Building interior and exterior wall fireproof material containing nano-porous flame-retardant material

A flame-retardant material and nanoporous technology, which is applied in fire-resistant coatings, building structures, and fire protection, and can solve problems such as undeveloped, complicated material components, and poorly controlled costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

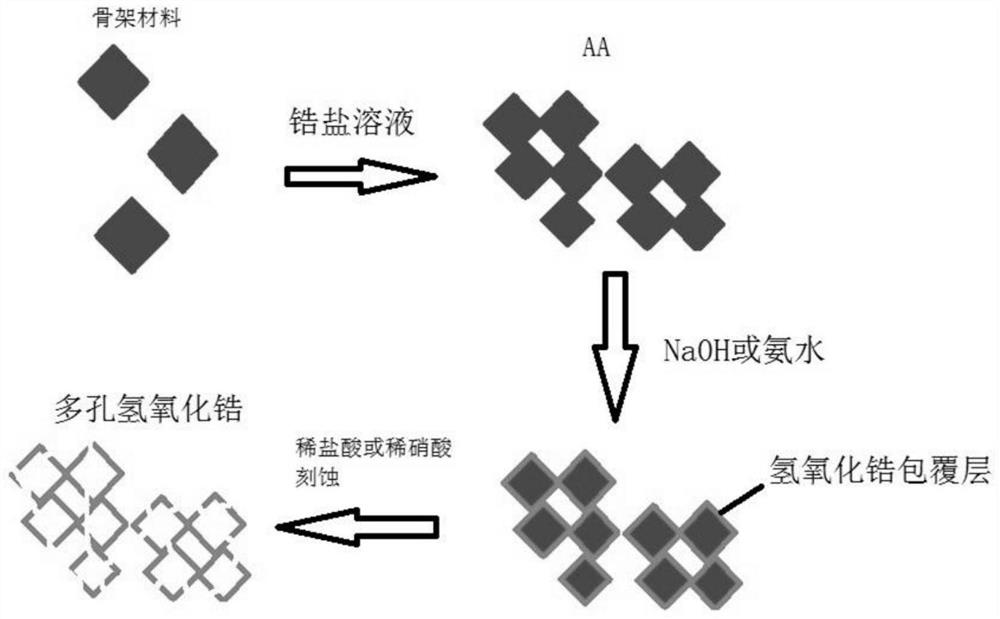

Method used

Image

Examples

Embodiment 1

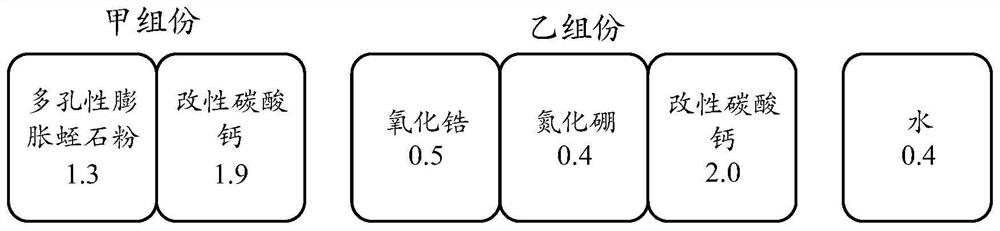

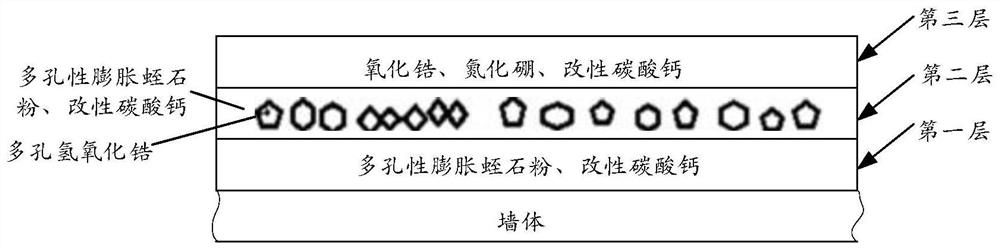

[0049] This embodiment specifically provides a kind of fireproof material for building interior and exterior walls containing nanoporous flame-retardant materials, including: porous expanded vermiculite powder, modified calcium carbonate (SiO2 / NaOH molar ratio is 8) Formed group A , the corresponding mass ratio is 1.3:1.9; the B component formed by zirconia, boron nitride, and modified calcium carbonate (SiO2 / NaOH molar ratio is 8), the corresponding mass ratio is 0.5:0.4:2.0; water, the mass ratio is 0.4, such as figure 1 shown.

Embodiment 2

[0051] This embodiment specifically provides a fireproof material for building interior and exterior walls containing nanoporous flame retardant materials, including: porous expanded perlite powder, modified calcium carbonate (SiO2 / NaOH molar ratio is 8) Formed group A , the corresponding mass ratio is 1.3:1.9; the B component formed by zirconia, boron nitride, and modified calcium carbonate (SiO2 / NaOH molar ratio is 8), the corresponding mass ratio is 0.5:0.4:2.0; water, the mass ratio is 0.4.

Embodiment 3

[0053] The present embodiment specifically provides a kind of building interior and exterior wall fireproofing material containing nanoporous fire-retardant material, comprises porous expanded vermiculite powder, modified calcium carbonate (SiO2 / NaOH molar ratio is 8) Formation group A, The corresponding mass ratio is 1.3:2.3; the corresponding mass ratio of component B formed by zirconia, boron nitride, and modified calcium carbonate (SiO2 / NaOH molar ratio is 8) is 0.5:0.4:2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com