Making method of negative-pressure marinated bacon

A production method and negative pressure technology, applied in the field of food processing, can solve the problems of long pickling time, labor-consuming, microbial pollution, etc., and achieve the effects of uniform pickling saltiness, golden and bright skin color, and less microbial pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

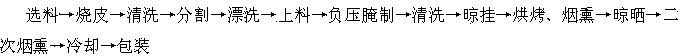

Image

Examples

Embodiment 1

[0032] The concrete steps of bacon making among the present invention comprise:

[0033] (1) Material selection: Select the pork forelegs or hind legs that have passed the inspection and quarantine, with skin and flesh, the average thickness of subcutaneous fat is 3-3.5cm, no bruises on the epidermis, and the deboning knife wound is controlled within 5mm.

[0034] (2) Burning skin cleaning: use a natural gas flame gun to spray and burn the surface of the skin until the skin turns slightly yellow, in order to remove the sweaty smell in the raw meat skin; use a knife to clean the residue produced during the burning process until it is completely .

[0035] (3) Segmentation: Segmentation requires that the skin and meat have the same width, the direction of the knife should follow the grain direction of the meat, the fat and lean parts should be connected, and the separated pieces of meat should be trimmed. The width is 4.2-4.5cm, and the length is the natural length of the meat....

Embodiment 2

[0054] The content of other steps is as in Example 1. In step (5), put the raw meat after feeding into a negative pressure container. After stacking neatly, vacuumize the container to 0.08MPa and close the container to keep it in this vacuum state for 4 days. Carry out marinating, the temperature of the marinating environment is 2°C; during the marinating process, the meat is turned over, that is, on the first day, the rough meat with the marinade is added to the tumbling for 35-45 minutes, and the speed is 11-13 rpm. Marinate for 1 day, then roll and knead for 35-45 minutes at a speed of 11-13 rpm, then marinate for 1 day, then roll and knead for 35-45 minutes and rotate for 11-13 rpm, then marinate for 2 days.

[0055] The ingredients in step (4) are calculated by mass parts per 100 parts of the meat divided in step (3) to prepare the marinade: 3.8 parts of salt, 0.5 parts of soy sauce, 0.2 parts of pepper, 0.2 parts of ginger, 1.8 parts of bean paste parts, 0.004 parts of s...

Embodiment 3

[0060] The content of other steps is as in Example 1. In step (5), put the raw meat after feeding into a negative pressure container. After stacking neatly, vacuumize the container to 0.082 MPa and close the container to keep it in this vacuum state for 4 days. Carry out marinating, the temperature of the marinating environment is 6°C; during the marinating process, the meat is turned over, that is, on the first day, the raw meat with the marinade is added to the tumbling for 35-45 minutes, and the speed is 11-13 rpm. Marinate for 1 day, then roll and knead for 35-45 minutes at a speed of 11-13 rpm, then marinate for 1 day, then roll and knead for 35-45 minutes and rotate for 11-13 rpm, then marinate for 2 days.

[0061] The ingredients in step (4) are calculated according to the weight of every 100 parts of meat divided in step (3) to prepare the marinade: 4.2 parts of salt, 1 part of soy sauce, 0.4 parts of pepper, 0.4 parts of ginger, 2.6 parts of bean paste parts, 0.004 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com