Wood plastic composite material cladding plywood formwork and manufacturing method thereof

A wood-plastic composite and plywood technology, which is applied in the direction of wood layered products, formwork/formwork components, chemical instruments and methods, etc., can solve the problems of low strength and poor durability, and achieve strong acid resistance, heat deformation, and smooth surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

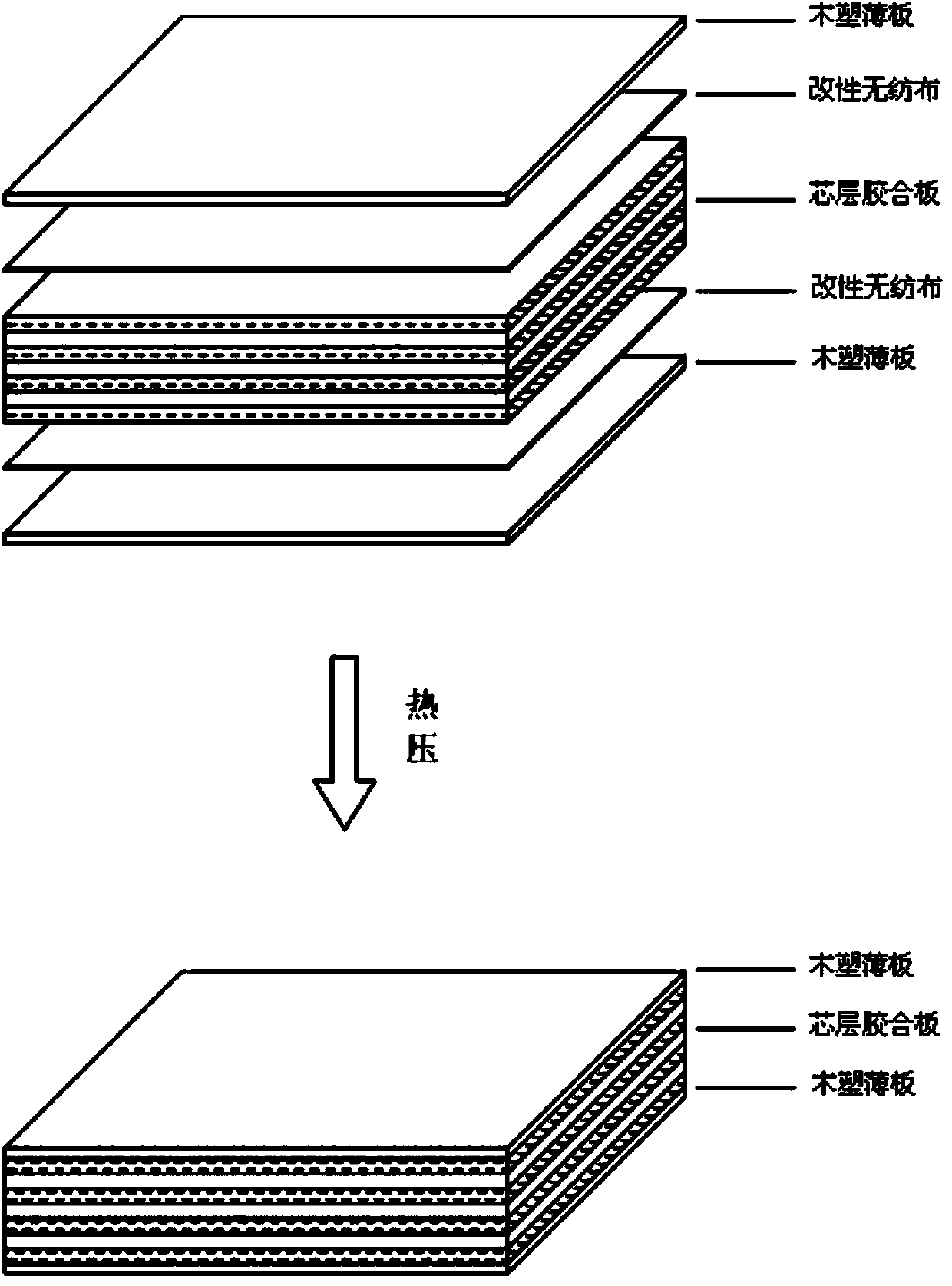

[0032] Embodiment 1: In this embodiment, a wood-plastic composite cladding plywood template is prepared from wood-plastic thin boards, modified non-woven fabrics and core plywood.

[0033] The surface of the wood-plastic composite clad plywood template prepared in this embodiment is flat and smooth, inert, easy and quick to demould, and has a small error in the flatness of the board surface. It has good water resistance, no delamination after long-term immersion in water, and good dimensional stability of the board. With the protection of wood-plastic veneer, the core plywood is not easy to absorb moisture and deform or swell. It solves the bonding problem between the large-format polar wood surface and the non-polar plastic surface. There is no water vapor generated during hot pressing, and hot pressing defects such as delamination and bubbling will not be caused; the wood is grafted by coupling agent The bonding strength of plywood and polyolefin is greatly improved; it can...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the wood-plastic thin board is prepared according to the following steps:

[0037] 1. Raw material preparation: Weigh 30-100 parts of thermoplastic, 20-200 parts of plant fiber powder, 20-100 parts of inorganic filler, 3-10 parts of coupling agent, 1-4 parts of lubricant, 1 ~4 parts of masterbatch and 3~10 parts of other fillers;

[0038] 2. Blending and granulation: Put the thermoplastics, plant fiber powder, inorganic fillers, coupling agents, lubricants, masterbatches and other fillers weighed in step 1 into a high-speed mixer, and control the temperature at 25 ° C ~ Mix at 150°C for 5min to 20min, then cool to room temperature to obtain a premix, then put the premix into a twin-screw granulator, control the temperature to 145°C to 235°C, and the speed to 30r / min to 100r / min , carry out granulation to obtain wood-plastic granules, and perform molding processing on the wood-plastic granules...

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the modified non-woven fabric is prepared by adding grafting monomers and initiators into an organic solvent to prepare a mixed solution, and then the mixed solution Spray evenly on the non-woven fabric, and then place it in an oven at a temperature of 50°C to 100°C to dry for 10 minutes to 30 minutes to obtain a modified nonwoven fabric;

[0047] The non-woven fabric is one of polypropylene, polyethylene, polyvinyl chloride and polystyrene or a mixture of several of them, and when it is a mixture, it is mixed in any ratio;

[0048] Described grafting monomer is maleic acid, maleic anhydride, methyl methacrylate, acrylic acid, glycidyl methacrylate, ethyl acrylate or styrene monomers;

[0049] Described initiator is dicumyl peroxide, benzoyl peroxide, tert-butyl benzoyl peroxide or di-tert-butane peroxide;

[0050] Described organic solvent is toluene, xylene, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com