Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Extended heat conduction path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

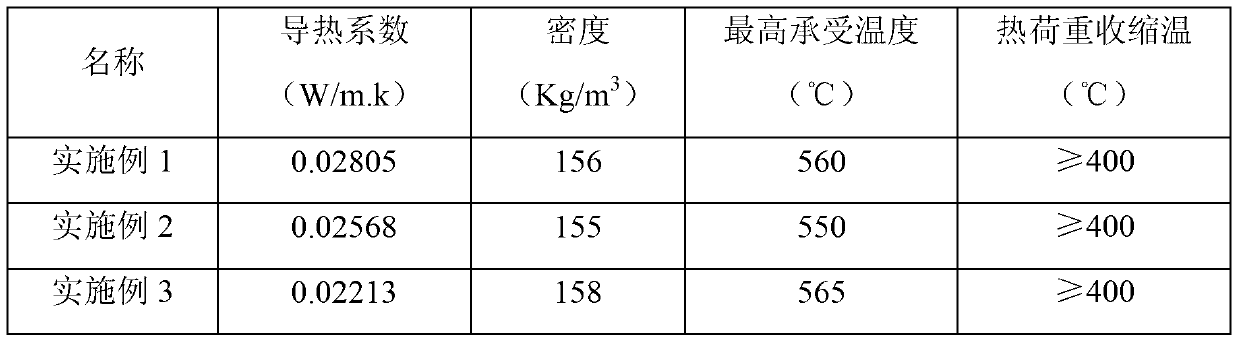

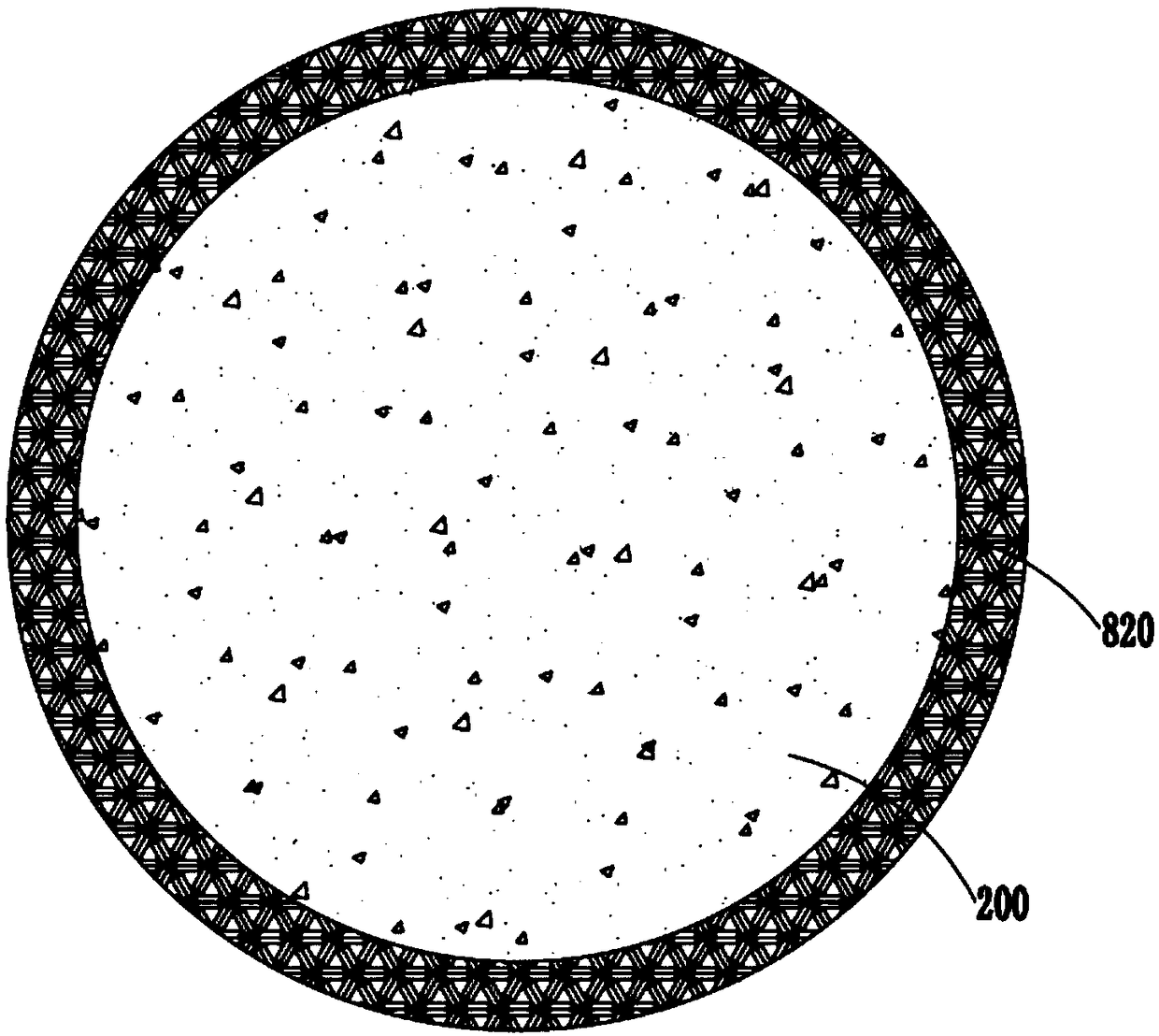

Vacuum insulation panel core material with high performance and low cost and manufacturing method thereof

ActiveCN102330475ALow costThe overall thickness is thinClimate change adaptationInsulation improvementGlass fiberSizing

The invention discloses a method for manufacturing a vacuum insulation panel core material with high performance and low cost. The method comprises the following steps of: pulping glass fiber cotton which is produced by a centrifuge method; diluting; screening; performing dehydration molding; performing pressure roller sizing; performing vacuum negative pressure dehydration; drying; cooling; and cutting. In the manufacturing method, the glass fiber cotton which is completely produced by the centrifuge method is used as a raw material of the vacuum insulation panel core material with high performance and low cost, the coefficient of thermal conductivity of the produced vacuum insulation panel core is between 0.003 and 0.008 W / m.k, and the coefficient of heat insulation is greatly improved;the thickness of the panel core material is between 0.5 and 30 mm, and the thickness is thinner; and the glass fiber cotton with the diameter of 3.5 to 5 mu m and the length of 5 to 20 mm has low cost and low overall manufacturing cost, and the overall cost of the vacuum insulation panel is lowered.

Owner:许立江

Glass-fiber vacuum insulation panel nano core material and preparation method thereof

ActiveCN103277631AUniform diameterPrevent collapseFibreboardThermal insulationGlass fiberAlkali free

The invention discloses a glass-fiber vacuum insulation panel nano core material. The core material is made of, in percentage by mass, 50-100% of medium-alkali glass fiber chopped strands with diameters of 3-6um and 0-50% of alkali-free glass fiber cotton with diameter of 0.5-1.5um. The invention further discloses a preparation method for the glass-fiber vacuum insulation panel nano core material. The preparation method includes the following steps: 1), selecting raw materials according to the matching proportion, 2), pulping to scatter the raw materials to obtain sizing agent, 3), diluting the obtained sizing agent, 4), performing deslagging treatment on the diluted sizing agent and obtaining glass fiber wet paper through wet-process forming, 5), performing dehydration treatment on the obtained wet paper to make the moisture percentage less than 20%, and 6), drying the dehydrated wet paper. The vacuum insulation panel nano core material is good in heat-insulating effect, high in mechanical strength, and long in service life; and with the preparation method, the above effects of the vacuum insulation panel nano core material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

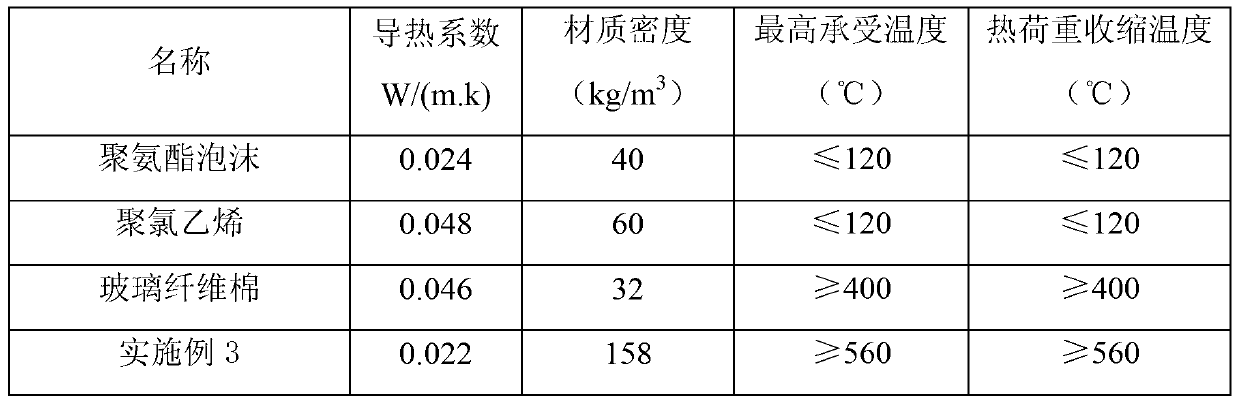

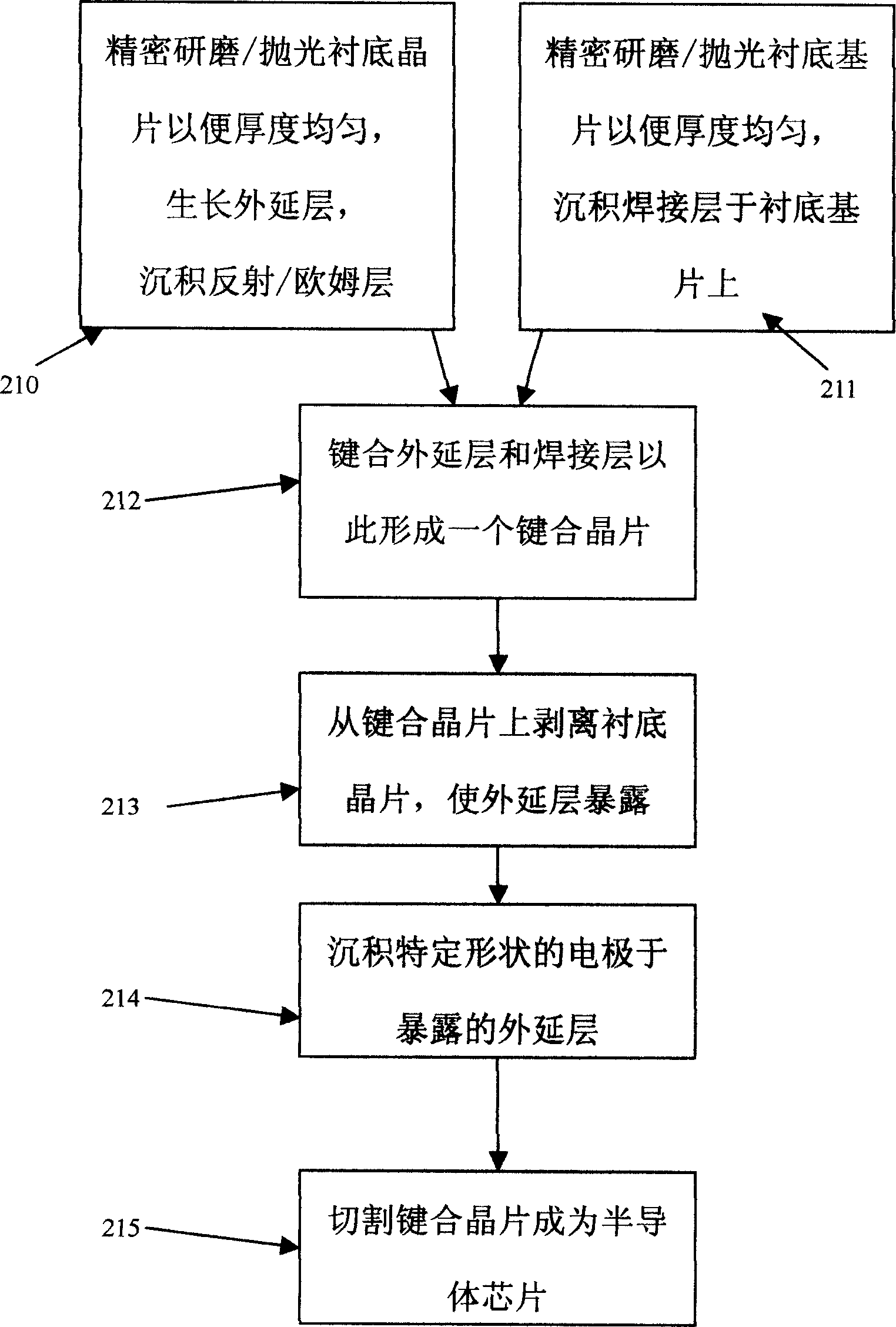

GaN based LED upside down welding combination, and lamp and chip horizontally upside down welding technique

InactiveCN1619844AIncrease productivitySimple production processSemiconductor/solid-state device detailsSolid-state devicesTotal internal reflectionSemiconductor chip

Owner:金芃

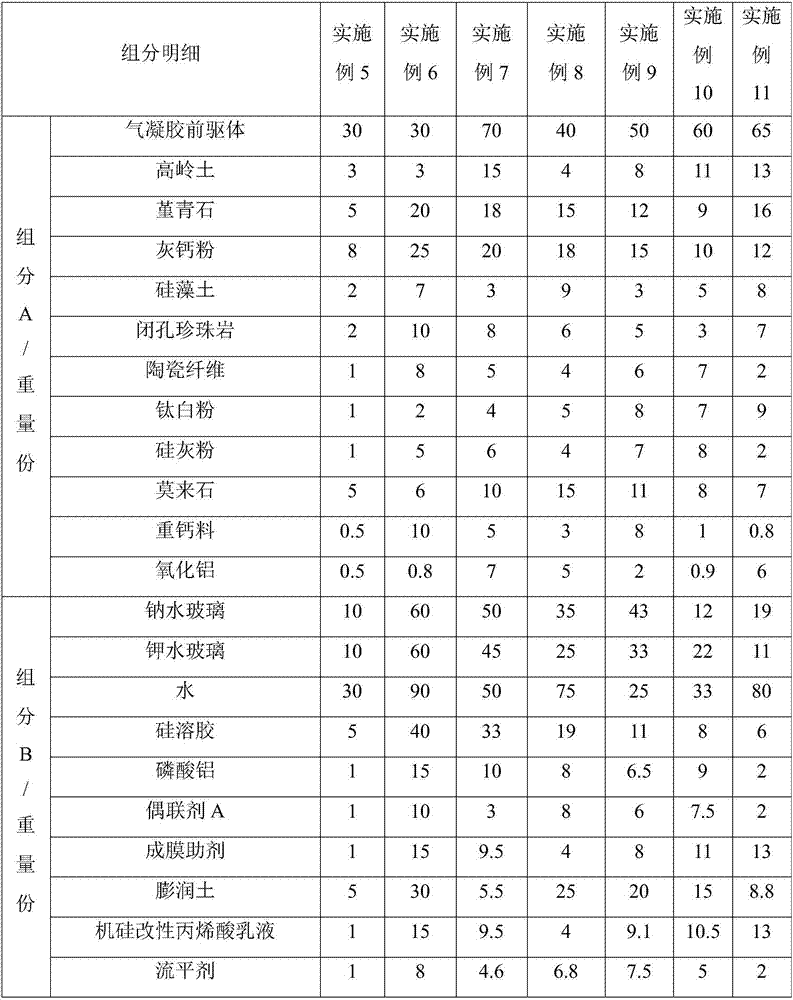

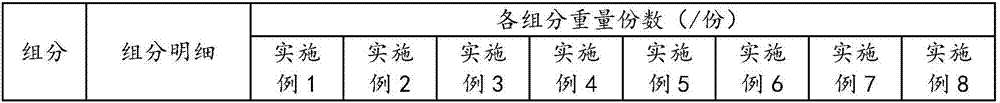

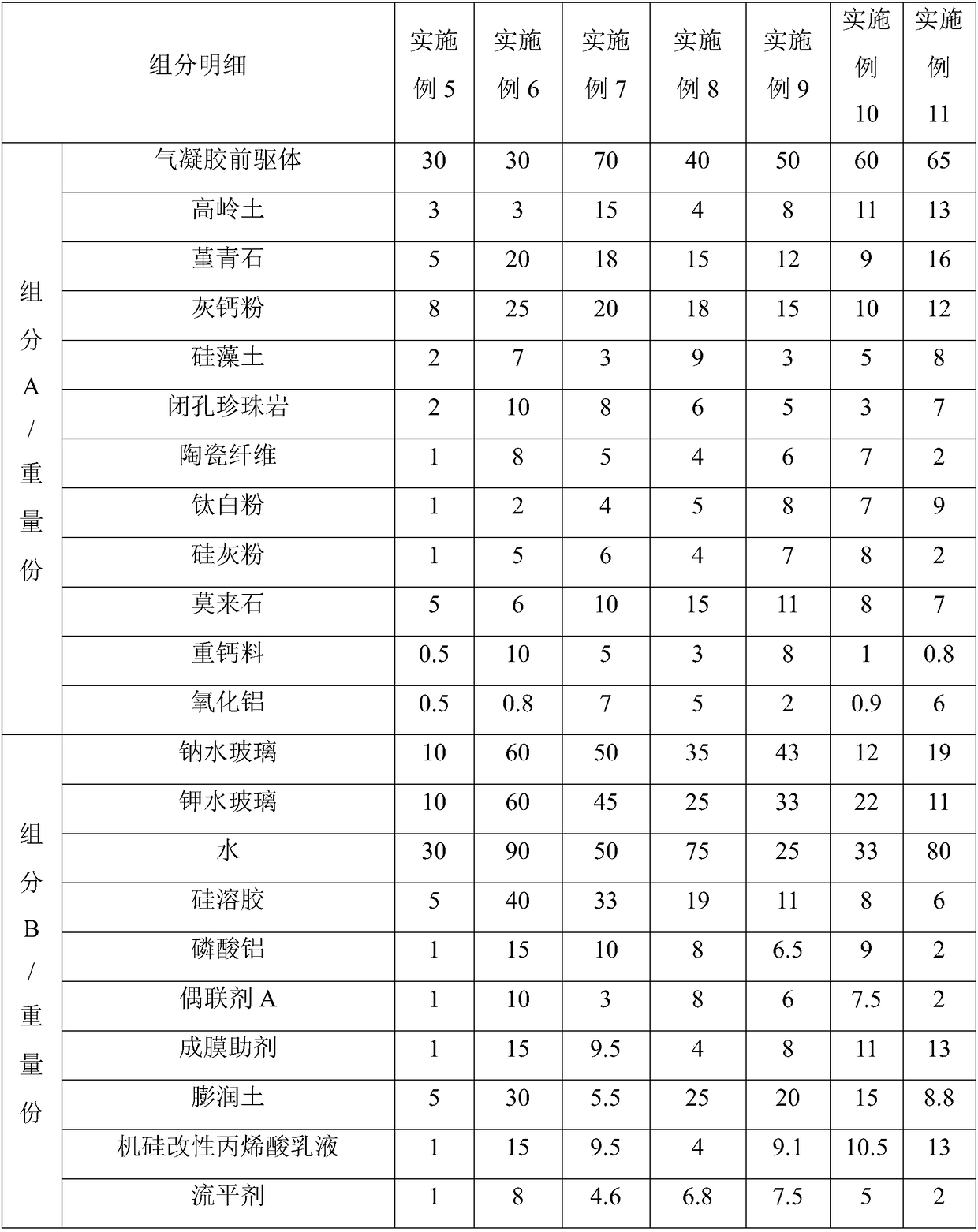

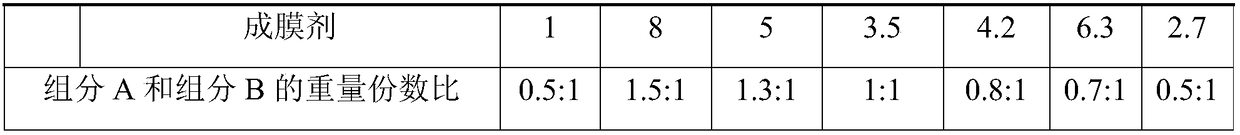

Ultrathin fireproof aqueous coating and preparation method thereof

ActiveCN107254204ADelay the heating processEnhanced Fire DurabilityFireproof paintsAlkali metal silicate coatingsThermal insulationThermal radiation

The invention belongs to the field of aqueous coatings and in particular relates to an ultrathin fireproof aqueous coating and a preparation method thereof. When the ultrathin fireproof aqueous coating is prepared, a component A and a component B are added, the component A comprises an aerogel precursor, stepless powder and the like, and the component B is used as a binding agent. The aerogel precursor is adopted as a core raw material to prepare the fireproof aqueous coating; as an aerogel material is of a nano three-dimensional structure and has characteristics that a solid heat conduction route is effectively prolonged, gas convective heat transfer is inhibited and thermal radiation is reduced, an aerogel fireproof coating made of the aerogel material has a thermal insulation property which is incomparable by conventional materials; after being applied to a steel material and dried, the ultrathin fireproof aqueous coating provided by the invention is relatively high in mechanical strength, achieves a fireproof grade A1, additionally has relatively good advantages of being waterproof and low in cost, and provides a novel material for buildings, environmental protection and industrial energy conservation.

Owner:天津朗华睿博科技有限公司

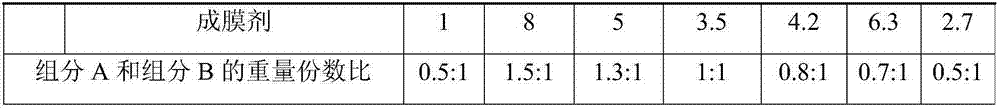

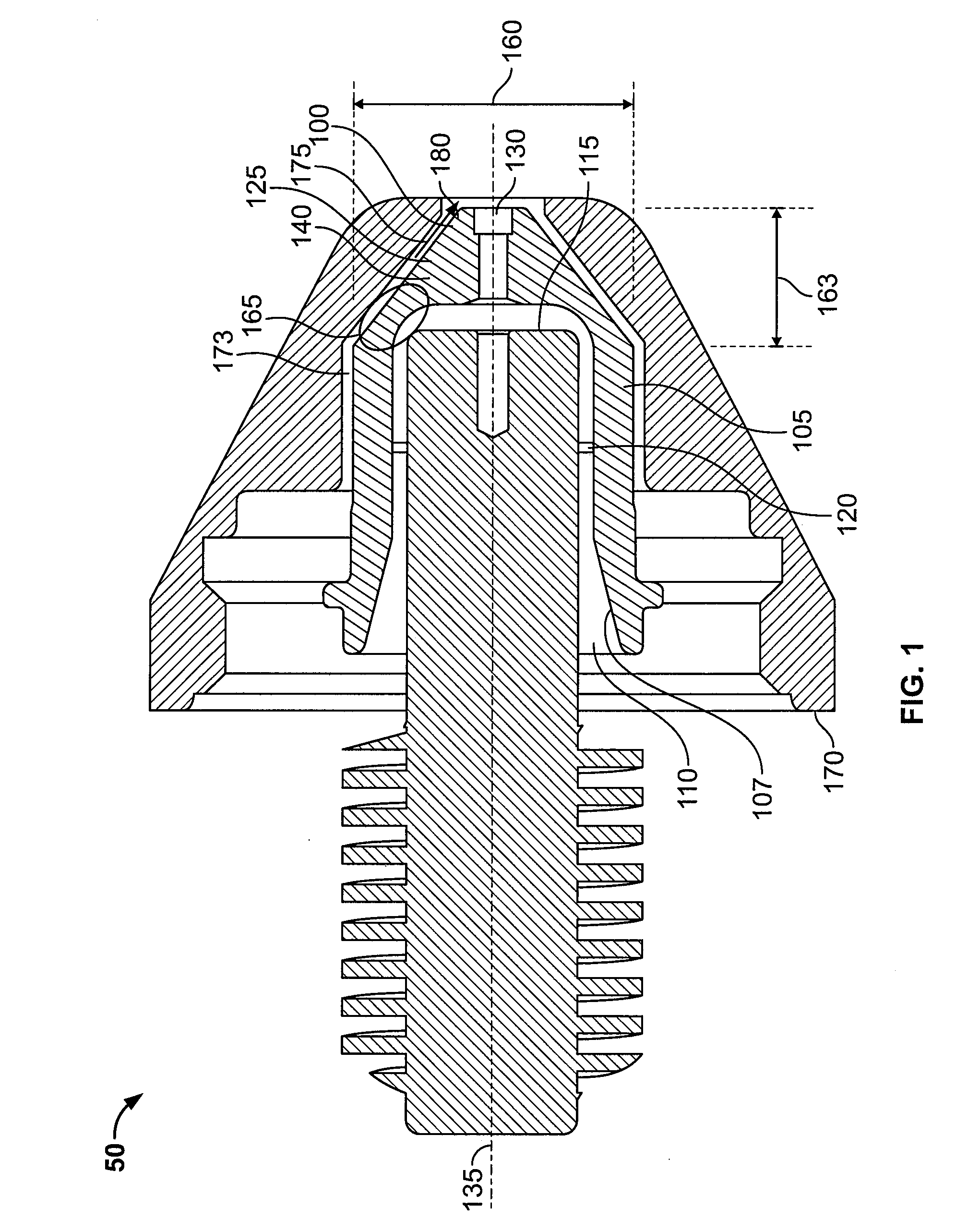

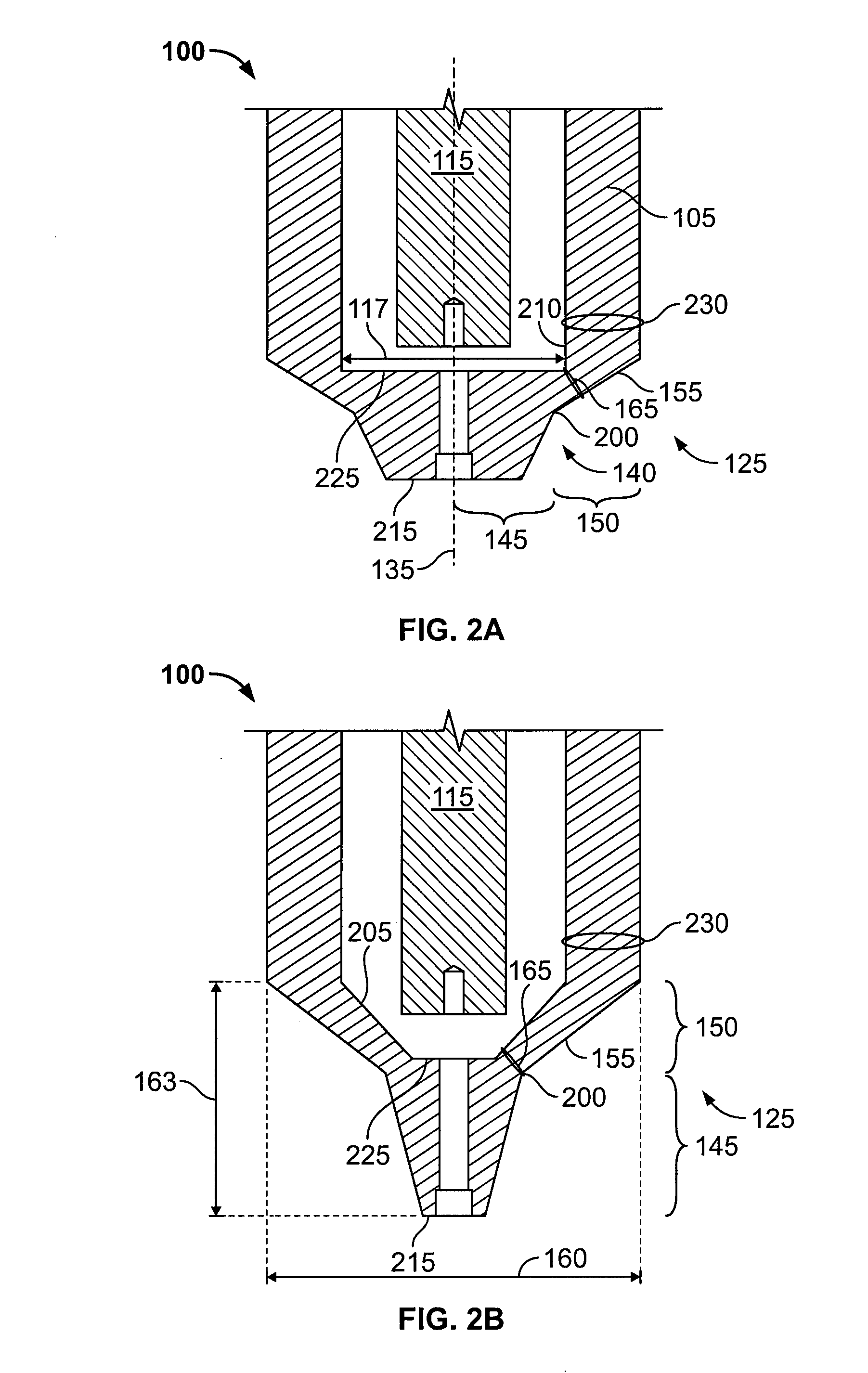

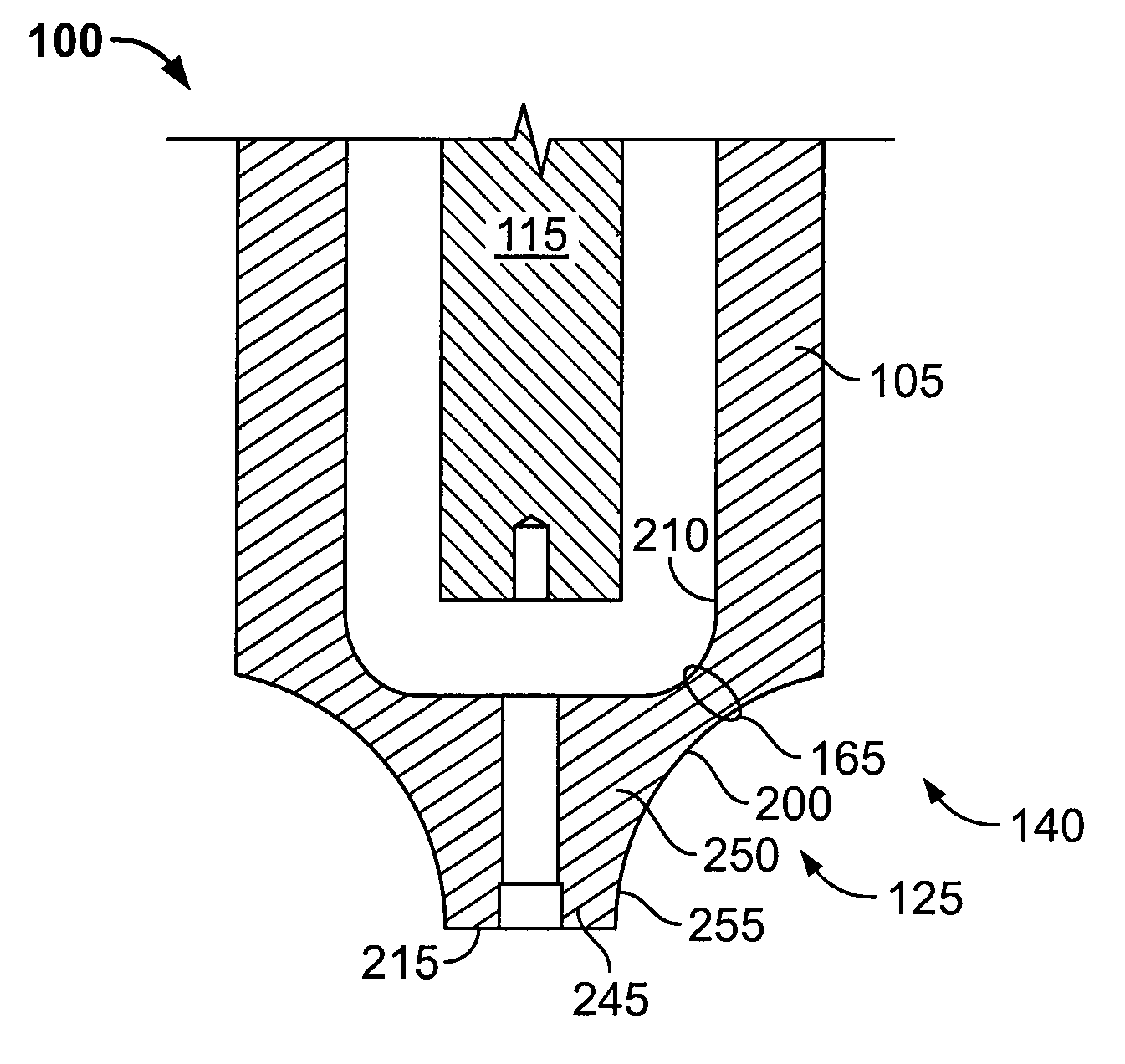

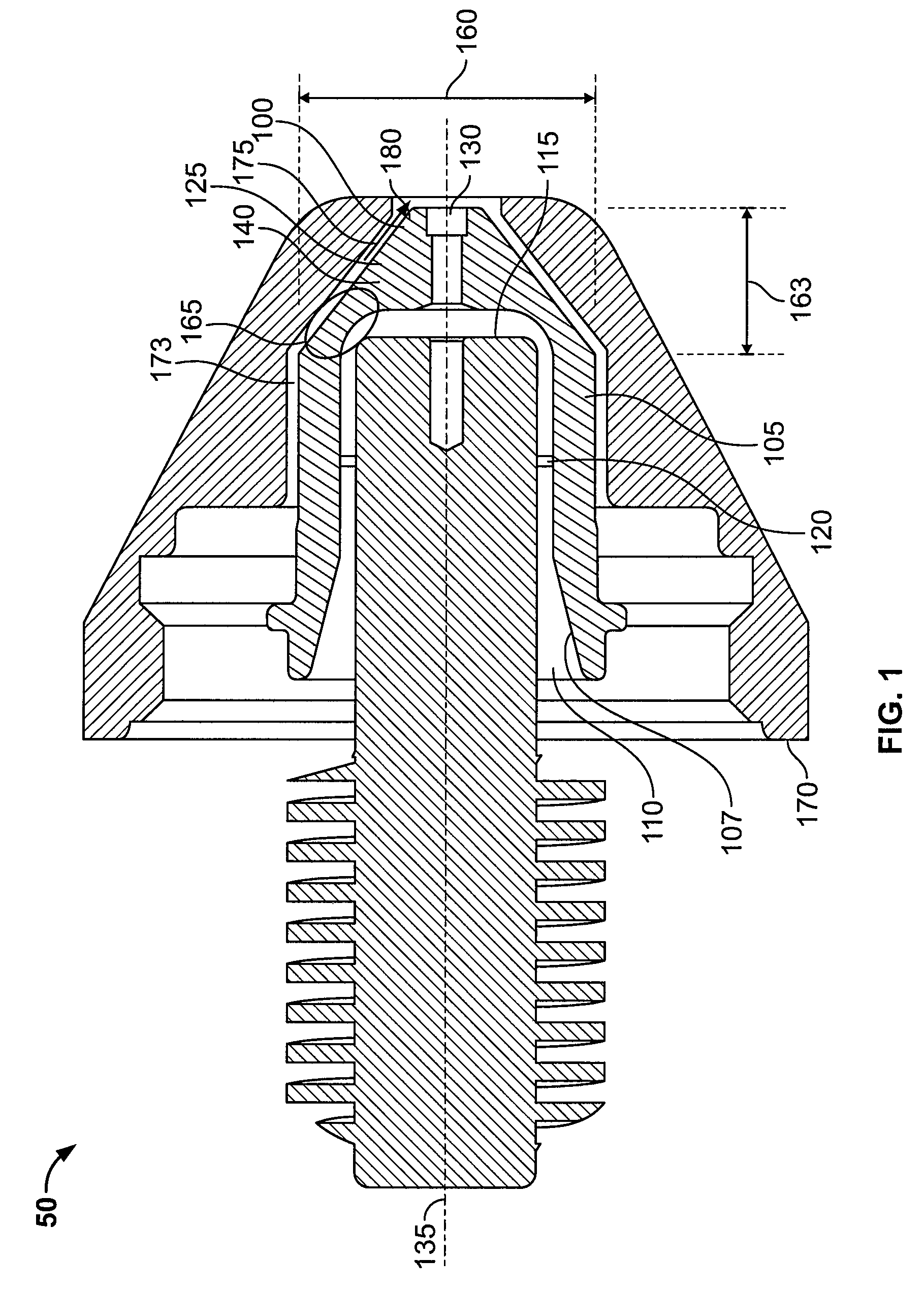

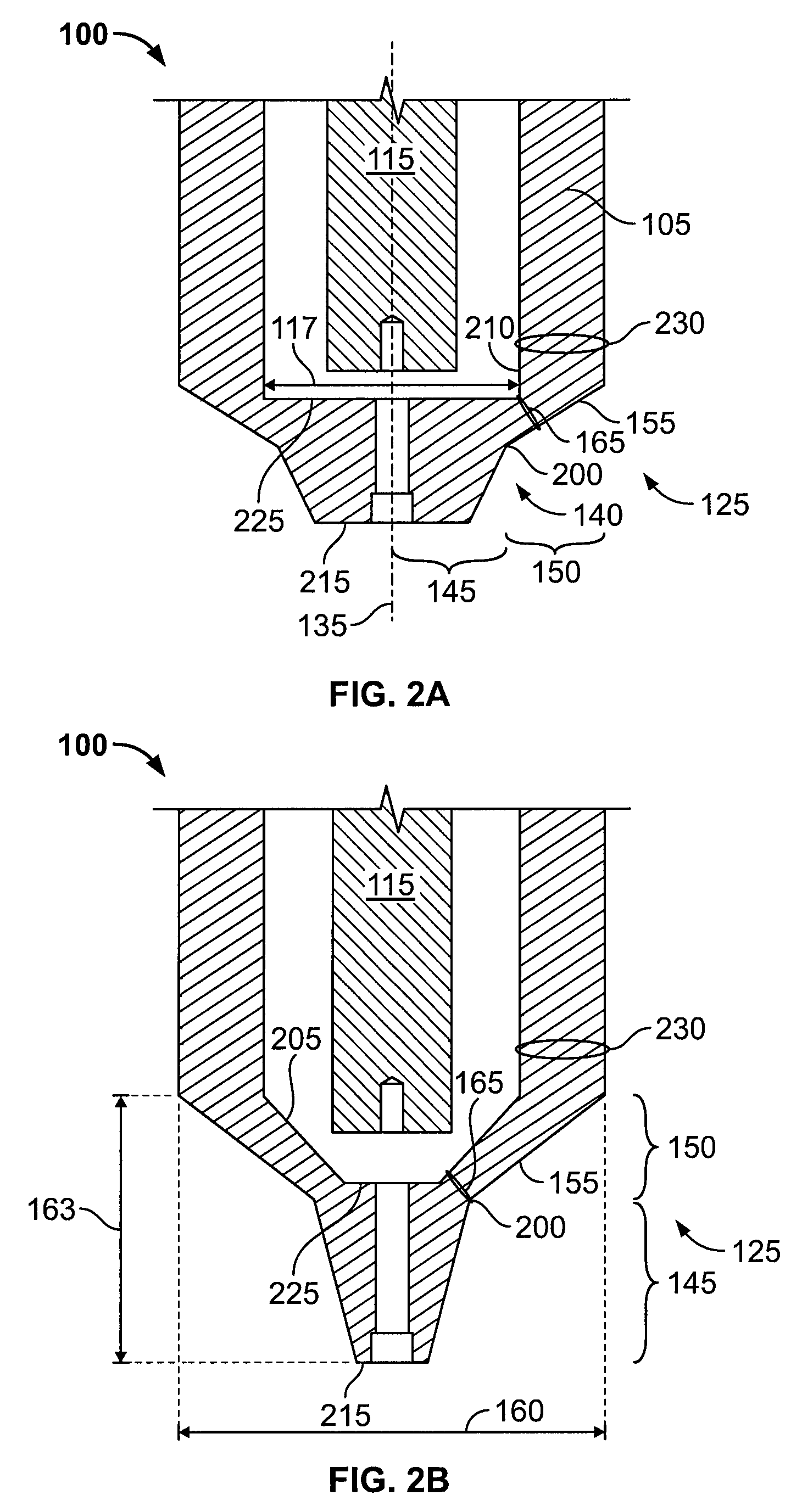

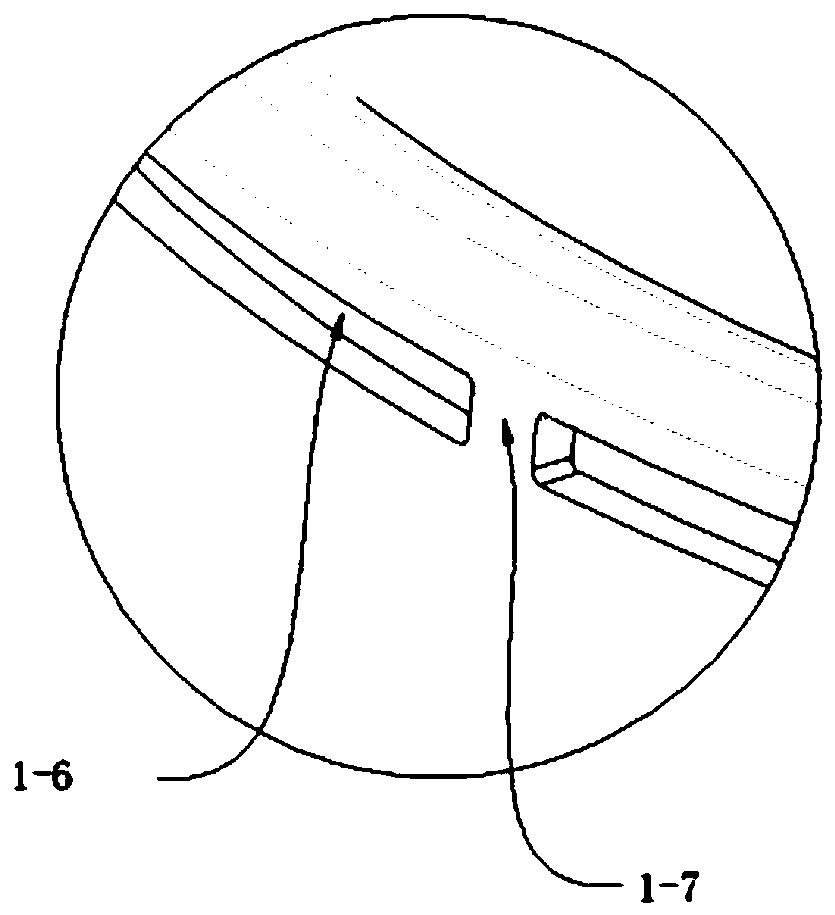

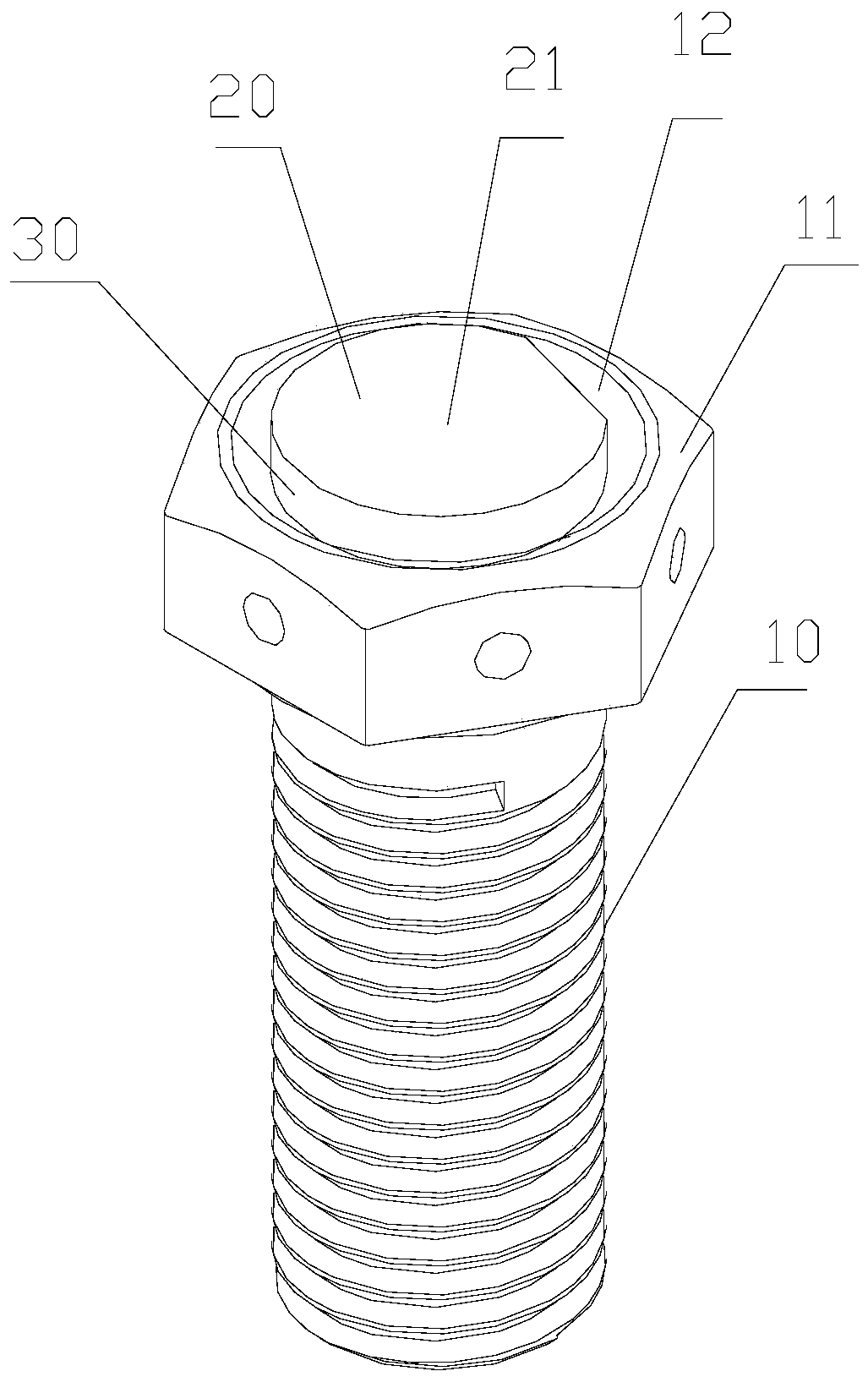

Nozzle Head with Increased Shoulder Thickness

ActiveUS20090255909A1Decreases thermal wear rateIncreased thermal wear ratePlasma welding apparatusWelding/cutting media/materialsVisibilityTorch

A consumable for a plasma arc torch, such as a nozzle, having a body and a head defining a shoulder portion having a frusto-conical portion and a flared portion. The flared portion increases the cross-sectional thickness to provide a greater heat-conduction path for removal of heat generated by a plasma arc, thereby extending consumable life. The frusto-conical portion provides a sharper, pointier nozzle head to simultaneously increase the operator's visibility of the workpiece. Methods of making and using the consumables are also included.

Owner:HYPERTHERM INC

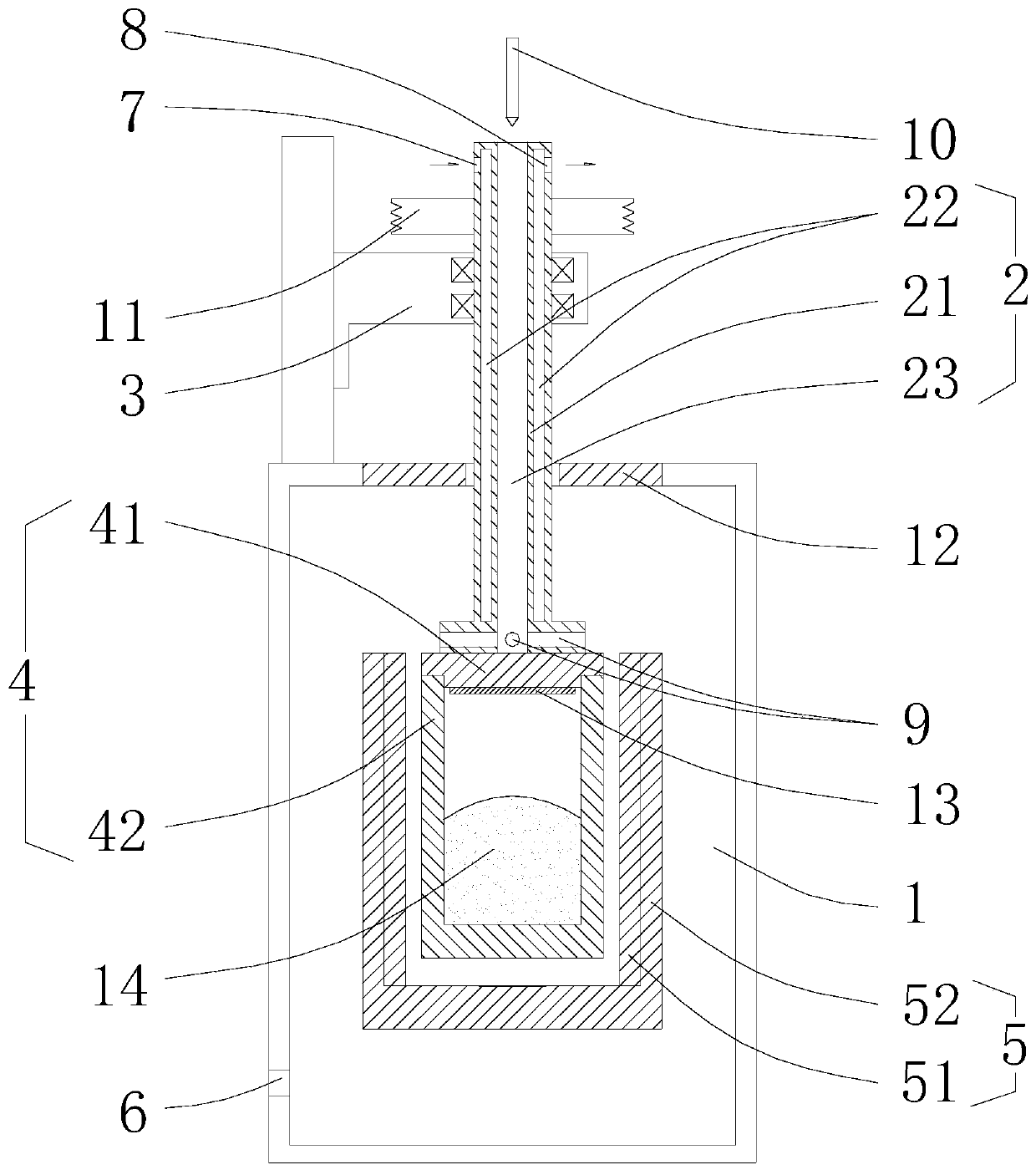

Silicon carbide single crystal growing device

PendingCN109913951AImprove growth qualityDirection to improve heat transferPolycrystalline material growthFrom condensed vaporsHeat conductingCrucible

The invention discloses a silicon carbide single crystal growing device. The silicon carbide single crystal growing device comprises a working chamber, a connecting rod penetrating into the working chamber in a liftable manner, a first driving mechanism for driving the connecting rod to lift, a crucible arranged inside the working chamber and a heating mechanism for heating the crucible, wherein the crucible comprises a crucible cover fixedly arranged at the bottom of the connecting rod and a crucible body detachably connected to the lower side of the crucible cover; the connecting rod comprises a rod body, a first passage formed in the rod body and used for inputting and outputting a refrigerant, and a second passage formed in the rod body and used for inflating process gas; the first passage and the second passage are mutually separated; the second passage communicates with the working chamber; the connecting rod is used for cooling the crucible cover through the refrigerant and / or the process gas; a gas outlet is further formed in the working chamber. The silicon carbide single crystal growing device optimizes a heat conducting path, so that heat is transferred only through thecrucible cover, a requirement on a temperature field with higher temperature on the lower part and lower temperature on the upper part is easier to achieve, and the silicon carbide single crystal growing quality is improved.

Owner:江苏星特亮科技有限公司

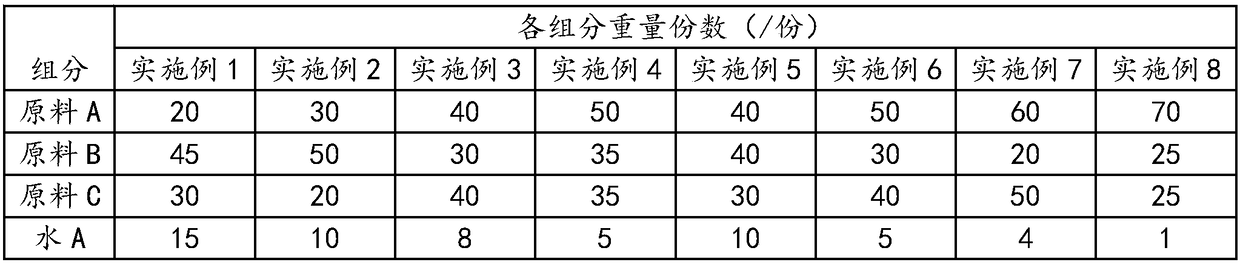

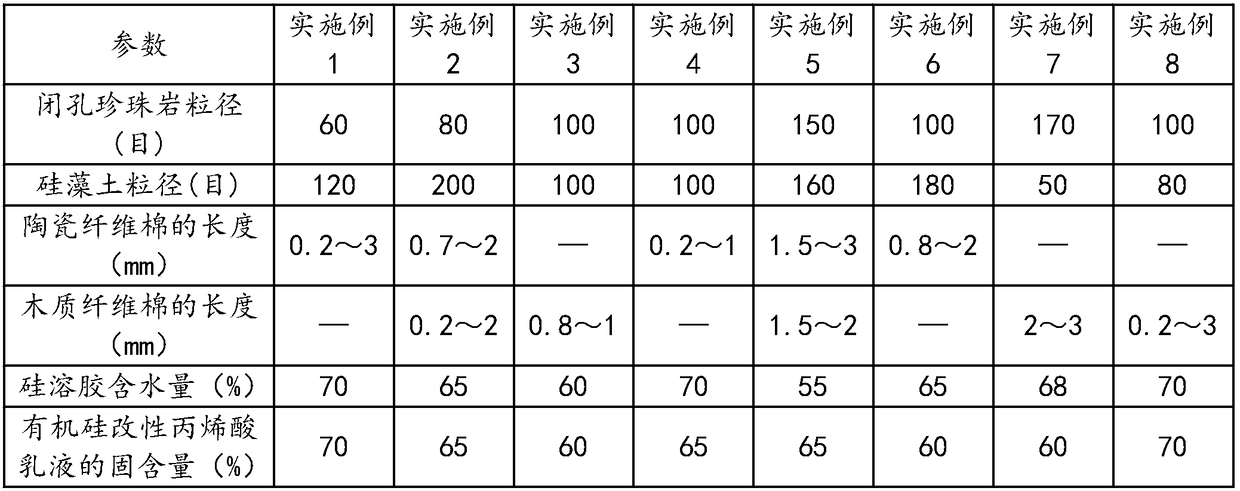

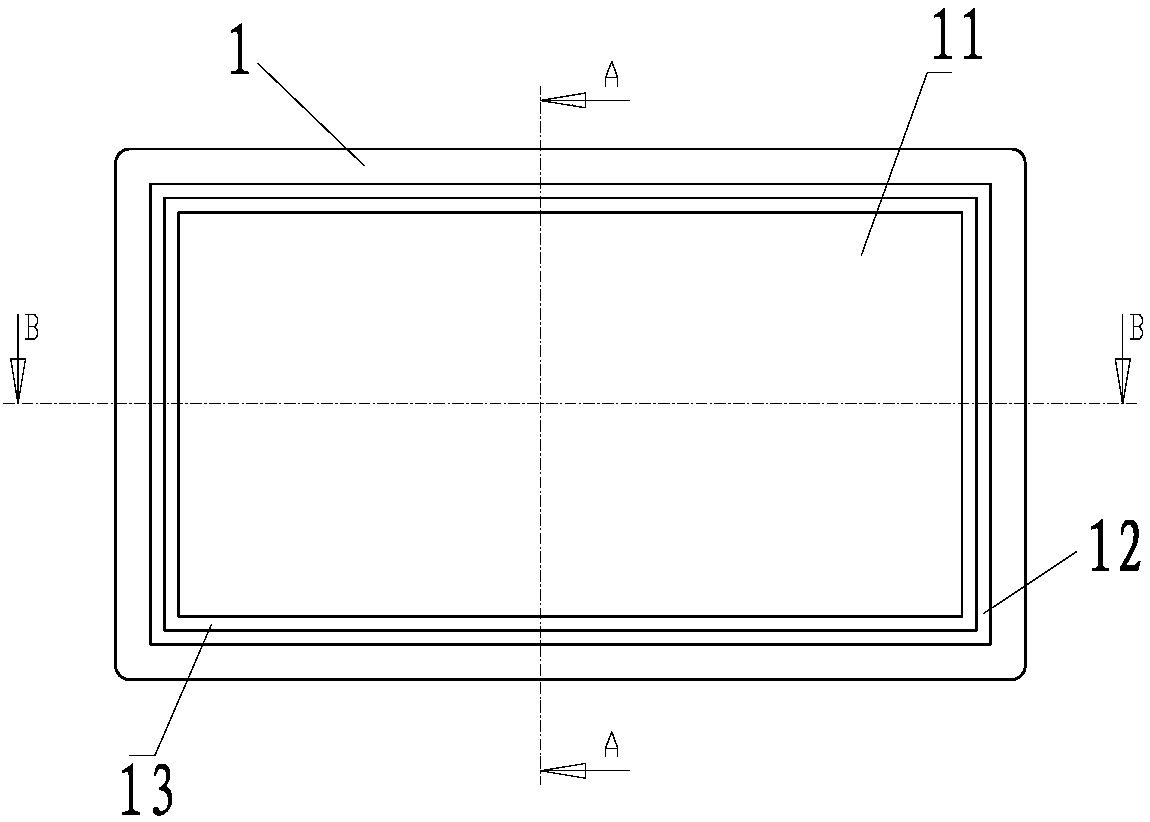

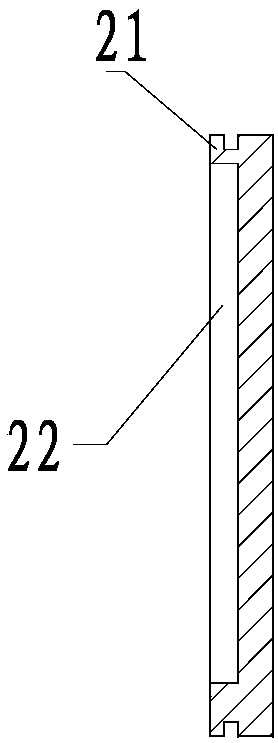

Fireproof, waterproof and environmentally friendly silica aerogel heat-insulation paste

ActiveCN108530011AIncrease the use of thicknessImprove fire resistanceBuilding energyThermal insulation

The invention belongs to the technical field of energy-saving and environmentally friendly materials, and particularly relates to a fireproof, waterproof and environmentally friendly silica aerogel heat-insulation paste for building and industrial energy-saving heat insulation. An aerogel precursor is added in the heat-insulation paste during preparation, silica sol and S=silicone modified acrylicemulsion are used as binding agent, and thus, the fireproof, waterproof and environmentally friendly silica aerogel heat-insulation paste has heat-insulation performance which is incomparable to a traditional material. After the heat-insulation paste is dry, the mechanical strength of the heat-insulation paste is high, fireproof A 1 level is realized, moreover, the fireproof, waterproof and environmentally friendly silica aerogel heat-insulation paste has the advantages of good waterproofness and low cost, and a novel material is provided for building energy conservation, environmental protection and industrial energy conservation.

Owner:TIANJIN WEIYUAN TECH DEV CO LTD

Portable heat preservation box

InactiveCN107640449AImprove the effect of the incubatorGood effectDomestic cooling apparatusLighting and heating apparatusCold chainConvex structure

The invention provides a portable heat preservation box. The box is composed of plates with good heat insulation performance, and comprises the side plates, the upper cover plate and the lower cover plate. The sides, opposite to each other, of the upper cover plate and the lower cover plate are both provided with a homocentric-squares-shaped groove; the side plates are provided with convex structures matched and connected with the grooves in an inserted mode; a heat preservation containing cavity is spliced after the side plates, the upper cover plate and the lower cover plate are connected inan inserted mode; the side, towards the heat preservation containing cavity, of each side plate is provided with a groove which is concave inwards in the direction away from the heat preservation containing cavity; cold sources are arranged in the grooves. When used, the novel structure heat preservation box can be installed into a transportation cold chain heat preservation box; when a box bodyreturns, the box can be detached into the plates, so that recycling and transportation are facilitated; the convex-concave structures on all sides of the box body have the function of a combined heatpreservation box, the box body can be well sealed, and a good heat preservation effect is achieved due to heat insulation.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

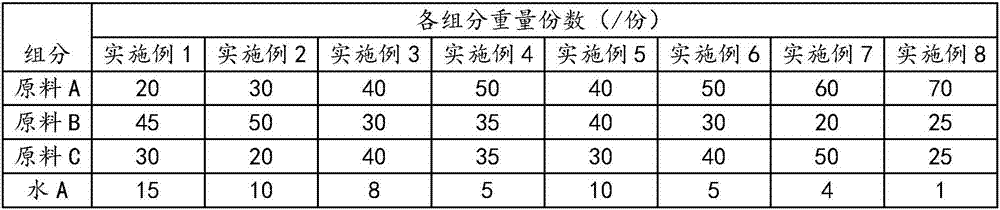

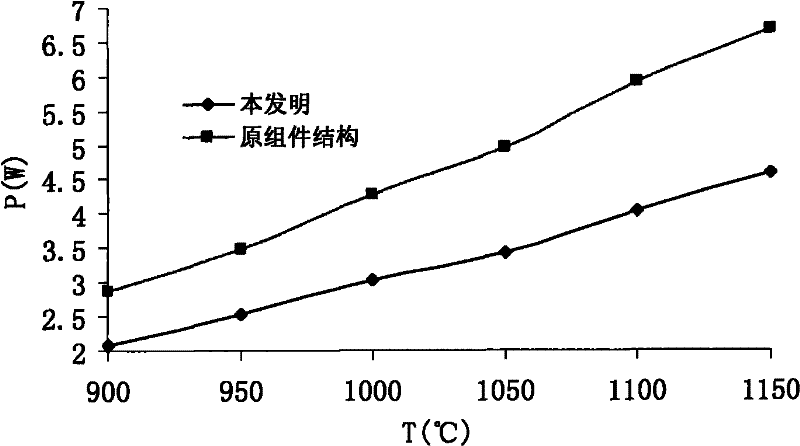

Heat insulation composition

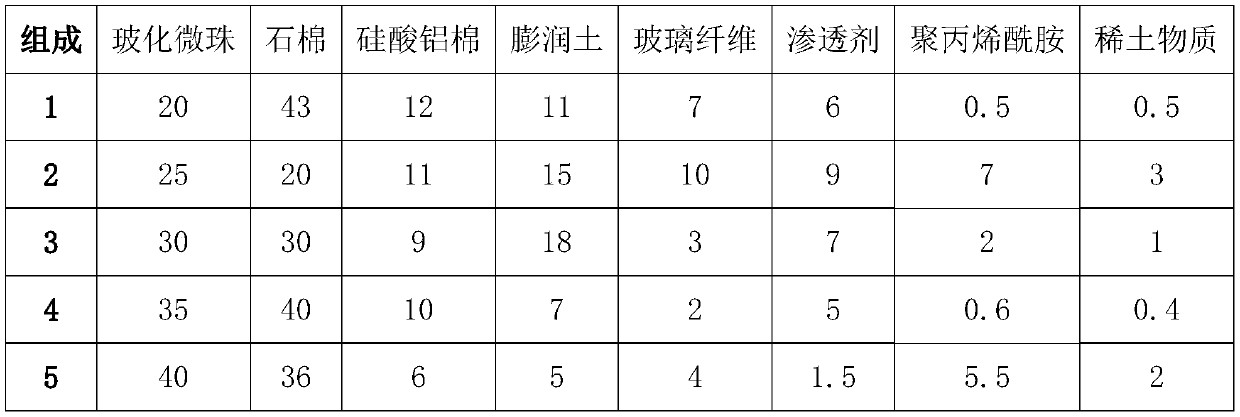

PendingCN110498636AExtended heat conduction pathLow thermal conductivityGlass fiberAluminum silicate

The invention discloses a heat insulation composition with a heat insulation effect. The problem that the volume weight of the heat preservation composition is large when the heat insulation effect isimproved in the prior art is solved. The heat insulation composition comprises 10-65 wt% of vitrified microbeads, 10-50 wt% of asbestos, 1-20 wt% of aluminum silicate wool, 5-20 wt% of bentonite, 1-10 wt% of glass fibers and 1-10 wt% of a penetrant. The heat insulation composition has the advantages of excellent heat insulation performance, low volume weight, reduction of the thickness by 50% orabove under a condition that the surface temperature is same to that of the aluminum silicate wool, and remarkable energy-saving effect due to great reduction of the heat dissipation area, so the adiabatic temperature range is greatly expanded, and the working temperature range can reach -40-1000 DEG C.

Owner:刘永平

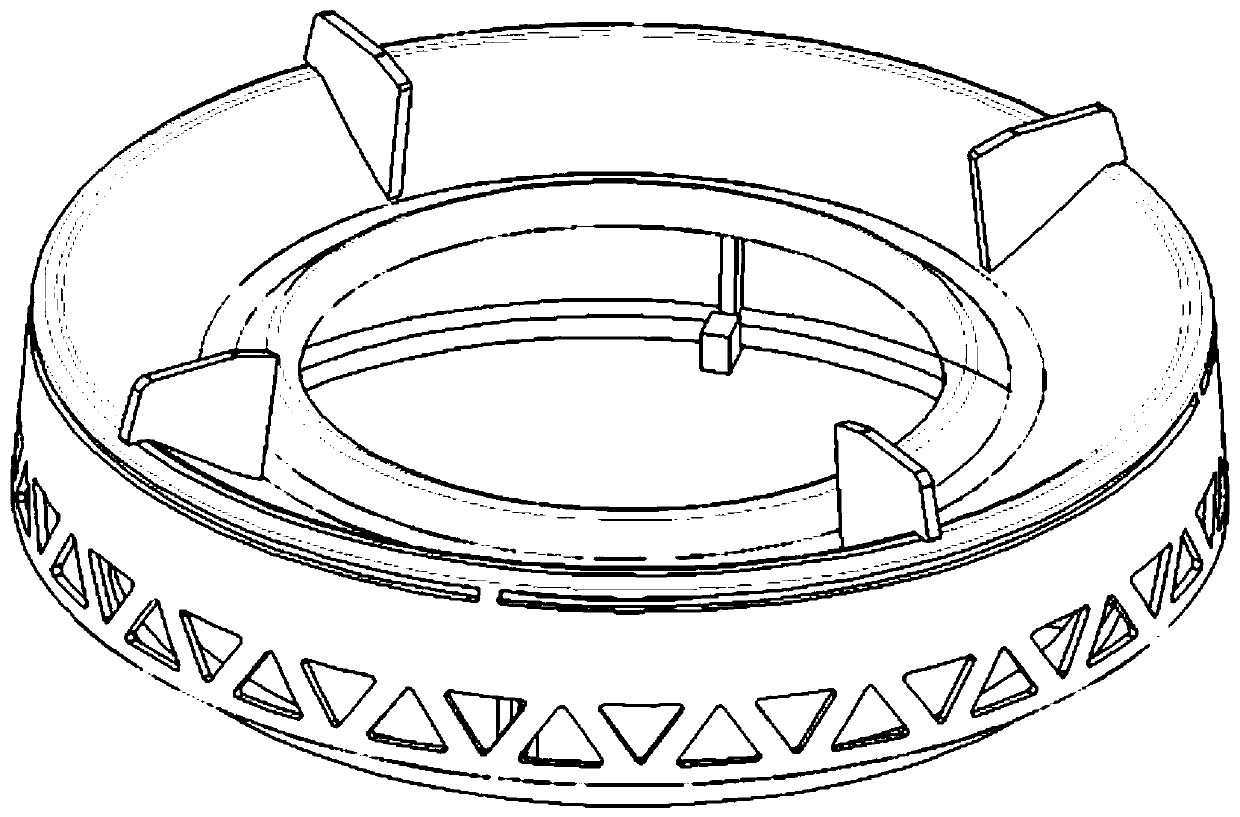

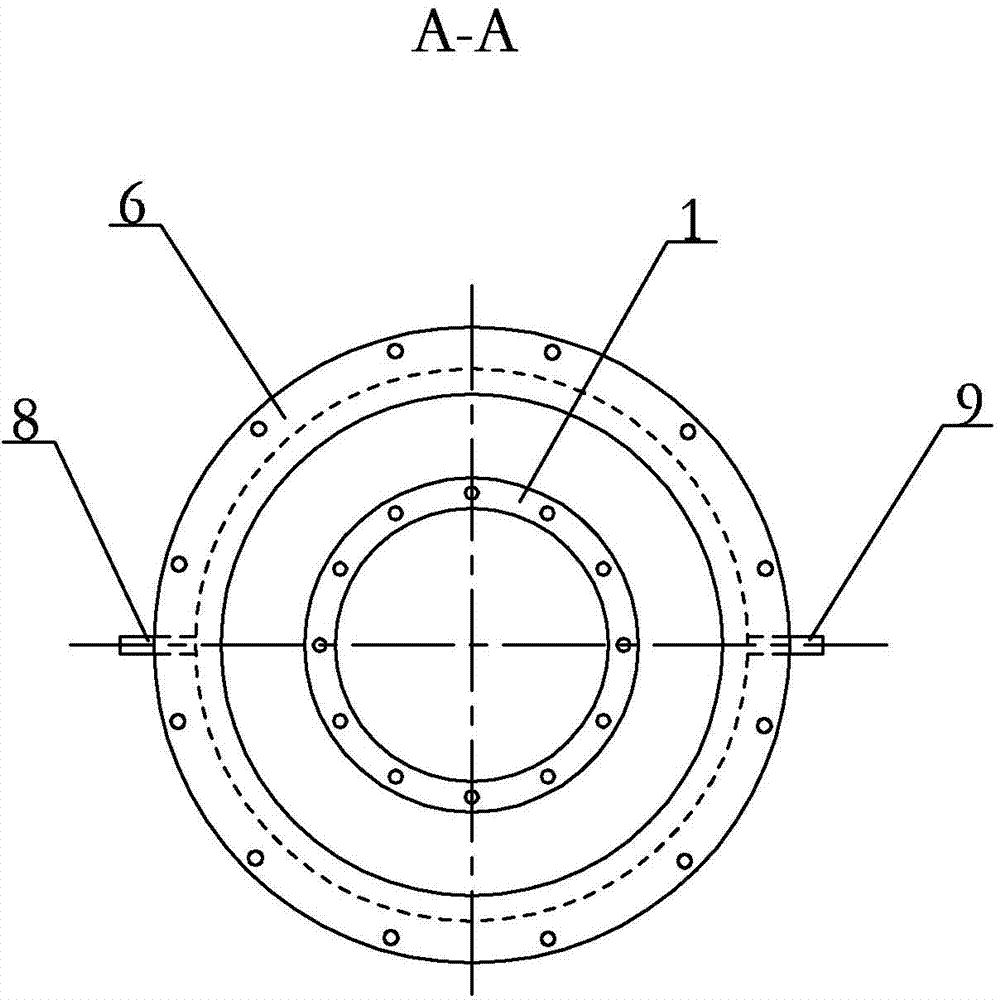

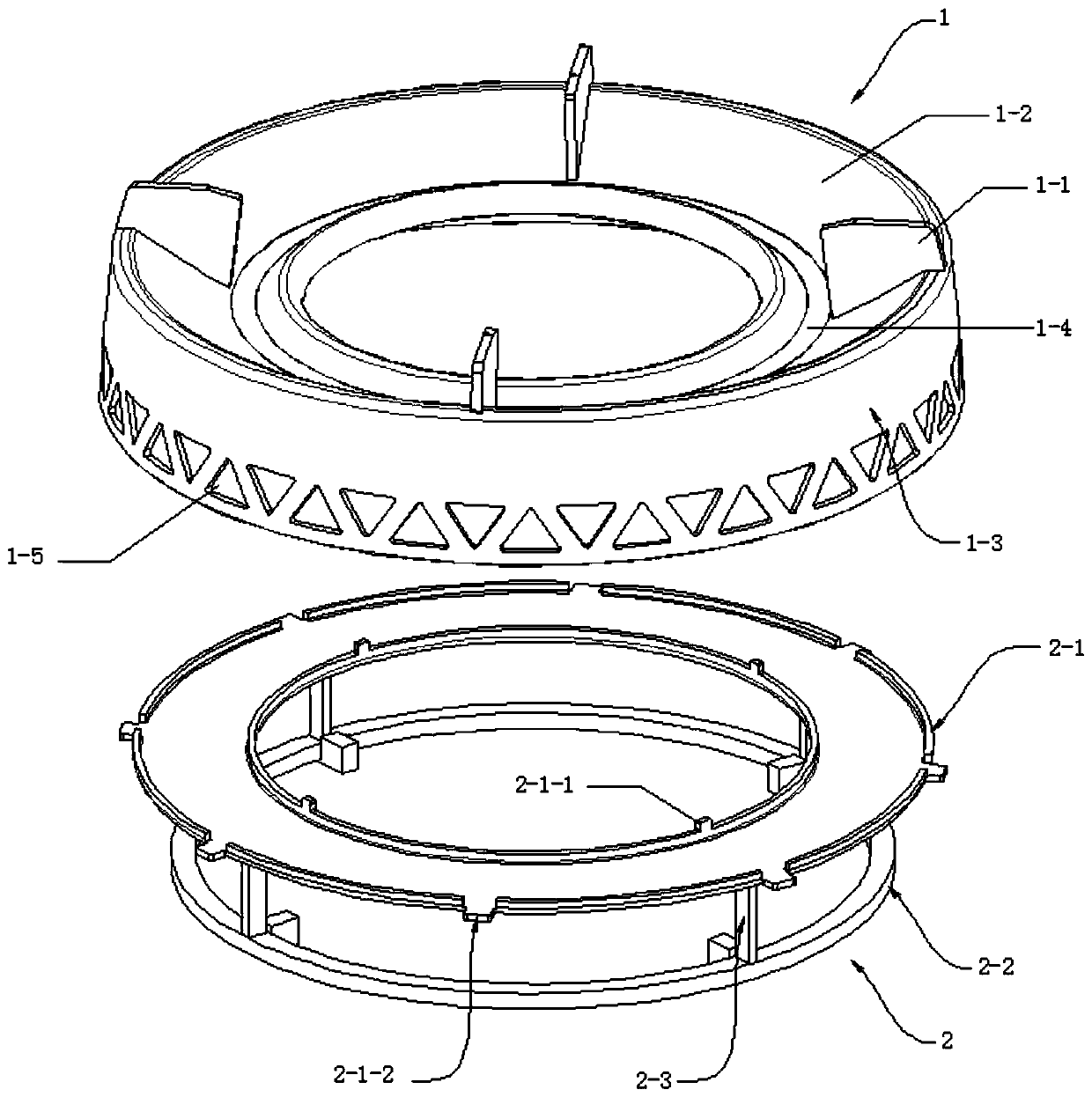

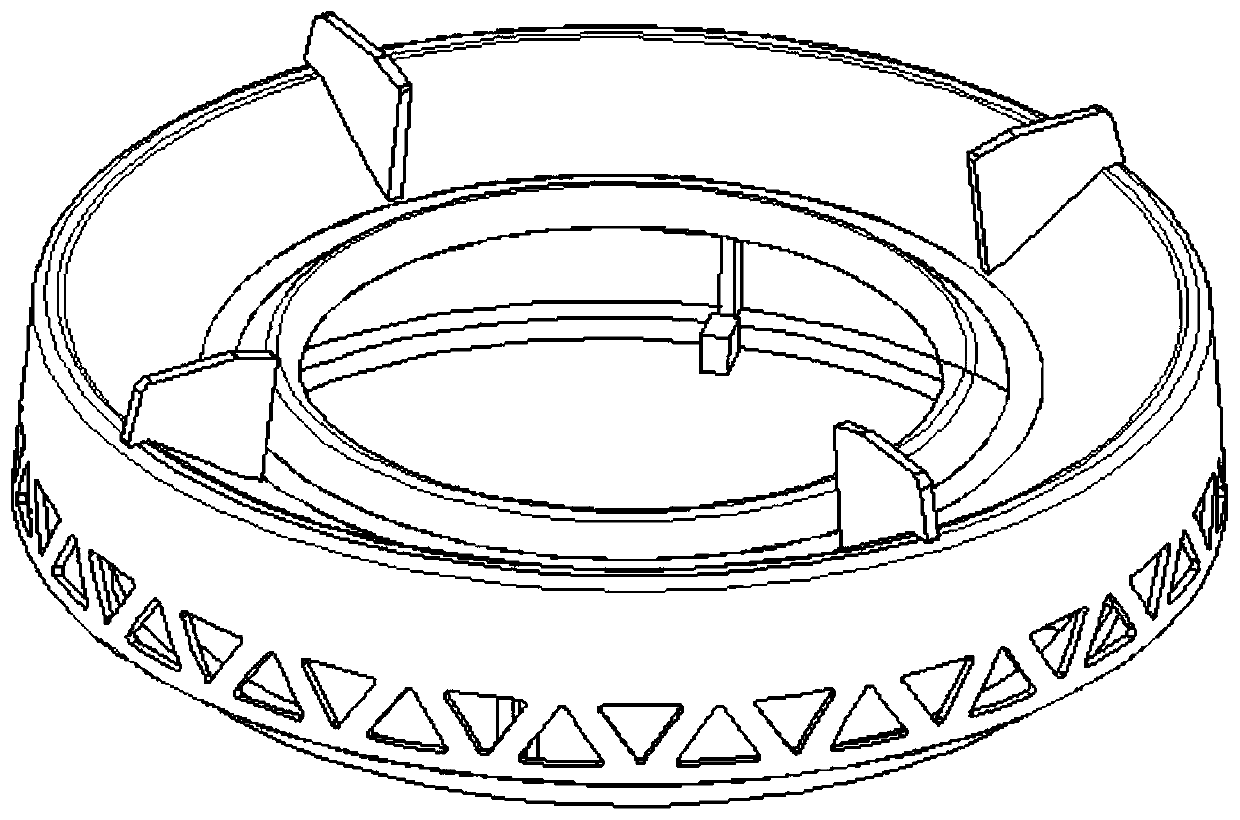

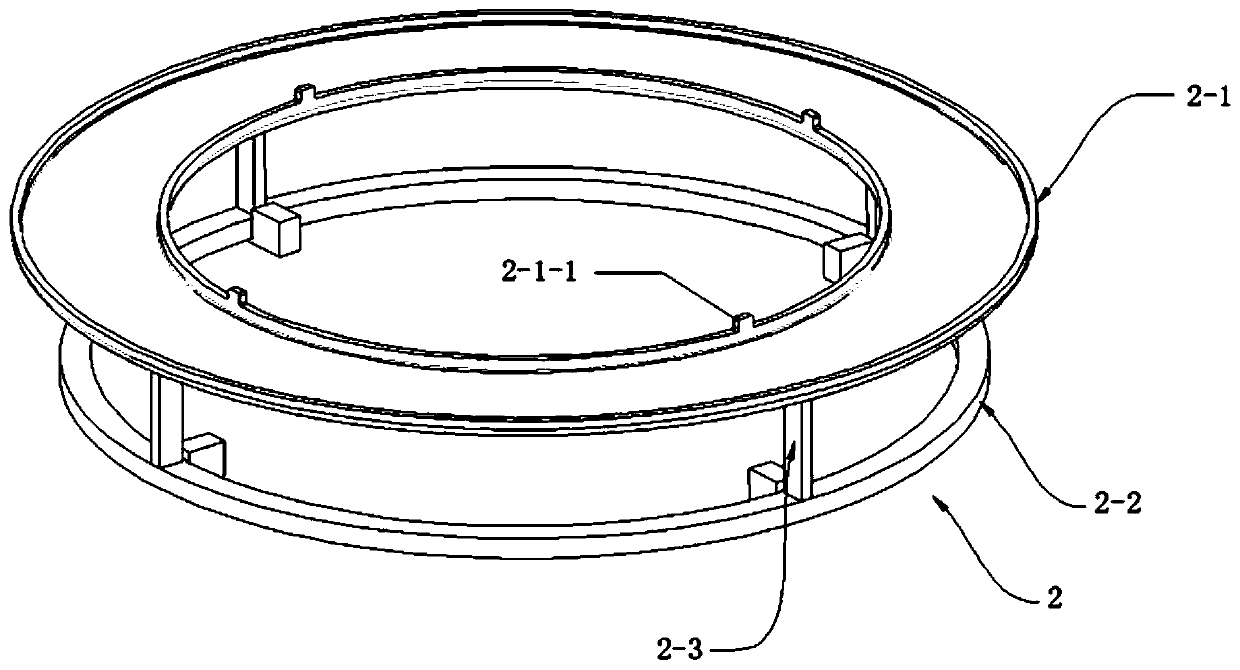

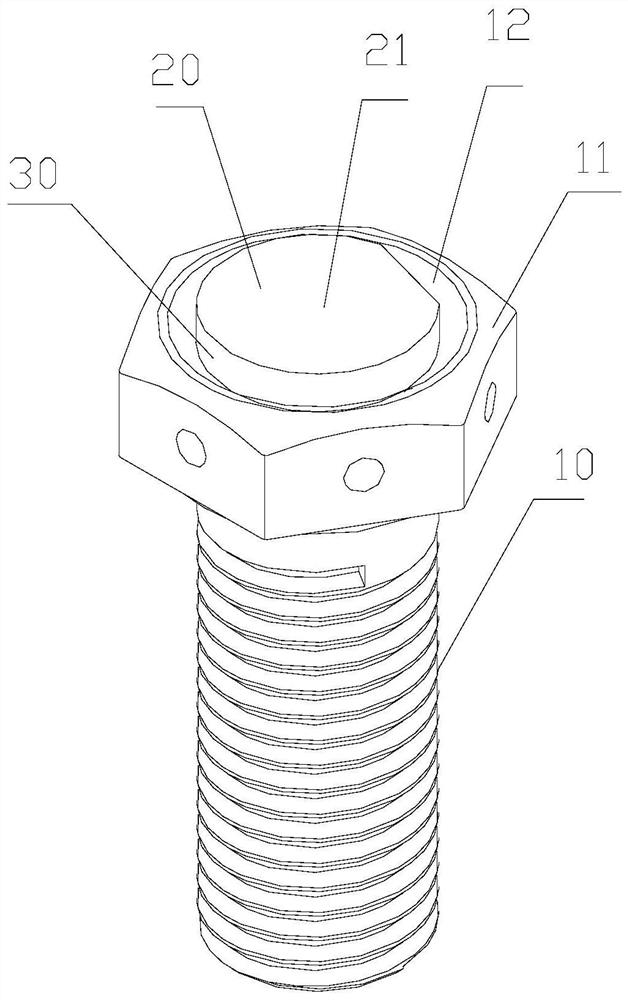

Building isolation bearing fire protection device

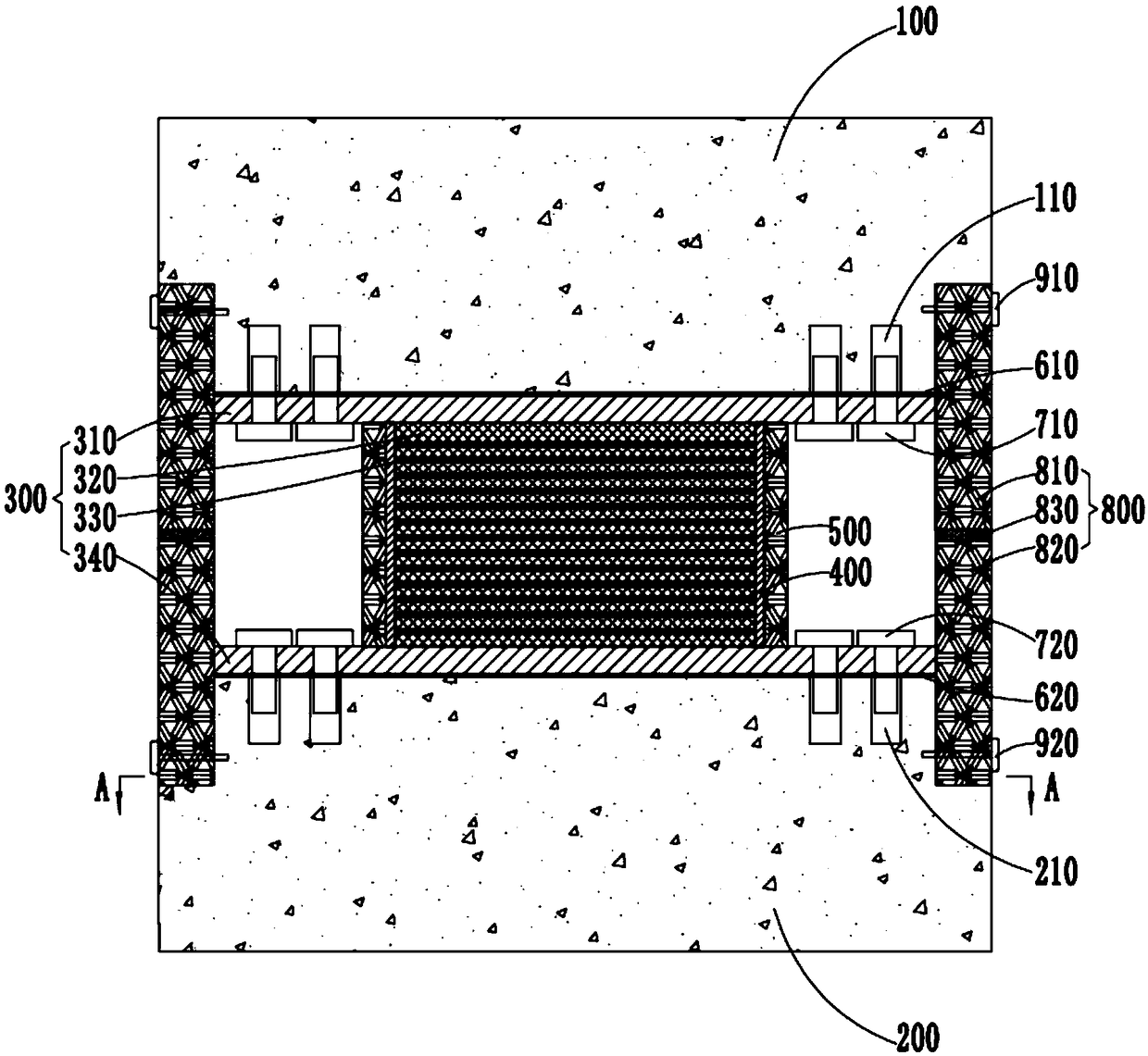

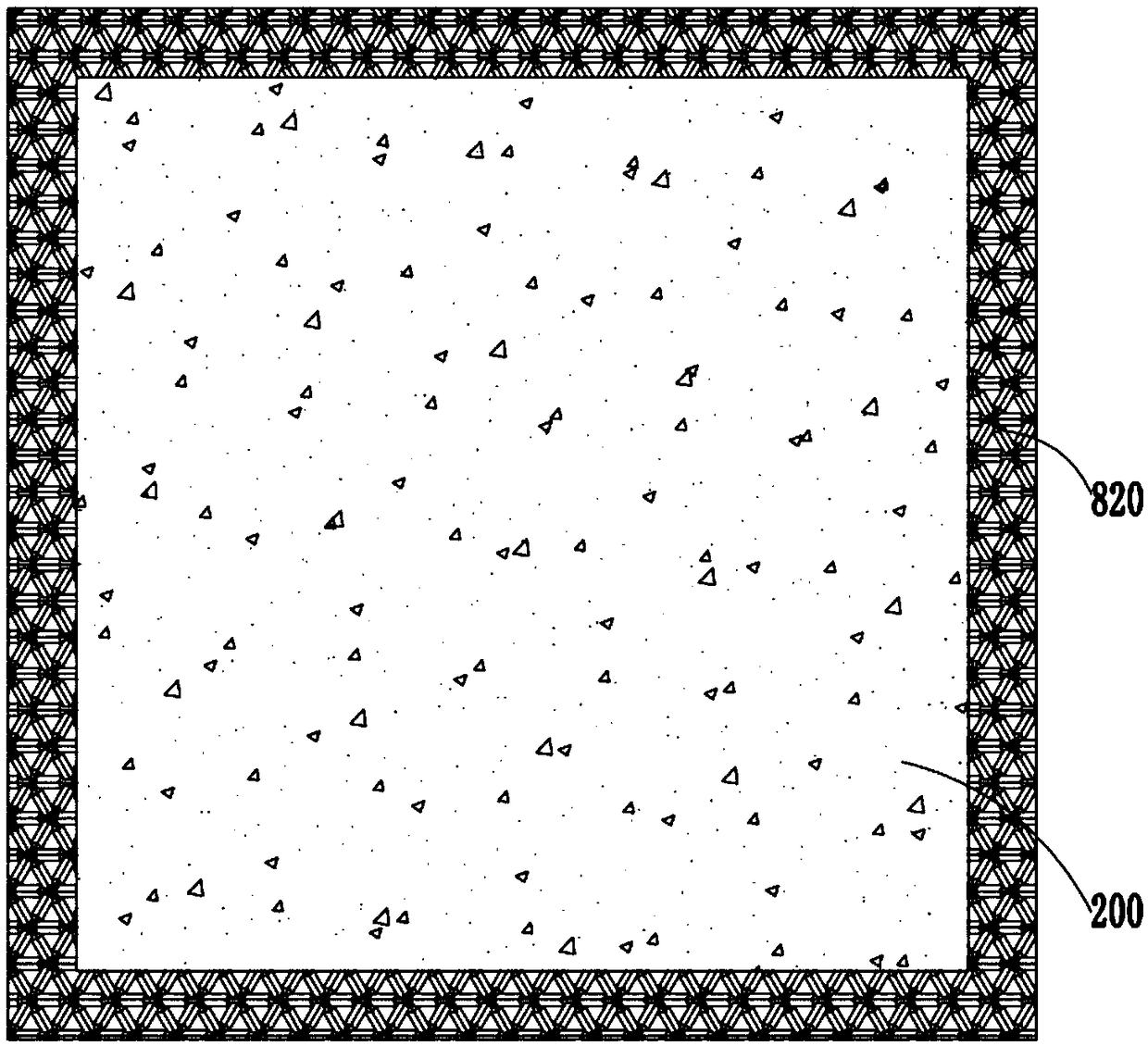

PendingCN109372148AAvoid spreadingAvoid damageProtective buildings/sheltersFire proofingFire protectionEngineering

The invention provides a building isolation bearing fire protection device, and relates to the technical field of building protection. The fire protection device is designed for solving the problem offire safety in existing isolation buildings. The building isolation bearing fire protection device comprises an upper pier column, lower pier column, a rubber isolation bearing, a fireproof board, aflame retardant protective layer and a fireproof coating layer; the fireproof board comprises an upper fireproof board, a lower fireproof board and elastic fireproof sealants; the upper fireproof board is connected with the upper pier column by fixing bolts, and the lower fireproof board is connected with the lower pier column by fixing bolts; a clearance is formed between the upper pier column and the lower pier column, and filled with the elastic fireproof sealants; and the flame retardant protective layer and the fireproof coating layer are wrapped on the body of the rubber isolation bearing in sequence, and a fireproof space is formed between the outer circumferential surface of the fireproof coating layer and the inner circumferential of the fireproof board. According to the buildingisolation bearing fire protection device provided by the invention, effective fire protection can be provided for isolation buildings.

Owner:SUZHOU HAIDER NEW MATERIAL TECH CO LTD

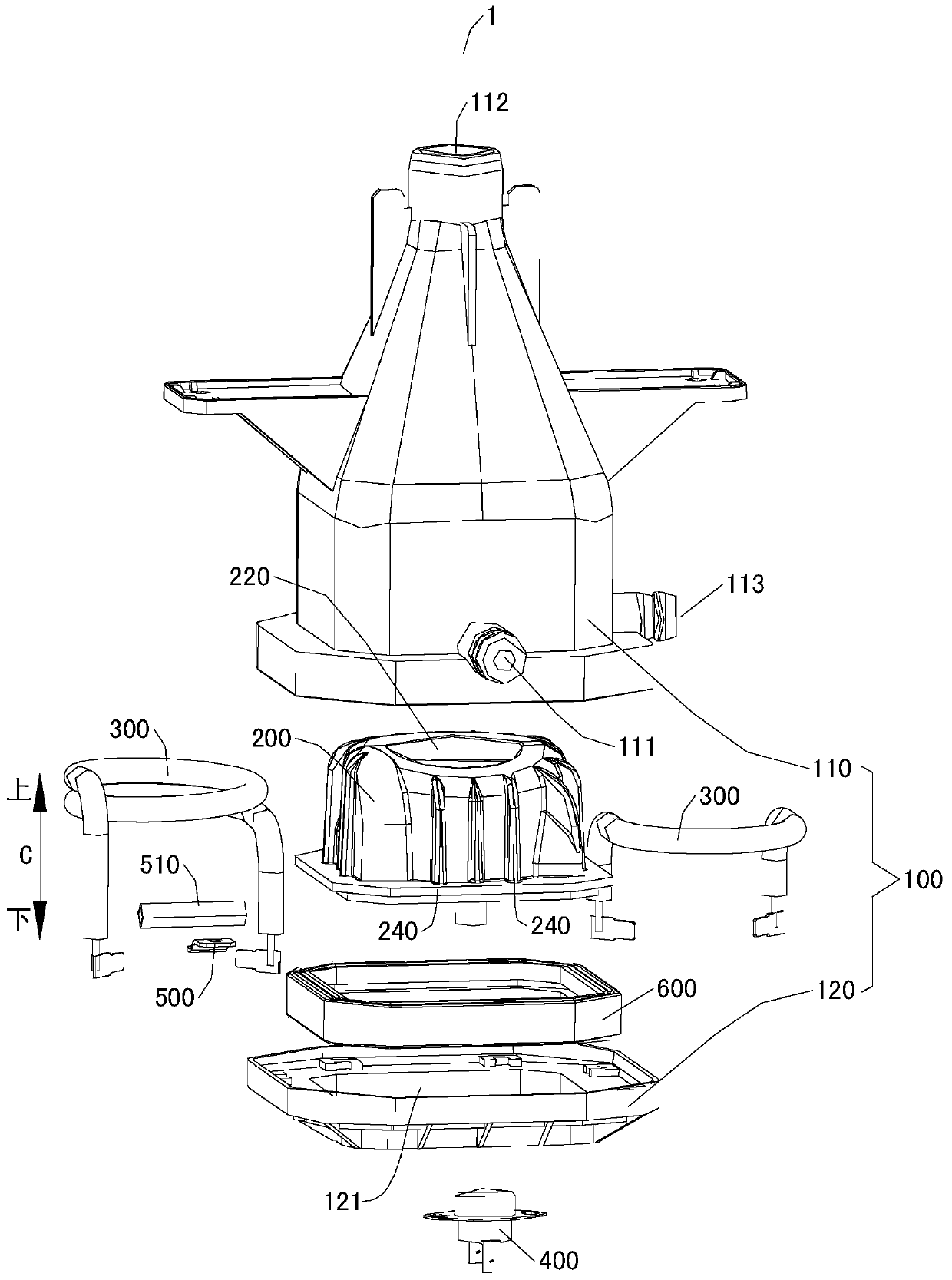

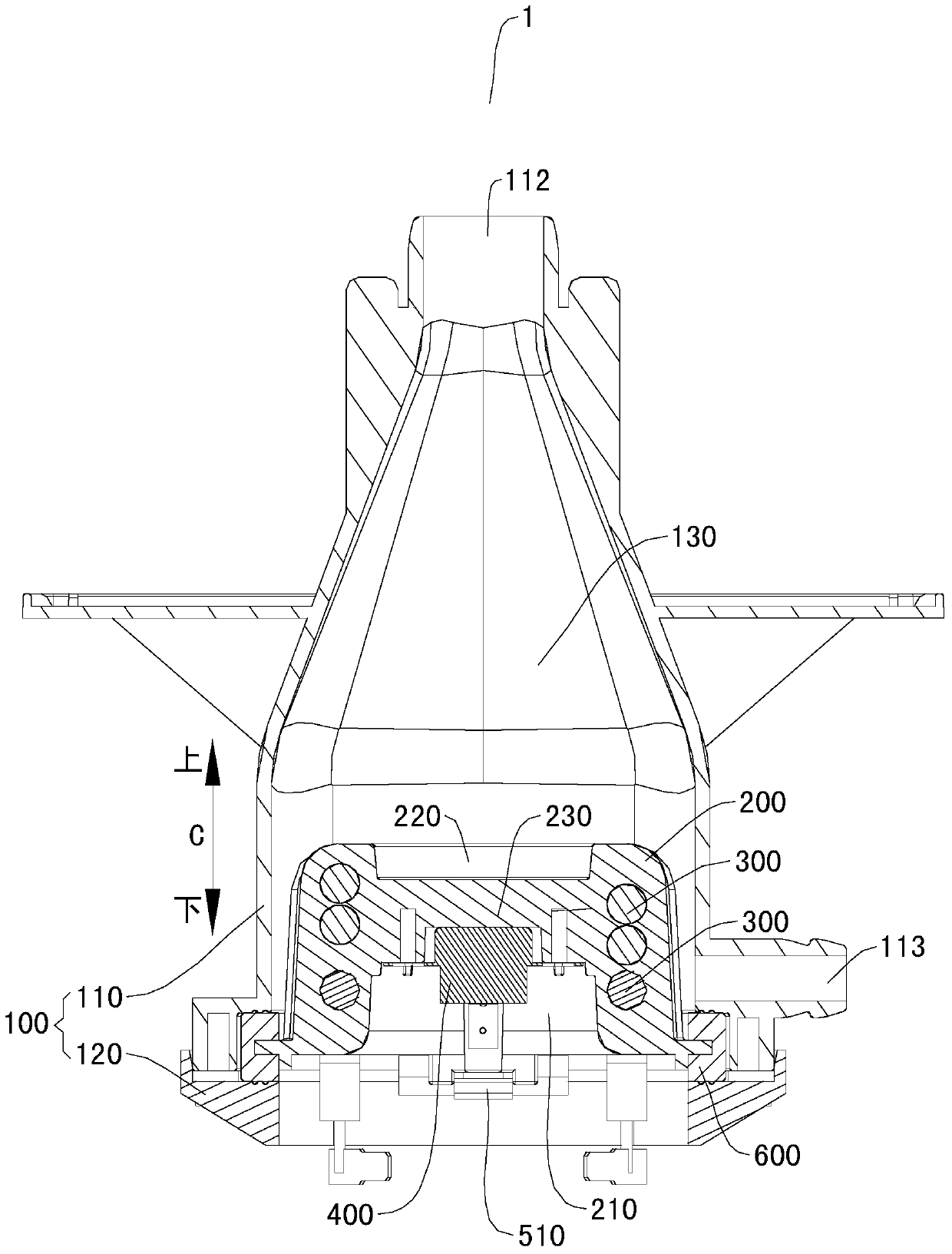

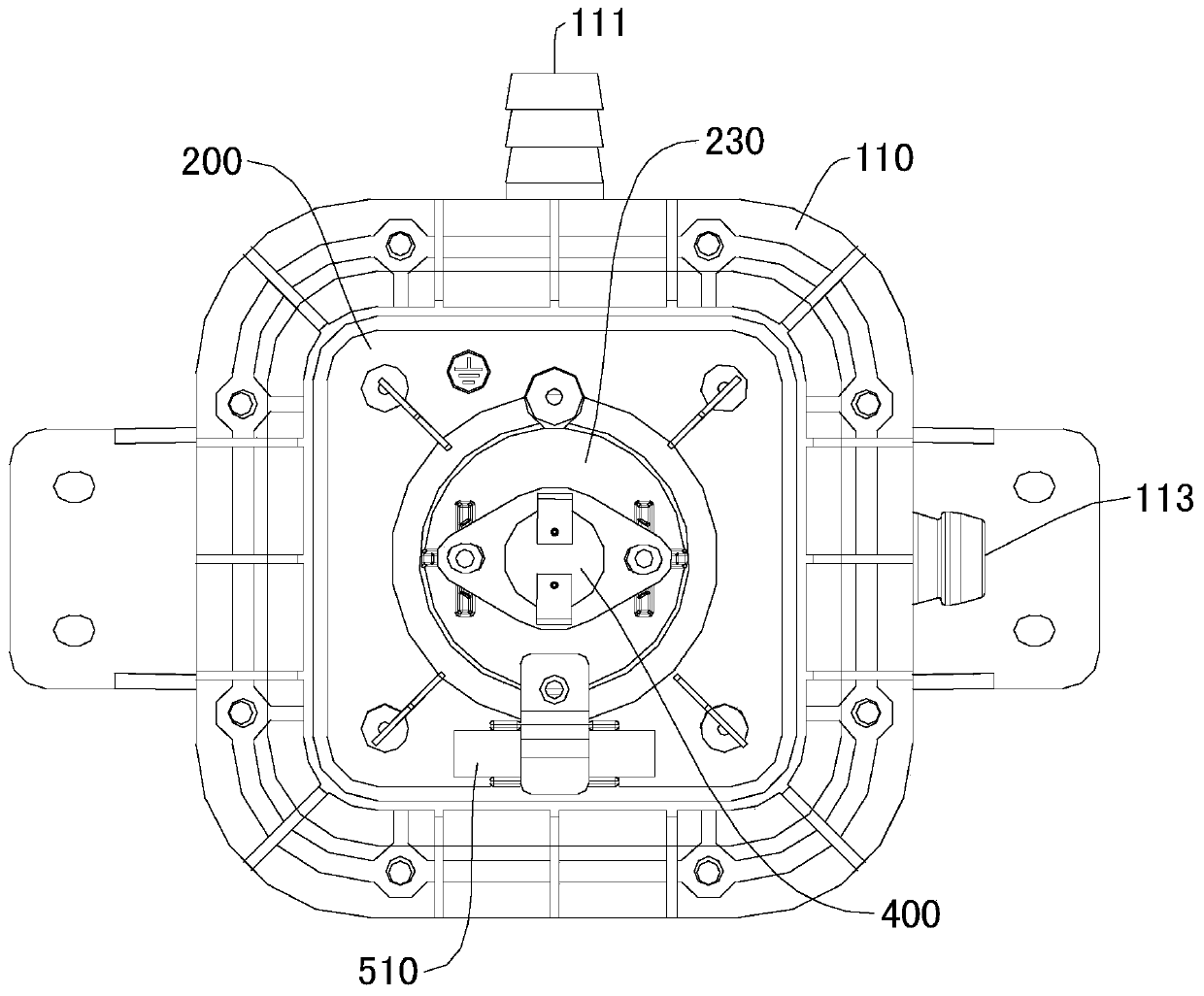

Steam generator, garment steamer and heater of steam generator

InactiveCN105509020AReduce high temperatureExtended heat conduction pathSteam generation heating methodsBoiler controlComing outWater storage tank

The invention discloses a steam generator, a garment steamer and a heater of the steam generator. The steam generator comprises a casing, the heater, a heating pipe and a temperature controller, wherein a cavity is formed in the casing, an water inlet and a steam outlet which are communicated with the cavity are formed in the casing, and an opening is formed in the lower end of the cavity; the heater is arranged in the cavity and fixed on the casing and blocks the opening, besides, the cavity above the upper surface of the heater is a steam generating cavity, the lower surface of the heater concaves upwards and inwards, a water storage tank is formed in the upper surface of the heater, and a step is arranged on the upper wall of the cavity; the heating pipe is buried in the heater, extends downwards out of the heater and comes out from the opening; and the temperature controller is arranged inside the recessed cavity and attached to the lower surface of the step. The steam generator has the following advantages: steam is not easy to cut off; the steam is stable; and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Nozzle head with increased shoulder thickness

ActiveUS8513565B2Reduce rateIncrease ratingsPlasma welding apparatusWelding/cutting media/materialsVisibilityEngineering

A consumable for a plasma arc torch, such as a nozzle, having a body and a head defining a shoulder portion having a frusto-conical portion and a flared portion. The flared portion increases the cross-sectional thickness to provide a greater heat-conduction path for removal of heat generated by a plasma arc, thereby extending consumable life. The frusto-conical portion provides a sharper, pointier nozzle head to simultaneously increase the operator's visibility of the workpiece. Methods of making and using the consumables are also included.

Owner:HYPERTHERM INC

Silica aerogel fireproof, waterproof, environment-friendly thermal insulation paste and preparation method thereof

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to a building, silica aerogel fireproof, waterproof, environment-friendly thermal insulation paste for industrial energy conservation and thermal insulation and a preparation method of the paste. According to the thermal insulation paste, an aerogel precursor is added during preparation, silicon sol and organic silicon modified acrylic emulsion serve as binding agents, and the paste has the incomparable heat insulation performance compared with a traditional material. After the thermal insulation paste is dried, the high mechanical strength is achieved, and the fireproof A1 grade is achieved; besides, the paste has relatively good waterproof performance and low cost, and a novel material is provided for building energy conservation, environmental protection and industrial energy conservation.

Owner:天津朗华睿博科技有限公司

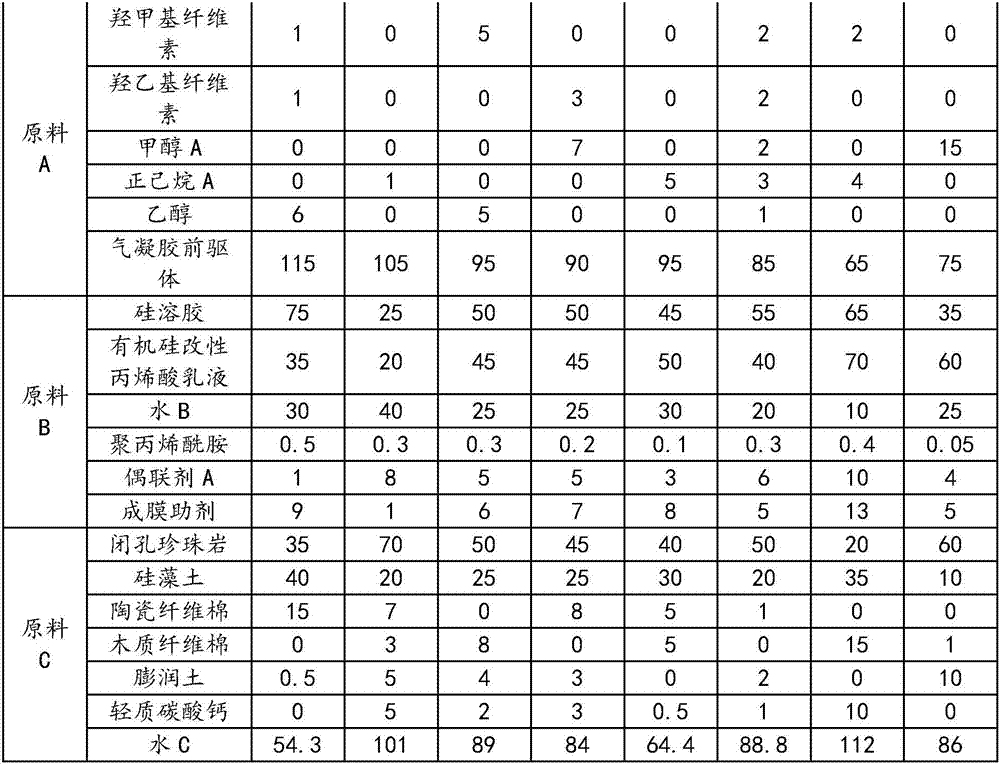

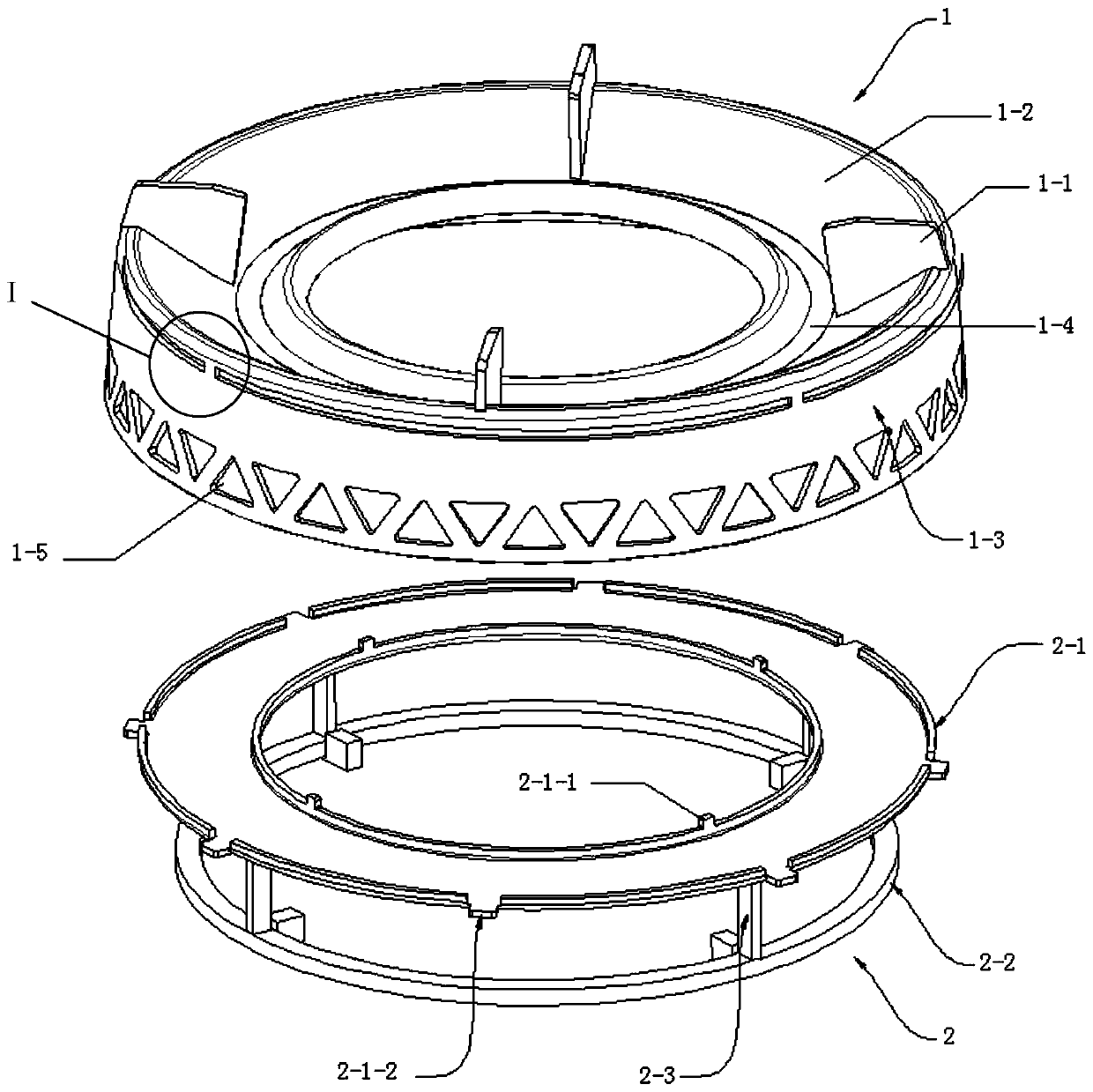

Energy-collecting pot support for improving temperature of gas cooker cavity and gas cooker

PendingCN110454828AReduce heat conduction areaAvoid passingDomestic stoves or rangesLighting and heating apparatusHeat lossesEngineering

The invention discloses an energy-collecting pot support for improving the temperature of a gas cooker cavity and a gas cooker. The energy-collecting pot support comprises an upper pot support in contact with a pot and a lower pot support for supporting the upper pot support, wherein the upper pot support comprises foot pieces and an outer side enclosing plate; a heat insulation groove is circumferentially formed in the outer side enclosing plate; and the lower pot support is of an annular supporting structure and is used for supporting and fixing the upper pot support. According to the energy-collecting pot support and the gas cooker, as the heat insulation groove is arranged, the heat loss of the bottom of the pot is reduced.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Heat-resistant sealing structure for high-temperature gas container

InactiveCN103775826AImprove sealingReduce the temperature of the sealed structureContainer filling methodsContainer discharging methodsEngineeringProduct gas

The invention discloses a heat-resistant sealing structure for a high-temperature gas container, relates to a heat-resistant sealing structure, and aims at solving the problem that an existing sealing gasket at a high temperature is relatively poor in sealing effect in comparison with a low-temperature sealing gasket universally. The heat-resistant sealing structure comprises an inner layer sealing structure and an outer layer sealing structure; the inner layer sealing structure comprises an inner layer sealing end cover, an inner layer high-temperature sealing gasket and an inner layer sealing support; the inner layer sealing end cover is arranged on the inner layer sealing support through an inner layer high-temperature sealing gasket sealing cover; the outer layer sealing structure comprises an outer layer sealing support, a normal-temperature sealing gasket, an outer layer sealing end cover and a water cooling jacket; the outer layer sealing support is fixedly arranged on the inner layer sealing support; the upper end face of the outer layer sealing support is higher than the upper end face of the inner layer sealing end cover; the outer layer sealing end cover is tightly arranged on the outer layer sealing support through a normal-temperature sealing gasket; and the water cooling jacket is arranged on the outer lateral wall of the outer layer sealing support in a sleeved mode. The heat-resistant sealing structure is applied to heat-resistant sealing of the high-temperature gas container.

Owner:HARBIN INST OF TECH

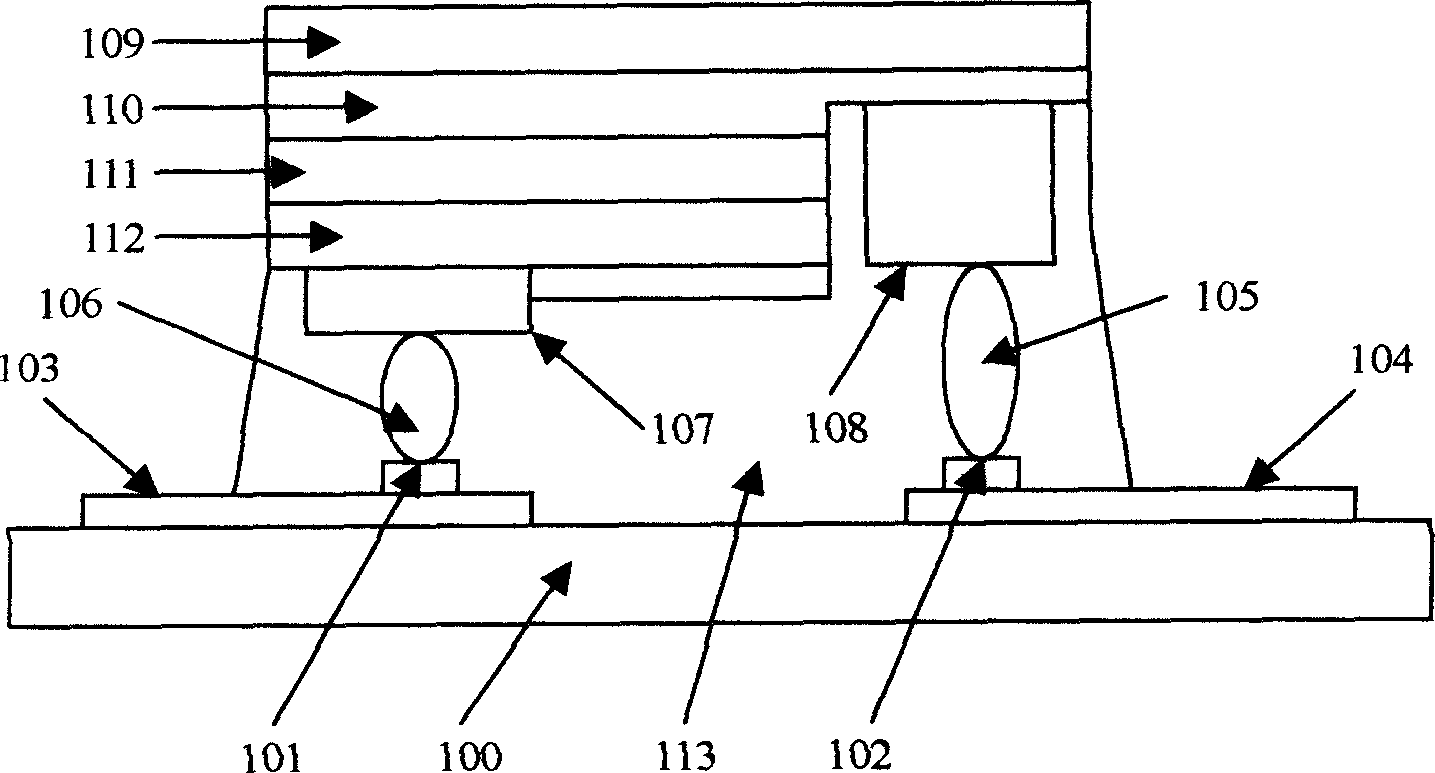

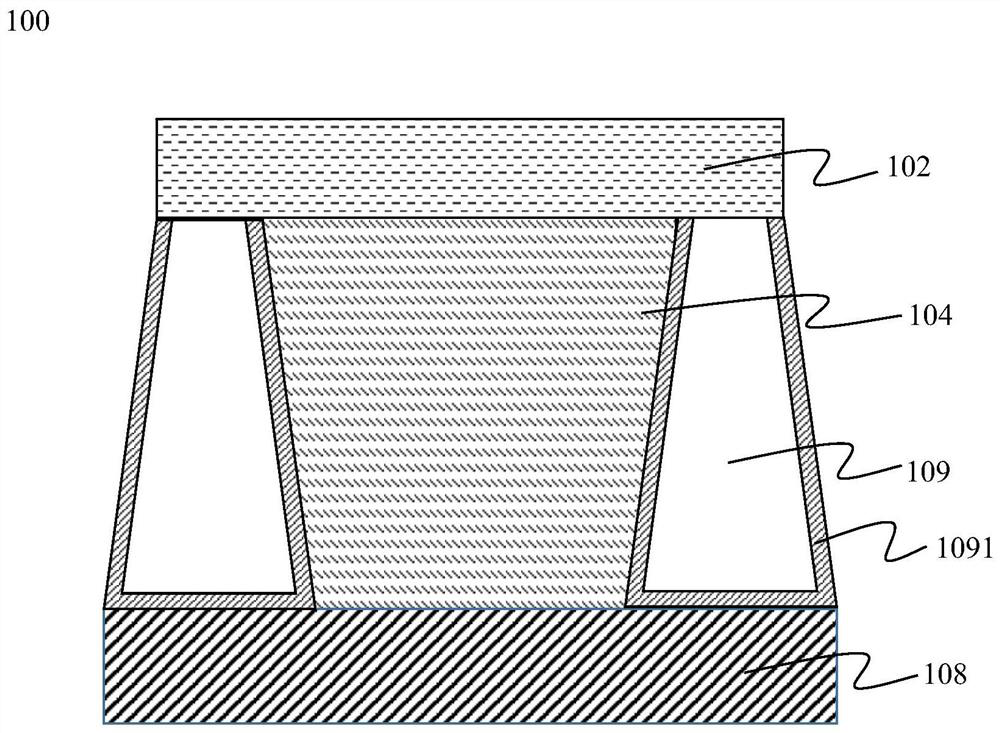

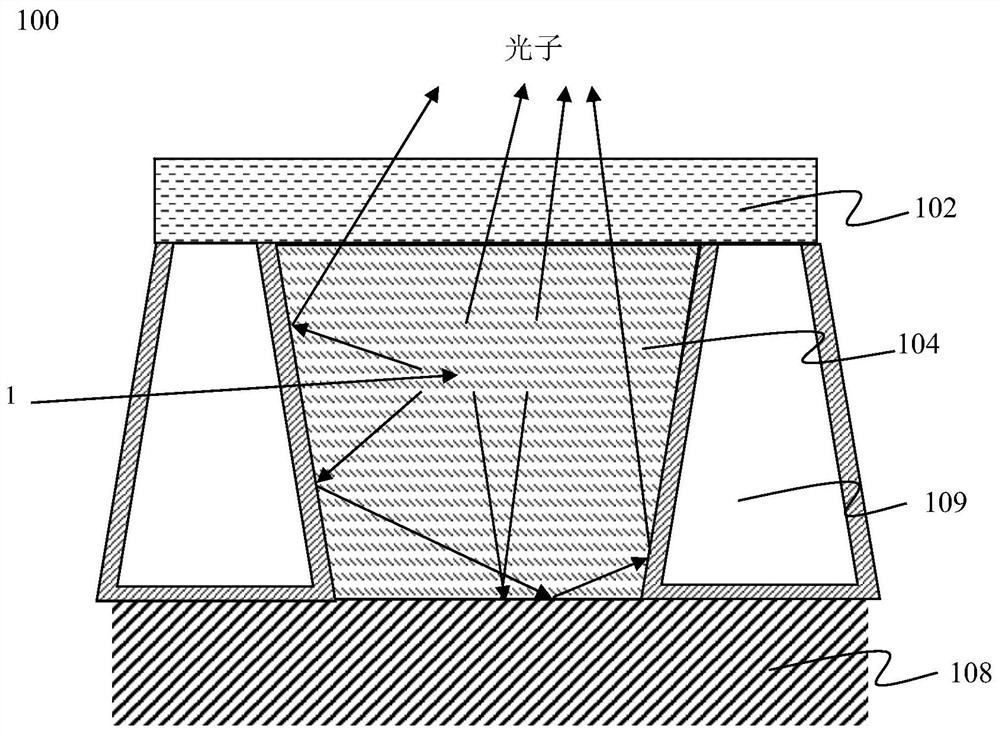

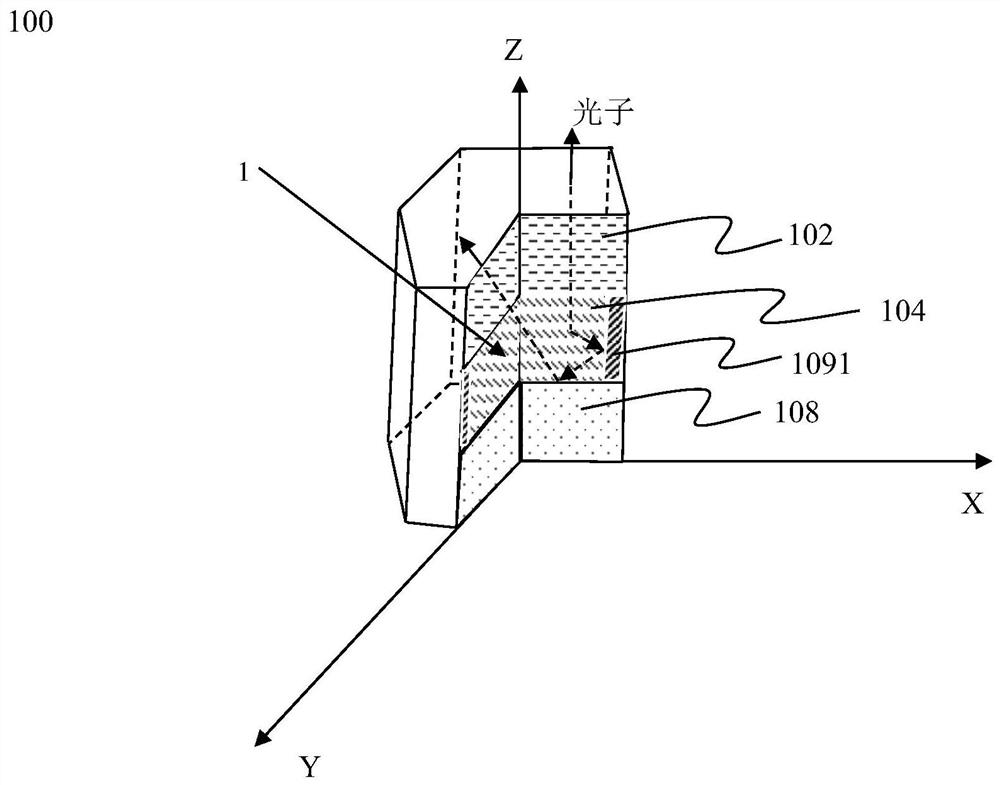

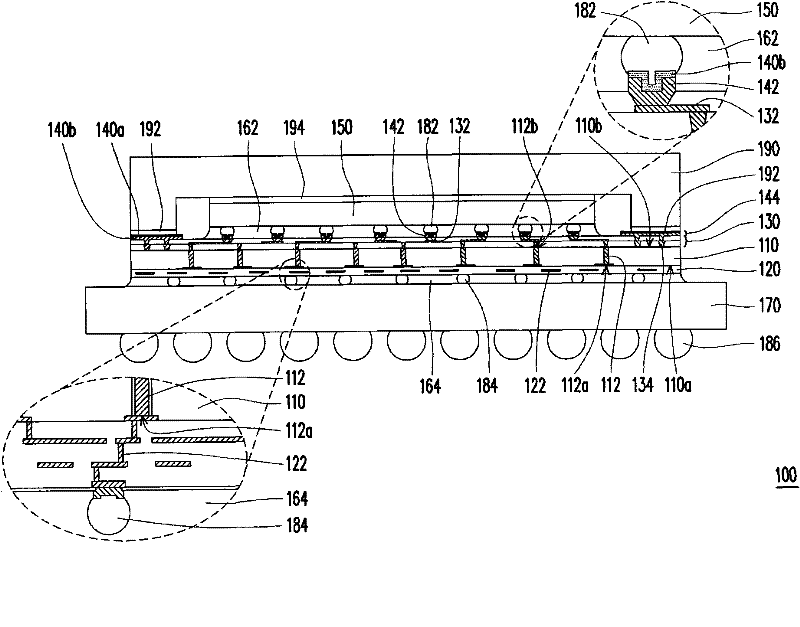

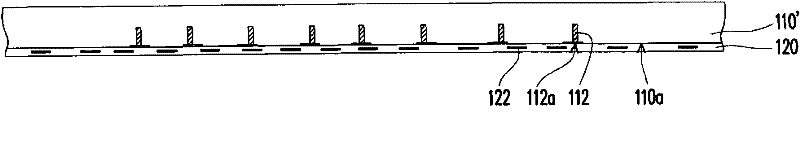

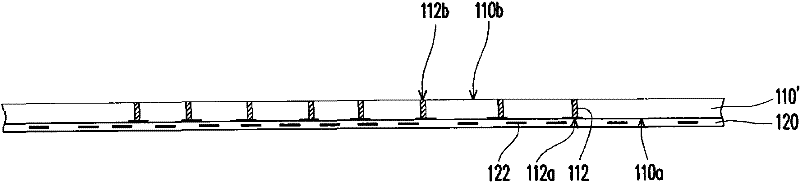

Thin film type semiconductor chip structure and photoelectric device using same

PendingCN113851563AEliminate shading effectHigh optical reflectivityOptical wave guidanceSemiconductor devicesOptical reflectionLight energy

The invention relates to a thin film type semiconductor chip structure. The structure is named as a light grid structure. According to the structure, metal materials are utilized, one of P-type metal and N-type metal is made to serve as a substrate, and the other metal serves as a metal side wall. The metal side wall is in insulated connection with the metal substrate to form a three-dimensional optical reflection cavity. The top of the optical reflection cavity is covered with a transparent conductive layer, and a photoelectric conversion layer is arranged in the optical reflection cavity, so that a light grid is formed. When the photoelectric conversion layer converts electric energy into light energy, the light grid become a light-emitting unit; and when the photoelectric conversion layer converts light energy into electric energy, the light grid becomes a generation unit of the electric energy. The three-dimensional light grid structure can only emit or collect photons through the plane where the transparent conducting layer of the optical reflection cavity is located. A plurality of light grids are gathered together to form a light grid array. The invention also relates to an optoelectronic device using the light lattice structure.

Owner:DR TECH CO LTD YIXING JIANGSU

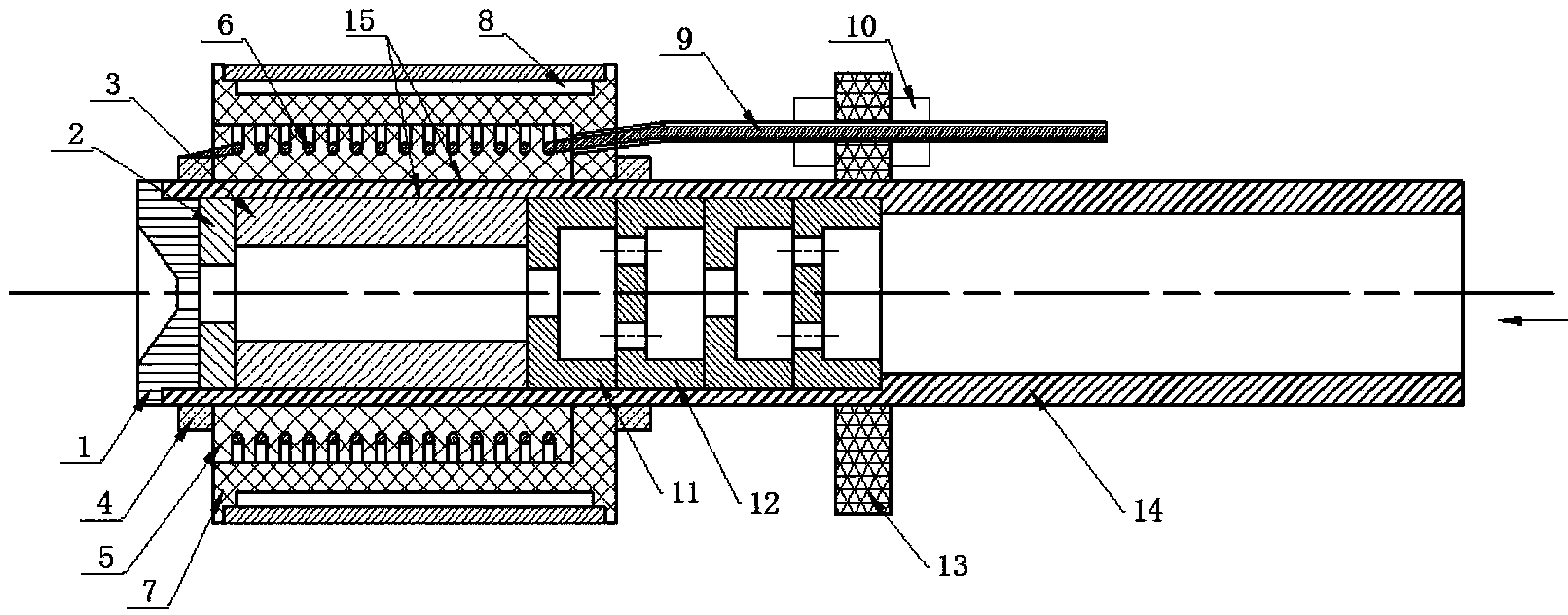

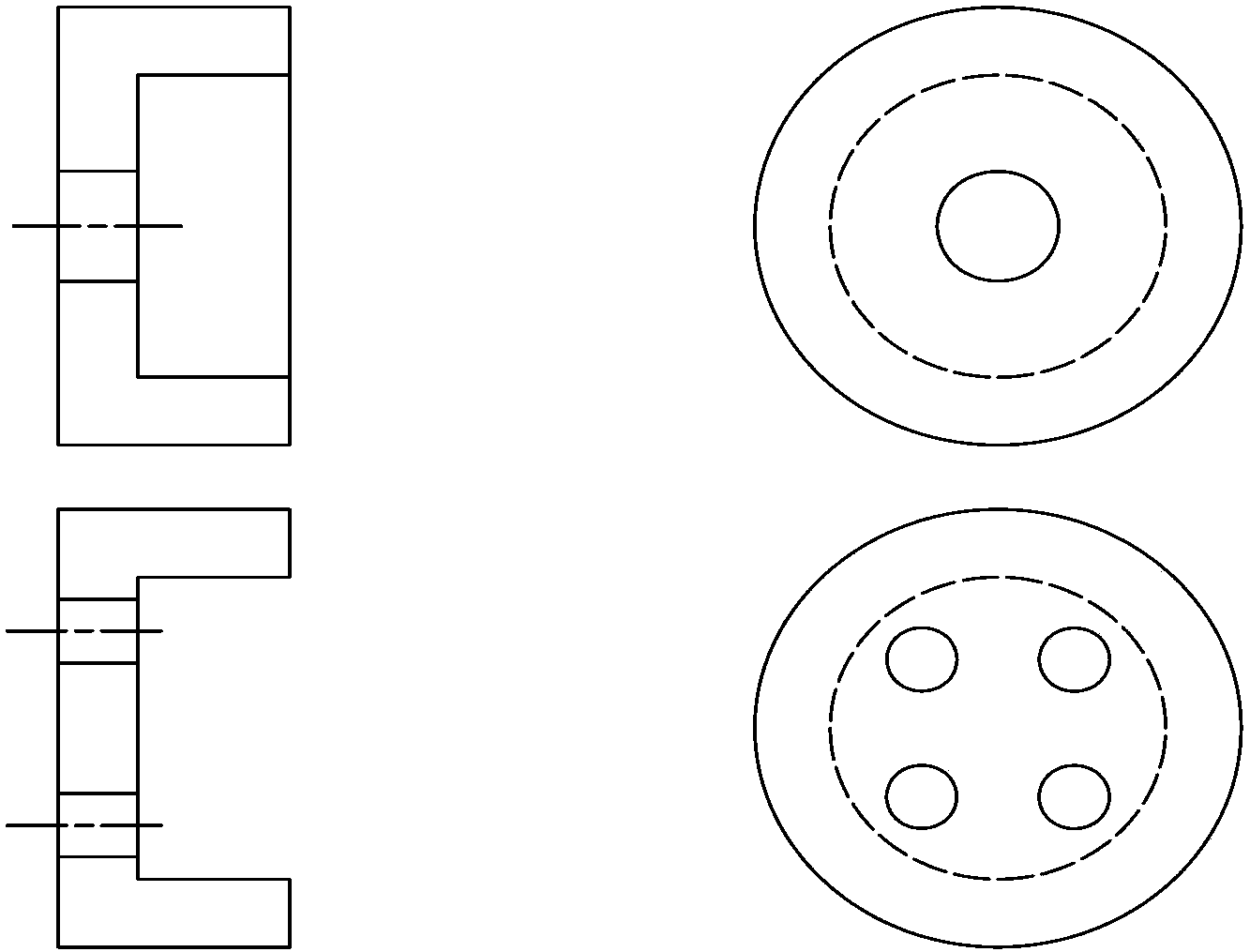

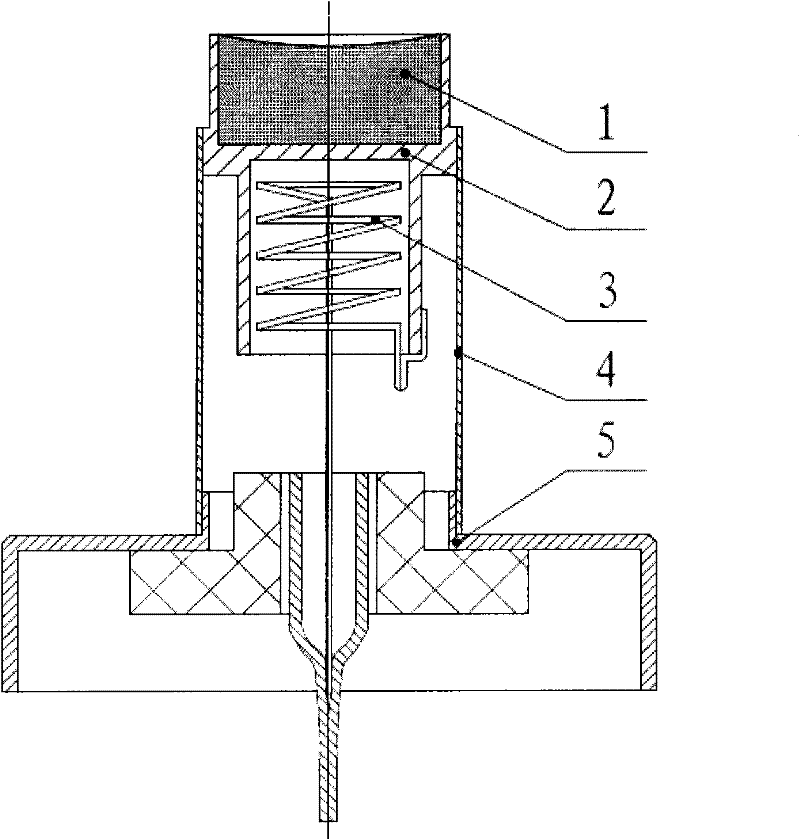

Hollow cathode assembly

InactiveCN102945778BImprove heating efficiencyStable emission currentMounting/support/spacing/insulation of electrode assembliesEngineeringHeat energy

The invention discloses a hollow cathode assembly and belongs to the field of a vacuum electronic technology. The assembly comprises a heater insulating barrel which is used as a hollow cathode, and a heat shielding barrel, wherein the heat shielding barrel is provided with a heat isolating groove; and a cathode tube is internally provided with single-hole and multi-hole inner separation rings which are alternatively arrayed. According to the hollow cathode assembly, the heater insulating barrel is arranged on the heat shielding barrel so as to reduce the contact area, reduce conduction heat energy, prolong a heat conduction path and reduce cathode heat energy loss; and the heater insulating barrel is arranged and is not reacted with a heater at a high temperature, so that the service life of the heater is prolonged, the service life of a cathode is prolonged and the hollow cathode assembly is applicable to majority of heat cathodes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Pot rack for preventing fragmentation of glass panel and gas stove

PendingCN110486759AAvoid chippingAvoid conductionDomestic stoves or rangesLighting and heating apparatusGas stovesAerospace engineering

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

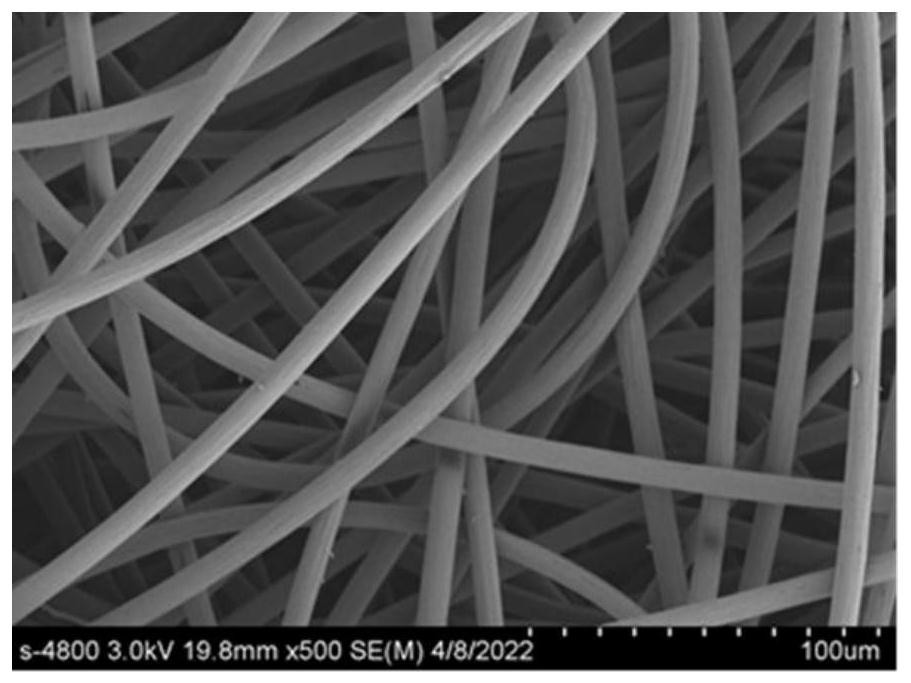

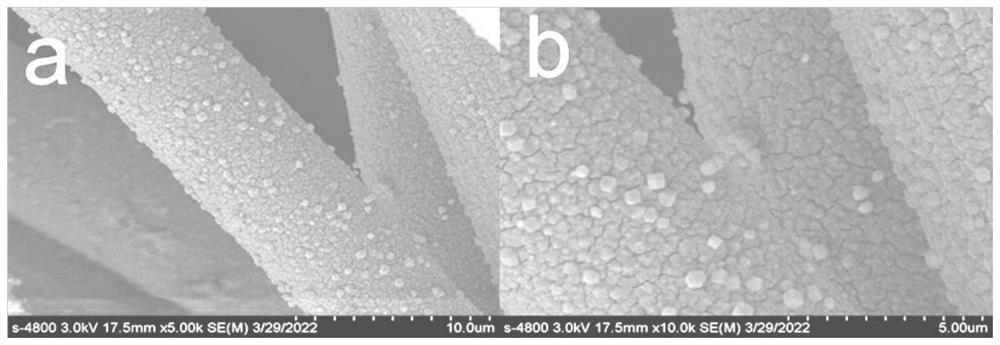

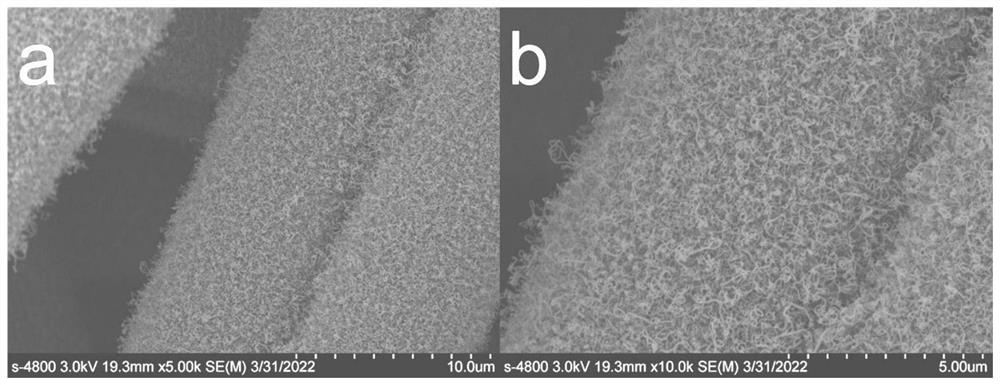

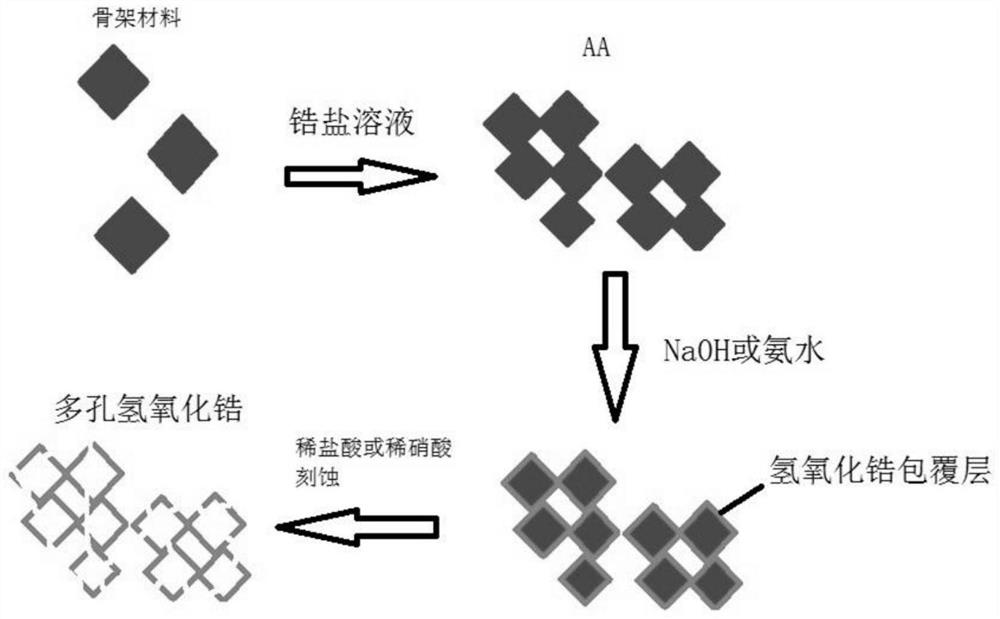

Carbon fiber felt and carbon nanotube/epoxy resin composite material and preparation method thereof

PendingCN114874584AHigh thermal conductivityReduce thermal contact resistanceEpoxyCatalytic pyrolysis

The invention discloses a carbon fiber felt and carbon nanotube / epoxy resin composite material and a preparation method thereof.The composite material is prepared by the steps that a carbon fiber felt serves as a template, after concentrated nitric acid modification and in-situ growth of ZIF-67 crystals are conducted, the carbon fiber felt with carbon nanotubes growing on the surface is obtained through the high-temperature catalytic pyrolysis and acid etching technology, and then the carbon fiber felt and the ZIF-67 crystals are obtained; and finally, preparing the carbon fiber felt and carbon nanotube / epoxy resin composite material by adopting a vacuum permeation epoxy resin process. A template pre-construction method is adopted, a carbon fiber felt framework is used as a template, adjacent carbon fibers are bridged and a heat conduction path is expanded by means of carbon nanotubes grown on the surfaces of the carbon fibers in situ, the contact thermal resistance between the carbon fibers is effectively reduced, meanwhile, a highly-interconnected three-dimensional network structure is constructed, and the heat conduction performance of the epoxy resin is effectively improved.

Owner:ANHUI UNIVERSITY

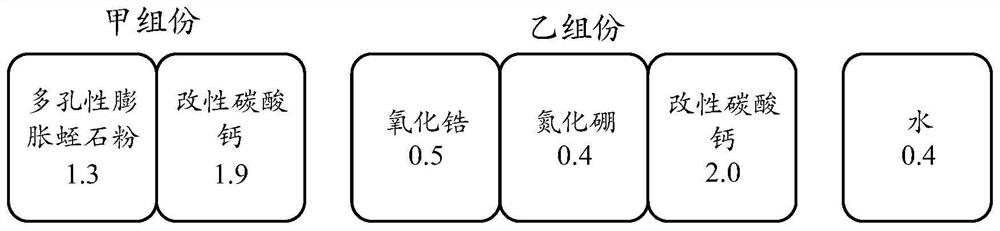

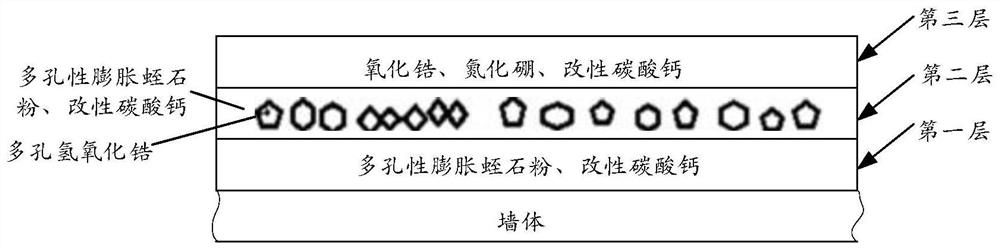

Building interior and exterior wall fireproof material containing nano-porous flame-retardant material

ActiveCN114381153ANo smokeHas completely non-combustible propertiesFireproof paintsAlkali metal silicate coatingsThermal insulationBoron nitride

The invention provides a building interior and exterior wall fireproof material containing a nano-porous flame-retardant material, the building interior and exterior wall fireproof material comprises a component A and a component B which are not mixed with each other or a component A and a component B and three components which are not mixed with each other, the component A comprises a heat insulation material, and the component B comprises a super-high-temperature-resistant fireproof material; wherein the thermal insulation material of the component A is used as a prime coat material and comprises a porous thermal insulation cooling material and a high-temperature-resistant inorganic coupling agent; the super-high-temperature-resistant fireproof material of the component B is used as a surface coating material and comprises a high-temperature-resistant inorganic coupling agent, zirconium oxide, boron nitride and / or aluminum phosphate. The material disclosed by the invention can keep a wall body at about normal temperature for a long time at the temperature higher than 1200 DEG C or above, so that the effects of heat insulation and fire prevention are achieved.

Owner:深圳市元亨高新科技高分子材料开发有限公司

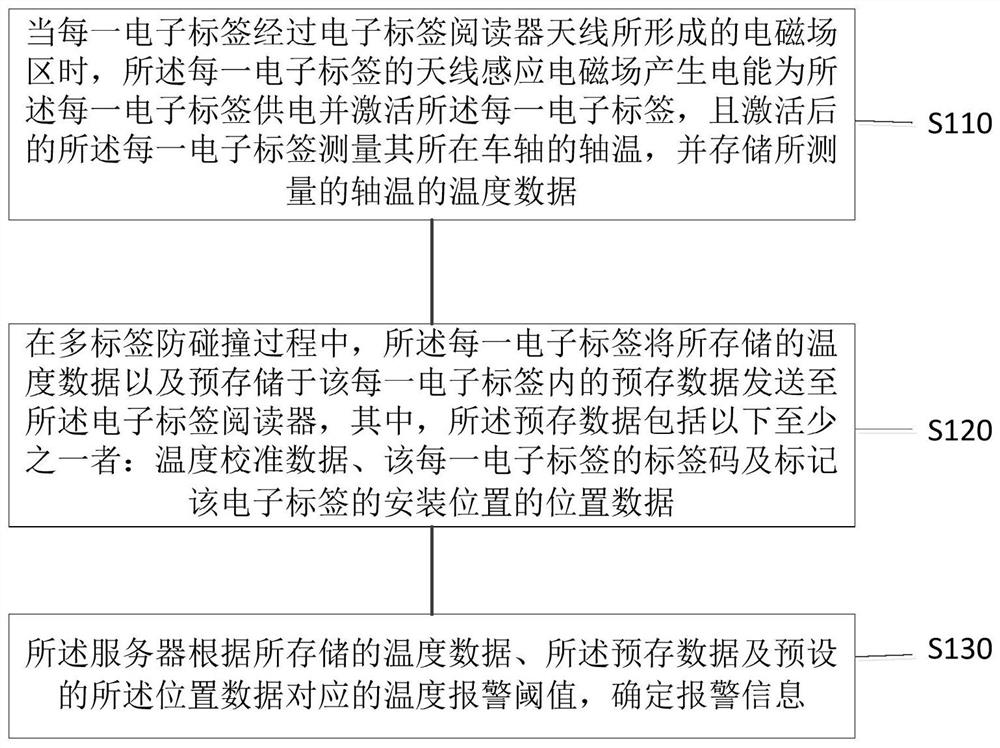

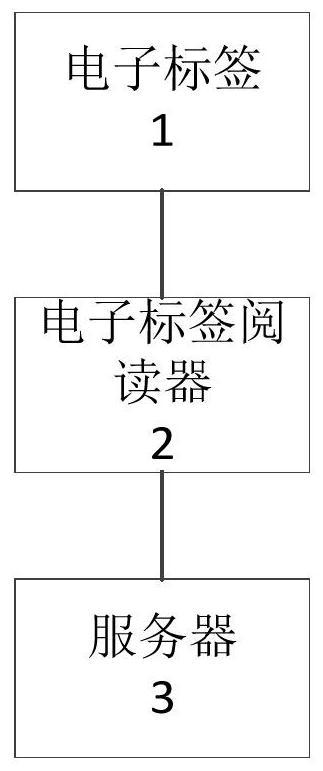

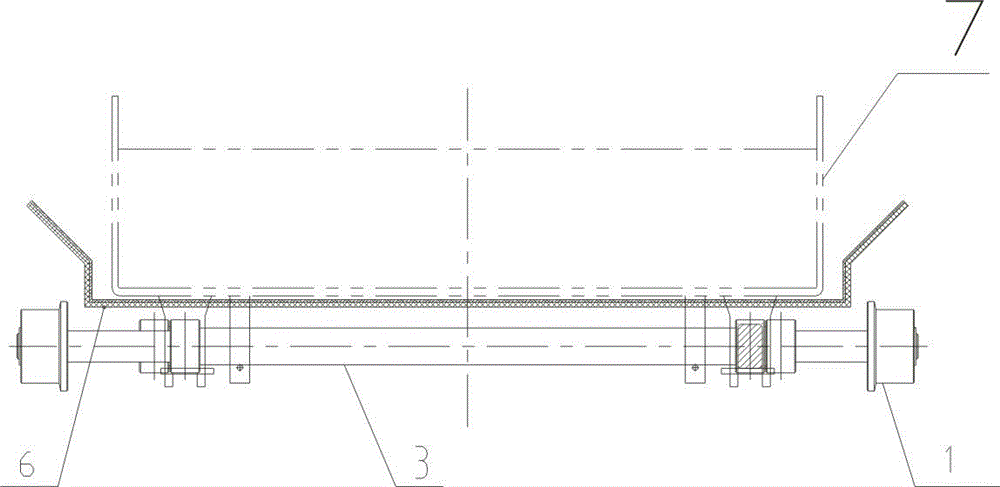

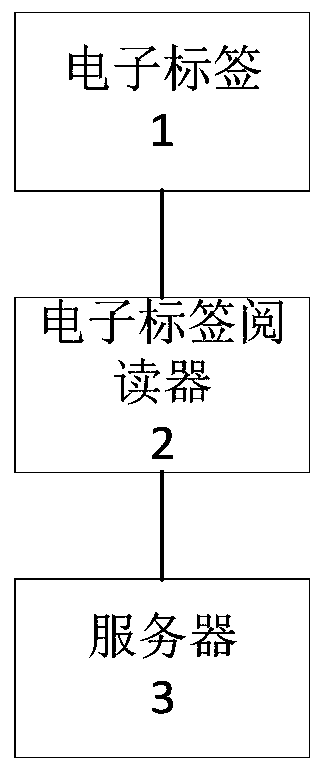

Axle temperature monitoring method and system for railway vehicles

ActiveCN110217261BReduce temperature measurement timeExtended heat conduction pathCo-operative working arrangementsRailway auxillary equipmentTemperature monitoringComputer science

Owner:CHINA SHENHUA ENERGY CO LTD +2

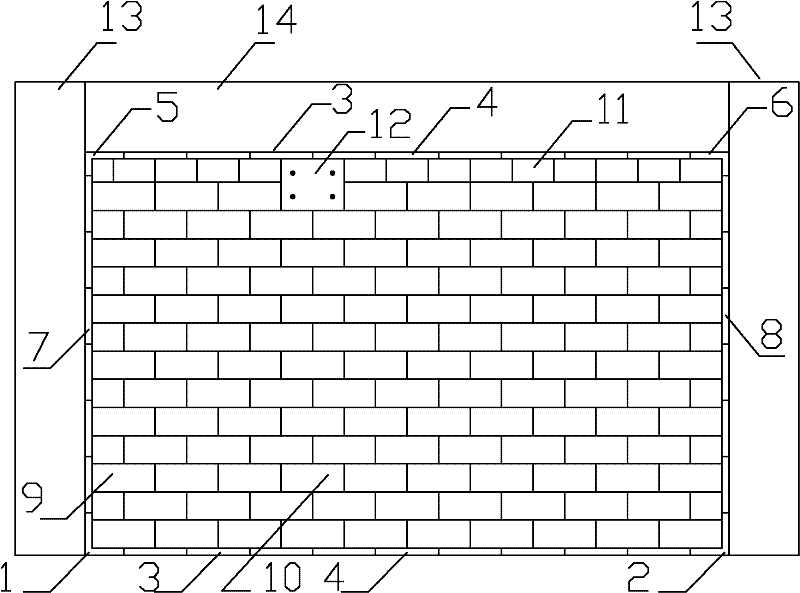

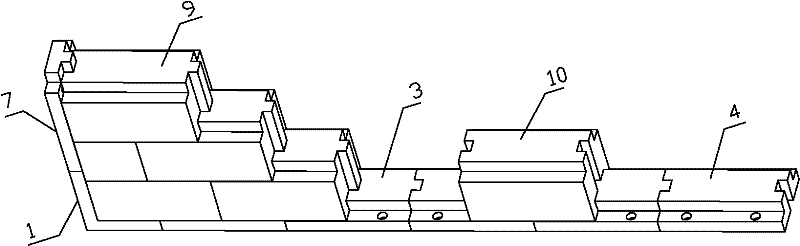

Wall body built by self-embedding insulation blocks

InactiveCN102071762BRealize dry operation constructionImprove ergonomicsConstruction materialWallsMaterial consumptionFlange

The invention relates to a wall body built by self-embedding insulation blocks, which comprises blocks including a bottom left type angle block, a bottom right type angle block, a horizontal side male-female type block, a horizontal side double-female type block, a top left type angle block, a top right type angle block, a vertical side left type block, a vertical side right type block, a wall body male-female type block, a wall body double-female type block, an edge folding layer block and a sealing block which are meshed with each other by matching a flange and a groove. Through the invention, the completely-dry construction of the wall body is realized without motar building, thereby simplifying the site construction process and improving the working efficiency of the wall construction; meanwhile, each block is made from the raw material of environmentally-friendly and recyclable plastic, has a hollow structure, and is filled with insulation material such as foaming plastic, thereby reducing material consumption of the building structure of the main body and reducing the weight of the wall body; and moreover, the mutually-meshed blocks improve the heat transfer path so that thewhole wall obtains obvious environmental protection, energy-saving and insulation effects.

Owner:SOUTHEAST UNIV

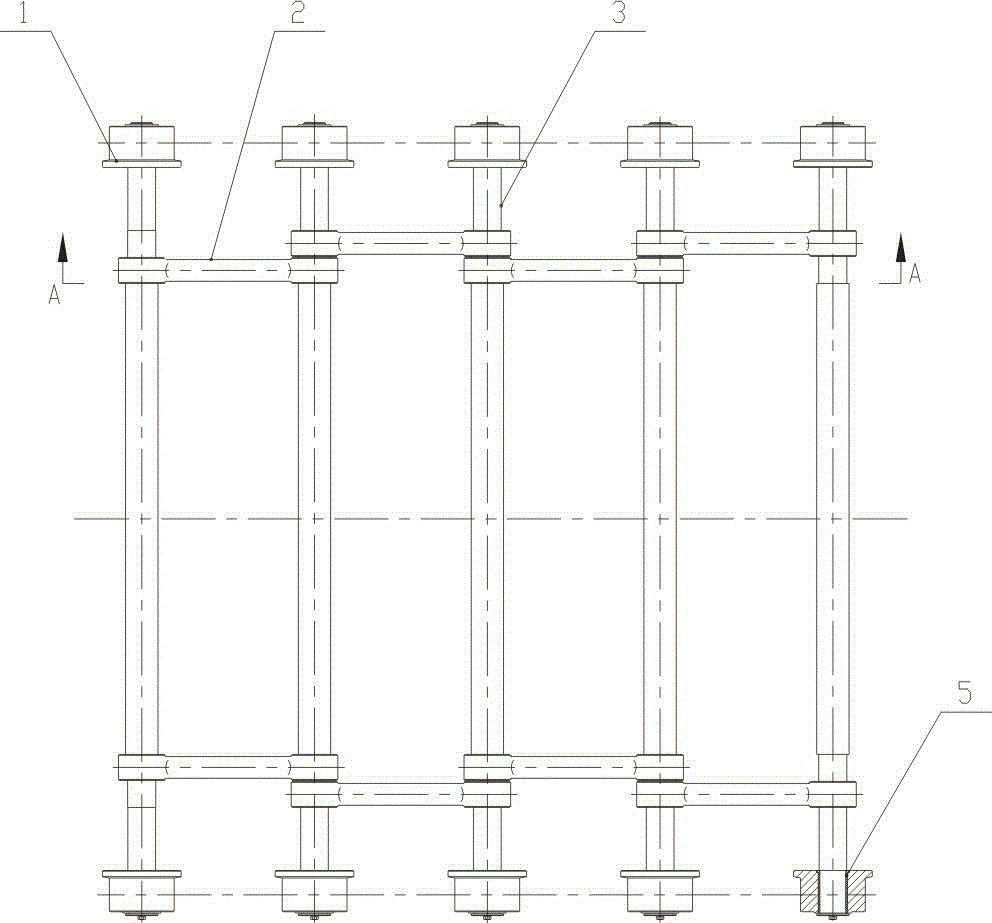

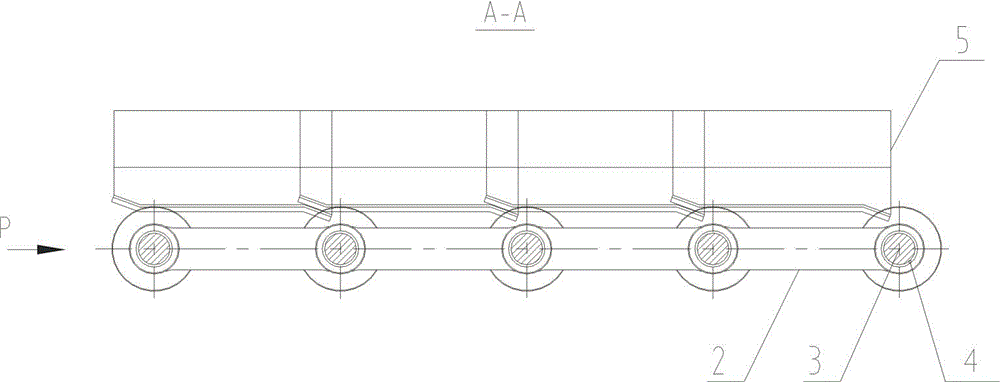

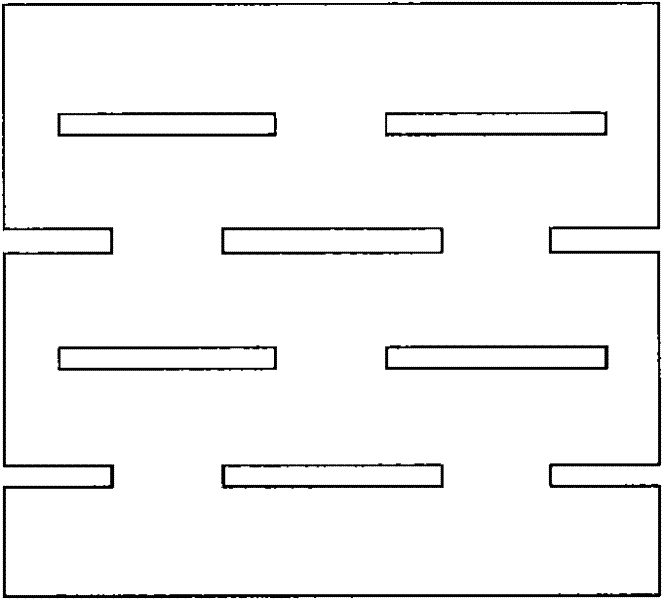

Heavy duty type high-temperature conveying chain

InactiveCN104787546AFirmly connectedWith high temperature resistanceConveyorsChinese charactersThermal insulation

A heavy duty type high-temperature conveying chain comprises a left row of chain bars and a right row of chain bars, the left row of chain bars and the right row of chain bars are connected in series by means of through shafts so as to form a grid shaped like the Chinese character 'jing', each chain bar is hinged to the corresponding through shaft through a self-lubricating bearing pad, each bearing sliding wheel is assembled on the corresponding through shaft through a sliding bearing, and a thermal insulation reflecting layer is installed on the grid shaped like the Chinese character 'jing'. The heavy duty type high-temperature conveying chain integrates the advantages of a bush roller chain, the advantages of a die-forged chain and the advantages of a mesh belt, is suitable for supporting trays or pans or hoppers or compartments containing high-temperature materials, and completes conveying tasks. The heavy duty type high-temperature conveying chain has the advantages that high temperature resistance is achieved, the conveying quantity is large, and secondary accessories are connected firmly and dismounted conveniently.

Owner:YIDU ZHONGQI HEAVY IND MASCH CO LTD

A kind of ultra-thin fireproof water-based paint and preparation method thereof

ActiveCN107254204BExtended heat conduction pathInhibition of convective heat transferFireproof paintsAlkali metal silicate coatingsWater basedThermal insulation

The invention belongs to the field of aqueous coatings and in particular relates to an ultrathin fireproof aqueous coating and a preparation method thereof. When the ultrathin fireproof aqueous coating is prepared, a component A and a component B are added, the component A comprises an aerogel precursor, stepless powder and the like, and the component B is used as a binding agent. The aerogel precursor is adopted as a core raw material to prepare the fireproof aqueous coating; as an aerogel material is of a nano three-dimensional structure and has characteristics that a solid heat conduction route is effectively prolonged, gas convective heat transfer is inhibited and thermal radiation is reduced, an aerogel fireproof coating made of the aerogel material has a thermal insulation property which is incomparable by conventional materials; after being applied to a steel material and dried, the ultrathin fireproof aqueous coating provided by the invention is relatively high in mechanical strength, achieves a fireproof grade A1, additionally has relatively good advantages of being waterproof and low in cost, and provides a novel material for buildings, environmental protection and industrial energy conservation.

Owner:广州蓝烟科技有限公司

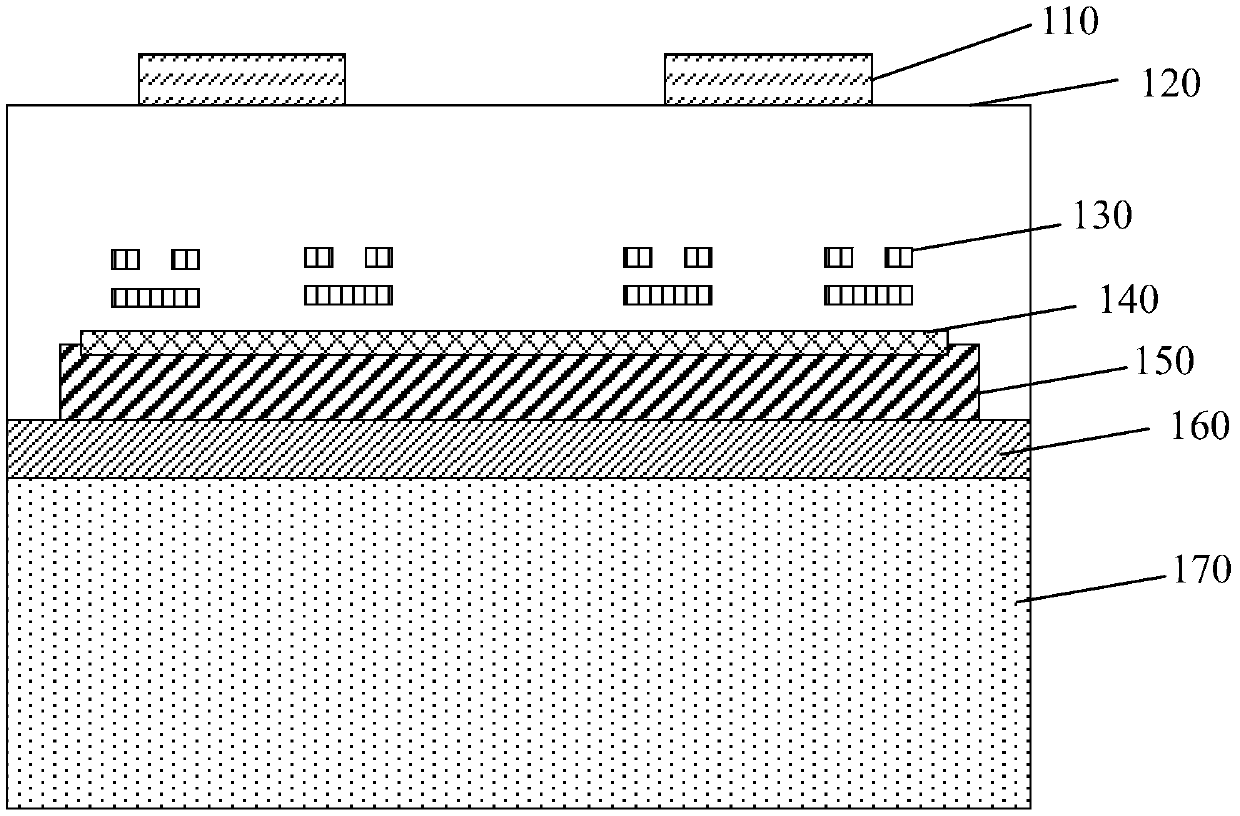

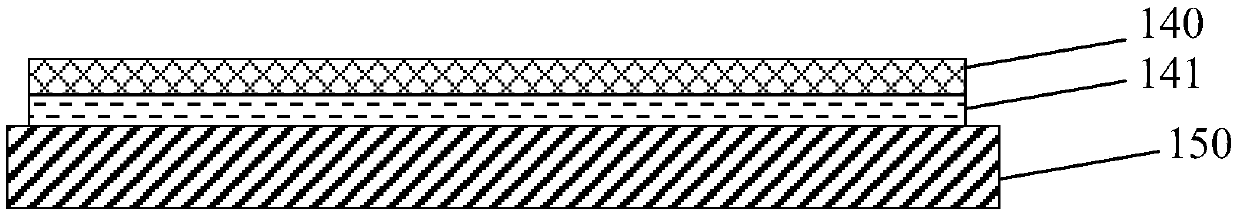

ICP etching machine and its insulating window film heater device and temperature control method

ActiveCN108022852BEasy to assemble and disassembleSimplify the maintenance processSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlThin membrane

The invention discloses an insulated window film heater device. The heater device comprises an electric insulation plate arranged at the top of an insulated window, an adhesive coating arranged on theelectric insulation plate and a film heater arranged on the adhesive coating; and the film heater is fixed to the electric insulation plate via the adhesive coating to form a heating module, and theheating module is fixed at the top of the insulated window via the electric insulation plate. The film heater is fixed on the electric insulation plate via the adhesive heater to form an integral body, the electric insulation plate is fixedly connected with the insulation window, the film heater is convenient to dismount and mount, the maintenance process of the film heater and the insulation window is simplified, and labor and time cost are reduced.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

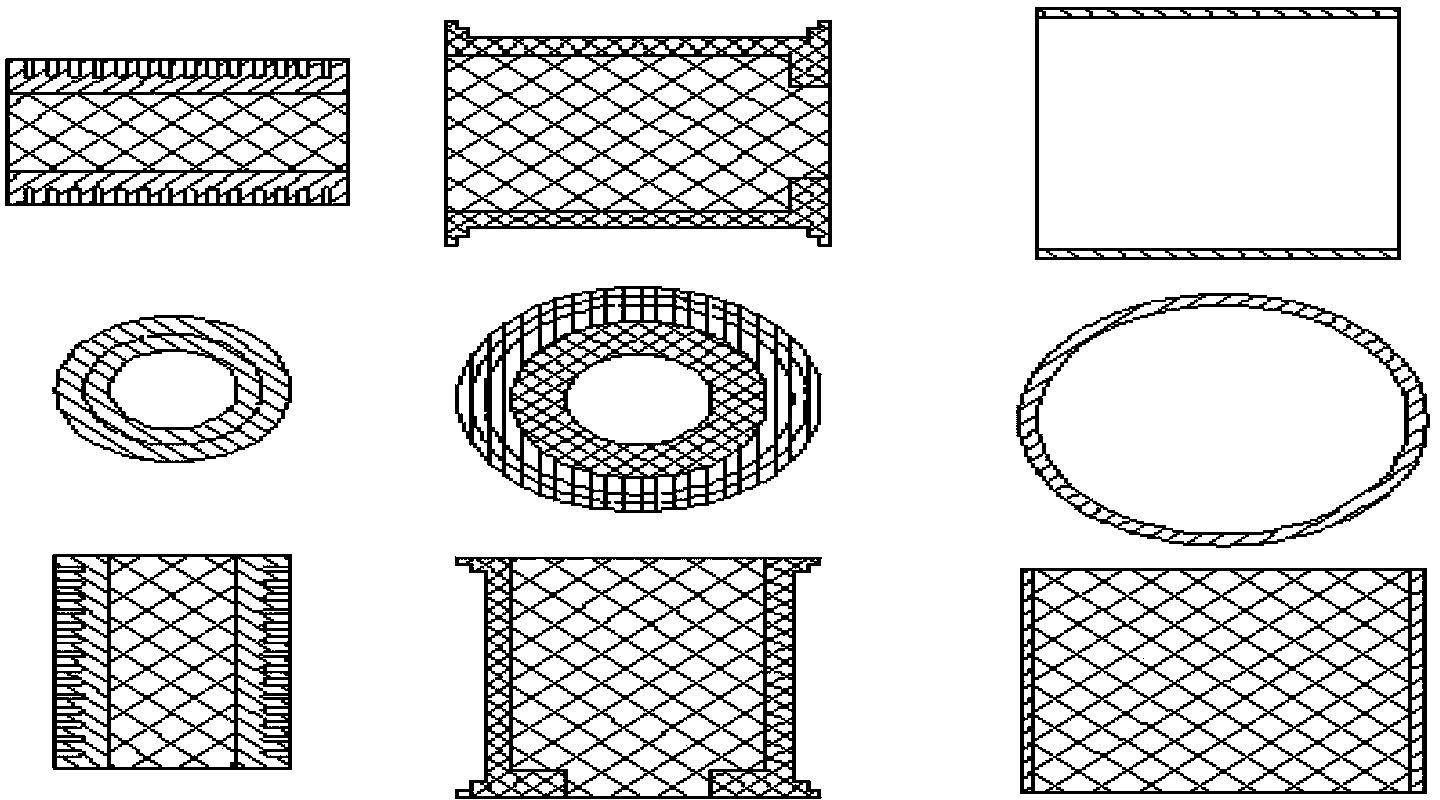

Structure for improving heating efficiency of cathode heater assembly and preparation method thereof

ActiveCN102087946BReduce heat transferHigh melting pointTransit-time tubesCold cathode manufactureControllabilityElectron

The invention discloses a structure for improving the heating efficiency of a cathode heater assembly and a preparation method thereof, relates to a vacuum electronic technology and is applied to development and production of space traveling wave tubes in wavebands X, ku and ka. A heat shield cylinder is made of a refractory metal or alloy leather with the thickness of 0.05mm. The heat shield cylinder is structurally a cylinder of which the surface is transversely provided with a heat insulation slot. The preparation method comprises the following steps of: processing the heat insulation slotwith the regular shape on the surface of the heat shield cylinder by adopting a spark cutting processing method; and carrying out local point connection between the heat shield cylinder and a cathodemolybdenum cylinder as well as a cathode base by using a point welding method. The cathode heater assembly with the structure has high reliability and a firm structure. By means of a method for lengthening a heat conduction path and reducing the contact surface, the conducted heat is reduced and the power consumption of a heater is obviously reduced, so that the heating efficiency of the cathode heater assembly is improved. The preparation method has the characteristics of simple process, low cost, strong controllability and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

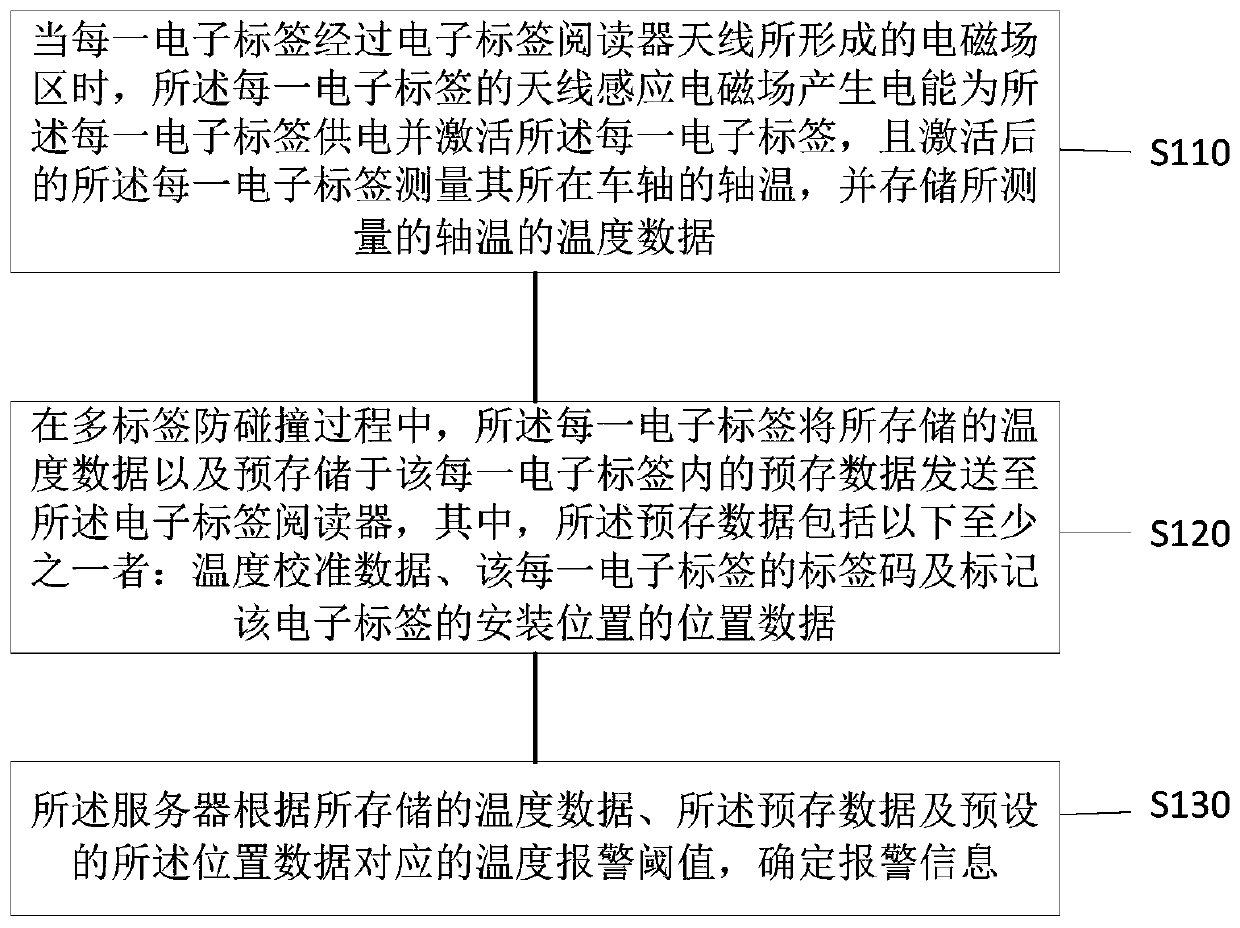

Railway vehicle axle temperature monitoring method and system

ActiveCN110217261AReduce temperature measurement timeExtended heat conduction pathCo-operative working arrangementsRailway auxillary equipmentAcquisition timeTemperature monitoring

The embodiment of the invention provides an axle temperature monitoring method and system for a railway vehicle, and relates to the field of axle temperature measurement; the axle temperature monitoring method comprises the following steps: each electronic tag measures and stores the axle temperature of the railway vehicle where each electronic tag is located based on an electric energy acquisition condition and a corresponding electric energy acquisition time of each electronic tag, wherein each electronic tag also stores pre-stored data comprising a tag TID / EPC code, temperature calibrationdata, and data related to an axle number, a bearing position number, an axle model, a bearing model and the like where a tag installation position is located; an electronic tag reader obtains the axletemperature and pre-stored data of the railway vehicle where each electronic tag is located, wherein the axle temperature and pre-stored data are stored in each electronic tag; and alarm informationis determined based on the axle temperature of the railway vehicle acquired by the electronic tag reader, the pre-stored data and a preset temperature alarm threshold value of the bearing position number. According to the method and system, the temperature measurement time can be reduced, and the temperature can be accurately monitored.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A kind of high thermal conductivity composite material and its preparation and application

ActiveCN111117063BDegradableGood heat transfer alignmentHeat-exchange elementsModifications by conduction heat transferPolymer scienceLiquid metal

The invention discloses a high thermal conductivity composite material and its preparation and application, belonging to the field of thermal conductivity composite materials. The invention mixes two-dimensional nanomaterials, liquid metal and cellulose nanofibers in water, then puts the mixed solution in an ultrasonic cell breaker, performs ultrasonic treatment on the mixed solution, and finally centrifuges and dries to obtain the thermally conductive filler. Subsequently, the obtained thermally conductive filler is dispersed in the polymer matrix to prepare a high thermally conductive composite material. The high thermal conductivity composite material of the present invention has good mechanical properties, excellent thermal conductivity and excellent flexibility, and has a wide range of applications in heat dissipation of electronic components, heat dissipation of printed electronics, and heat dissipation of 5G communication equipment.

Owner:SOUTH CHINA UNIV OF TECH

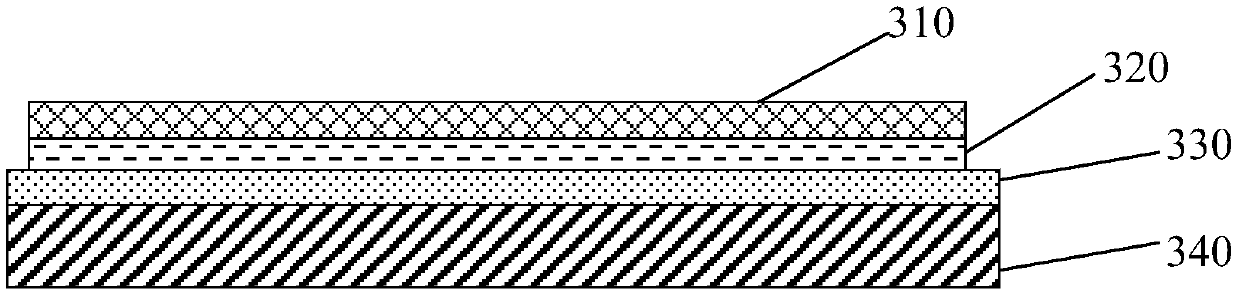

Semiconductor structure and manufacturing method thereof

ActiveCN101980360BImprove joint strengthImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureHeat conducting

The invention discloses a semiconductor structure and a manufacturing method. In the semiconductor structure, conductive through holes and a radiation layer are arranged on the periphery of the back side of a lower chip for improving the bonding strength of a radiation fin assembled subsequently and for providing a good heat conducting path for improving the radiation efficiency of the semiconductor structure. The invention also provides a manufacturing method of the semiconductor structure.

Owner:ADVANCED SEMICON ENG INC

Vacuum insulation panel core material with high performance and low cost and manufacturing method thereof

ActiveCN102330475BLow costThe overall thickness is thinGlass making apparatusClimate change adaptationGlass fiberSizing

The invention discloses a method for manufacturing a vacuum insulation panel core material with high performance and low cost. The method comprises the following steps of: pulping glass fiber cotton which is produced by a centrifuge method; diluting; screening; performing dehydration molding; performing pressure roller sizing; performing vacuum negative pressure dehydration; drying; cooling; and cutting. In the manufacturing method, the glass fiber cotton which is completely produced by the centrifuge method is used as a raw material of the vacuum insulation panel core material with high performance and low cost, the coefficient of thermal conductivity of the produced vacuum insulation panel core is between 0.003 and 0.008 W / m.k, and the coefficient of heat insulation is greatly improved;the thickness of the panel core material is between 0.5 and 30 mm, and the thickness is thinner; and the glass fiber cotton with the diameter of 3.5 to 5 mu m and the length of 5 to 20 mm has low cost and low overall manufacturing cost, and the overall cost of the vacuum insulation panel is lowered.

Owner:许立江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com