Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Avoid stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

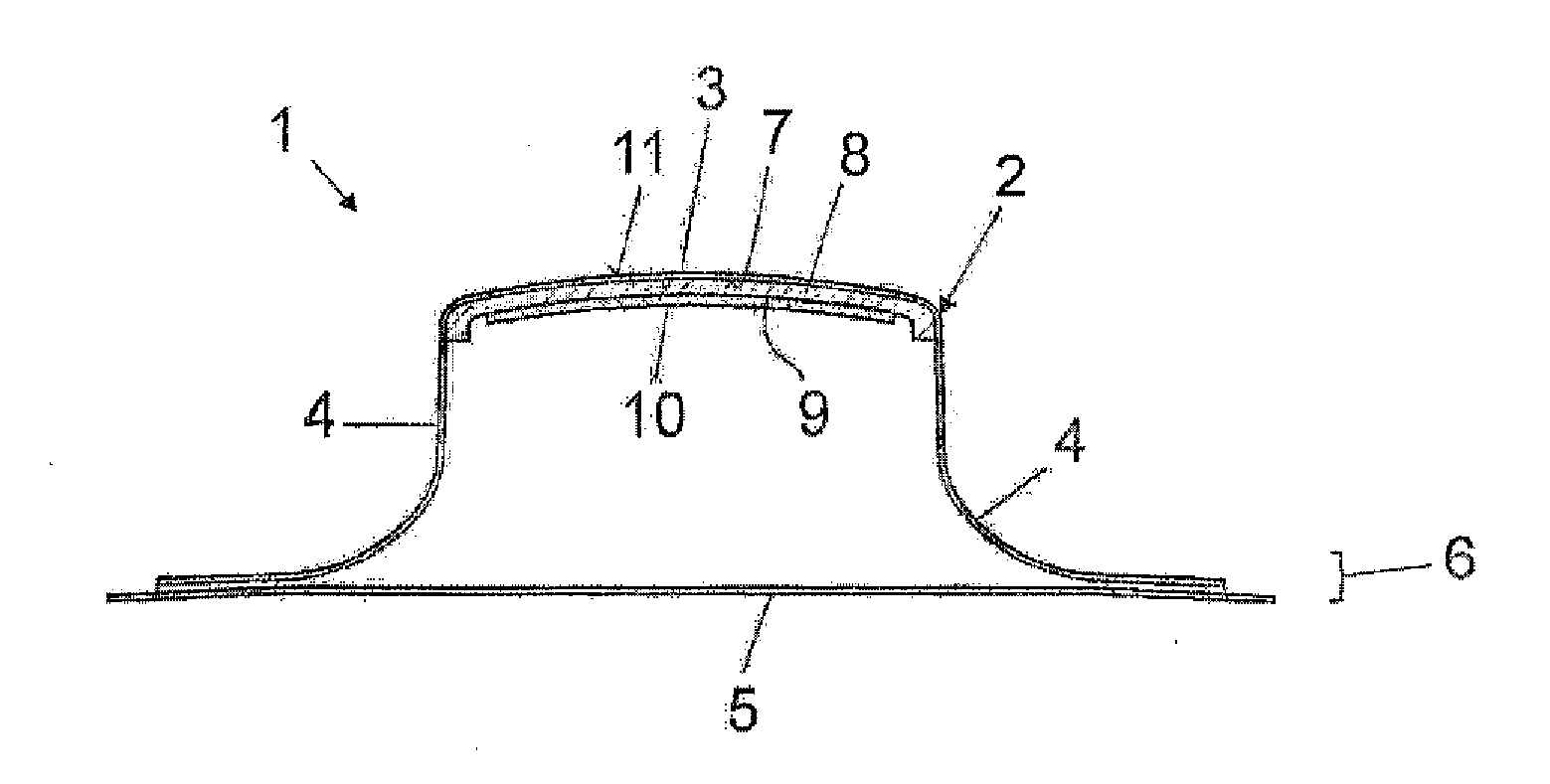

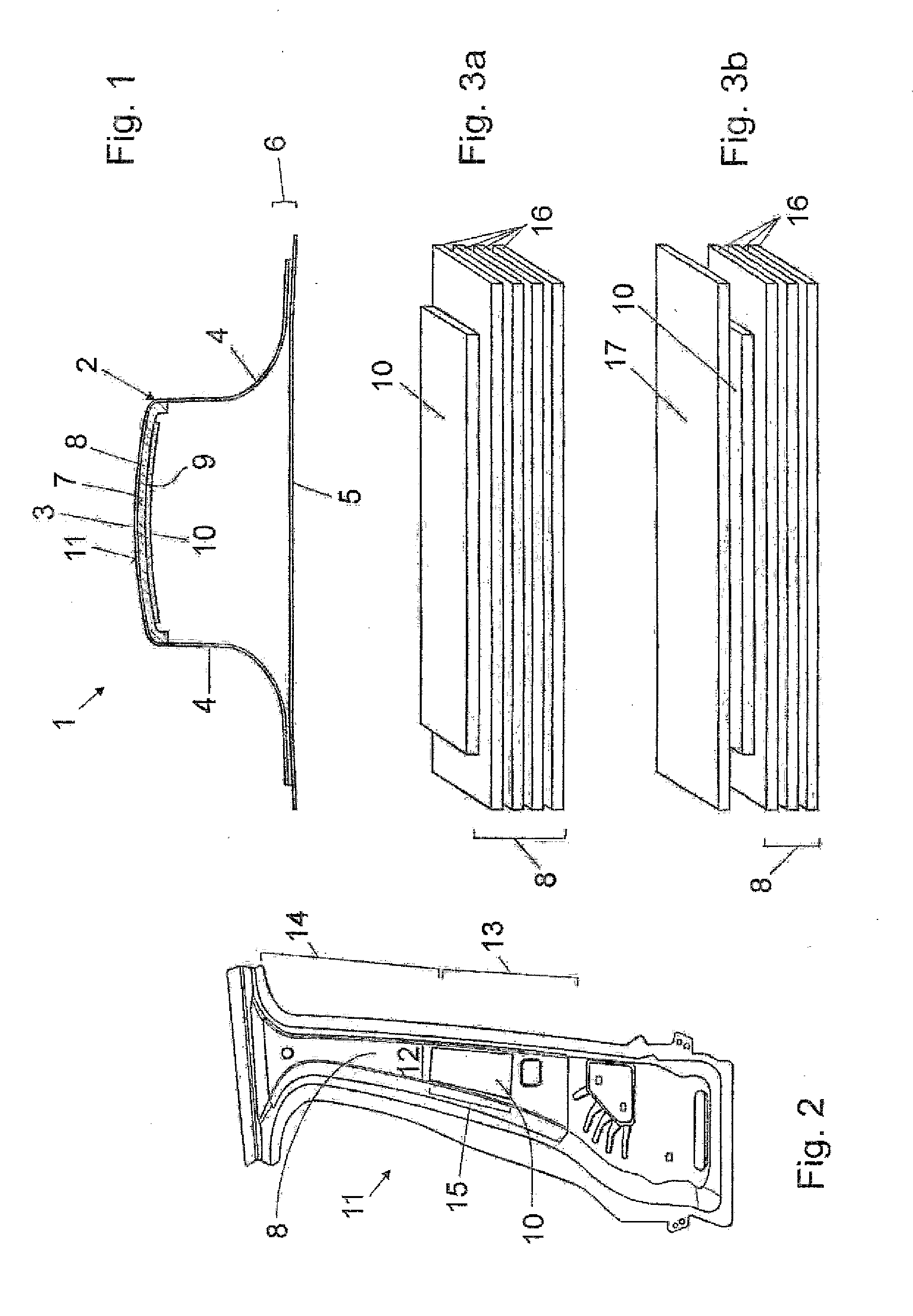

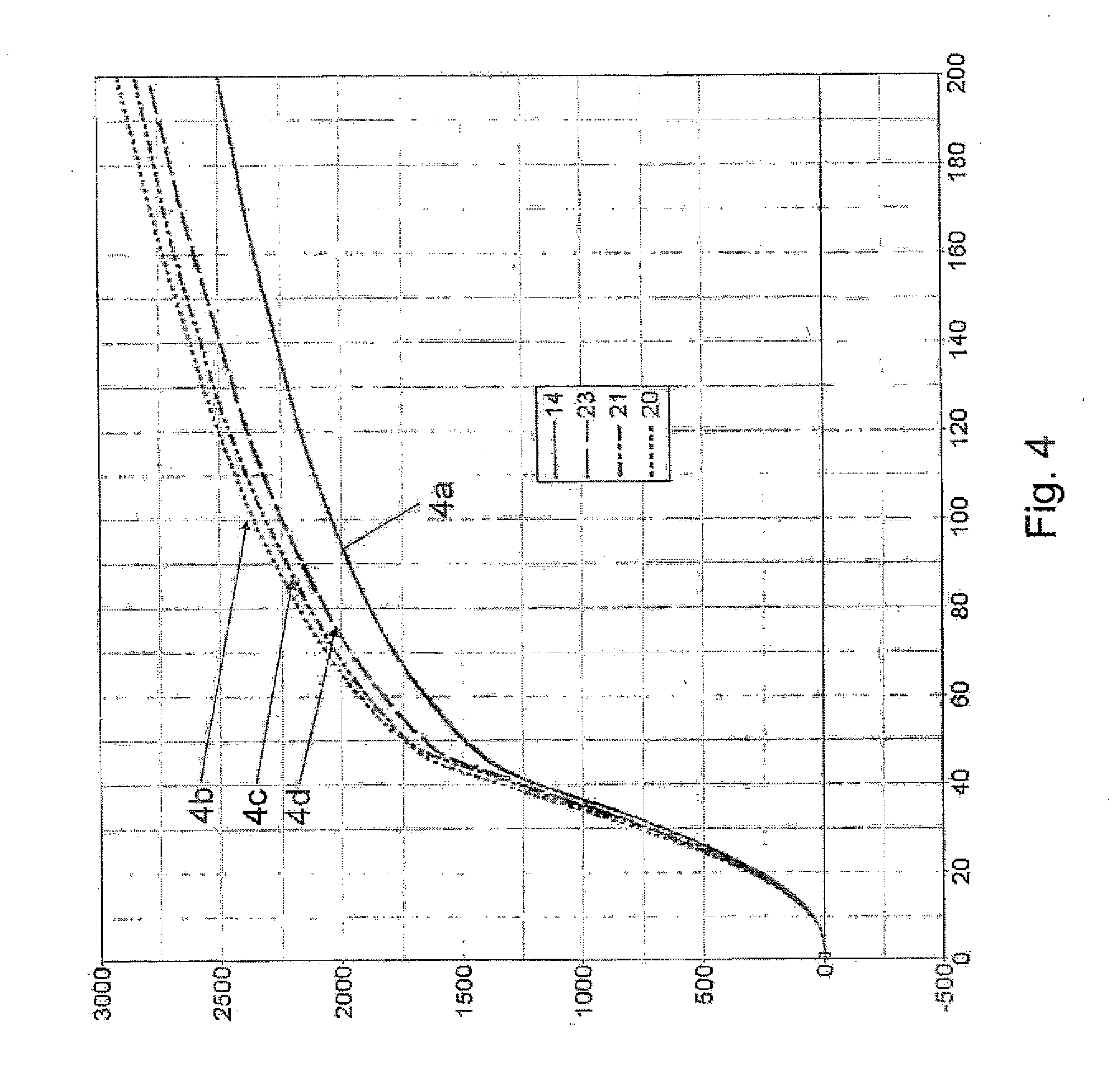

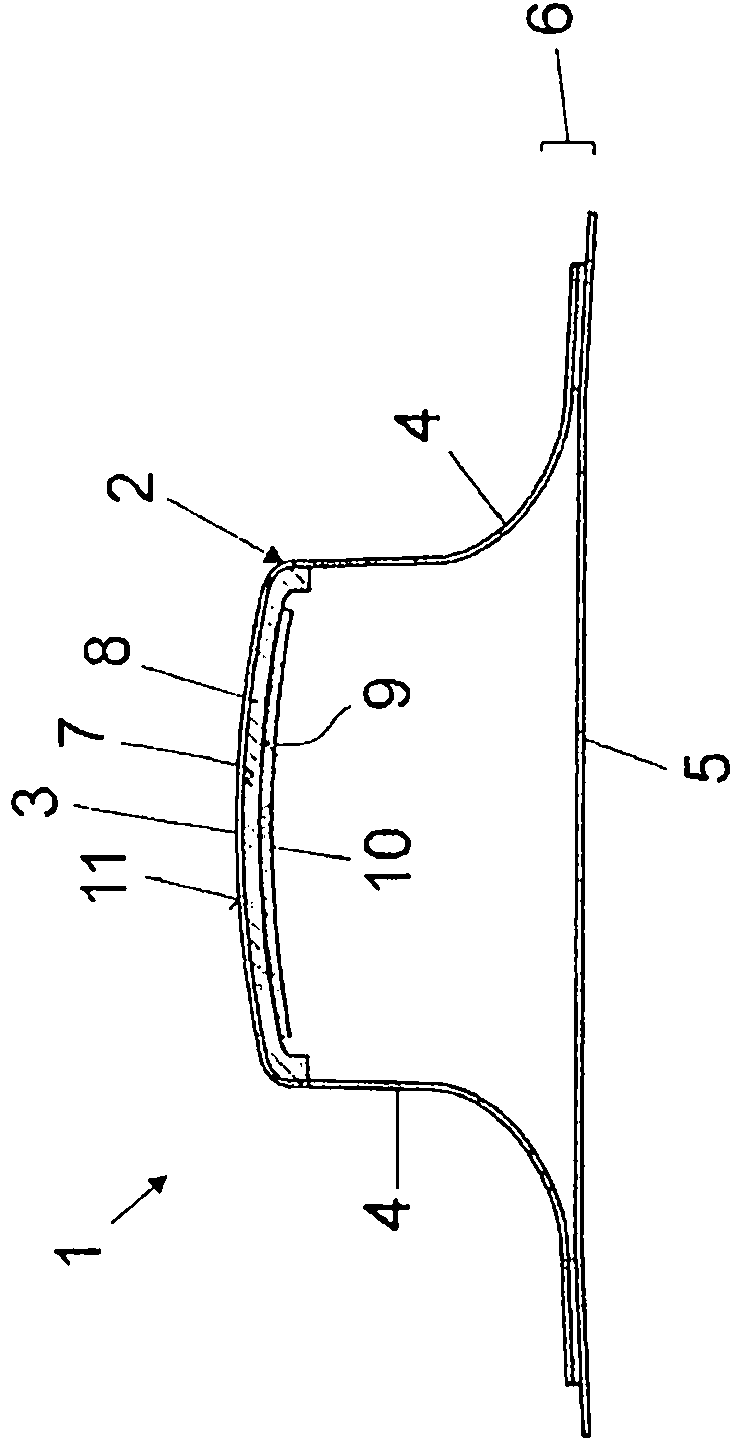

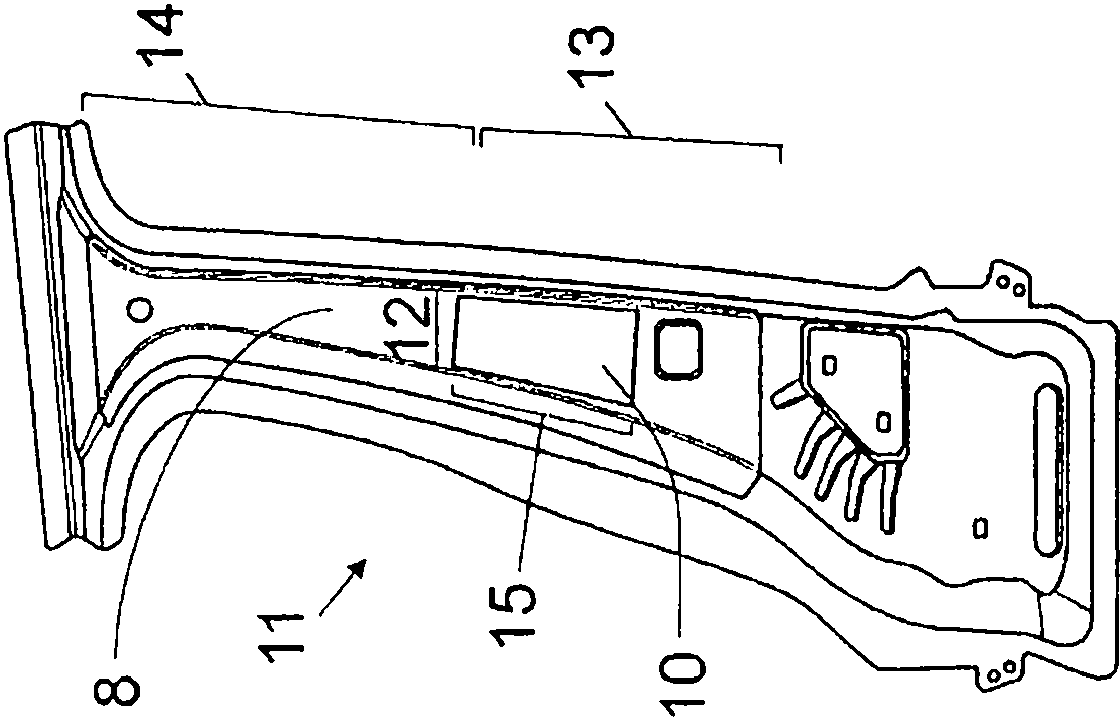

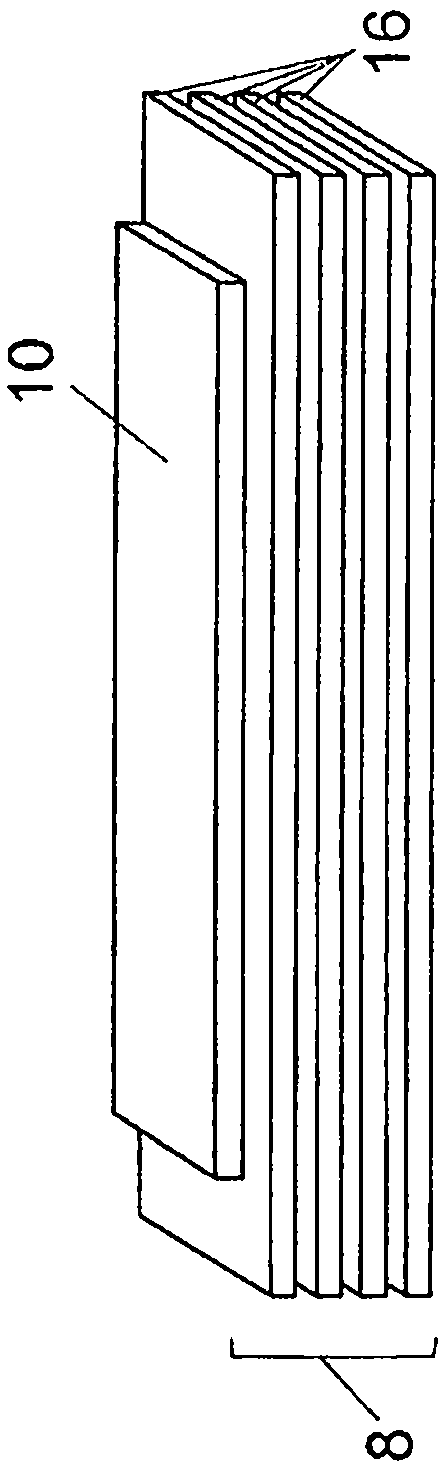

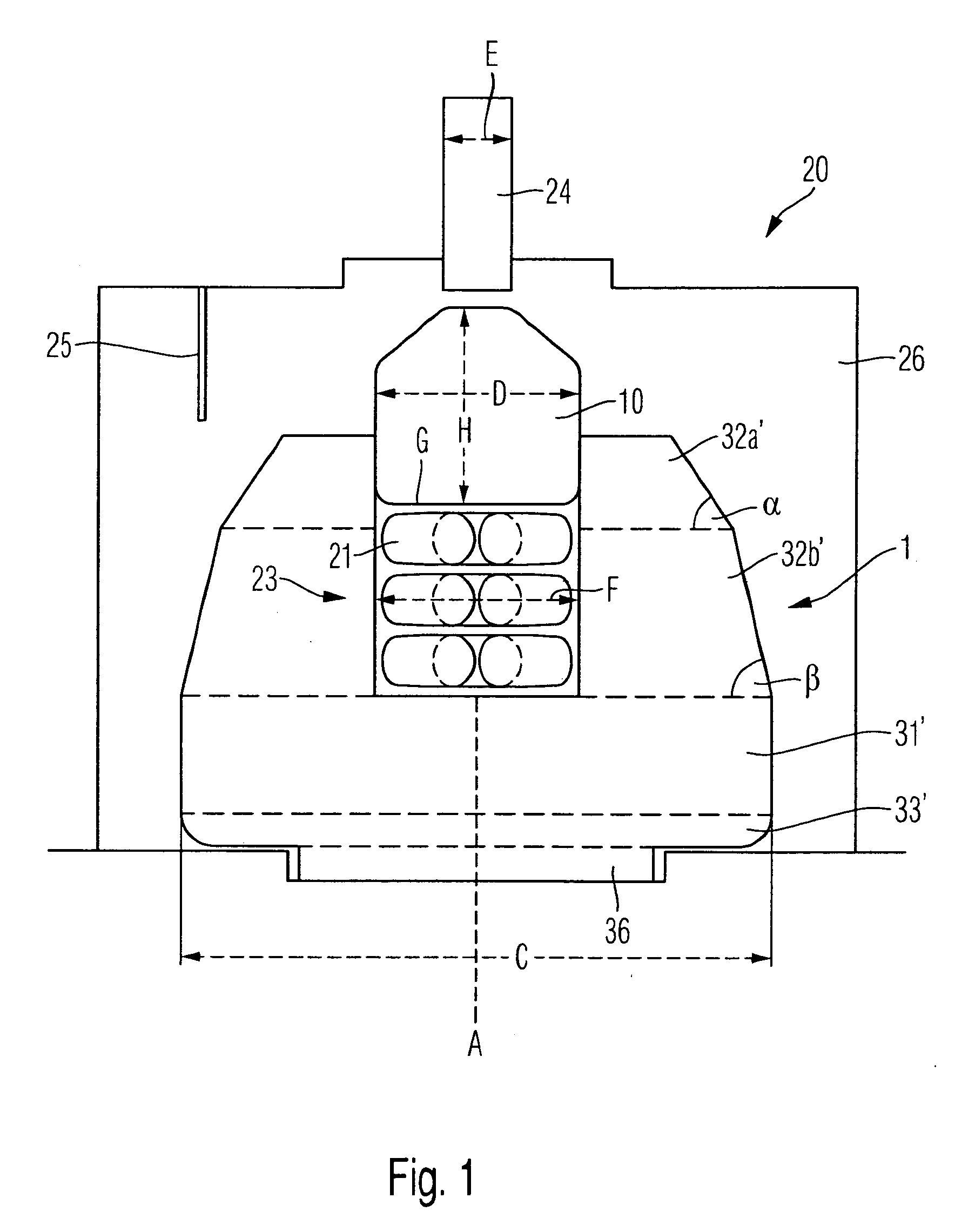

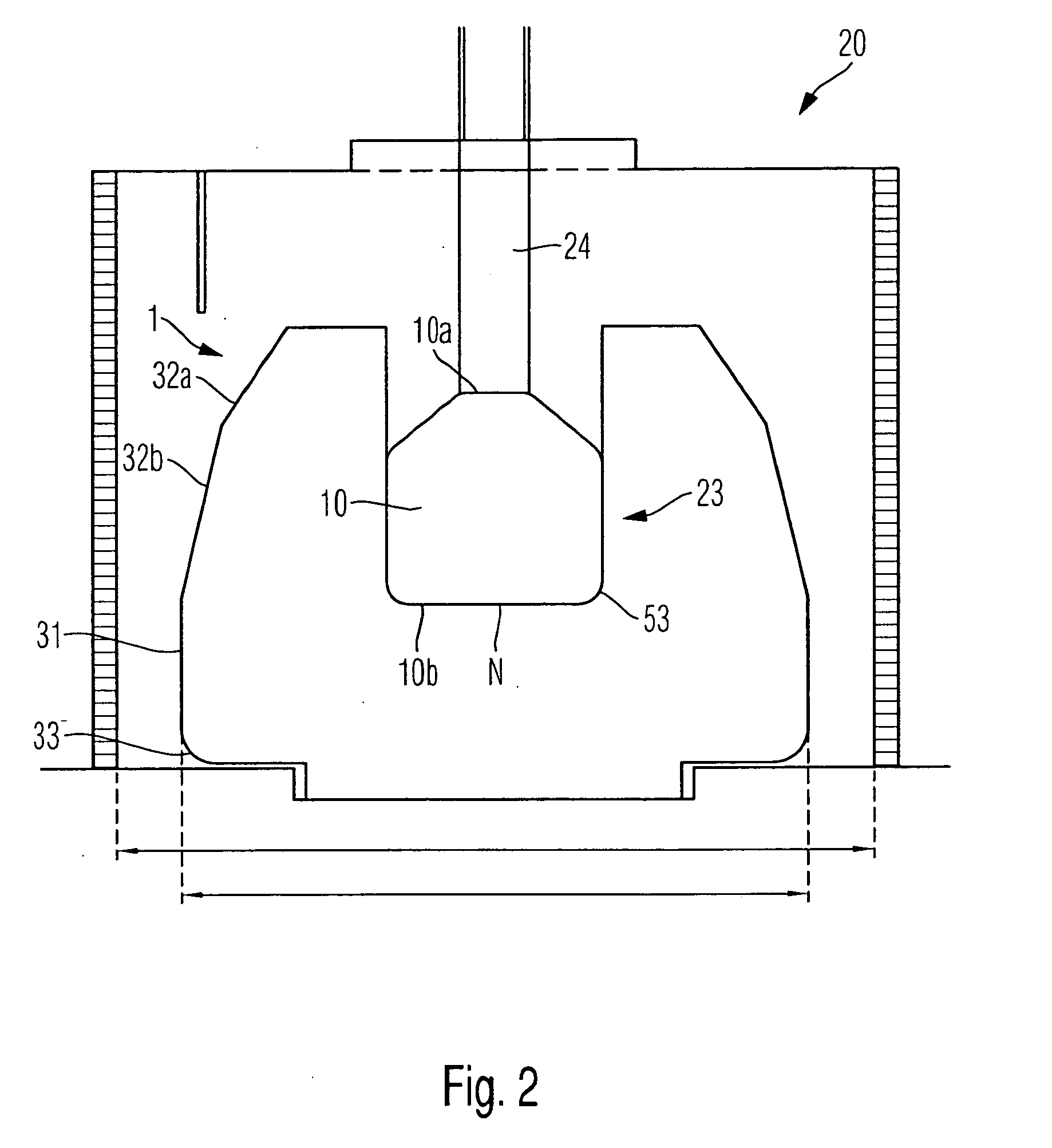

Method for producing a motor vehicle component and motor vehicle component

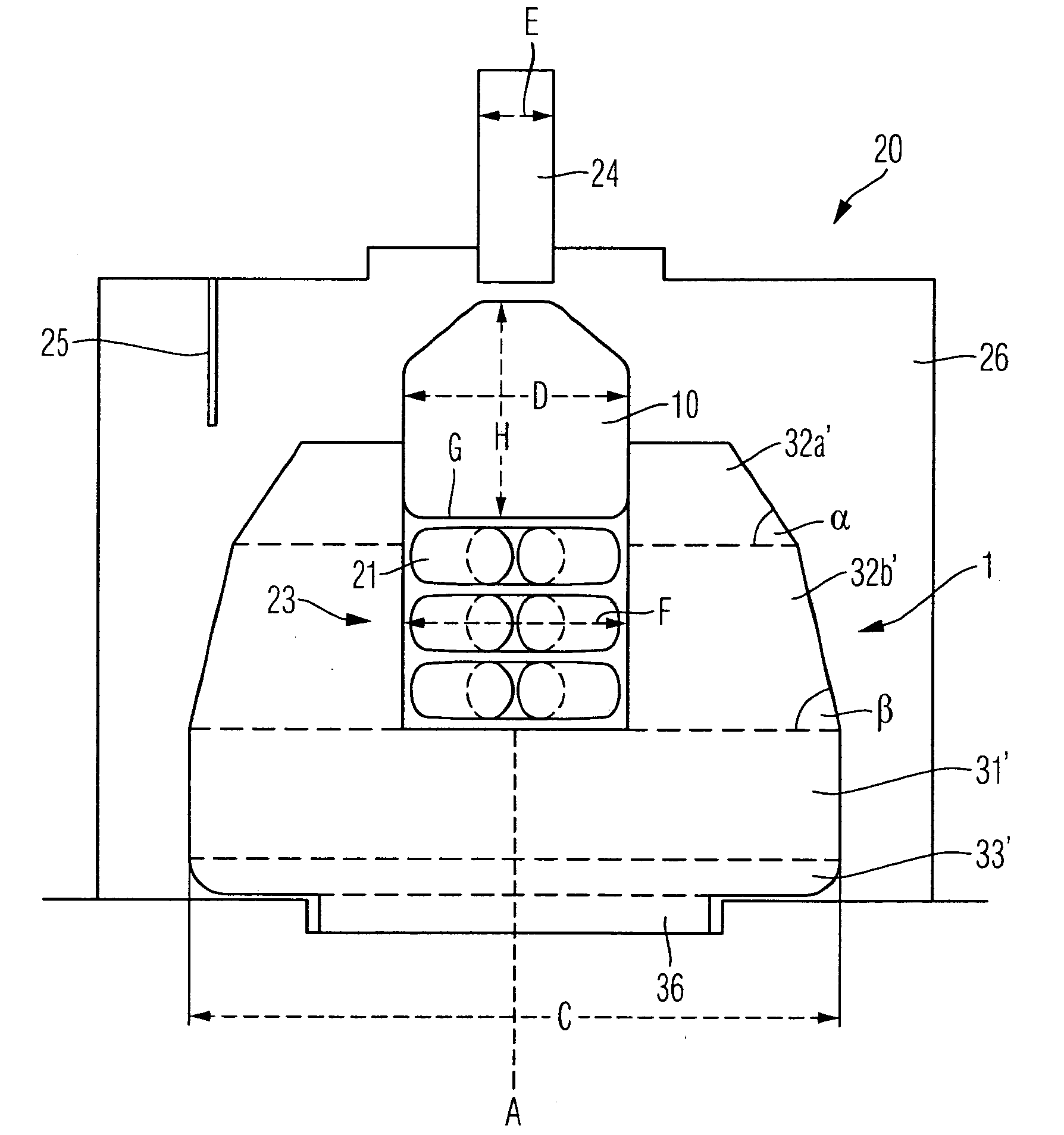

InactiveUS20130106138A1Prevent stress crackingAvoid stress crackingVehicle seatsAdhesive processes with adhesive heatingFibrous compositesMetallic materials

A method for producing a motor vehicle hybrid component and motor vehicle hybrid component are disclosed, wherein the motor vehicle hybrid component has a base body produced from a metallic material which is then reinforced with a reinforcement patch made from a fiber composite material. A metallic layer is then applied onto the reinforcement patch. The metallic layer increases the strength of the component while maintaining an approximately identical specific component weight.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

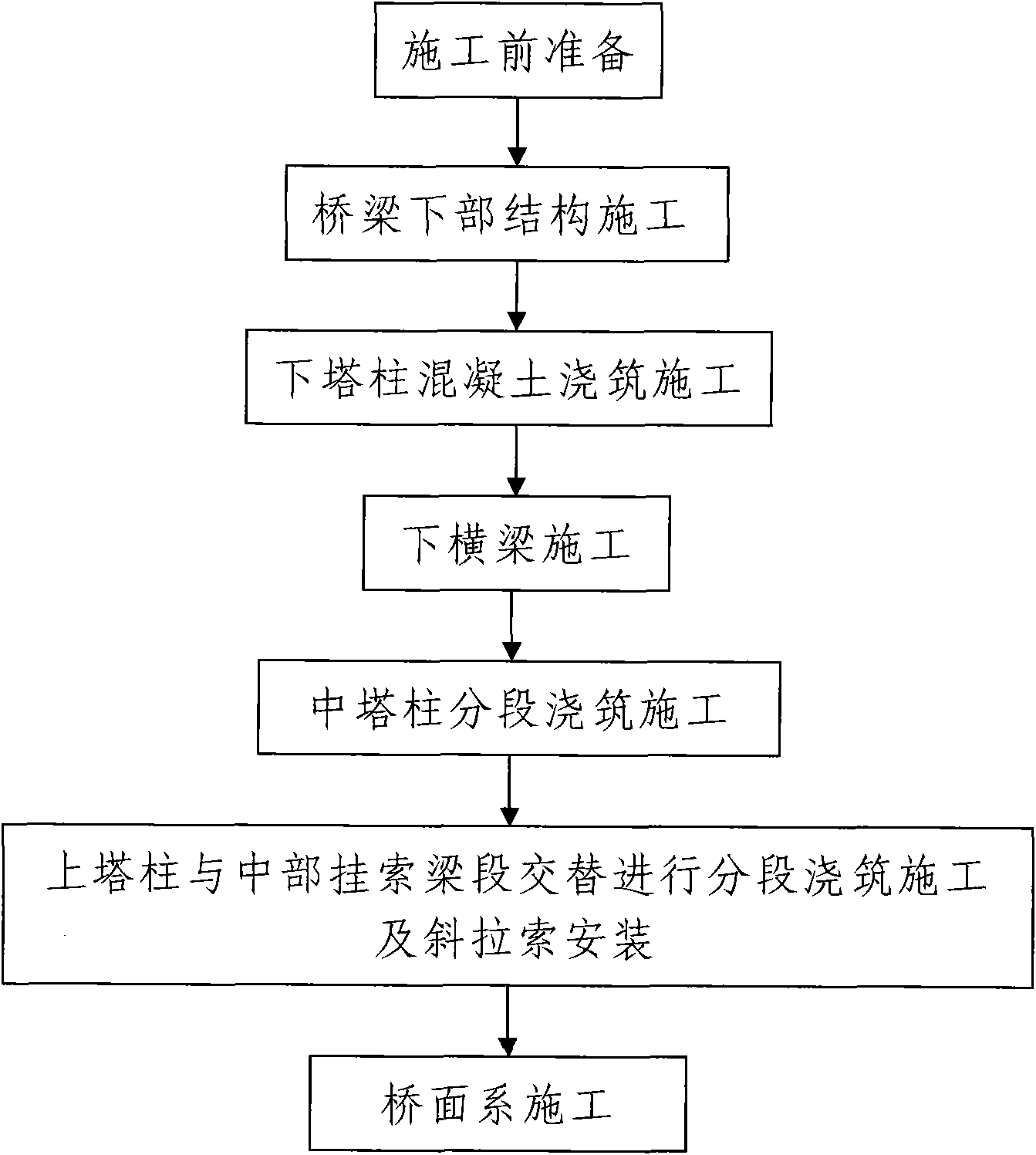

Construction method of single-pylon cable-stayed bridge without dorsal cables

ActiveCN101781879AStable structureGood construction performanceCable-stayed bridgeBridge erection/assemblyCable stayedSystem construction

The invention discloses a construction method of a single-pylon cable-stayed bridge without dorsal cables. The construction method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction, which comprises the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The construction method has reasonable step design, convenient construction, safe and reliable construction, high construction quality, short construction period and less and simple construction hardware equipment and can effectively overcomes the defects and deficiencies of complicated construction process, difficult guarantee of construction quality, various hardware equipment needed, and the like in the construction process of the single-pylon cable-stayed bridge without dorsal cables.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Method for producing a motor vehicle component and motor vehicle component

ActiveCN103085293AAvoid stress crackingSuperstructure subunitsDomestic articlesMetallic materialsFibrous composites

A method for producing a motor vehicle hybrid component(1) and motor vehicle hybrid component are disclosed, wherein the motor vehicle hybrid component has a base body produced from a metallic material which is then reinforced with a reinforcement patch (8)made from a fiber composite material. A metallic layer is then applied onto the reinforcement patch(8). The metallic layer (10) increases the strength of the component while maintaining an approximately identical specific component weight.

Owner:SGL CARBON SE

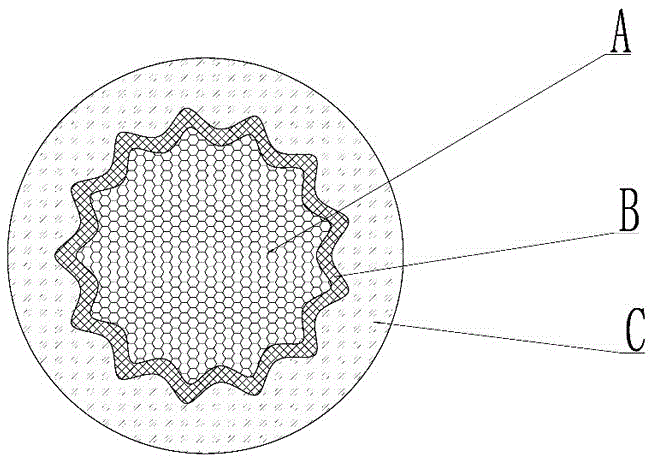

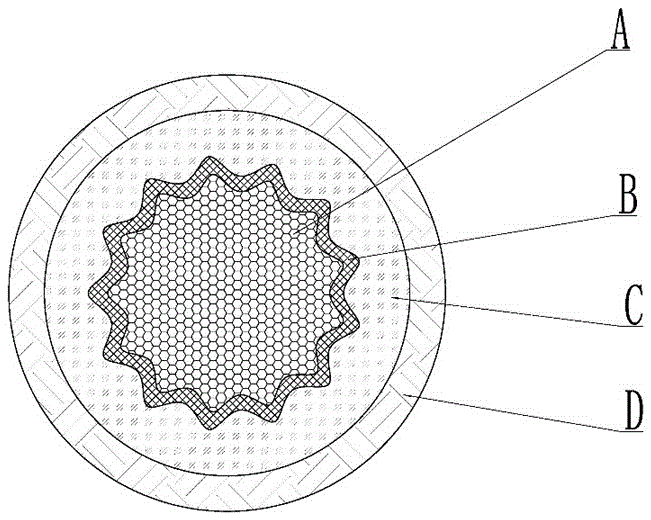

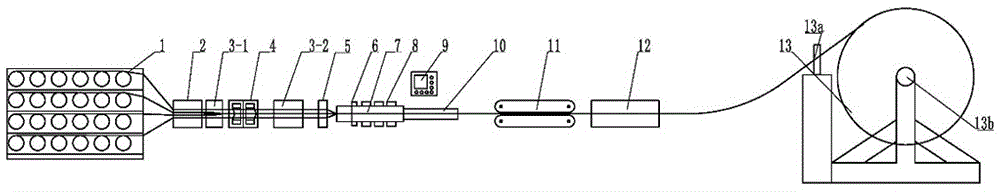

Eccentric-wear-resistant carbon fiber reinforced composite material continuous sucker rod and manufacturing device and method thereof

ActiveCN105625951AIncrease contact areaImprove wear resistanceDrilling rodsDrilling casingsCarbon fiber reinforced compositeWear resistant

The invention relates to an eccentric-wear-resistant carbon fiber reinforced composite material continuous sucker rod and a manufacturing device and method thereof.The continuous sucker rod is mainly composed of a carbon fiber reinforced layer along the axial direction of a rod body, a high-modulus glass fiber winding layer, and a wear-resistant high-modulus glass fiber reinforced layer along the axial direction of the rod body, the carbon fiber reinforced layer on the inner layer and along the axial direction of the rod body is formed by continuous acrylonitrile-based carbon fibers, the high-modulus glass fiber winding layer is a high-modulus glass fiber winding layer, the wear-resistant high-modulus glass fiber reinforced layer along the axial direction of the rod body is formed by wear-resistant high-modulus glass fibers, and a resin matrix is a multifunctional group epoxy resin system.The continuous sucker rod has the advantages that the winding layer is added, the inside of the continuous sucker rod is of a wavy structure, and three structural layers are solidified and formed in one time, so that contact area between carbon fibers and glass fibers is increased, interlayer bonding force is increased, layering among different reinforced materials when the rod body twists due to a concentric circle structure is avoided, radial and axial compressive strength is improved, and bending diameter is reduced.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

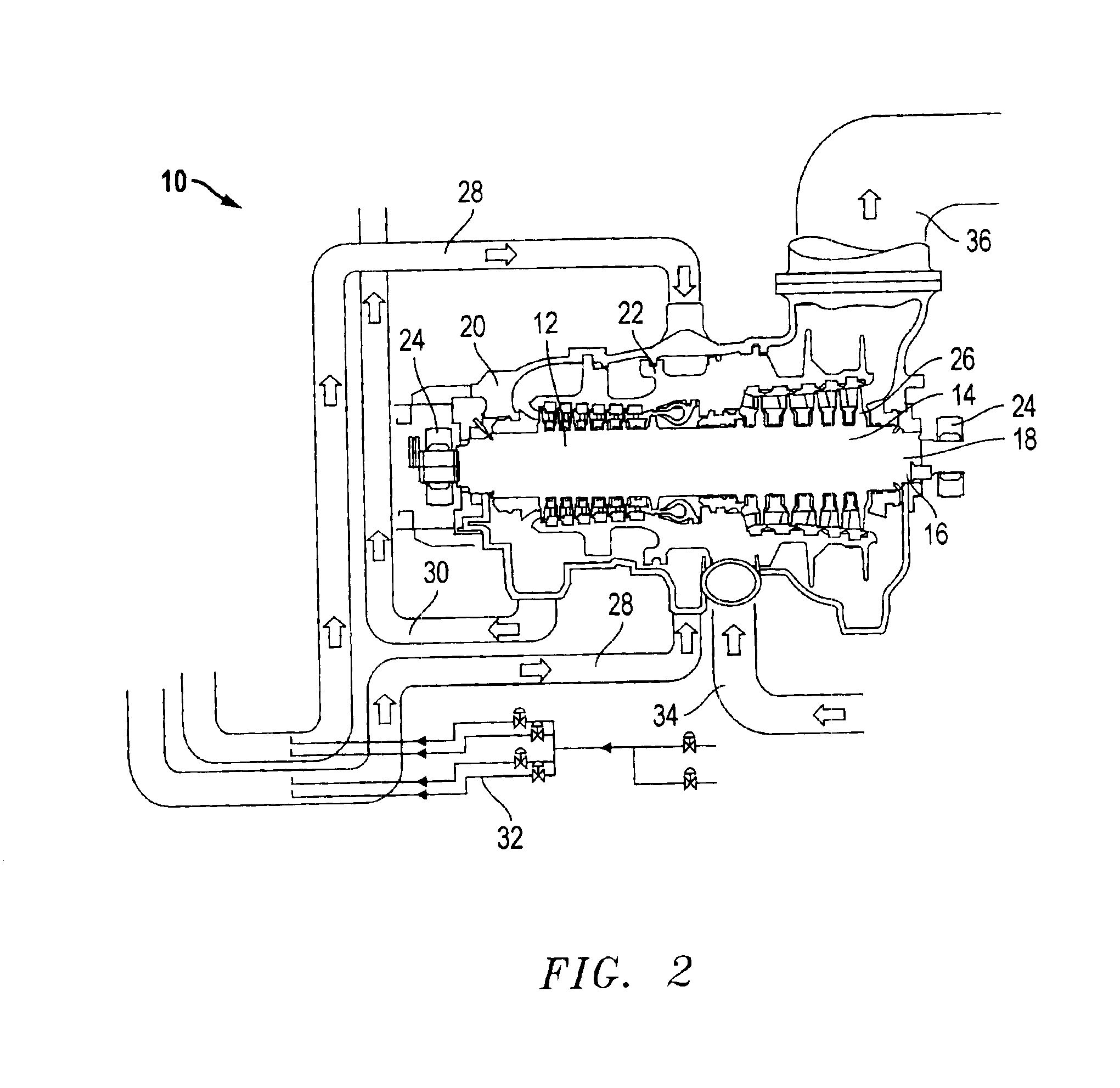

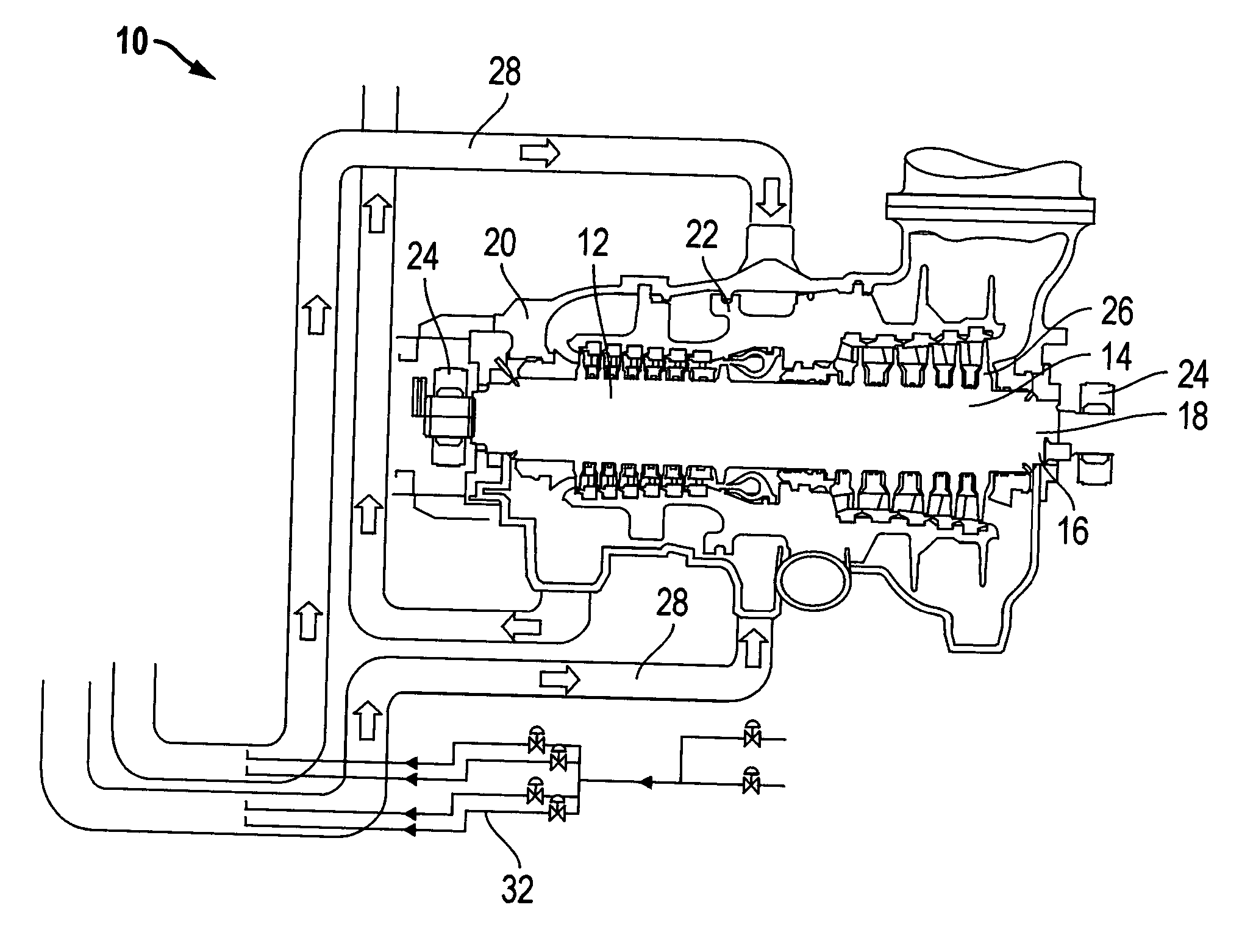

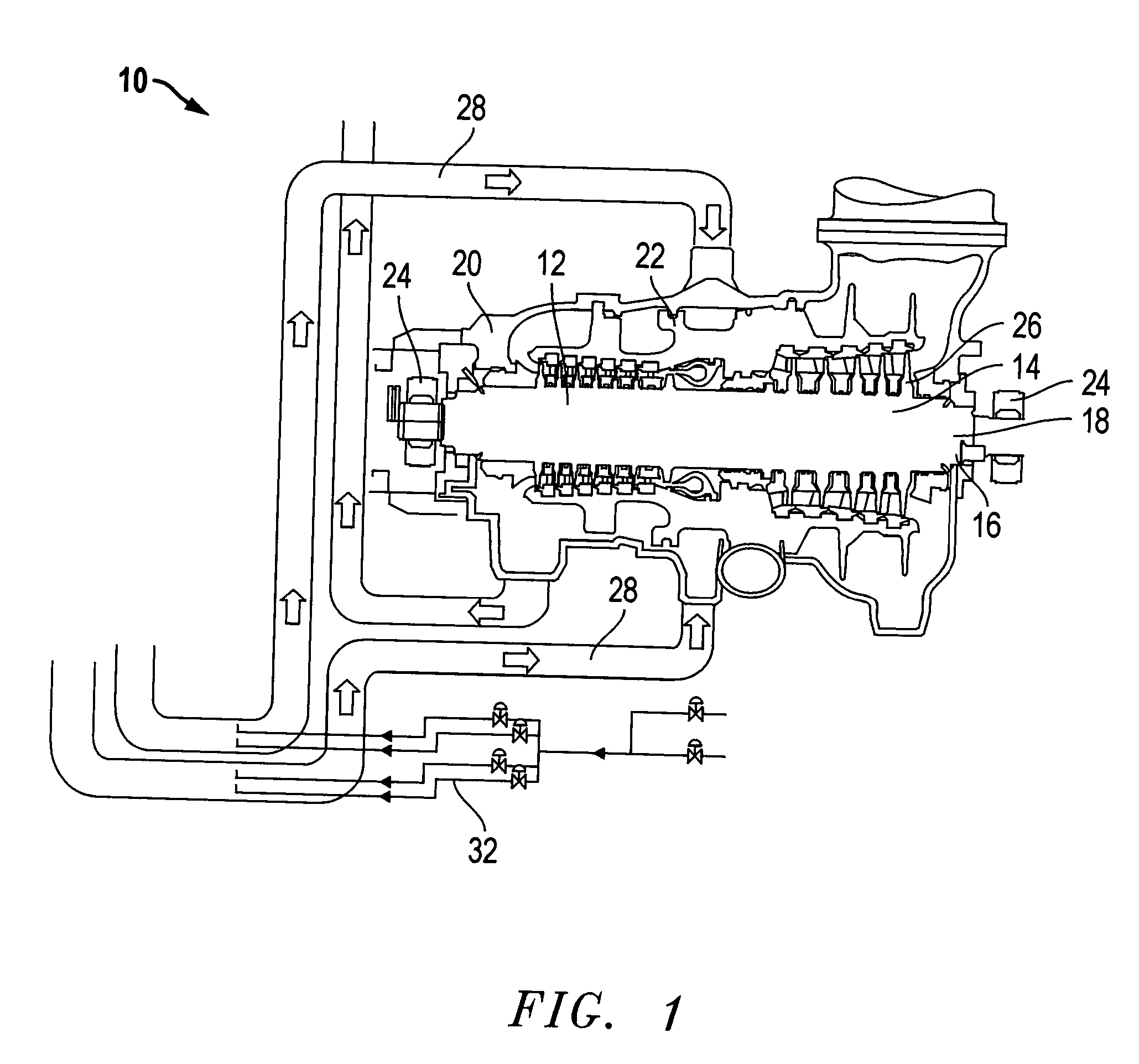

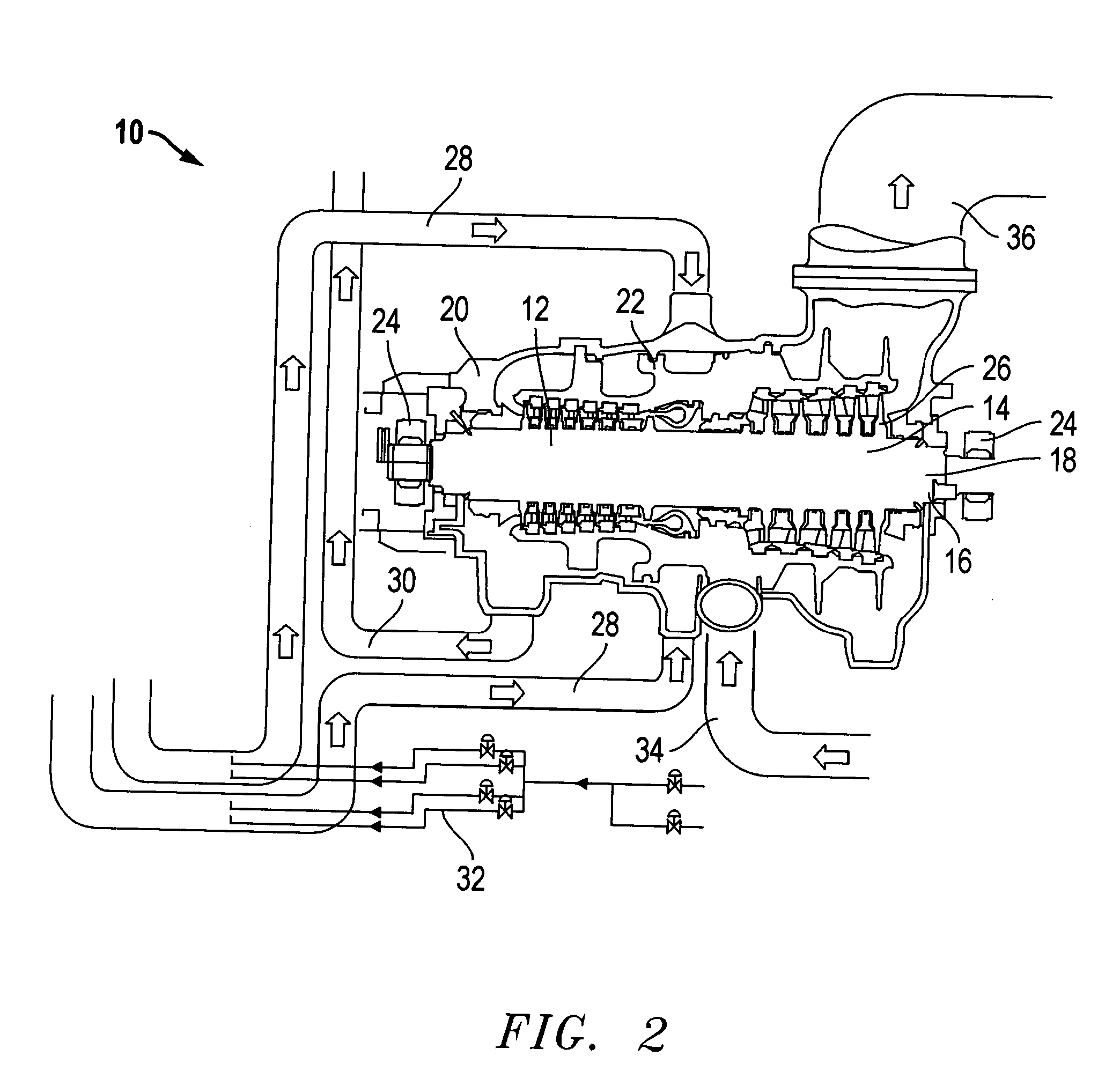

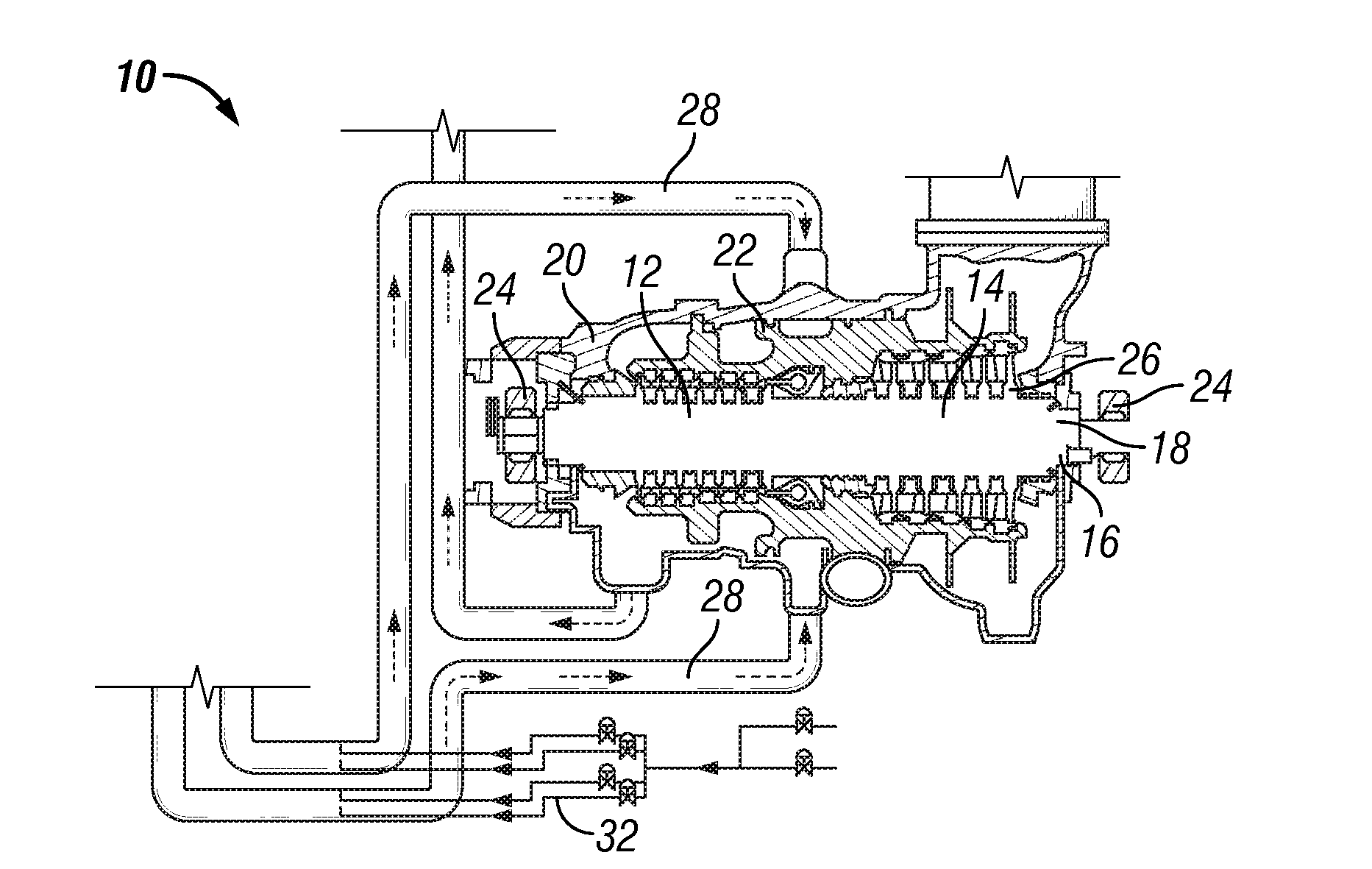

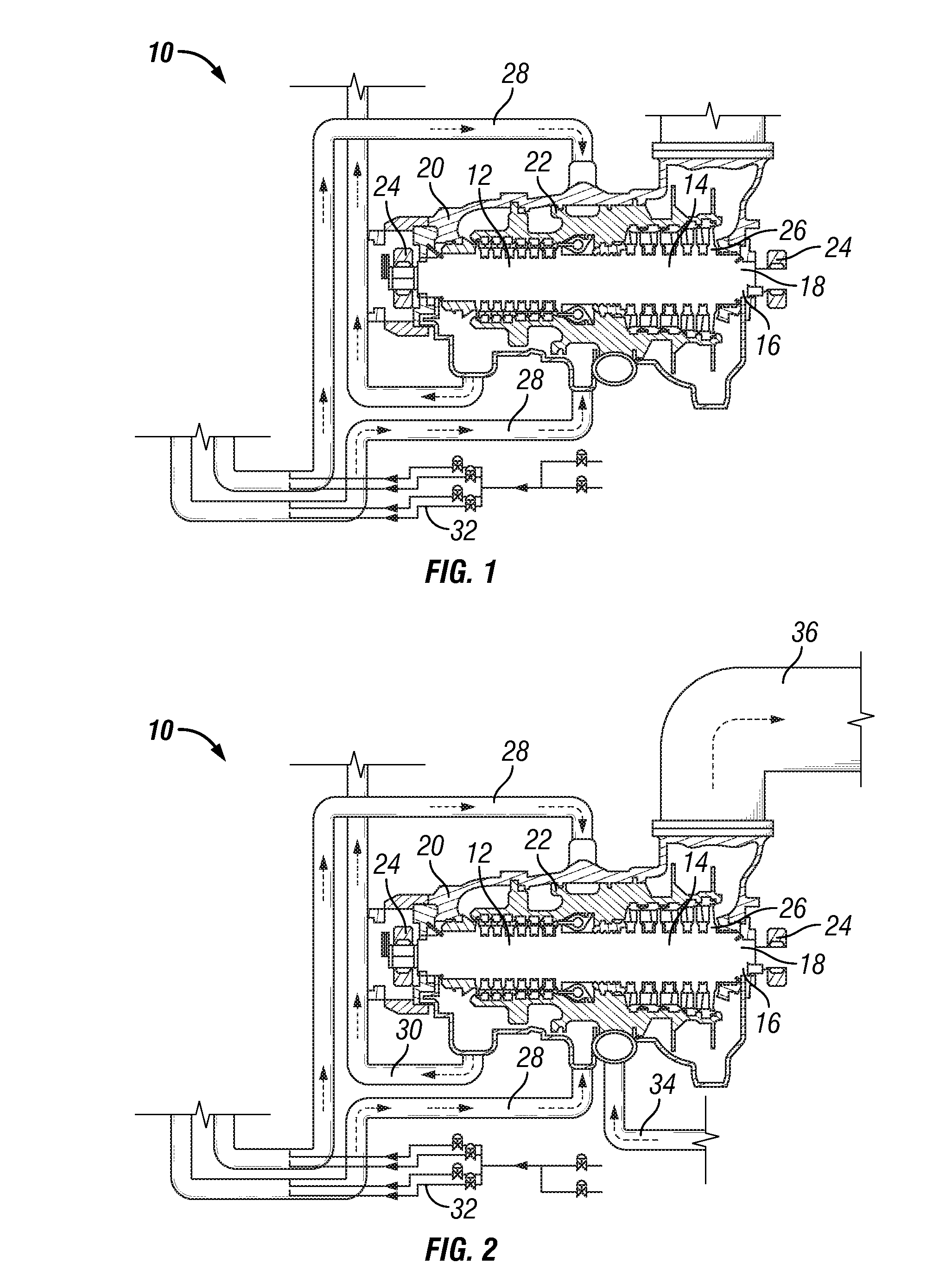

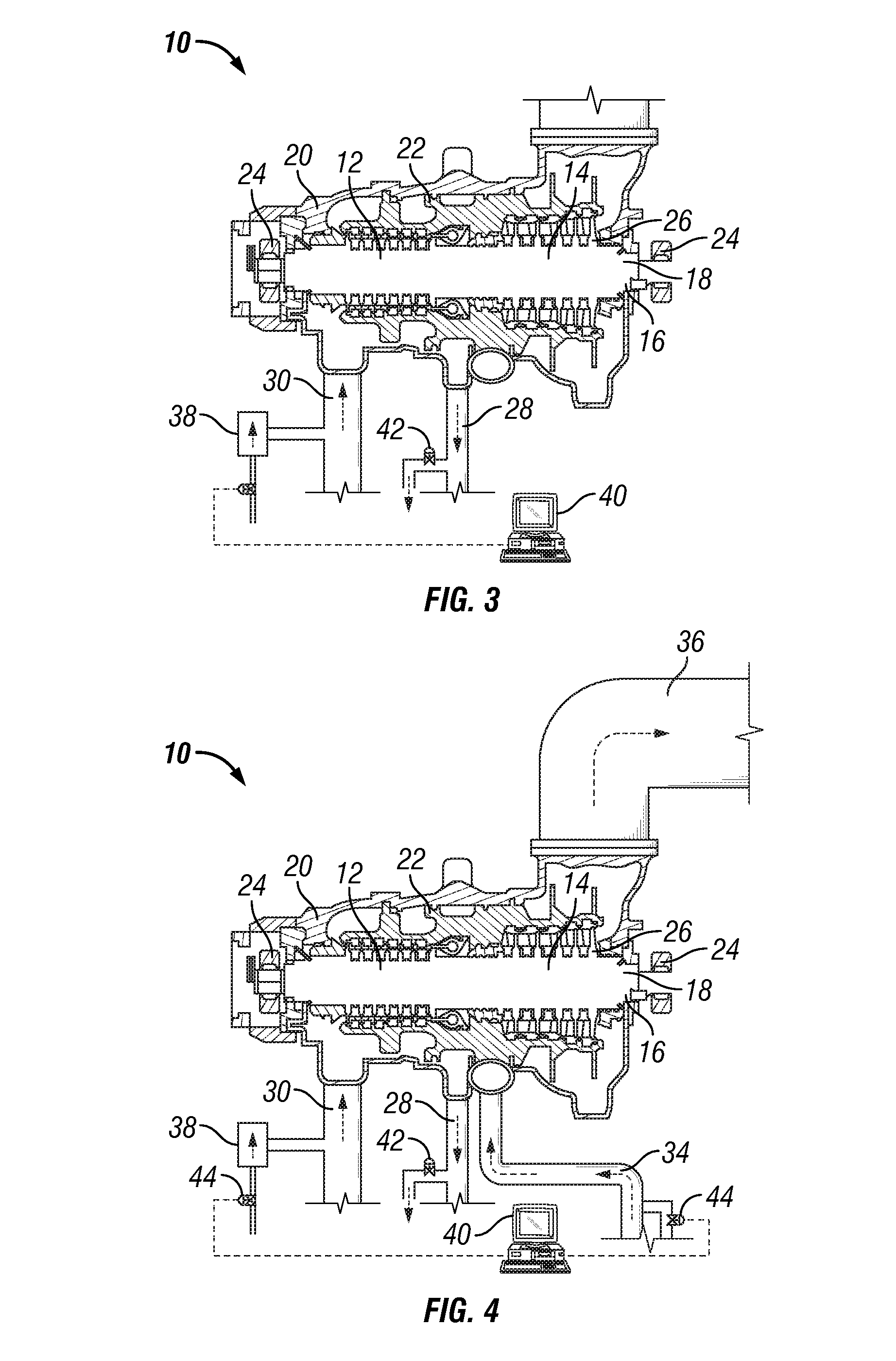

System and method of cooling steam turbines

InactiveUS6898935B2Improve efficiencyReduce CooldownLiquid degasificationPump componentsPower stationDowntime

A system and method of cooling a steam turbine having internal moving components to a predetermined temperature by controlling a flow of nitrogen through the turbine, thus decreasing the downtime associated with maintaining the turbine. This provides a more efficient and cost effective method of operating a power plant.

Owner:BAKER HUGHES INC

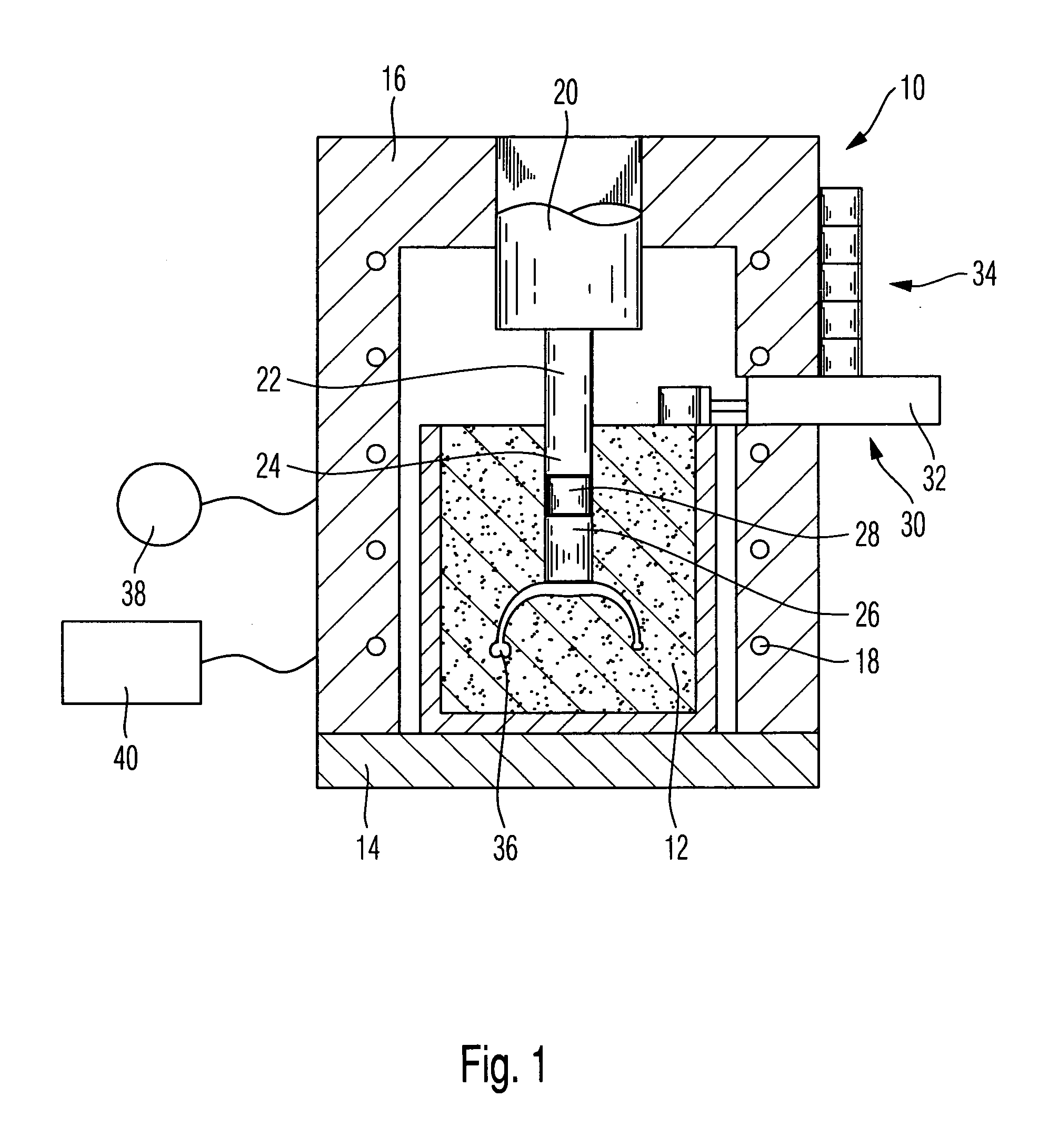

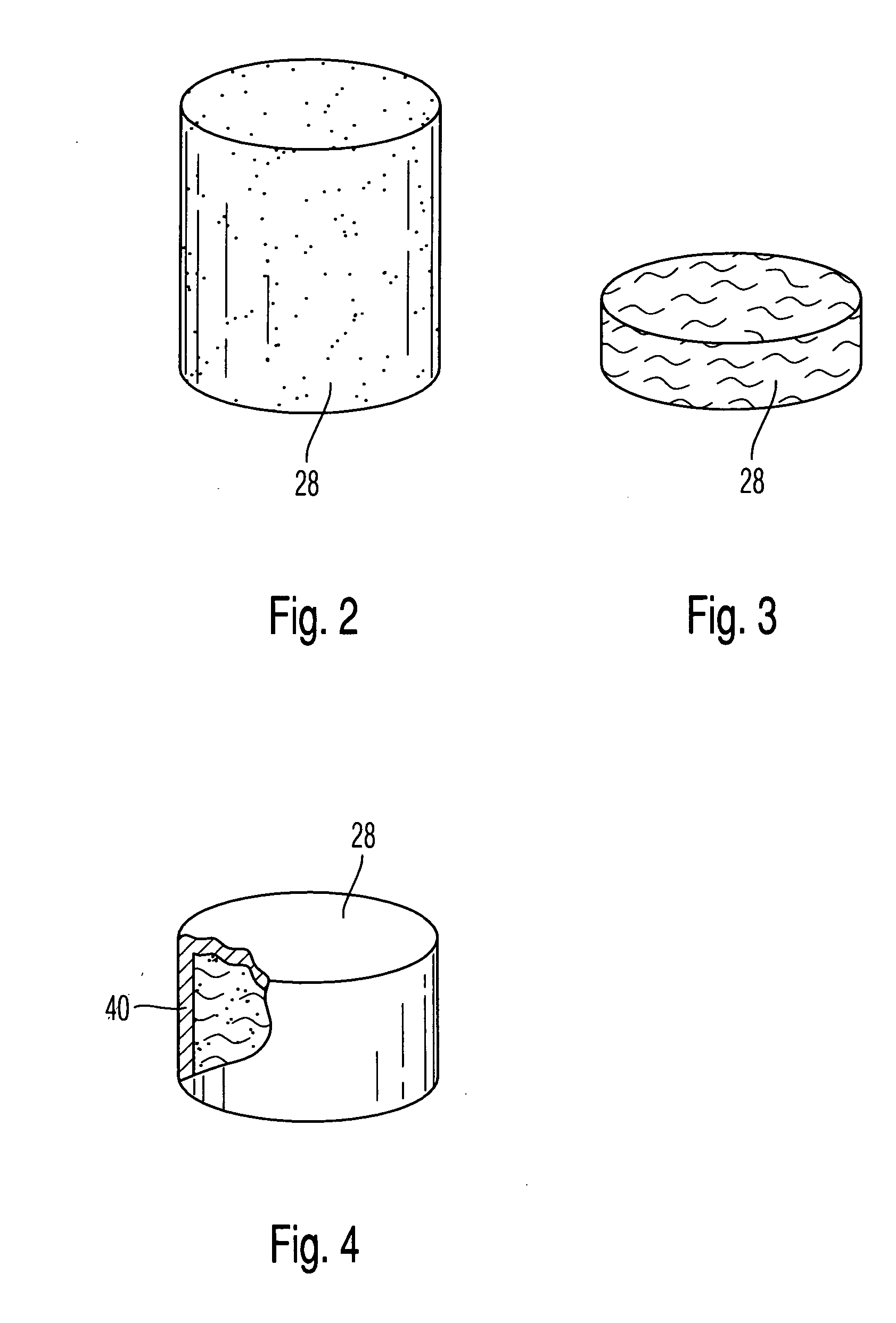

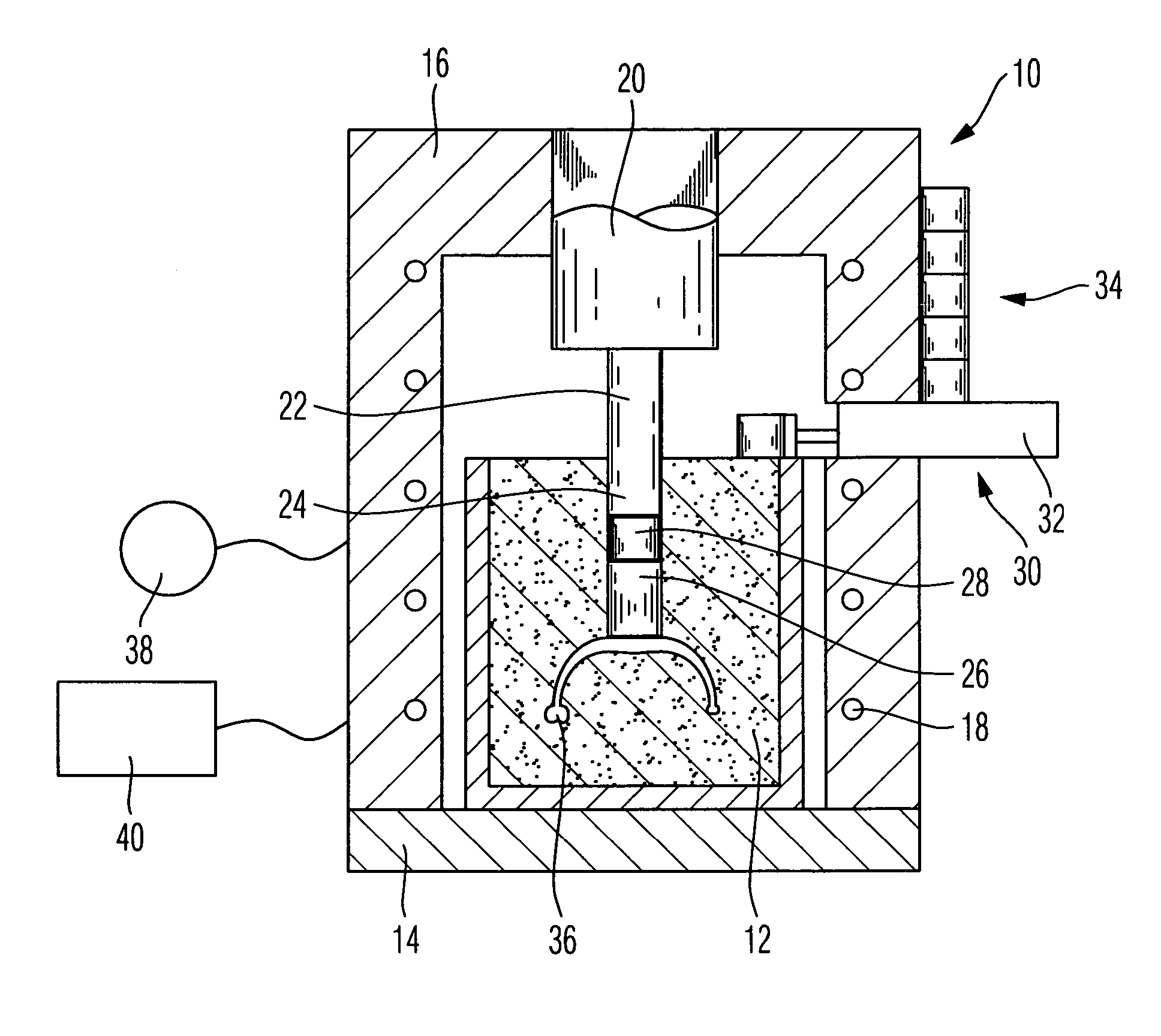

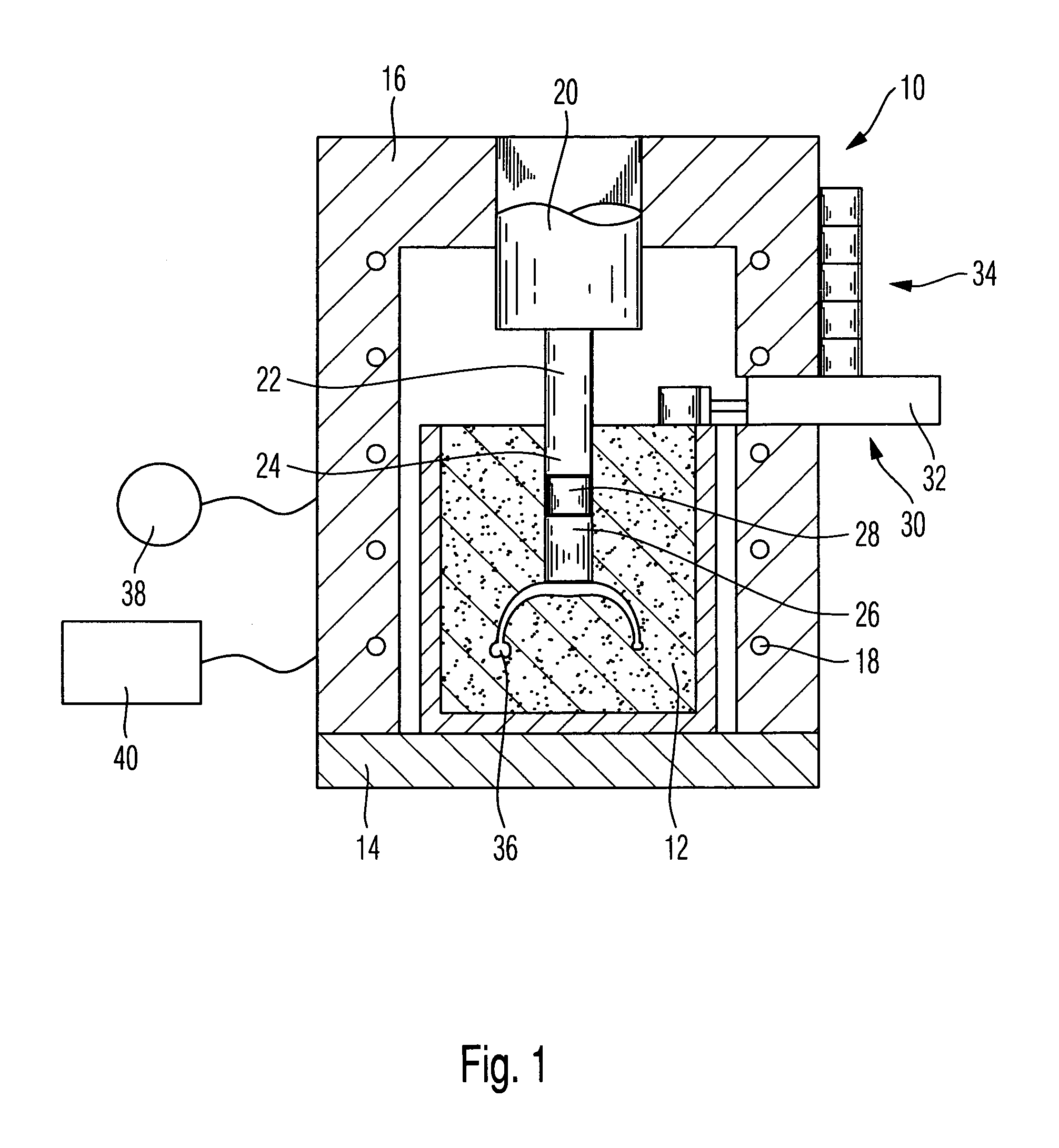

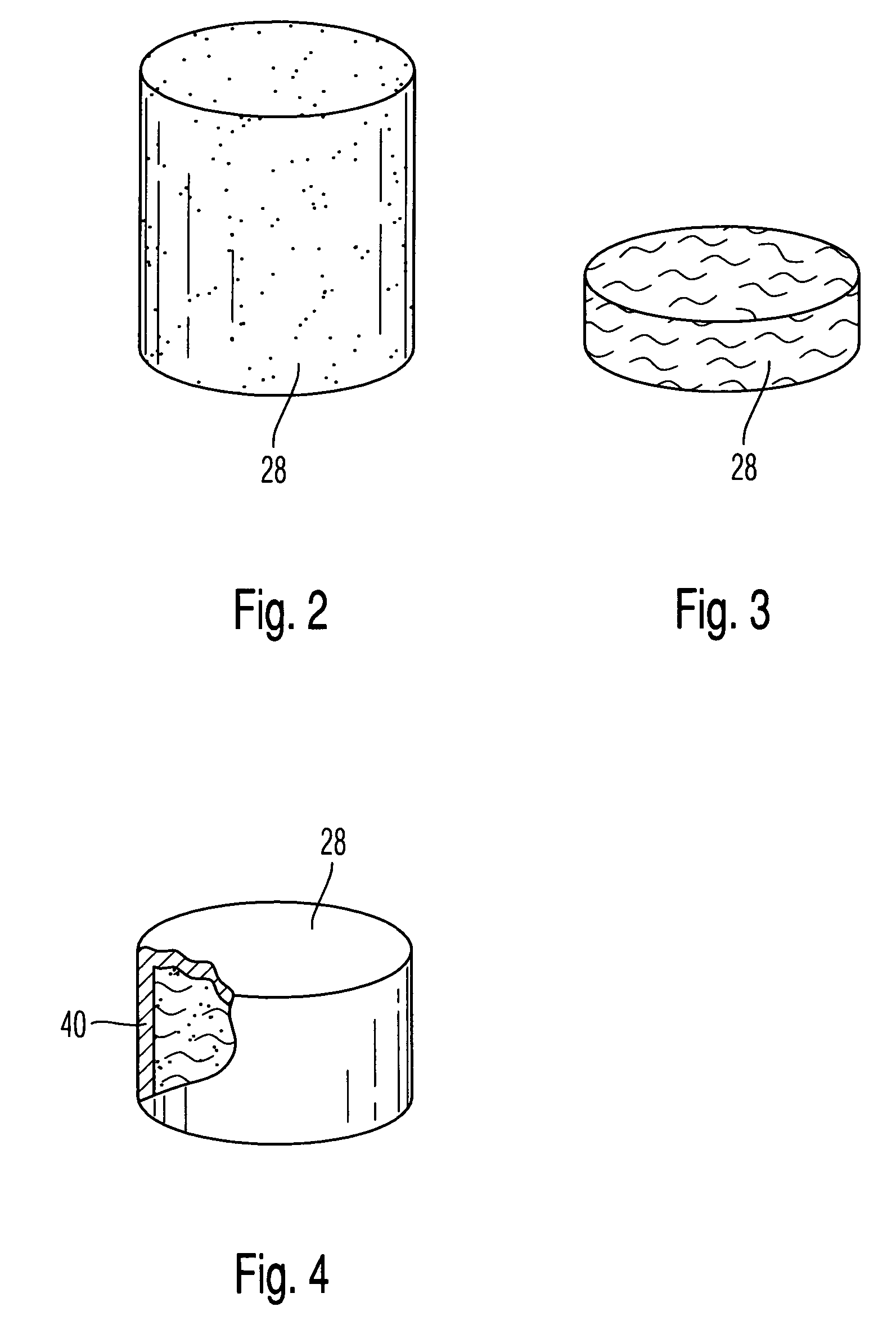

Press oven including an intermediate body, and method for use

InactiveUS20050204796A1Rapid and stress-minimized press cycleMinimal capital costShaping toolsCeramic shaping apparatusHeat conductingEngineering

A press oven, especially for the pressing of dental material, includes a press stamp via which pressure can be exerted on a blank in a matrix mass of a muffle. An intermediate body is positionable between the press stamp and the blank and the heat conducting capability of the intermediate body (28) is less than that of the blank (26), the press stamp (22) or the matrix mass of the muffle (12).

Owner:IVOCLAR VIVADENT AG

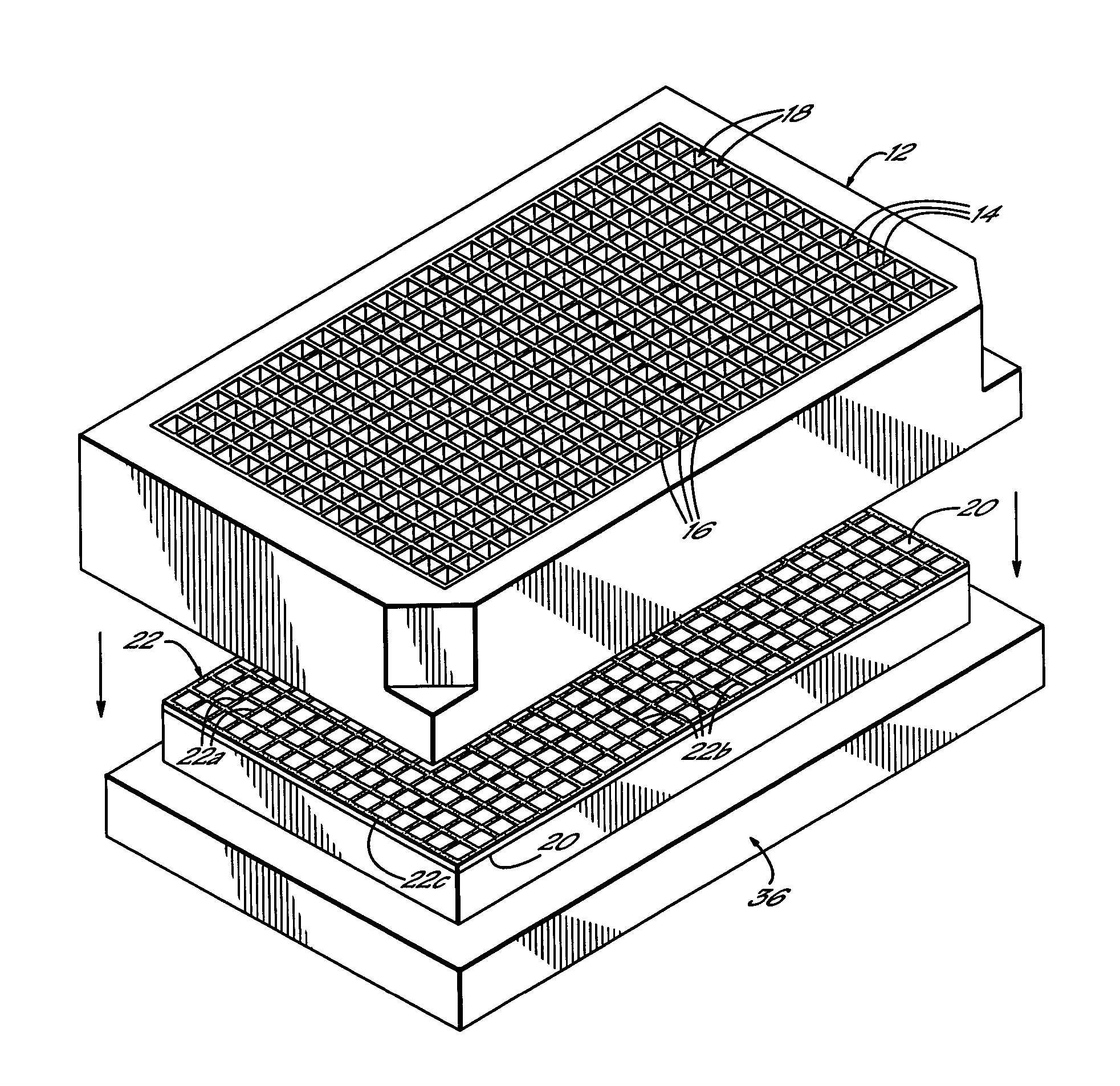

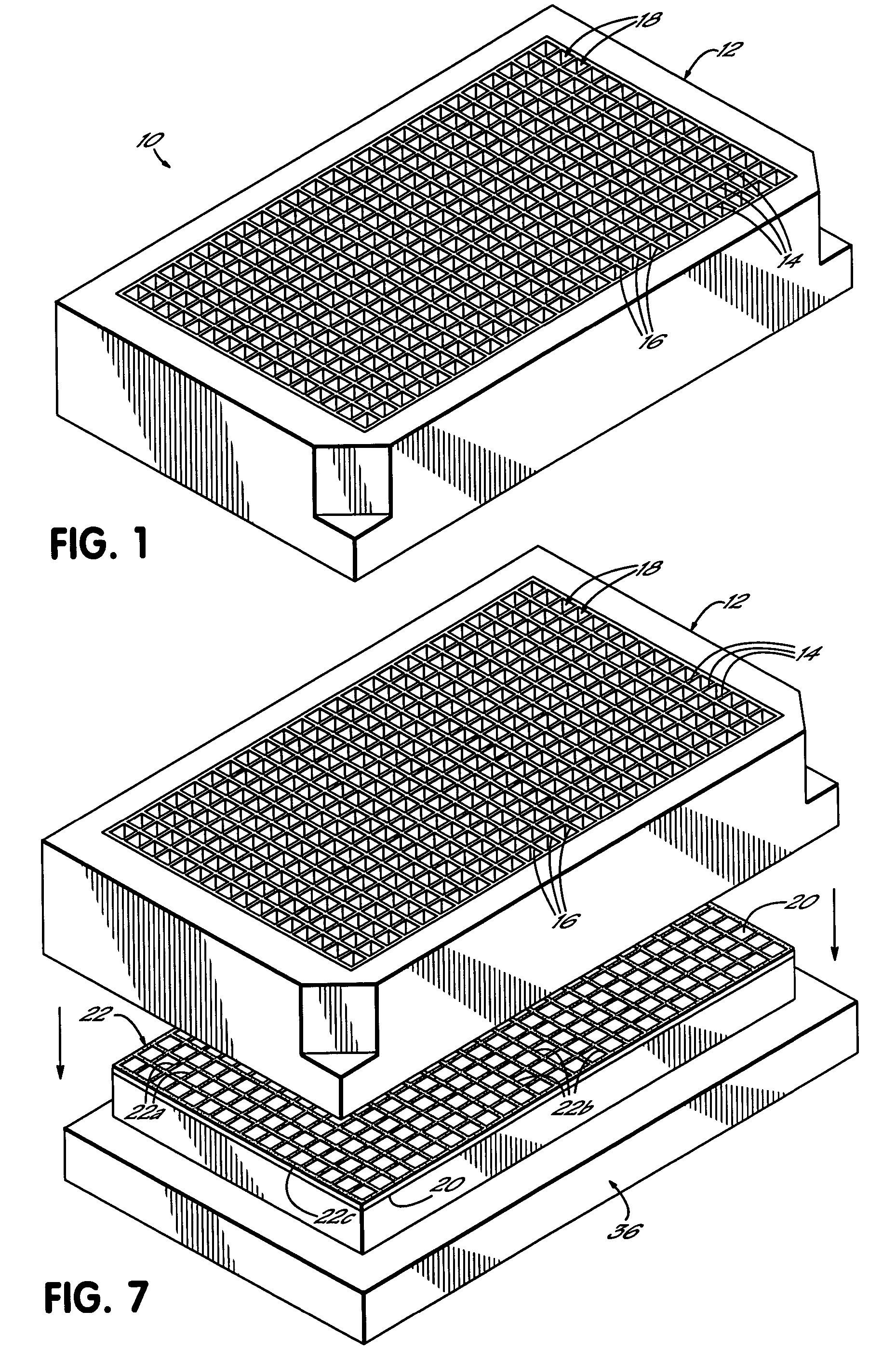

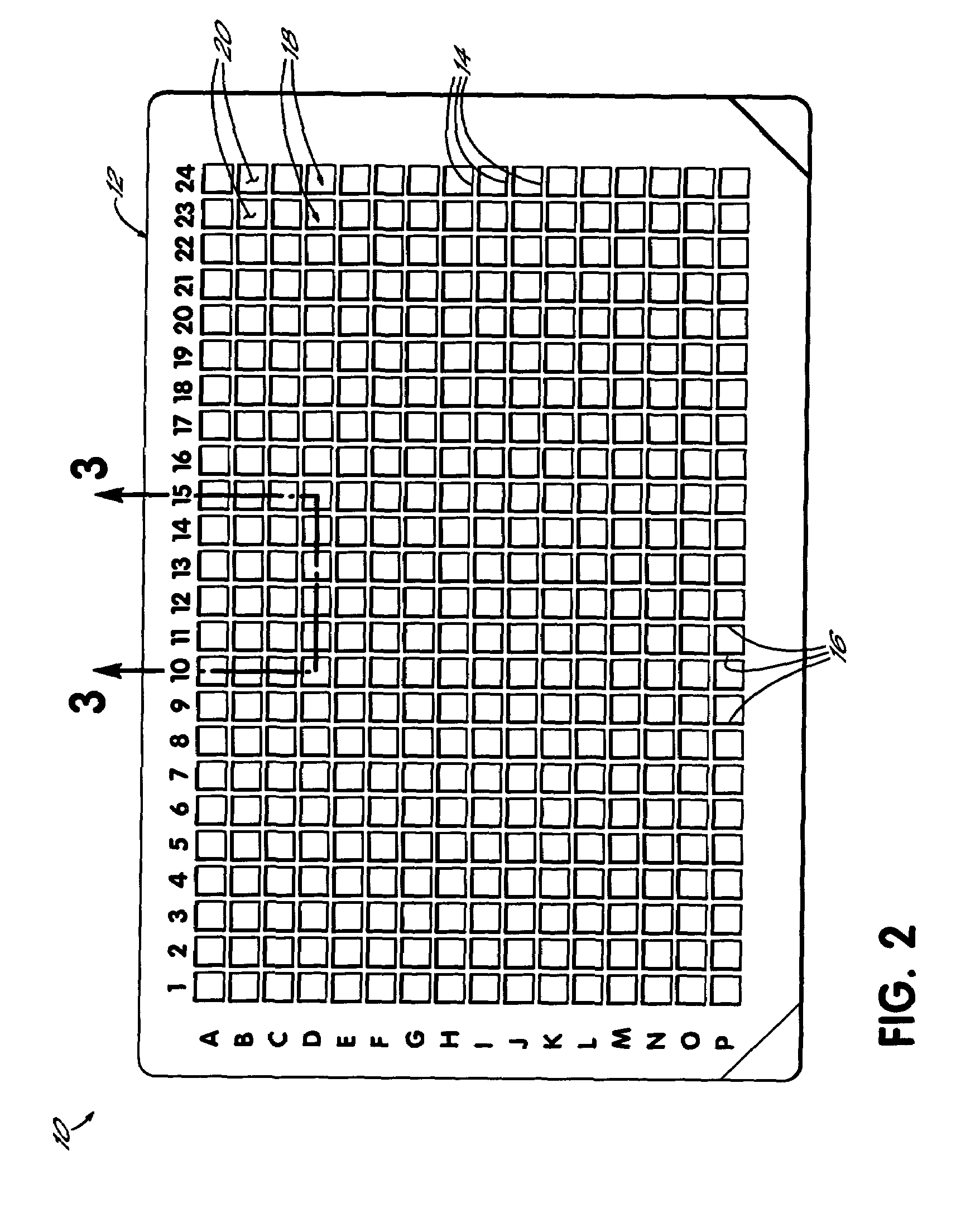

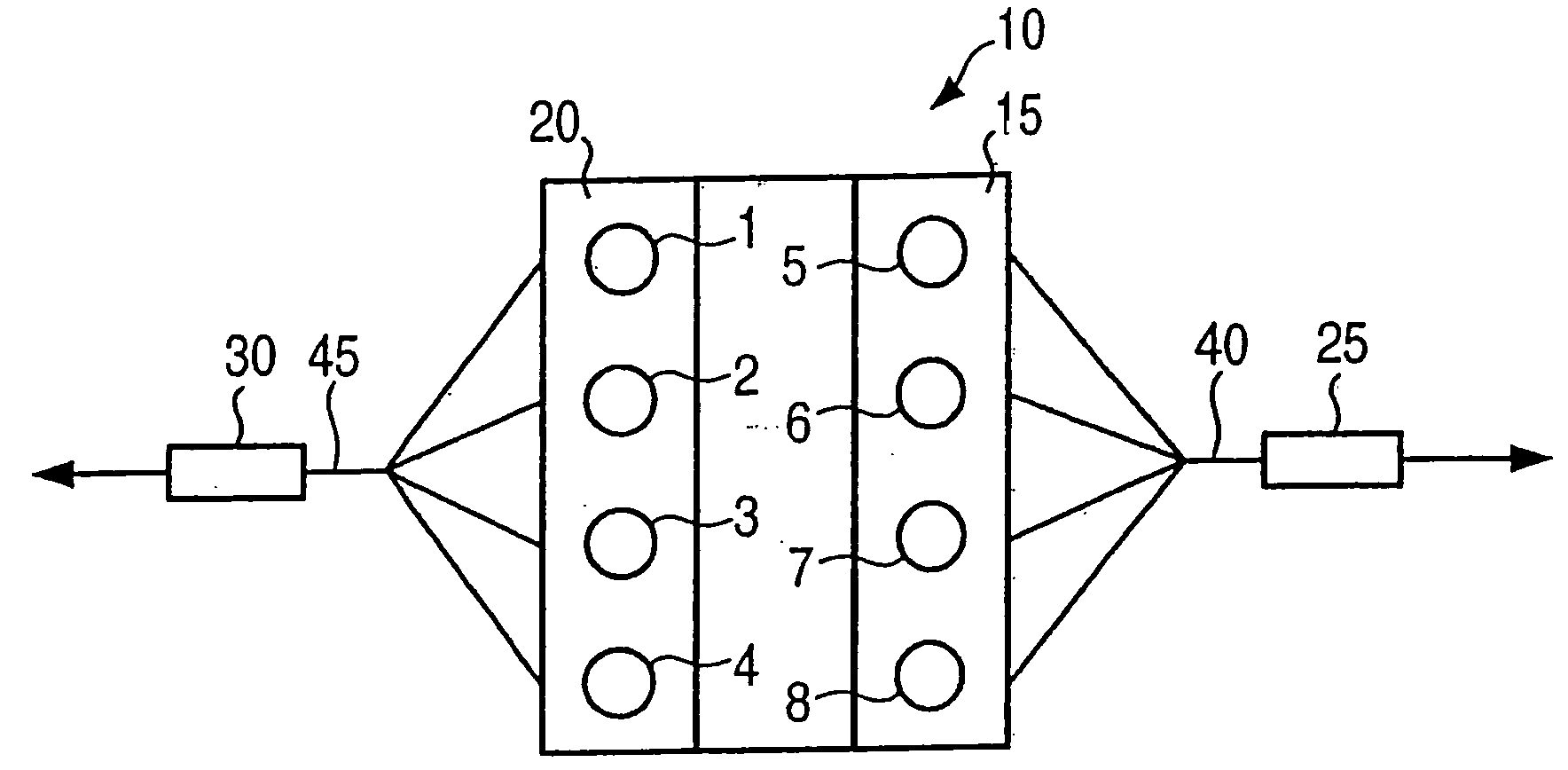

Method of making a multi-well test plate having adhesively secured transparent bottom panel

InactiveUS7005029B2Minimize flowAccurate placementBioreactor/fermenter combinationsBiological substance pretreatmentsNon toxicityAdhesive

A method of making a multi-well test plate including an upper frame portion and a glass panel secured to a lower side of the upper frame portion with a layer of light-curable adhesive. The upper frame portion includes a plurality of walls defining adjacent wells for receiving assay samples. The adhesive has various properties, such as high viscosity, thixotropicity, transparency, water insolubility, non-autofluorescence, and non-toxicity, as well as others that are advantageous when constructing and using the multi-well test plate. The adhesive is preferably applied by a screen transfer process that takes advantage of the adhesive properties.

Owner:NALGE NUNC INTERNATIONAL

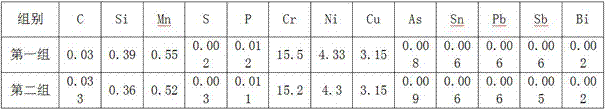

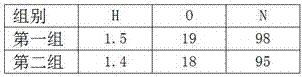

Precipitation-hardening martensitic stainless steel 17-4PH smelting technology

ActiveCN107385144AReduce manufacturing costReduce smelting timeElectric furnaceProcess efficiency improvementMartensitic stainless steelPrecipitation

The invention belongs to the field of stainless steel smelting, and particularly relates to a precipitation-hardening martensitic stainless steel 17-4PH smelting technology. The smelting technology comprises the steps that an EAF / IF-LF-VOD-LF-VD-IC technological route is adopted, and low-phosphorous and low-five-harmful-element primary smelting molten steel in a smelting electric furnace, medium-frequency melting alloy and electric furnace tapping steel are industrially blended and then enter an LF refining furnace for chemical component adjustment; drossing is conducted, VOD vacuum oxygen blowing and primary reduction are conducted, and then comprehensive reduction and alloy fine adjustment are conducted in a refining furnace; and VD degassing and mold-casting steel pouring are conducted, and 17-4PH stainless steel which is low in carbon, gas, impurity and five-harmful elements is produced. The invention aims at overcoming the detects that in the prior art, steel obtained in 17-4PH smelting is higher in H, O and N content, and the using property of products is seriously affected, and providing the low-gas-content and low-impurity precipitation-hardening martensitic stainless steel 17-4PH smelting technology.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Method for producing alloy plastic die steel using direct hot delivery and hot charging technique

A method which adopts direct hot feeding and hot charging technique for manufacturing alloy plastic mold steel belongs to the technical field of medium steel plate. The technique comprises the steps of furnace revolving, LF desulfurizing, RH vacuum degassing, continuous casting, cutting, hot feeing, hot charging and heating. The continuous casting sheet billet with thickness of 200-380mm is hot fed and hot charged into a heating furnace after wire cutting without slowly cooling or annealing. The superheat degree of continuous casing pouring is controlled to 10-30 DEG C. The pulling rate is matched with superheat degree and is controlled to 0.7-1.0m / min. The plate bank is directly fed to a heating furnace through the hot feeding roller conveyor after linear fixed-length cutting. The plate blank can be executed with the hot charging technique after linear fixed-length cutting if surface checking or other production organization problem occurs. The plate blank is hotly charged into the heating furnace at a temperature which is larger than or equal to 550 DEG C after checking out of production line. When the plate blank is charged into the heating furnace, the temperature of heating furnace is between 500 and 700 DEG C, and the temperature of preheating section is between 450 and 600 DEG C. The method of the invention has the advantages of excellent heating quality of plate blank according to the technique, shorted production period, and reduced energy consumption of heating furnace.

Owner:SHOUGANG CORPORATION +1

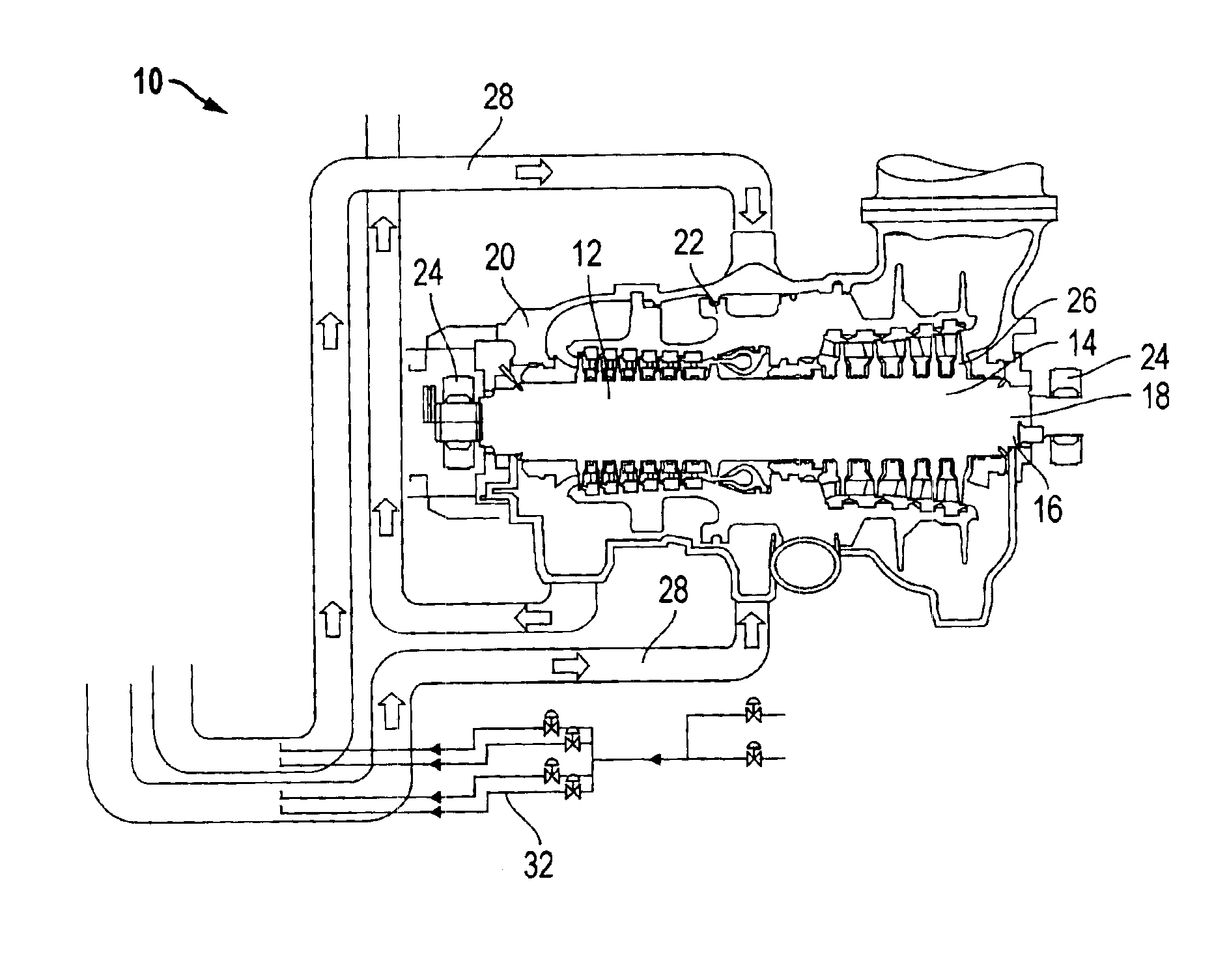

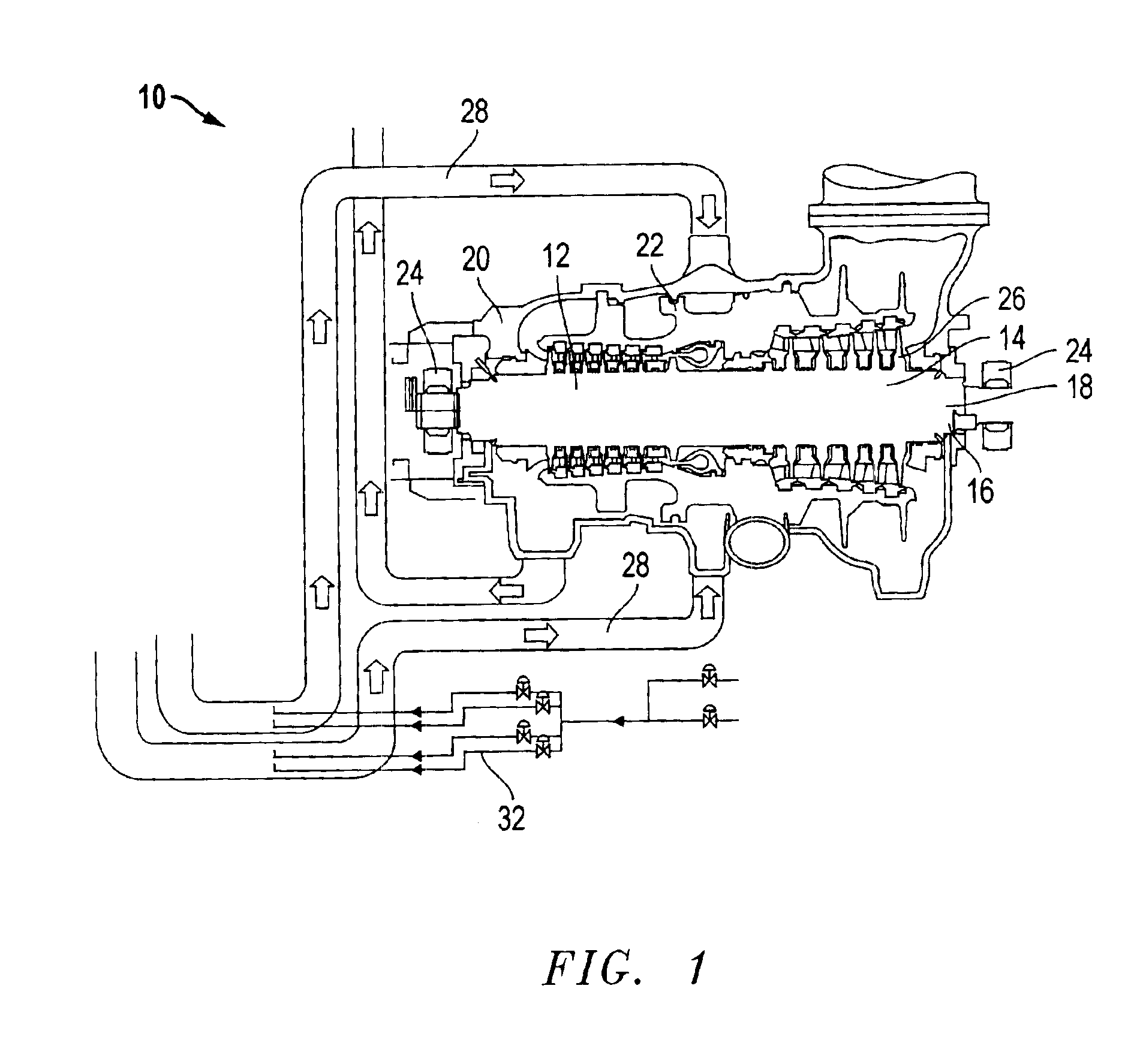

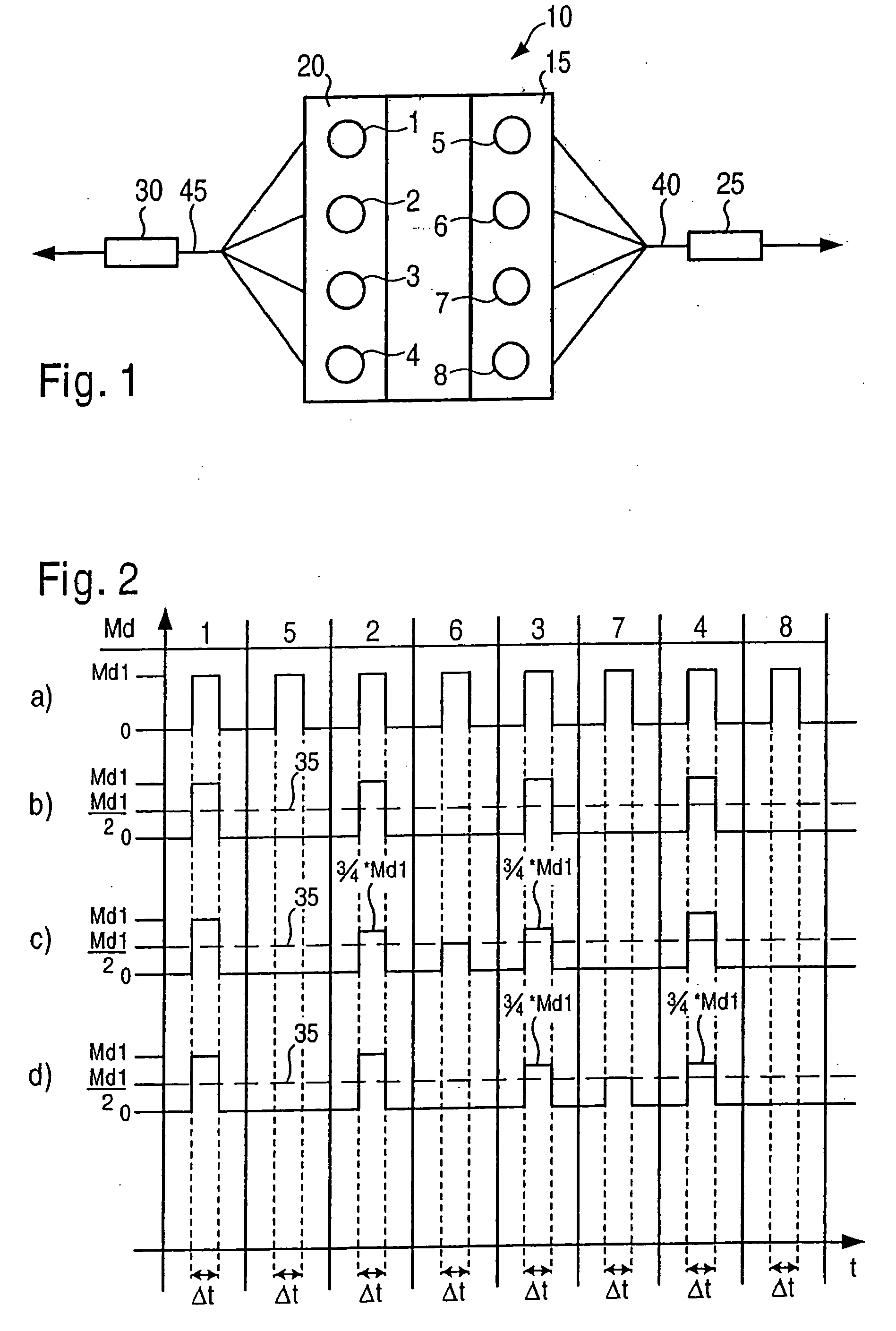

Method for Operating an Internal Combustion Engine having a plurality of cylinder banks

InactiveUS20090133662A1Ensure maintenanceExtended durationOutput powerMachines/enginesEngineeringInternal combustion engine

A method is provided for operating an internal combustion engine having a plurality of cylinder banks, of which at least one first cylinder bank is able to be deactivated. At least one cylinder of the first cylinder bank is intermittently activated again during the deactivation of the first cylinder bank.

Owner:ROBERT BOSCH GMBH

System and method of cooling steam turbines

InactiveUS20050016175A1Reduce downtimeEfficient and cost-effectiveLiquid degasificationPump componentsPower stationDowntime

A system and method of cooling a steam turbine having internal moving components to a predetermined temperature by controlling a flow of nitrogen through the turbine, thus decreasing the downtime associated with maintaining the turbine. This provides a more efficient and cost effective method of operating a power plant.

Owner:BAKER HUGHES INC

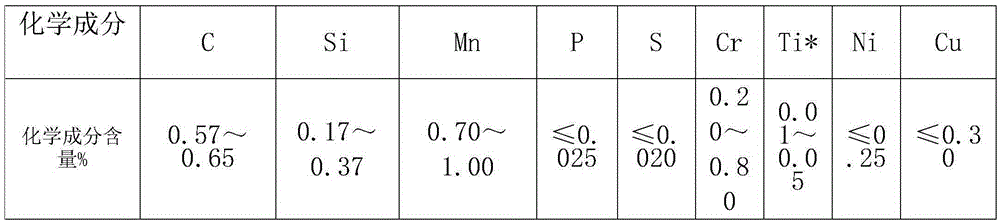

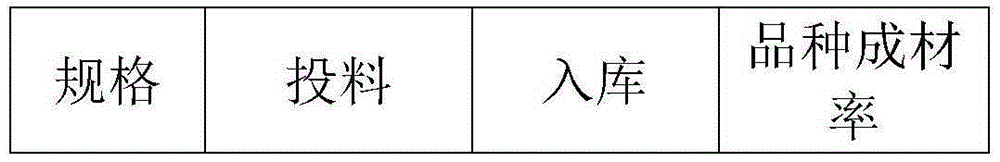

Manufacturing method for anti-abrasion seamless steel pipe for concrete pump truck

The invention discloses a manufacturing method for an anti-abrasion seamless steel pipe for a concrete pump truck. The manufacturing method includes the following steps of steelmaking, wherein molten iron desulphurization, converter / electric furnace utilization, LF refining furnace utilization, VD vacuum treatment and round blank continuous casting are involved; pipe rolling, wherein a pipe blank is heated in an annular furnace and heated at the temperature of 1150 DEG C-1230 DEG C, and pipe blank rolling is finished through perforating, rolling of a mandrel pipe mill, diameter reducing of a stretch-reducing mill and straightening; stress relieving of the steel pipe, wherein a continuous furnace is used for annealing treatment. The process of VD continuous casting blank forming, hot rolling, stress relieving, flaw detection and follow-up treatment is adopted to stably produce the anti-abrasion seamless steel pipe for the concrete pump truck, the qualified product ratio of the steel pipe is greatly increased, production cost is reduced, the seamless steel pipe is high in hardness and abrasion resistance, and the manufacturing method is simple, high in qualified product ratio and suitable for large-scale production operation.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

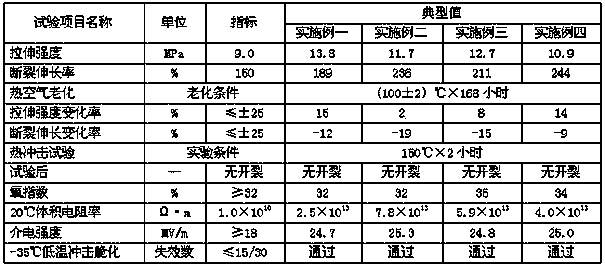

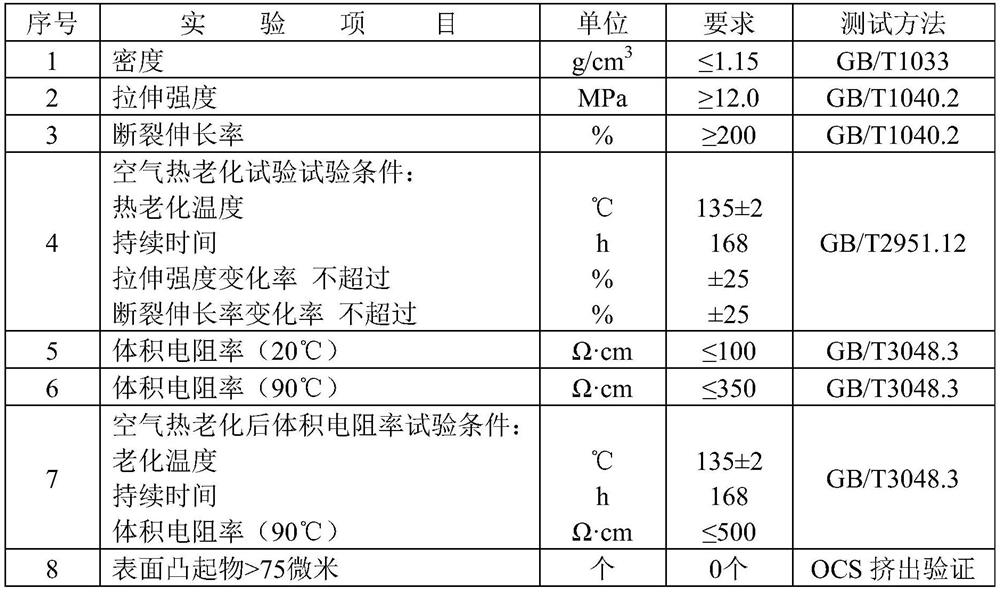

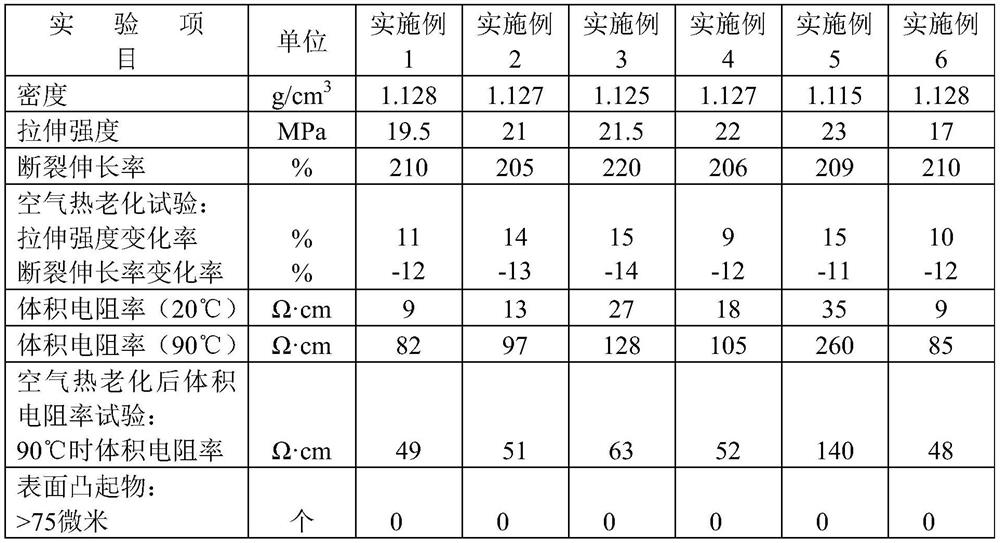

Thermoplastic low-smoke zero-halogen flame-retardant polyolefin sheath material with high heat shock resistance and preparation method thereof

InactiveCN104194168AExcellent stretch and resilienceAvoid stress crackingPlastic/resin/waxes insulatorsInsulated cablesThermoplasticAntioxidant

The invention relates to a thermoplastic low-smoke zero-halogen flame-retardant polyolefin sheath material with high heat shock resistance and a preparation method thereof. The preparation method is characterized by comprising the following steps: mixing and stirring polyolefin elastomer, high-density polyethylene resin, K-resin, functionalized polyolefin resin, a flame retardant, a surface modifier, an antioxidant and a processing aid by virtue of a high-speed stirrer and then extruding by virtue of a twin-screw mixer-extruder to obtain particles, namely, the thermoplastic low-smoke zero-halogen flame-retardant polyolefin sheath material with high heat shock resistance. Since the sheath material needs no crosslinking, the preparation cost is relatively low, the production efficiency is high and the sheath material is easily subjected to extrusion molding and has high heat shock resistance.

Owner:WUXI JAKE PLASTIC

Press oven including an intermediate body, and method for use

InactiveUS7325433B2Rapid and stress-minimized press cycleMinimal capital costShaping toolsCeramic shaping apparatusHeat conductingEngineering

A press oven, especially for the pressing of dental material, includes a press stamp via which pressure can be exerted on a blank in a matrix mass of a muffle. An intermediate body is positionable between the press stamp and the blank and the heat conducting capability of the intermediate body (28) is less than that of the blank (26), the press stamp (22) or the matrix mass of the muffle (12).

Owner:IVOCLAR VIVADENT AG

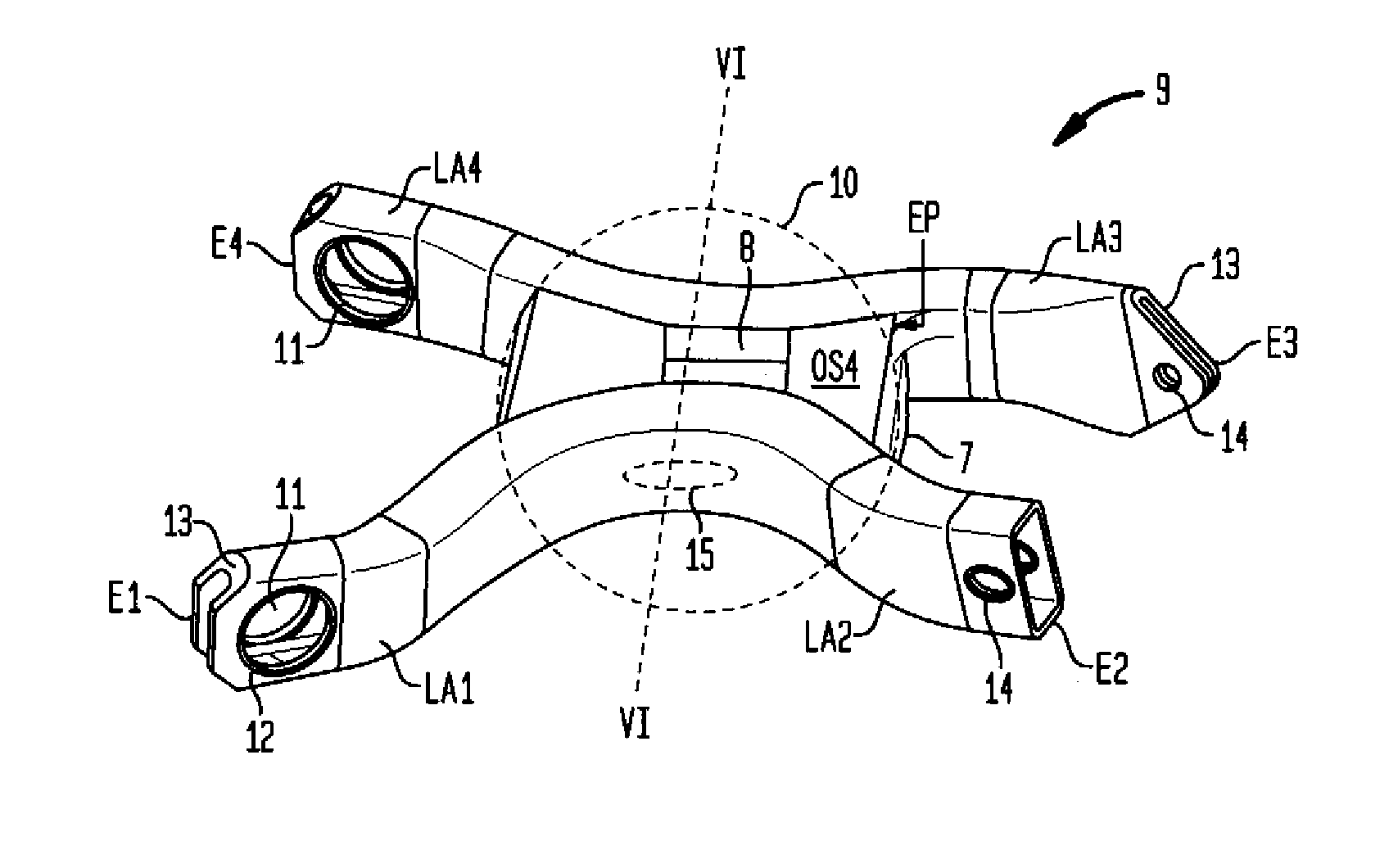

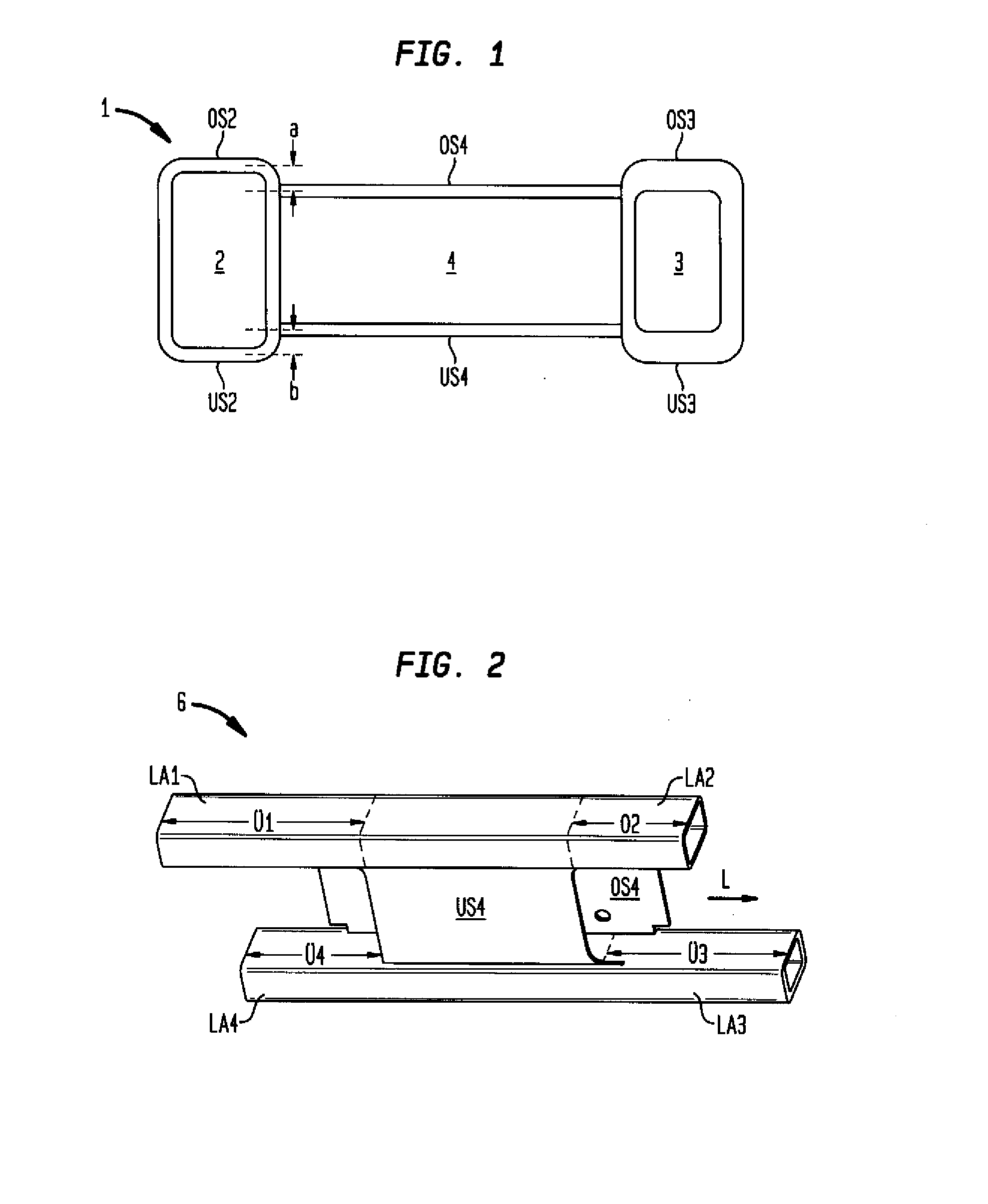

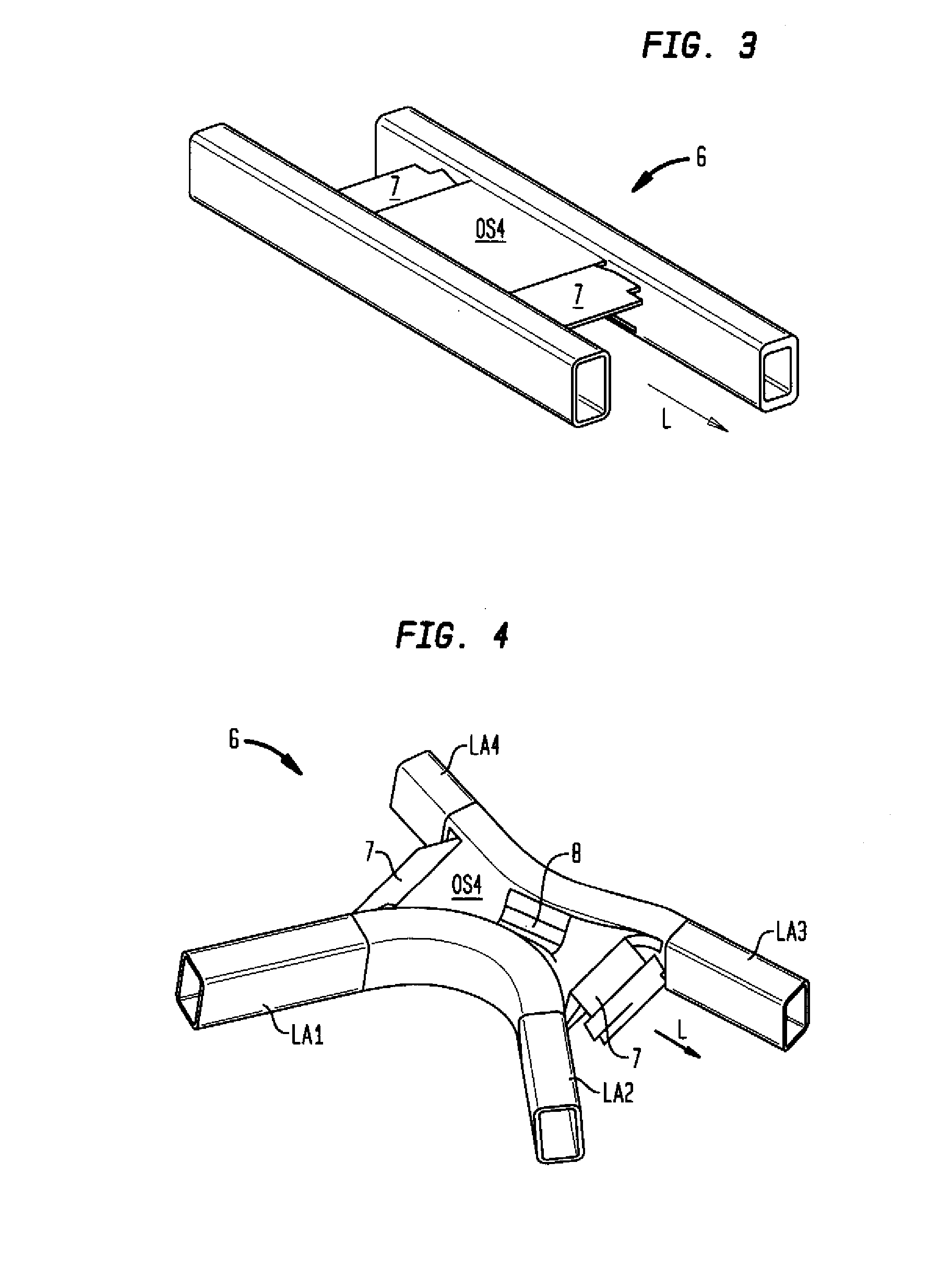

Transverse link, and method for producing a transverse link

InactiveUS20120299264A1Improves cross section geometryIncreases respective bending stiffness of structureResilient suspensionsPivoted suspension armsEngineeringWork in process

In a method of producing a transverse link for arrangement on a motor vehicle axle, a semifinished product is produced from an extrusion profile of light metal with at least three hollow chambers in side-by-side relationship. A top side and a bottom side of a middle one of the chambers is trimmed at ends thereof so that outer ones of the chambers form bearing arms which project beyond a base body. The middle chamber is formed with flanges which are bent and coupled with the base body. The bearing arms are bent and mounts for attachment are formed.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Muffle for the production of dental prostheses

InactiveUS20090136900A1Narrow diameterAvoid stress crackingDental implantsImpression capsDenturesEngineering

Owner:IVOCLAR VIVADENT AG

System and method of cooling turbines

InactiveUS20100043438A1Extended cooldownReduce CooldownLiquid degasificationPump componentsNitrogenInjection point

A method of cooling a turbine having internal moving components to a predetermined temperature is disclosed. The method comprises taking the turbine offline. While the turbine is offline, nitrogen is flowed through the turbine until the turbine reaches the predetermined temperature while controlling the flow of nitrogen from at least one injection point to prevent damage to the moving components of the turbine by achieving uniform cooling of the internal moving components. Then the flow of nitrogen is stopped. A method and assembly for cleaning a turbine having a deposit formed on an internal surface of the turbine is also disclosed.

Owner:BAKER HUGHES INC

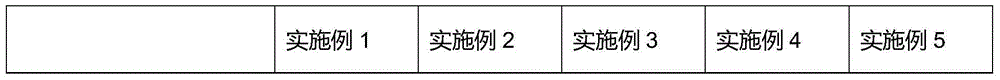

Low foam lubricating liquid for food beverage chain conveying belt

InactiveCN104479841AImprove the lubrication effectGood water solubilityLubricant compositionSolubilityPreservative

The invention discloses a low foam lubricating liquid for a food beverage chain conveying belt, wherein 0.1-5% by weight of water-soluble emulsified silicone oil, 0.1-5% by weight of alkyl glucoside, 0.1-2% by weight of an anti-foaming lubricant, 0-0.5% by weight of an anti-rust agent, 0-1% by weight of a scale inhibitor, 0.2-1.0% by weight of a preservative, and the balance of water are mixed, and a pH value adjusting agent is added to adjust the pH value to 6.0-7.0 so as to obtain the low foam lubricating liquid. The low foam lubricating liquid has characteristics of good lubricity, good cleaning effect, good water solubility, low foam, no toxicity, no corrosion, good environmental compatibility, easy production, and convenient use.

Owner:HANGZHOU WAHAHA TECH

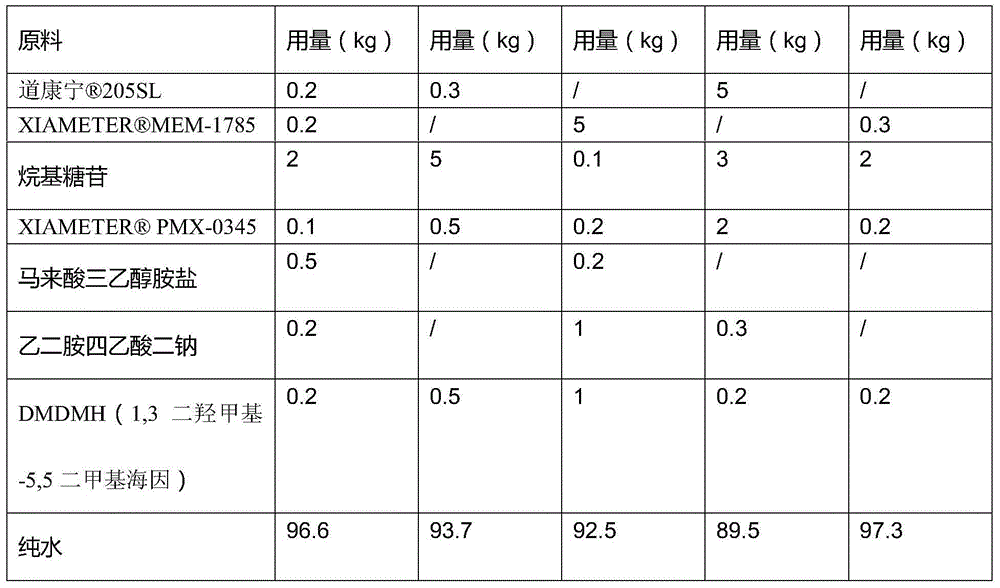

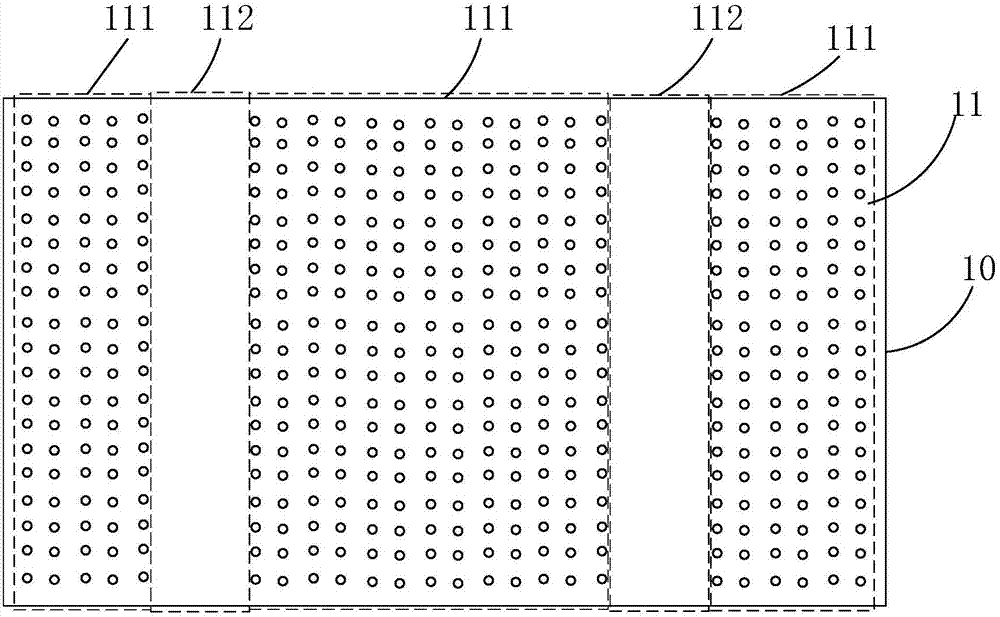

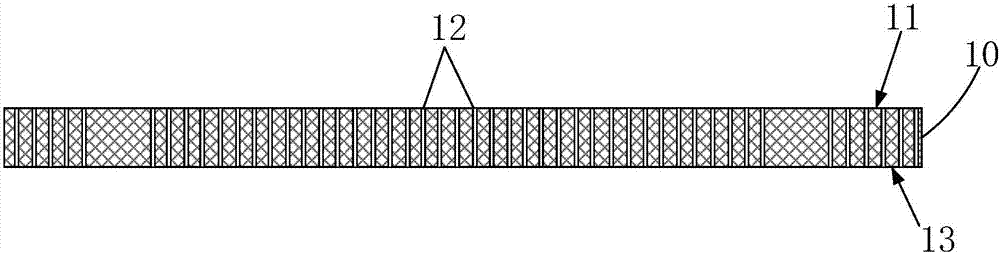

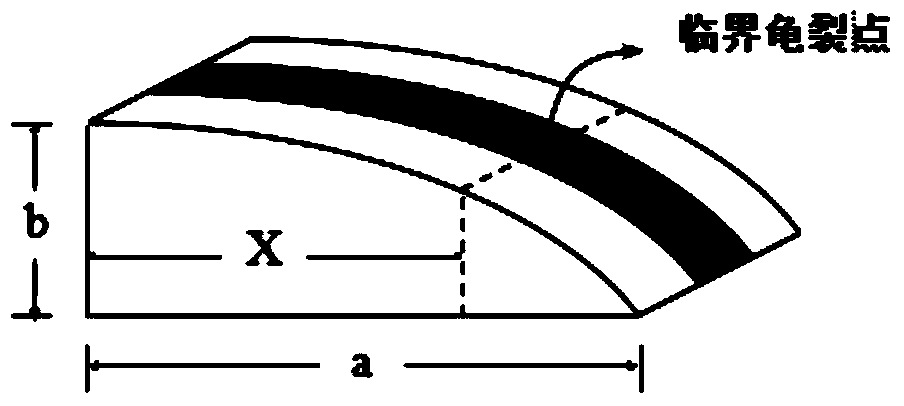

Supporting layer and machine board for cutting substrate as well as method for cutting substrate by adopting machine board

ActiveCN106966578AAvoid stress cracksAvoid adsorption hole areaGlass severing apparatusAir currentEngineering

The invention provides a supporting layer and machine board for cutting a substrate as well as a method for cutting the substrate by adopting the machine board. The supporting layer comprises a supporting layer body, wherein the supporting layer body comprises a putting surface for putting a to-be-cut substrate and an opposite end face opposite to the putting surface; the putting surface comprises an air current channel area and an air current closing area; the putting surface can realize air current communication in the air current channel area and the opposite end face and cannot realize the air current communication in the air current closing area and the opposite end face; a projection of a precutting line of the to-be-cut substrate on the putting surface is positioned in the air current closing area. The supporting layer for cutting the substrate, provided by the invention, is arranged on the machine board for cutting the substrate; the air current channel area and the air current closing area are formed on the putting surface for supporting the to-be-cut substrate, and can be used for adsorbing and fixing the to-be-cut substrate, preventing the cutting line of the to-be-cut substrate from passing through an adsorbing hole area, and preventing the edge of the to-be-cut substrate from generating stress cracks.

Owner:BOE TECH GRP CO LTD

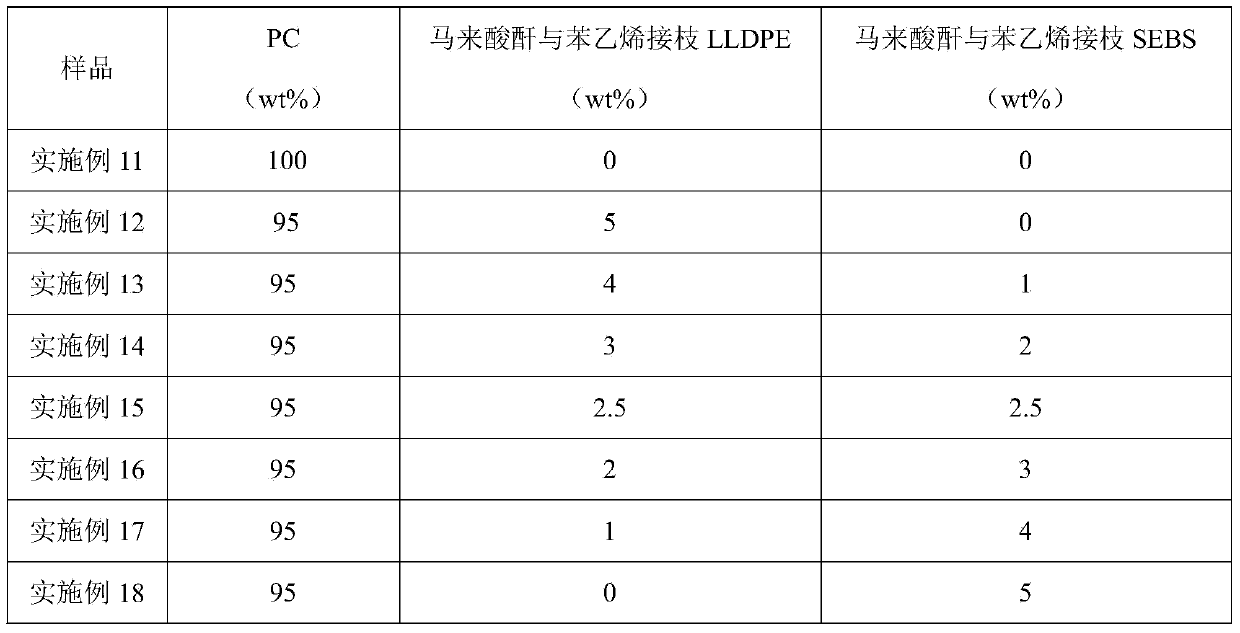

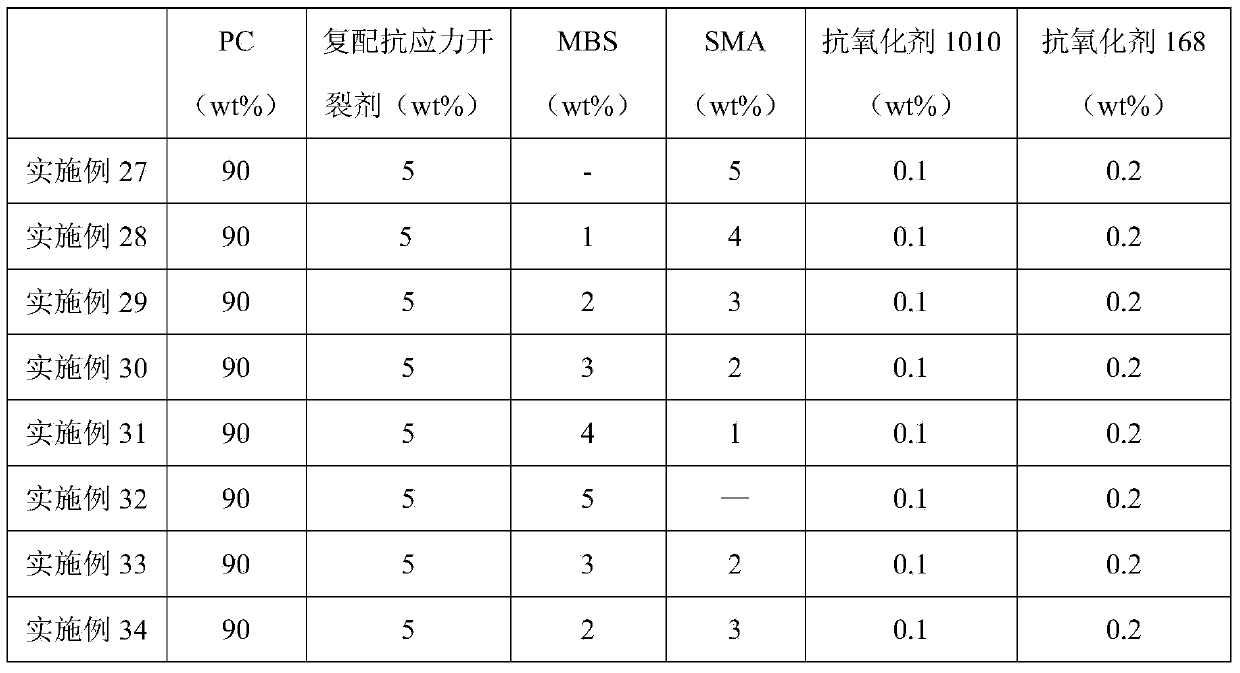

Anti-stress cracking agent, preparation method and application thereof as well as anti-stress PC (Poly Carbonate) polyester

ActiveCN103435753AGood compatibilityImprove interface affinityLinear low-density polyethyleneLow-density polyethylene

The invention relates to an anti-stress cracking agent as well as anti-stress PC (Poly Carbonate). The anti-stress cracking agent is linear low-density polyethylene grafted by maleic anhydride and styrene or hydrogenated SBS (Styrene Butadiene Styrene) grafted by the maleic anhydride and styrene. The mass ratio of the maleic anhydride to the styrene to the linear low-density polyethylene in the linear low-density polyethylene grafted by the maleic anhydride and styrene is (1-5):(1-5):(50-100); the mass ratio of the maleic anhydride to the styrene to the hydrogenated SBS in the hydrogenated SBS grafted by the maleic anhydride and the styrene is (1-5):(1-5):(50-100). The anti-stress cracking agent disclosed by the invention is a composition of the linear low-density polyethylene grafted by the maleic anhydride and the styrene and the hydrogenated SBS) grafted by the maleic anhydride and the styrene in a weight ratio of (1-3):(1-2). Being detected by an anti-stress test, the anti-stress PC disclosed by the invention has good anti-stress cracking performance.

Owner:北京航天凯恩新材料有限公司 +1

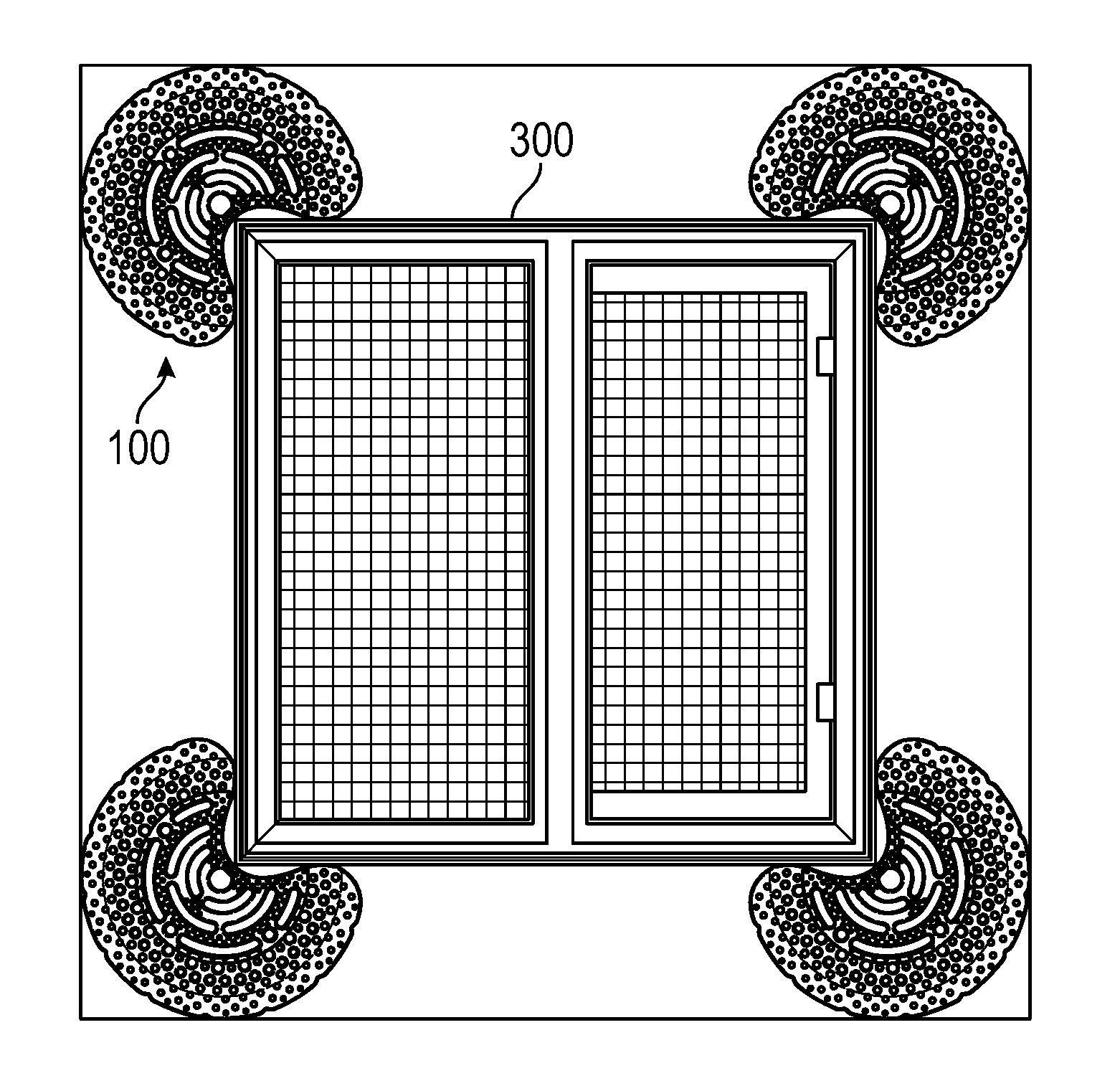

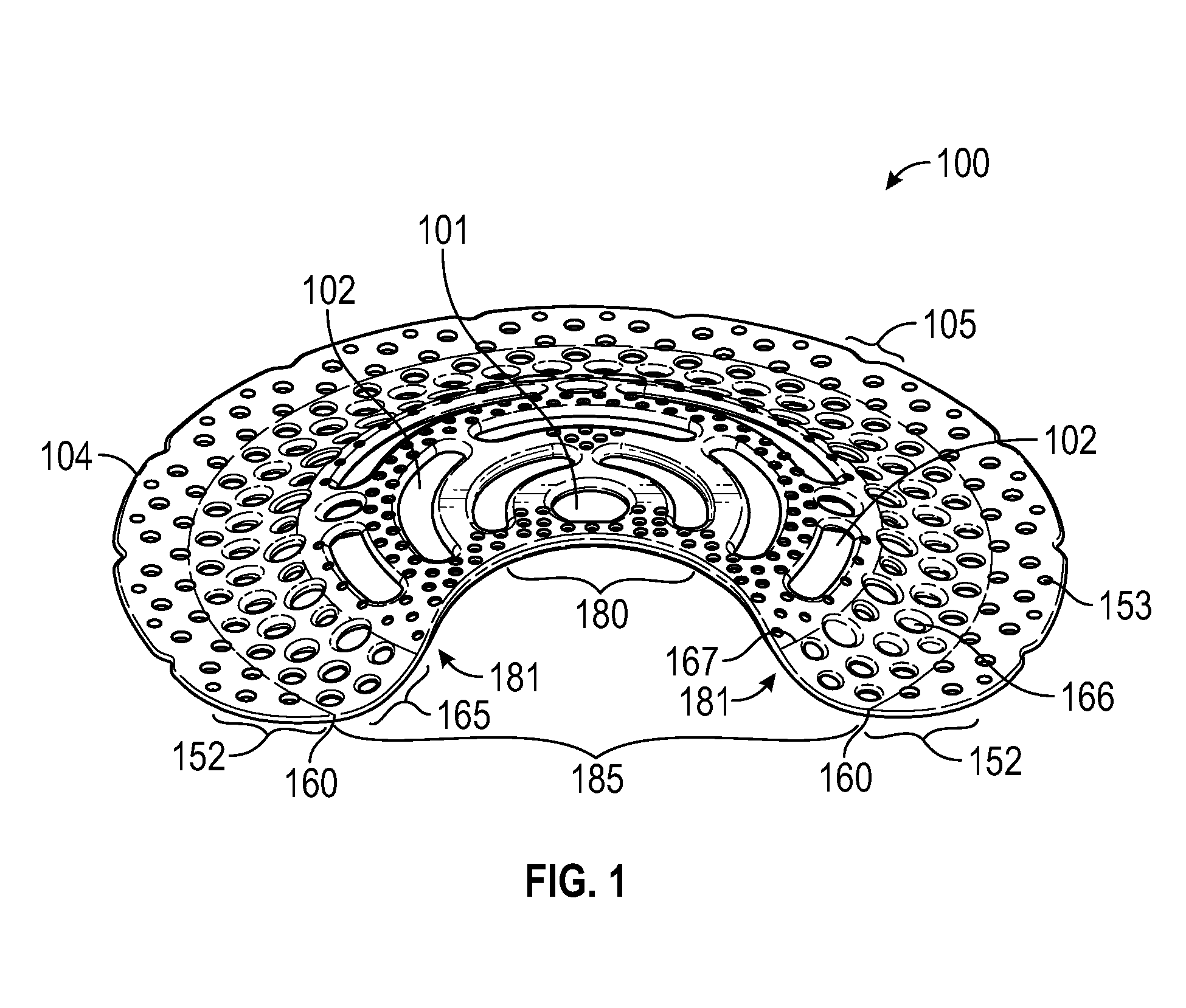

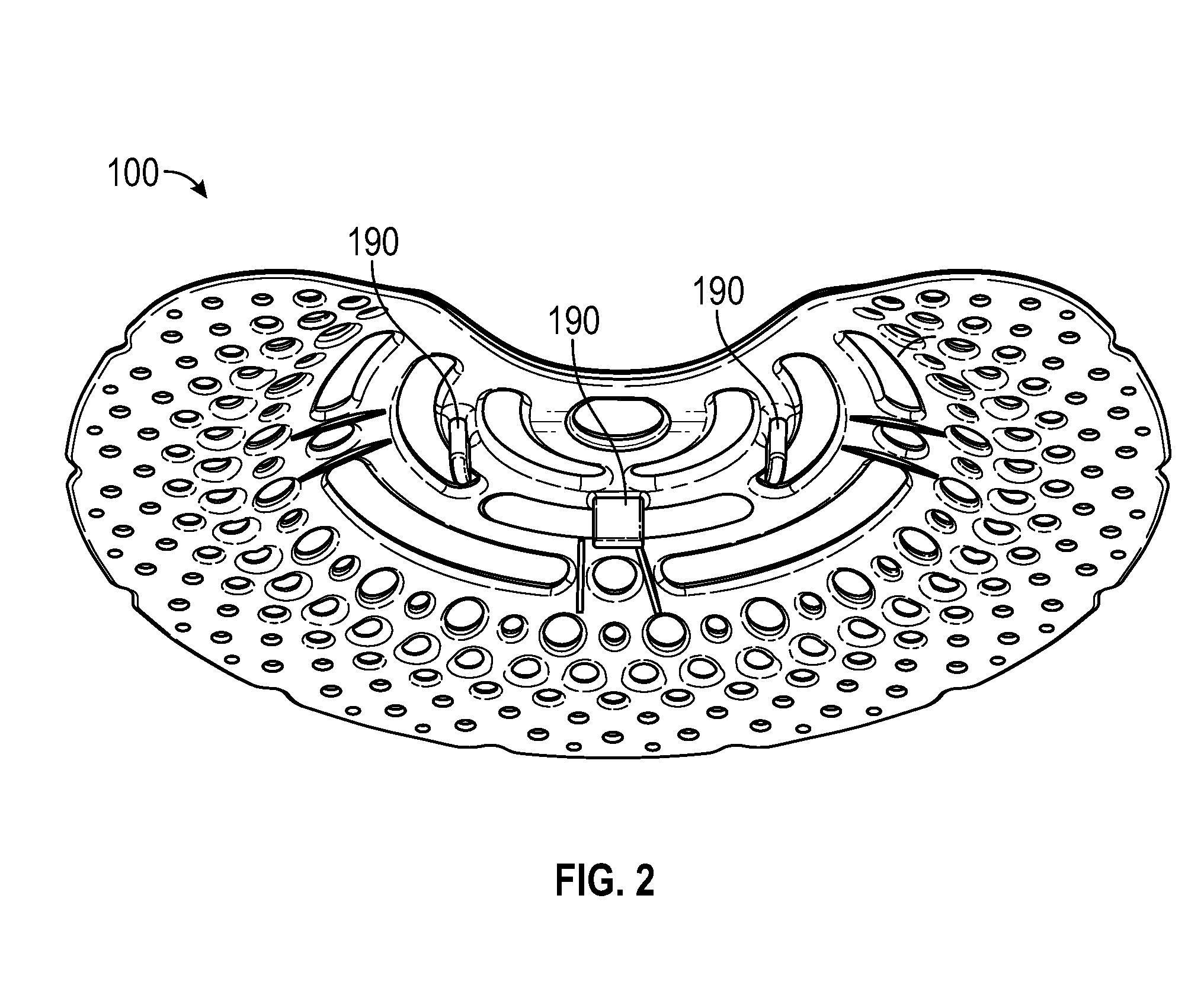

Stucco Crack Reduction at Corners

ActiveUS20170037638A1Mitigation be reduced and eliminatedLess flammableCovering/liningsEngineeringBuilding material

Stucco cracks at doors and windows are reduced or eliminated by use of a corner element fastened at a corner juncture before stucco coats are applied. The disclosed corner element spreads out or evenly dissipates differential movement or buckling often occurring at exterior corner junctures. The corner element may comprise various concentric circle attributes useful in stopping or reducing cracks in stucco and related building materials. The corner element embodiments may be secured at widow and door corner areas and then integrated with traditional stucco applications.

Owner:GOMES HAROLD FURTADO

High-toughness and high-thermal-conductivity high-molecular material

The invention relates to the technical field of high-molecular materials, and in particular, relates to a high-toughness and high-thermal-conductivity high-molecular material comprising the components: 10-15 parts of glycidyl ester epoxy resin, 35-45 parts of epoxide polydibutene, 10-25 parts of polyethylene glycol, 60-75 parts of a composite thermal conductive filler, 3-8 parts of a flame retardant, 2.5-3.6 parts of a chain extender, 1-10 parts of a toughening filler, 0.3-1.3 parts of an antioxidant, and 0.5-4 part of a dispersant. The toughening filler and the chain extender have a toughening effect on the composite material, and the added toughening agent has good performance of low-temperature impact resistance, so the composite material has the advantages of high thermal conductivity and high toughness, also reduces the thermal conduction linear expansion coefficient, and avoids stress cracking of products.

Owner:ANHUI ELECTRIC GRP SHARES

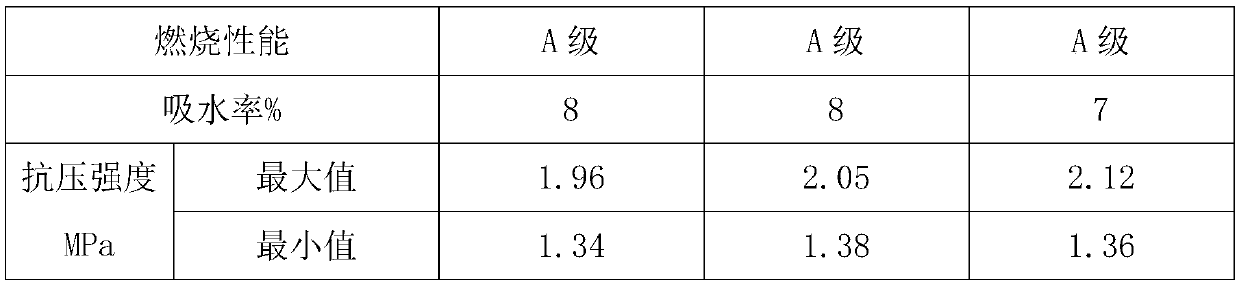

Light-weight anti-cracking cement foaming heat insulation plate

InactiveCN108675821AImprove impact resistanceImprove stress resistanceCeramicwareFiberPulverized fuel ash

The invention relates to the technical field of a heat insulation material, in particular to a light-weight anti-cracking cement foaming heat insulation plate, The heat insulation plate is prepared from the following ingredients: 70 to 80 parts of Portland cement, 25 to 30 parts of pulverized fuel ash, 15 to 20 parts of nanometer bentonite, 10 to 18 parts of lightweight ceramic powder elastomers,3 to 6 parts of inorganic fiber, 2 to 5 parts of water glass, 1 to 1.4 parts of water reducing agents, 7 to 10 parts of foaming agents, 1.3 to 2.5 parts of foam stabilizing agents and 250 to 280 partsof water, wherein the lightweight ceramic powder elastomer is a novel material formed by compounding porous ceramsite micro powder and polyurethane elastomers; the nanometer bentonite uses interlayercation as sodium bentonite of sodium ions; the water reducing agents are lignosulfonate or naphthalenesulfonate water reducing agents; the foaming agents are hydrogen peroxide; the foam stabilizing agents are calcium stearate modified by a nanometer intercalation technology. The heat insulation plate has the advantages that the flame retardant performance is high; the material is light; the goodpressure-resistant performance and anti-impact performance are realized; fracture cannot easily occur.

Owner:合肥语林装饰工程有限公司

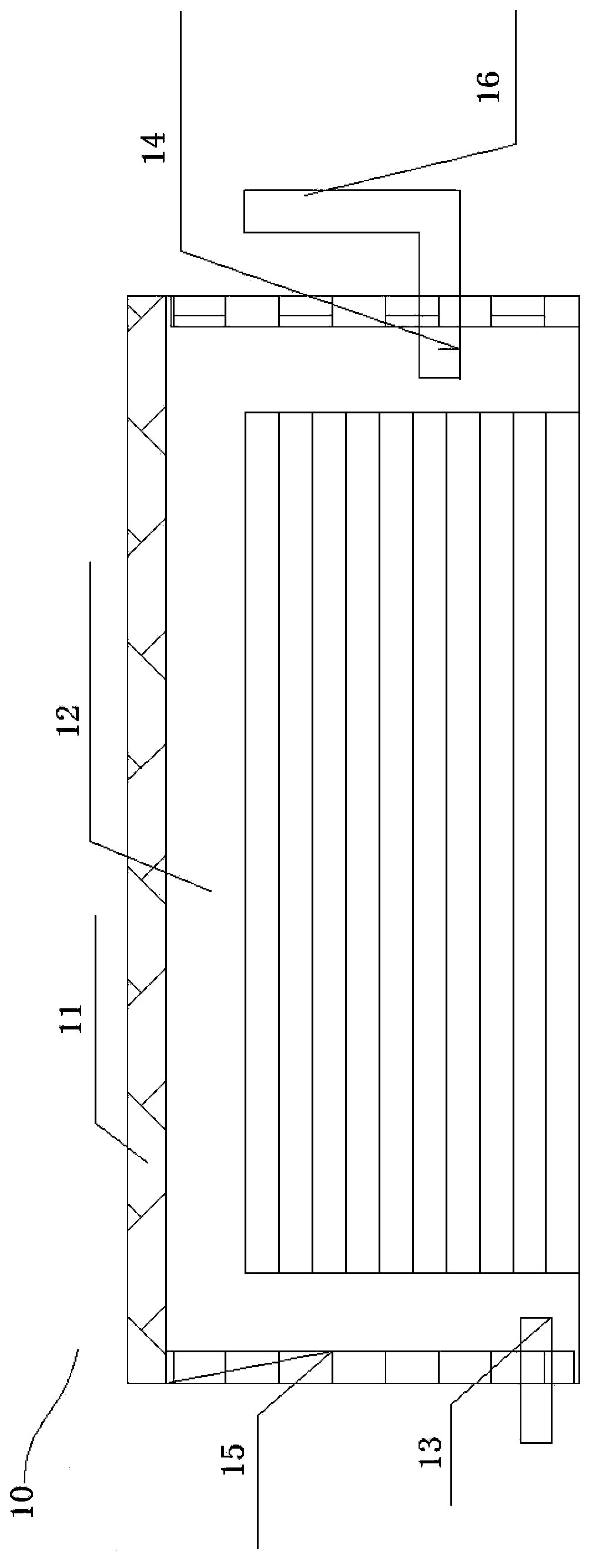

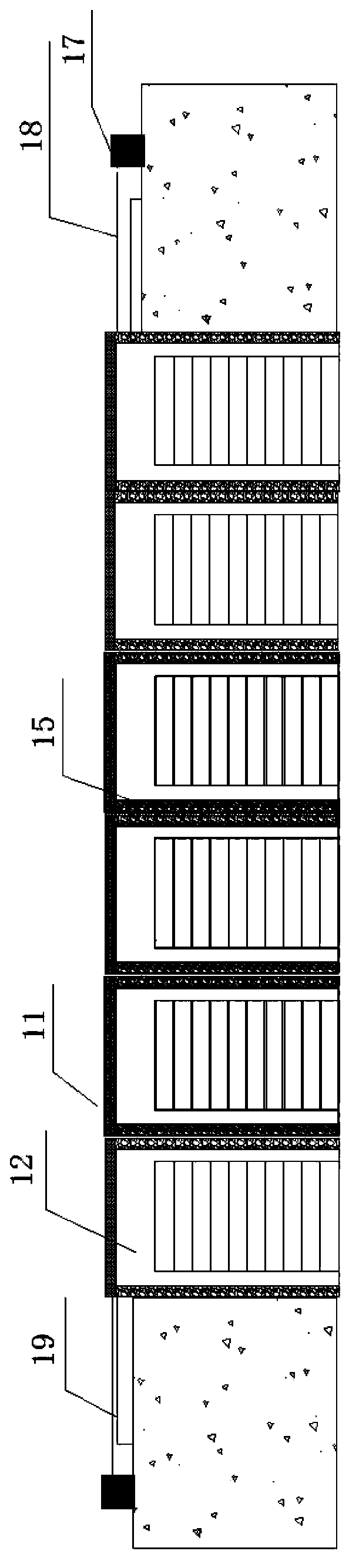

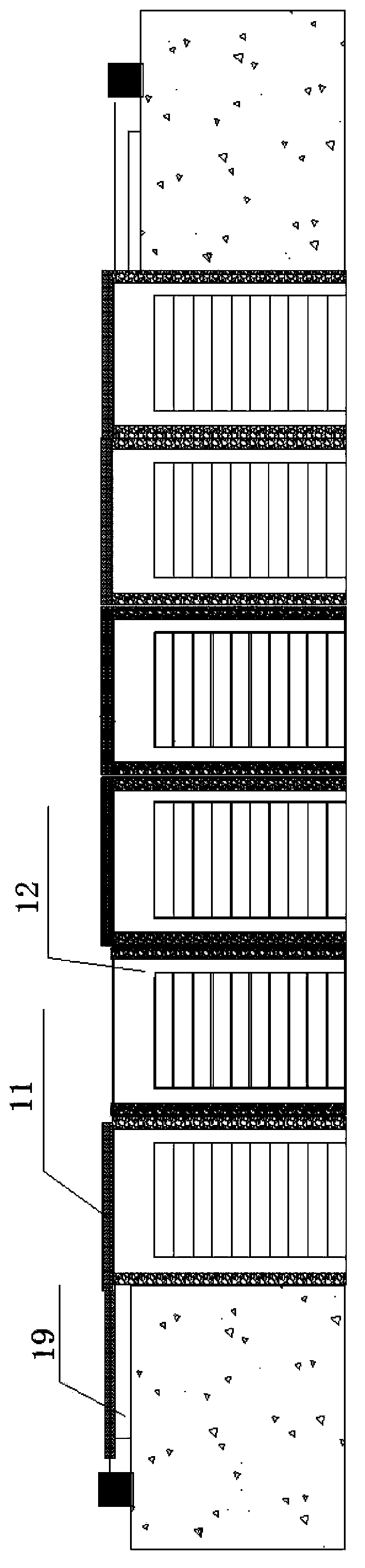

Slab burial pit with adjustable cooling speed

The invention discloses a slab burial pit with an adjustable cooling speed. The slab burial pit comprises a pit body, a pit cover, a pit wall, a heating burner, an air door and a chimney, wherein the pit body is encircled by the pit wall, and buried under the ground; the pit cover is covered on the top; the heating burner is arranged at one side; the air door and the chimney are arranged at the other opposite side; the opening of the air door is adjustable. By adopting the technical scheme disclosed by the invention, the slab temperature can be flexibly adjusted according to the production rhythms of the upper and lower procedures, the slab is prevented from generating a stress crack, meanwhile, the capability of simultaneously slowly cooling large quantities of slabs is provided, and the problem of rapid cooling of the slab in fact caused by ambient cold air also can be avoided in the process of storing the slab. Meanwhile, normal logistics above the ground is not affected under the condition that the large quantities of slabs are simultaneously slowly cooled by the pit body arranged below the horizontal plane, and the slow cooling requirements of the slab are completely met.

Owner:BAOSTEEL STAINLESS STEEL

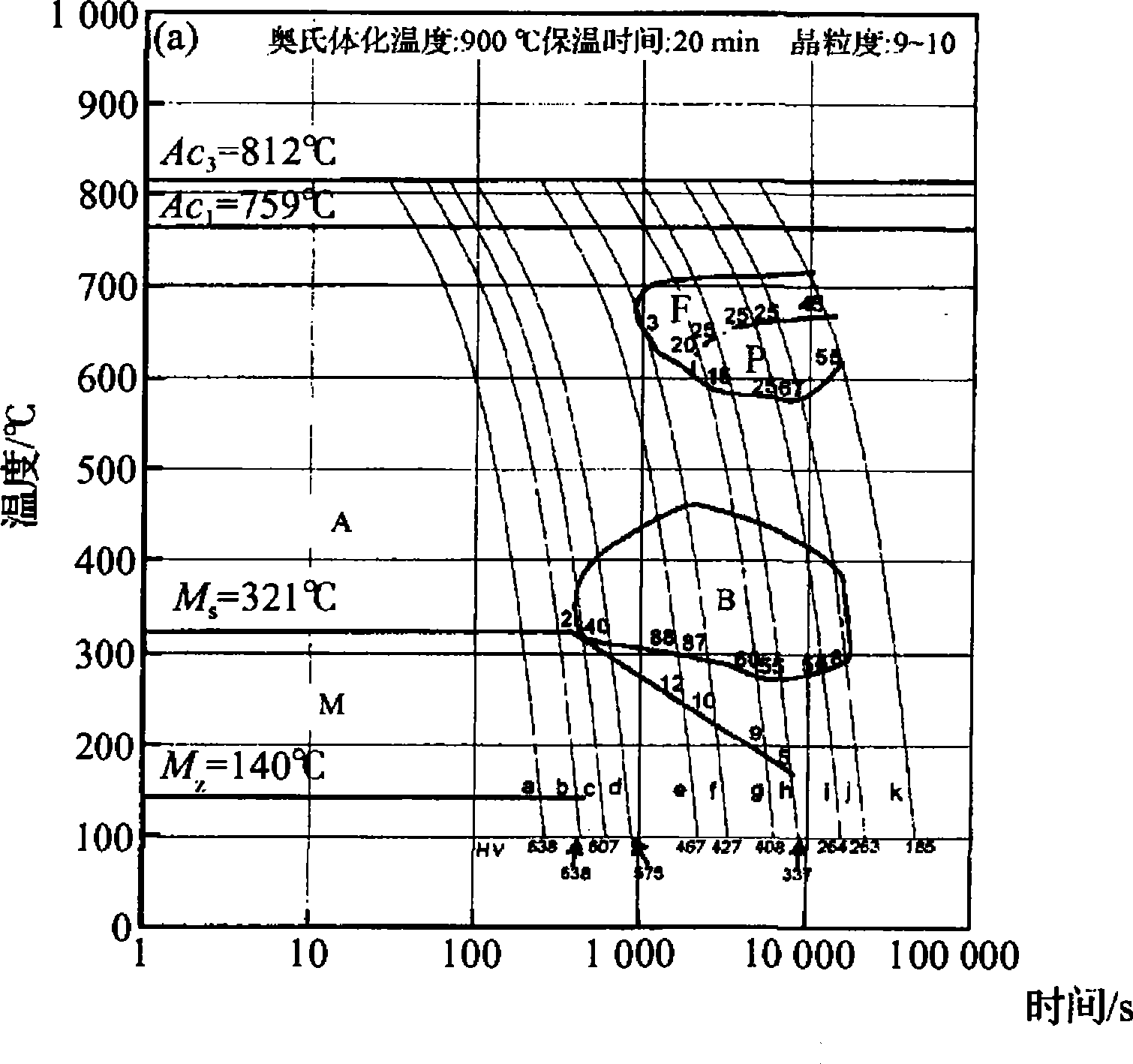

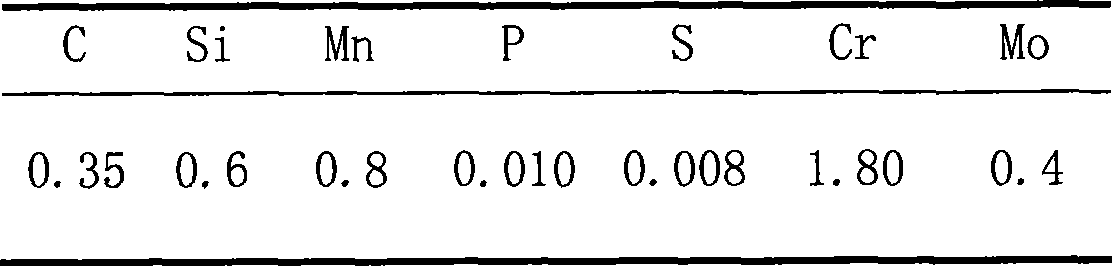

Production method of producing chromium-molybdenum steel plate made by steel ingot direct rolling molding

InactiveCN111793742AHeating evenlyAvoid internal cold and external heatFurnace typesWork cleaning devicesIngotUltimate tensile strength

The invention provides a production method of producing a chromium-molybdenum steel plate made by steel ingot direct rolling molding, and belongs to the technical field of metallurgy. The method comprises the processes of steel ingot pouring, annealing, heating, rolling and hot treatment; and the heating process comprises the steps of: (1) distressing step heating: a steel ingot is subjected to heat preservation at 680 to 730 DEG C for 6 to 7h, and then subjected to heat preservation at 890 to 930 DEG C for 2 to 3h; (2) low-temperature long-time heat preservation: the steel ingot is heated to1240 to 1280 DEG C and subjected to heat preservation for 15 to 18h, and the furnace pressure is controlled at 0 to 3MPa; and (3) before-tapping turn-over: the steel ingot is turned over and heated for 4-6h before being drawn out of a furnace. The steel plate produced is 15 to 35t in weight, the superficial quality of the steel plate is good, the grinding amount is low, and the flaw detection qualification rate is higher than or equal to 97%; and after high-temperature long-time die welding treatment, the high-temperature tensile yield strength of the steel plate at 454 DEG C is higher than orequal to 338MPa and the tensile strength is higher than or equal to 461MPa.

Owner:WUYANG IRON & STEEL

ABS two-layer composite plate and preparation method thereof, liner and preparation method thereof as well as refrigeration equipment

InactiveCN107053794AHigh glossLow priceSynthetic resin layered productsDomestic articlesFoaming agentSurface layer

The invention provides an ABS two-layer composite plate which comprises a base material layer and a surface layer formed on the base material layer, wherein the surface layer contains an extrusion-grade ABS material; the base material layer contains an ABS special material and high glue powder; the number-average molecular weight of an acrylonitrile component in the ABS special material is greater than or equal to 180,000. The ABS two-layer composite plate provided by the invention has high gloss and is resistant to the corrosion of a foaming agent. The invention also provides a preparation method of the ABS two-layer composite plate, a liner using the ABS two-layer composite plate, a preparation method of the liner and refrigeration equipment using the liner.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

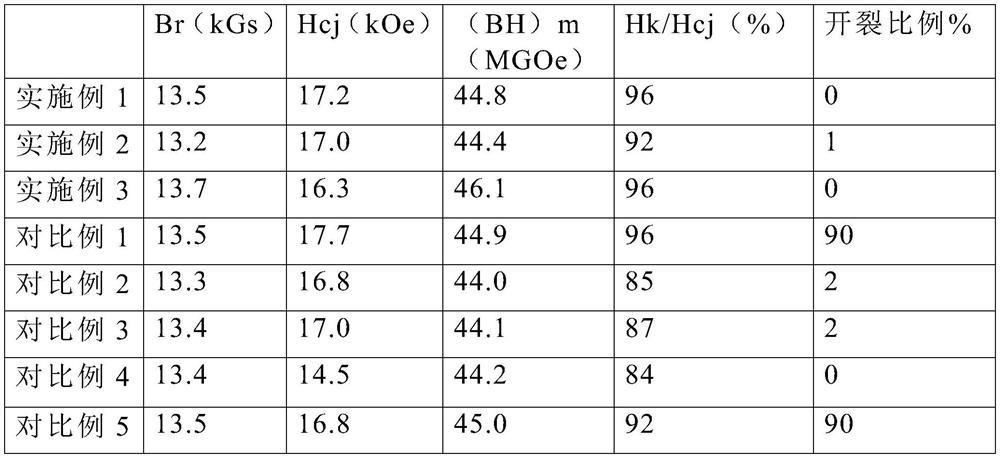

Preparation method of high-performance magnetic ring

ActiveCN112435847AReduce the probability of crackingImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsSpinningTempering

A preparation method of a high-performance magnetic ring provided by the invention comprises the following steps of: (1) preparing raw materials according to alloy components of the magnetic ring, smelting the prepared raw materials, carrying out casting and melt-spinning on the raw materials to obtain a quick-setting sheet with the average thickness of 0.2-0.4 mm; (2) carrying out high-temperature heat treatment on the quick-setting sheet; (3) carrying out hydrogen decrepitation on the quick-setting sheet subjected to high-temperature heat treatment to obtain coarse crushing powder, carryingout dehydrogenation heat treatment to enable the hydrogen content of the coarse crushing powder to be less than or equal to 600 ppm, and then feeding the coarse crushing powder into a jet mill for milling to obtain jet mill magnetic powder; (4) adding a lubricating agent into the jet mill magnetic powder, stirring the mixture for 2-6 hours, feeding the mixture into a magnetic ring magnetic field pressing machine for orientation forming after stirring, and then carrying out isostatic pressing treatment; and (5) conducting high-temperature sintering, cooling and tempering heat treatment on the product. The prepared magnetic ring has excellent magnetic performance, is not easy to crack, and can meet the requirements of the high-end application field.

Owner:宁波金鸡强磁股份有限公司

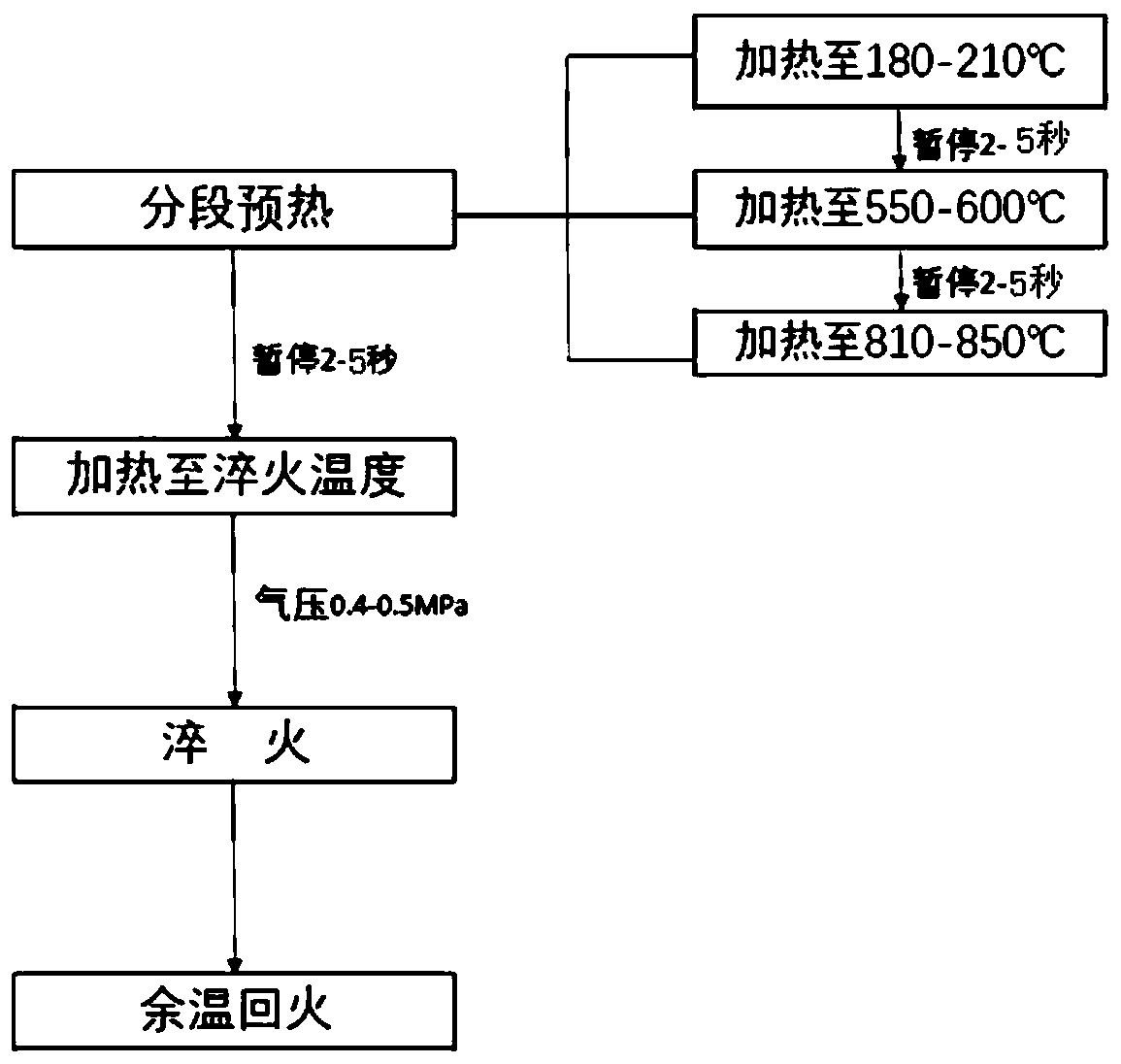

Induction quenching process for hardening alloy cast iron camshaft by using compressed air

InactiveCN110964898AEven temperature inside and outsideReduces the possibility of crackingFurnace typesIncreasing energy efficiencyPhysicsCast iron

The invention provides an induction quenching process for hardening an alloy cast iron camshaft by using compressed air, which comprises the following steps: S1, preheating is carried out: the camshaft is heated to 180-210 DEG C in an induction manner in a first stage, heating is suspended for 2-5 seconds, in a second stage, after the camshaft is inductively heated to 550-600 DEG C, heating is suspended for 2-5 seconds, and in a third stage, after the camshaft is inductively heated to 810-850 DEG C, heating is suspended for 2-5 seconds, wherein the heating rates of the three stages are all 40-50 DEG C / s; S2, heating to a quenching temperature is carried out: induction heating is carried out on the camshaft preheated in the step S1 to 900-940 DEG C at a heating rate of 40-50 DEG C / s; S3, quenching is conducted, specifically, compressed air with the pressure of 0.4-0.5 MPa is adopted as a quenching medium to quench the camshaft, and the camshaft is cooled to 250-300 DEG C; and S4, afterheat tempering is carried out. The alloy cast iron camshaft product quenched by using the process method disclosed by the invention does not crack in the quenching process, and the hardness index of the quenched alloy cast iron camshaft product can meet the technical requirements, so that the rejection rate of the product is reduced, and the production cost is greatly saved.

Owner:荆州环球汽车零部件制造有限公司

Semiconductive shielding material and preparation method and application thereof

ActiveCN112724500AAvoid separationWith skeleton support effectClimate change adaptationPower cables with screens/conductive layersPolymer scienceVulcanization

The invention provides a semiconductive shielding material and a preparation method and application thereof. The semiconductive shielding material comprises the following components: an ethylene-butyl acrylate copolymer, high-density polyethylene, conductive carbon black, PE wax, zinc stearate, a dispersing agent and an antioxidant. The mass ratio of the ethylene-butyl acrylate copolymer to the high-density polyethylene is 1:(0.05-0.2), preferably 1:(0.07-0.1). According to the semiconductive shielding material, the ethylene-butyl acrylate copolymer is used as a matrix, and the high-density polyethylene is added, so that the material has a skeleton supporting effect after being extruded, an insulating layer is prevented from being separated from a shielding layer, and a stress cracking phenomenon in a vulcanization process is prevented.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

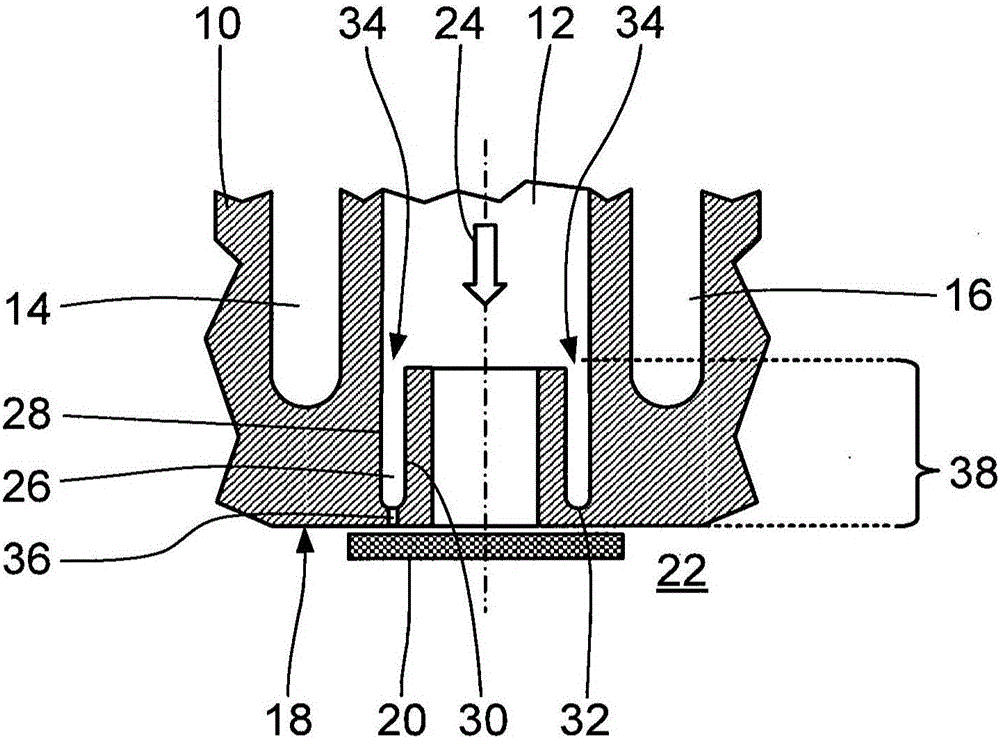

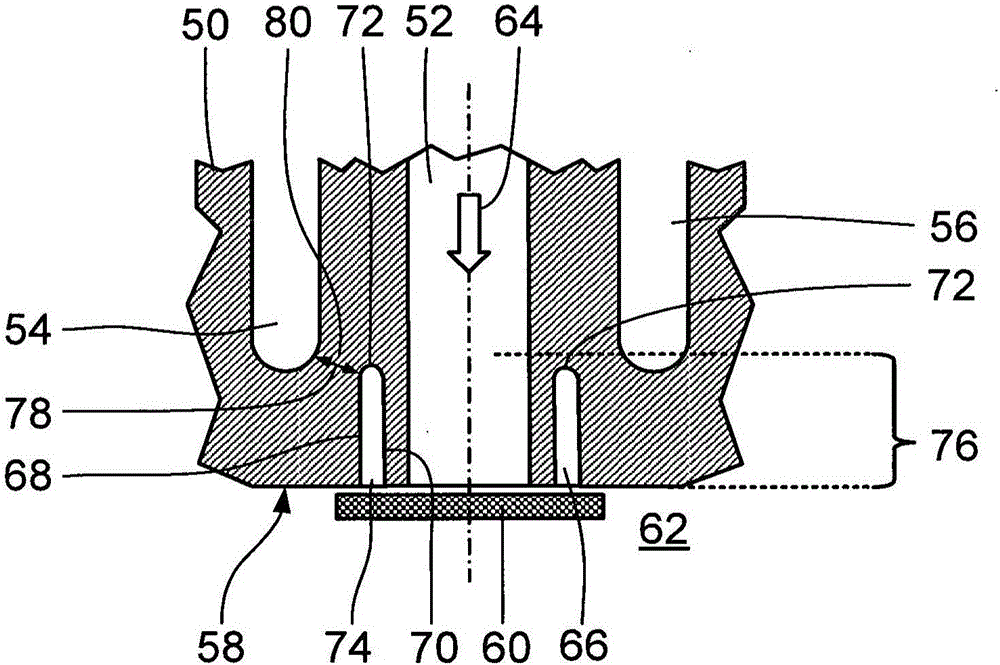

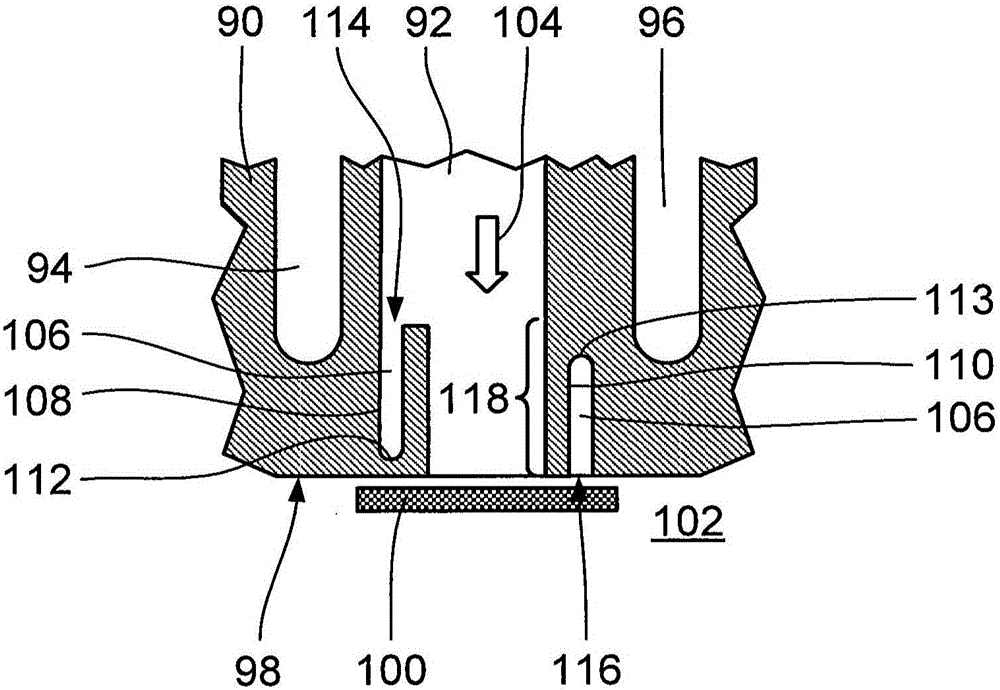

Cylinder head for an air compressor

ActiveCN105793566ASmall mechanical drive powerReduce mechanical drive powerPositive displacement pump componentsPositive-displacement liquid enginesCylinder headGas compressor

The invention relates to a cylinder head (10, 50, 90, 130) for an air compressor, having at least one intake duct (12, 52, 92, 132) for the intake of non-compressed air from the surroundings, and having at least one pressure duct for discharging the compressed air, and also having a cooling water duct (14, 16, 54, 56, 94, 96, 136), wherein the at least one intake duct (12, 52, 92, 132) can be closed off in pressure-tight fashion with respect to a compression chamber (22, 62, 102, 142) by means of at least one intake lamella (20, 60, 100, 140) arranged on an underside (18, 58, 98, 138) of the cylinder head. It is provided according to the invention that the at least one intake duct (12, 52, 92, 132) is surrounded in sections by a substantially concentric annular groove (26, 66, 106, 146) which is close to the intake lamella. In this way, heating of the air flowing out of the surroundings into the cylinder head (10, 50, 90, 130) via the at least one intake duct (12, 52, 92, 132) is advantageously reduced.

Owner:ZF CV SYST EURO BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com