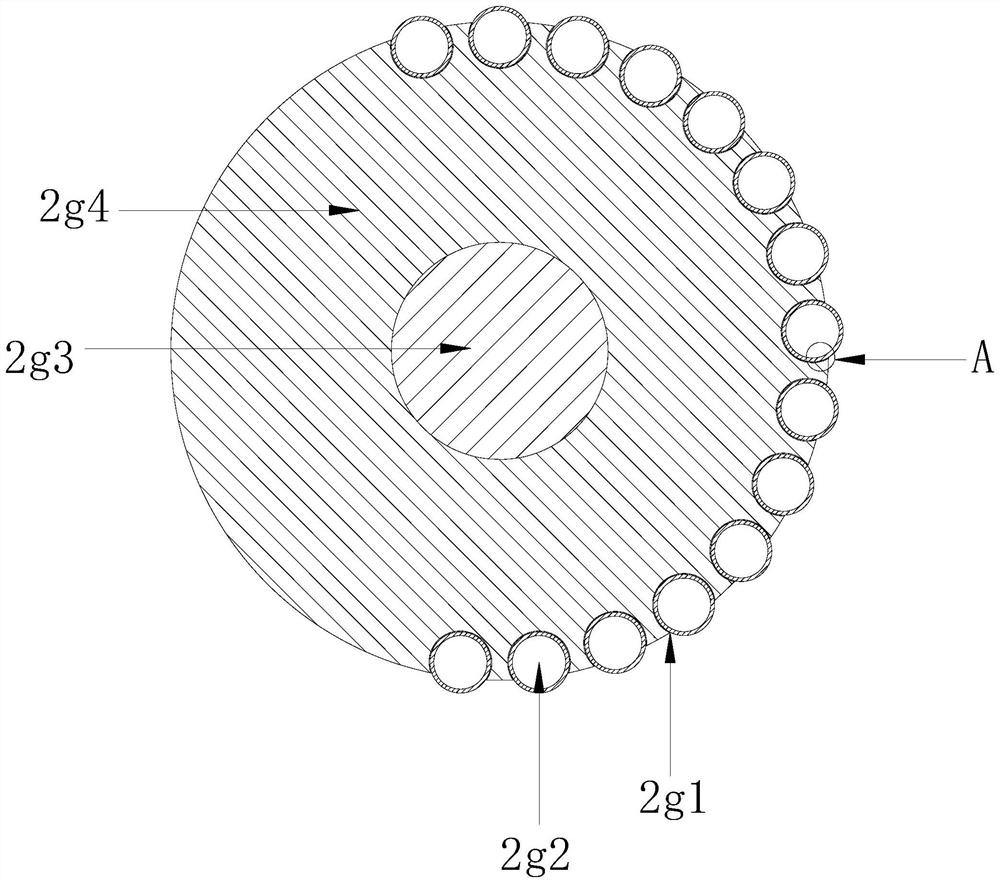

A continuous type press

PendingCN106607971ARealize continuous productionIncrease production capacityPlywood pressesVeneer pressesThermal isolationEngineering

The invention provides a continuous type press comprising a pre-heating and pressurizing unit, a heating and pressurizing unit, a cooling and pressurizing unit and a steel belt conveying unit used for connecting the heating and pressurizing unit and the cooling and pressurizing unit in series. The pre-heating and pressurizing unit comprises a first roller group mechanism used for providing pressure and a heating device used for providing non-contact heating, as well as a conveying device which is arranged between the first roller group mechanism, cooperates with the first roller group mechanism and is used for conveying mechanisms. The cooling and pressurizing unit comprises a second roller group mechanism used for providing pressure and a thermal isolation device used for maintaining the internal temperature of the cooling and pressurizing unit. The continuous type press has the advantages of low energy consumption, low cost, long service life, short production cycle, high plywood production efficiency and high forming quality.

Owner:CHINA FOMA GROUP

Hot pressing exhaust device in artificial board manufacture process and hot pressing exhaust method

InactiveCN102615691AReduce defectsImprove product qualityWood working apparatusDomestic articlesFuel tankEngineering

A hot pressing exhaust device in an artificial board manufacture process comprises a membrane base plate and a hydraulic pressure and oil supply mechanism. The membrane base plate comprises two layers of elastic metal boards which are laminated together, strip-shaped gap ways communicating from front to back are arranged between the two layers of elastic metal boards at intervals, and oil inlet and outlet collection pipes are respectively arranged at the front ends and the back ends of the strip-shaped gap ways to be communicated with all the strip-shaped gap ways. The hydraulic pressure and oil supply mechanism comprises a hydraulic pressure station, a large oil cylinder, a small oil cylinder and an oil tank, wherein the large oil cylinder is connected with the hydraulic pressure station to form a loop, the small oil cylinder, the membrane base plate and the oil tank are serially connected to form a loop, and piston push rod ends of the large oil cylinder and the small oil cylinder are both fixed on the same connection plate. A hot pressing exhaust method is implemented through the hot pressing exhaust device. By using the hot pressing exhaust device and the hot pressing exhaust method for hot pressing exhausting in the artificial board manufacture process, hot pressing defects are eliminated, product quality is improved, hot pressing time is shortened, and production efficiency is improved.

Owner:刘强

Modified phenolic resin adhesive and preparation method and application thereof and preparation method of bamboo-wood composite board

ActiveCN108274555ALow in free phenolsInhibition releaseWood treatment detailsReed/straw treatmentWater contentPhenols

Owner:FUJIAN HEQIZU FORESTRY SCI & TECH CO LTD +1

Method for improving weather resistance and mechanical property of bamboo plywood

ActiveCN109015954AHigh strength propertiesExcellent mechanical propertiesOther plywood/veneer working apparatusAldehyde/ketone condensation polymer adhesivesWeather resistanceAdhesive

The invention discloses a method for improving the weather resistance and the mechanical property of bamboo plywood, and belongs to the technical field of bamboo processing. The method for improving the weather resistance includes the steps that a high-voltage electric field is applied when bamboo pieces coated with adhesives are assembled and hot-pressed, and the direction of the electric field is the same as the pressing direction of hot-pressing, and further includes the following steps of drying bamboo pieces, coating the treated bamboo pieces with the adhesives, assembling the bamboo pieces, hot-pressing and applying the high voltage electric field, shutting the high voltage electric field after reaching the hot-pressing time, pressure relief, cooling, and pre-forming and standby application. The method for improving the weather resistance and the mechanical property of the bamboo plywood can solve the problems of poor weather resistance, poor gluing property and mechanical property of the bamboo plywood, and has the advantages of low cost and high production efficiency.

Owner:NANJING FORESTRY UNIV

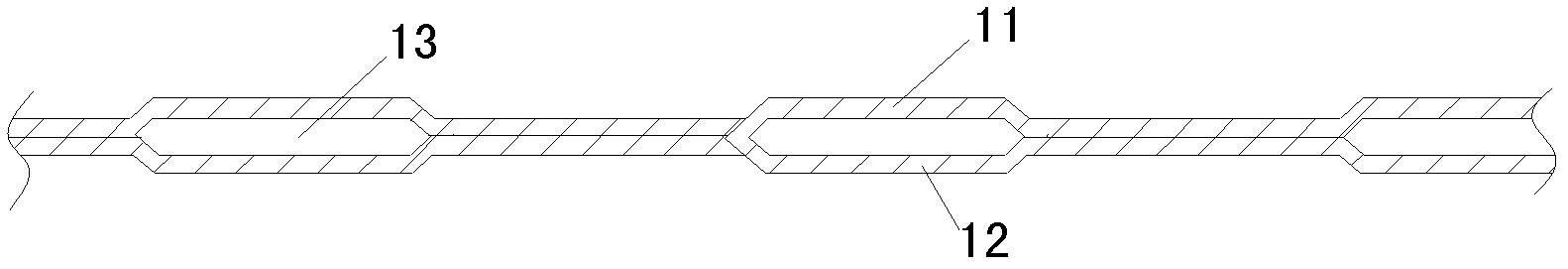

Non-formaldehyde recombined laminated wood and manufacture method thereof

InactiveCN105799004AFill in the gapsSolve the problem of sticky boardMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesEmulsionPolyvinyl acetate

The invention relates to non-formaldehyde recombined laminated wood and a manufacture method thereof. The non-formaldehyde recombined laminated wood is formed by a scrimber veneer strip and an adhesive layer. The scrimber veneer strip is formed through diametral plane splicing and chord plane gluing, the scrimber veneer strip comprises recombination bamboo and recombination wood, during the diametral plane splicing process, the adhesive arranged on the adhesive layer is a polyvinyl acetate emulsion adhesive or an aqueous high-molecular isocyanate adhesive, and during the chord plane gluing process, the adhesive arranged on the adhesive layer is an isocyanate adhesive. With respect to the non-formaldehyde recombined laminated wood, non-aldehyde adhesives are employed, during the diametral plane splicing process, the polyvinyl acetate emulsion adhesive (white emulsion) or the aqueous high-molecular isocyanate adhesive is employed, and during the chord plane gluing process, the isocyanate adhesive is employed, the formaldehyde release amount of the non-formaldehyde recombined laminated wood is far lower than 1.5 mg / L which is prescribed in the national standard E1 grade, and the non-formaldehyde aim is achieved.

Owner:LANGFANG HUARI FURNITURE CO LTD

Bamboo plate manufacturing process

ActiveCN102744760AEasy to moveEasy to storeWood working apparatusFlat articlesWear resistanceEnergy conservation

The invention discloses a bamboo plate manufacturing process. The bamboo plate manufacturing process comprises the following steps of manufacturing cut bamboo, i.e. raw bamboo, into a bamboo plate through the following processes sequentially: post-processing the raw bamboo, sewing the raw bamboo, drying the raw bamboo for the first time, gluing the raw bamboo, drying the raw bamboo for the second time, making the raw bamboo into a blank, and thermally rolling the blank. Bamboo curtains are sewed into bamboo curtain mats; in the gluing process, the liquid glue is dried according to a centrifugal principle; and in the thermally rolling process, a thermal-in and thermal-out process, a phased temperature increasing and decreasing and pressure increasing and decreasing method and the like are adopted. The technical bias of the prior art is overcome, the production cost can be also effectively reduced, the production efficiency is improved, the energy source consumption is effectively reduced, energy conservation and emission reduction are achieved, and the environment is protected. At the same time, a product manufactured by the process is lighter in mass, more stable in performance, good in surface flatness, good in abrasion performance and longer in service life.

Owner:洪敏雄

Hot-pressing equipment for composite non-woven fabric

InactiveCN111845011AEasy to panAvoid Rigid CollisionsLamination ancillary operationsLaminationNonwoven fabricGlass wool

The invention discloses hot pressing equipment for a composite non-woven fabric. The hot pressing equipment structurally comprises a machine body, a first guide roller, a first hot-pressing roller, athird guide roller, a composite non-woven fabric winding device, a second hot-pressing roller, a second guide roller, a non-woven fabric roll, an interlayer fabric roll and an inner fabric roll, wherein the non-woven fabric roll, the interlayer fabric roll and the inner fabric roll are sequentially arranged on the machine body. Compared with the prior art, the invention has the following beneficial effects: the contact area of the non-woven fabric and a heating roller can be greatly increased, which is beneficial for improvement of hot pressing efficiency and reduction in hot pressing time; invirtue of magnetism principles and the fact that an air suction ball is pressed to exhaust air and sucks air to realize resetting, the composite non-woven fabric can be adsorbed and clamped, so the composite non-woven fabric is allowed to quickly enter an annular cavity, and the composite non-woven fabric is located in the annular cavity for hot pressing; and heat preservation and insulation areconducted through glass wool, and an inner roller is hidden in an outer roller to prevent the inner roller from being exposed outside, so heat dissipation can be effectively reduced, and hot pressingcompositing of the non-woven fabric is better facilitated.

Owner:陈晓瑜

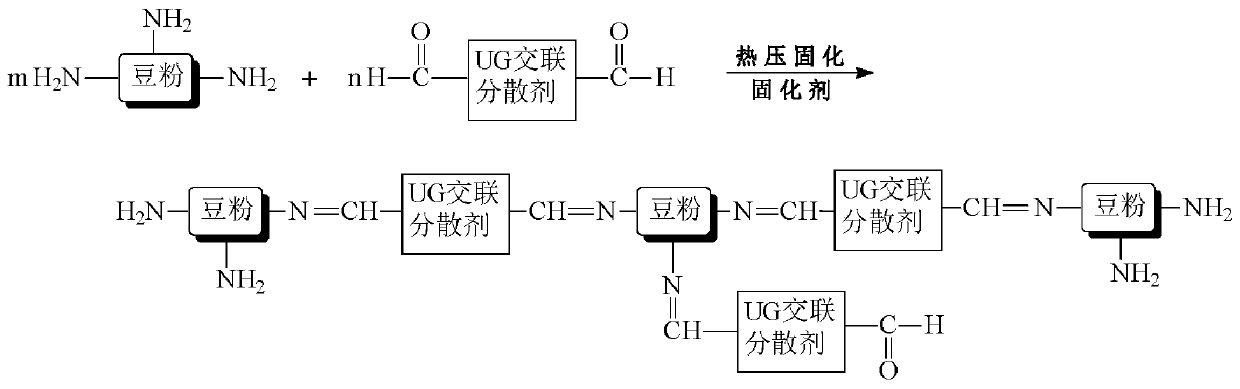

Preparation method of low-cost formaldehyde-free cross-linking dispersing agent and soybean adhesive prepared by using same

ActiveCN110713581AModerate viscosityImproved coating propertiesProtein adhesivesMacromolecular adhesive additivesPolymer scienceFirming agent

The invention discloses a preparation method of a low-cost formaldehyde-free cross-linking dispersing agent and a soybean adhesive prepared by using the same, and relates to a preparation method of across-linking dispersing agent and an adhesive prepared by using the cross-linking dispersing agent. The invention aims to solve the problems that an artificial board prepared from an existing urea-formaldehyde resin adhesive is difficult to meet the requirement on formaldehyde release amount, and a formaldehyde-free PAE type soybean adhesive is high in cost. The preparation method comprises the following steps: 1, uniformly mixing a glyoxal solution with water, adjusting the pH value, heating the mixture, adding urea, heating the mixture, and carrying out a thermal insulation reaction to obtain a cross-linking dispersant; 2, cooling the mixture and adding water to obtain a low-cost formaldehyde-free cross-linking dispersing agent; the soybean adhesive prepared by utilizing the cross-linking dispersing agent is prepared by stirring the cross-linking dispersing agent which is low in cost and free of formaldehyde, bean flour and a curing agent at room temperature. The invention relates to the preparation method of the low-cost formaldehyde-free cross-linking dispersing agent and the soybean adhesive prepared by using the same.

Owner:浙江蓝歌新材料科技有限公司

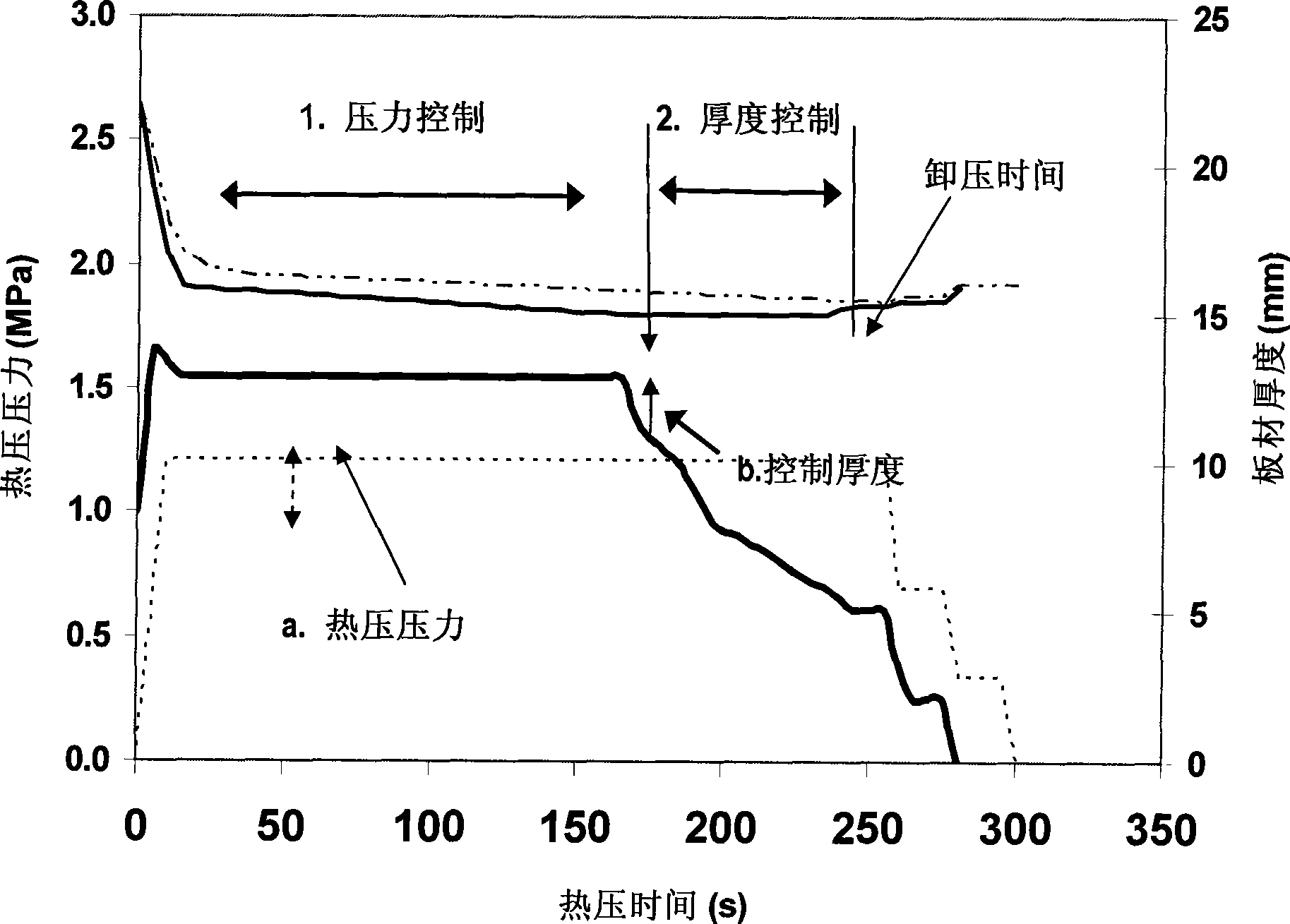

Heat pressing novel method for manufacturing wood veneer/laminated veneer lumber

InactiveCN101367217AIncrease profitShorten the hot pressing timeWood veneer joiningWood veneerEngineering

The invention provides a novel hot pressing method for producing a veneer / laminated veneer lumber so as to solve the problems of long period, low wood utilization rate, uneven thickness of products, great compression loss, easy bubbling, variation of heat-pressing process along with tree species, veneer density and water ratio and the like, existing in the prior hot pressing process. In the method, pressure control and position control simultaneously act on a hot pressing period, and the first phase of hot pressing is controlled by constant pressure which is 0.1 to 1.0Mpa higher than the prior hot pressing pressure so as to accelerate heat transfer and plate blank compression; when the plate achieves the target thickness, the system automatically enters the second phase, namely the position control phase, herein the thickness of the plate does not change, but the pressure automatically drops; and when a glue film in the center of the plate reaches the temperature of solidification, the system enters pressure relief phase. The method can effectively improve the evenness of the plate thickness and the utilization rate of wood, shorten hot pressing period, improve the production efficiency of a hot press, ensure product quality, simplify the operation of the hot press, and improve the stability of hot pressing process.

Owner:NANJING FORESTRY UNIV

CCD alignment pulse thermocompression welding system and welding method

InactiveCN113399856AImprove welding precisionImprove welding qualityPrinted circuit assemblingWelding/cutting auxillary devicesPhysicsCcd camera

The invention relates to a CCD alignment pulse thermocompression welding system and a welding method, and relates to the technical field of thermocompression welding. According to the CCD alignment pulse thermocompression welding system and the welding method, images shot by a laser flatness measuring instrument and a CCD camera are analyzed through an image analysis module, the welding spot thickness and the flatness of a flexible circuit board and a rigid circuit board are analyzed, the welding spot thickness range and the flatness are preset in the image analysis module, the actual welding spot thickness and the flatness are compared with preset values, the thermocompression temperature and the thermocompression pressure of a welding head of pulse thermocompression welding are adjusted according to a comparison result, preset maximum thermocompression pressure is set in a control module, and when the thermocompression pressure is adjusted to exceed the preset maximum thermocompression pressure, the pulse voltage of the welding head is adjusted, so that the welding precision is improved, the welding quality is improved, and therefore the quality of the circuit boards is improved.

Owner:SHENZHEN TECHSON AUTOMATION SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com