Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Narrow diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

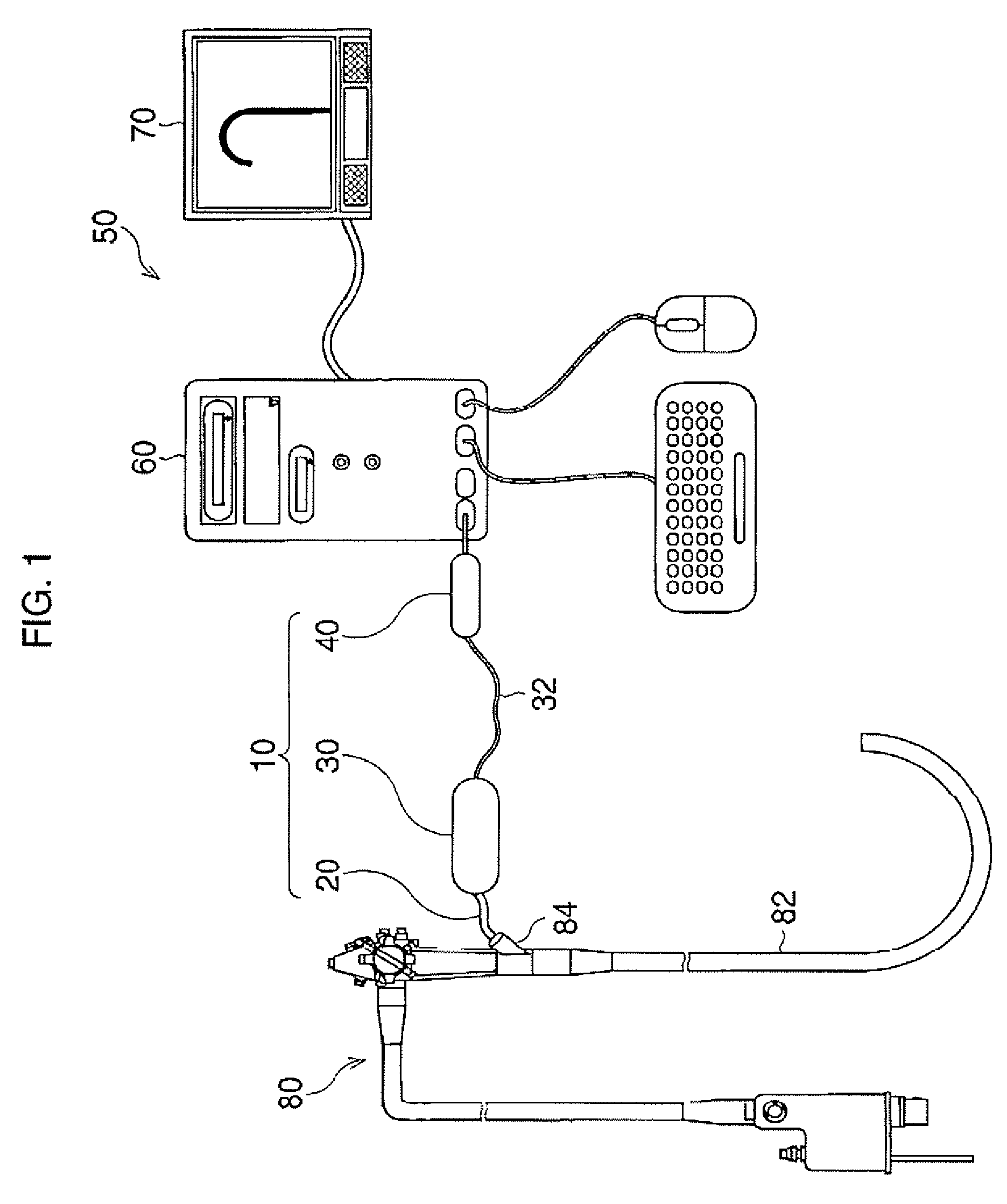

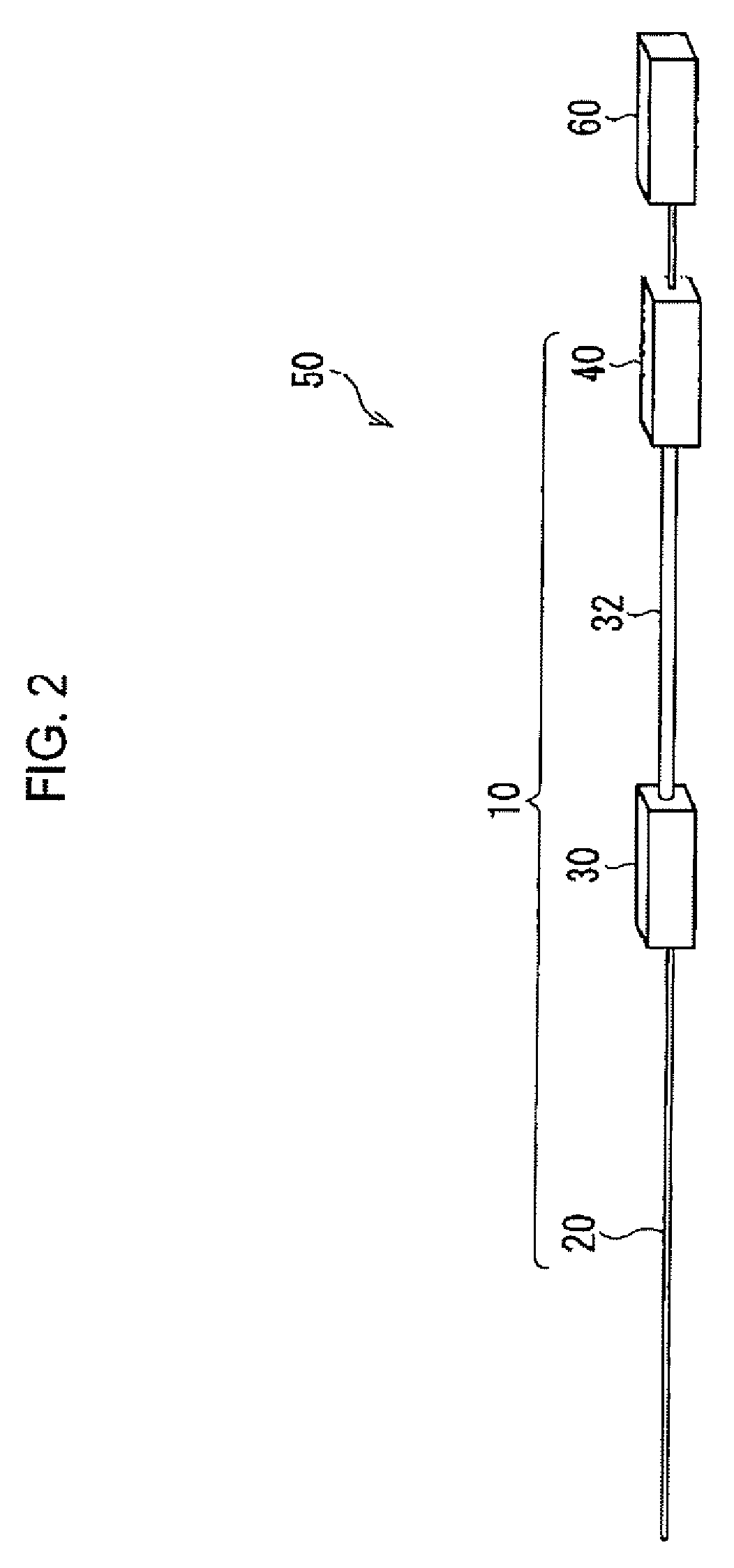

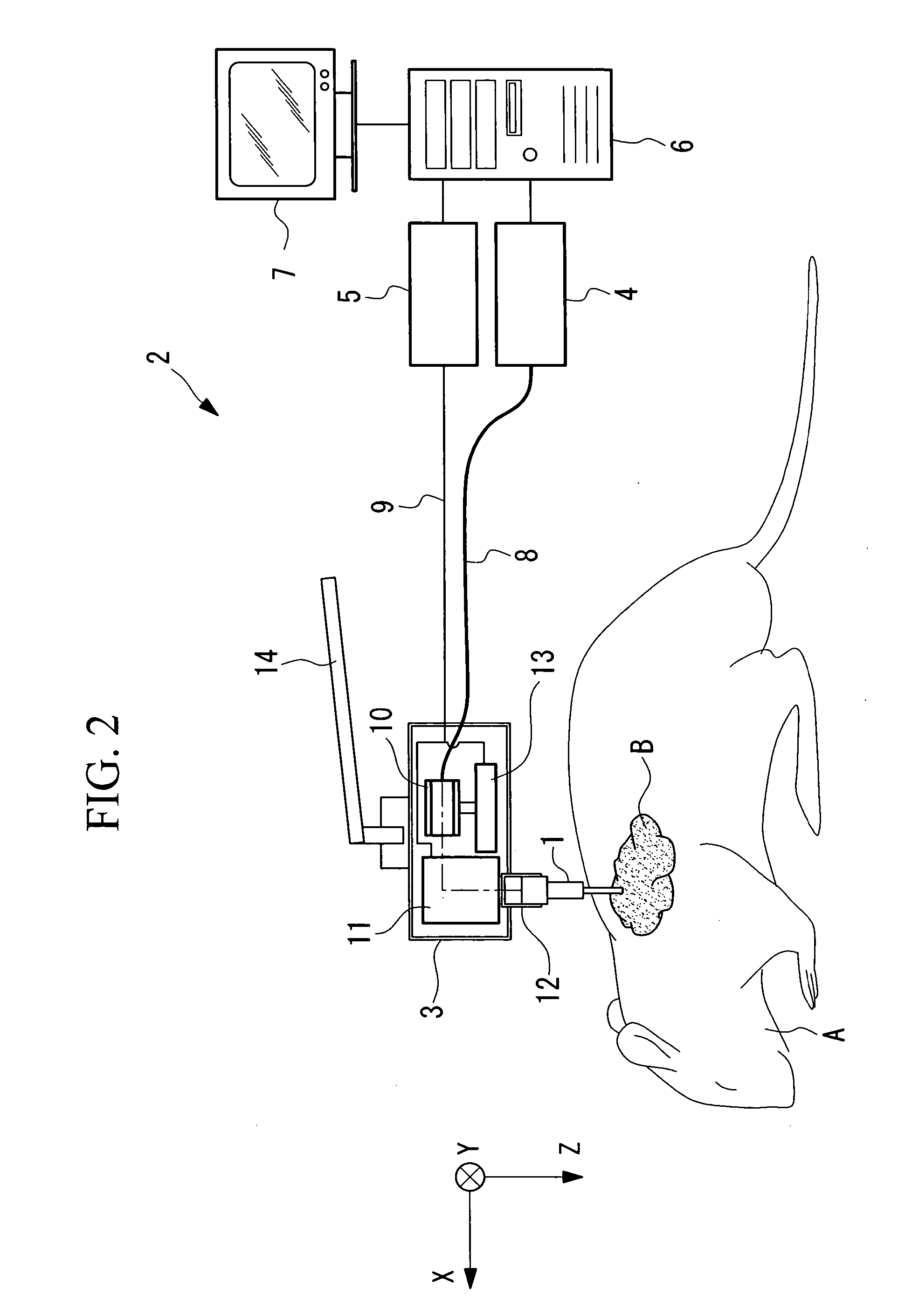

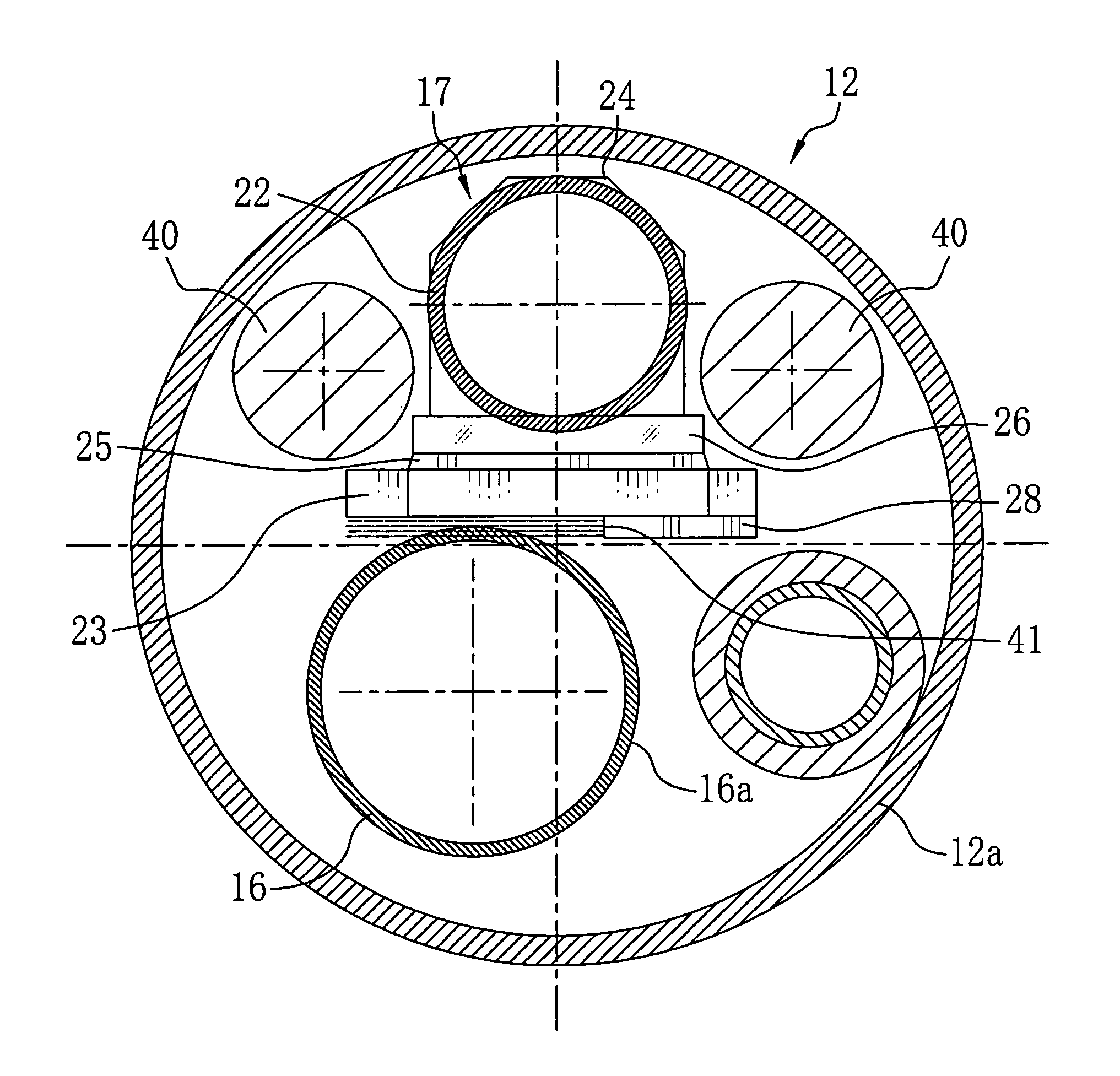

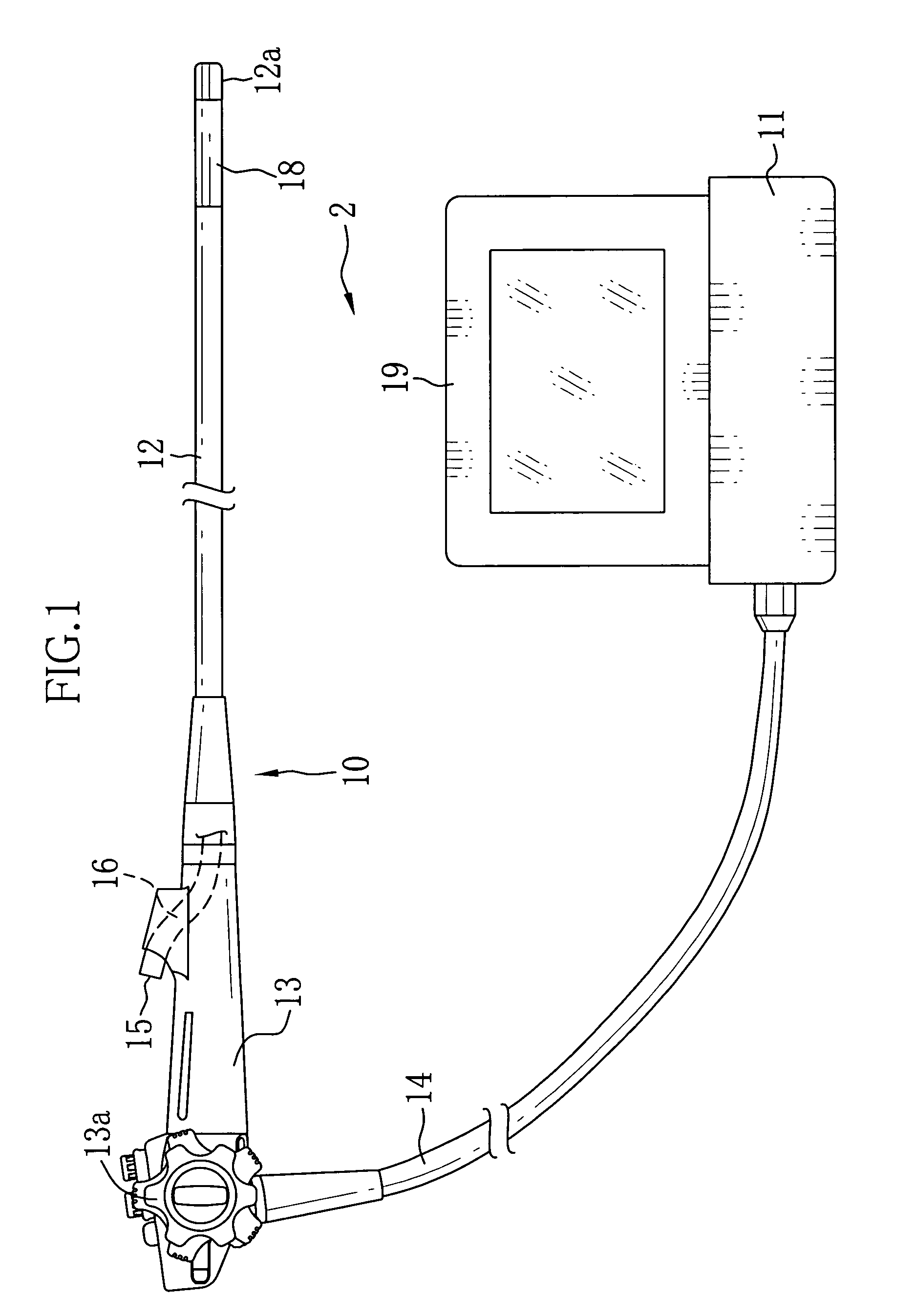

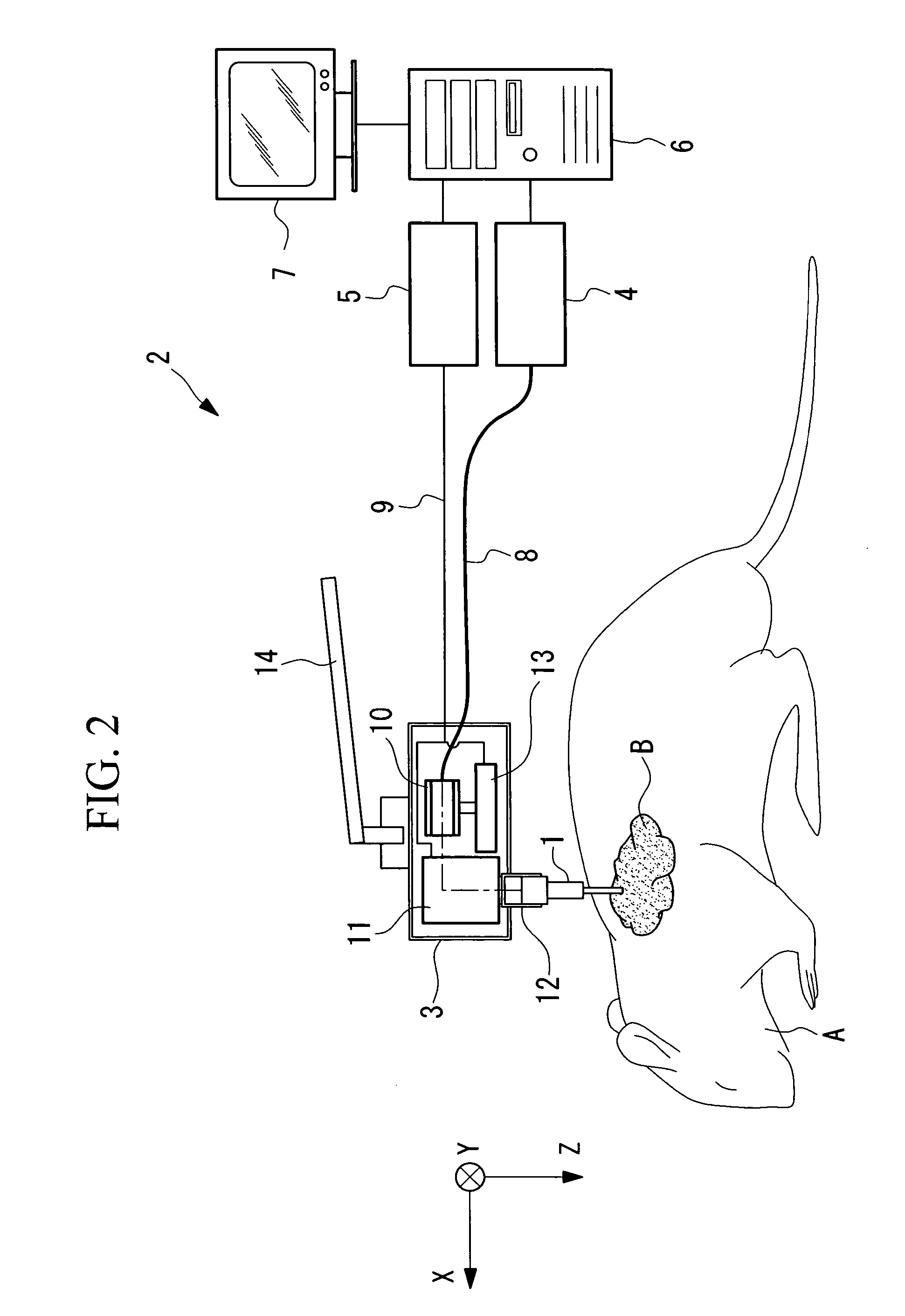

Configuration detection device for endoscope

InactiveUS20070116415A1High precision of detectionNarrow diameterSurgeryEndoscopesLight reflectionLength wave

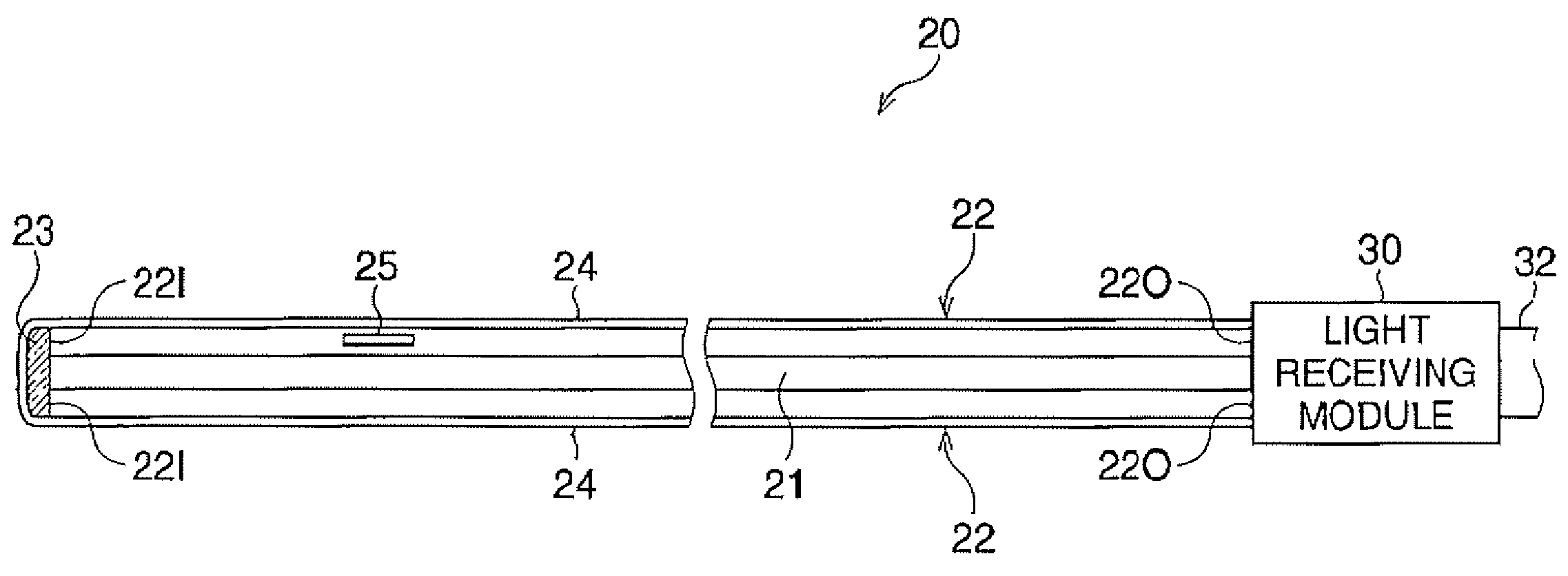

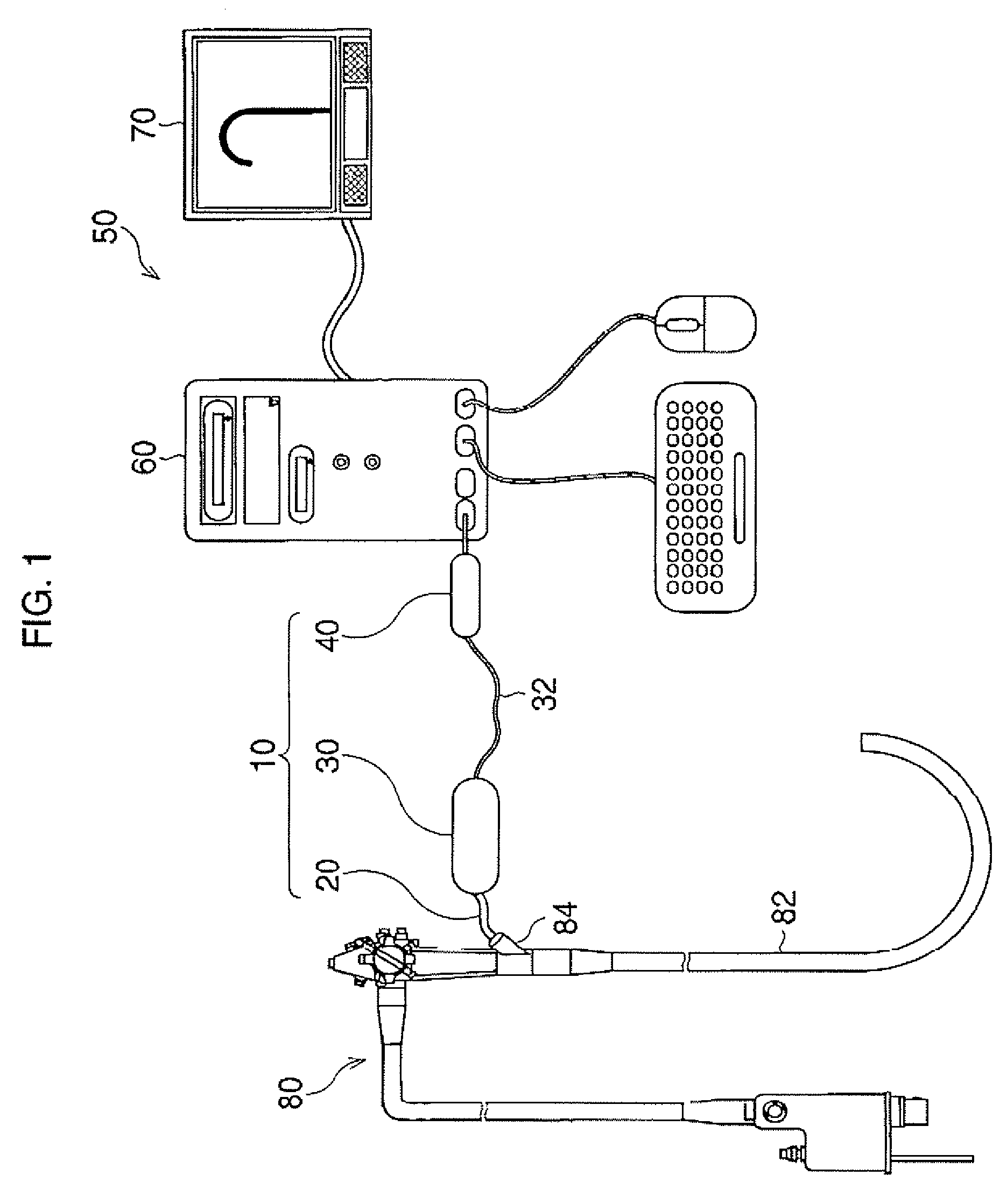

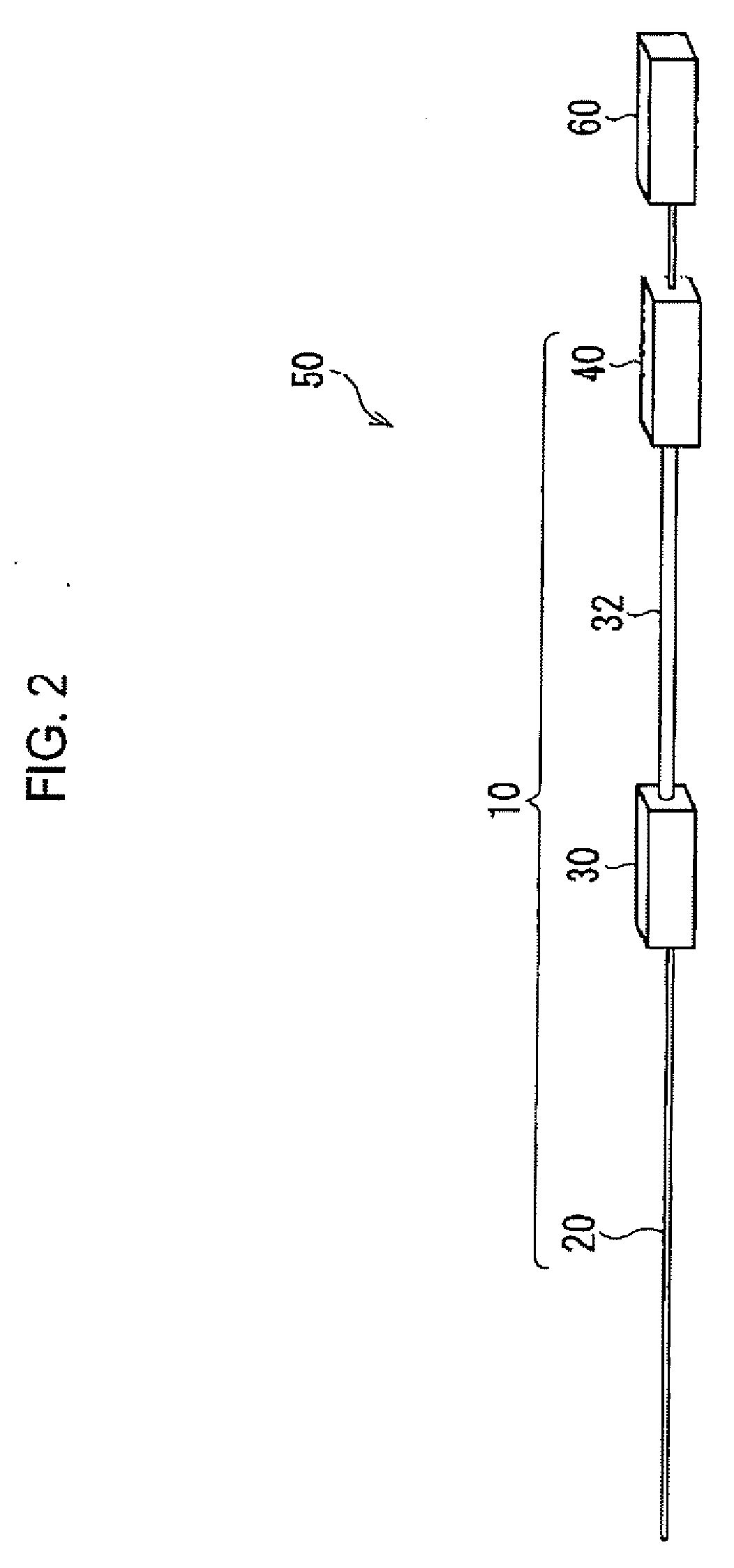

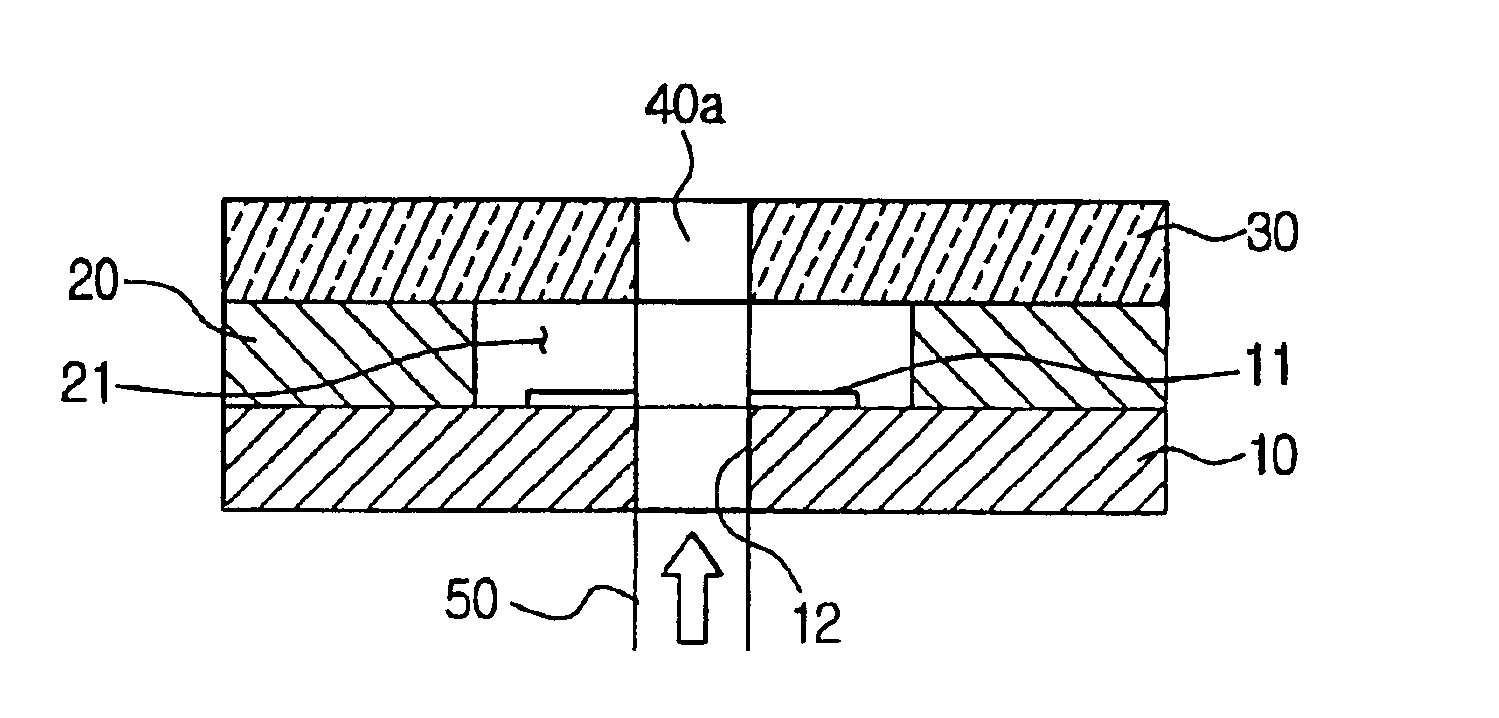

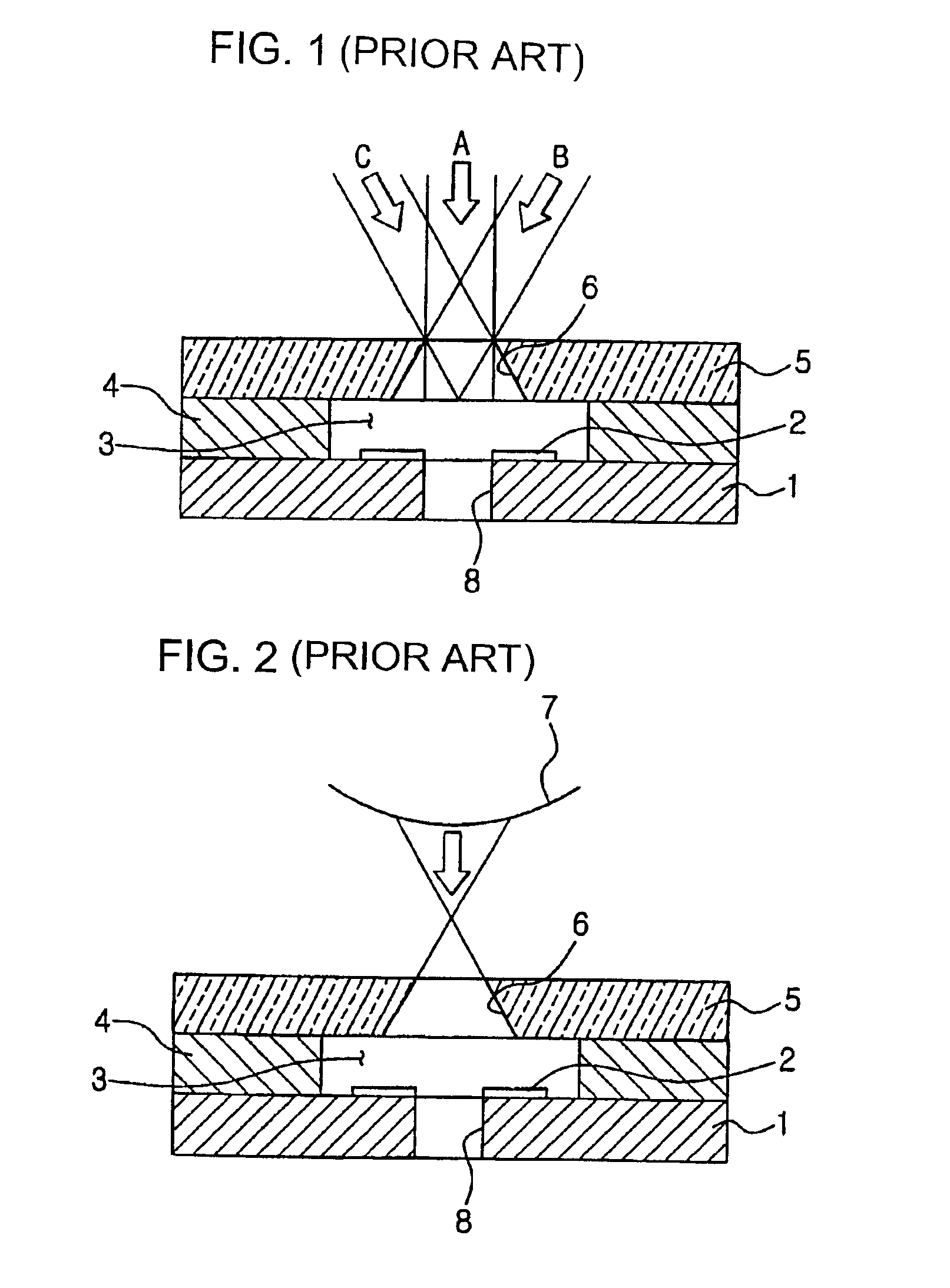

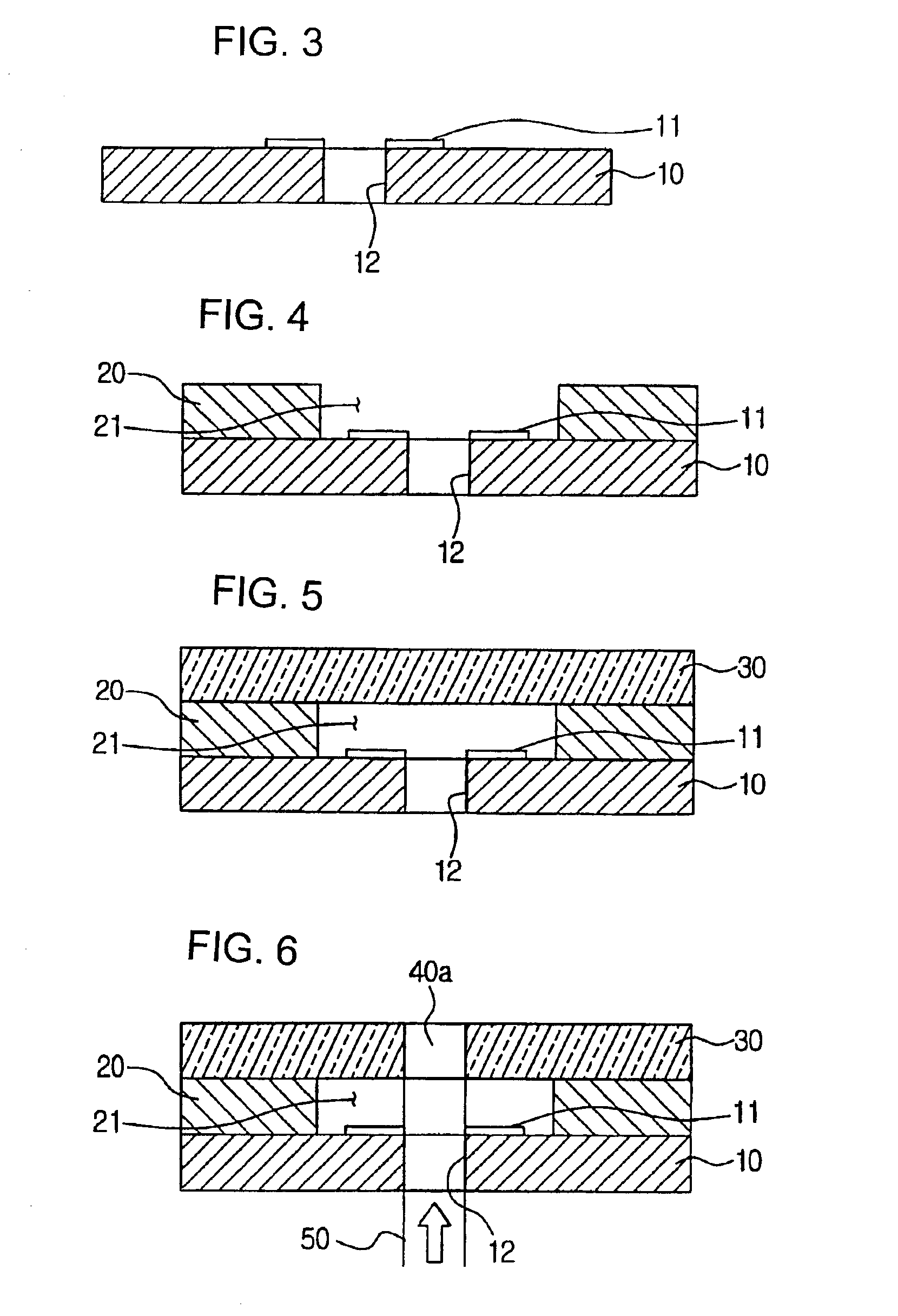

A configuration detection device includes a light-providing optical fiber, a light reflector a curvature-detecting optical fiber, and a light modulator. The light-providing optical fiber transmits detection light in a plurality of wavelength ranges that have different wavelengths from one another, The light reflector reflects the detection light as reflected light. The curvature-detecting optical fiber transmits the reflected light, and is bent together with an endoscope. The light modulator modulates at least one of the strength or the wavelength of the reflected light for each of the wavelength ranges. Based on at least one of the strength or the wavelength of the reflected light that is pre-modulated and post-modulated, and based on the distance between the light modulator and the output end of the curvature-detecting optical fiber, the configuration of the endoscope is detectable.

Owner:HOYA CORP

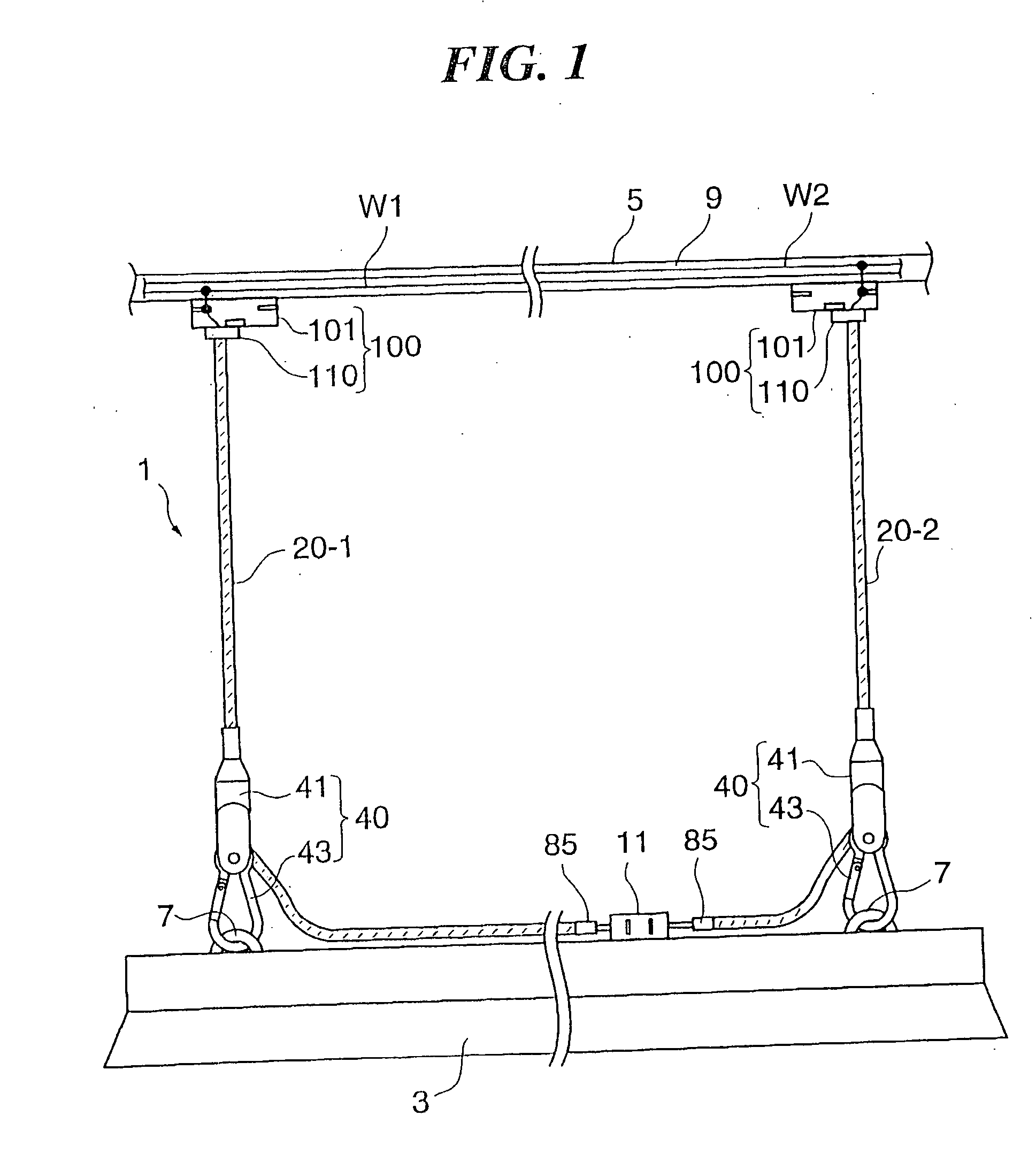

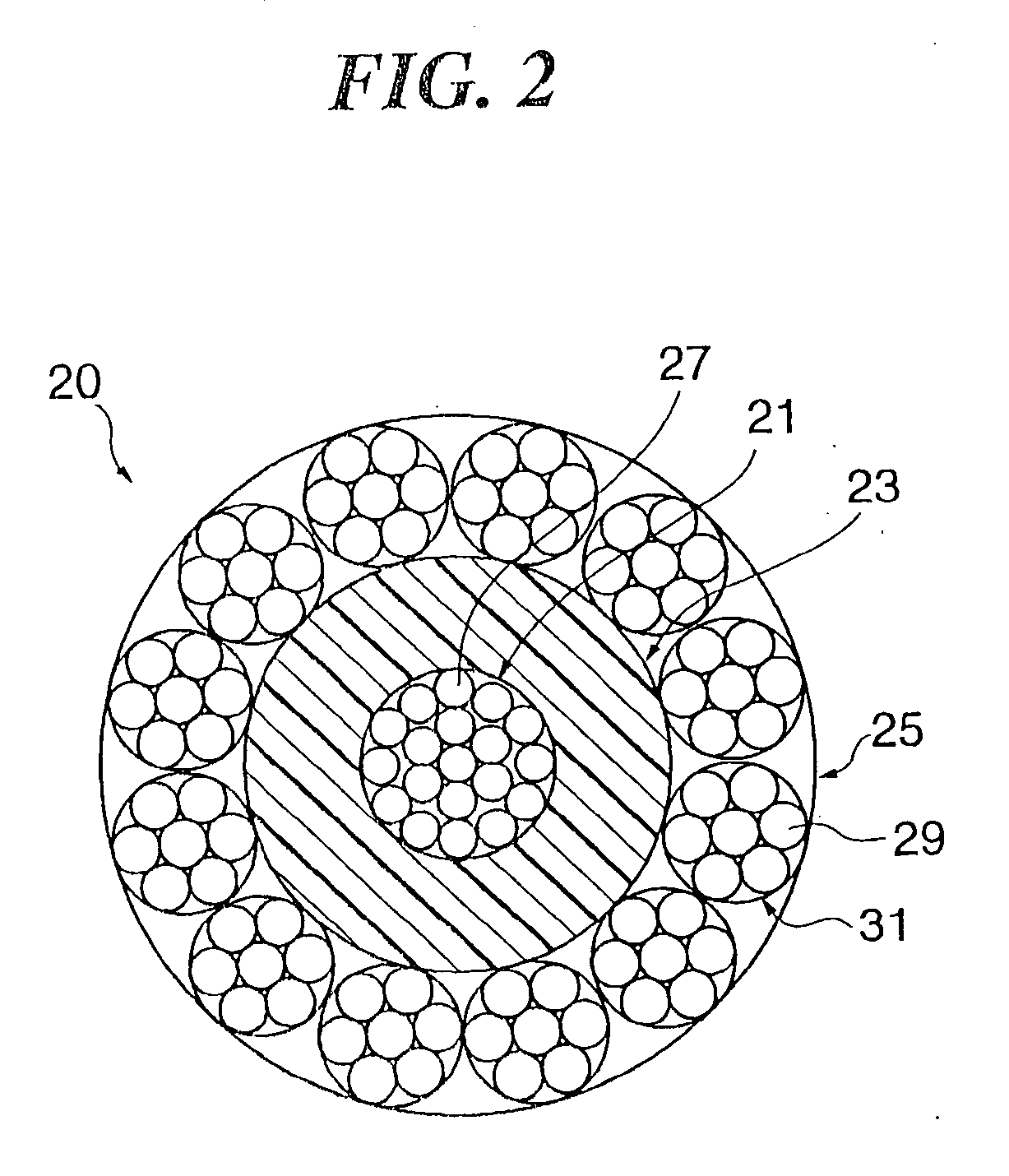

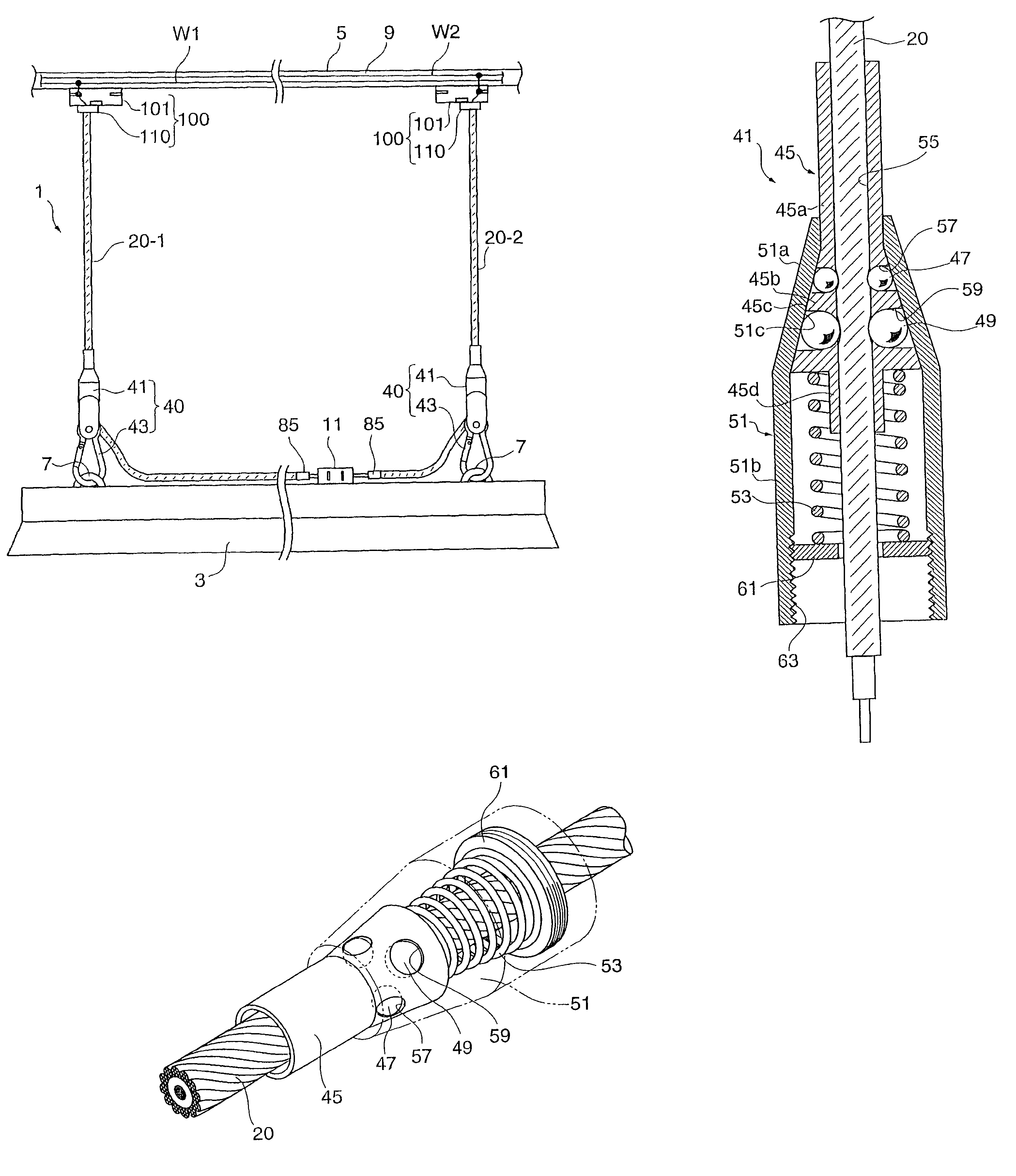

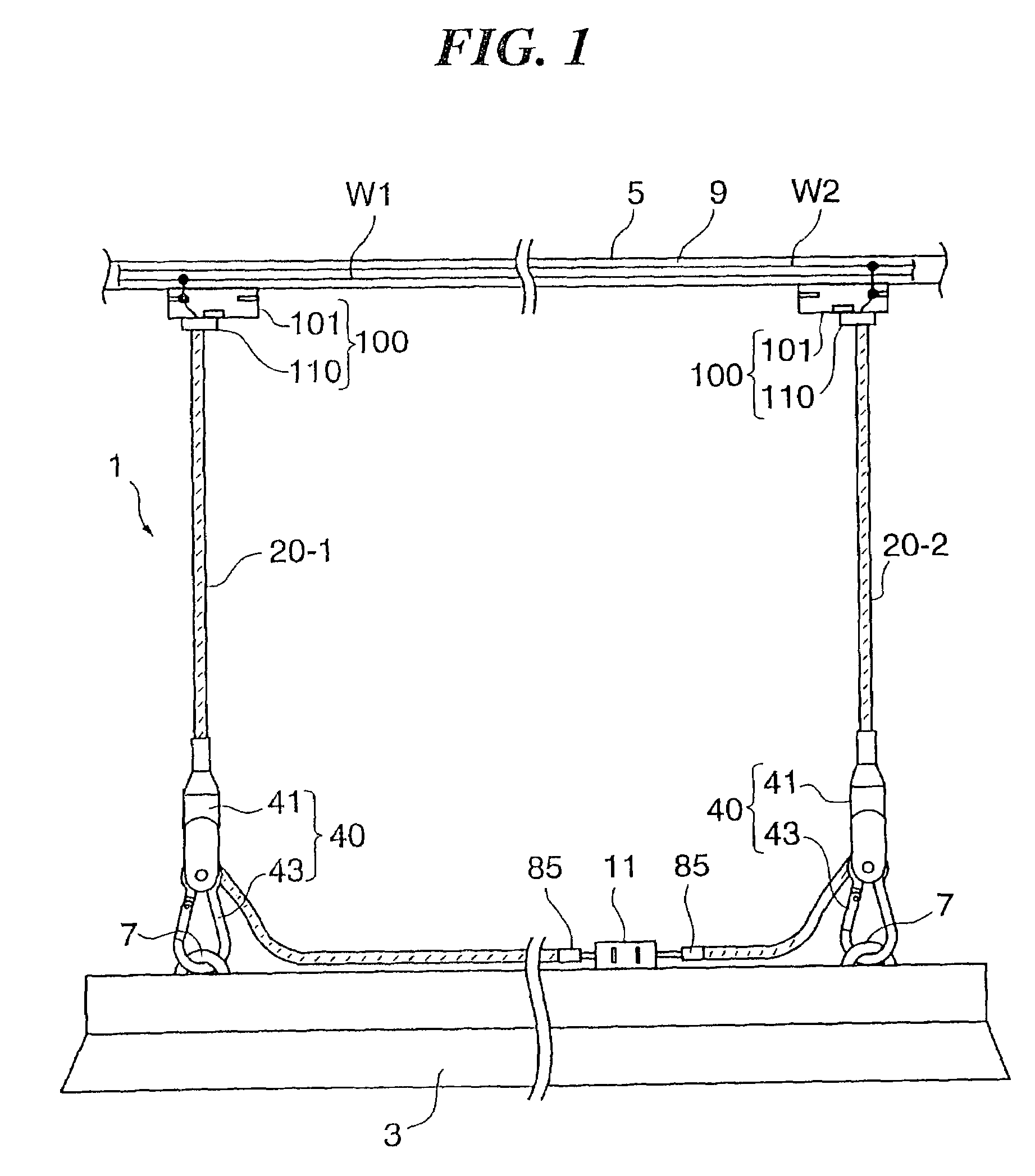

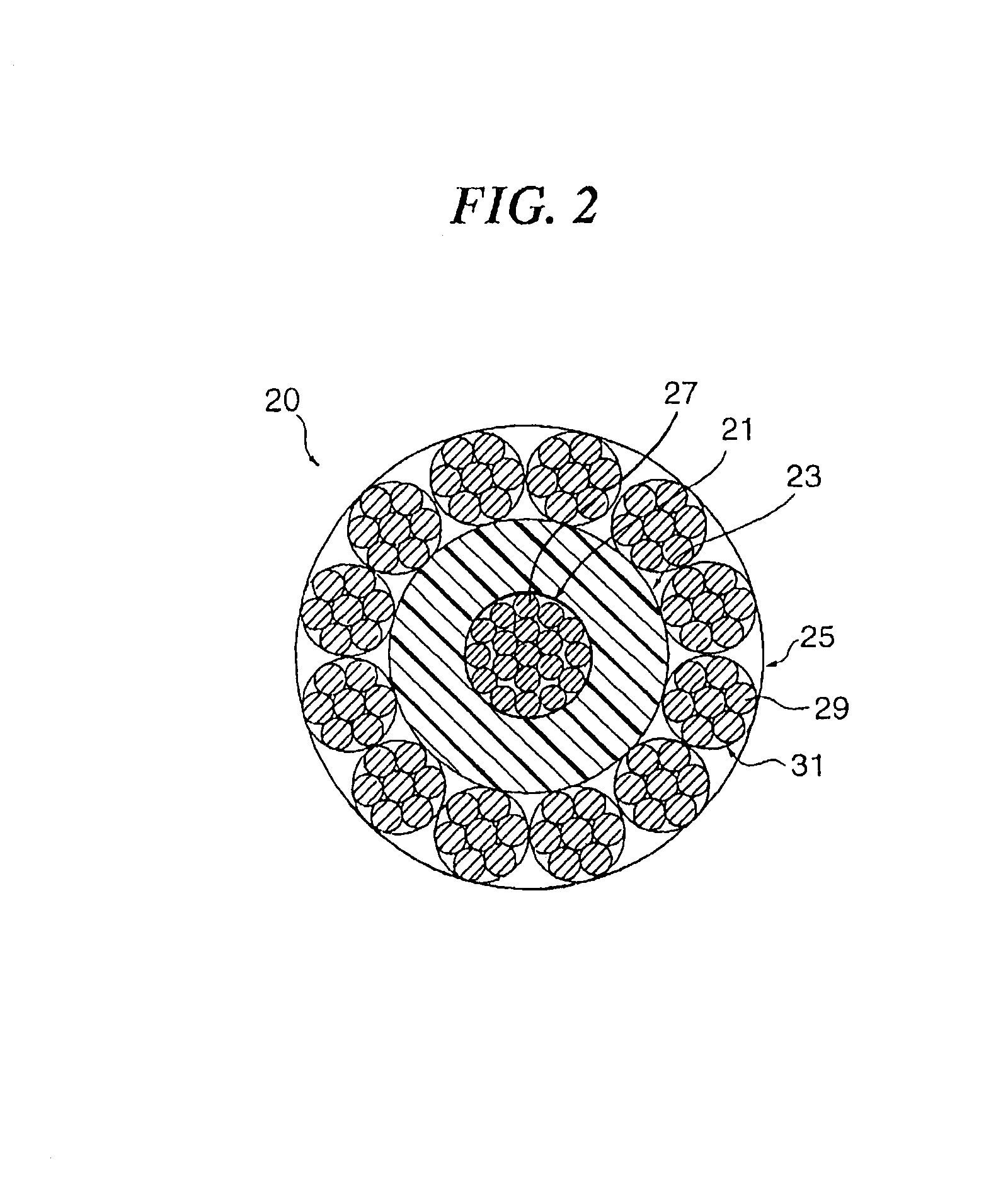

Power supply wire, wire grip, electric appliance suspending device, and electric appliance suspending method

ActiveUS20060000634A1Easy to handleReadily contractedNon-insulated conductorsLighting support devicesElectrical conductorEngineering

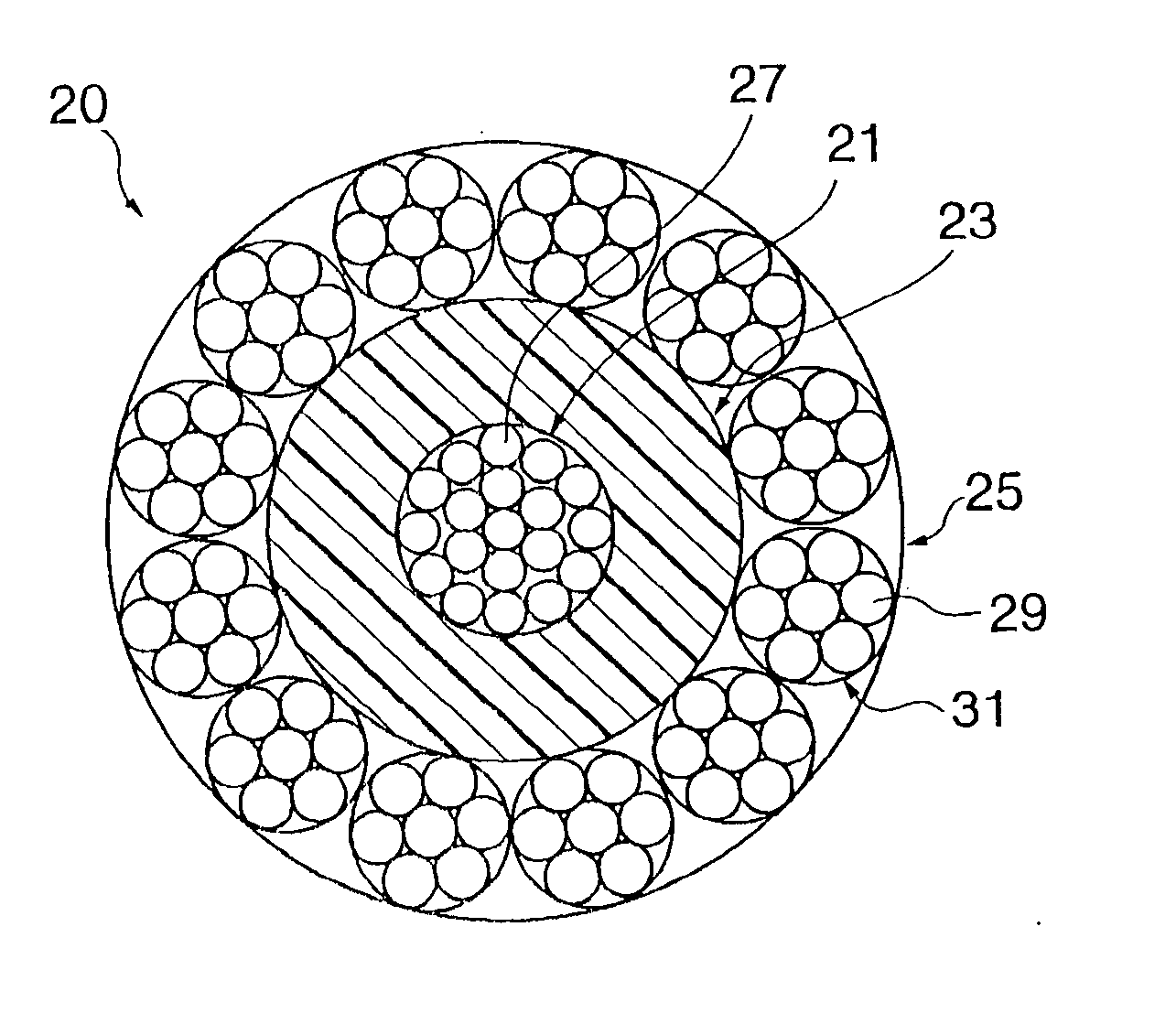

The electrical apparatus suspension unit 1 is provided with two power supply wires 20-1 and 20-2 by which the electrical apparatus 3 is conducted and suspended from the ceiling 5. Each of the wires 20 is connected to the hung member of the electrical apparatus 3 at the lower end by the a lower holder 40, and connected to the rail 9 laid on the ceiling 5 at the upper end by an upper holder 100. The power supply wire 20 comprises a core wire 21, an insulating layer 23 covering the core wire 21 and an outer layer 25 covering the insulating layer 23. The core wire 21 of the power supply wire 20-1 conducts to a grounded conductor cable W1 and the core wire 21 of another power supply wire 20-2 conducts to a voltage applied conductor cable W2. The power supply wires 20 having high tensile strength enables to suspend the electrical apparatus and also supply power thereto.

Owner:A G K

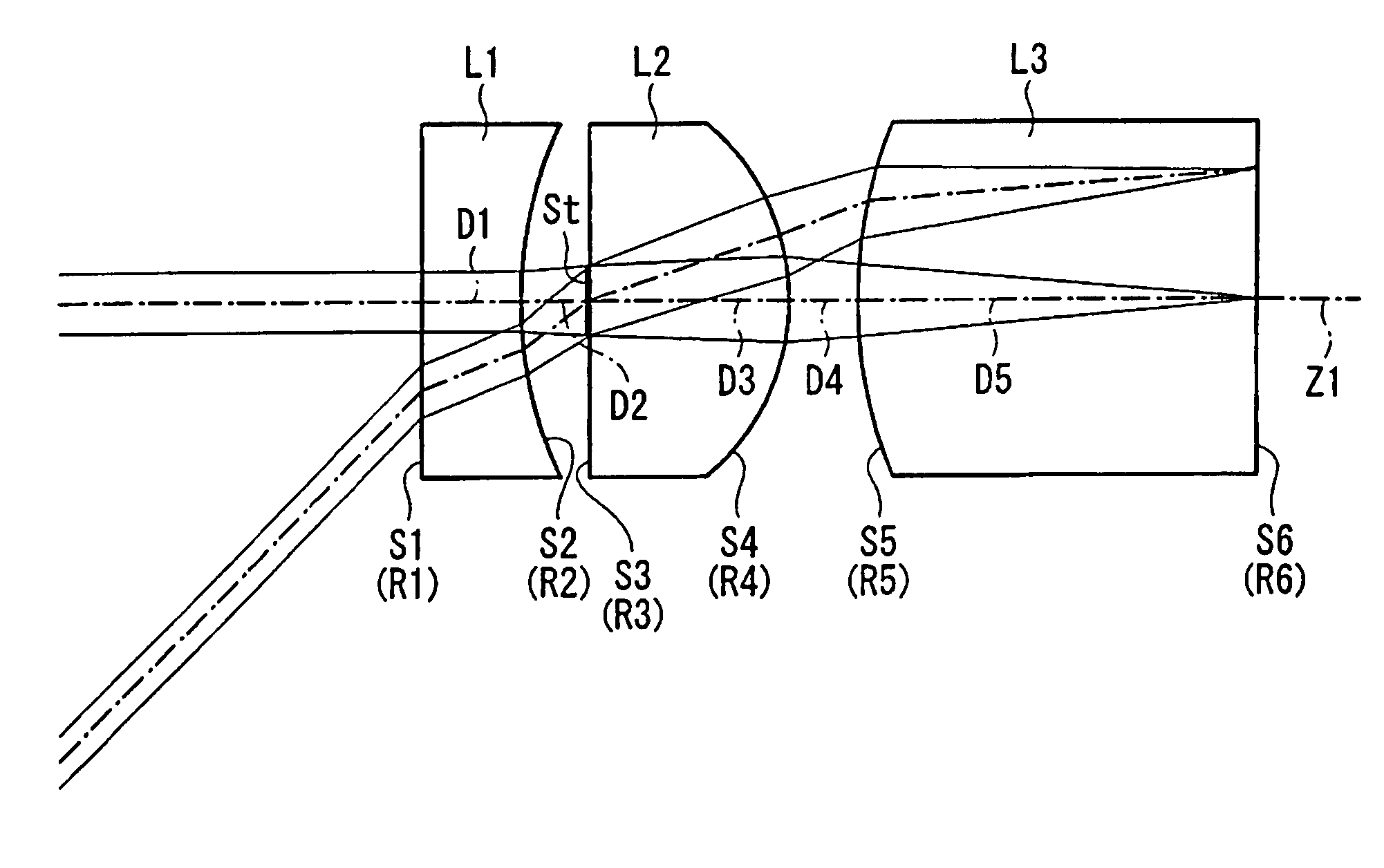

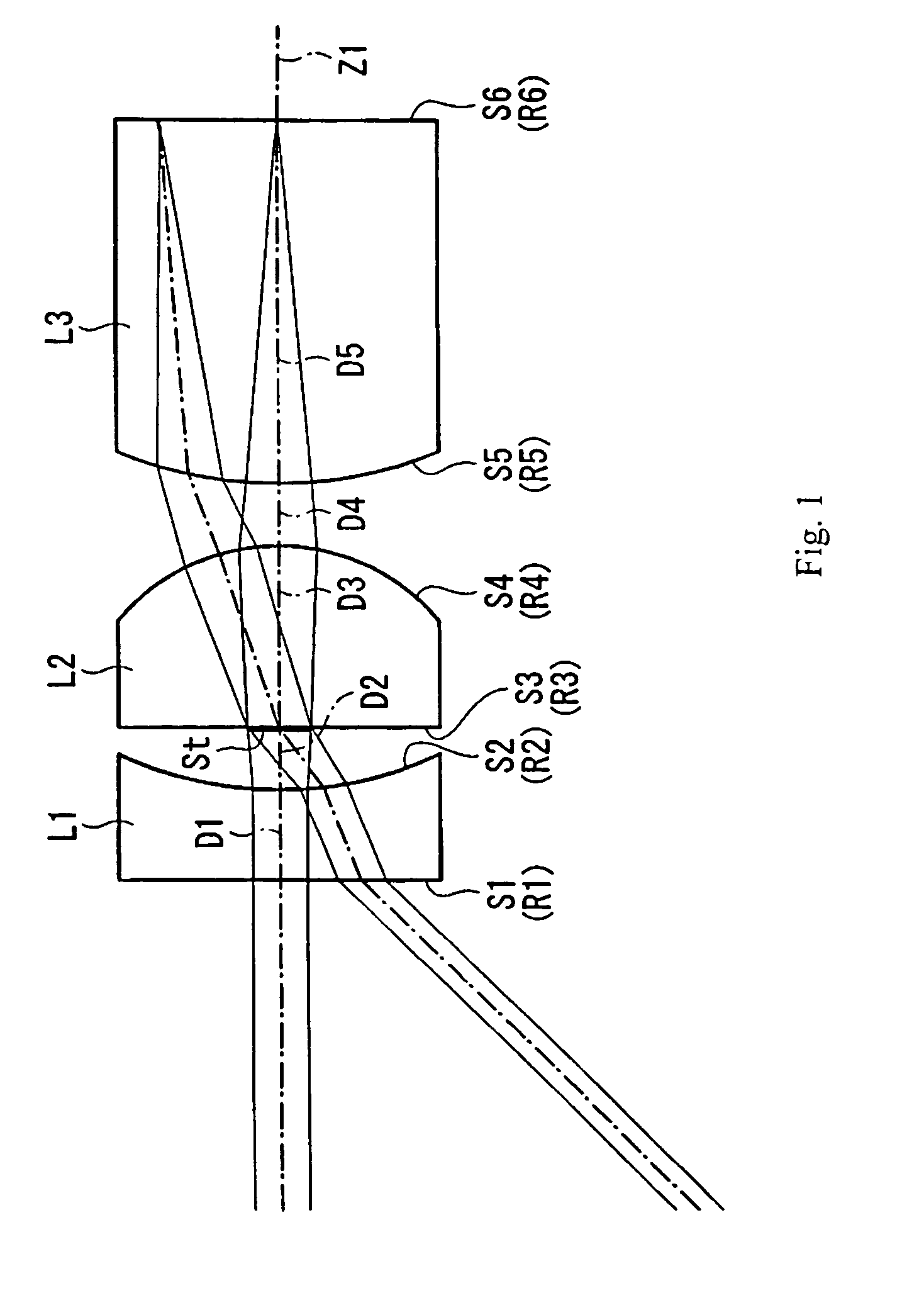

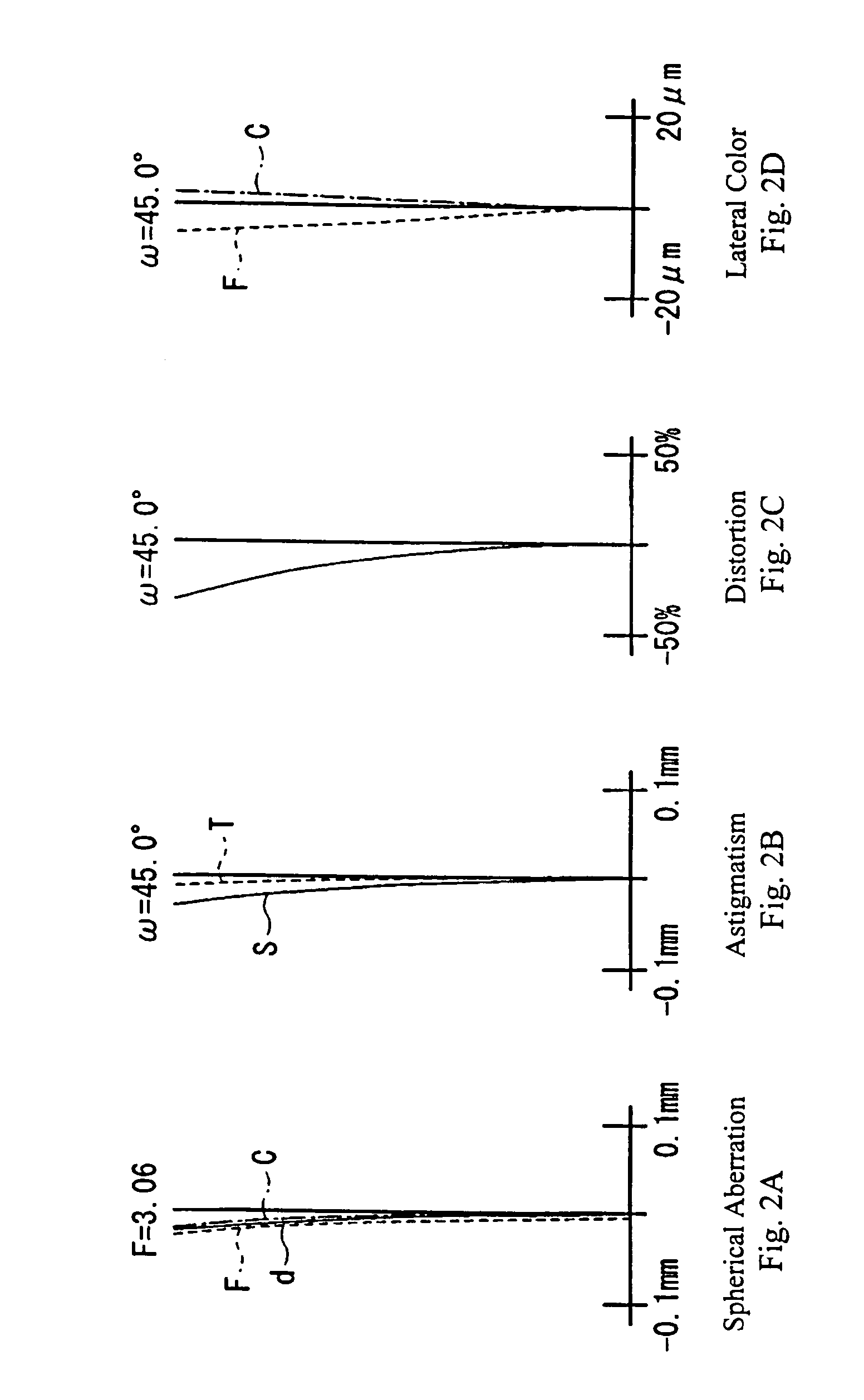

Endoscope objective lens

An endoscope objective lens with a three-group, three lens element construction, is formed of, in order from the object side, a first lens element having either a negative meniscus shape or a plano-concave shape with its concave surface on the image side, a stop, a positive second lens element having a plano-convex shape with its convex surface on the image side, and a positive third lens element having a plano-convex shape with its convex surface on the object side. The stop is positioned on or in contact with the object-side surface of the second lens element so that the endoscope objective lens is substantially telecentric. Specified conditions are satisfied in order to reduce aberrations and make the manufacture of the endoscope objective lens easier and less expensive.

Owner:FUJI PHOTO OPTICAL CO LTD

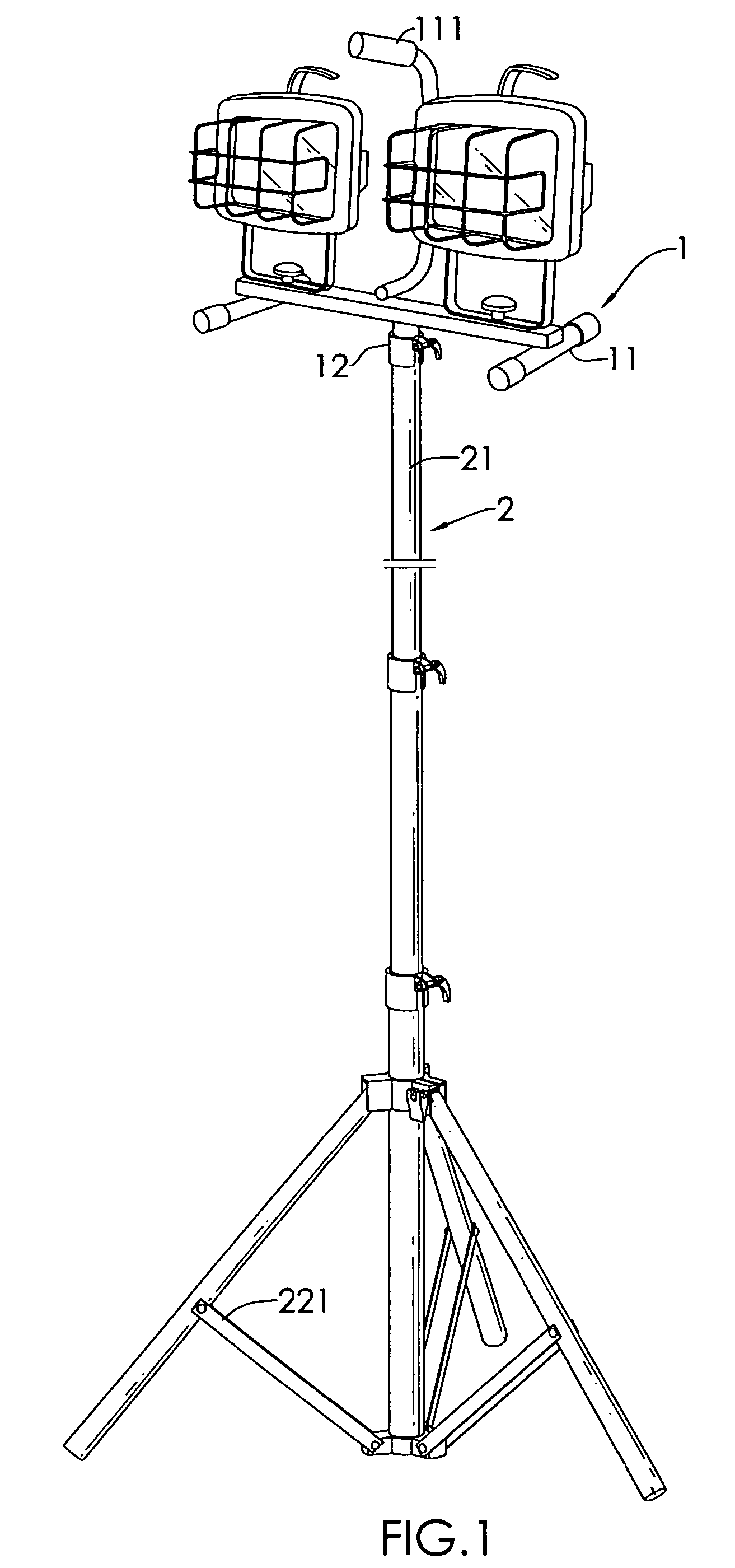

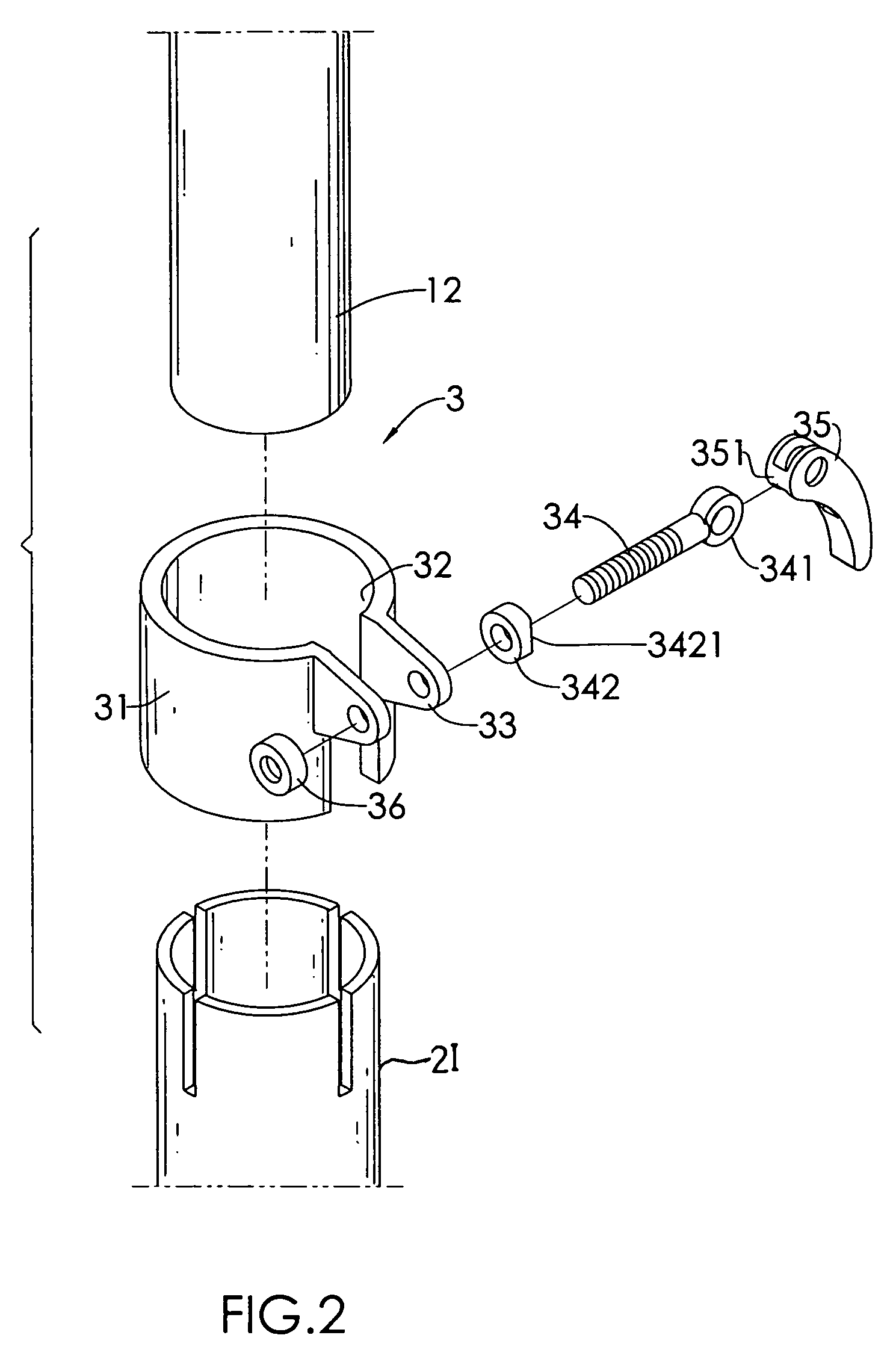

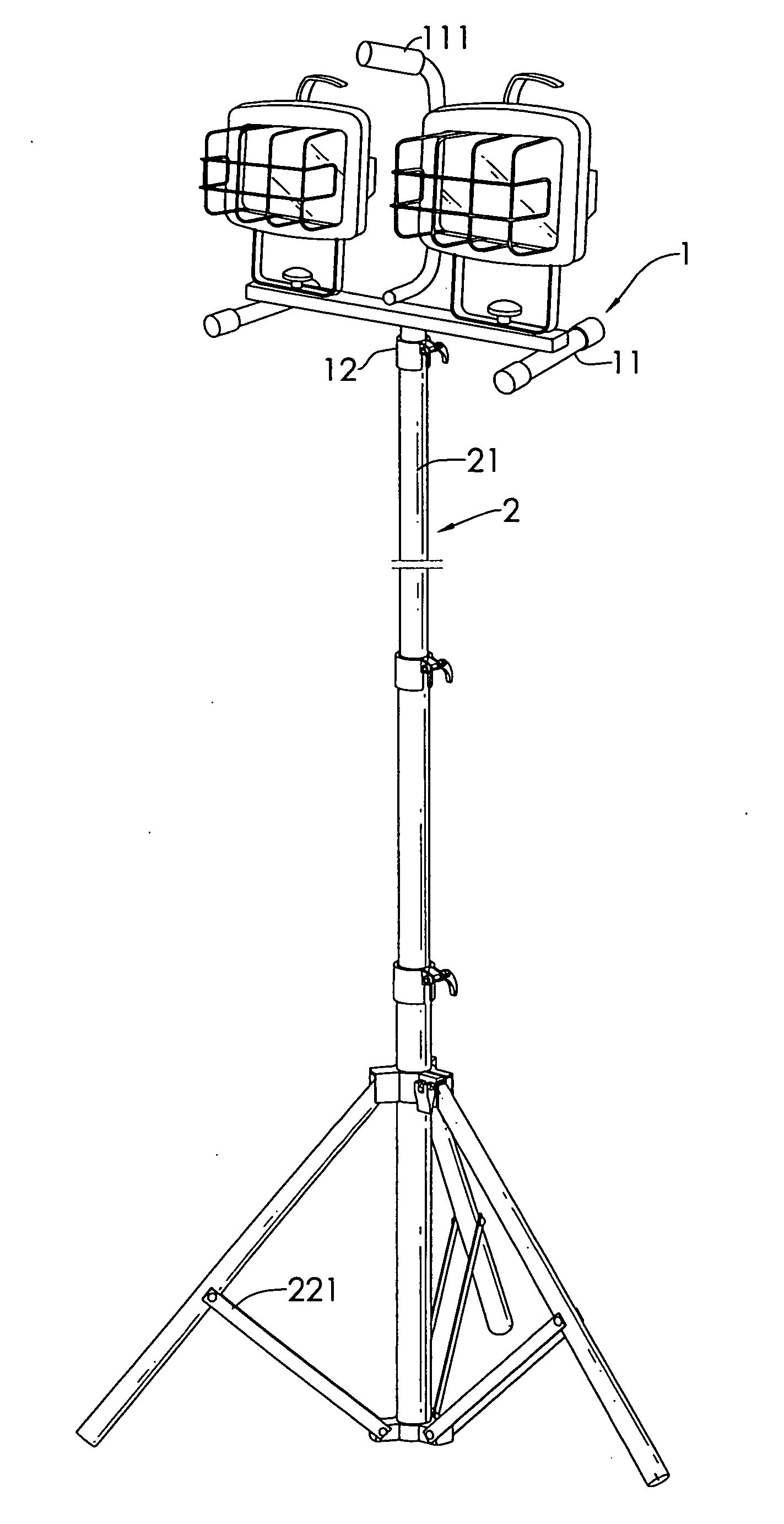

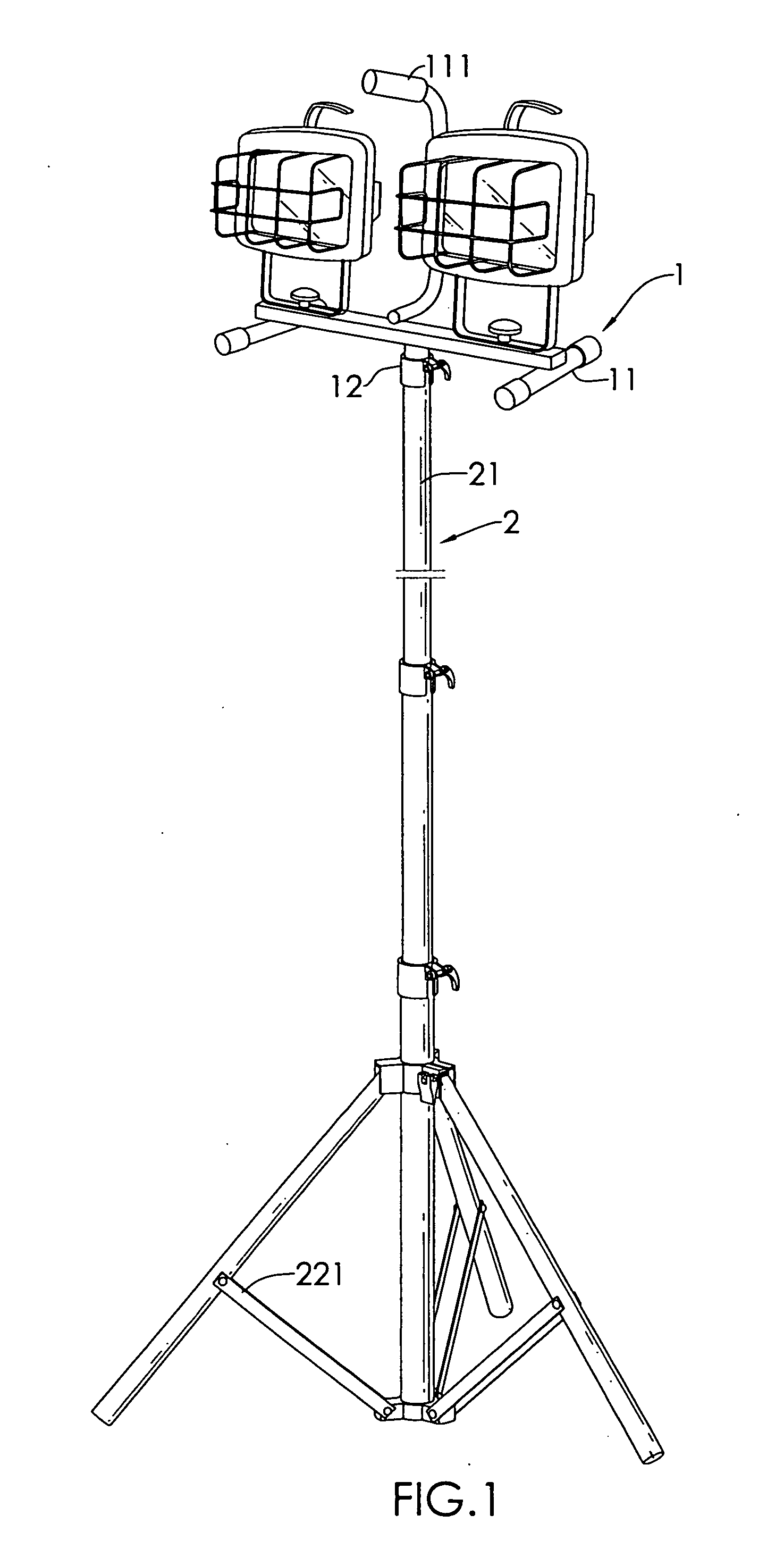

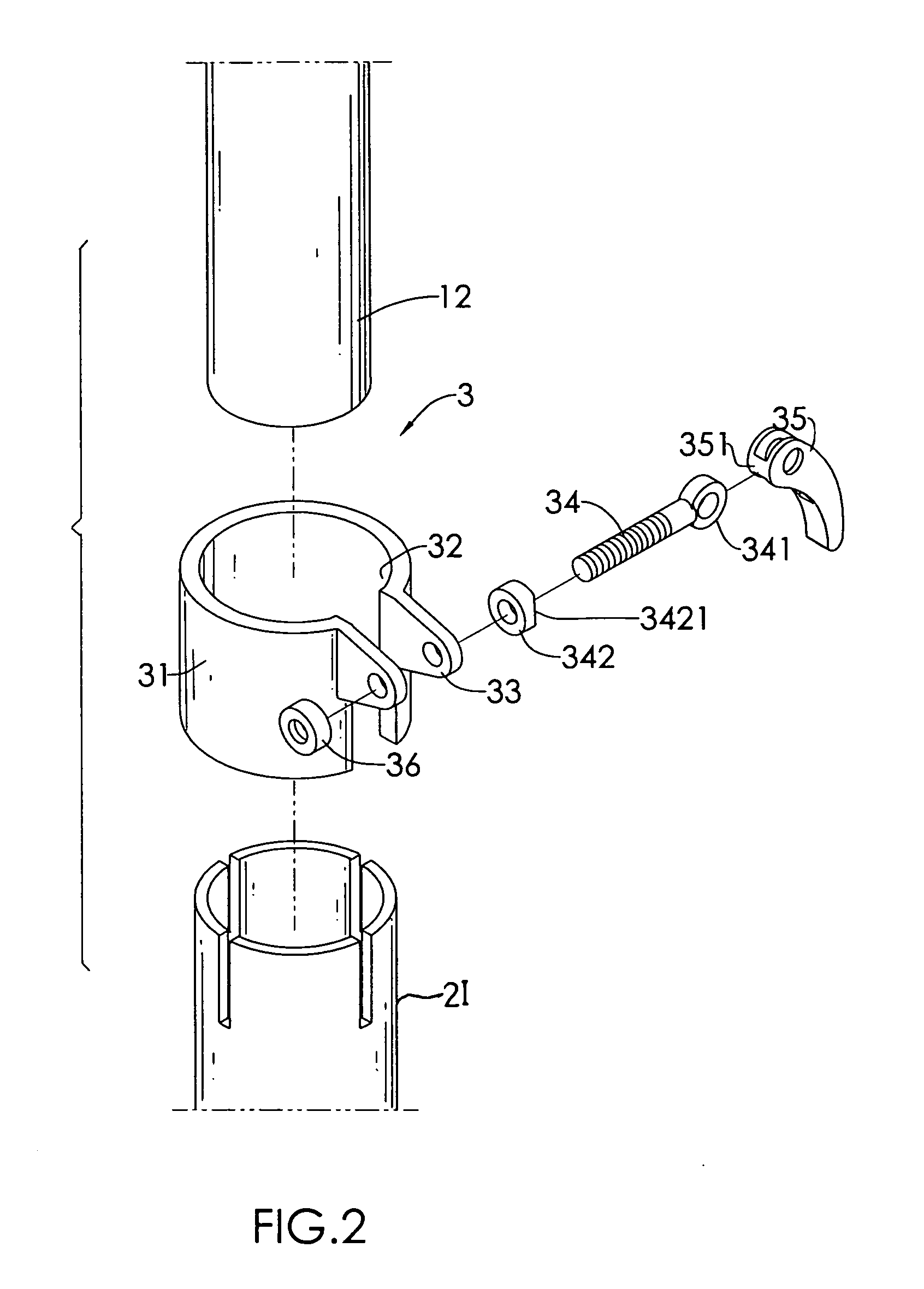

Worklight support with stand

A worklight support includes a platform for mounting thereon worklights and has an extension extending from on a bottom of the platform for extension into one of the stand sections. A stand includes couplers applied for combination of each of the stand sections. Each coupler includes an annular ring for receiving therein a portion of one of the stand sections and a portion of the extension of the worklight support and a pivotal handle pivotally connected to the annular ring via a threaded bolt to selectively reduce an internal diameter of the annular ring to abut an outer periphery of the extension so as to fix the extension relative to one of the stand sections.

Owner:TSAI PETER

Configuration detection device for endoscope

InactiveUS7440661B2High precision of detectionNarrow diameterSurgeryEndoscopesLight reflectionLength wave

A configuration detection device includes a light-providing optical fiber, a light reflector a curvature-detecting optical fiber, and a light modulator. The light-providing optical fiber transmits detection light in a plurality of wavelength ranges that have different wavelengths from one another, The light reflector reflects the detection light as reflected light. The curvature-detecting optical fiber transmits the reflected light, and is bent together with an endoscope. The light modulator modulates at least one of the strength or the wavelength of the reflected light for each of the wavelength ranges. Based on at least one of the strength or the wavelength of the reflected light that is pre-modulated and post-modulated, and based on the distance between the light modulator and the output end of the curvature-detecting optical fiber, the configuration of the endoscope is detectable.

Owner:HOYA CORP

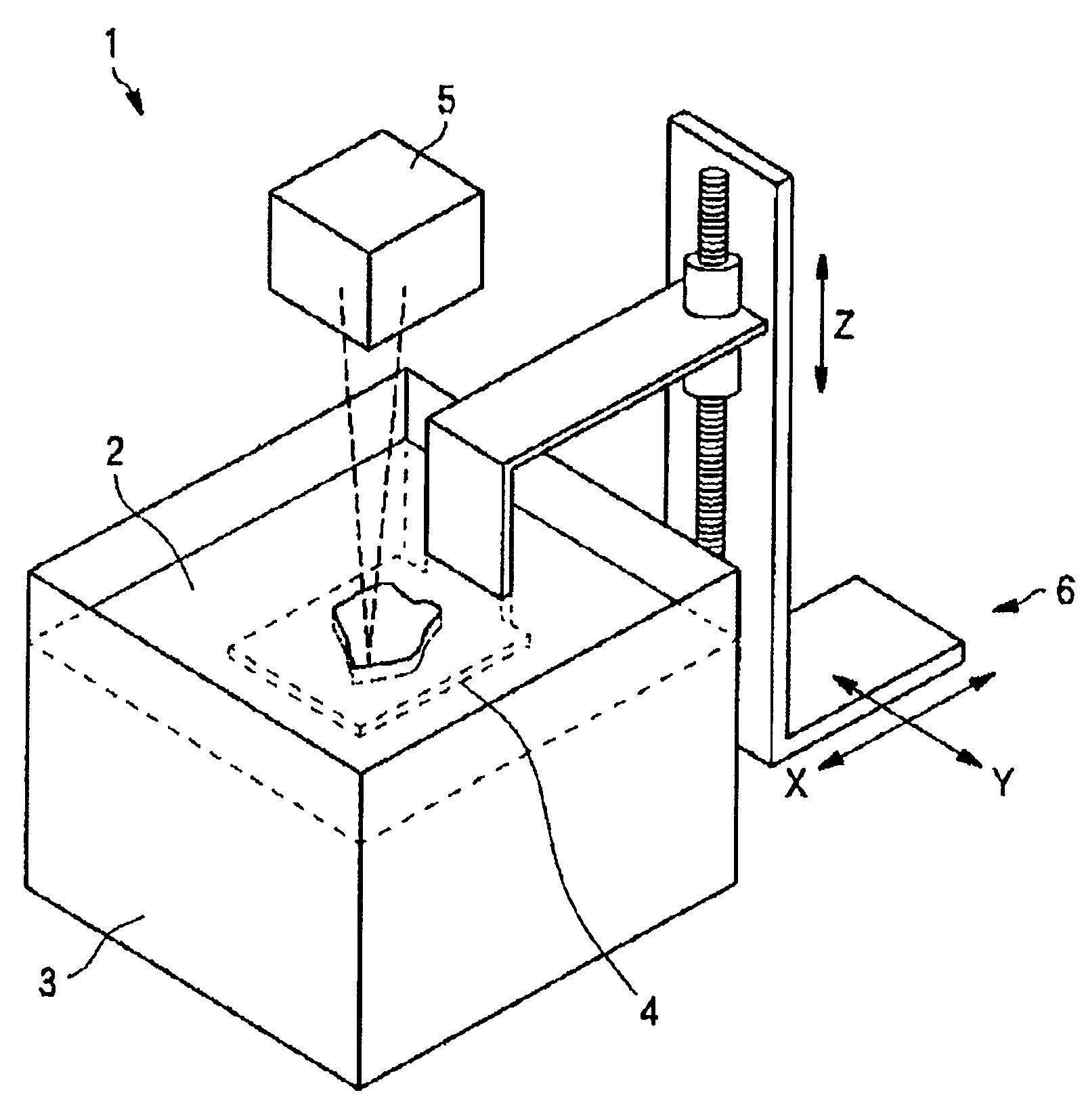

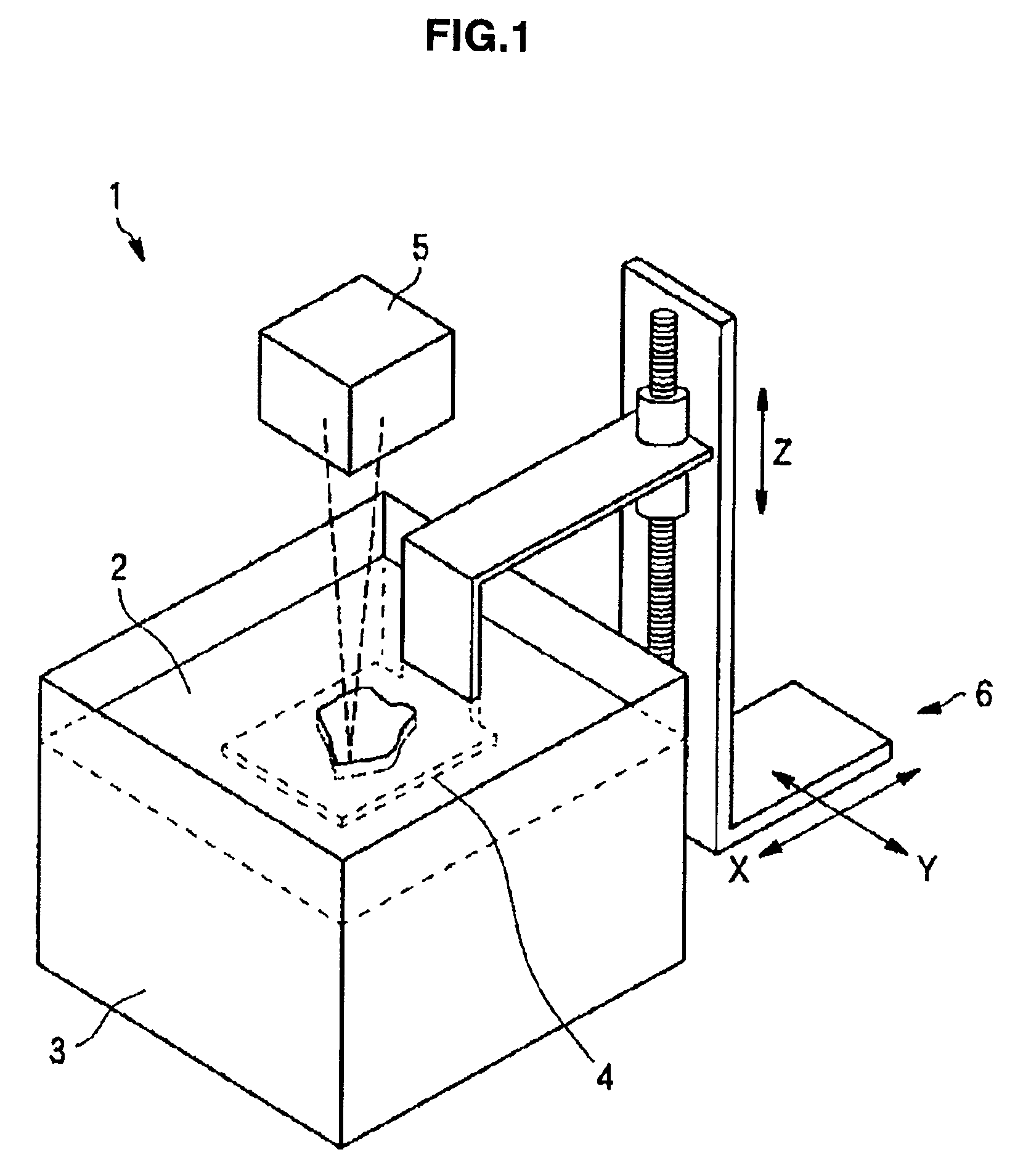

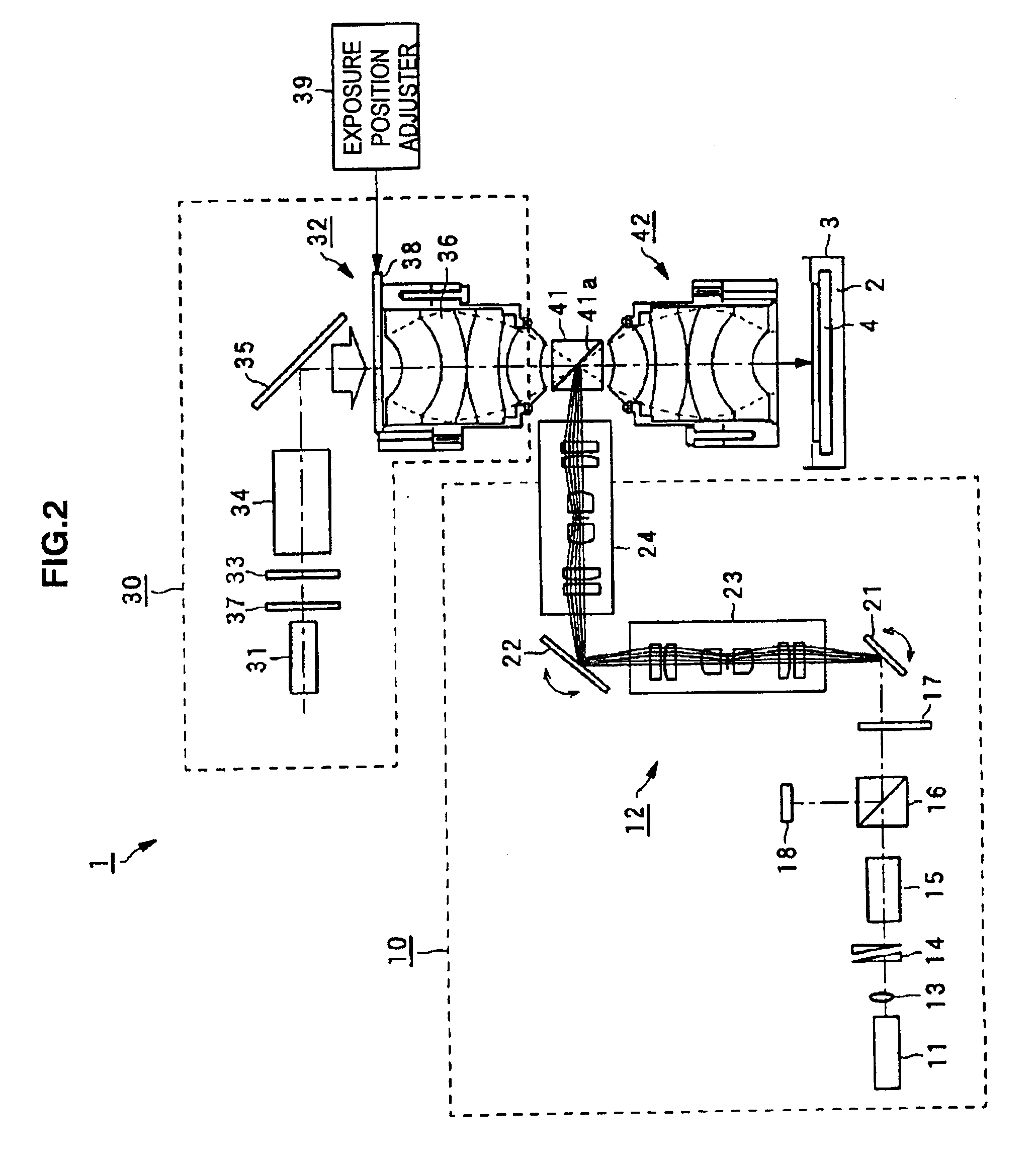

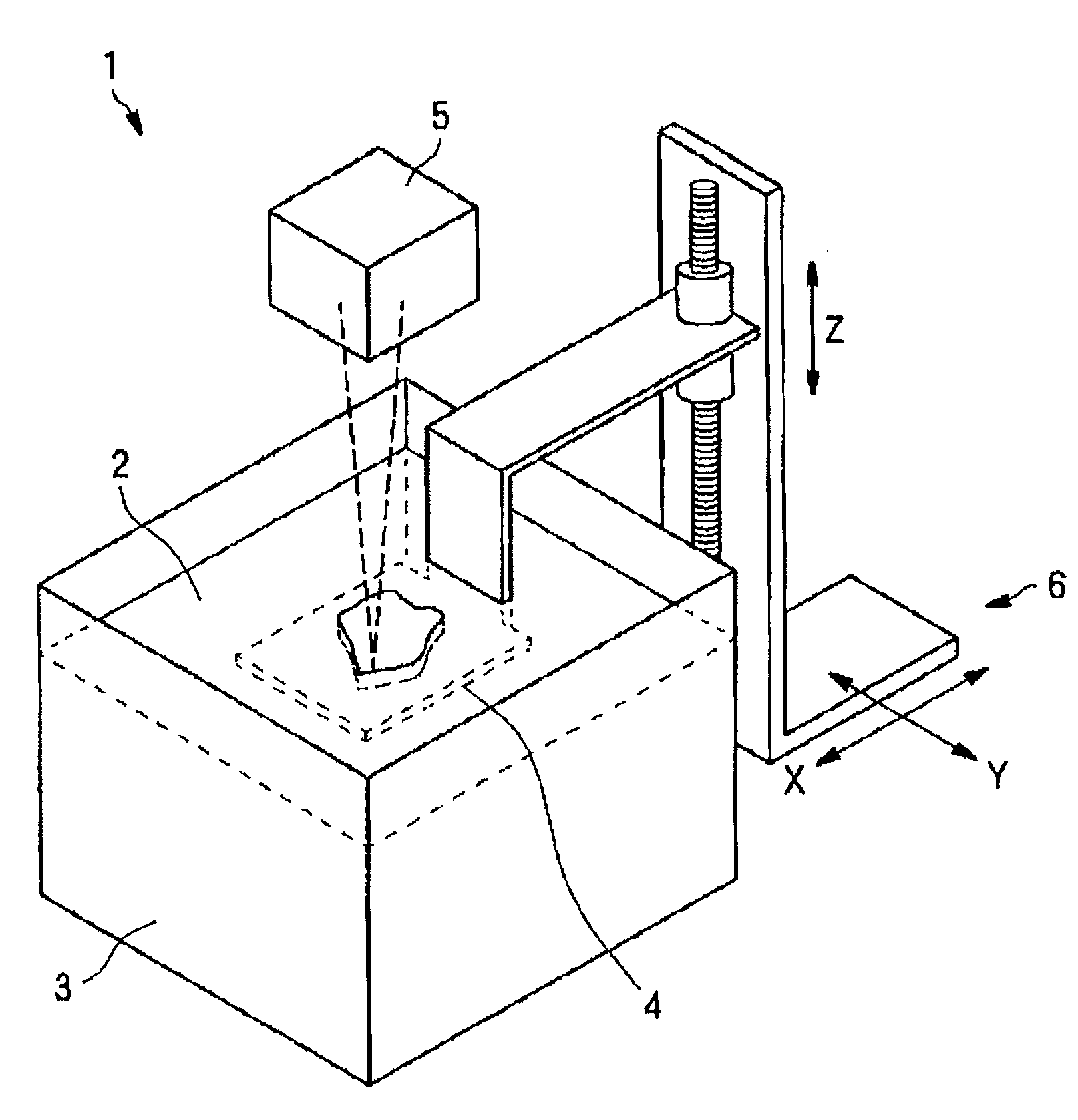

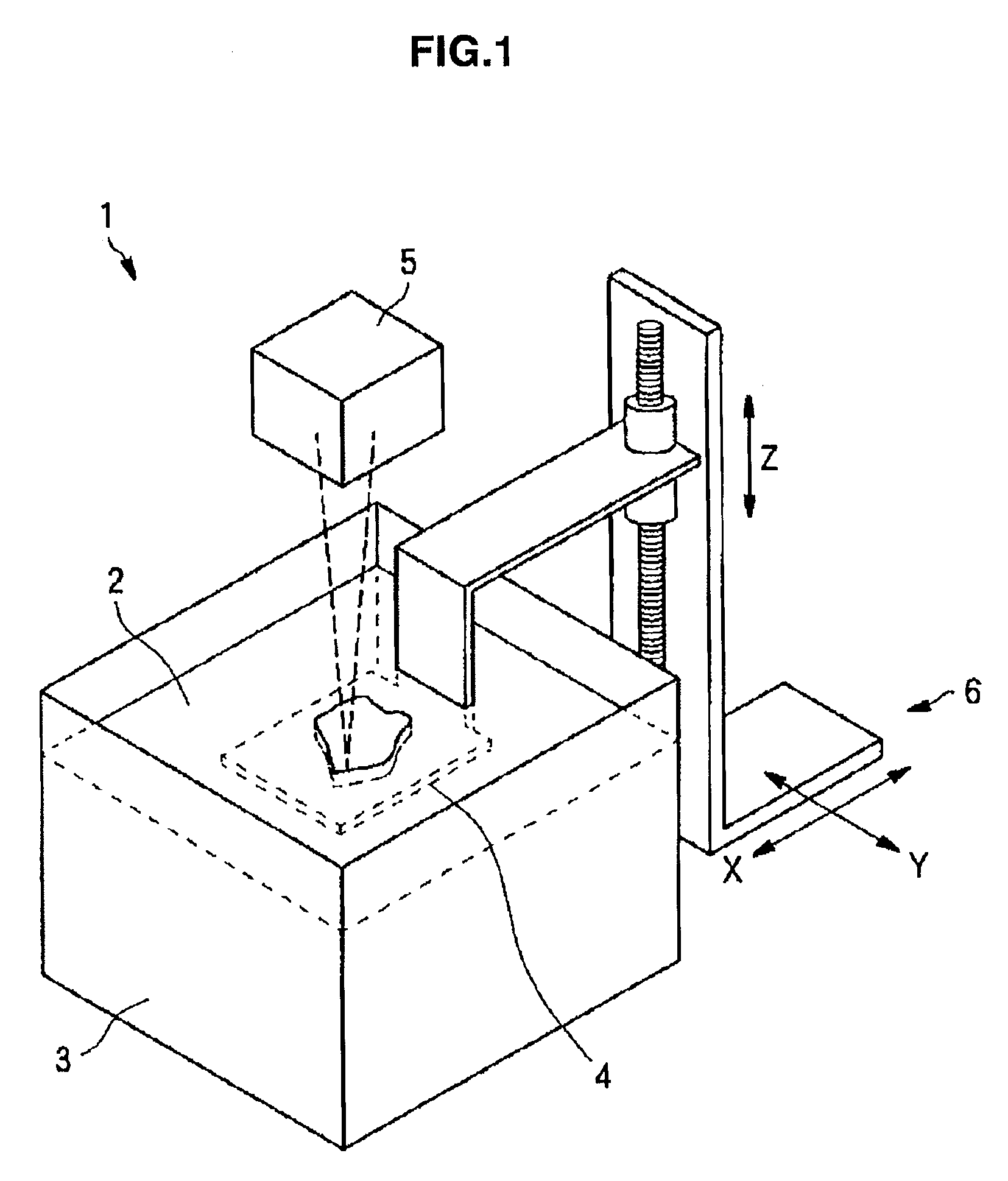

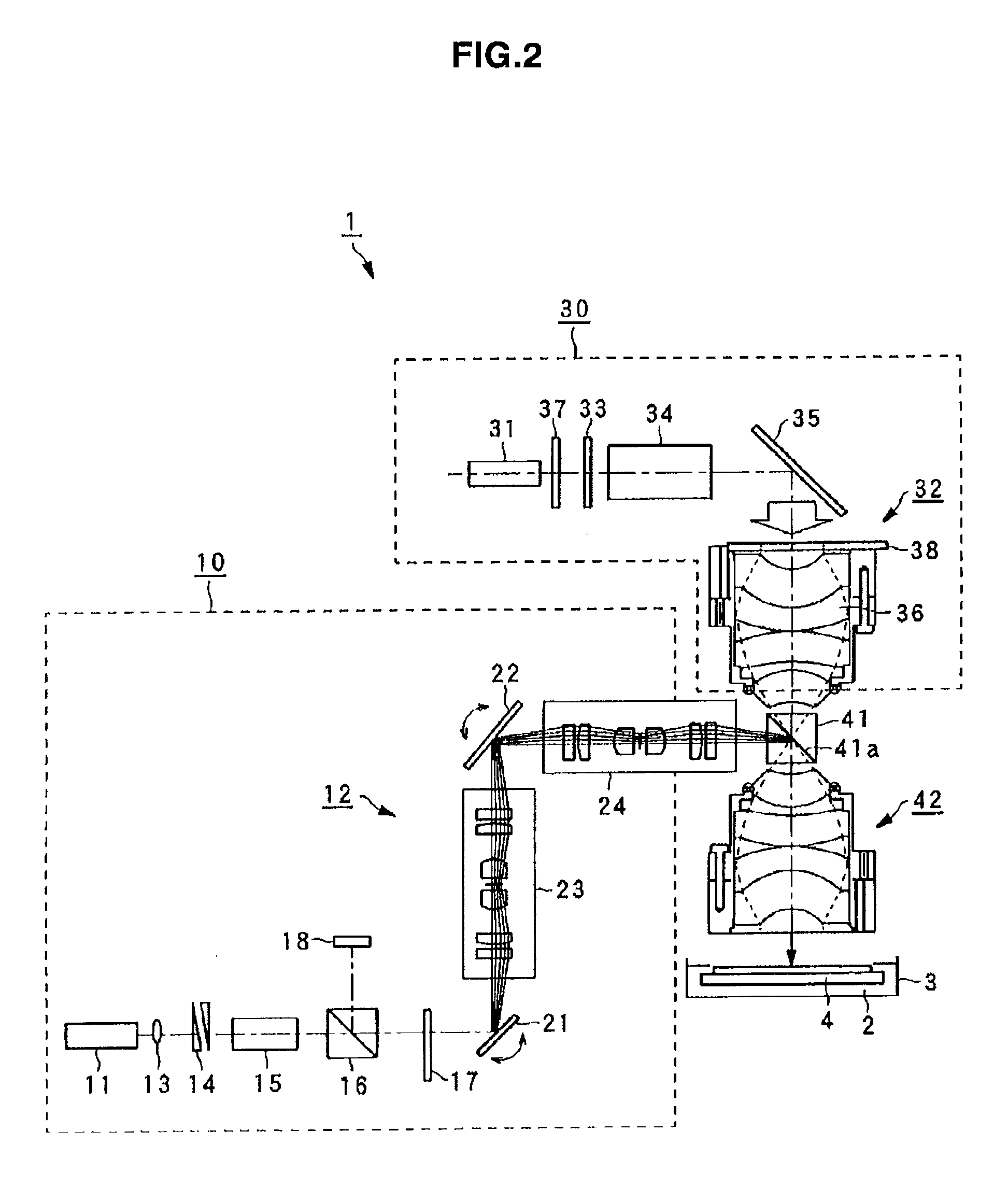

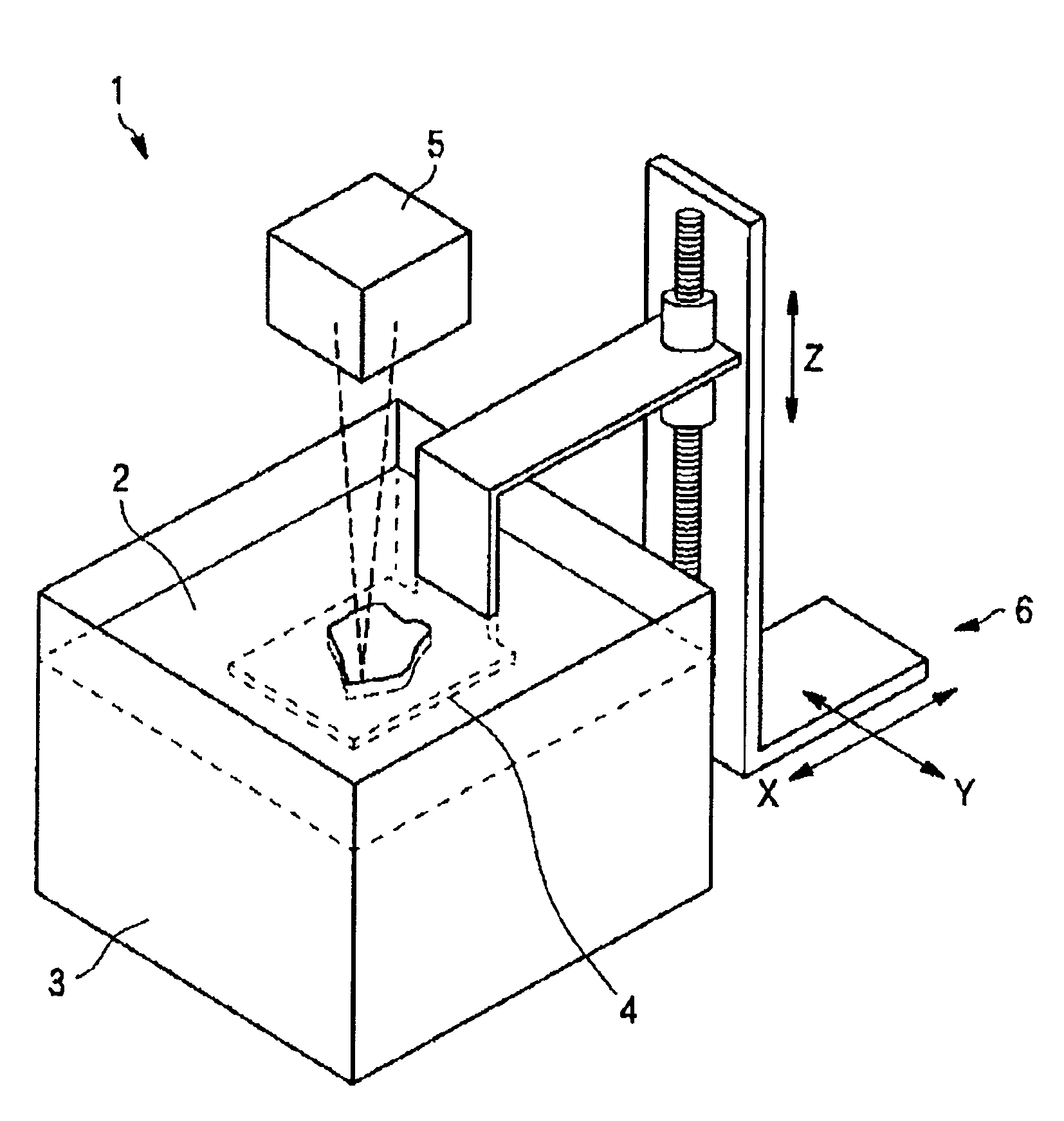

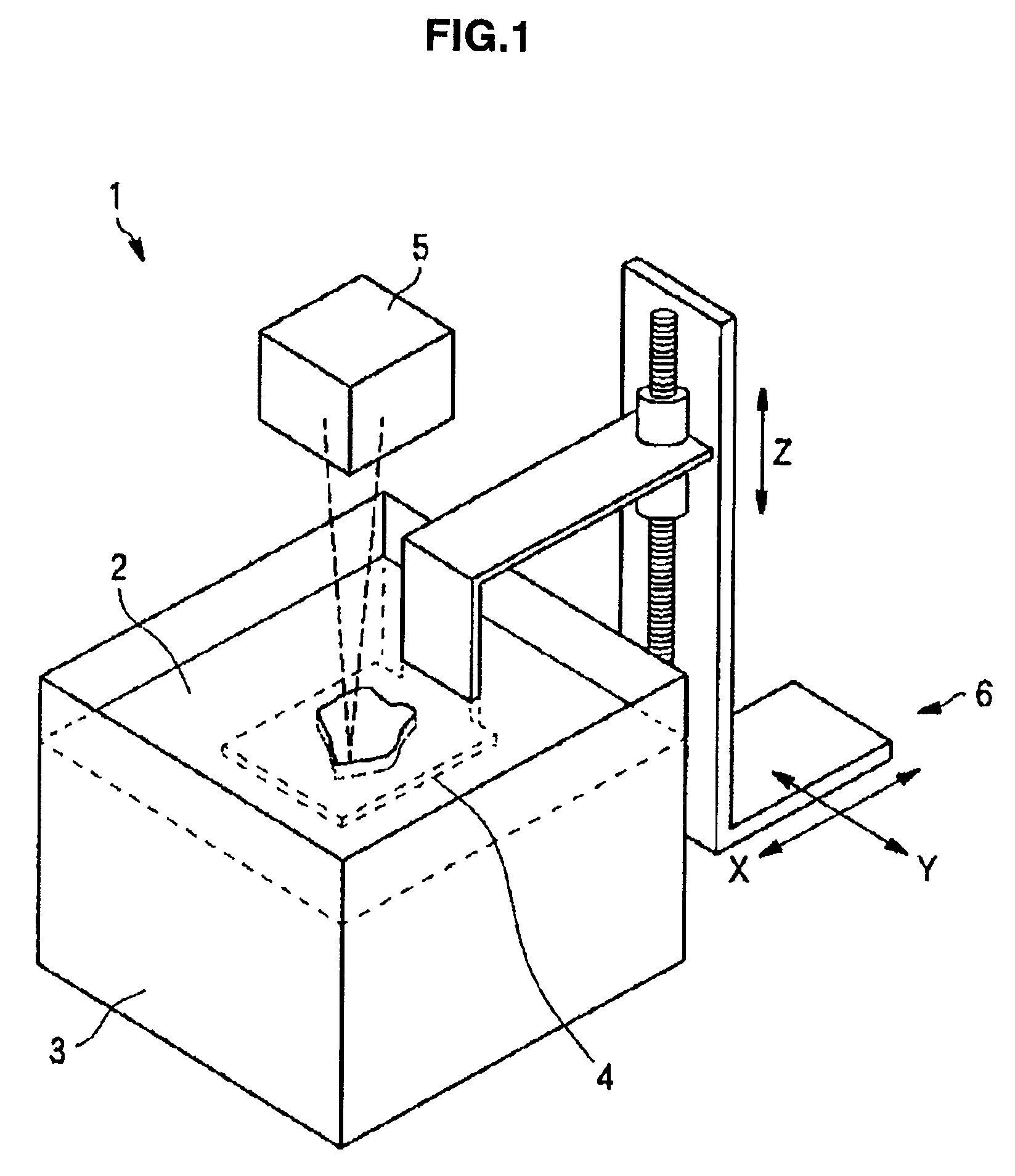

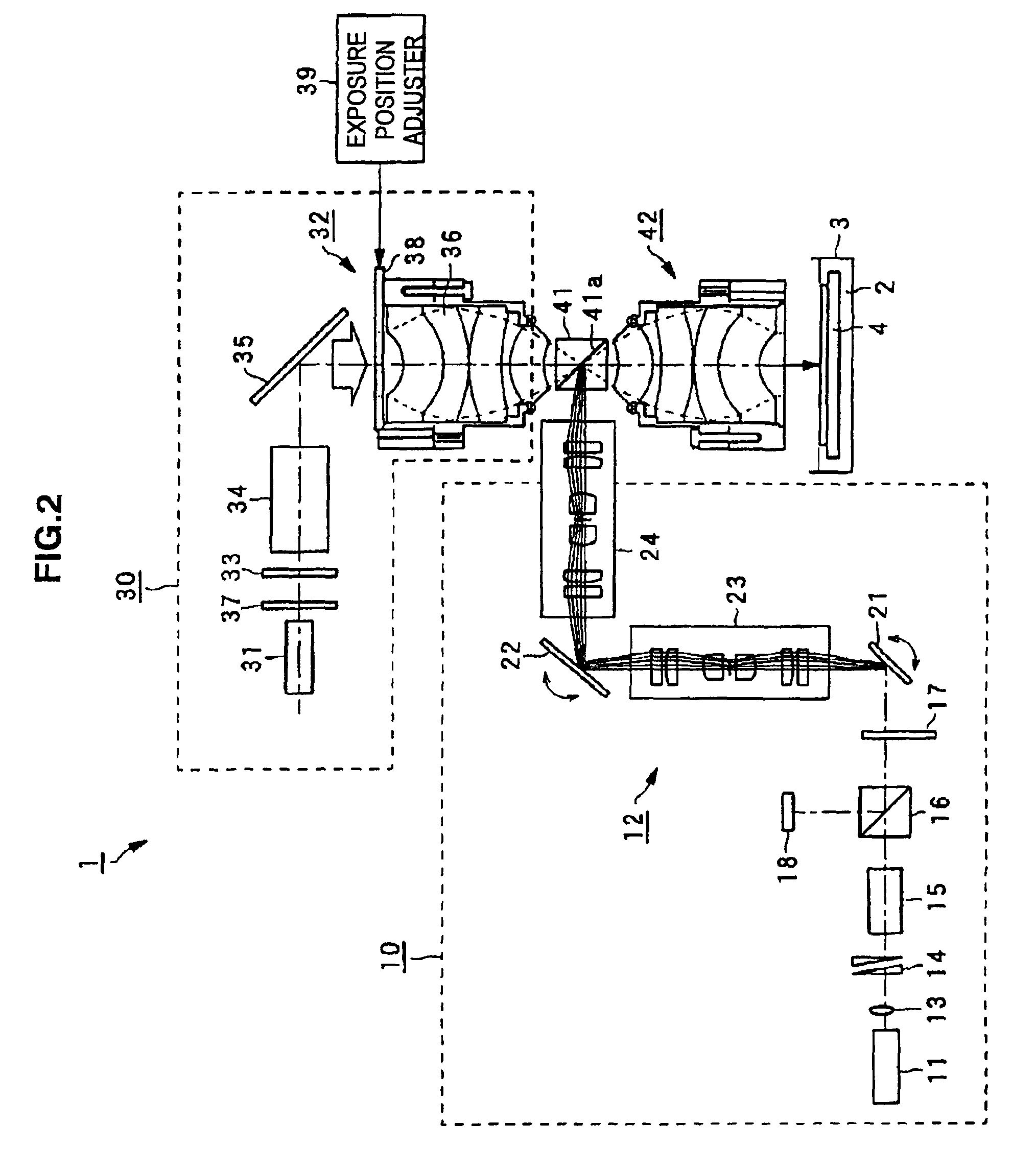

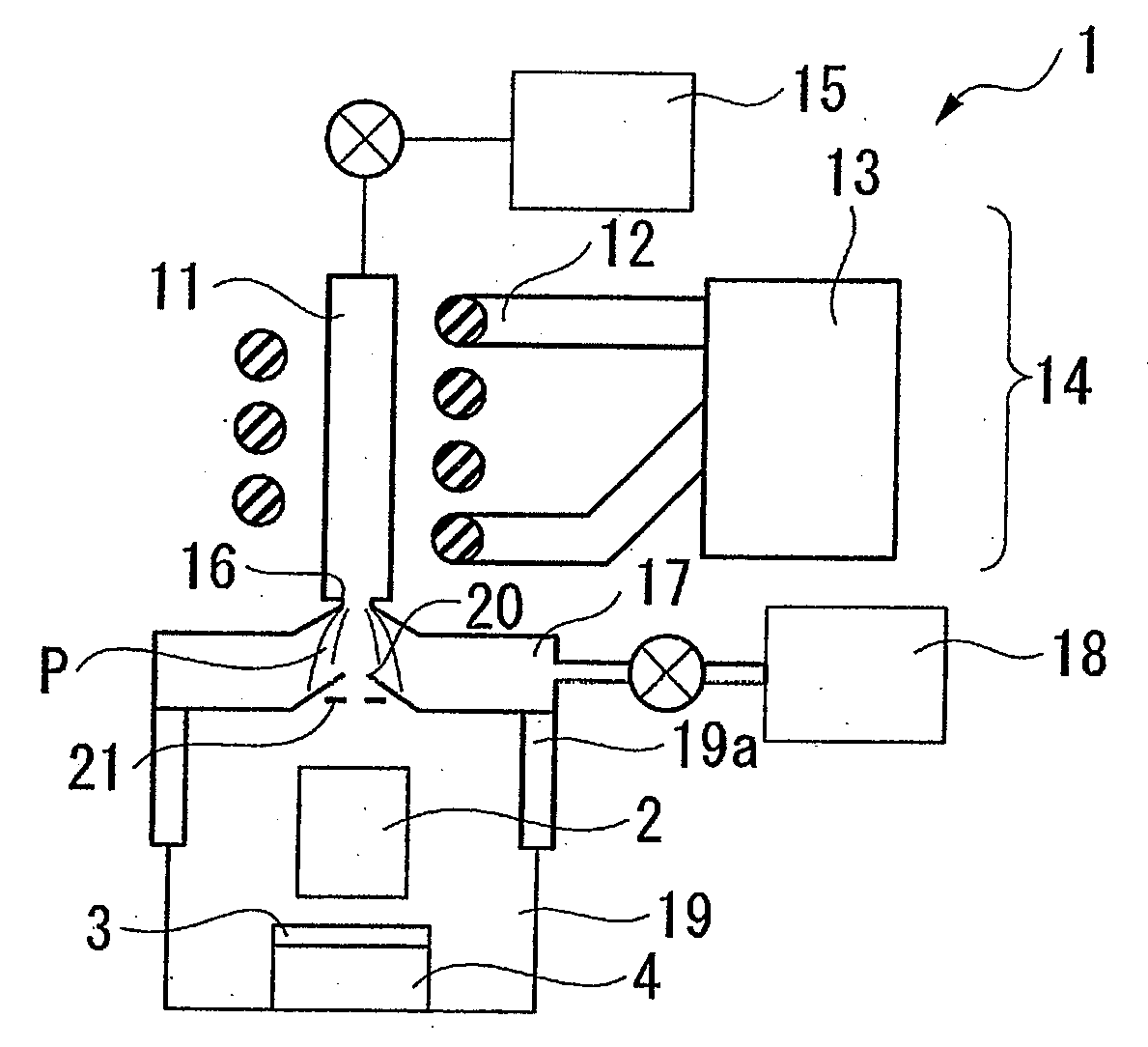

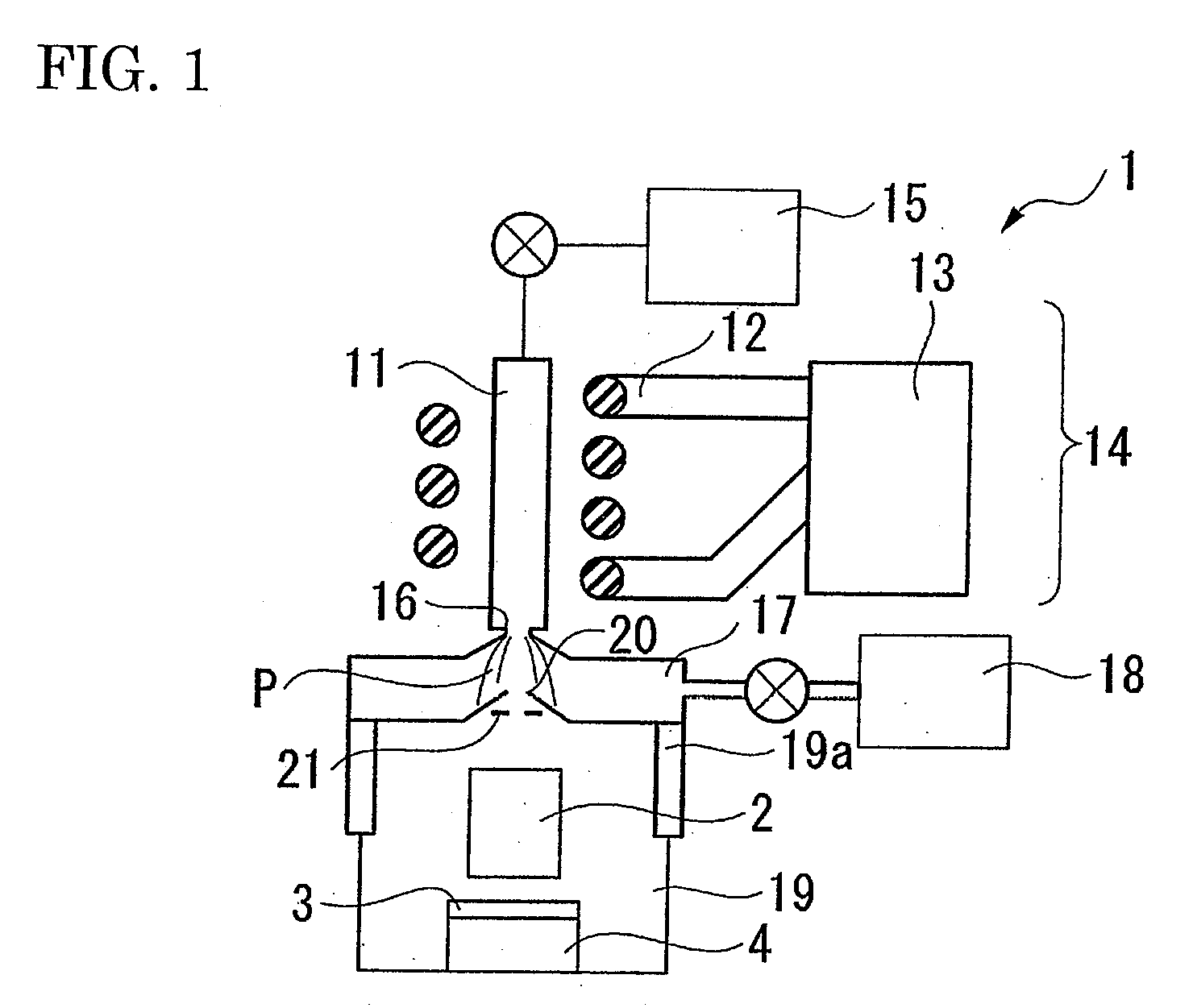

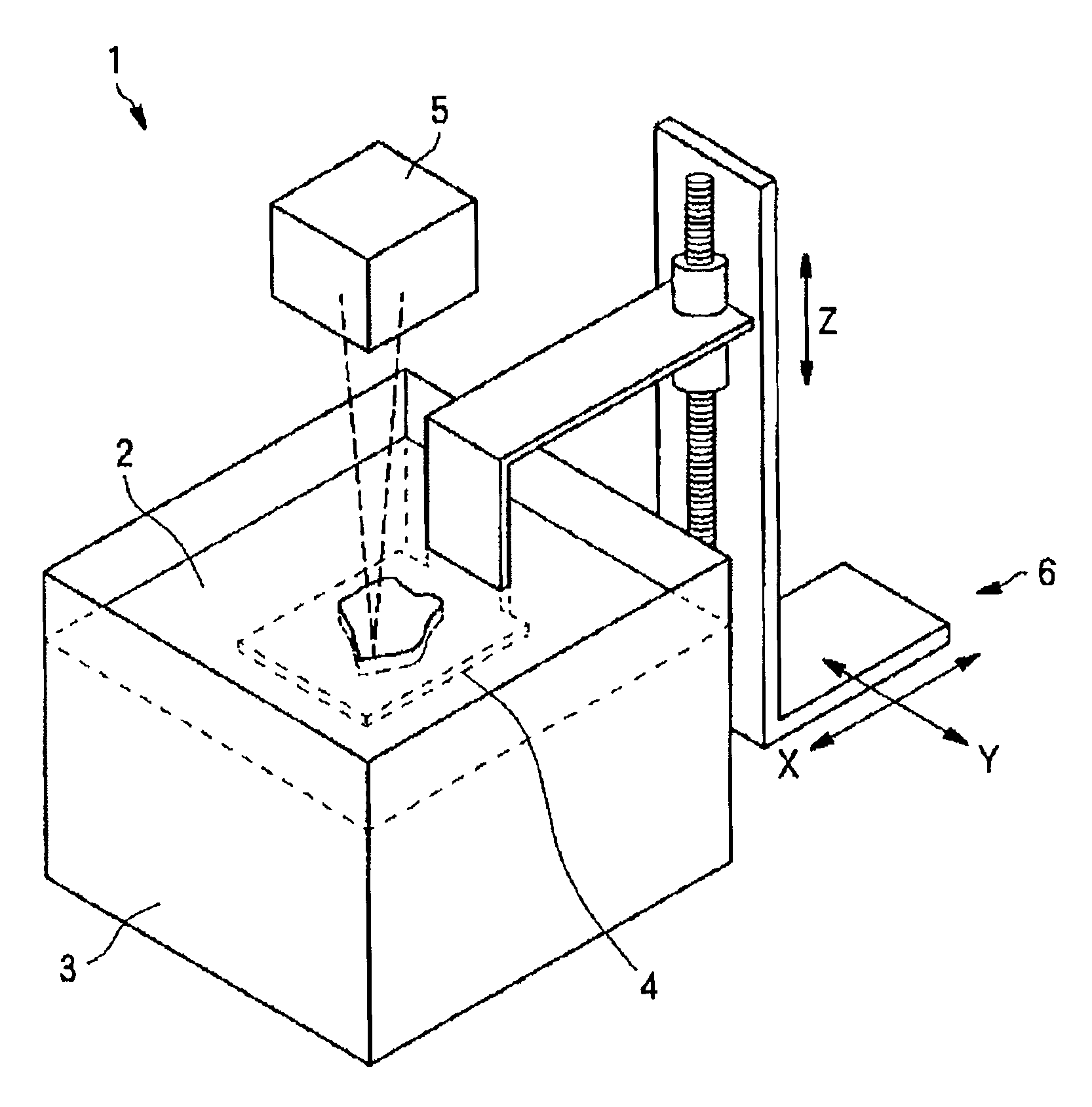

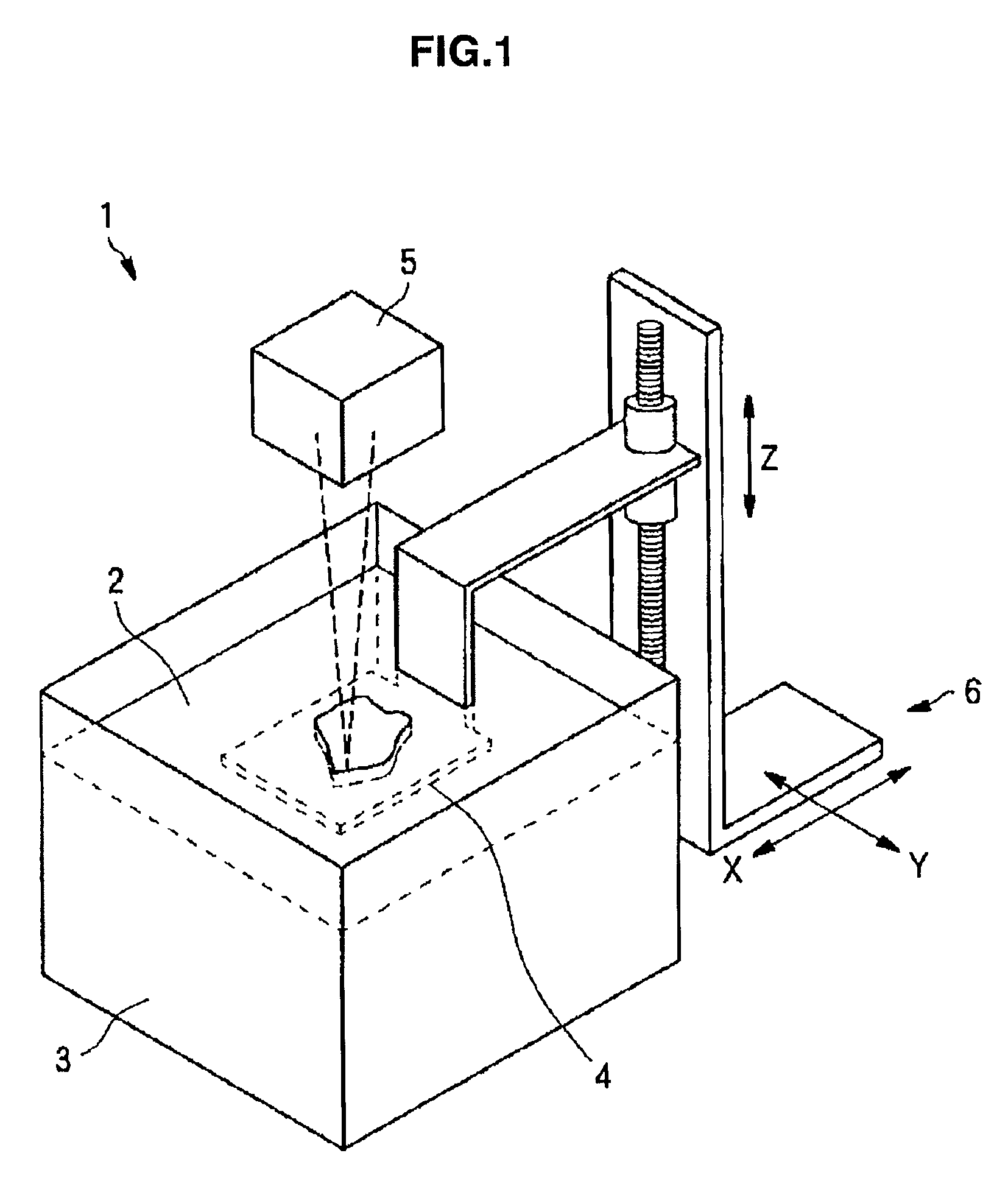

Optical modeling apparatus

InactiveUS20080157412A1Short timeReduced strengthAdditive manufacturing apparatusOptical articlesSpatial light modulatorLight beam

There is provided an optical modeling apparatus that forms a model of a desired shape by sequentially forming hardened layers by irradiating a light curable resin with light. The apparatus includes a first light source that emits a light beam for plotting on the resin, a scanning device that scans the light beam from the first light source over the resin, a second light source that emits light that irradiates one fixed region of the resin at a time, a spatial light modulator that spatially modulates the light from the second light source and blanket-exposes a specified region of the resin, and an exposure position adjuster that moves, in at least one direction, the light from the spatial light modulator. The light beam from the scanning device and the light from the spatial light modulator form each hardened layer.

Owner:SONY CORP

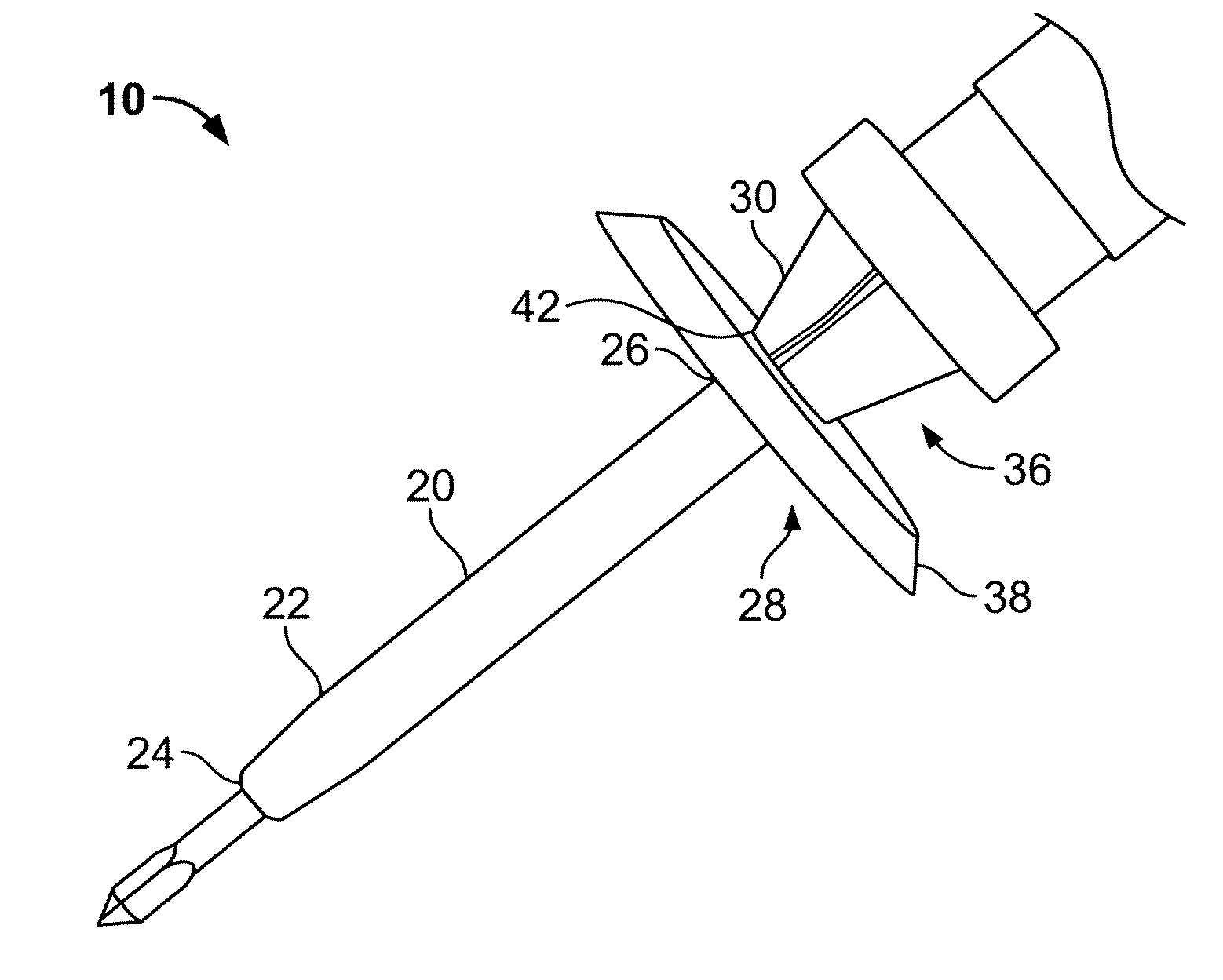

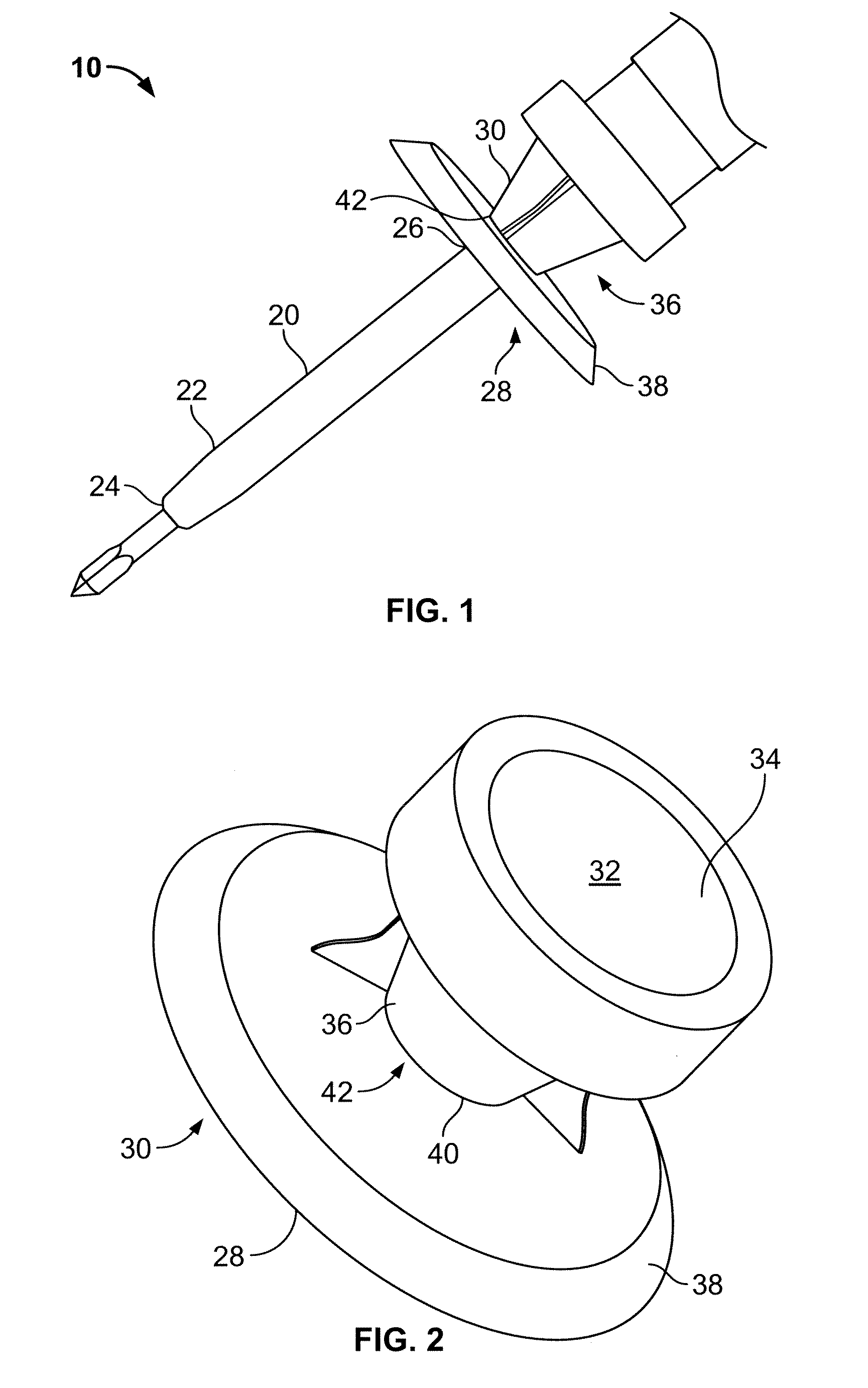

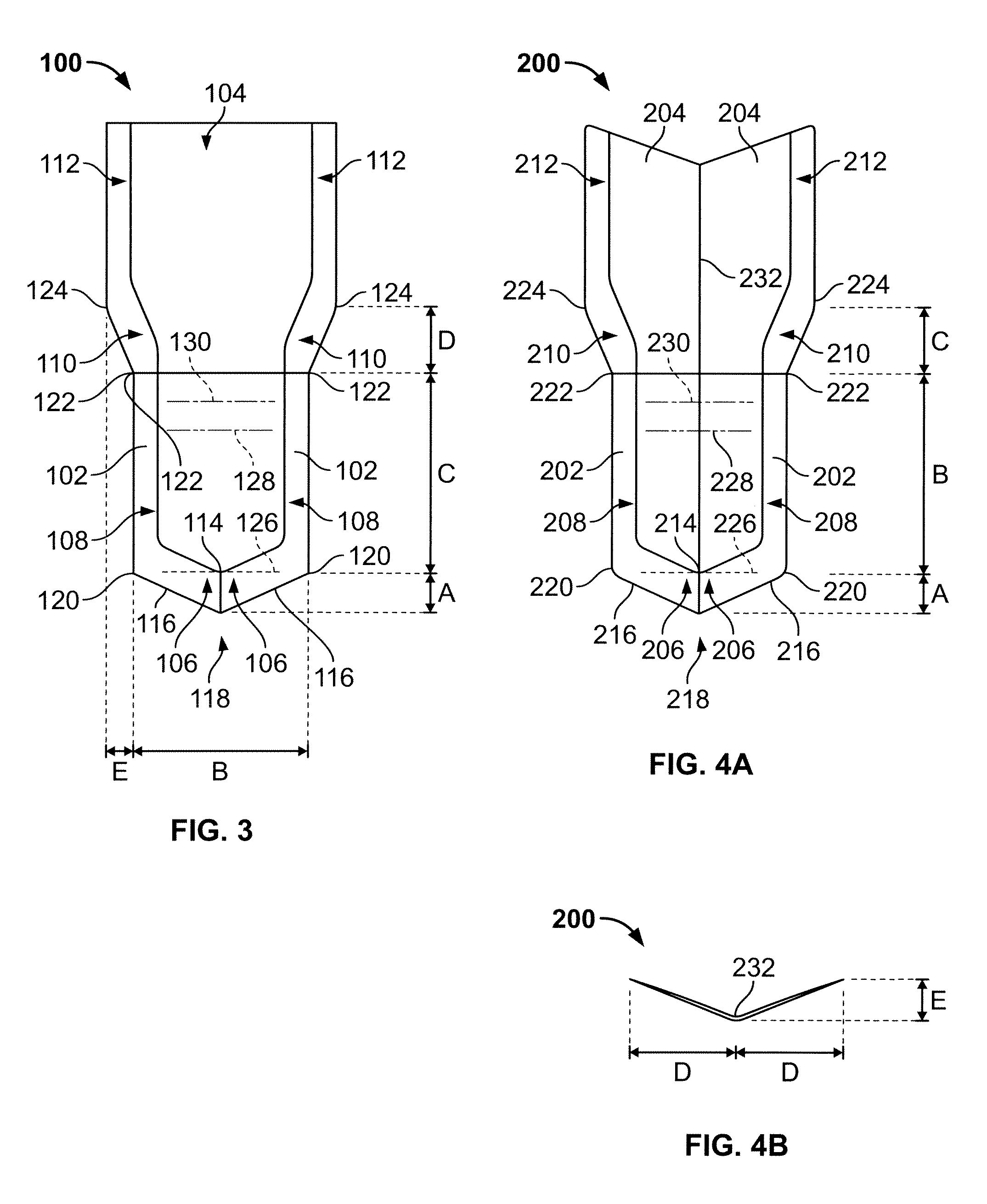

Surgical blade and trocar system

InactiveUS20080215078A1Minimize bendingEasily and rapidly removedEye surgeryCannulasEye SurgeonSurgical blade

The present invention provides an improved surgical blade and trocar system for accessing the retina and other parts of the eye while doing vitreo-retinal and cataract surgeries, including surgeries for macular degeneration. The eye surgeon uses an improved surgical blade for vitreo-retinal and cataract surgeries having a generally flat, V-shaped, W-shaped, or “extended W” shaped cross-section. Using the improved surgical blade, the surgeon creates a multi-planar, self-sealing surgical wound, first by directing the surgical blade substantially perpendicular to the eye surface, then redirecting the blade to follow the general curvature of the eye globe, and finally redirecting the blade to enter the interior of the eye. The improved surgical blade is used with an improved trocar system having two main parts-a relatively rigid, wide-mouthed outer segment and a generally thin-walled, collapsible plastic polymer or metal mesh sleeve that spans the surgical wound and substantially molds to its contour. The improved surgical blade and trocar system can be adapted for use in either vitreo-retinal or cataract surgeries.

Owner:BENNETT MICHAEL D

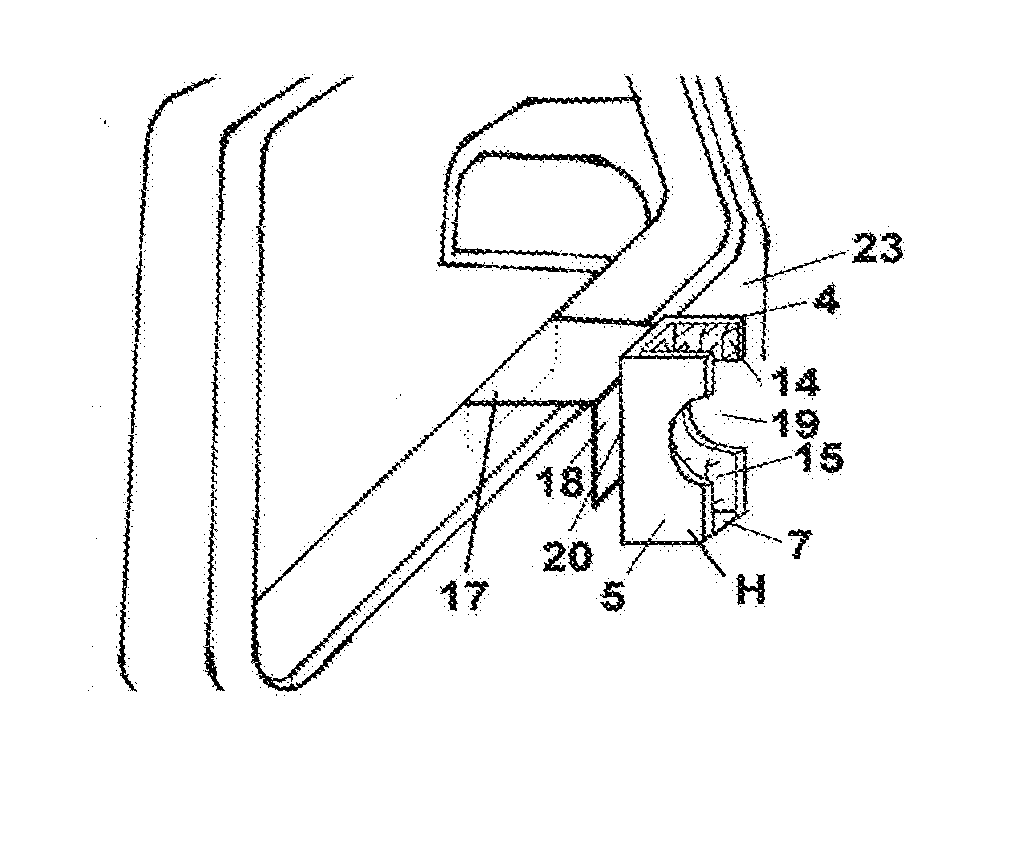

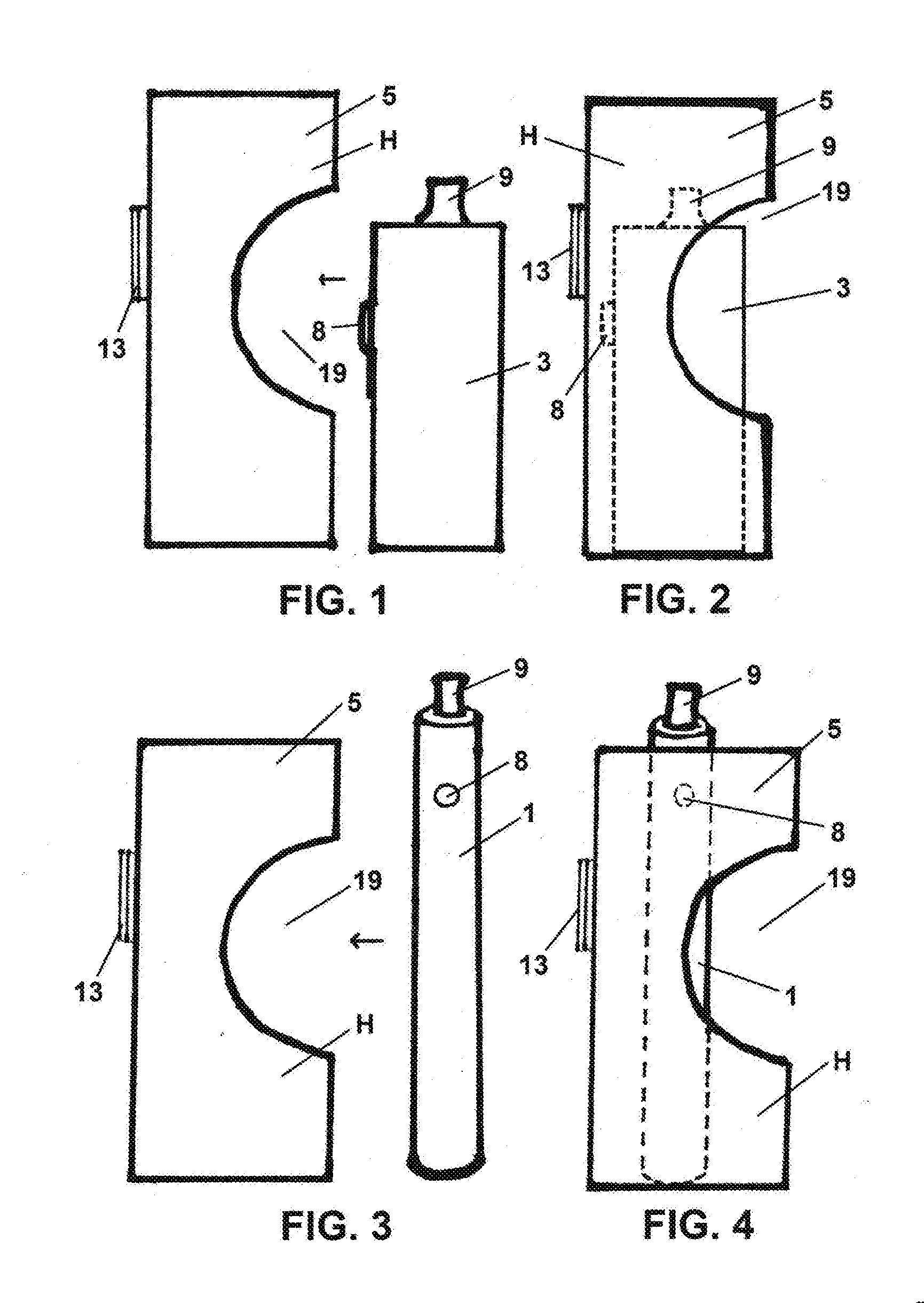

Device for holding and securing Electronic Cigarettes in a motor vehicle

Device for holding and securing Electronic Cigarettes within a motor vehicle comprising a box-like structure having side panels, a rear panel, and a bottom panel, accessible from the top and the front. The device contains a plurality of upper and lower flexible constructs within the interior of the device acting as securing means to secure either cylindrical or box-type Electronic Cigarettes of varying dimensions. The device holds and secures, alternately, cylindrical or box-type Electronic Cigarettes, in the same space within the holder, as opposed to having separate compartments for each type of Electronic Cigarette. The invention also introduces a multi-bracket vehicle door panel mounting system where different size brackets are employed to conform to vehicle door panels of varying depths.

Owner:WALLACE MICHAEL W +1

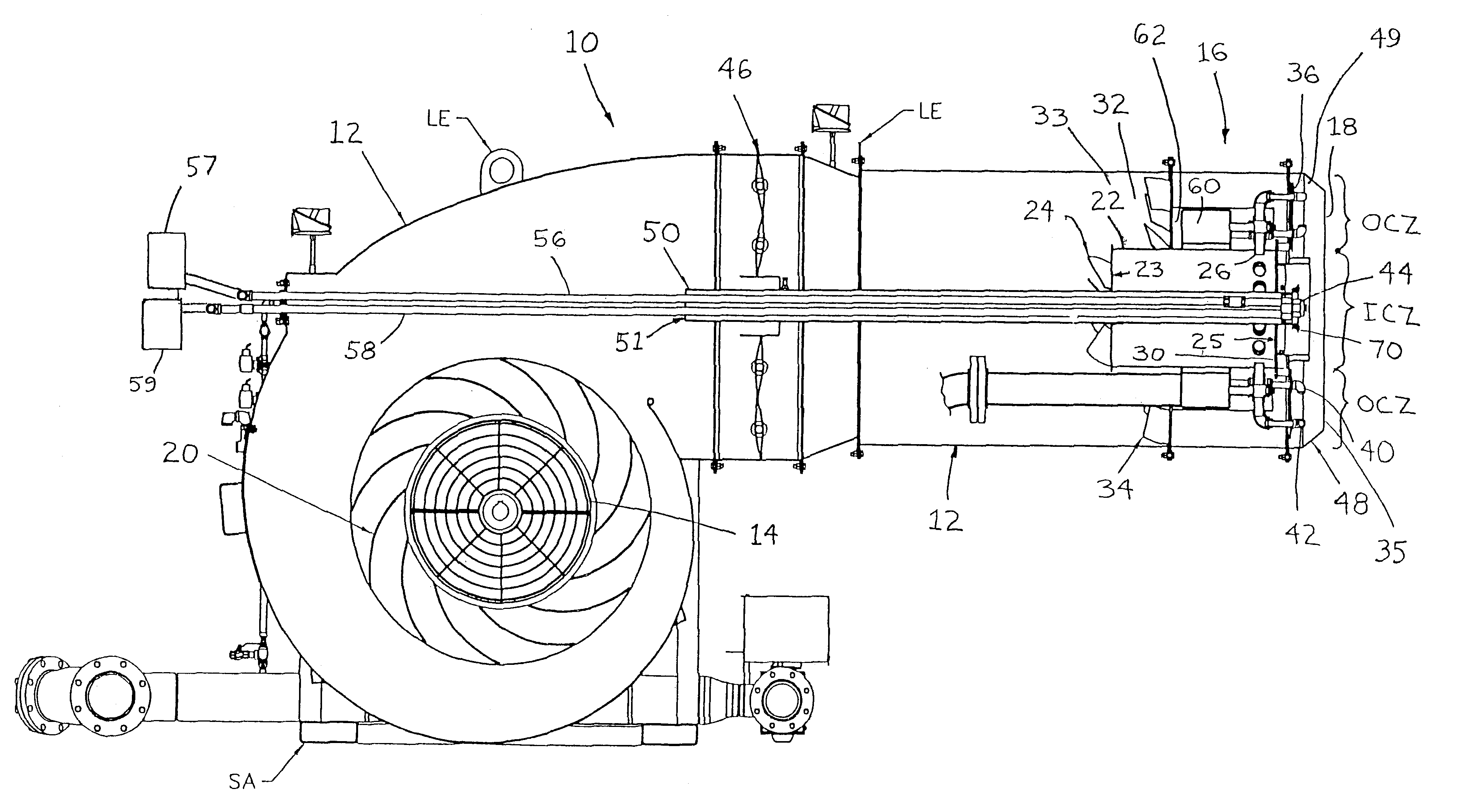

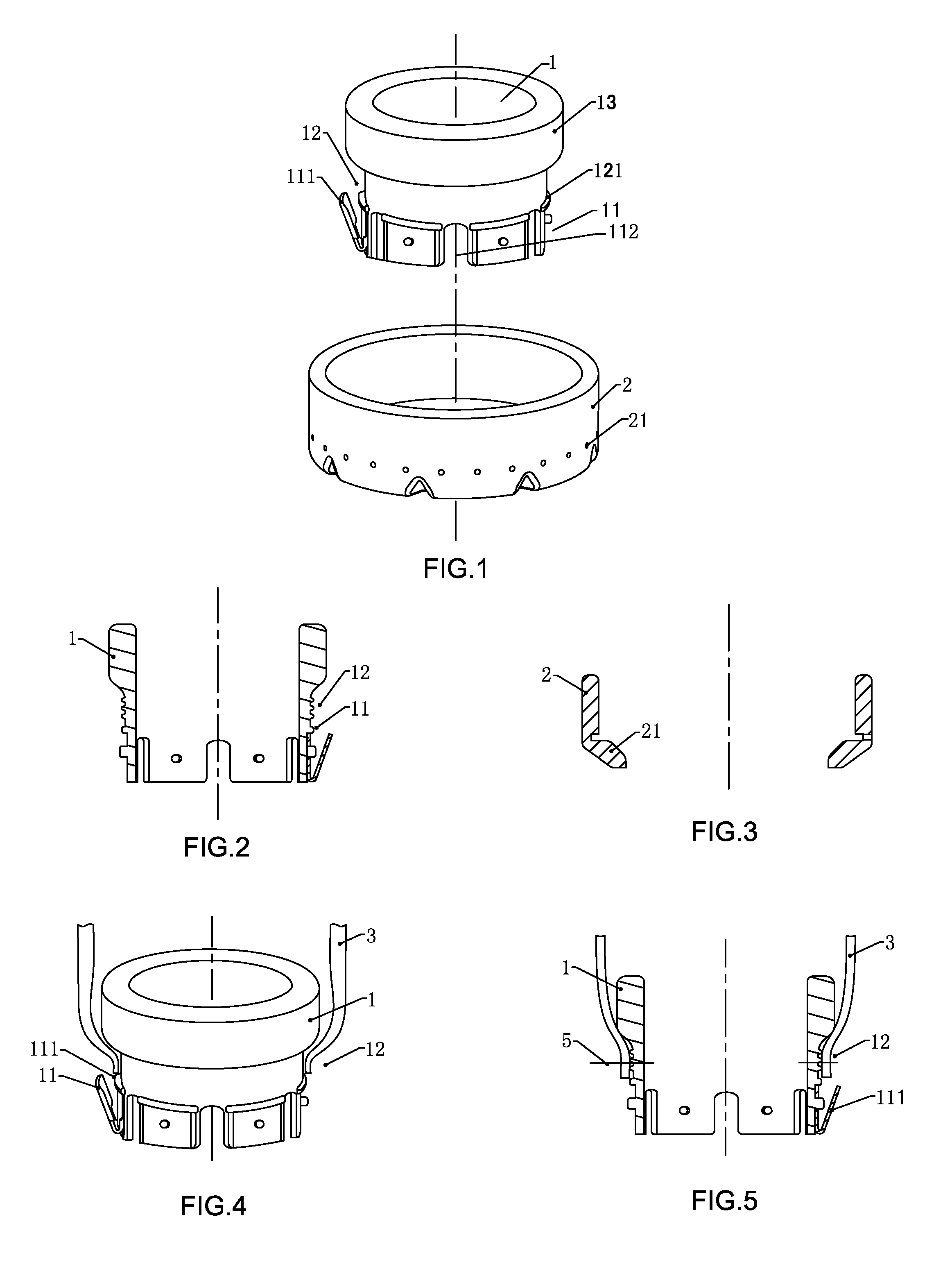

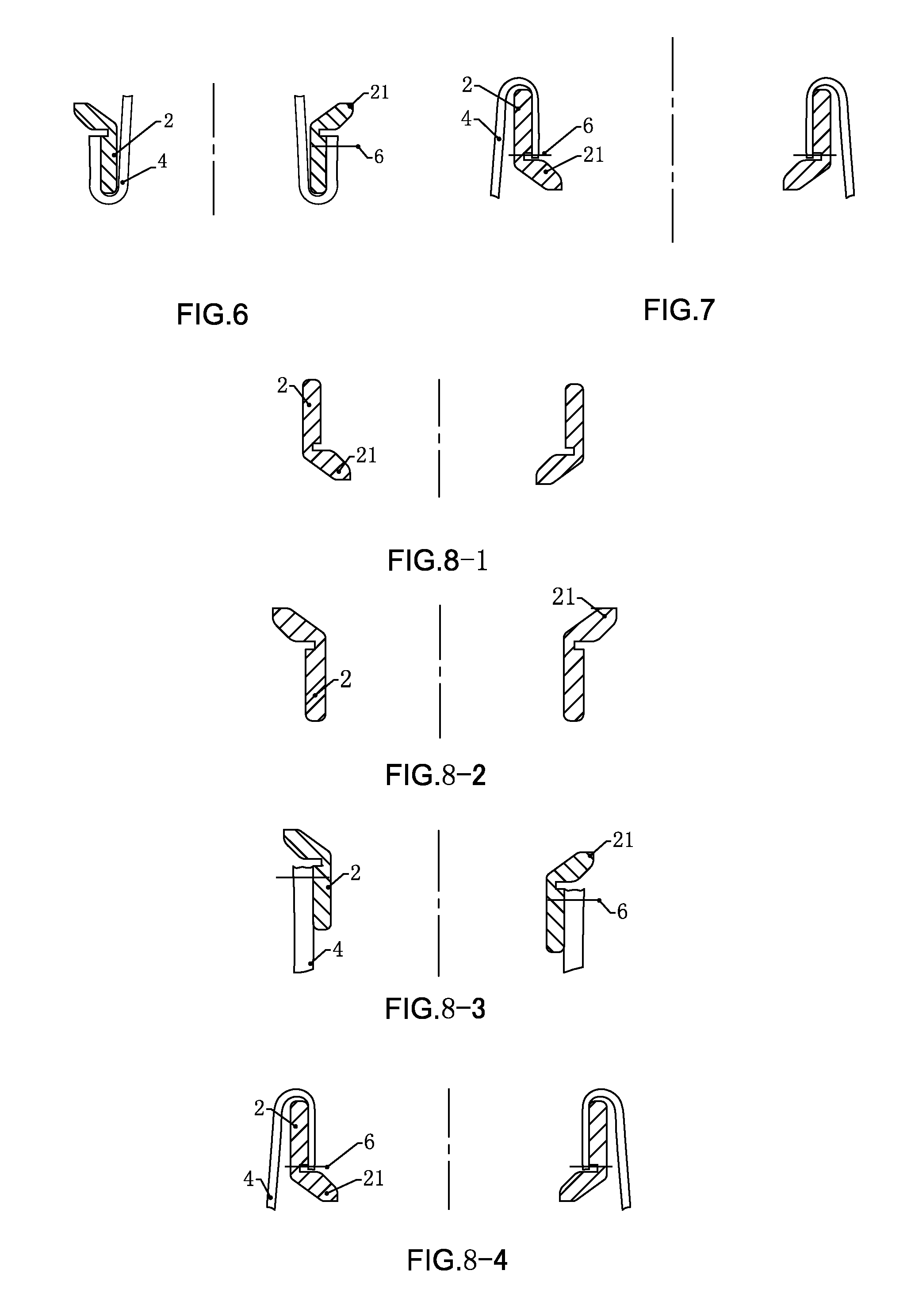

Burner assembly

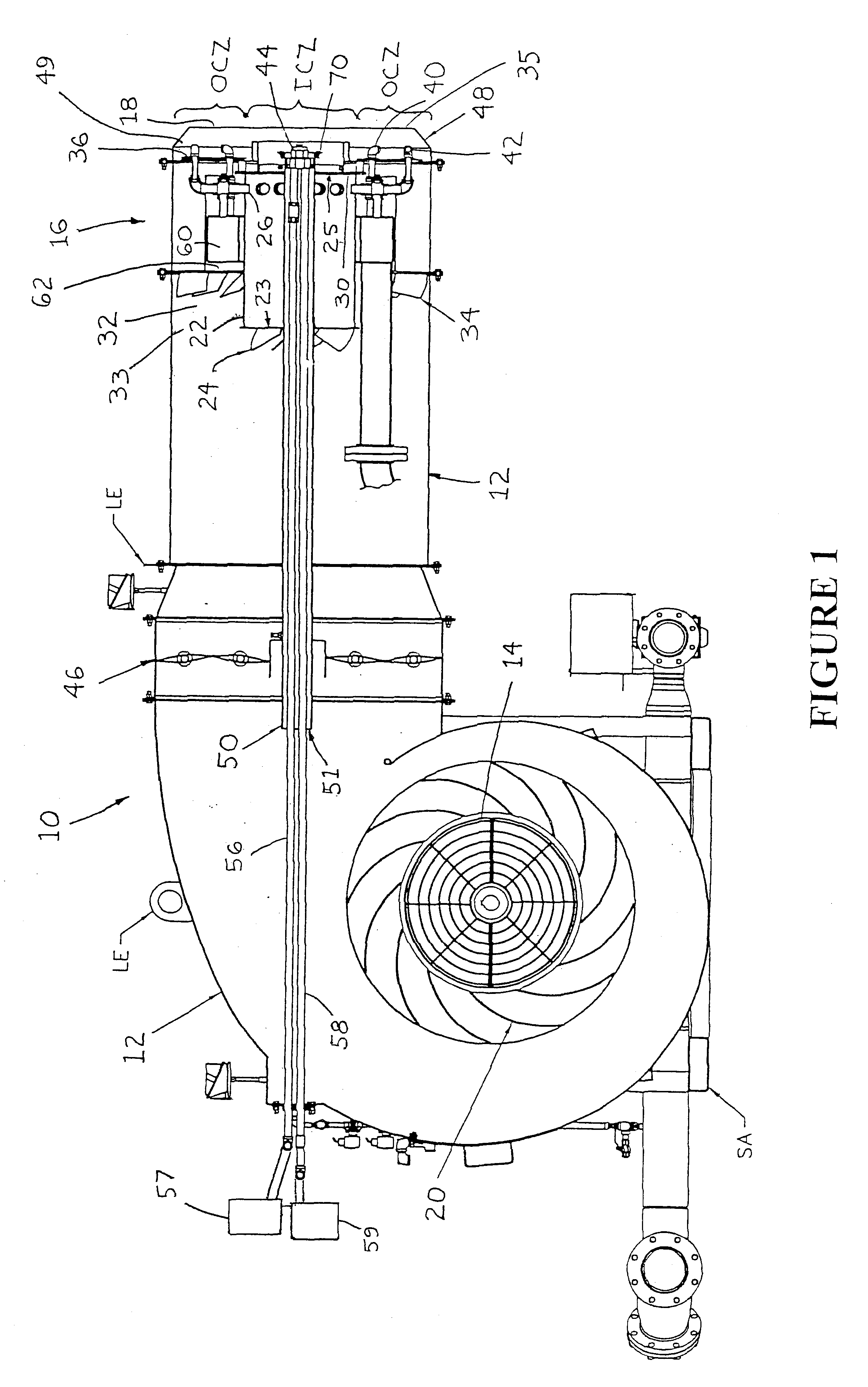

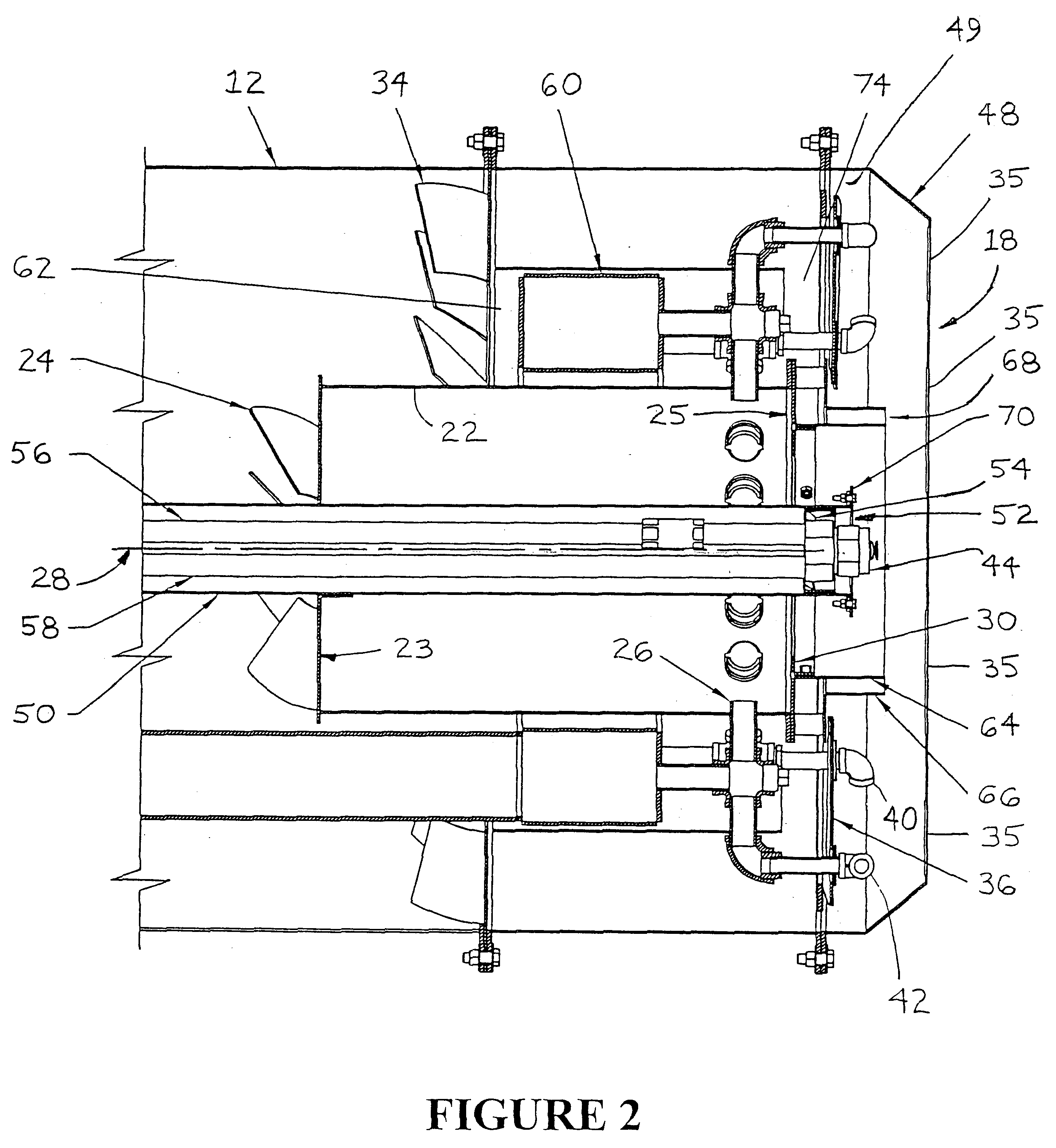

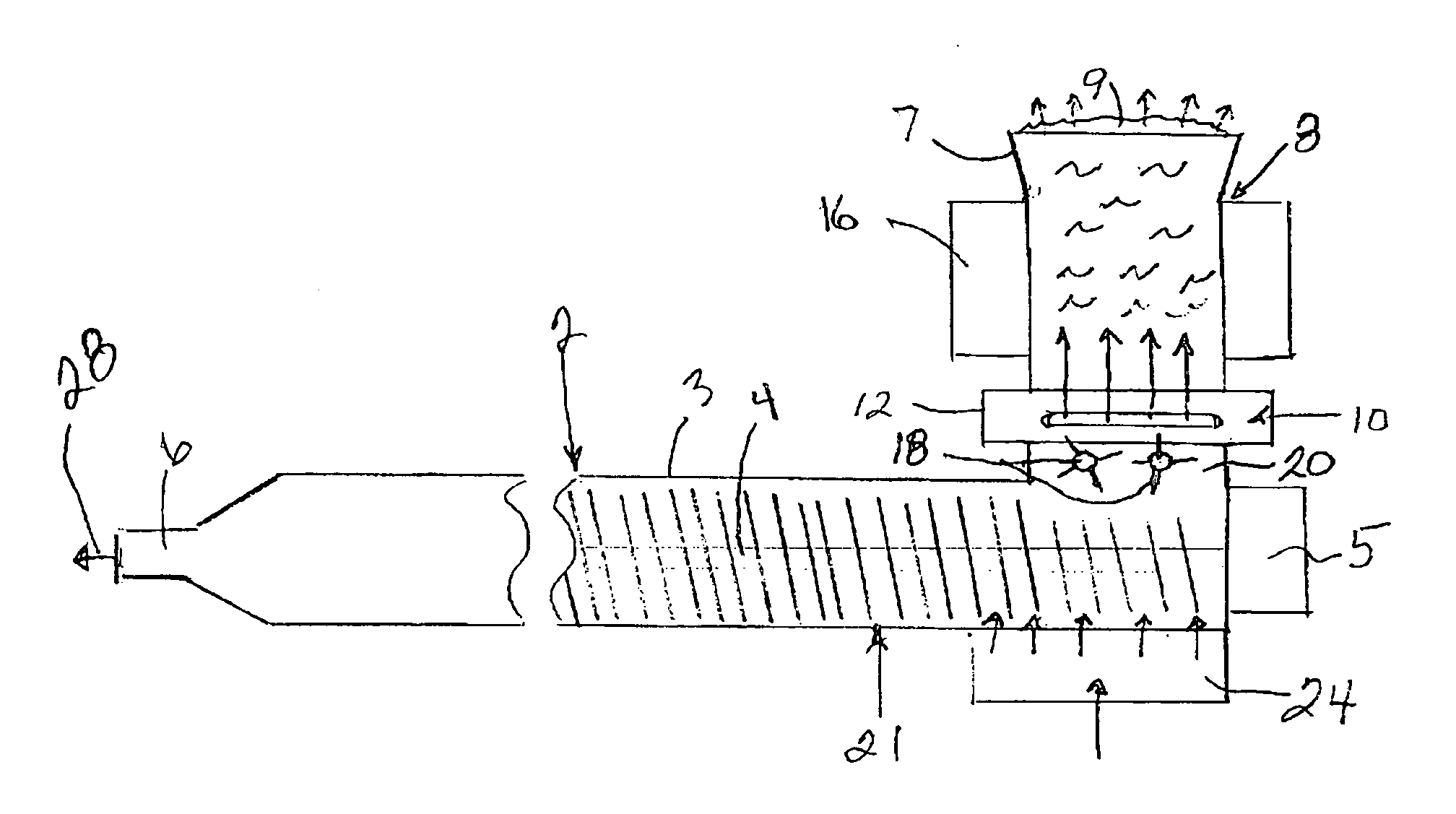

InactiveUS6652268B1Improve combustion intensityReducing combustion space requiredPilot flame ignitersBafflesImpellerCombustor

A burner assembly including a housing having an air inlet and a burner end. An impeller that is mounted in the housing is in communication with the air inlet and adapted to direct air toward the burner end of the housing. The burner assembly also includes an inner air tube that is mounted in the burner end of the housing so as to define an inner combustion zone and an outer combustion zone. The assembly further includes a plurality of radiation plates that are mounted in the burner end of the housing adjacent to the outer combustion zone, an inner air spin vane that is mounted on the inner air tube so as to direct some of the air from the impeller into the inner combustion zone, an inner gas injection nozzle mounted on the inner air tube so as to direct gaseous fuel into the inner combustion zone, an outer air spin vane that is mounted in the burner end of the housing so as to direct some of the air from the impeller into the outer combustion zone, and a plurality of outer gas injection nozzles that are mounted in the burner end of the housing so as to direct gaseous fuel into the outer combustion zone. A first castellated ring is mounted around the periphery of the inner air tube, and a second castellated ring is mounted around the periphery of the burner end of the housing.

Owner:ASTEC

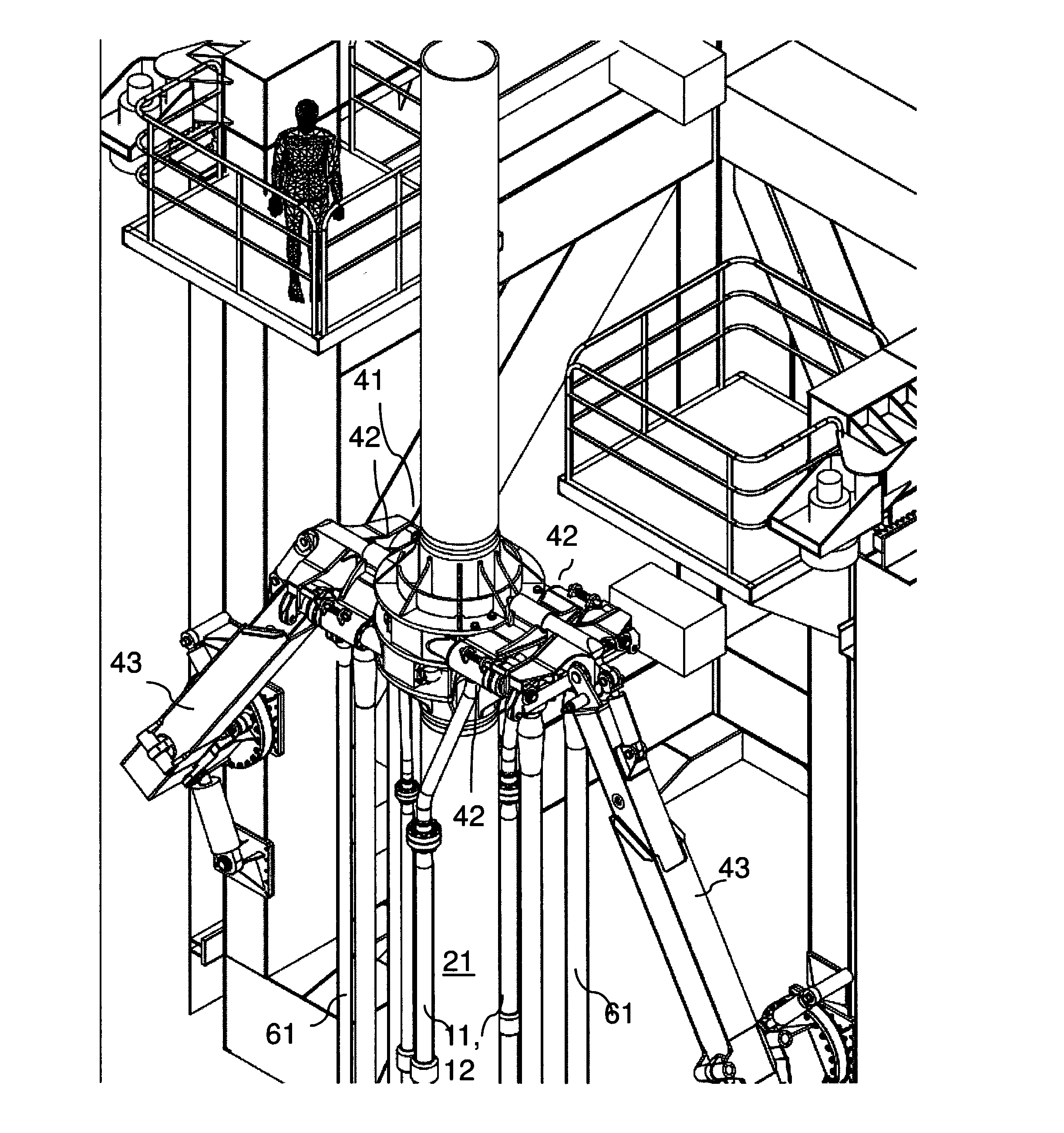

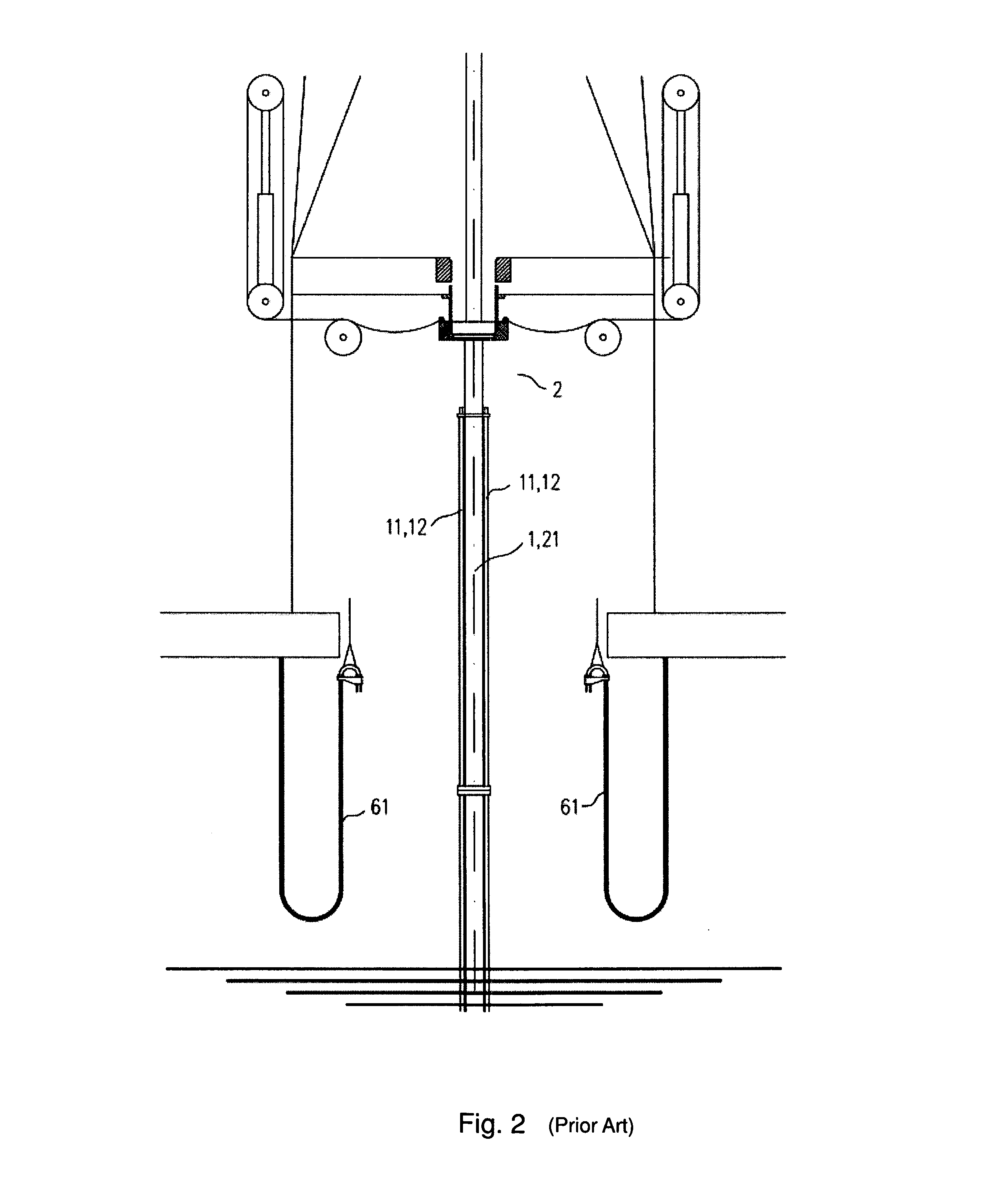

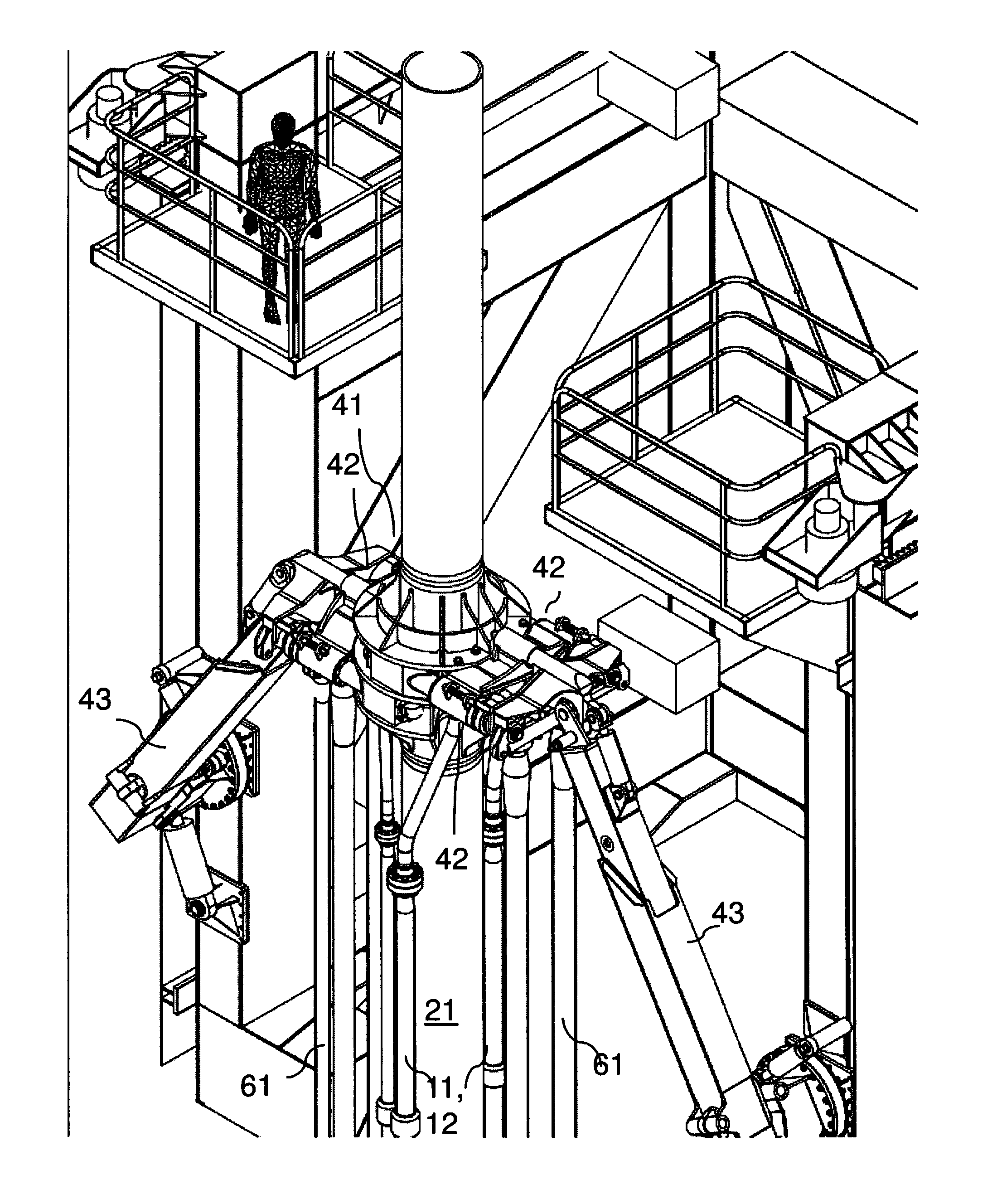

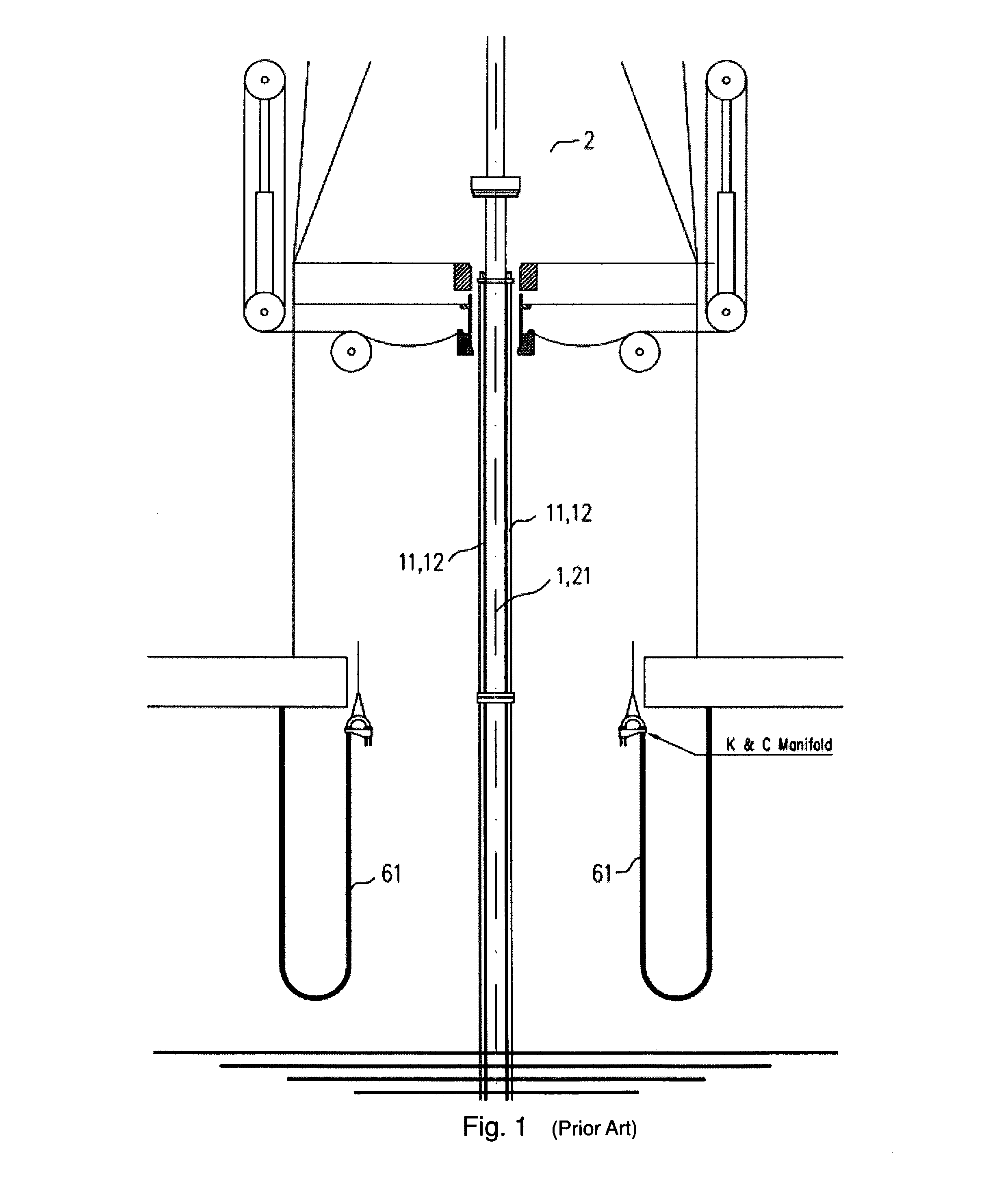

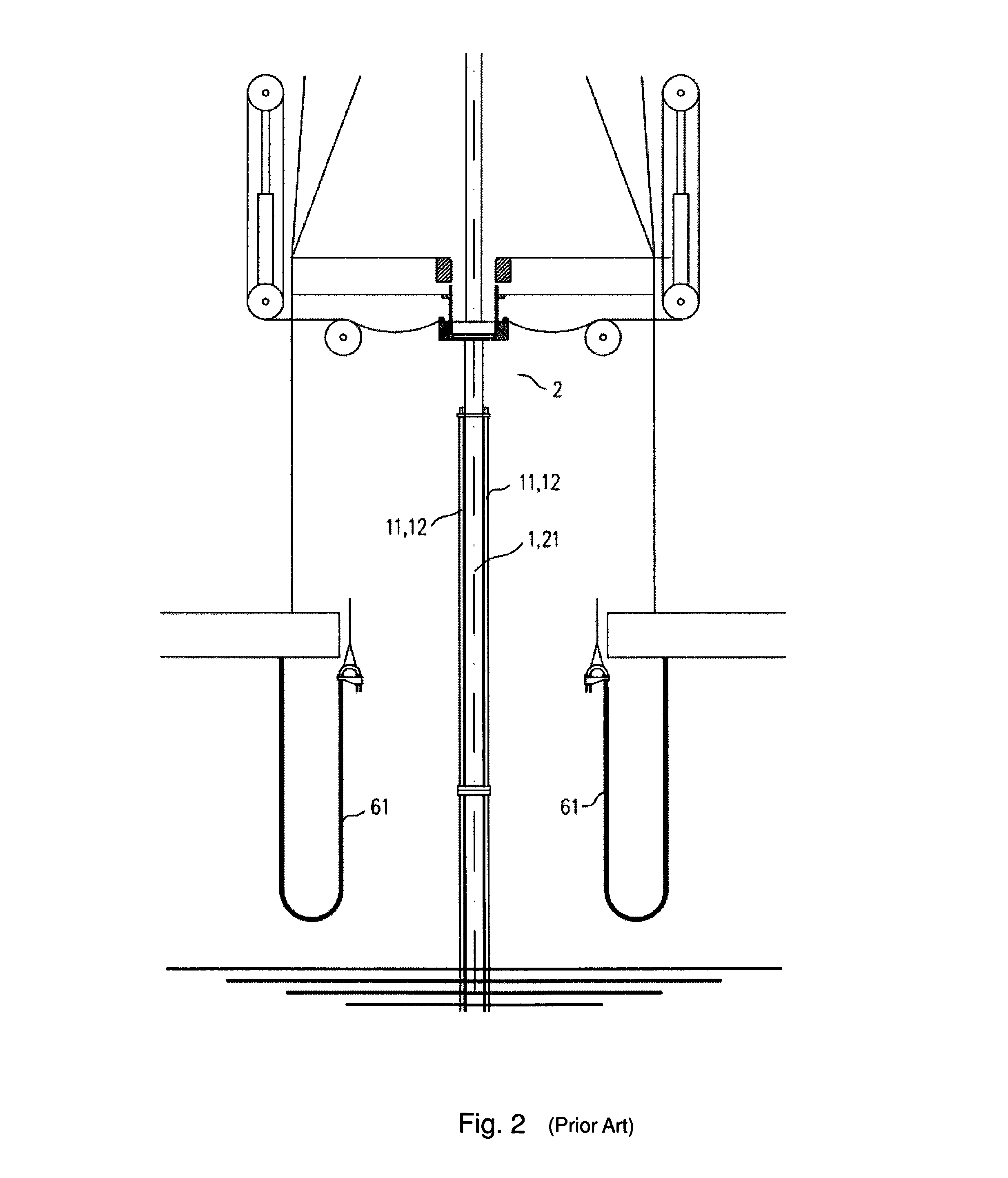

Connecting device for kill/choke lines between a riser and a floating drilling vessel

ActiveUS20120318517A1Fast conductionFirmly connectedDrilling rodsFluid removalSlip jointMechanical engineering

A connector device for kill- and choke lines between a riser and a floating drilling platform includes a slip joint on top of the riser including an outer barrel, a kill- and choke manifold arranged on the platform and provided with flexible kill- and choke hoses to the slip joint's outer barrel, and wherein the slip joint's outer barrel is provided with a horizontally directed kill- and choke-manifold.

Owner:FUTURE PROD

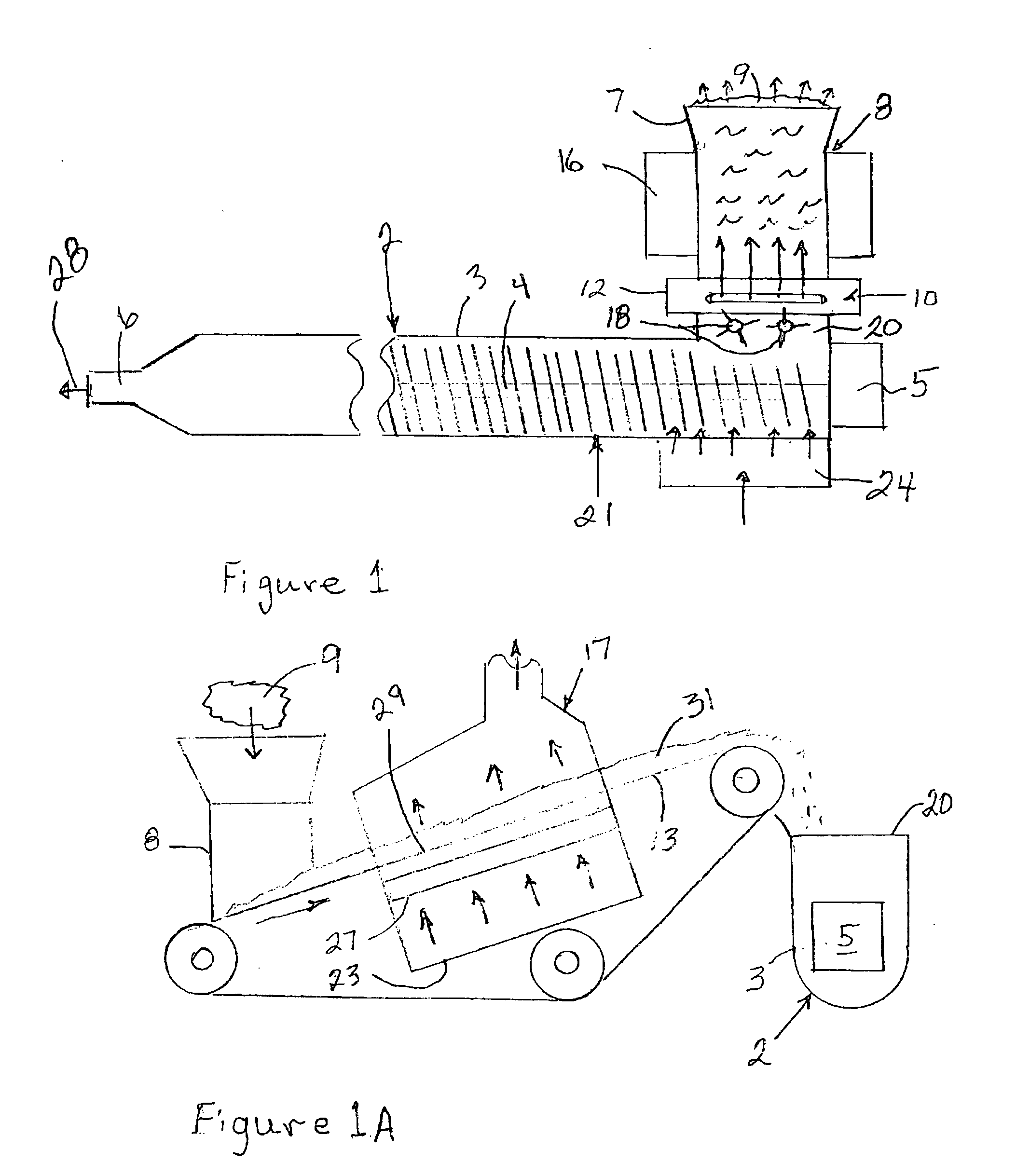

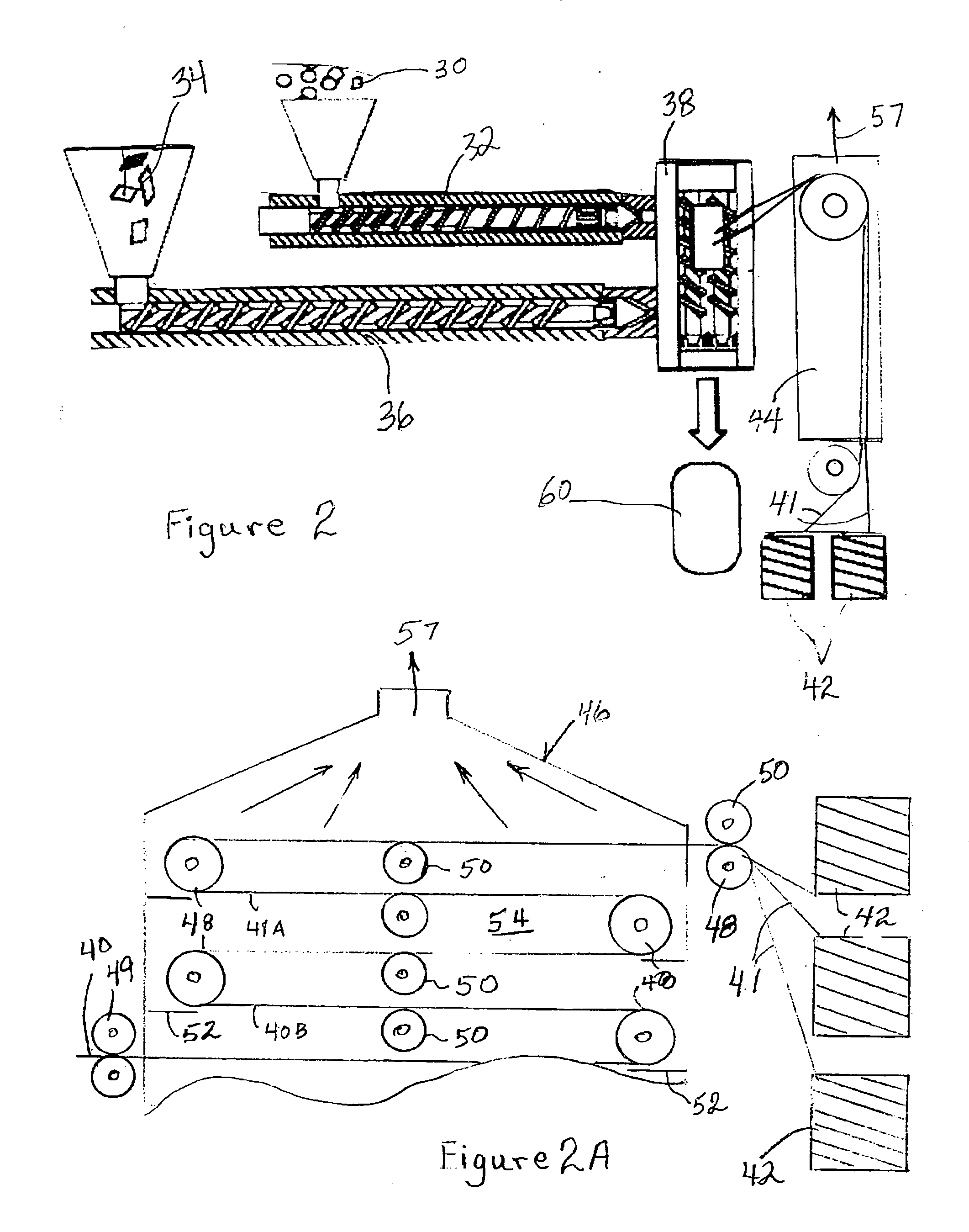

Methods and systems for making fiber reinforced products and resultant products

InactiveUS20060057319A1Reduce frequencyNarrow diameterSynthetic resin layered productsThin material handlingSolventThermoplastic polymer

Methods and systems for making fiber reinforced moldable mixtures for making FRP products by mixing and / or compounding of at least one, normally hot, polymer and at least one wet fiber product. Intermediate FRP moldable mixtures and finished FRP products produced by the methods and systems are also disclosed. The polymers preferred are thermoplastic polymers, but mixtures that form thermoset polymers are can also be used. Wet fiber product(s) containing water, a solvent, or other liquid are used by the systems and methods disclosed. Packaged wet roving fiber strand products are also disclosed. The FRP products made with the invention have lower cost, more complete and uniform fiber dispersion and / or more uniform and improved appearance and / or physical properties than conventional FRP products made using conventional dry reinforcing fiber products.

Owner:JOHNS MANVILLE CORP

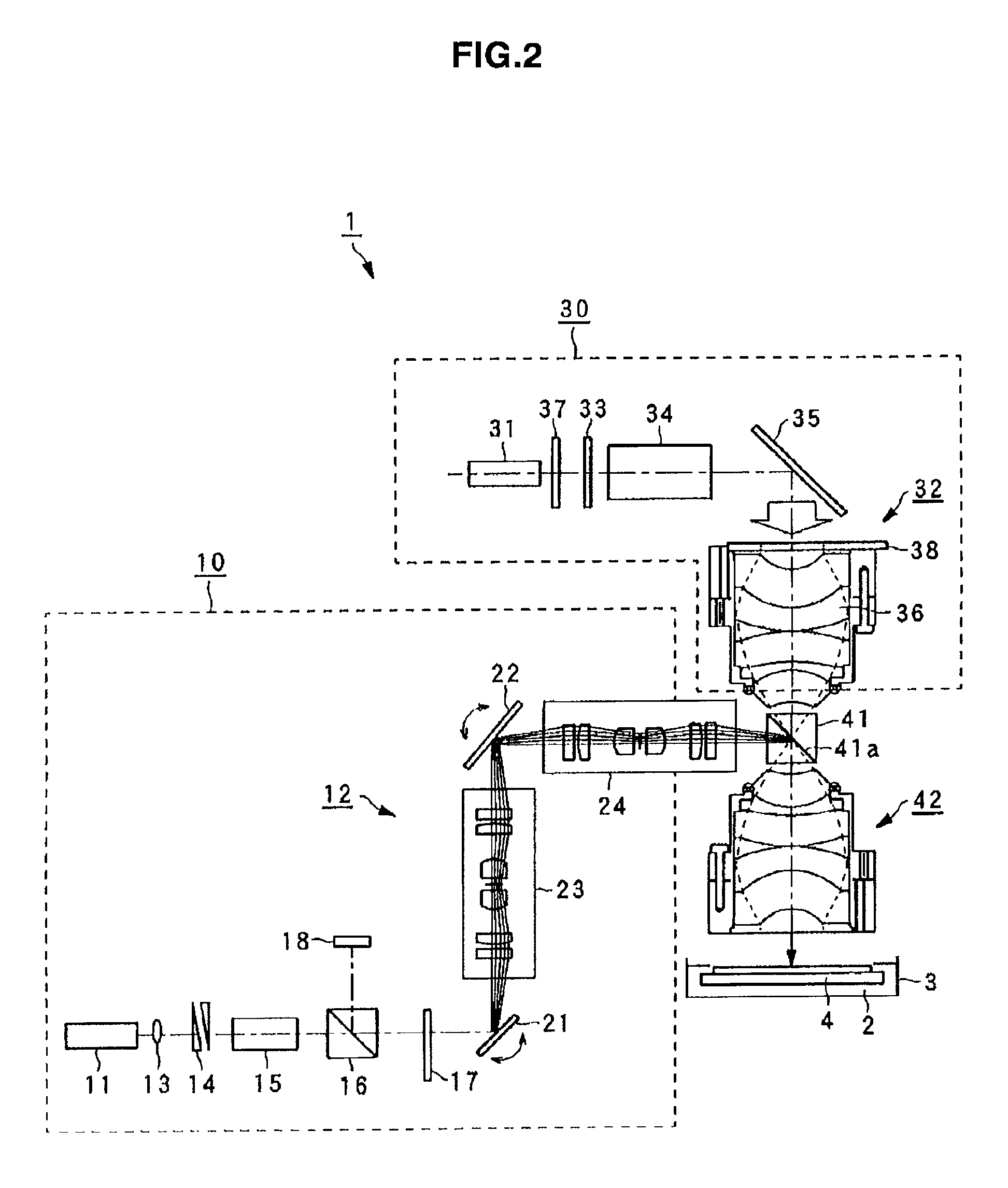

Optical modeling apparatus

InactiveUS20080169587A1Short timeHigh resolutionAdditive manufacturing apparatusPhotomechanical apparatusSpatial light modulatorLight beam

There is provided an optical modeling apparatus that forms a model of a desired shape by sequentially forming hardened layers by irradiating a light-curable resin with light. The apparatus includes a first light source that emits a light beam for plotting on the resin, a scanning device that scans the light beam from the first light source over the resin, a second light source that emits light that irradiates one fixed region of the resin at a time, and a spatial light modulator that spatially modulates the light from the second light source to blanket-expose a specified region of the resin. The light beam from the scanning device and the light from the spatial light modulator form each hardened layer.

Owner:SONY CORP +1

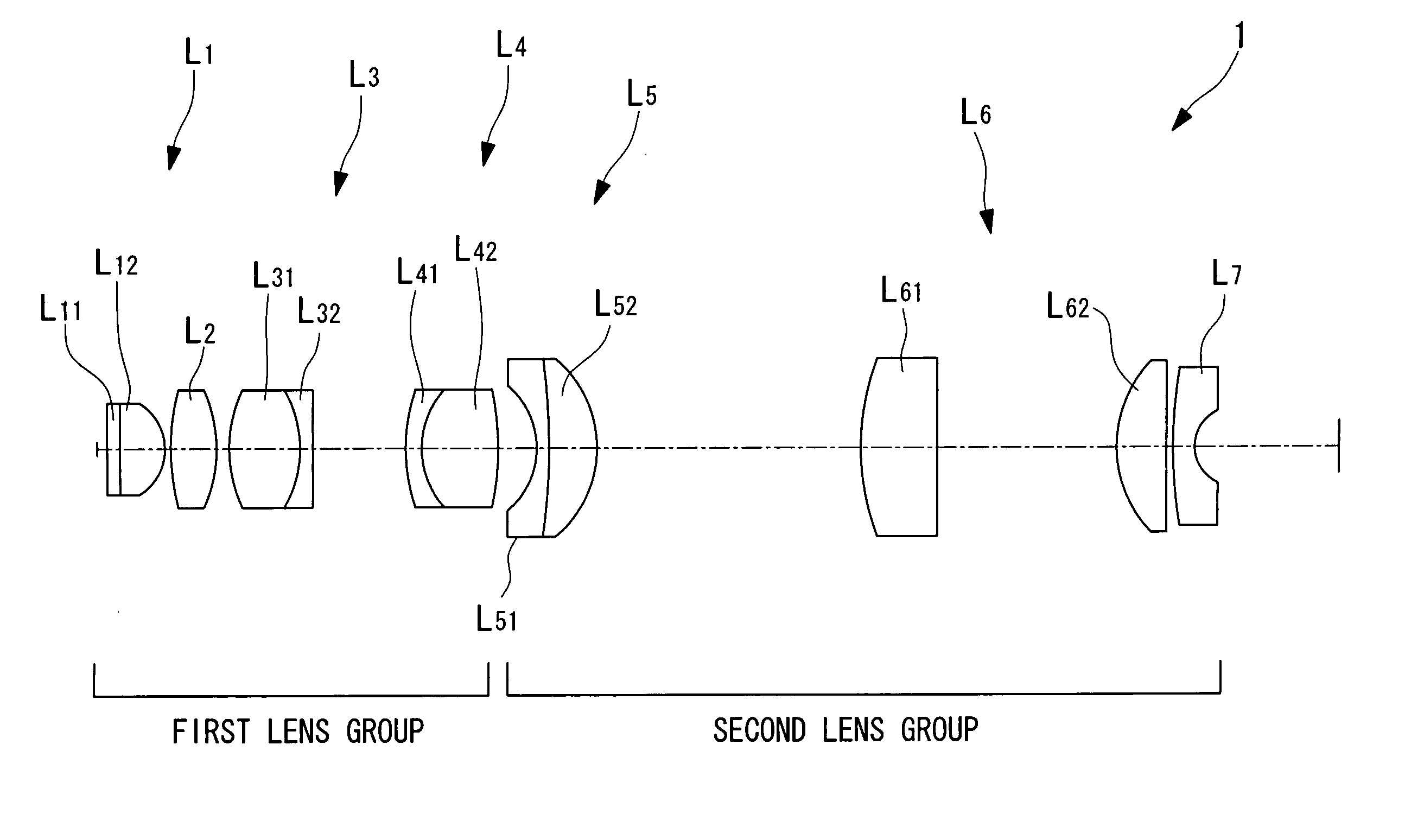

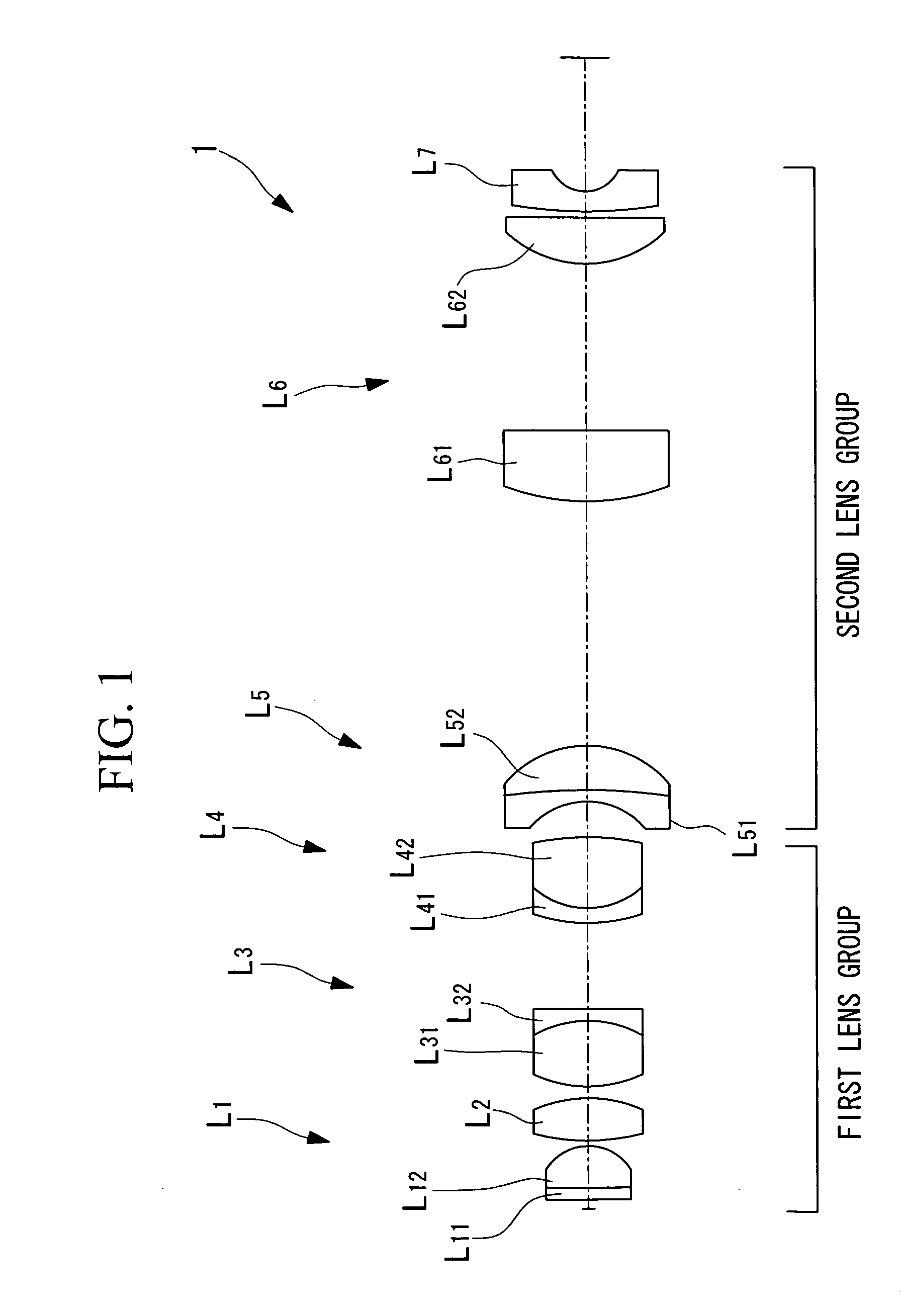

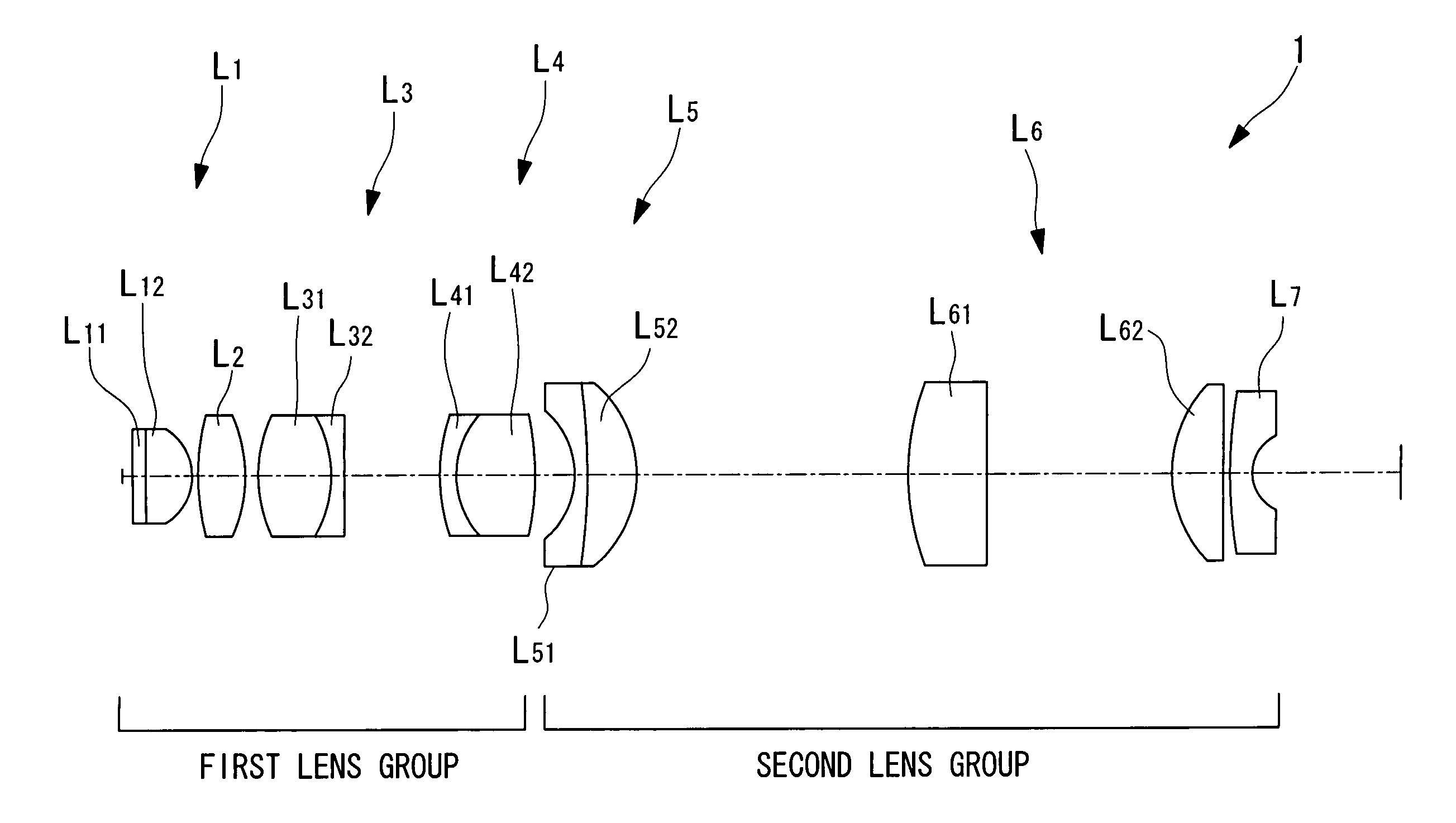

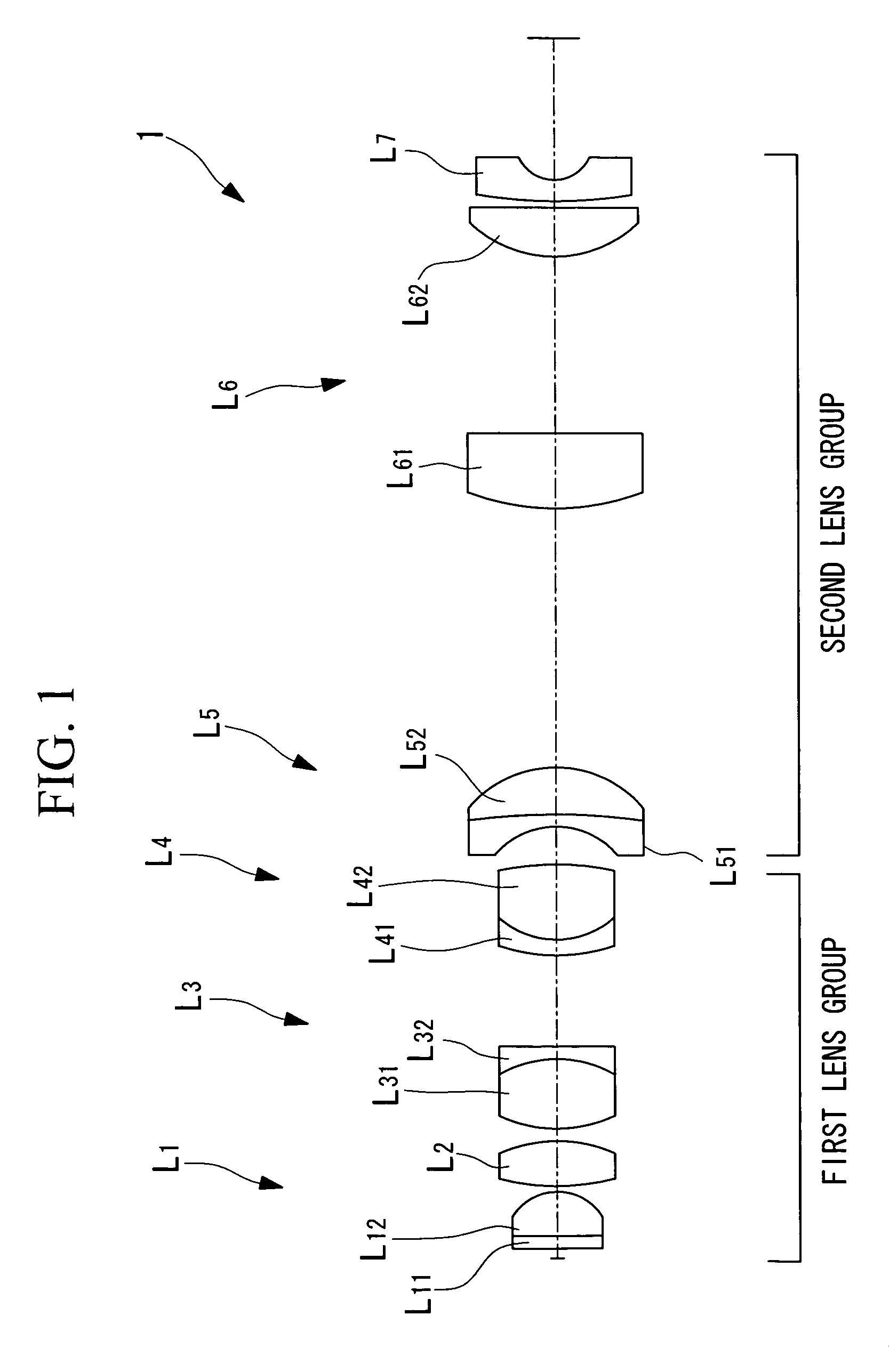

Liquid-immersion objective optical system

ActiveUS20060007558A1Minimal invasivenessHigh resolutionMicroscopesConditional expressionMagnification

The invention provides a liquid-immersion objective optical system including a first lens group and a second lens group. The first lens group includes a first lens component having positive refractive power, an object side thereof being a flat surface and a convex surface thereof facing an image-plane side; a second lens component having positive refractive power, a convex surface thereof facing the image-plane side; a third lens component having positive refractive power as a whole, formed by cementing a biconvex positive lens and a negative lens; and a fourth lens component formed by cementing a negative lens and a biconvex positive lens. The second lens group includes a fifth lens component formed by cementing a lens having a concave surface facing the object side and a lens having a convex surface facing the image-plane side; a sixth lens component having positive refractive power; and a seventh lens component having negative refractive power. The focal length F1 of the entire first lens group, the magnification M of the objective optical system, the distance LT between the object plane and the image plane, and the distance LG between the object side of the first lens component L1 and the image side of the fourth lens component L4 satisfy the following conditional expressions: 0.2<|M·F1 / LT|<0.45 0 / 2<|LG1 / LT|<0.4

Owner:EVIDENT CORP

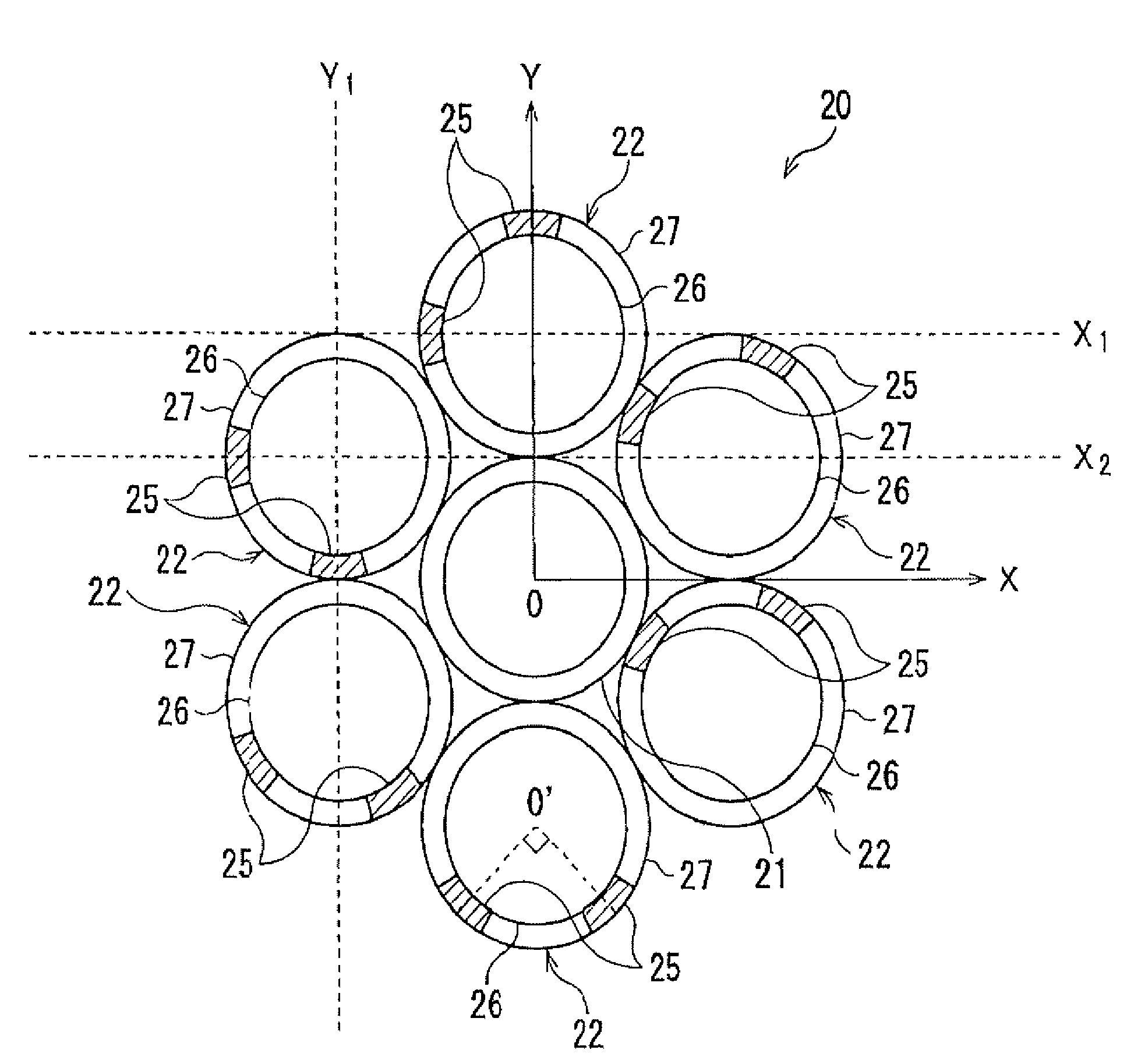

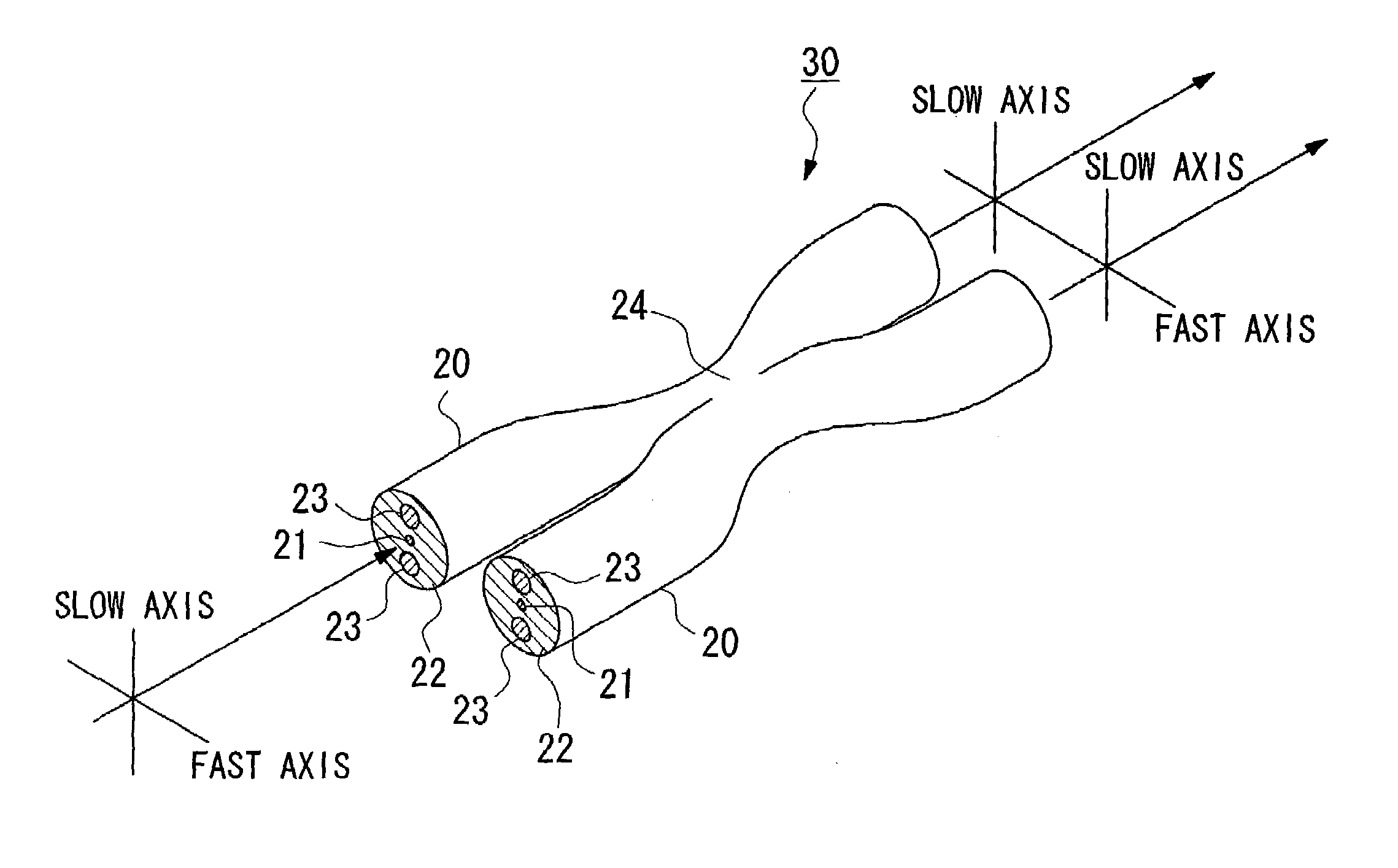

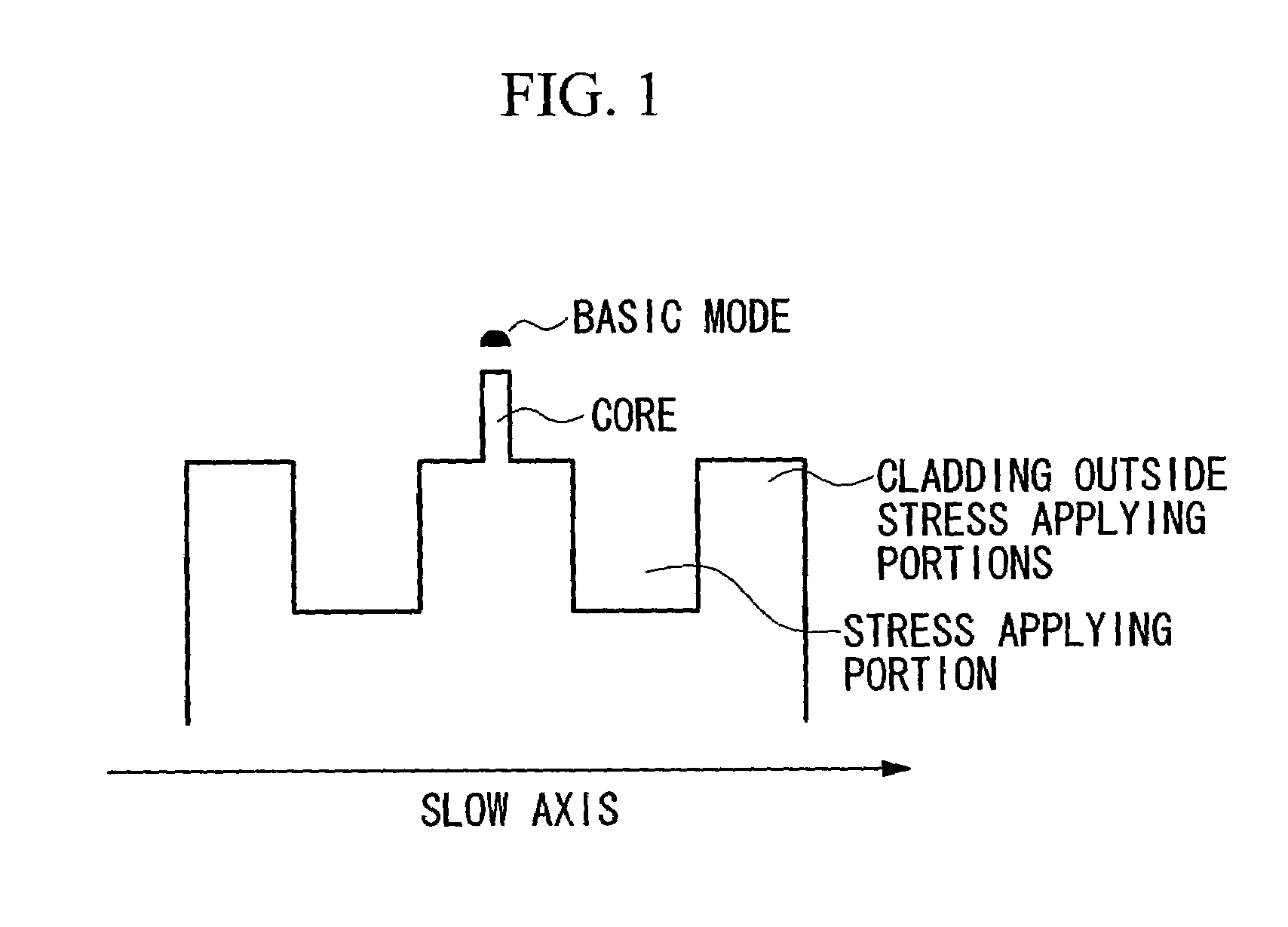

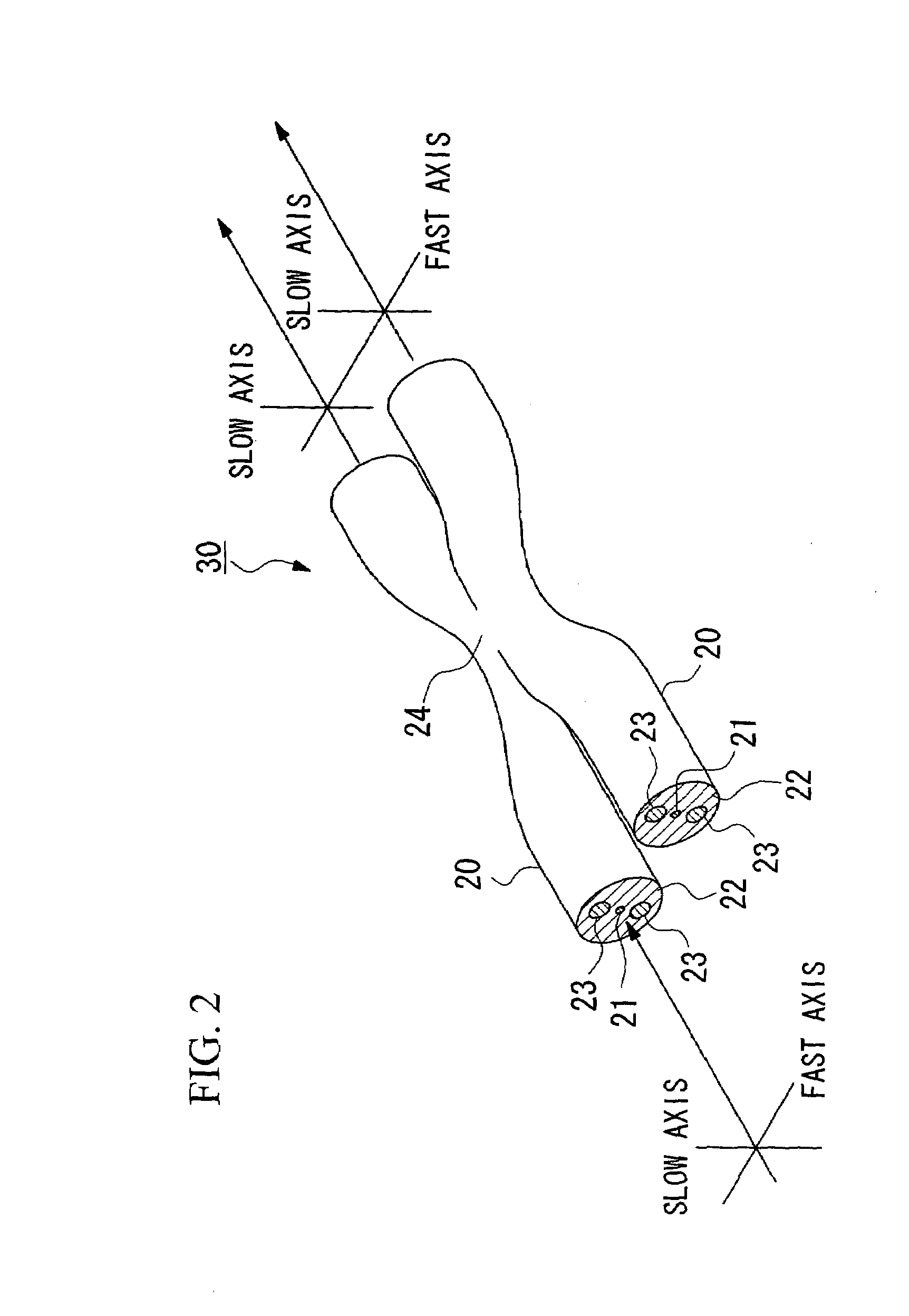

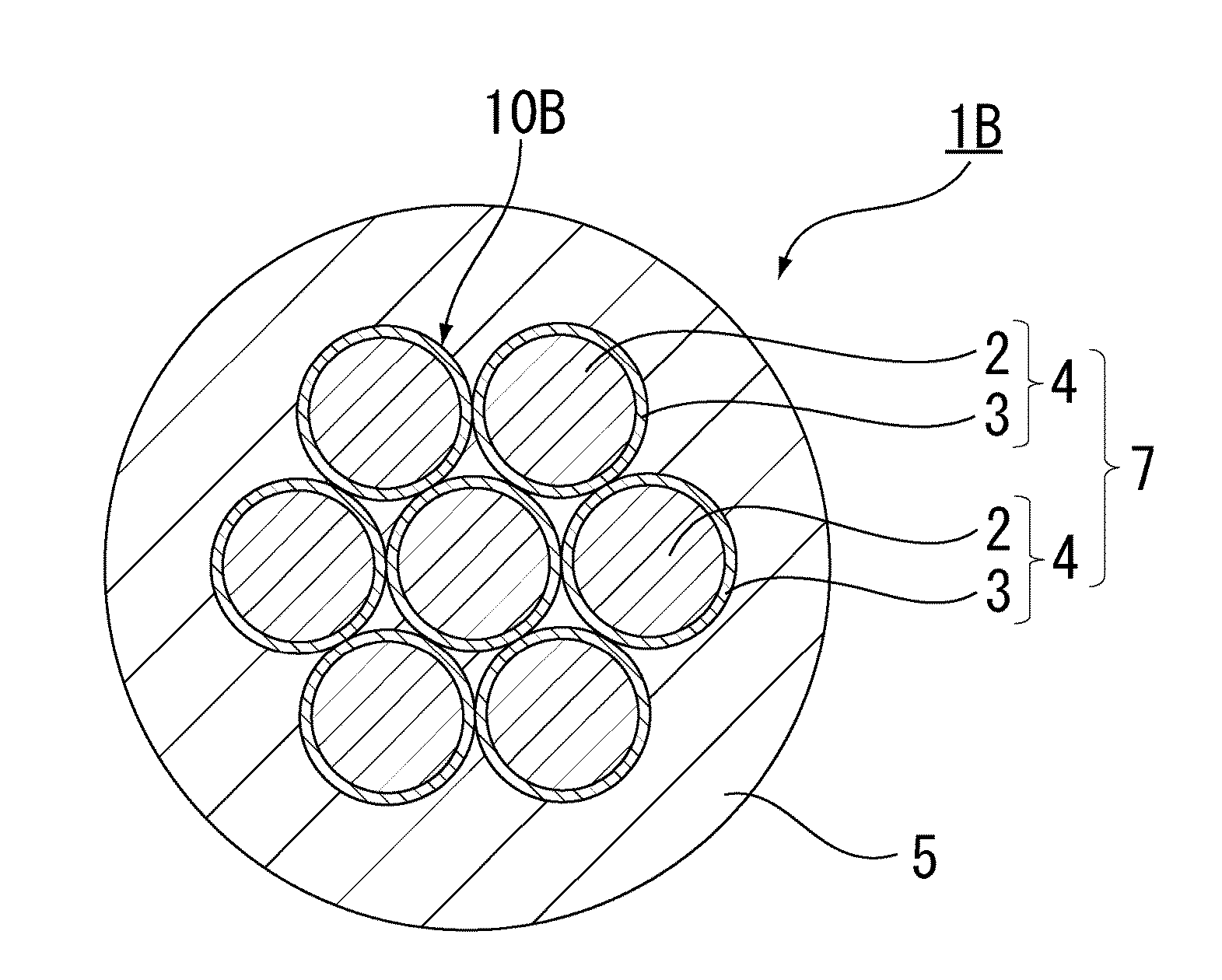

Polarization maintaining optical fiber coupler and method of manufacturing same

InactiveUS7203397B2Narrow diameterGlass making apparatusCladded optical fibrePolarization-maintaining optical fiberOptoelectronics

There is provided a polarization maintaining optical fiber coupler and a method of manufacturing this polarization maintaining optical fiber coupler in which manufacturing is simplified and excess loss is reduced. A polarization maintaining optical fiber coupler is provided in which, in at least one of the polarization maintaining optical fibers forming the fused and extended portion, the ratio of the [diameter of the core / the diameter of the cladding] or [the distance between the two stress applying portions / the diameter of the cladding] is greater than the ration of the [diameter of the core / the diameter of the cladding] or [the distance between the two stress applying portions / the diameter of the cladding in the portions of the polarization maintaining optical fibers that do not form the fused and extended portion]. In addition, in this polarization maintaining optical fiber coupler, in the fused and extended portion, the stress applying portions are enveloped by the cladding. Moreover, polarization maintaining optical fibers are used in which the distance between adjacent outer circumferences of the two stress applying portions is 20 μm or more.

Owner:THE FUJIKURA CABLE WORKS LTD

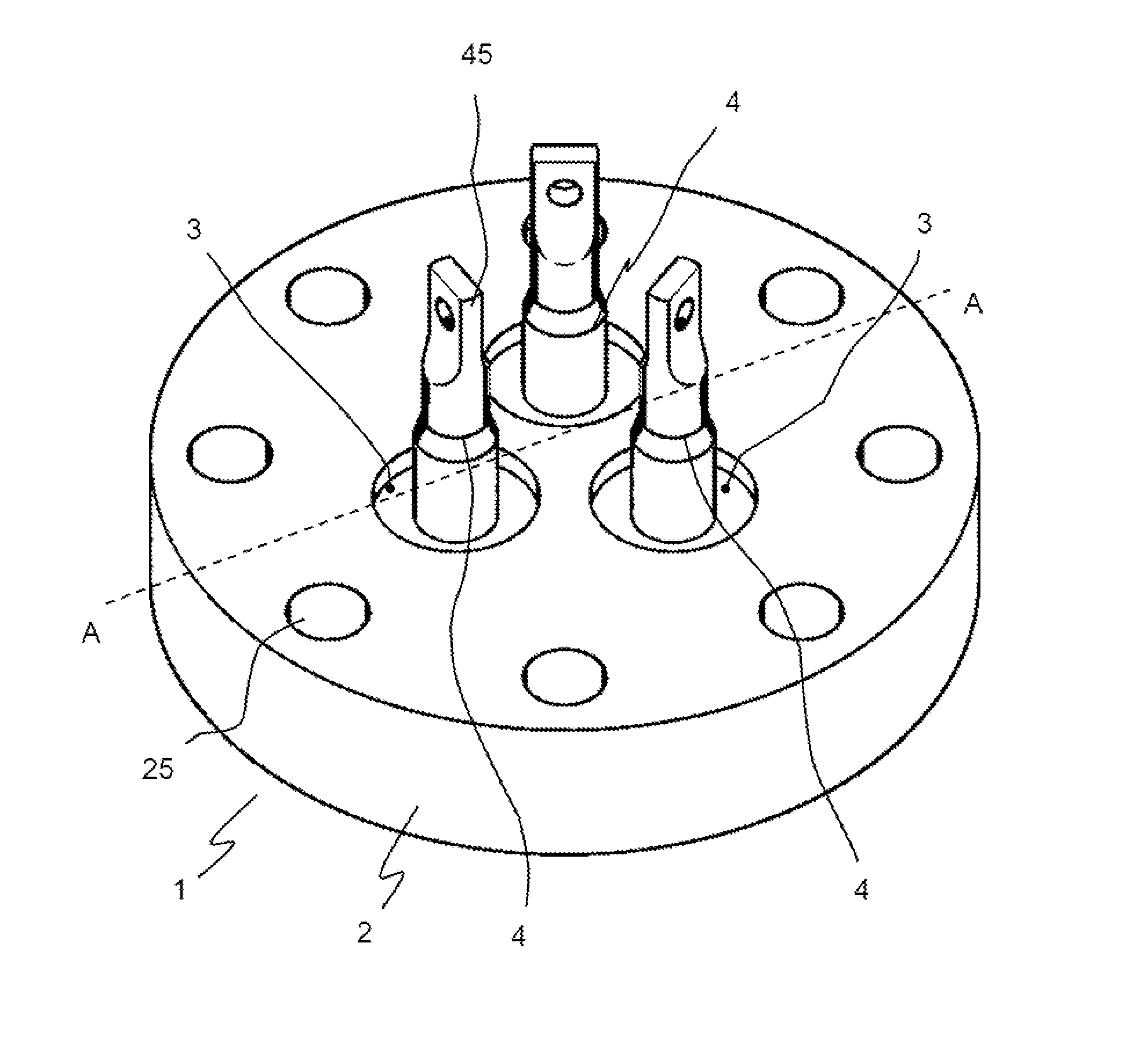

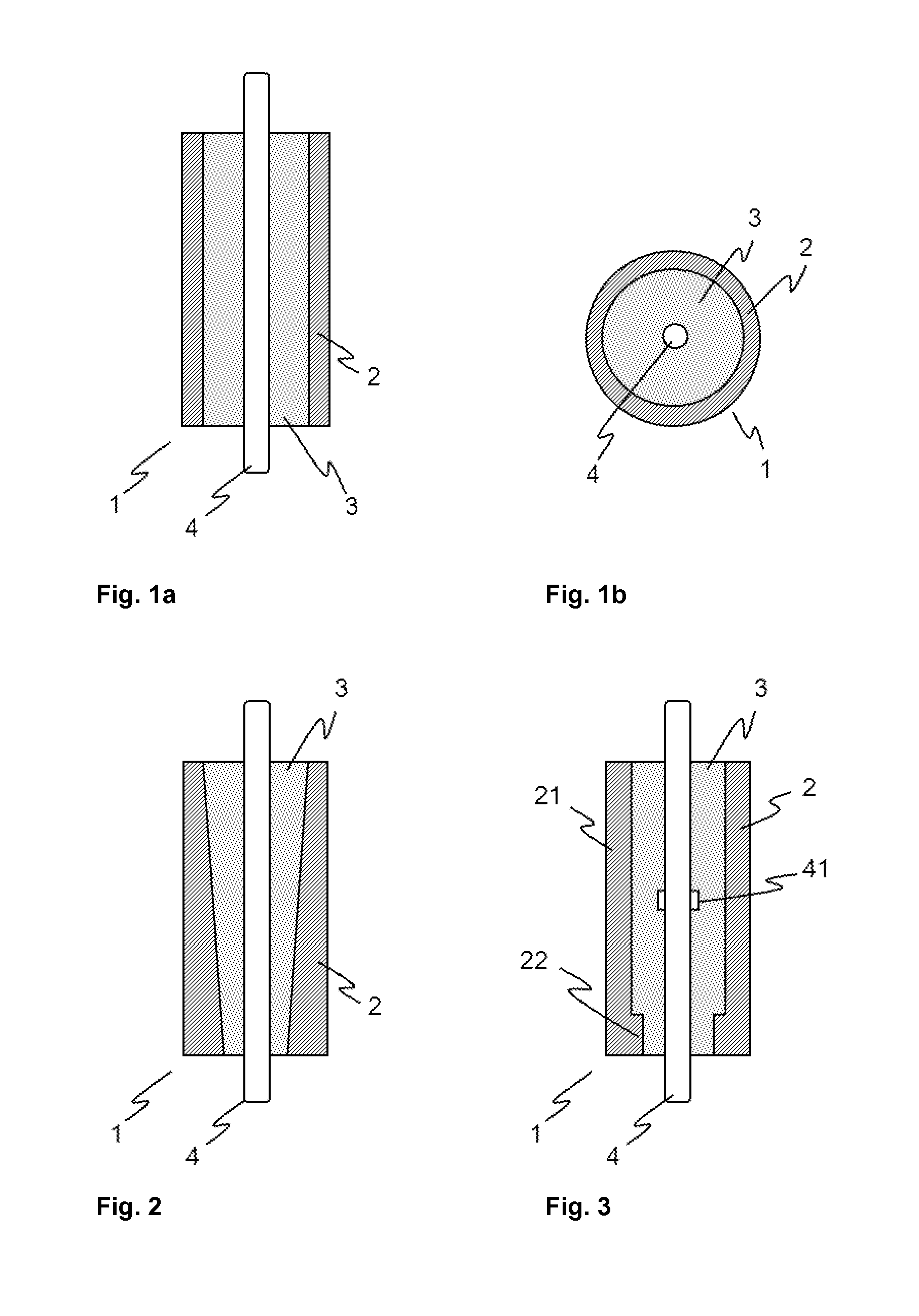

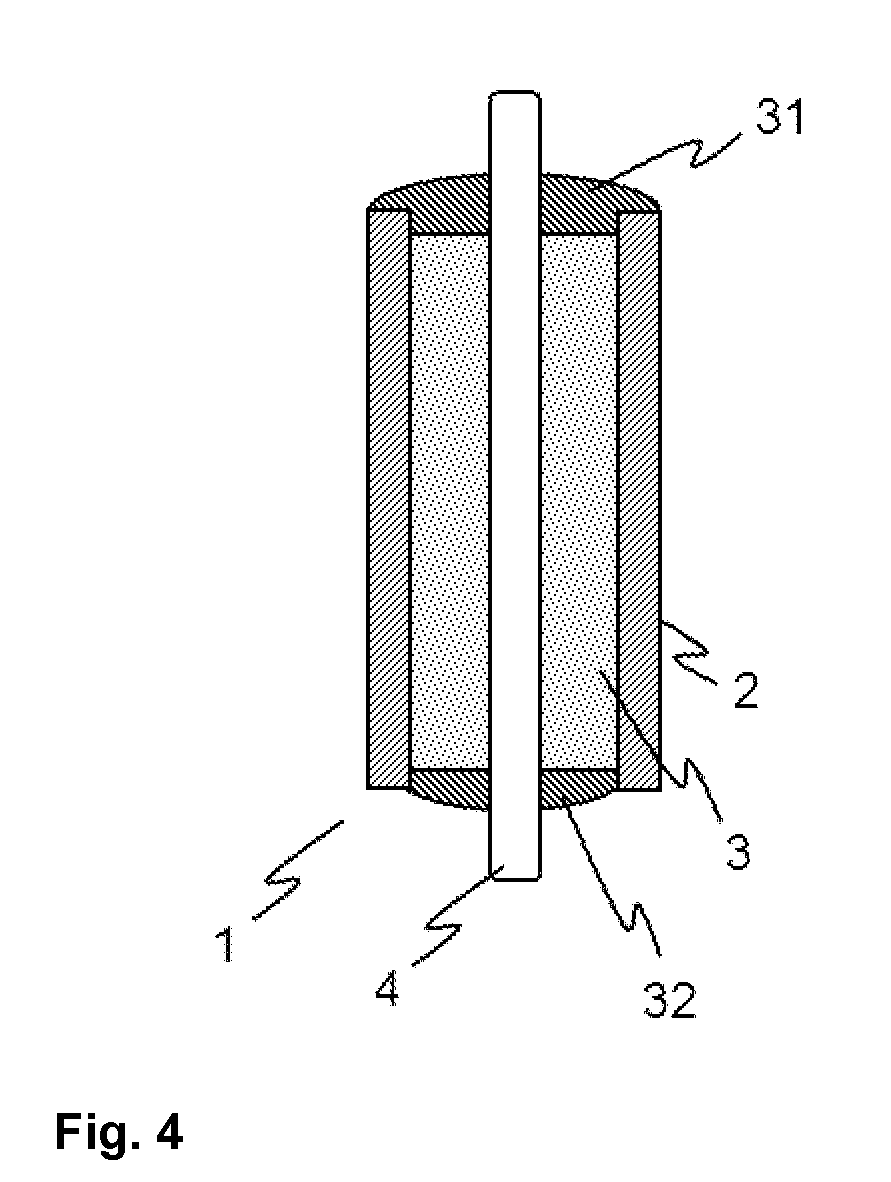

Gtms connector for oil and gas market

ActiveUS20150083487A1Improve stress resistanceReduce the overall diameterDrilling rodsNuclear energy generationGas marketOil and natural gas

A feed-through element for harsh environments is provided that includes a support body with at least one access opening, in which at least one functional element is arranged in an electrically insulating fixing material. The electrically insulating fixing material contains a glass or a glass ceramic with a volume resistivity of greater than 1.0×1010 Ωcm at the temperature of 350° C. The glass or a glass ceramic has a defined composition range in the system SiO2—B2O3-MO.

Owner:SCHOTT AG

Connecting device for kill/choke lines between a riser and a floating drilling vessel

A connector device for kill- and choke lines between a riser and a floating drilling platform includes a slip joint on top of the riser including an outer barrel, a kill- and choke manifold arranged on the platform and provided with flexible kill- and choke hoses to the slip joint's outer barrel, and wherein the slip joint's outer barrel is provided with a horizontally directed kill- and choke-manifold.

Owner:FUTURE PROD

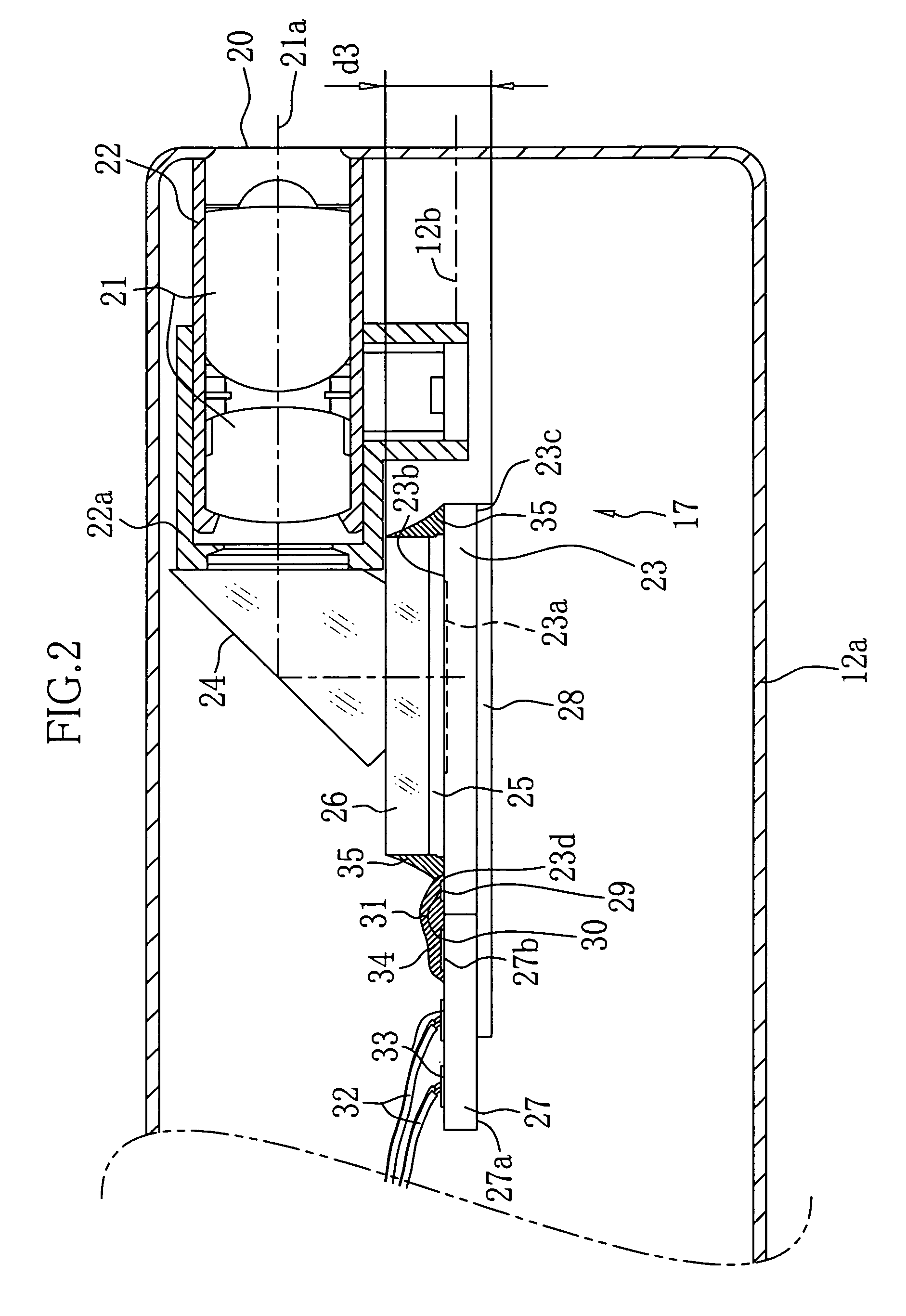

Imaging apparatus for electronic endoscope and electronic endoscope

InactiveUS8179428B2Reduce thicknessDiameter of the insertion section of the electronic endoscope can be narrowedTelevision system detailsSurgeryForcepsElectrical connection

An imaging apparatus for an electronic endoscope includes a bare chip of CCD, a circuit board with approximately the same thickness as the bare chip, and a conducting plate with no less than 1 / 4 width of the bare chip. The bare chip has terminals on the surface with an imaging surface. The terminals are arranged near the edge facing the rear end of an insertion section of the electronic endoscope. The circuit board has terminals on the surface near the edge facing the front end of the insertion section. These terminals are connected by wire bonding. The conducting plate is attached along one side of the rear surface of the CCD and the circuit board for electrical connection. A forceps channel is provided such that its outer circumference fits partially into a cut portion formed on the rear surfaces of the CCD and the circuit board by the conducting plate.

Owner:FUJIFILM CORP

Power supply wire, wire grip, electric appliance suspending device, and electric appliance suspending method

ActiveUS7335836B2High strengthImprove conductivityNon-insulated conductorsLighting support devicesElectrical conductorVoltage

Owner:A G K

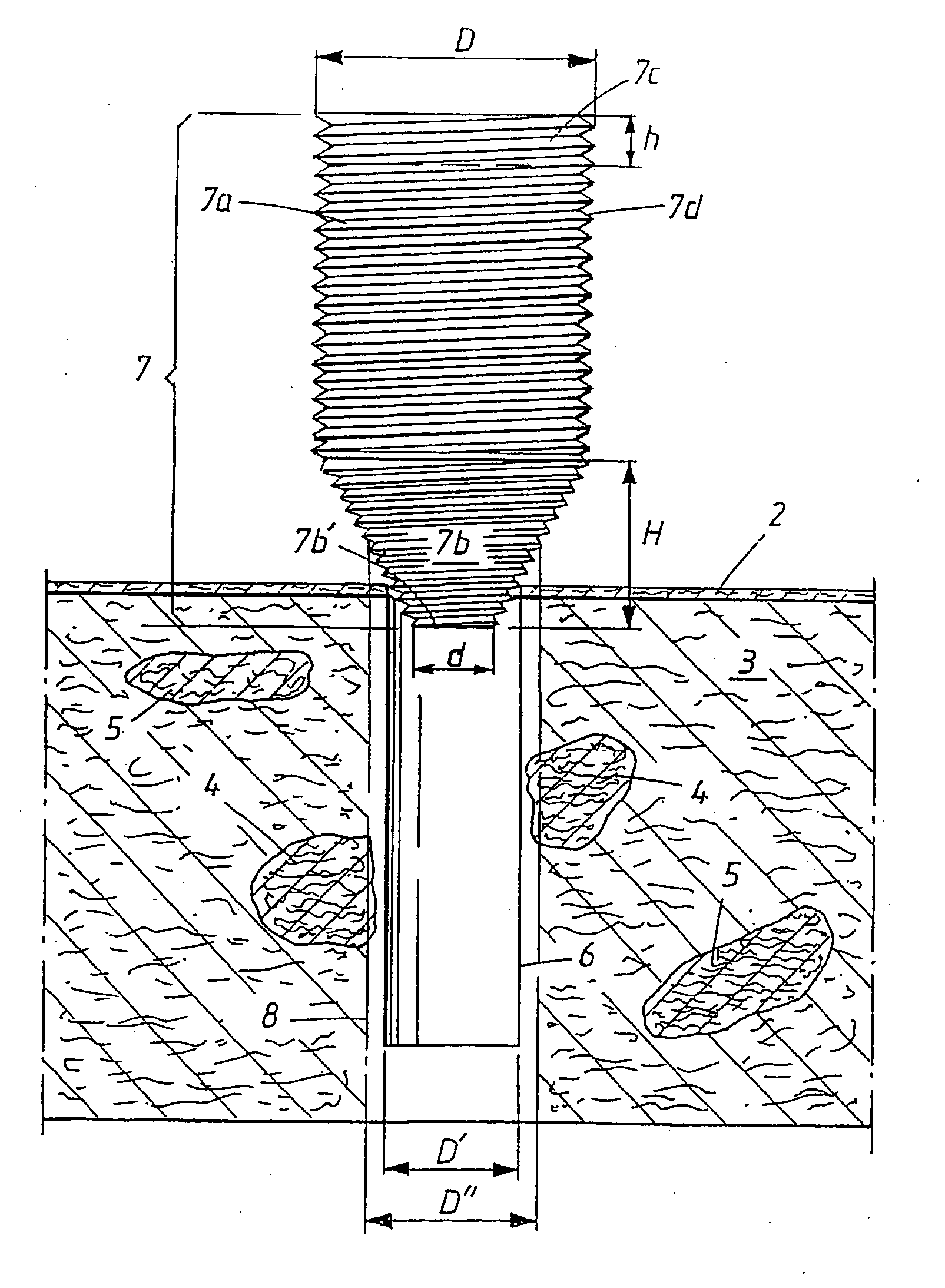

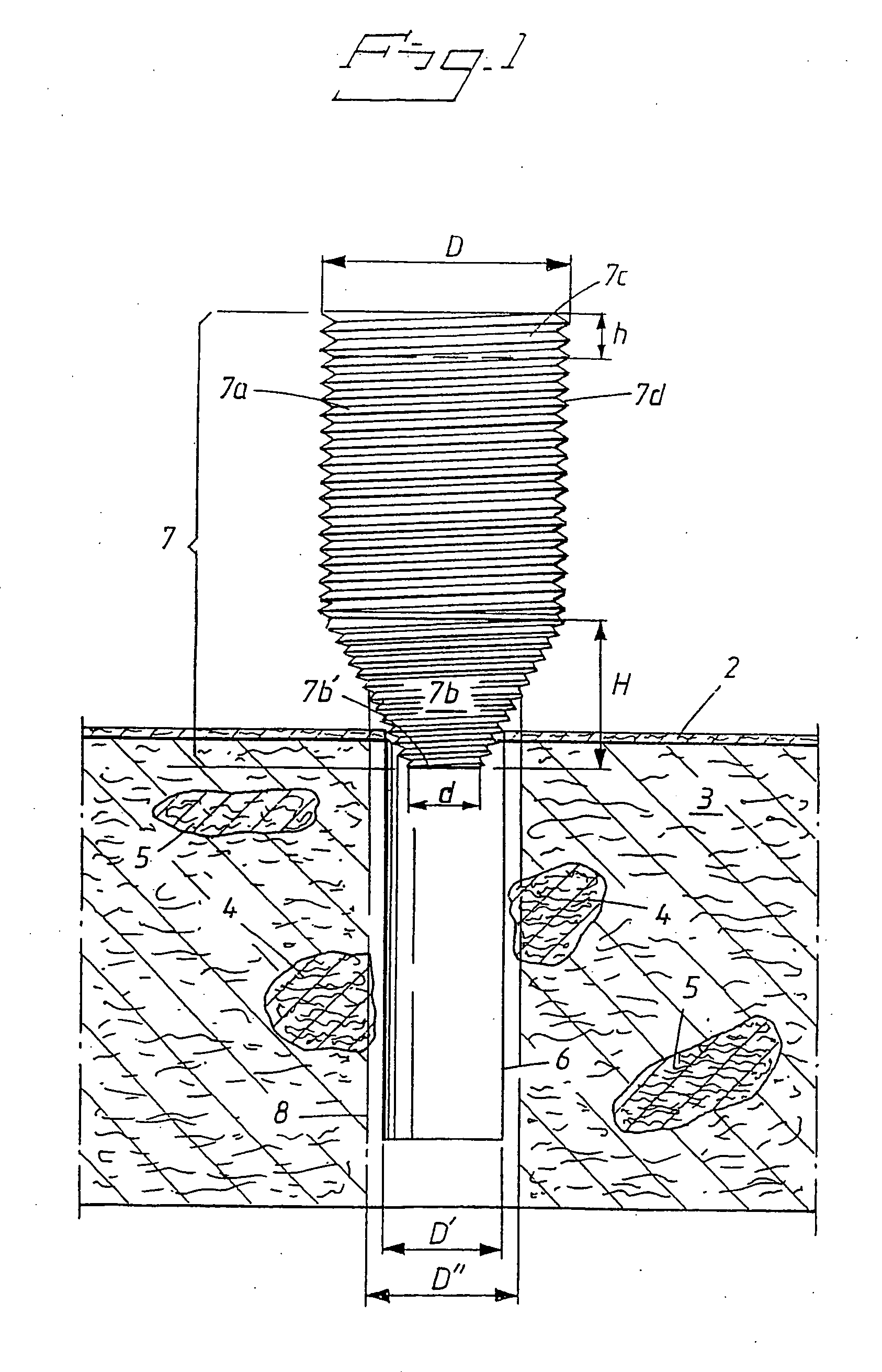

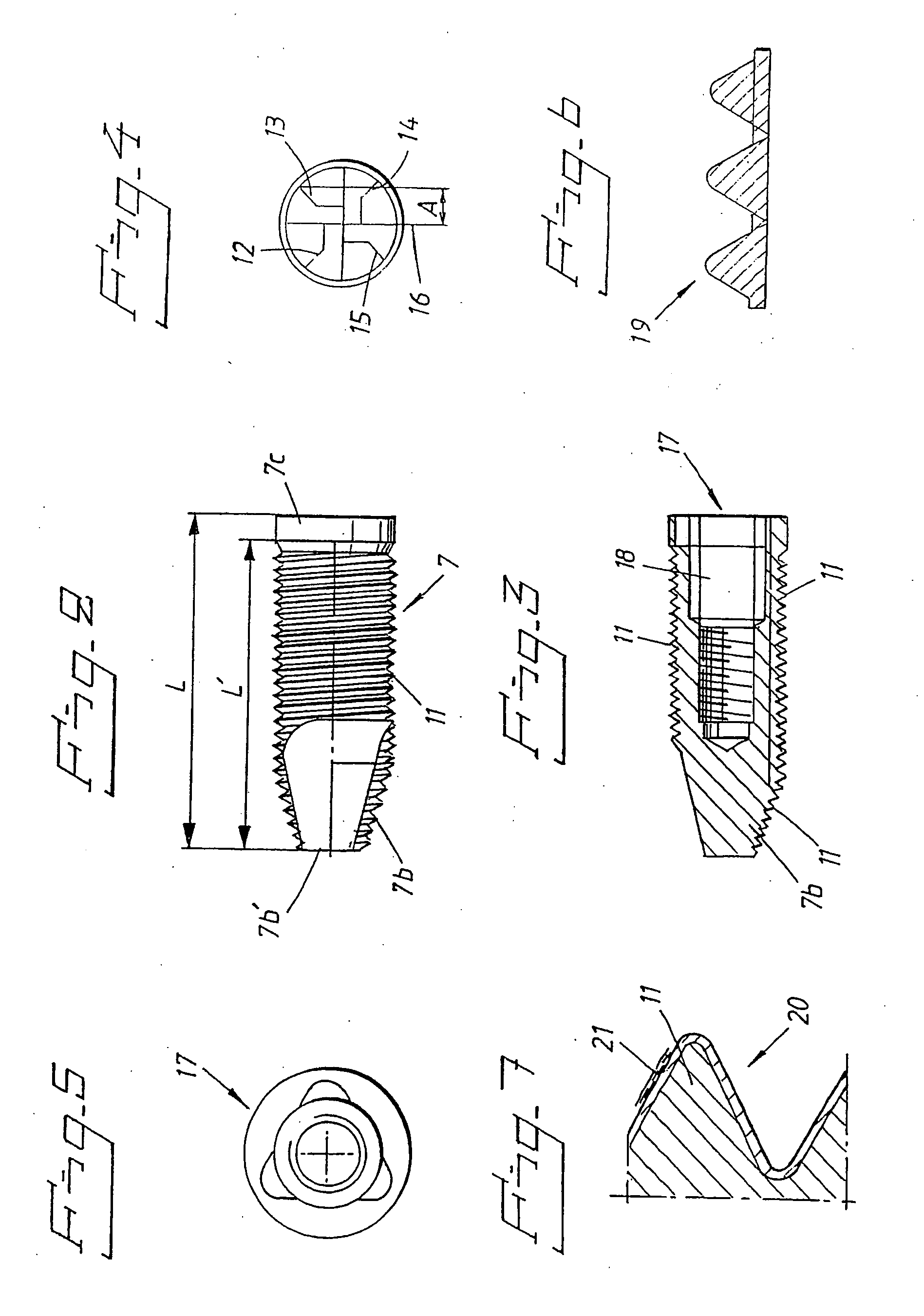

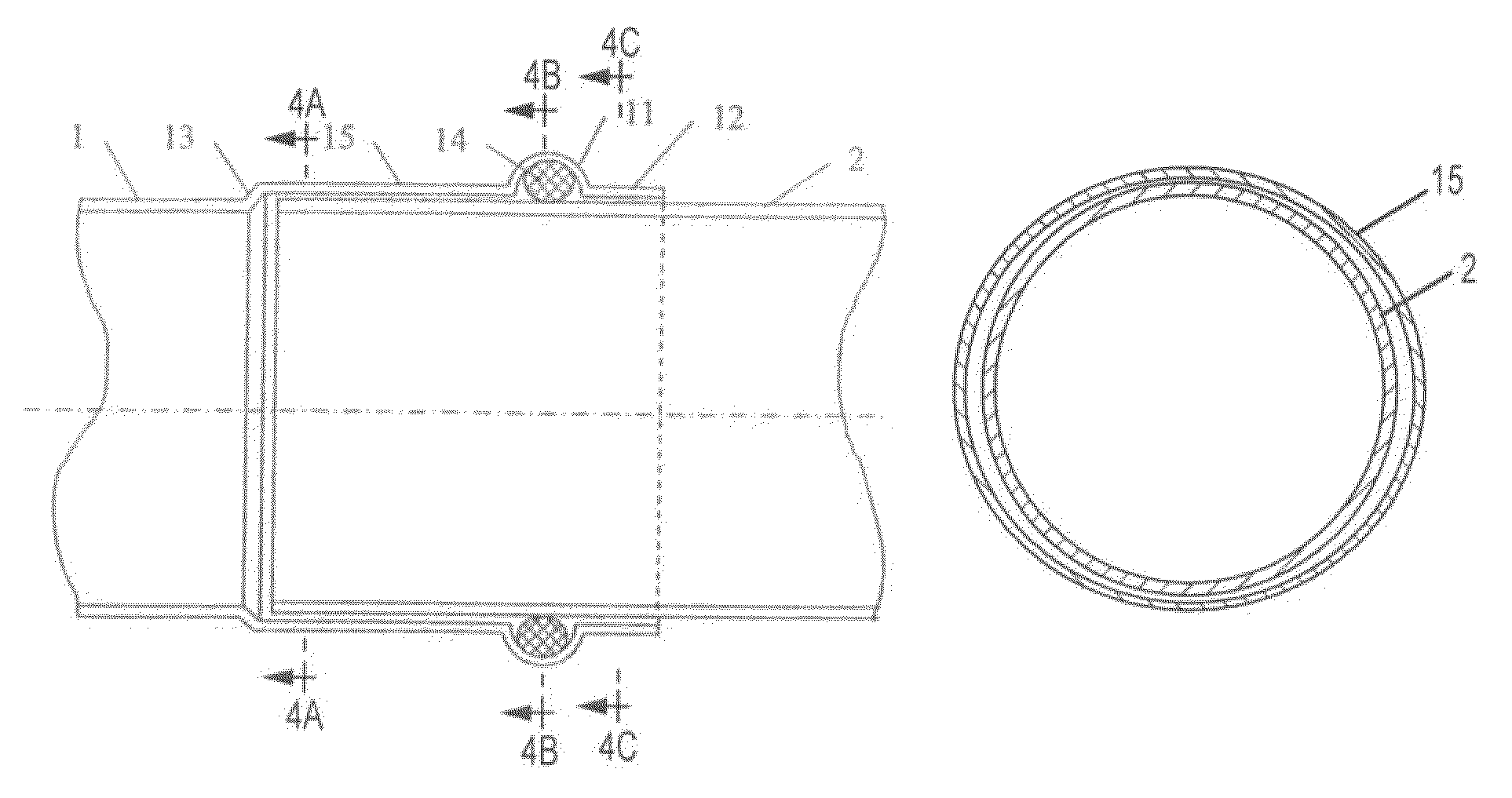

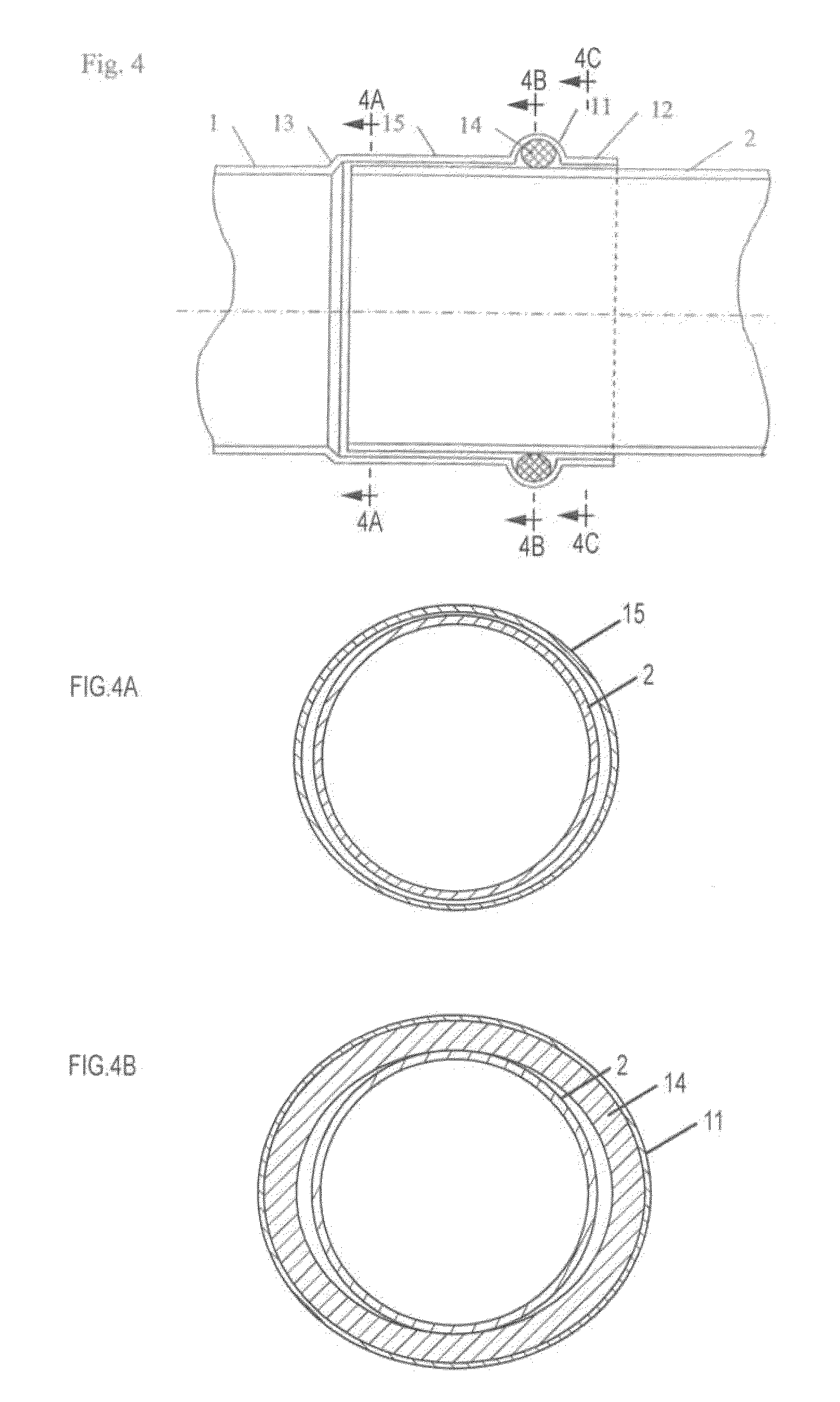

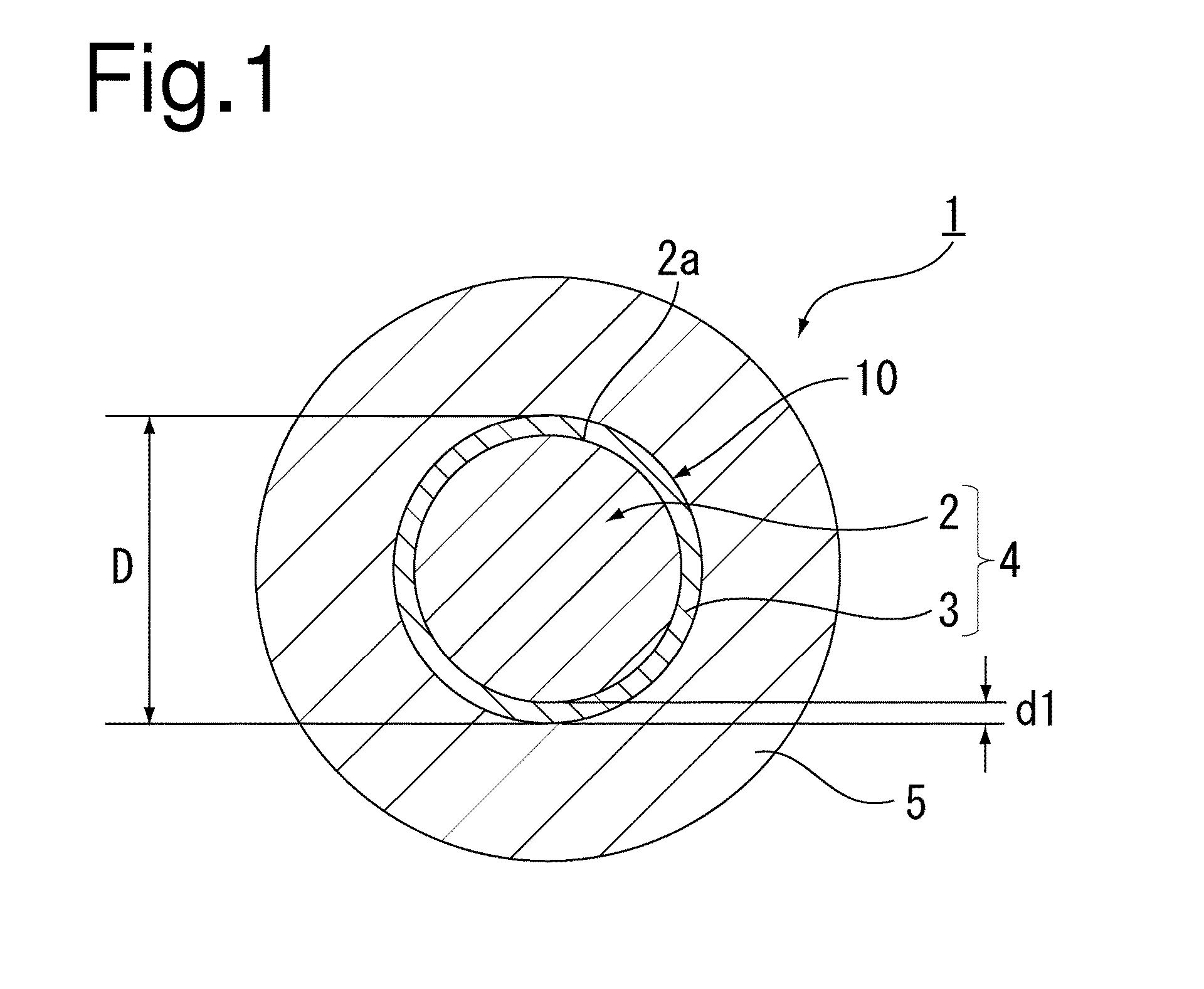

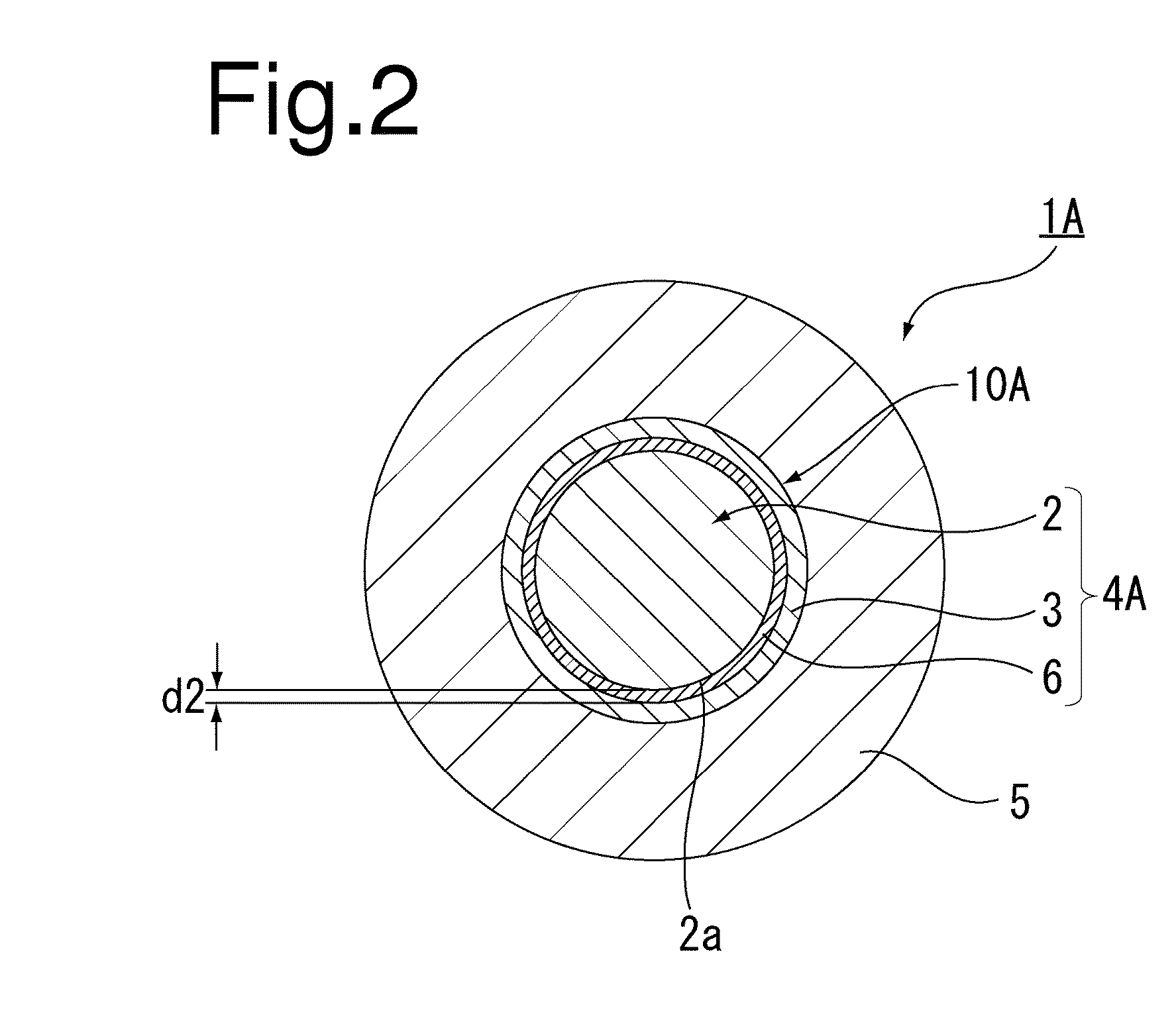

Fixture for anchoring in jaw bone

To anchor a fixture in a jaw bone, the fixture is applied in a hole which is substantially smaller than the diameter of the fixture. The fixture has a front portion which from the point of view of diameter grows very much narrower and which is arranged with both a cutting function and a threading function. The fixture is provided with a thread, with one, two or more thread turns extending down along the greatly narrowing portion while substantially maintaining their thread profile. One or more porous layers arranged on the thread turns can also be included. In this way the fixture can exploit the clamping effect from the soft parts of the jaw bone and still effectively penetrate through any hard parts possibly present in the jaw bone, without these hard parts being pressed inward upon fixture application. An effective fusion of the fixture in the jaw bone is achieved with the aid of said porous outer layers.

Owner:NOBEL BIOCARE SERVICES AG

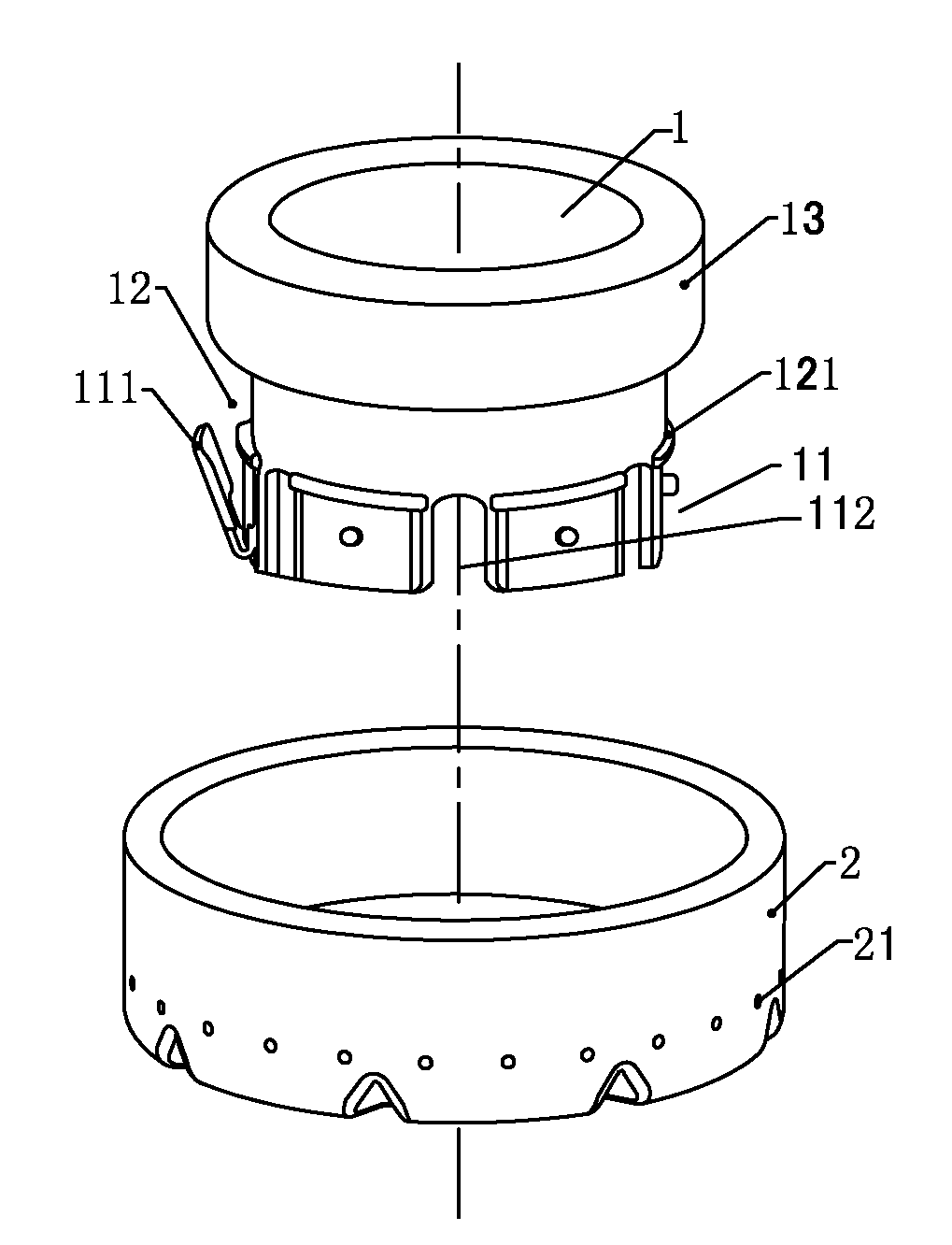

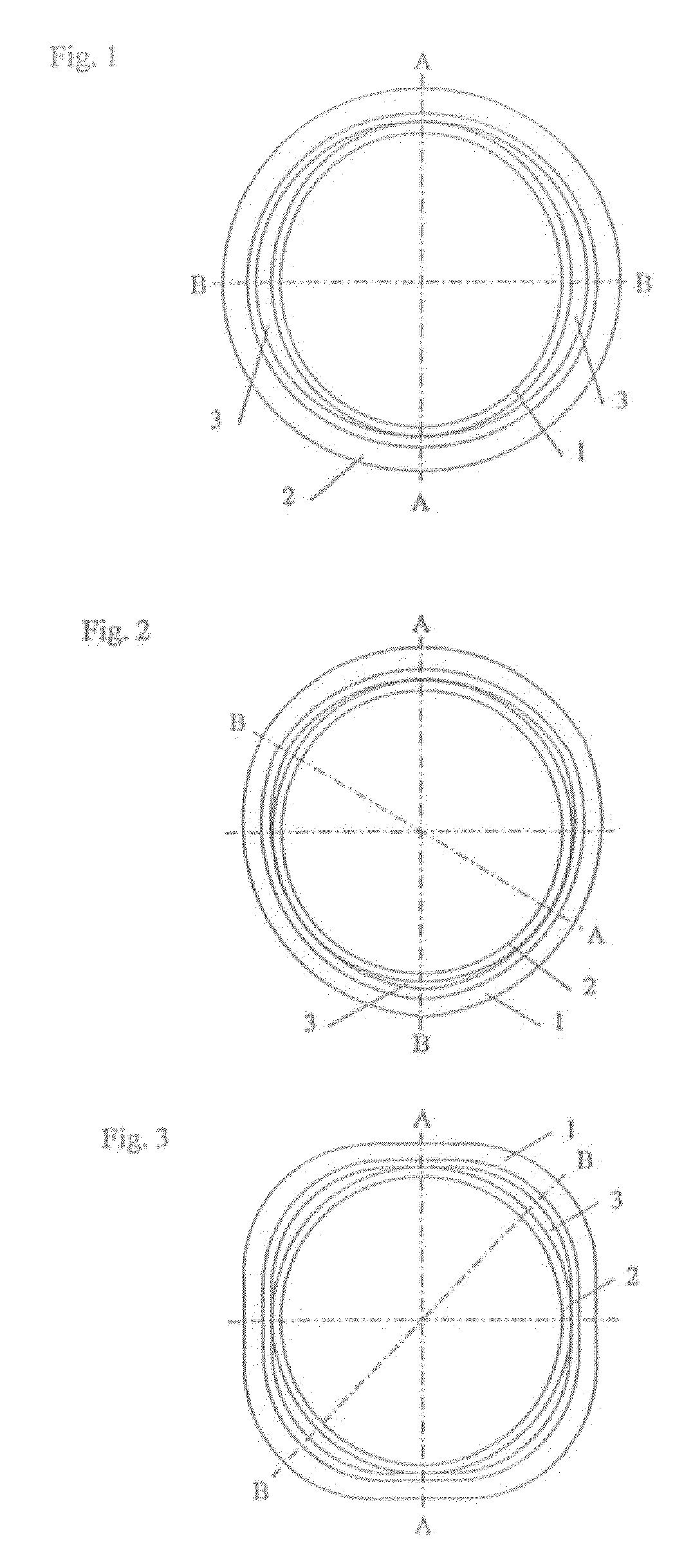

Sleeve type fixing method and device for anastomosis for tubular organs such as intestines, stomach, esophagus etc

A sleeve type fixing method for anastomosis for tubular organs, using an anastomosis device which has an inner and an outer ring. The outer ring is made of elastic material, and the inside of the lower portion of the outer ring has an inwardly protruding ring. The protruding ring is clamped to the connecting portion of the inner ring. In operation, one intestine is sleeved and fixed on the flange of the anastomosis portion of the inner ring, and the outer ring is overturned to let the lower edge overturn. Then another intestine is sleeved and fixed on the outer ring, and both the outer ring and the intestine are overturned so that the intestine is connected in the inner edge of the outer ring. Finally the inner ring is inserted and the two intestines overlapped on the anastomosis portion of the inner and outer ring.

Owner:LIU ZHONGCHEN

Optical modeling apparatus

InactiveUS7758329B2Reduce difficultyIncrease surface areaAdditive manufacturing apparatusOptical articlesSpatial light modulatorLight beam

Owner:SONY CORP

Fitting

InactiveUS7722093B2Low production costNarrow diameterSleeve/socket jointsFluid pressure sealed jointsRidgeElectrical and Electronics engineering

The invention relates to a fitting for connecting lengths of pipe by compression, having a substantially cylindrical internal contour. The fitting has a ridge which is configured in a radially outward direction and in which a sealing element is provided. The fitting is slidable onto the lengths of pipe, the internal contour having a region of non-circular cross-section. The invention also relates to a connecting arrangement for connecting lengths of pipe by compression, comprising a length of pipe and a fitting plus a sealing element which is arranged in the ridge. One axial gap which extends over the entire connecting region is formed between the length of pipe and the internal contour of the fitting in the uncompressed state. Such an axial gap with an open end would ensure that a leak exists even in the region of the sealing element in an uncompressed state.

Owner:YORKSHIRE FITTINGS

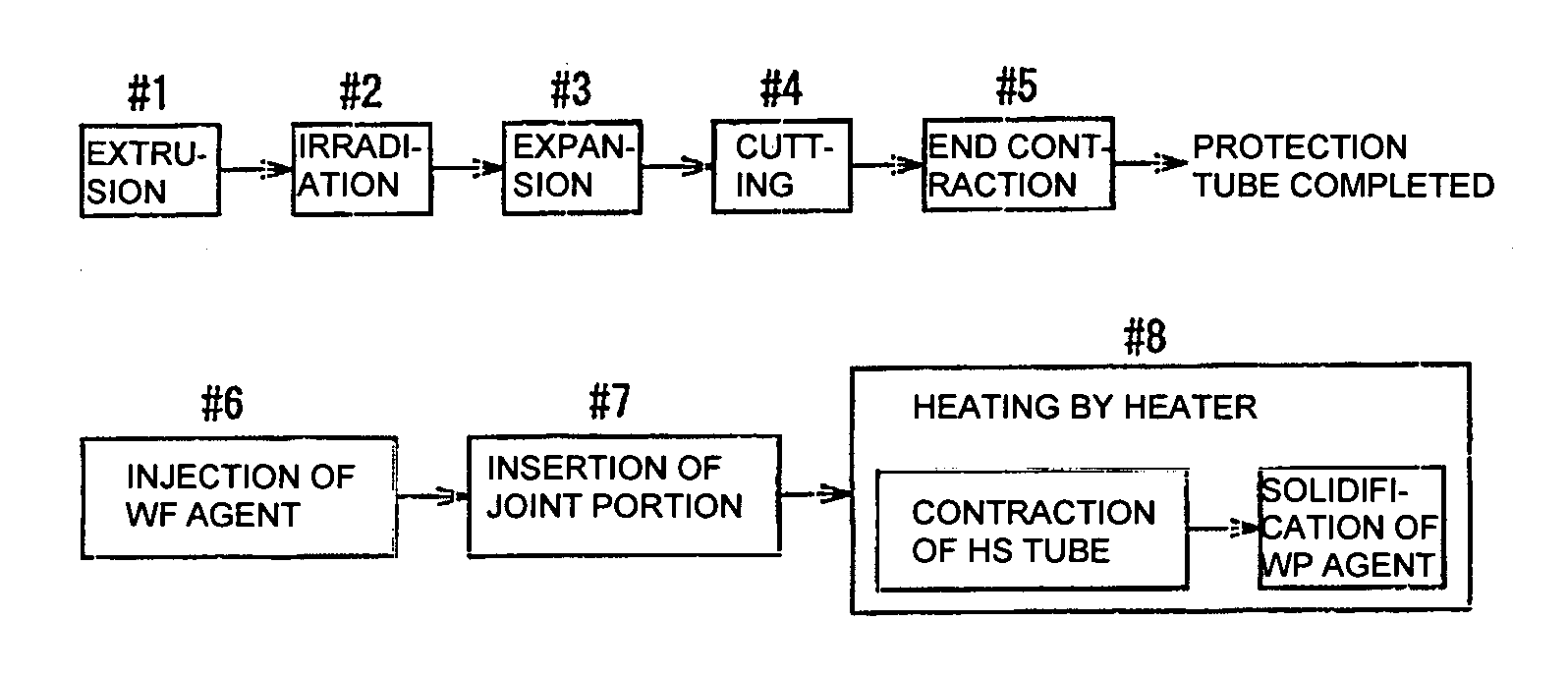

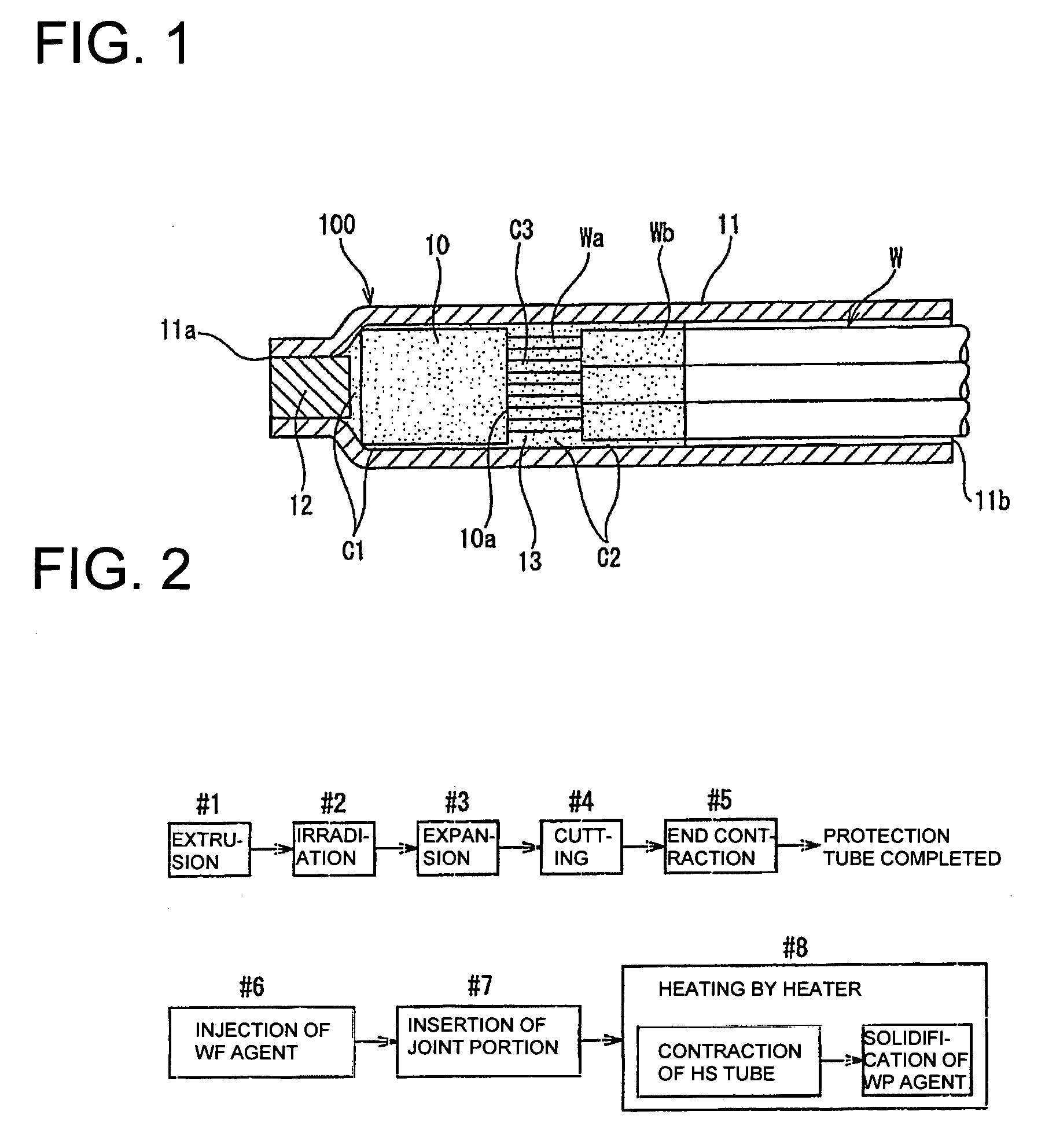

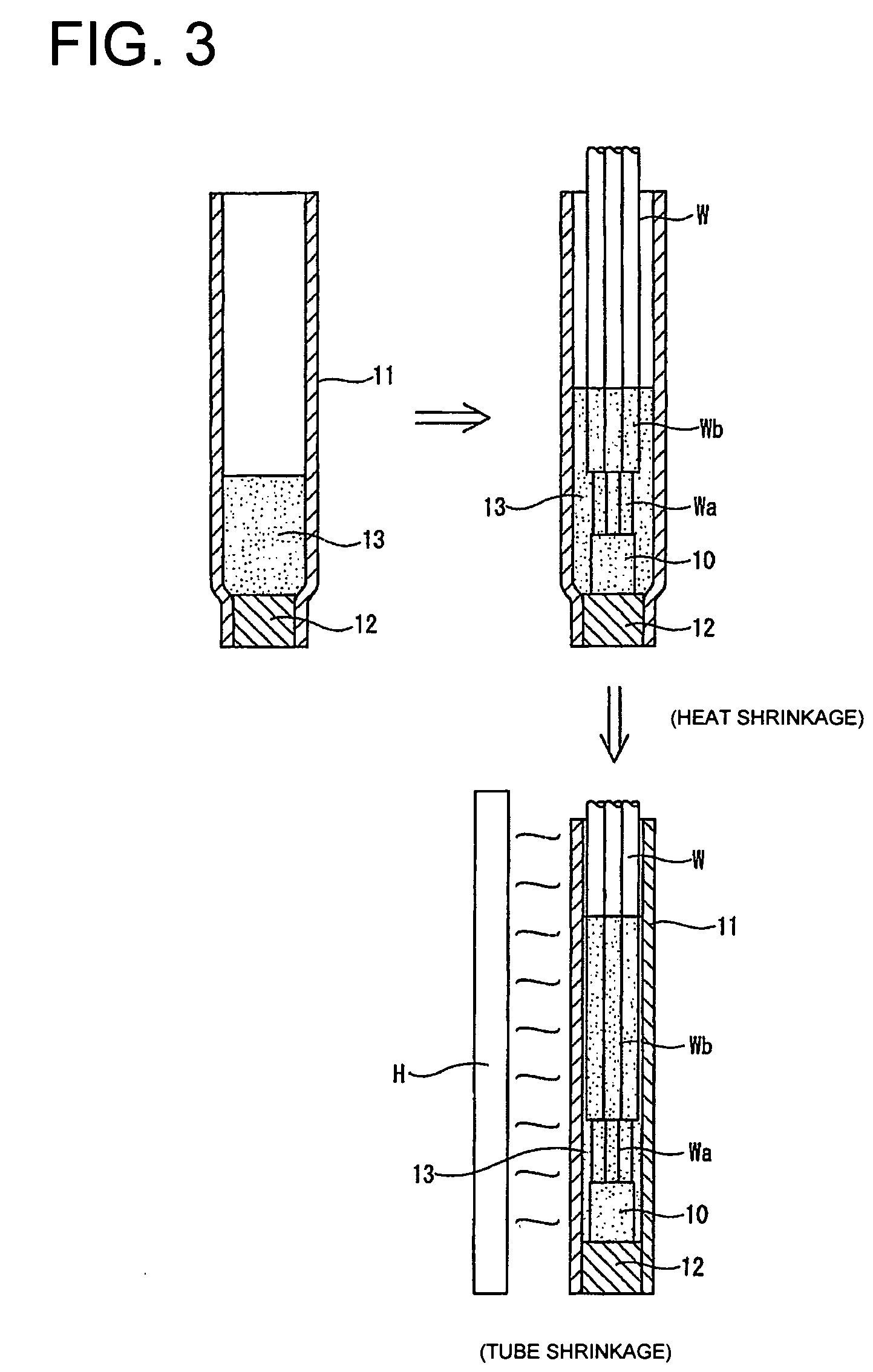

Waterproof method and construction for a wire end joint portion

ActiveUS7850806B2Low costIncrease spacingCoupling device detailsLaminationEngineeringBuilding construction

A waterproof method for a wire end joint includes expanding a heat shrinkable tube radially outwardly. The method then includes inserting the wire end joint and a melted thermosetting waterproofing agent through an opening at an end of the waterproof protection tube. A solidification starting temperature of the waterproofing agent is set higher than a shrinkage starting temperature of the heat shrinkable tube. The method then applies heating so that the heat shrinkable tube shrinks to the original diameter and so that the waterproofing agent is not solidified. The heating is continued to the solidification starting temperature after the heat shrinkable tube is shrunk to a set inner diameter, thereby causing the thermosetting waterproofing agent to be solidified.

Owner:SUMITOMO WIRING SYST LTD

Liquid-immersion objective optical system

The invention provides a liquid-immersion objective optical system including a first lens group and a second lens group. The first lens group includes a first lens component having positive refractive power, an object side thereof being a flat surface and a convex surface thereof facing an image-plane side; a second lens component having positive refractive power, a convex surface thereof facing the image-plane side; a third lens component having positive refractive power as a whole, formed by cementing a biconvex positive lens and a negative lens; and a fourth lens component formed by cementing a negative lens and a biconvex positive lens. The second lens group includes a fifth lens component formed by cementing a lens having a concave surface facing the object side and a lens having a convex surface facing the image-plane side; a sixth lens component having positive refractive power; and a seventh lens component having negative refractive power. The focal length F 1 of the entire first lens group, the magnification M of the objective optical system, the distance LT between the object plane and the image plane, and the distance LG between the object side of the first lens component L 1 and the image side of the fourth lens component L 4 satisfy the following conditional expressions: <?in-line-formulae description="In-line Formulae" end="lead"?>0.2<|M.F1 / LT|<0.45<?in-line-formulae description="In-line Formulae" end="tail"?> <?in-line-formulae description="In-line Formulae" end="lead"?>0 / 2<|LG1 / LT|<0.4.<?in-line-formulae description="In-line Formulae" end="tail"?>

Owner:EVIDENT CORP

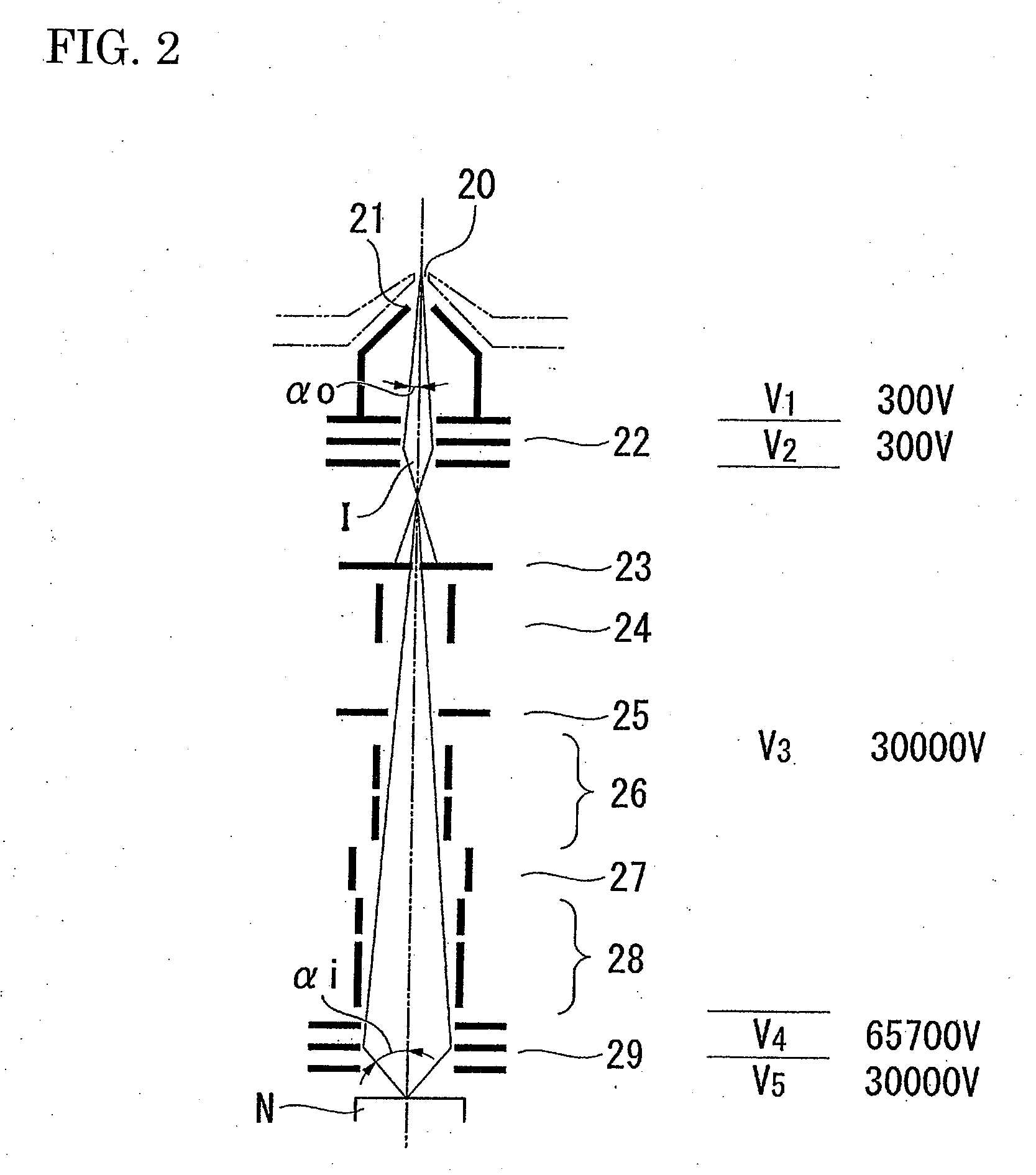

Focused Ion Beam Apparatus

InactiveUS20080156998A1Narrow diameterReduce light transmittanceStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsIon beamMagnification

A focused ion beam apparatus including a plasma type gas ion source for generating an ion beam, and an ion optical system for gathering the ion beam generated from the plasma type gas ion source onto a sample. The ion optical system is constructed by a constitution having 2 pieces of basic electrostatic lenses and an ion optical system magnification of the 2 pieces of basic electrostatic lenses is set to be equal to or smaller than 1 / 300.

Owner:SII NANOTECHNOLOGY INC

Optical modeling apparatus

InactiveUS7833000B2Increase surface areaNarrow diameterAdditive manufacturing apparatusPhotomechanical apparatusSpatial light modulatorLight beam

Owner:SONY CORP +1

Method of manufacturing head of inkjet printer

InactiveUS6922892B2Improve discharge efficiencyEfficient manufacturing processError preventionWave amplification devicesSpray nozzleProduction rate

A method of manufacturing a head of an inkjet printer includes forming a heater on a substrate and also forming an ink feeding passage through the substrate in a vertical relation to a surface where the heater is formed, forming an ink chamber communicating with the ink feeding passage of the substrate; attaching the substrate to the nozzle plate, and forming a tapered nozzle in the nozzle plate, the tapered nozzle being narrower in diameter in an inside of the nozzle plate than an outside of the nozzle plate, by radiating a laser beam from inside toward the outside of the nozzle plate, wherein the substrate is used as a mask. Since the nozzle is formed by radiating the laser beam to the nozzle plate through the ink feeding passage of the substrate after attaching the nozzle plate to the substrate, the accuracy of the nozzle in form and position improves, and the nozzle of desirable structure of the improved ink discharge efficiency can be obtained by radiating the laser beam only once. Also, the manufacturing process becomes simpler, and due to improved manufacturing process, the productivity increases.

Owner:HEWLETT PACKARD DEV CO LP

Automotive wire

ActiveUS20130105197A1High breaking strength and electrical conductivityImprove corrosion resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorMetallurgy

The present invention is an automotive wire provided with a conductor including at least one solid wire composed of a core and a metal film that covers the surface of the core, and an insulator that covers the conductor, wherein the core is composed of carbon steel, and the metal film has a thickness of 12.4 μm to 29.6 μm.

Owner:THE FUJIKURA CABLE WORKS LTD

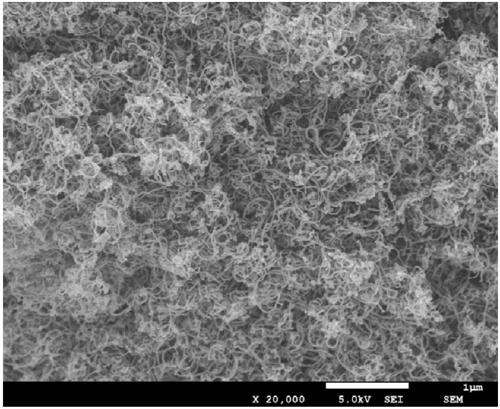

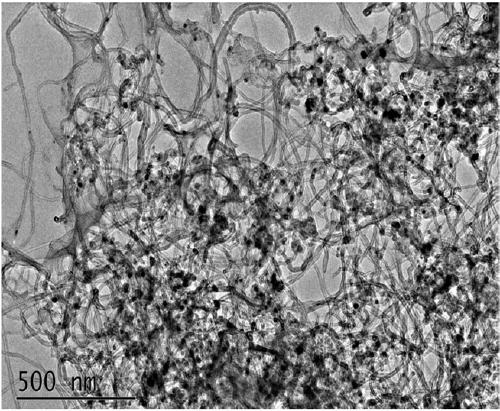

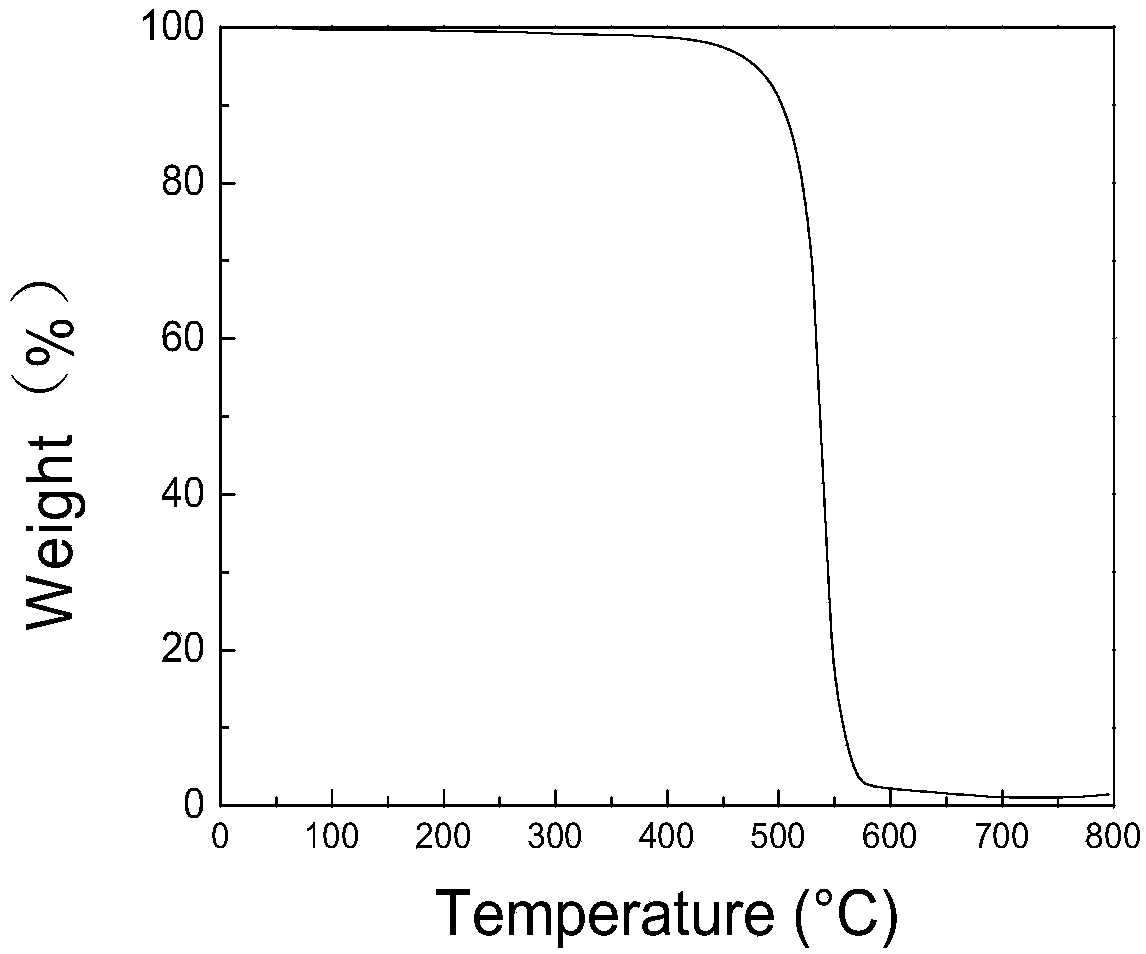

Method for preparing carbon nanotube

InactiveCN109399611AReduce pollutionAvoid pollutionCarbon compoundsMetal/metal-oxides/metal-hydroxide catalystsPolyolefinCombustion

The invention belongs to the technical field of synthetic carbon nanotube materials and provides a method for preparing carbon nanotubes from polyolefin as a carbon source, loaded type double-metal Co-Mo as a catalyst and carbon black as a splitting synergist through physical commixing and splitting. The method is characterized in that the polyolefin is pure and recycled polyolefin, the carbon black is a nano-grade synergist which participates in carbon nanotube synthesis, and the catalyst is a double-metal efficient catalyst. The materials are comixed according to a certain ratio, and carbonnanotubes are prepared through high-temperature combustion or high-temperature splitting in the presence of an inert gas. The method is simple in equipment, convenient to operate, good in repeatability, low in cost, high in yield and good in carbon nanotube quality. The recycled polyolefin is resource reuse, environment pollution can be solved, due to adoption of the nano-grade carbon black, non-carbon impurities in a product can be reduced, and due to adoption of the double-metal catalyst, the quality of the carbon nanotubes can be improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Worklight support with stand

InactiveUS20060291961A1Easy to disassembleNarrow diameterDry-dockingNon-electric lightingEngineering

A worklight support includes a platform for mounting thereon worklights and has an extension extending from on a bottom of the platform for extension into one of the stand sections. A stand includes couplers applied for combination of each of the stand sections. Each coupler includes an annular ring for receiving therein a portion of one of the stand sections and a portion of the extension of the worklight support and a pivotal handle pivotally connected to the annular ring via a threaded bolt to selectively reduce an internal diameter of the annular ring to abut an outer periphery of the extension so as to fix the extension relative to one of the stand sections.

Owner:TSAI PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com