Thermoplastic low-smoke zero-halogen flame-retardant polyolefin sheath material with high heat shock resistance and preparation method thereof

A polyolefin sheath, thermoplastic technology, applied in the field of plastic particles and its preparation, can solve the problems of high rubber material cost, low production efficiency, high manufacturing cost, etc., achieve low manufacturing cost, high production efficiency, and prevent stress cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

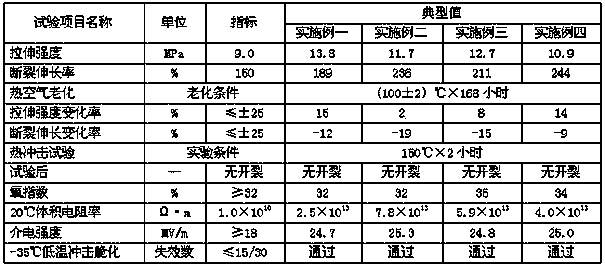

Examples

Embodiment 1

[0018] First select 50 parts by weight of polyolefin elastomer, 10 parts by weight of high-density polyethylene resin, 25 parts by weight of K-resin, 15 parts by weight of functionalized polyolefin resin, 140 parts by weight of flame retardant, 1 part by weight of The surface modifier, the antioxidant of 0.5 parts by weight, the processing aid of 1.5 parts by weight.

[0019] Then, put the flame retardant in a high-speed mixer and stir at a high speed until the temperature is not lower than 80°C.

[0020] Afterwards, the surface modifier was added to the high-speed mixer and stirred for 3 minutes.

[0021] Afterwards, the polyolefin resin, high-density polyethylene resin, K-resin, functionalized polyolefin resin, antioxidant and processing aid were put into a high-speed mixer and continued to stir for 3 minutes.

[0022] Finally, feed the stirred material into a twin-screw mixing extruder with four temperature zones with a feeder, extrude into pellets, and dry to obtain a hig...

Embodiment 2

[0034] First select 80 parts by weight of polyolefin elastomer, 10 parts by weight of high-density polyethylene resin, 5 parts by weight of K-resin, 5 parts by weight of functionalized polyolefin resin, 150 parts by weight of flame retardant, 1 part by weight of The surface modifier, the antioxidant of 2 parts by weight, the processing aid of 6 parts by weight.

[0035] Then, put the flame retardant in a high-speed mixer and stir at a high speed until the temperature is not lower than 80°C.

[0036] Afterwards, the surface modifier was added to the high-speed mixer and stirred for 4 minutes.

[0037] Afterwards, the polyolefin resin, high-density polyethylene resin, K-resin, functionalized polyolefin resin, antioxidant and processing aid were put into a high-speed mixer and continued to stir for 4 minutes.

[0038] Finally, feed the stirred material into a twin-screw mixing extruder with four temperature zones with a feeder, extrude into pellets, and dry to obtain a high heat...

Embodiment 3

[0050] First select 50 parts by weight of polyolefin elastomer, 25 parts by weight of high-density polyethylene resin, 10 parts by weight of K-resin, 15 parts by weight of functionalized polyolefin resin, 180 parts by weight of flame retardant, 3 parts by weight of The surface modifier, the antioxidant of 2 parts by weight, the processing aid of 9 parts by weight.

[0051] Then, put the flame retardant in a high-speed mixer and stir at a high speed until the temperature is not lower than 80°C.

[0052] Afterwards, the surface modifier was added to the high-speed mixer and stirred for 4 minutes.

[0053] Afterwards, the polyolefin resin, high-density polyethylene resin, K-resin, functionalized polyolefin resin, antioxidant and processing aid were put into a high-speed mixer and continued to stir for 4 minutes.

[0054] Finally, feed the stirred material into a twin-screw mixing extruder with four temperature zones with a feeder, extrude into pellets, and dry to obtain a high h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com