Heavy duty type high-temperature conveying chain

A conveying chain, high temperature technology, applied in the field of heavy-duty high-temperature conveying chain, can solve the problems of reduced strength, chain wear resistance and tensile strength, unsuitable for tensile strength, etc., to achieve the effect of good carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

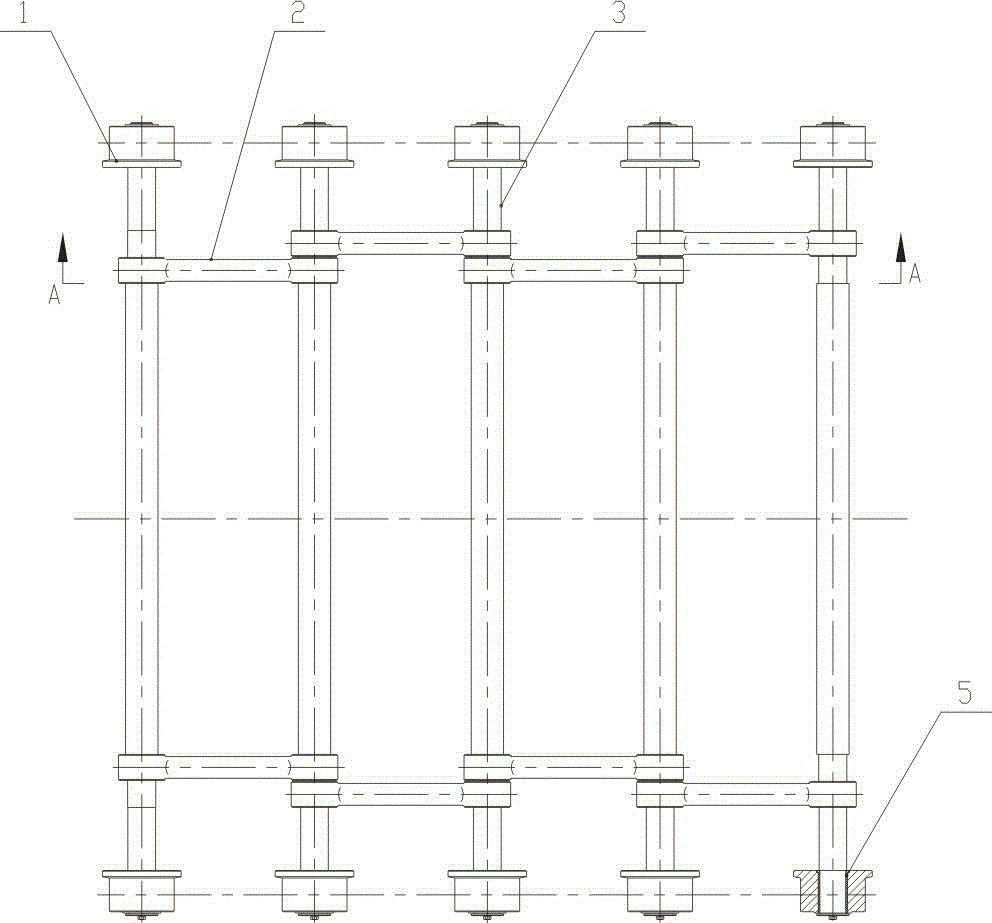

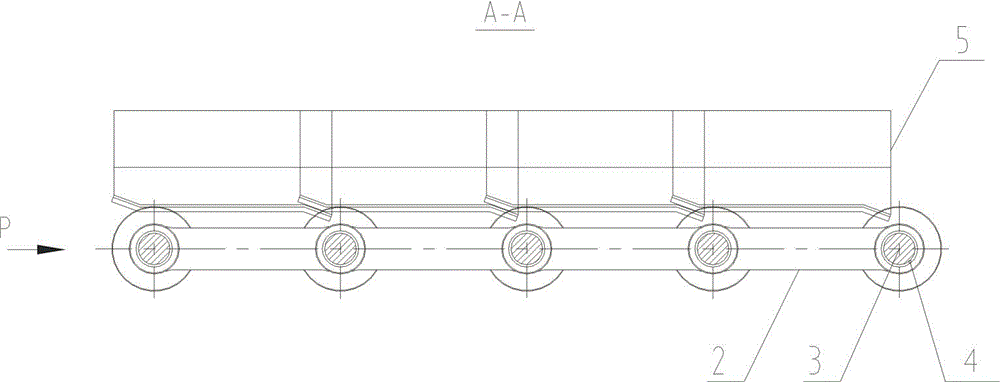

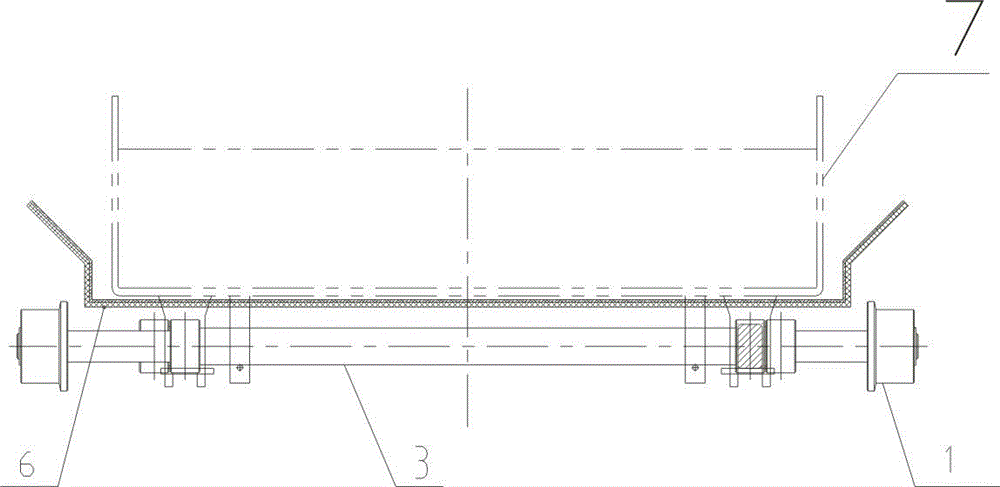

[0026] like Figure 1~Figure 3 As shown, a heavy-duty high-temperature conveyor chain includes left and right rows of chain rods, the left and right rows of chain rods are connected in series through the through shaft 3 to form a well-shaped grid, and the chain rod 2 and the through shaft 3 pass through the self-lubricating bearing bush 4 Hinged, the bearing roller 1 is assembled with the through shaft 3 through the sliding bearing 5, and the well-shaped grid is equipped with a heat-insulating reflective layer 6. A certain distance is formed between the bearing roller 1 and the chain rod 2 through the shaft extension of the through shaft 3 , which is used to extend the heat conduction path of the bearing roller 1 . The chain rod 2 is shaped by die forging.

[0027] exist figure 1 In the general assembly drawing, the carrying roller 1 and the chain rod 2 form a certain distance through the axial extension of the through shaft 3 to extend the heat conduction path of the carryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com