Substrate leveling jig, leveling method and probe card

A substrate and fixture technology, applied in the field of probe cards, can solve the problems of overflowing tin and connecting tin, the pressure block cannot achieve uniform solder joints, and the flatness requirements cannot be met, so as to improve the flatness, avoid the decline of welding ability, The effect of improving test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

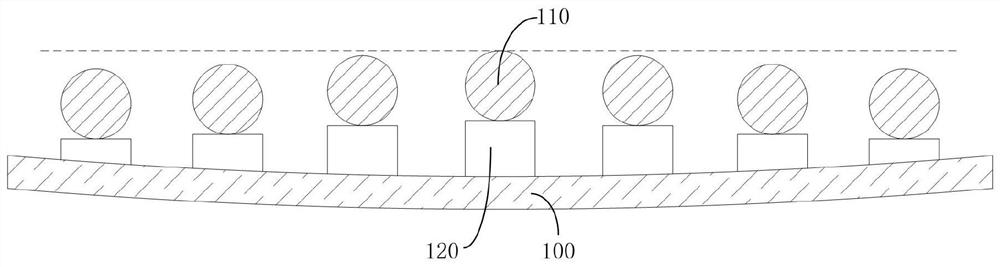

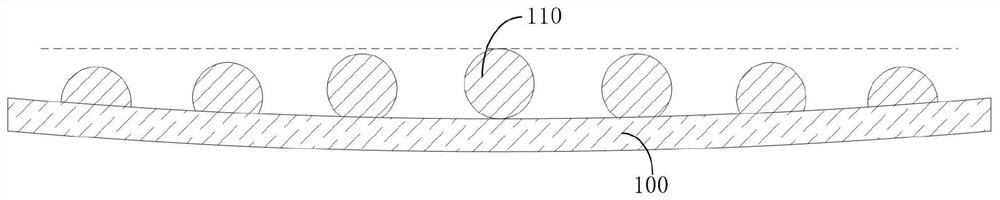

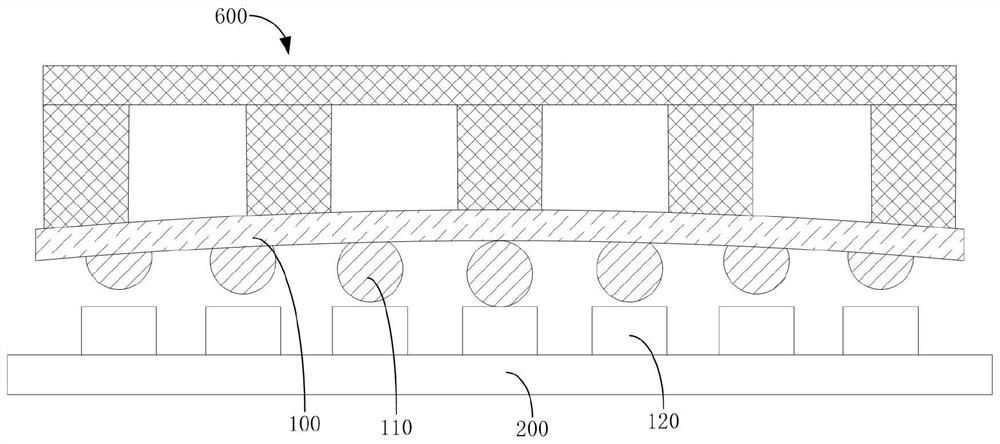

[0051] The space transformer can be a multi-layer organic board or a multi-layer ceramic board, which is used to fix metal probes for signal transmission with the chip and to test the parameters of the chip, hereinafter referred to as the substrate 100 . The precision of the vertical probe card in the horizontal and vertical directions largely determines the basic performance of the probe card in the test process. The precision may include the flatness of the test area of the PCB test board 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com