An intelligent three-dimensional warehouse and its storage control method, device and system

A control method and warehouse technology, applied in the field of logistics management, can solve the problems of unplanned placement, difficulty in delivery, waste of time when goods are delivered from the warehouse, etc., and achieve the effect of shortening the warehousing time, saving warehouse space, and quick warehousing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

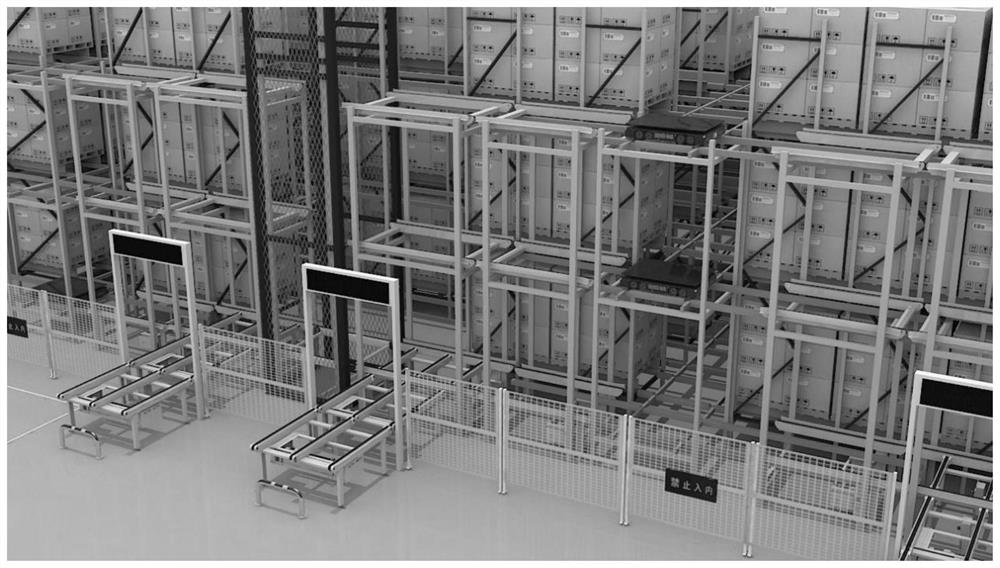

[0037] Embodiment 1 of the present application provides an intelligent three-dimensional warehouse, such as figure 1 As shown, it includes two warehouses on the left and right (hereinafter referred to as the left warehouse and the right warehouse) and shuttle cars, and a plurality of shuttle cars are respectively placed in the left warehouse and the right warehouse;

[0038] Among them, the left warehouse and the right warehouse are separated by a firewall, and the firewall is separated from the ground floor of the warehouse to the top floor of the warehouse; since the efficiency of the shuttle car going to the warehouse on the other side through the firewall is very low, in order to save time and improve the efficiency of the shuttle car, under normal circumstances Shuttle vehicles are not allowed to shuttle between the left and right warehouses;

[0039] Both the left and right warehouses include multi-layer shelves, and each shelf is divided into multiple shelf areas divide...

Embodiment 2

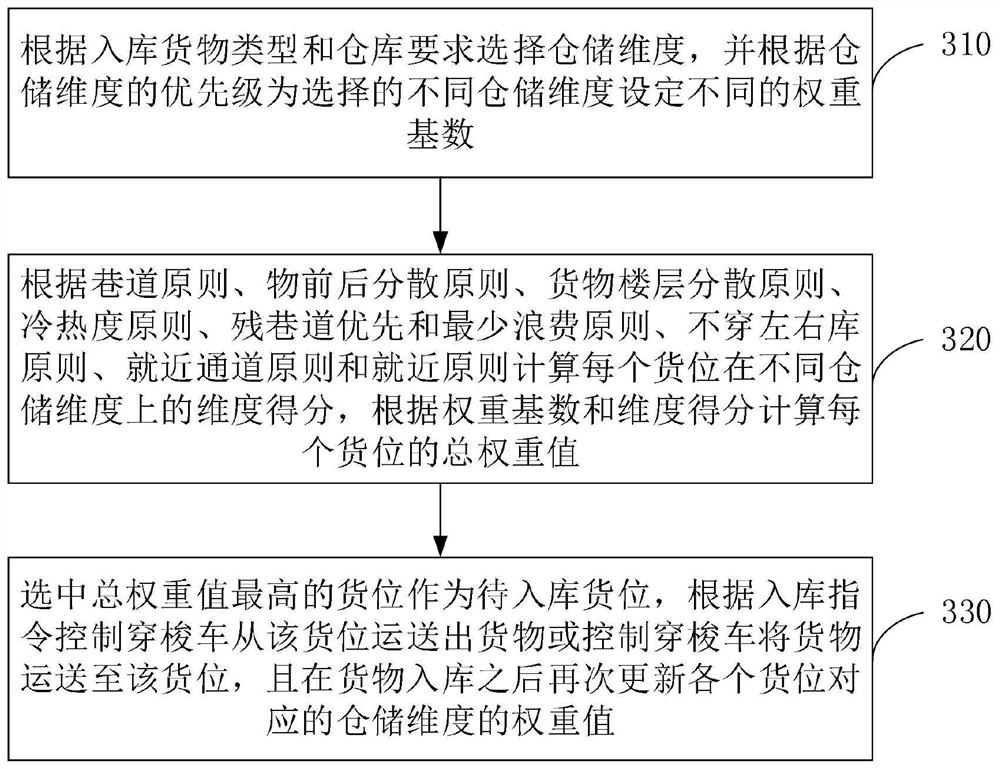

[0046] Based on the intelligent three-dimensional warehouse provided in the first embodiment, the second embodiment of the present application provides the storage control method of the intelligent three-dimensional warehouse, such as image 3 shown, including:

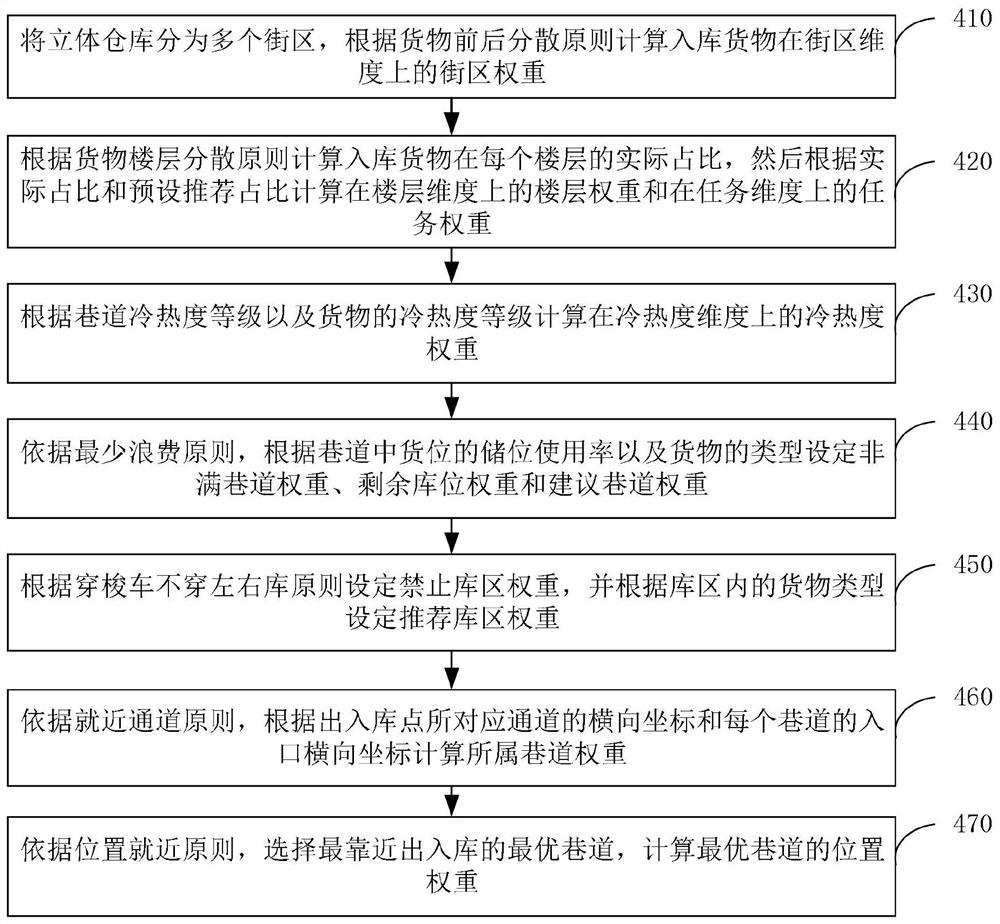

[0047] Step 310, selecting a storage dimension according to the type of inbound goods and warehouse requirements, and setting different weight bases for the selected storage dimensions according to the priority of the storage dimension;

[0048] In the embodiment of this application, storage dimensions include, but are not limited to, block dimensions, floor dimensions, task dimensions, coldness and heat dimensions, partial aisle dimensions, remaining storage location dimensions, suggested aisle dimensions, forbidden storage area weights, recommended storage area dimensions, The aisle dimension, location dimension, etc., select the most suitable storage dimension from the above storage dimensions according to the type...

Embodiment 3

[0100] Embodiment 3 of the present application provides a warehousing control device, the device executes the warehousing control method described in Embodiment 2; and provides a warehousing system, including the intelligent three-dimensional warehouse described in Embodiment 1, and the embodiment 2. The warehousing control device; the warehousing control device controls the warehousing of goods in the intelligent three-dimensional warehouse through wireless communication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com