ICP etching machine and its insulating window film heater device and temperature control method

A temperature control method and thin-film heater technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as waste of labor and time costs, burden of cleaning the insulating window 150, and burning out of heating elements , to reduce the demand for maximum output power, save manpower and time costs, and increase the effect of heat conduction paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

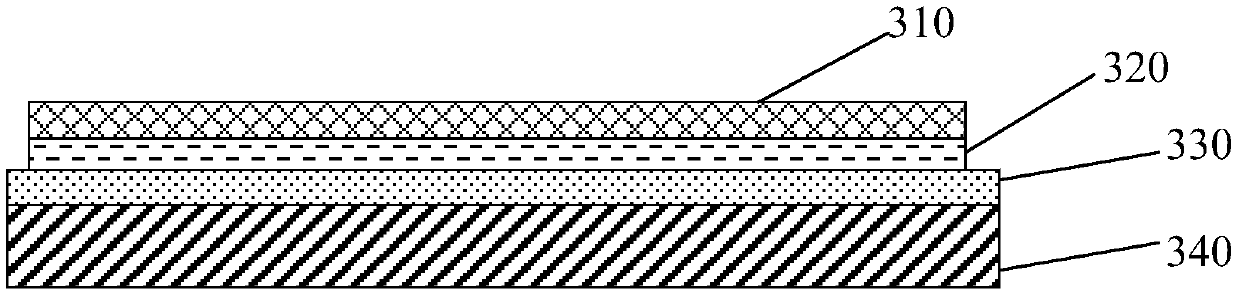

[0038] Such as image 3 As shown, it is a structural schematic diagram of Embodiment 1 of the insulating window thin film heater device, and the insulating window thin film heater device includes: an electric insulating plate 330 arranged on the top of the insulating window 340, an adhesive layer arranged on the electric insulating plate 330 320, and a thin film heater 310 disposed on the adhesive layer 320.

[0039] Both sides of the adhesive layer 320 are attached to the thin film heater 310 and the electrical insulating plate 330 respectively, so that the thin film heater 310 is fixed to the electrical insulating plate 330 through the adhesive layer 320 to form a heating module, and the heating module is fixed to the insulating plate 330 through the electrical insulating plate 330. Window 340 top.

[0040] The electrical insulating plate 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com