Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

245results about How to "Sound-absorbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material thermal insulation plate

InactiveCN1511808ANo pollution in the processStrong self-breathing functionThermal insulationSolid waste managementAdhesiveHeat conducting

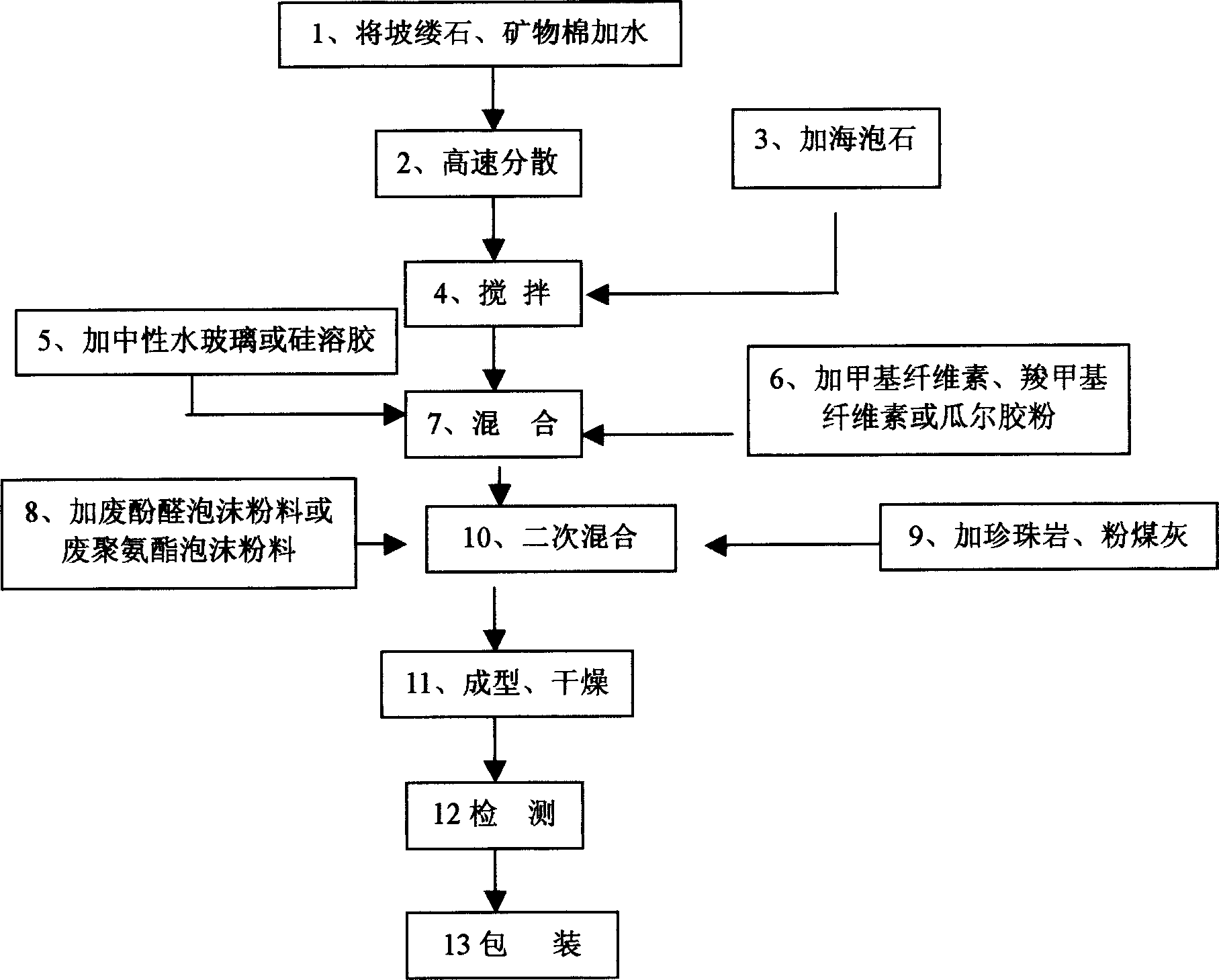

The thermal insulating plate of composite material is produced with waste foamed phenolic plastic powder as basic heat insulating material, flyash as stuffing, expanded perlite as aggregate, mineral wool, glass wool, sepiolite and palygorskite as reinforcing material, neutral water glass or silica sol as inorganic adhesive and guar gum, methylcellulose or CMC as organic adhesive, and through high speed dispersion, stirring, mixing, molding, forming and drying. The thermal insulating plate has low heat conducting coefficient, is non-inflammable, smell-less, non-toxic, long in service life and wide in application range. The production process adopts industrial waste as main components and produces no waste, and used plate may be reused, so that the present invention is significant in environment protection.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

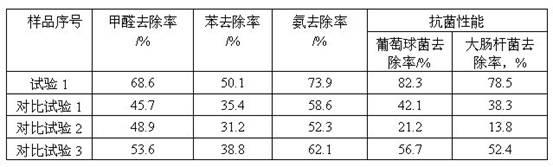

The invention belongs to the technical field of inorganic materials and in particular relates to a kieselguhr-based environmentally-friendly glaze material for an inner wall brick and the inner wall brick prepared by using the same as well as a preparation method. The kieselguhr-based environmentally-friendly glaze material for the inner wall brick comprises kieselguhr, a nano TiO2 / tourmaline composite material, a sintering adjuvant, ceramic pigment, a dispersing agent and water, wherein the weight ratio of kieselguhr to nano TiO2 / tourmaline composite material to sintering adjuvant to ceramic pigment to dispersing agent to water is (40-92):(6-40):(2-15):(0-8):(0.1-4):(60-250). According to the invention, a functional raw material nano TiO2 / tourmaline composite material is introduced in the environmentally-friendly glaze material for the inner wall brick, and the functional raw material has multiple functions of obviously dispelling poisonous and harmful gases such as formaldehyde, ammonia, benzene, volatile organic compound (VOC) and the like which are released by various decoration and finishing materials, furniture and the like, releasing negative ions, resisting bacterium and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for preparing fiber wallboard through wet process

InactiveCN101638874ALarge stockWide variety of sourcesWater-repelling agents additionPaper/cardboardFiberHigh intensity

The invention discloses a method for preparing a fiber wallboard through a wet process. The method comprises the following steps: 1) pulping: mixing non-wood type natural plant fiber pulp with gramineous plant pulp according to a dry weight ratio of 1:0-1.5 and adding water into the raw materials to dilute the pulp; 2) storing the pulp: placing the obtained mixture pulp into a pulp storage pond and adding water for dilution; 3) carrying out suction filter and formation: inputting the pulp obtained from the previous step into a die cavity for cold-pressing, dehydration and formation so as to obtain a wet blank; and 4) carrying out hot-pressing formation and drying; transferring the wet blank into a hot-pressing mould for hot pressing, removing water generated during the hot pressing, and obtaining the fiber wallboard. The fiber wallboard obtained by using the method has the characteristics of environment-friendliness and high strength.

Owner:陈集双

Composite interior material for motor car and preparation method thereof

InactiveCN102619022AGood compatibilityImprove functionalityNon-woven fabricsAdhesivesWork in processHot pressing

The invention relates to a composite interior material for a motor car and a preparation method thereof. The composite interior material comprises 60-80% of high performance fibers, 10-20% of flame retardant fibers and 10-20% of hot-melt fibers; and the preparation method comprises the following specific steps of: 1) opening the high performance fibers, the flame retardant fibers and the hot-melt fibers by a bale opener; reopening the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a rough opener; and then mixing the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a cotton blending machine; finely opening the mixture by using a fine opener; and combing the mixture by using a carding machine; 2) by using a nonwoven needle-punched machining technology, lapping the combed fibers in a cross way by a lapping machine; and then carrying out needle punching on the fibers by using a needle machine; and processing the fibers by using a singeing machine and a glazing calendar; and 3) carrying out composite hot pressing on a fiber felt which is a needle-punched, singed and calendared semi-finished product; and finally, forming the composite interior material together with a thermoplastic resin.

Owner:NANTONG UNIVERSITY +1

Method for producing ceramic tile using polished waste material

The waste material collected from polish waste water and waste slag via deposition, press filtering and ageing is mixed with high temperature sand, kaolin and low temperature sand. The mixture is wet milled in a ball mill, 250-mesh sieved, iron eliminated and spray dried to form powdered material; the powdered material is dry formed into ceramic tile adobe in a ceramic press; and the ceramic tile adobe is baked in a roller hearth kiln at 1140-1200 deg.c in 40-75 min. The said method utilizes the waste reasonably and the product has excellent performance.

Owner:FOSHAN OCEANO CERAMICS

Sound absorptive environment protection paint

InactiveCN1425720ASound-absorbingImprove tensile propertiesRadiation-absorbing paintsEmulsion paintsHigh resistanceHigh wear resistance

The present invention relates to building material and is especially a kind of building material with floating bead. The sound absorbing environment protecting paint consists of paint and floating flyash bead, which has specific weight of 0.38 and accounts for 1-3 % of the total weight. Owing to porous and light floating bead, the paint has excellent sound absorbing effect; and owing to high strength and high wear resistance of floatinb bead, the paint has high tensile strength and good color and luster.

Owner:梅派

Vacuum insulation panel core material with high performance and low cost and manufacturing method thereof

ActiveCN102330475ALow costThe overall thickness is thinClimate change adaptationInsulation improvementGlass fiberSizing

The invention discloses a method for manufacturing a vacuum insulation panel core material with high performance and low cost. The method comprises the following steps of: pulping glass fiber cotton which is produced by a centrifuge method; diluting; screening; performing dehydration molding; performing pressure roller sizing; performing vacuum negative pressure dehydration; drying; cooling; and cutting. In the manufacturing method, the glass fiber cotton which is completely produced by the centrifuge method is used as a raw material of the vacuum insulation panel core material with high performance and low cost, the coefficient of thermal conductivity of the produced vacuum insulation panel core is between 0.003 and 0.008 W / m.k, and the coefficient of heat insulation is greatly improved;the thickness of the panel core material is between 0.5 and 30 mm, and the thickness is thinner; and the glass fiber cotton with the diameter of 3.5 to 5 mu m and the length of 5 to 20 mm has low cost and low overall manufacturing cost, and the overall cost of the vacuum insulation panel is lowered.

Owner:许立江

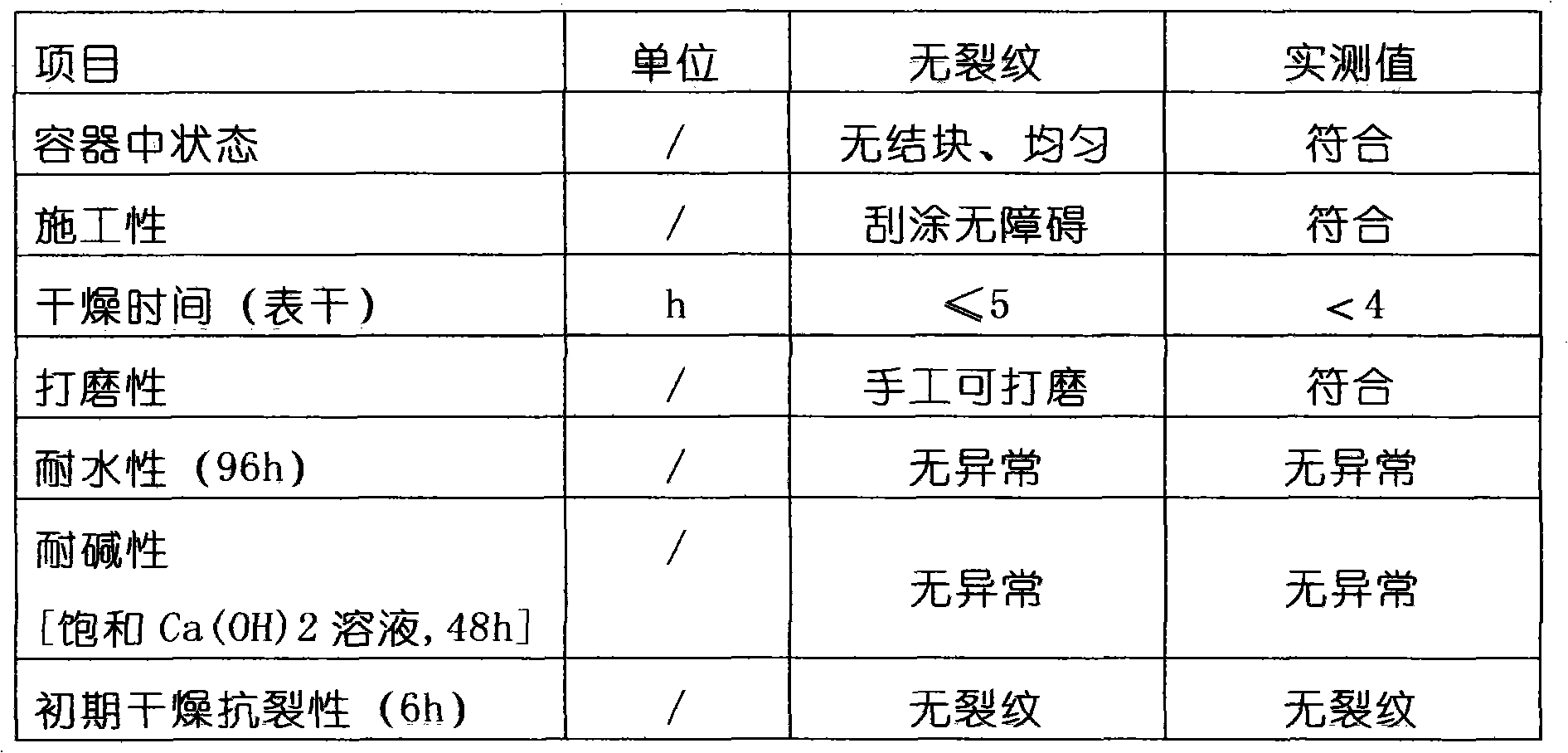

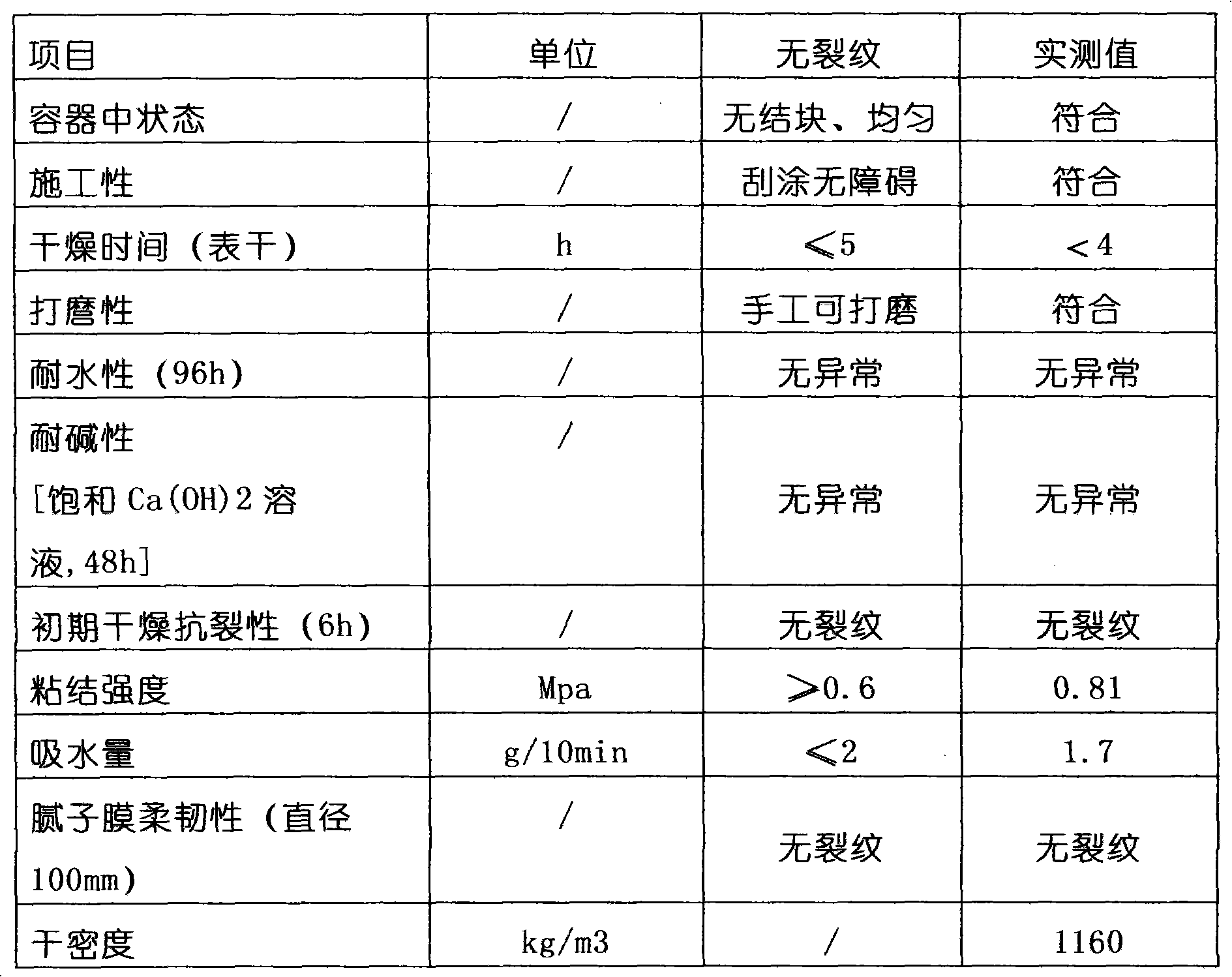

Energy-saving leveling putty powder

The invention relates to energy-saving leveling putty powder, which is characterized by being prepared from the following raw materials in percentage by weight: 20 to 30 percent of white cement, 5 to 10 percent of gray calcium powder, 40 to 60 percent of heavy calcium carbonate powder, 5 to 15 percent of 50 to 100-mesh light sand, 0.1 to 1 percent of reinforcing fiber, 0.1 to 1.5 percent of polyvinyl alcohol, 0.1 to 1.8 percent of cellulose and 1 to 3 percent of polymer powder, wherein the light sand is polyphenyl particles, vitrified micro bubbles or expanded perlite; the reinforcing fiber is 2-mm polypropylene fiber; and the cellulose is carboxymethyl cellulose. The energy-saving leveling putty powder has the characteristics of high strength, high water resistance, no toxicity or odor, yellowing resistance and the like; moreover, by adding the light sand with heat preservation and thermal insulation function, the putty powder has the obvious characteristics of light weight, heat preservation, high thermal insulation, abrasion resistance, corrosion resistance, high electric insulating performance, radiation protection and the like, while the basic performance is ensured.

Owner:陈文光

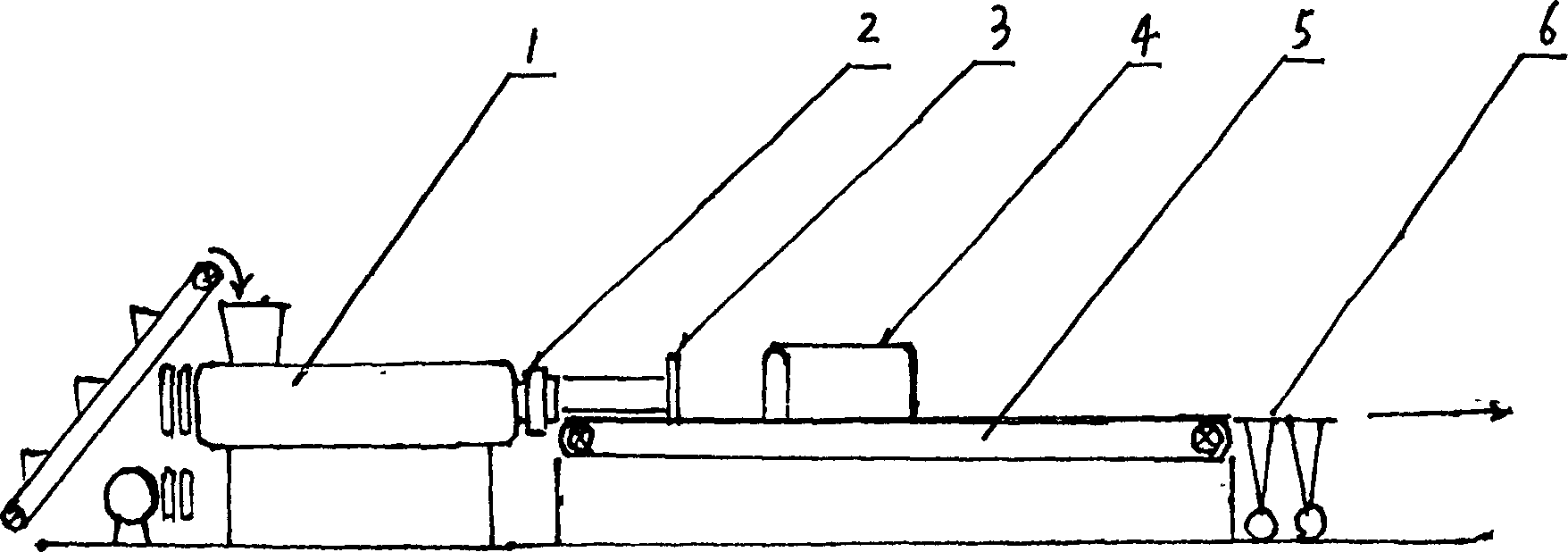

Manufacture method of core material of vacuum heat insulation plate

ActiveCN101775850AFlame retardantSatisfied flame retardantClimate change adaptationInsulation improvementHigh volume manufacturingFire resistance

The invention provides a manufacture method of a core material of a vacuum heat insulation plate through aiming at the problem of high cost of the core material of the vacuum heat insulation plate in the prior art. The method comprises the following steps: rock wool fiber pulping and net covering; shaping and rolling; vacuum dehumidifying; and cooling and material forming. The invention adopts the rock wool fiber, and the produced core material of the vacuum heat insulation plate can satisfy performance required by the core material of the vacuum heat insulation plate , and also has the obvious advantages of fire resistance, sound absorption and the like. More importantly, the production process is simple, and the invention can meet the requirement of fast mass production of building industry.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Multifunctional composite ornamental board

InactiveCN101220702AReduce generationEasy to useCovering/liningsMoisture absorptionVibration isolation

The invention discloses a multifunctional compound decorative board, which includes a decoration surface, a gluing layer, a plate bottom and a functional material and is characterized in that the decoration surface and the plate bottom are compounded with one or more functional materials (the various functional materials can be mutually overlapped, covered, permeated or mixed); the decoration surface is bonded on the plate bottom and the plate bottom is bonded on the functional material; the functional material can be selected from heat insulating material, sound-proof material, vibration isolation material, damping material, hazardous material or gasses adsorption material, beneficial matters releasing material, flame retardant and fireproof material, sound absorbing material, moisture absorption and moistureproof material, etc., therefore, a compound multifunctional heat-insulating, sound-insulating, vibration-isolating, noise-absorbing, environment-protective, flame-retardant, fire-fighting, moisture-absorbing and moistureproof decorative board can be produced.

Owner:刘涛

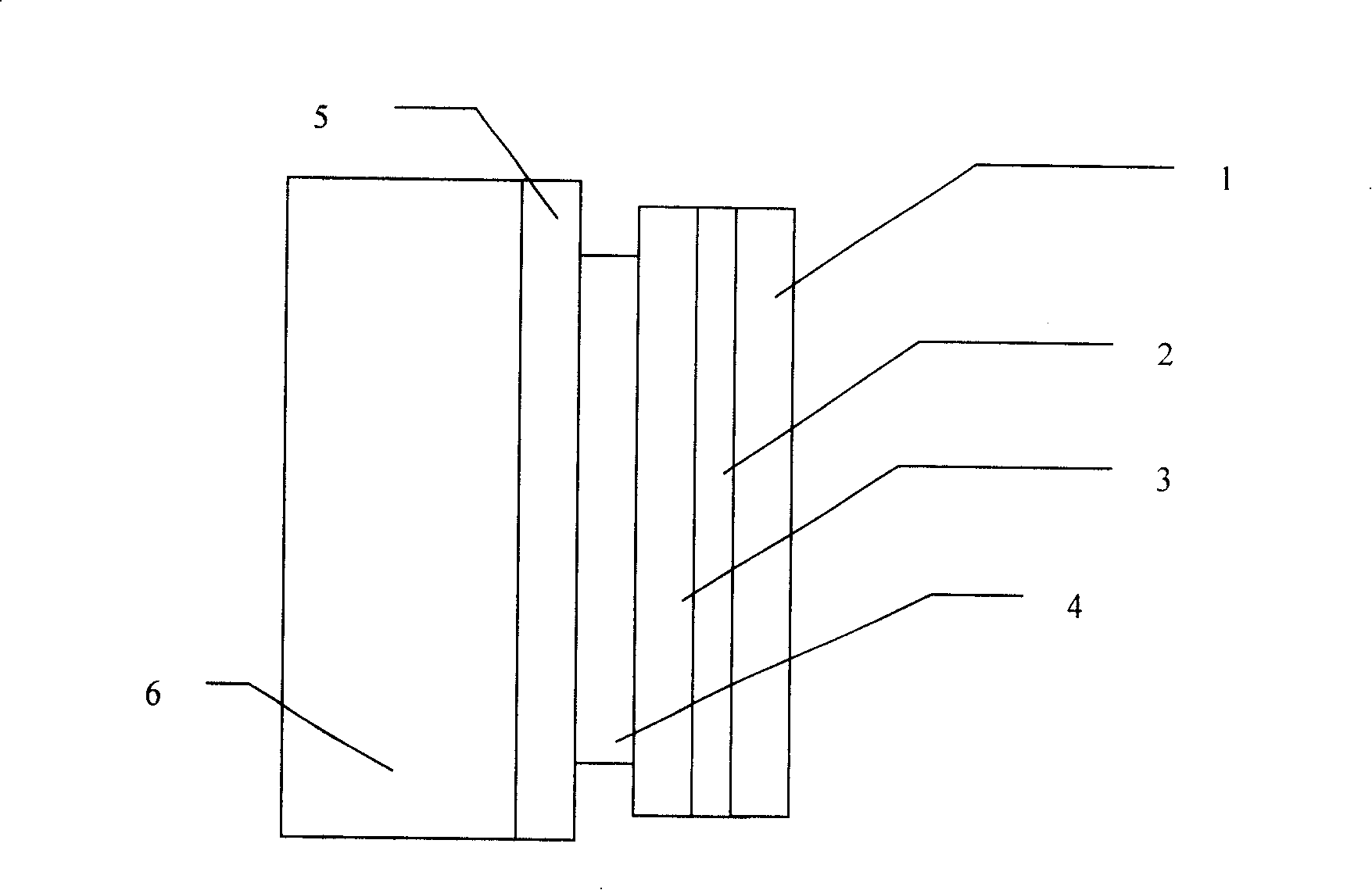

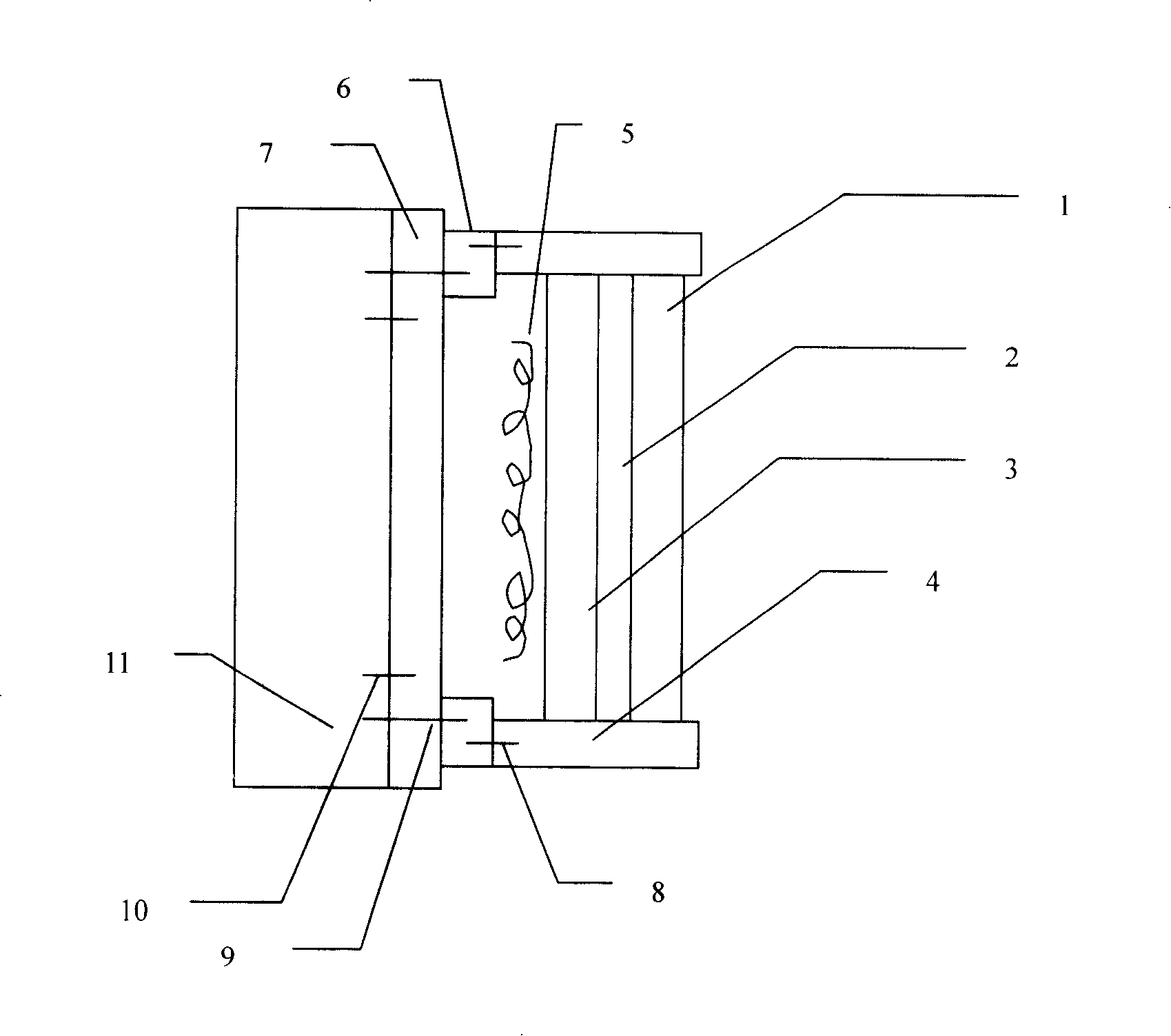

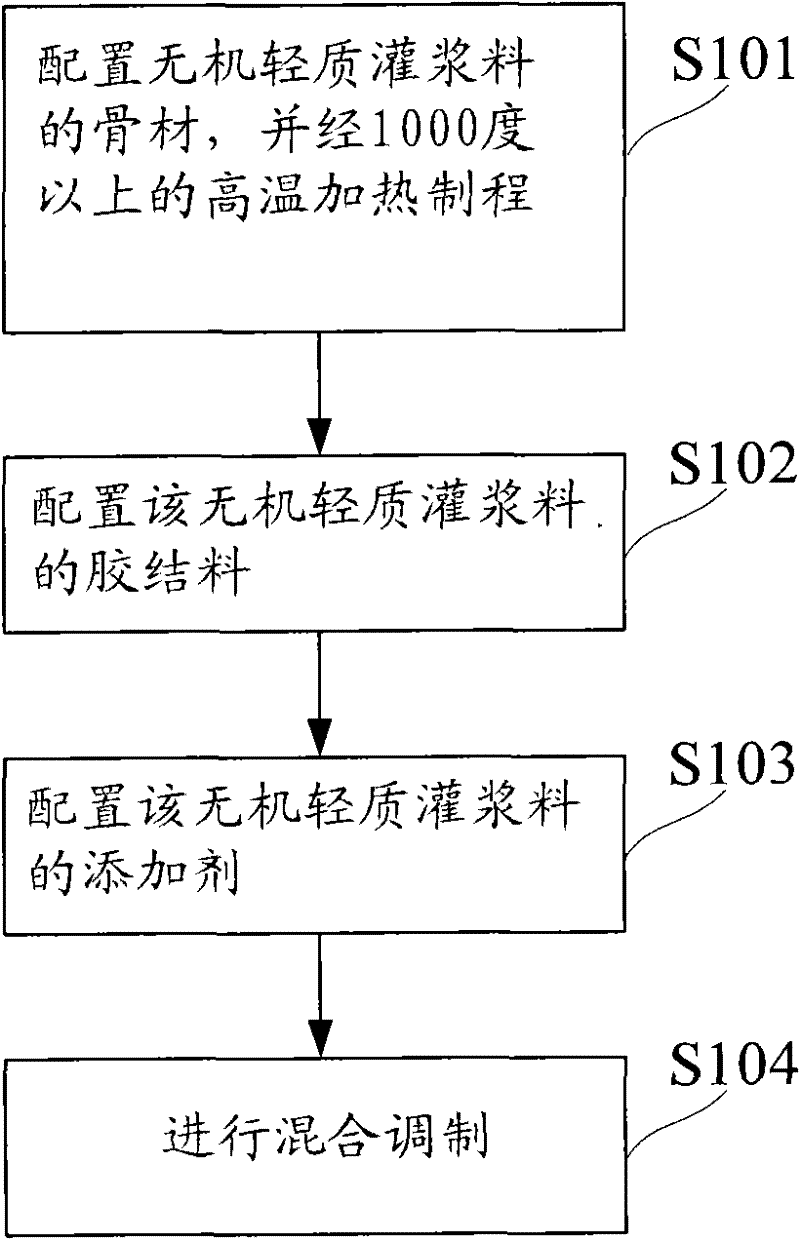

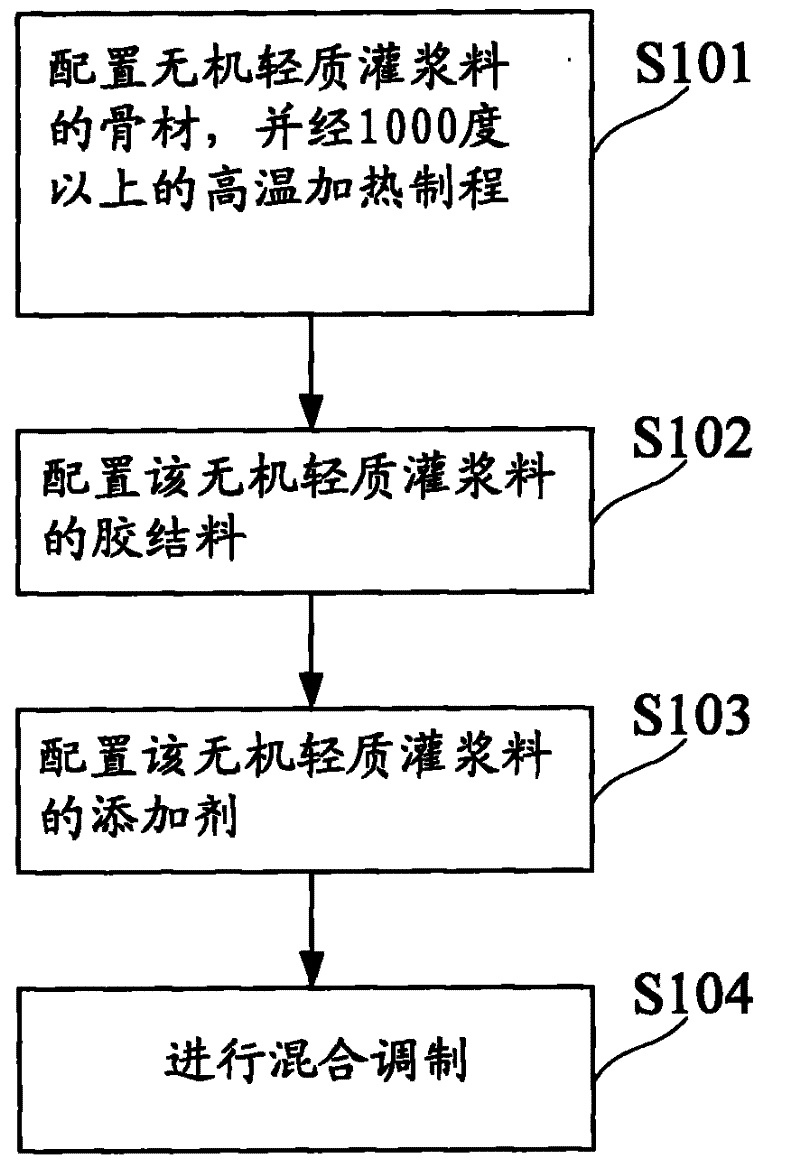

Inorganic lightweight grouting material, and manufacture method thereof

The invention discloses an inorganic lightweight grouting material, and a manufacture method thereof. The inorganic lightweight grouting material provided by the invention is manufactured from a low-density, surface-sealed and inside-hollow granular expanded ore such as pitch stone or perlite as main raw material, a powdery adhesive, an additive and the like through blending at a proper ratio. The inorganic lightweight grouting material is practically used by adding water according to a certain ratio, uniformly stirring, pouring into building wall and carrying out hydration reaction to form the grouting material for wall filling. The grouting material has the advantages of slight expansion, low specific gravity (smaller than water), good heat preservation and fireproof effects, strong high-temperature resistance, good sound absorbing property, low cost, etc.

Owner:古金盛 +1

Steel slag and cement stabilized base material

The invention provides a steel slag and cement stabilized base material comprising components of steel, cement, water, and an additive. The weight ratio of steel to cement to water is 100:4-6:4-6; and the weight of the additive is 0.6-6% of the weight of cement. According to the invention, graded steel slag serves as an aggregate, and is used for replacing crushed stones. The voids of the aggregate are filled by using a certain amount of a cementing material and the volume of enough mortar. The materials are paved and compacted according to an interlocking principle. The strength of the base is high. With increasing age periods, the base rapidly turns into a board body. Therefore, the material has high strength, high water permeability and high freezing resistance. The material can be used in road base constructions.

Owner:MCC BAOSTEEL TECH SERVICE

Plastic wood composite floor

The invention relates to the technical field of civil construction plate, particularly to a plastic wood composite floor, which comprises a PVC floor surface layer and a plastic-wood substrate, the PVC floor surface layer and the plastic-wood substrate are cemented together through environment-protective waterproof glue. Since the PVC floor with various color and good waterproof performance is selected as the surface layer, users can choose the color of indoor floor according to personal taste. Meanwhile, the plastic-wood substrate is adopted and cemented under the PVC floor surface layer by glue, thus, comparing to conventional PVC floor, the invention has the advantages of convenient paving, low paving cost, and leaving no welding seams after pavement.

Owner:CHANGZHOU DONGJIA DECORATIVE MATERIALS

Cystosepiment for passenger car inner decoration ceiling

The present invention discloses a decorative bubble panel used in vehicles, in particular to a bubble panel for a canopy of inner decoration, which is characterized in that the bubble panel is produced by a froth technology of the following weight percentage of materials: a mixture of polyether polyol and polyester polyol which comprises 40-60 percent of polyether polyol, 0.8-1 percent of bubble stabilizer should be added, material A comprises 3-5 percent of water and 0.08-0.1 percent of amine activator, mixed with isocyanate(material B) to create a combined material, with a froth proportion of A:B=1:1.3-1.5, be frothed to form a bubble panel for a canopy of inner decoration; the production is characterized in even density, good structure of bubble holes and high pressure resistance, washing out ODS completely, stopping the destruction of the ozonosphere of the atmosphere radically.

Owner:YANTAI ZHENGHAI HIGH TECH

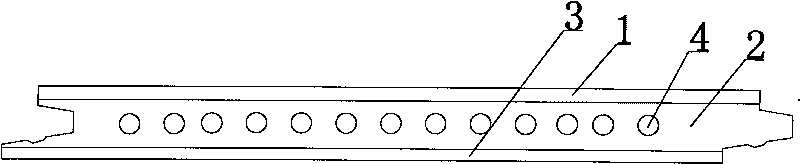

Composite efficient energy-saving heat-insulating material, and its manufacturing method and special apparatus

InactiveCN1470471AGood vacuum insulation effectGood heat insulationThermal insulationPipe protection by thermal insulationFiberSodium Bentonite

The composite high-effective energy-saving heat-insulating material comprises the following components: aluminium silicate fibre, glass fibre, quick T, sepiolite, brucite, expansive pearlite, piaozhuor diatomite, bentonite, catalyst and adhesive. Its production method includes the following steps: placing the soaked aluminium silicate fibre, glass fibre and quick T into stirring machine to obtain slurry material, adding sepiolite and brucite, then adding expansive pearlite and piaozhu, adding bentonite, catalyst and adhesive, stirring them to obtain paste-like finished product, pipe blank and wall plate blank material respectively.

Owner:谢文丁

Silicone rubber composite material with gradient bubble structure, and preparation method of silicone rubber composite material

The invention belongs to the field of silicone rubber foam materials, and relates to a silicone rubber composite material with a gradient bubble structure, and a preparation method of the silicone rubber composite material. The invention provides the preparation method of the silicone rubber composite material with the gradient bubble structure. The preparation method comprises the following steps: (1) preparing a silicone rubber composite material; (2) preparing a silicone rubber composite material green body; (3) carrying out supercritical fluid foaming: covering part of the green body, obtained in the step (2), with a metal material, and then putting the green body into a high pressure reaction kettle, introducing gas for foaming, heating, and pressurizing until the gas is converted into supercritical fluid; after the supercritical fluid reaches a saturated state in the green body, using a rapid pressure relief method to enable composite material green body to be foamed so as to obtain a foamed material; (4) vulcanizing. The preparation method provided by the invention is not only simple and stable in process, low in requirement for equipment and simple to operate, but is also good in controllability, thus having a very good application prospect.

Owner:SICHUAN UNIV

Heat-preservation fireproof board and preparation method thereof

ActiveCN103951369AGood heat insulationHigh ignition pointSolid waste managementSilicon dioxideFire prevention

A heat-preservation fireproof board is prepared by the following raw materials: 80-100 parts by weight of magnesium oxide, 2-3 parts by weight of dimethyl silicone oil, 4-6 parts by weight of aluminum nitride powder, 20-30 parts by weight of anhydrous magnesium chloride, 3-5 parts by weight of hollow glass beads, 8-12 parts by weight of tetrapod-shaped zinc oxide whiskers, 3-6 parts by weight of aerosil, 3-5 parts by weight of polyvinyl acetate emulsion, 20-30 parts by weight of refractory materials, 3-6 parts by weight of rock wool, 3-5 parts by weight of methylisothiazolinone, 2-4 parts by weight of ferriferrous oxide, 5-8 parts by weight of methyl sodium silicate, 1-2 parts by weight of sodium dodecyl benzene sulfonate, and 130-150 parts by weight of water. By virtue of adding the multiple types of refractory materials, the board can be high in burning point and good in flame retardation effect; and with the addition of the fly ash hollow beads, the board can be good in heat insulation effect and fine in fireproof effect. In brief, the board of the invention is a novel inorganic heat-preservation and heat-insulation building material integrating characteristics of heat preservation, heat insulation, high strength, fire prevention, water proofing, sound absorption, sound insulation, and decoration.

Owner:安徽颐鑫节能材料有限公司

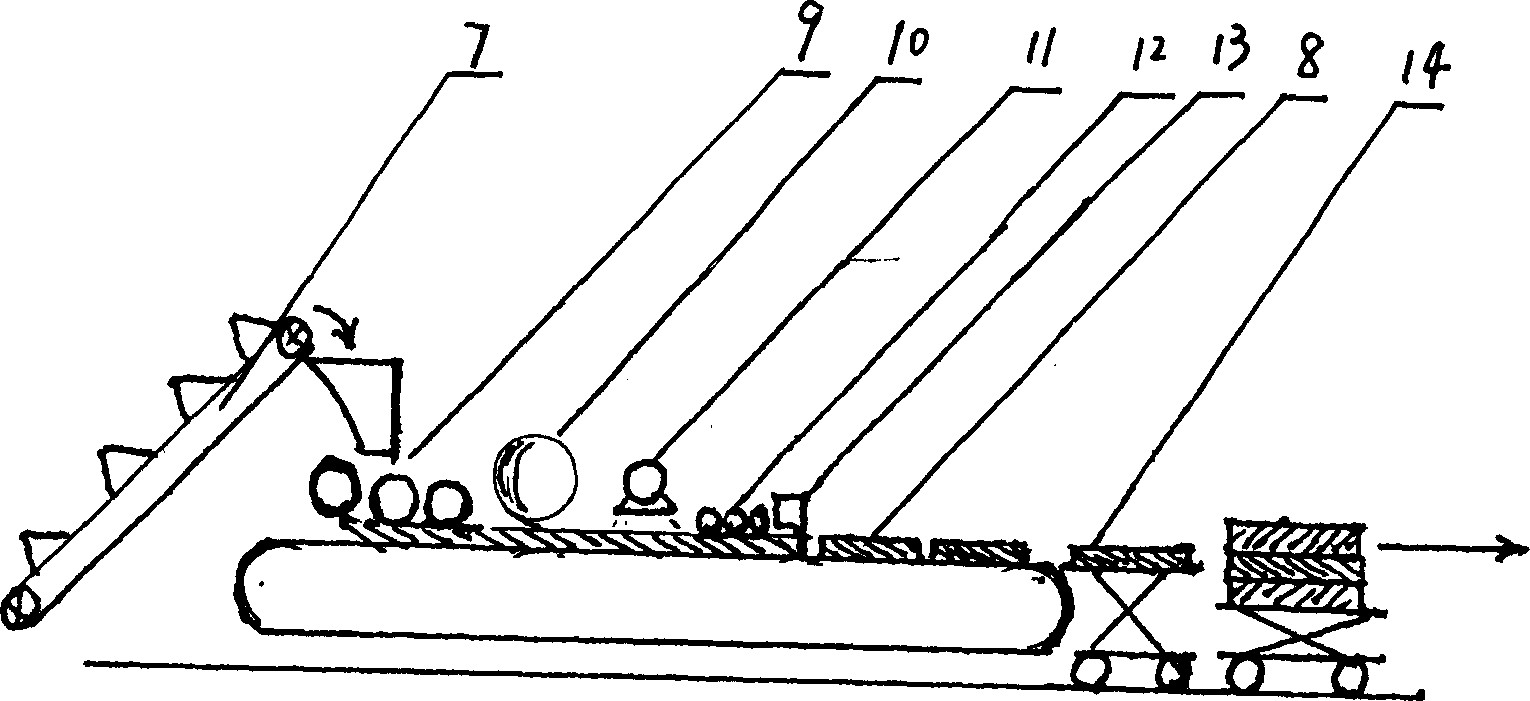

Bar section synthesized by using depleted stalk of plant, and prepartion method

This invention discloses a method for manufacturing profile from waste plant straws. The profile is composed of: powder of waste plant straws 30-50 wt.%, plastic resin 20-40 wt.%, calcium carbonate 15-25 wt.%, flame retardant 3-7 wt.%, anti-aging agent 2-5 wt.%, and silicone oil 1-3 wt.%. The method comprises: (1) fracturing waste plant straws, drying to a water content of 6-10%, and pulverizing to 50-200 mesh; (2) homogeneously mixing the raw materials, extruding in a twin-screw extruder at 150-180 deg.C, and cooling. The profile has such advantages as low cost, abundant raw materials, simple manufacturing process, high compactness, good mechanical properties, good noise absorption, good heat resistance, good flame retardance, good corrosion resistance, high anti-aging capacity and good processability.

Owner:ZHEJIANG UNIV

Thermal insulating material and preparation method thereof

The invention discloses a thermal insulating material. The thermal insulating material is prepared from the following raw materials in parts by weight: 40-55 parts of pitchstone glazed bead, 4-5 parts of light-weight magnesium oxide, 0.5-1.2 parts of sodium fluorosilicate, 0.4-1 part of aluminum dihydrogen phosphate, 0.2-0.5 part of polyvinyl alcohol, 0.6-0.8 part of kaolin, 2-2.5 parts of fly ash, 2-3 parts of attapulgite, 2.5-3.5 parts of sepiolite fibre, 1-1.5 parts of disodium sulfosuccinate and 2-3 parts of cement. As for the thermal insulating material prepared from the raw materials in proportions, disclosed by the invention, the dry density can be less than 400kg / m<3>, the thermal conductivity can be less than 0.085W / (m.k), and the fireproof performance can reach the national A2-level requirements. In addition, the thermal insulating material has excellent characteristics of high strength, aging resistance and sound absorption, and is long in service life.

Owner:广西青龙化学建材有限公司

Method for preparing artificial vesuvianite building block from Bayer red mud

InactiveCN102491730ALess investmentSimple processCeramic materials productionCeramicwareBuilding productFoaming agent

The invention discloses a method for preparing an artificial vesuvianite building block from Bayer red mud. The method for preparing the artificial vesuvianite building block from Bayer red mud comprises the following steps of carrying out milling and slurrying of Bayer red mud, carrying out mixing and blank preparation, carrying out drying and sintering, and carrying out cooling. The method for preparing the artificial vesuvianite building block from Bayer red mud has a low investment cost and simple processes, realizes the preparation of the artificial vesuvianite building block which is a novel artificial non-metallic porous material vesuvianite building block, and provides a novel and reliable approach for Bayer red mud comprehensive utilization. Because of addition of fine coal powder, a leavening agent, a foaming agent and a molding binder in ingredients, a sintered blank has regular or irregular micro-apertures, small apertures and big apertures thereby forming the artificial vesuvianite building block which is a sponge-like ceramic building product. The artificial vesuvianite building block can absorb sound, reduce noise, improve a hearing environment, adjust air humidity by its unique breathing function and improve an ecological environment. Therefore, the artificial vesuvianite building block can be widely utilized for masonry building, floor building and wall decoration, and is an ideal, eco-friendly and energy-saving building and decorative material.

Owner:四川海吉尔环保科技发展有限公司

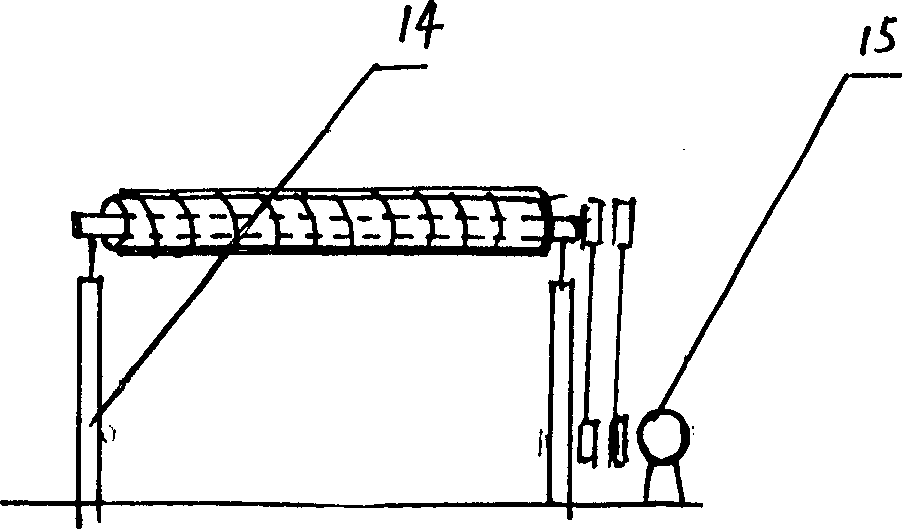

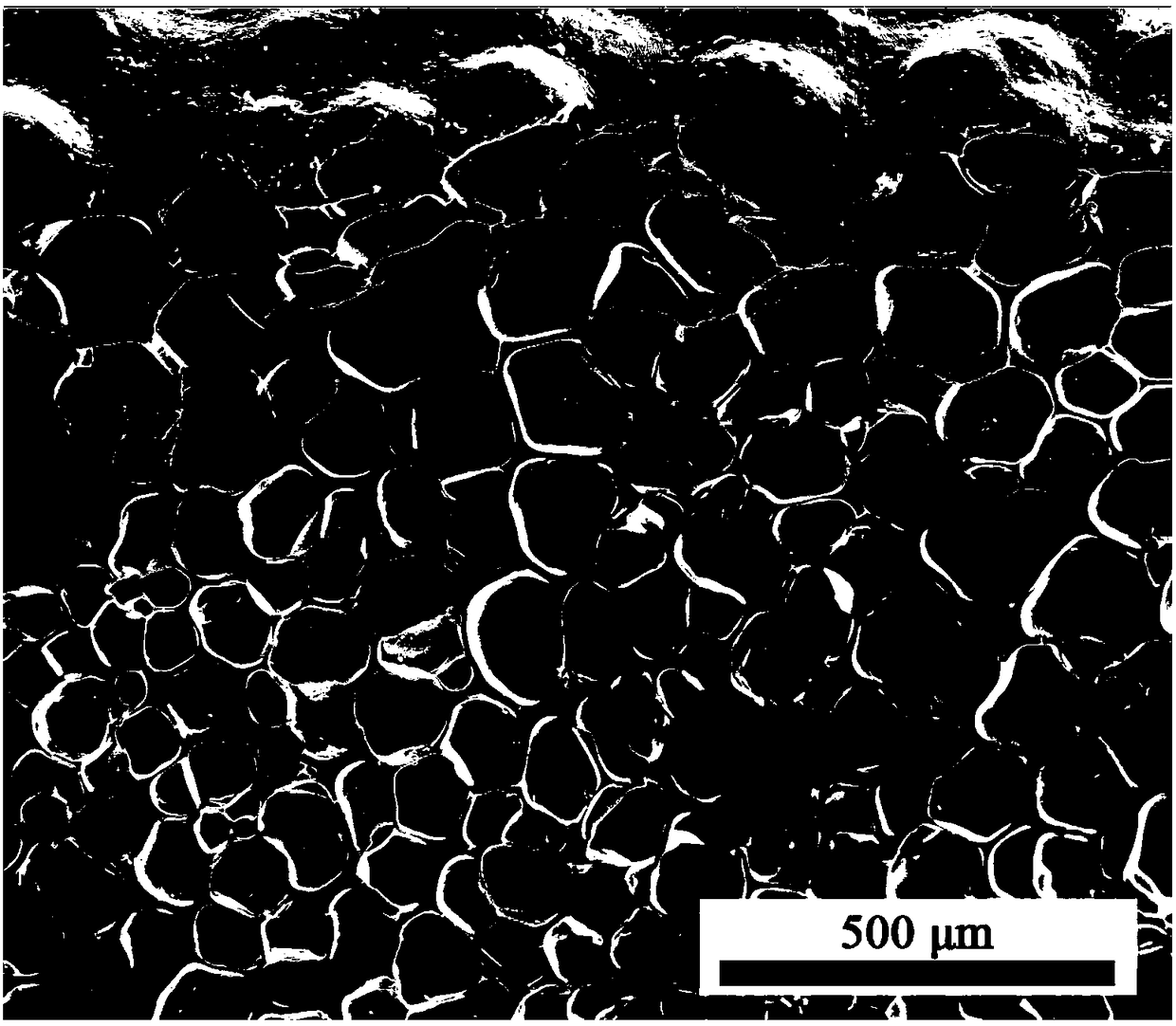

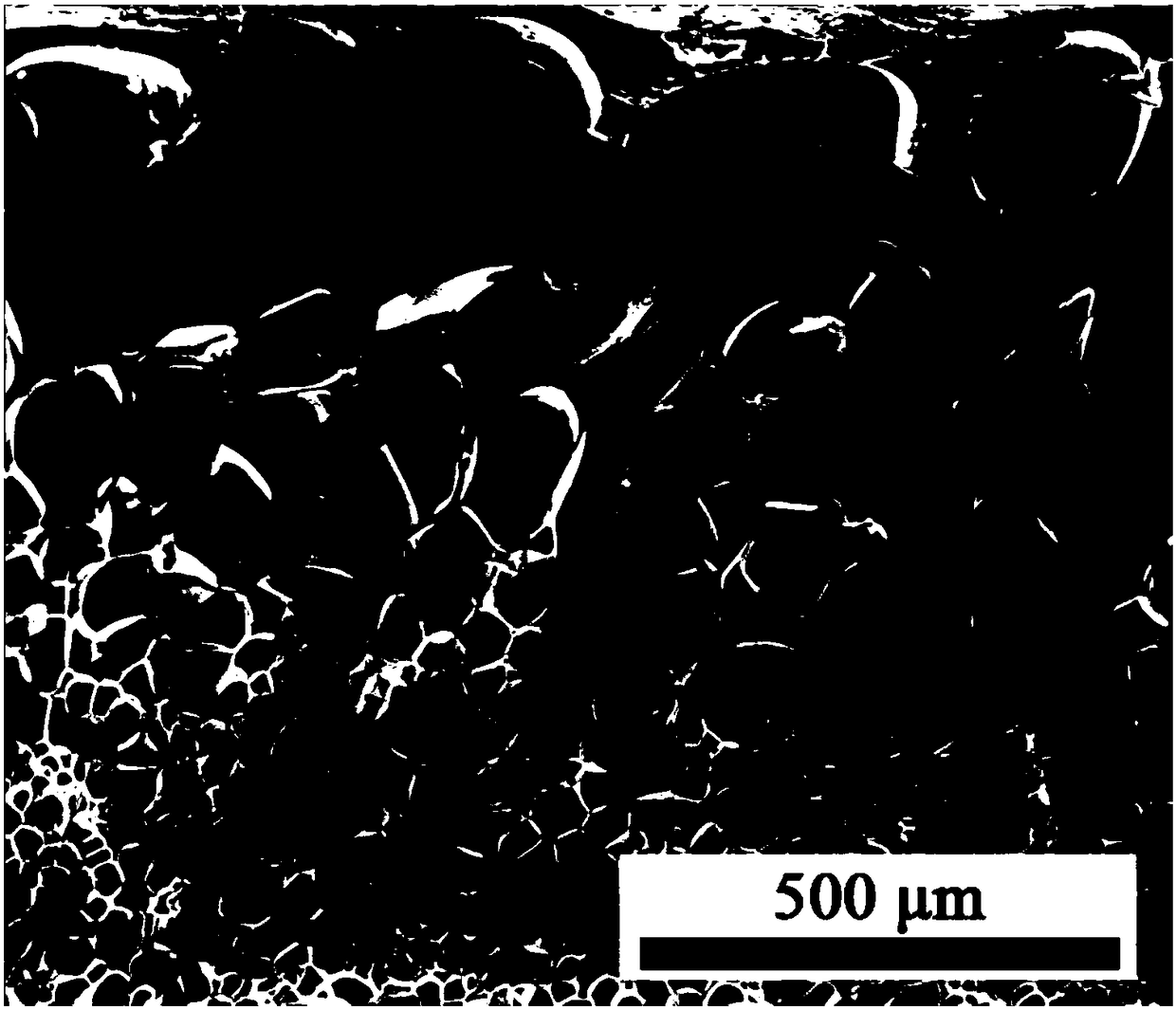

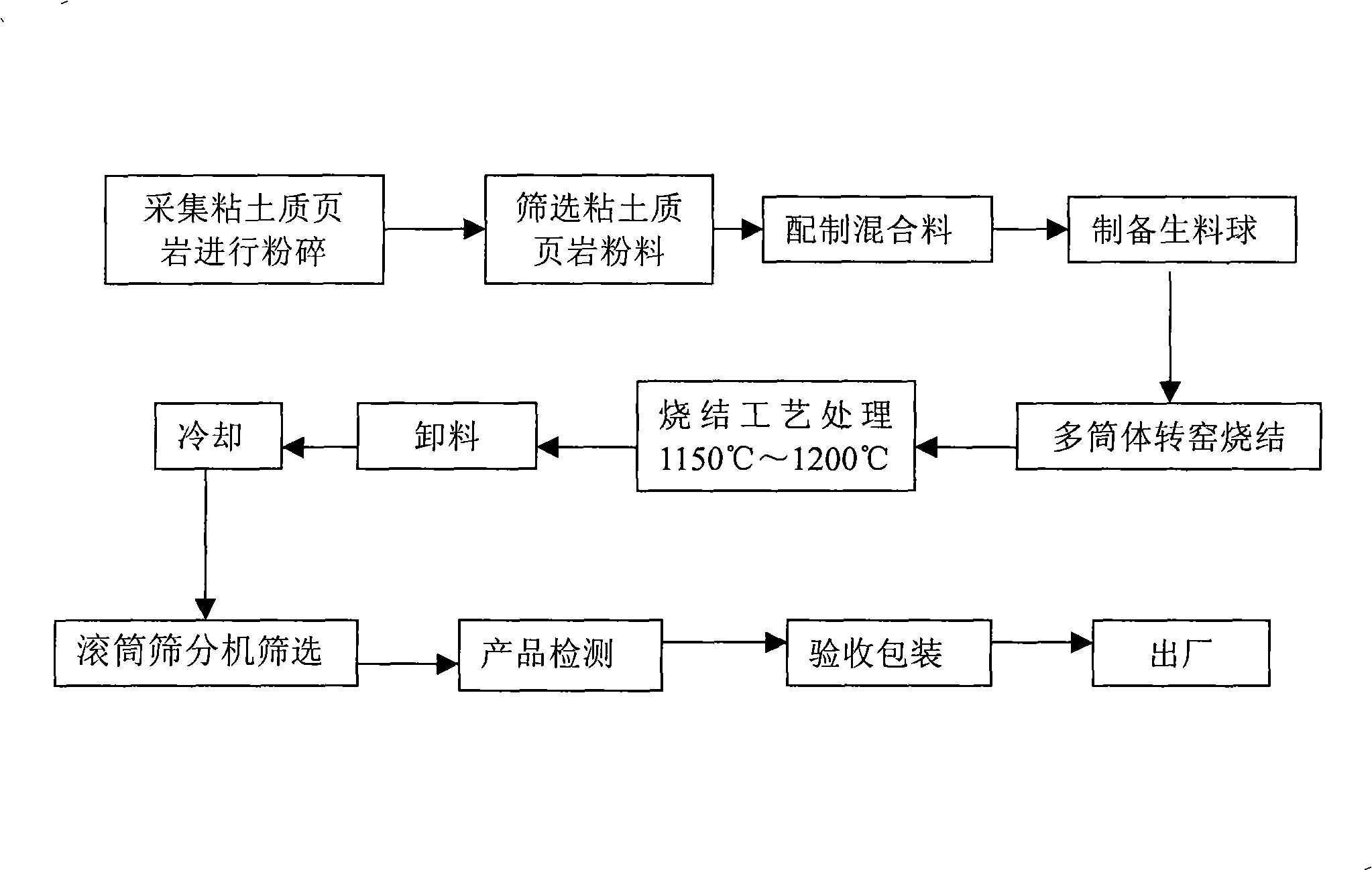

Light aggregate shale porcelain granule and production method thereof

InactiveCN101298381AImprove protectionBeneficial to industrial use valueCeramic materials productionClaywaresPulverized fuel ashSizing

The invention discloses a light-weight aggregate shale ceramic particle and a production method thereof, which includes powdered argillaceous shale, pulverized fuel ash, additive and water; the ratio of the ingredients is that: 15-90 parts of powdered argillaceous shale, 5-60 parts of pulverized fuel ash, 1-12 parts of additive and 4-15 parts of water. The production method includes the conventional collection of argillaceous shale and the crashing process, besides, the invention also comprises the following steps: (1)screening; (2) the mixing materials is prepared; (3) the mixing material is added into a marble machine so as to produce raw meal pellets and is discharged; (4) the raw meal pellets are fed into a multi-cylinder rotary kiln for drying and sintering and finally the shale ceramic particles are formed; (5) the products of shale ceramic particles, ceramic sand and ceramic block can be obtained after the cooling and the sizing screening process by a trommel screen. The product is sintered in a multi-cylinder rotary kiln at temperature of 1150-1200 DEG C and the material property is changed and is sound-insulating, light in weight, shock-resistant, weather-resistant, and corrosion-resistant, has distinct energy-saving effect and is beneficial to generalization and implementation.

Owner:杨普安 +2

Non-metal inorganic powdery composite flame-proof material and its production method, and sheet and its production method

InactiveCN1884438AComply with non-flammability requirementsNonflammable withFireproof paintsMechanical energyMaterials science

The invention relates the non-metal inorganic powder composite non-inflammable material and preparing method, sheet material and preparing method. The material comprises 55-70% non-metal inorganic powder, 10-30% binder, 10-15% reinforced materials, 2-4% auxiliary agent and 1-3% modifier. The method comprises the following steps: putting the non-metal inorganic powder into mixing machine, stirring, adding reinforced materials, auxiliary agent and modifier, stirring to 120Deg.C, putting them into cooling mixing machine, stirring to normal temperature, adding binder, and getting the product. The preparing method of sheet material comprises the following steps: heating the non-metal inorganic powder composite non-inflammable material by extrusion machine, squeezing with forming die, rolling, and getting the product. The invention has the advantages of low cost, environment protection, safety, and high mechanical energy. The product can be used in ship, marine drilling platform, battleship, furniture, nonbearing wall and baffle wall.

Owner:袁新周

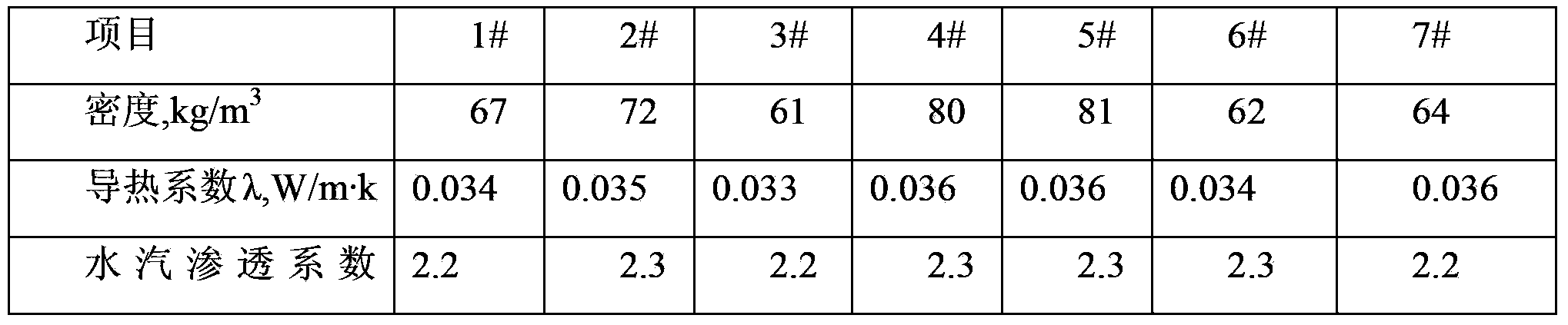

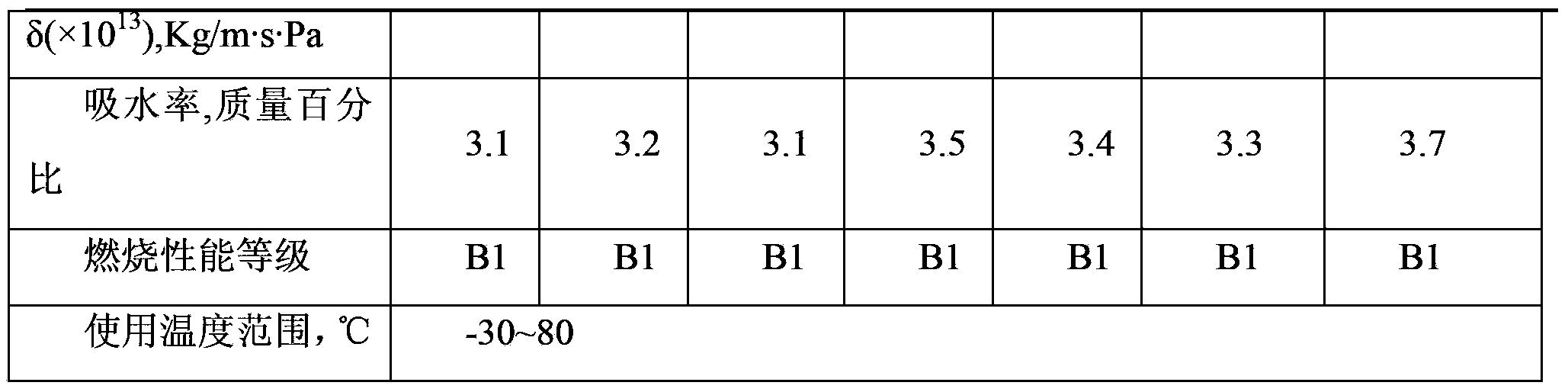

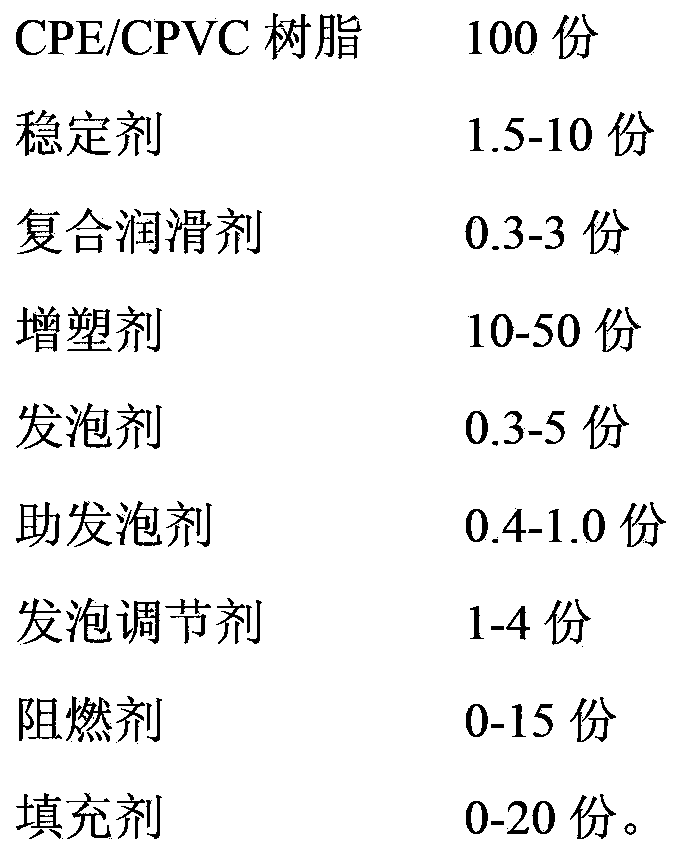

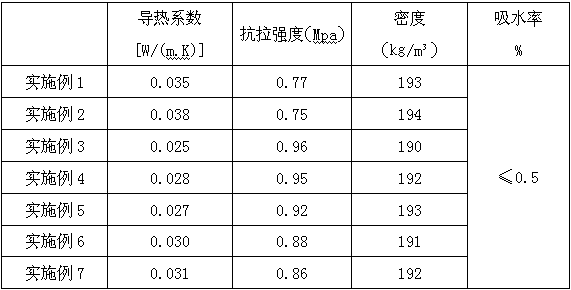

CPE/CPVC rubber-plastic thermal-insulation material and preparation method thereof

The invention relates to a CPE / CPVC rubber-plastic thermal-insulation material and a preparation method thereof and belongs to the field of polymer synthesis and processing application. The CPE / CPVC rubber-plastic thermal-insulation material is prepared from 100 parts by mass of CPE / CPVC resin, 1.5-10 parts by mass of a stabilizing agent, 0.3-3 parts by mass of a composite lubricant, 10-50 parts by mass of a plasticizer, 0.3-5 parts by mass of a foaming agent, 0.4-1.0 part by mass of a foaming aid, 1-4 parts by mass of a foaming adjustment agent, 0-15 parts by mass of a fire retardant and 0-20 parts by mass of a filling material. The CPE / CPVC rubber-plastic thermal-insulation material has excellent performances such as softness, flexing damage resistance, cold resistance, heat resistance, flame retardation, water resistance, low heat-conduction coefficient, cushioning effect and sound absorption and has ideal use effects in the aspect of thermal insulation for heat loss prevention. The preparation method of the CPE / CPVC rubber-plastic thermal-insulation material is simple and continuous, has high production efficiency, is suitable for streamline batch production and can be widely used in industries of building, light textile, medicine, chemical engineering, metallurgy and ship-building.

Owner:CHINA PETROLEUM & CHEM CORP

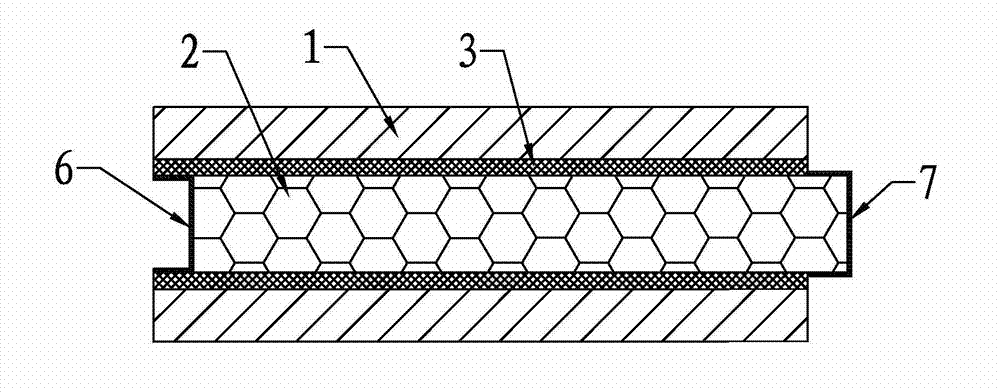

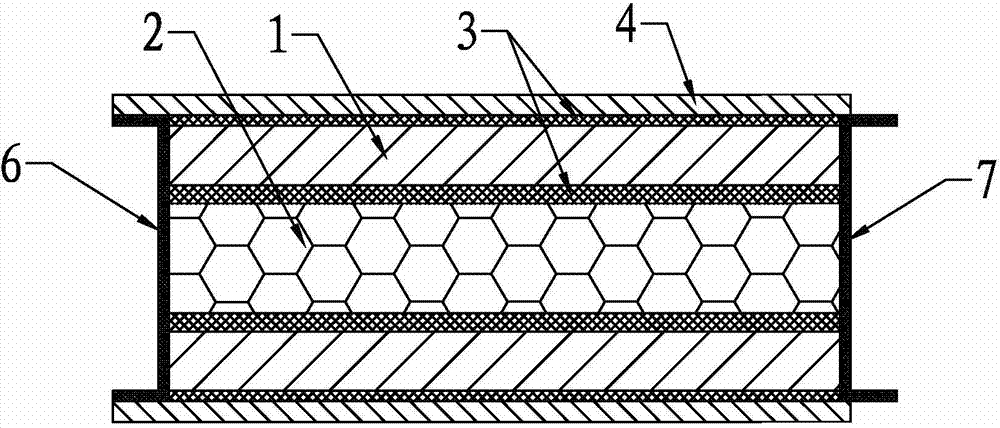

Construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for prefabricated building

The invention provides a construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for a prefabricated building. The mortar board comprises an inner PC board layer, an outer PC board layer and a filling material layer arranged between the inner PC board layer and the outer PC board layer. A preparation method of the mortar board comprises the following steps of performing hammering, vibrating, crushing, grinding and other processes on concrete and brick slag in construction wastes to form a regenerated building aggregate; performing high-speed rotation on the regenerated building aggregate to obtain regenerated micro powder, and collecting the regenerated micro powder; mixing the regenerated building aggregate, the regenerated micro powder, a polymer, cement, rice hulls and straws, basalt fibers and glass fibers, ceramsite and other auxiliaries to obtain the PC board layers; mixing polystyrene foam, asbestos foam or nano-sized aerogel with the polymer to obtain the filling material layer; and finally, compounding the PC board layers and the filling material layer to obtain the construction waste-containing high-strength light-weight composite PC mortar board for the prefabricated building. The preparation method is simple; and as regenerated building agricultural wastes are taken as a large part of raw materials, on the basis of guaranteeing high strength and light weight, the cost is reduced, and the mortar board is green and environment friendly.

Owner:SHAOXING YISHENG MORTAR

Light-weight high-strength foamed ceramic board material and preparation method thereof

PendingCN105541376AHigh wall strengthImprove rigidityCeramic materials productionCeramicwareEmulsionMoisture resistance

The invention provide a light-weight high-strength foamed ceramic board material, which is characterized by being prepared from the following components, by weight part: 50-60 parts of coal ash, 10-20 parts of bentonite, 10-20 parts of dolomite, 6-12 parts of potassium and sodium feldspar, 8-15 parts of magnesite slag, 5-10 parts of waste glass, 1-2 parts of an anionic surfactant, 0.5-1.5 parts of a silicon resin polyether emulsion, 0.1-0.5 part of a foaming agent, 0.1-0.5 part of a dispersant, and 200-250 parts of water. Cost of raw materials is reduced, and resources are saved. The light-weight high-strength foamed ceramic board material has characteristics of environmental protection, fire prevention, sound absorption, heat insulation, moisture resistance, seepage resistance, freezing resistance, and flame retardation, and conforms to a modern construction energy-saving standard, so that the material can be used as a wall insulation material, a sound-insulation noise-reduction material, or a heat-insulation thermal-insulation material in other fields.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

High-water-permeability environment-friendly water-permeable brick produced by utilizing industrial residues and preparation method thereof

InactiveCN105399370AIncrease hardening speedHigh strengthSolid waste managementCeramic shaping apparatusEnvironmental resistanceBrick

The invention discloses a high-water-permeability environment-friendly water-permeable brick produced by utilizing industrial residues, and belongs to the technical field of construction materials. The water permeable brick comprises a surface layer and a bottom layer, wherein the bottom layer is prepared from the following components in percentage by mass: 30-40 percent of fine-sand and pulverized fuel ash particles, 25-35 percent of dump slag, 10-20 percent of a concrete stone material and 15-25 percent of cement; the surface layer is prepared from the following components in percentage by mass: 15-20 percent of cement, 60-70 percent of quartz sands and 15-20 percent of decorative stone particles; the fine-sand and pulverized fuel ash particles are prepared from the following components in percentage by mass: 70-80 percent of pulverized fuel ash, 10-20 percent of fine sands, 0.1-0.15 percent of water glass and 5-10 percent of cement; and the grain diameters of the fine-sand pulverized fuel ash particles and concrete stone material are 2-4mm. The invention further provides a preparation method of the high-water-permeability environment-friendly water-permeable brick. The high-water-permeability environment-friendly water-permeable brick has the advantages of strong water permeability, good moisture retention, sliding prevention, high strength, cold resistance, weathering tolerance, noise reduction, sound absorption and the like.

Owner:CHIFENG JINGHUAN ENERGY SAVING BUILDING MATERIAL MFG CO LTD

Preparation method of hemp fabric construction morph-genetic ceramic composite material

InactiveCN101838146AGood sensing and electromagnetic shieldingBroaden the field of applicationHot pressOxide

The invention discloses a method for preparing a hemp fabric construction morph-genetic ceramic composite material, comprising the following steps: preparing a hemp fabric construction formwork or hemp fabric construction / precursor composite formwork; placing into a vacuum hot-pressing furnace; heating the two formworks at vacuum or inert gases protective atmosphere; cooling in the furnace or cooling by temperature control to prepare a morph-genetic carbon formwork or the morph-genetic ceramic composite material; performing liquidoid silicon seepage or gases phase silicon seepage on the morph-genetic carbon formwork at vacuum or inert gases protective atmosphere; repeatedly dipping precursor solution or precursor sol on the morph-genetic carbon formwork, a morph-genetic carbonization composite material, a nitride ceramic composite material or an oxidization ceramic composite material; performing carbon heat returning reaction to obtain the hemp fabric construction morph-genetic ceramic composite material. The preparation method of the invention not only leads the morph-genetic material to inherit manually manufactured arrangement manner and arrangement structure of hemp fabric and multi-layer multi-dimensional intrinsic fine structure of the hemp fabric organism, but also endows new functions thereof.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Bamboo carbon plate and its manufacturing technology

InactiveCN1686687AHigh strengthReduce releaseFlat articlesDomestic articlesManufacturing technologyMaterials science

A charred bamboo board for furniture or as floor board or decorative board able to clean air and insulate sound is proportionally prepared from aged bamboo powder, new bamboo powder, charred bamboo powder and urea-formaldehyde resin.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

Synthesized stalk profile and its prepn

The synthesized stalk profile is prepared with crop stalk powder 40-70 wt%, plastic resin 20-40 wt%, calcium carbonate 5-15 wt%, fire retardant 1-3 wt%, antiager 1-2 wt%, lubricant 1-3 wt% and brightener 1-2 wt%. The preparation process includes the following steps: drying crop stalk to water content of 8-15 wt% and crushing to 100-300 mesh; mixing materials in the said proportion and blending in a blender at 130-170 deg.c for 10-15 min; extruding in a double screw extruder and cooling to form. The present invention has low cost, rich material source and simple preparation process, and the profile has high compactness, excellent mechanical performance and other advantages.

Owner:ZHEJIANG UNIV

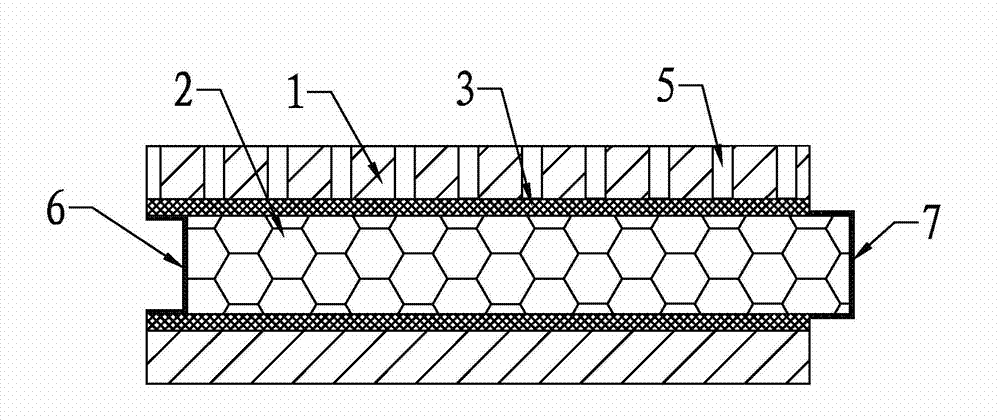

Sound-insulating fireproof wallboard

The invention discloses a sound-insulating fireproof wallboard which at least comprises a reinforced protection layer and an inorganic foaming material which is arranged in the reinforced protection layer in a clamped mode. The reinforced protection layer and the inorganic foaming material are bonded and fixed to each other through a bonding layer. The bonding layer comprises an adhesive and an anti-cracking fiber net. The anti-cracking fiber net is attached to at least one surface of the adhesive of the bonding layer. The reinforced protection layer has high strength so that the requirement that the wallboard serves as a main support of a wall can be met. The inorganic foaming material enables an inner layer of the wallboard to be a multifunctional composite layer which is light, capable of insulating and absorbing sound, and resistant to fire. According to the bonding layer, the anti-cracking fiber net is uniformly added to the adhesive, so that the bonding force of a contact surface between the bonding layer and the inorganic foaming material is increased, and the bonding strength of the bonding layer and the inorganic foaming material is enhanced. Due to the fact that the whole wallboard is made of an inorganic material, the wall cannot generate poisonous gas or smoke even if the wall is heated and burns, and the heat transfer performance of the whole wall is low.

Owner:罗广应

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com