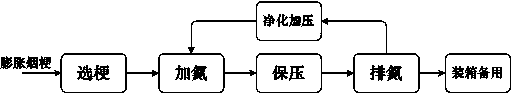

Treatment process for expanded tobacco stems

A treatment process and technology for expanding tobacco stems, which is applied in the field of main and auxiliary materials processing in the tobacco industry, achieving the effects of low processing cost, low miscellaneous gas, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The microwave-expanded tobacco stems are classified according to thickness and length, and put into pressure vessels respectively; air is introduced into the pressure vessel to uniformly mix the tobacco stems with nitrogen, the pressure in the vessel is: 8MPa; the pressure is maintained for 40 minutes ; Discharge the nitrogen in the pressure vessel, the nitrogen will be recycled after being purified and pressurized, and the treated expanded tobacco stems will be taken out and sorted into boxes or bags for later use; product.

Embodiment 2

[0041] The microwave-expanded tobacco stems are classified according to their thickness, and put into pressure vessels respectively; nitrogen with a purity of 100% is introduced into the pressure vessel to make the tobacco stems and nitrogen evenly mixed, and the pressure in the vessel is normal pressure; Keep the pressure for 30 minutes; discharge the nitrogen in the pressure vessel, the nitrogen is recycled after purification and pressure treatment, take out the treated expanded tobacco stems, and classify them into boxes or bags for use; , Stem particles and other products.

Embodiment 3

[0043] The microwave-expanded tobacco stems are classified according to their lengths and put into a pressure vessel respectively; nitrogen with a purity of 85% is introduced into the pressure vessel to make the tobacco stems and nitrogen evenly mixed, and the pressure in the container is: 5MPa; Pressure for 30 minutes; discharge the nitrogen in the pressure vessel, the nitrogen is recycled after purification and pressure treatment, take out the treated expanded tobacco stems, and classify them into boxes or bags for later use; Stem particles and other products.

[0044] Tobacco stems treated by the process of the invention have the characteristics of strong tobacco mellow aroma and low woody odor, and the softness and elasticity after moisture regain are not significantly different from those of tobacco stems after storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com