Vacuum embossing roll

An embossing wheel and vacuuming technology, applied in the field of vacuuming embossing wheels, can solve the problems of difficult to control working temperature, large storage space occupied, large number of embossing wheels, etc., to achieve controllable working temperature, easy storage, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with specific embodiment:

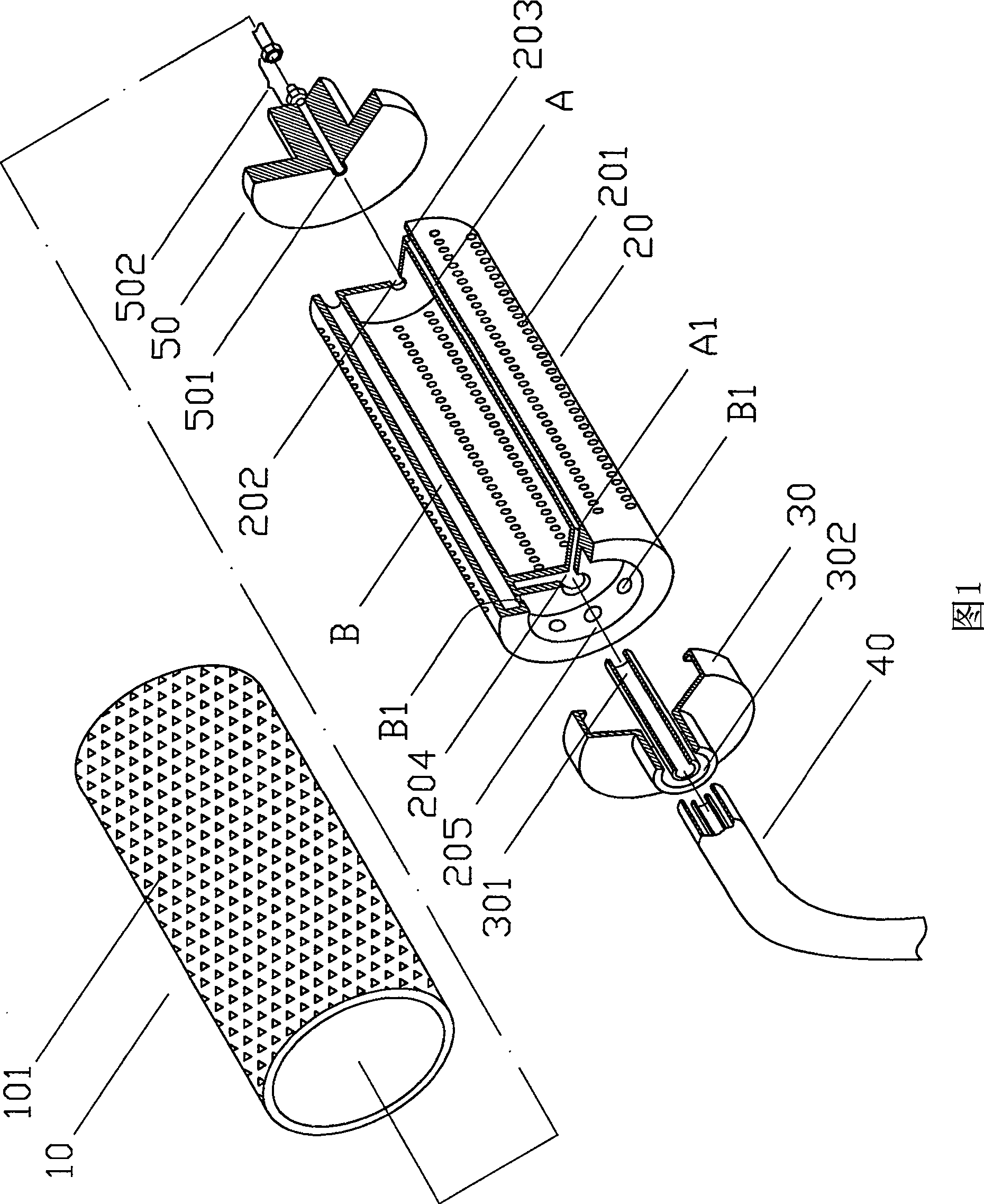

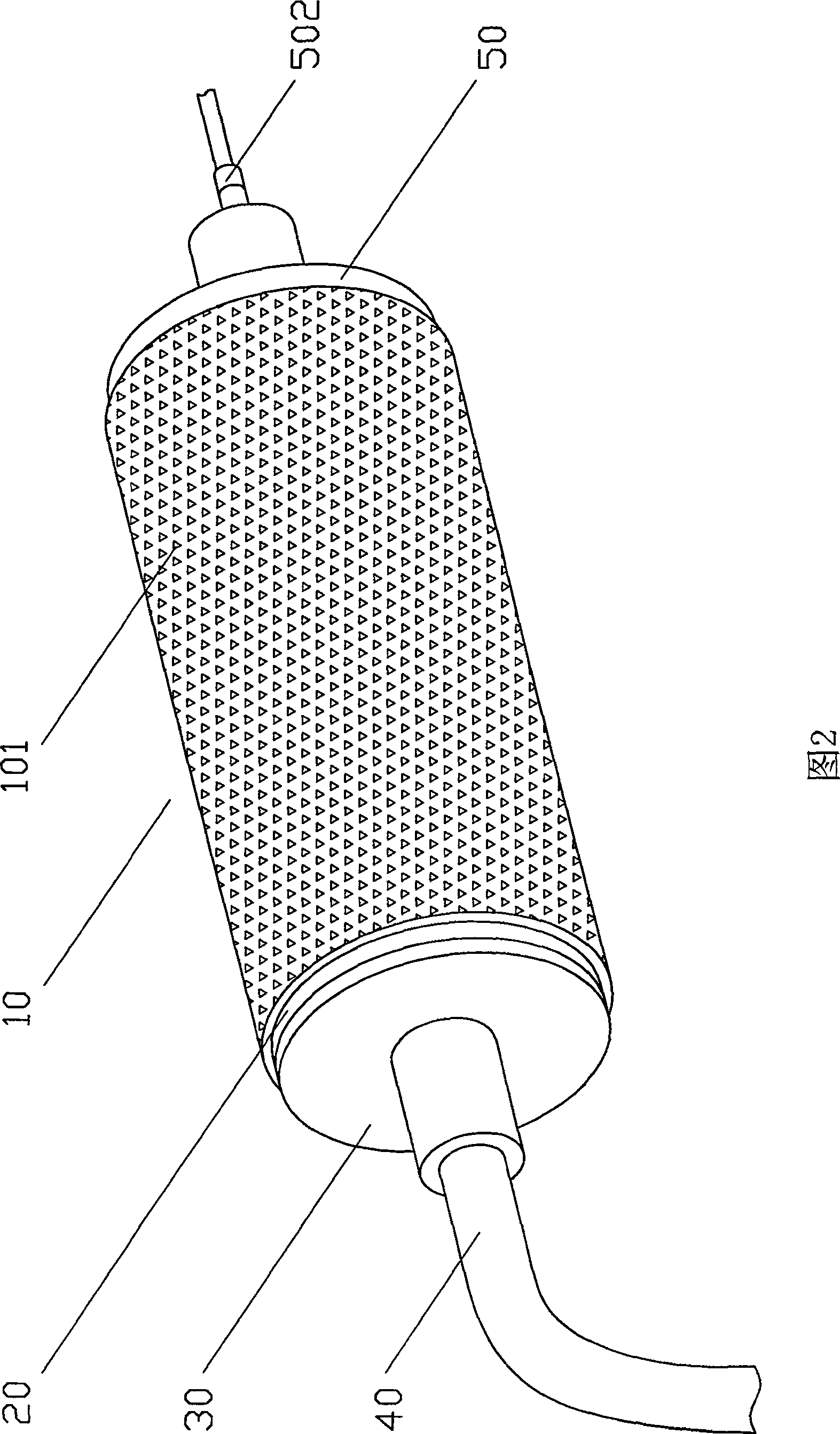

[0019] See Figure 1-4: Vacuum embossing wheel is characterized in that it is mainly composed of a leather sheath 10 and a metal roller 20, and the leather sheath 10 is set on the outer surface of the metal roller 20, wherein:

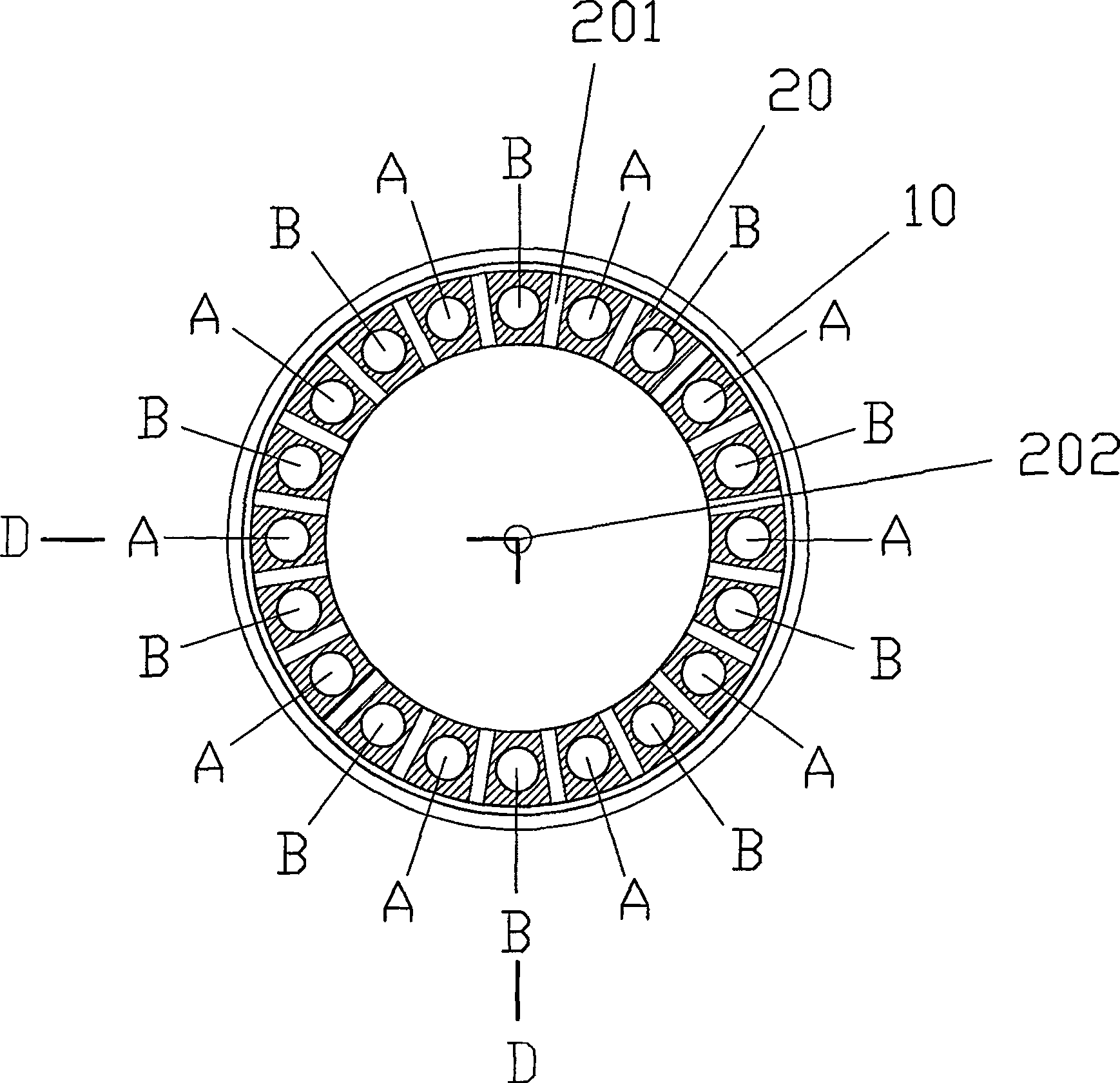

[0020] Metal roller 20: It is a hollow cylinder, on the tube wall of the hollow cylinder, there are radially provided with several evenly distributed tiny air holes 201 penetrating the tube wall, and on one end surface of the hollow cylinder, there are The end cap 50, the suction rotary joint 502 is connected to the vent hole 202 through the conduit 501, and communicates with the hollow part in the cylinder and the tiny vent hole 201, and the water inlet pipeline A is arranged in the tube wall of the hollow cylinder and at intervals along the circumference And the return pipe B, the water inlet pipe A meets in the chamber 203 on one side of the cylinder and communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com