Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Even temperature inside and outside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

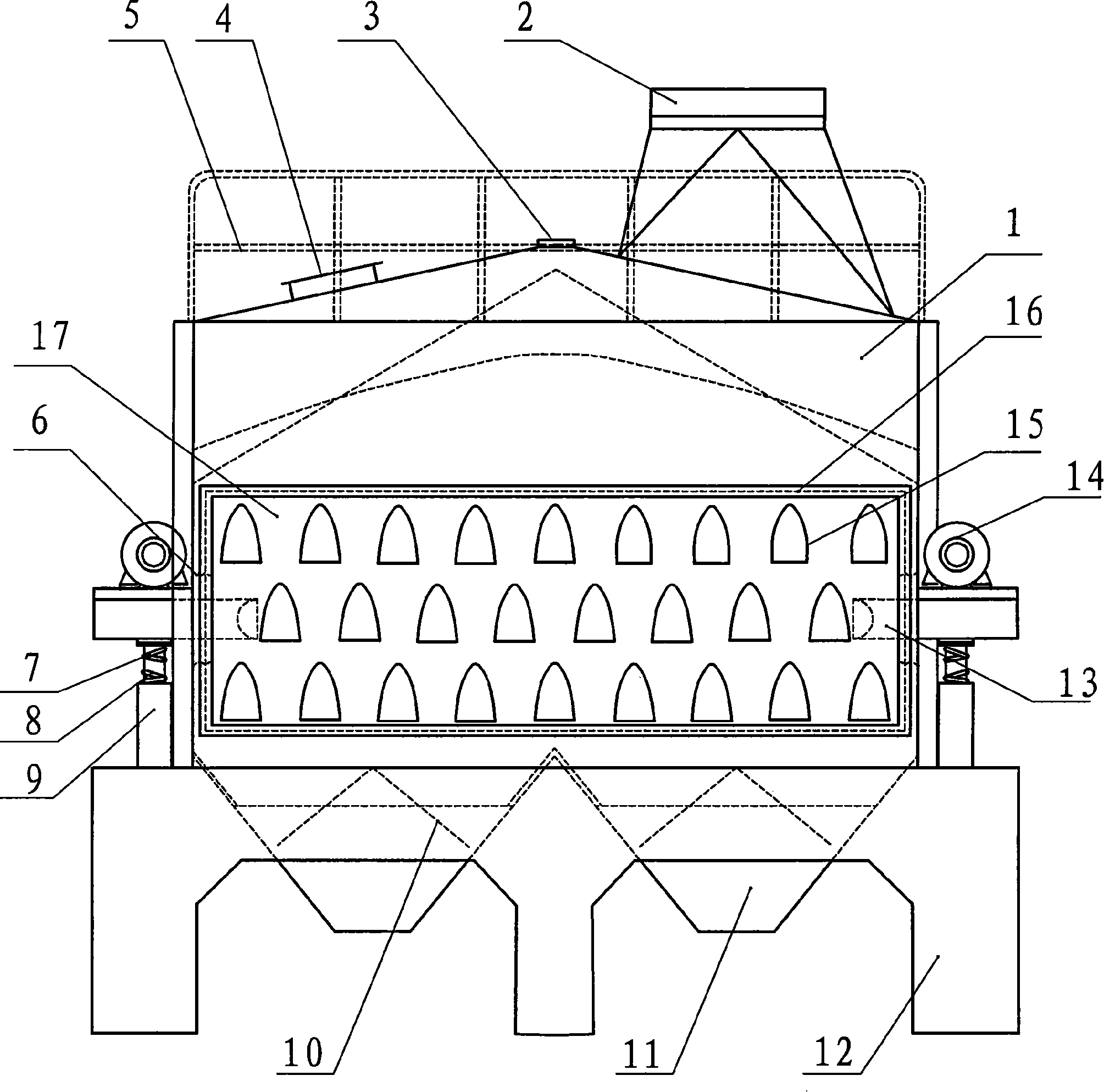

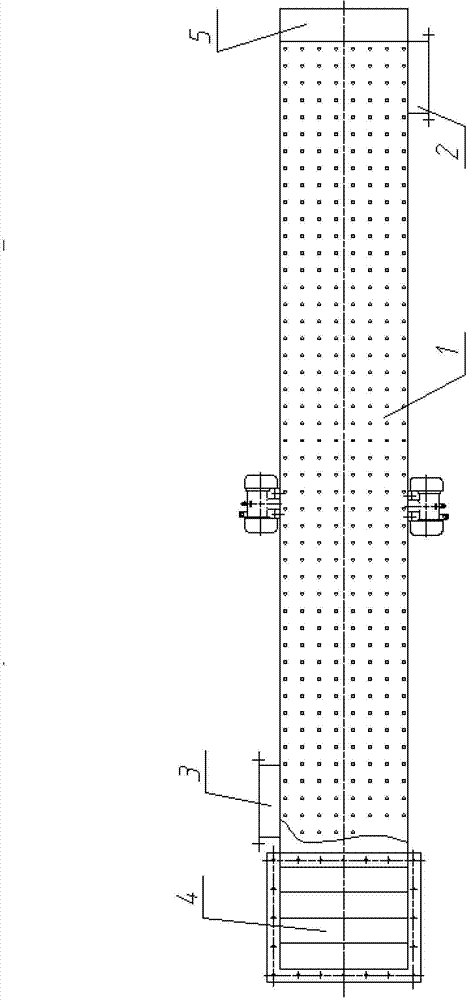

Granule material vibration cooling machine

InactiveCN101187533AEven temperature inside and outsideImprove cooling effectDirect contact heat exchangersCold airCooling chamber

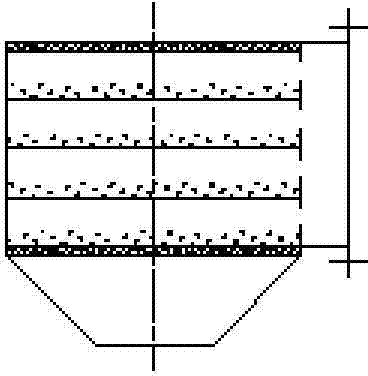

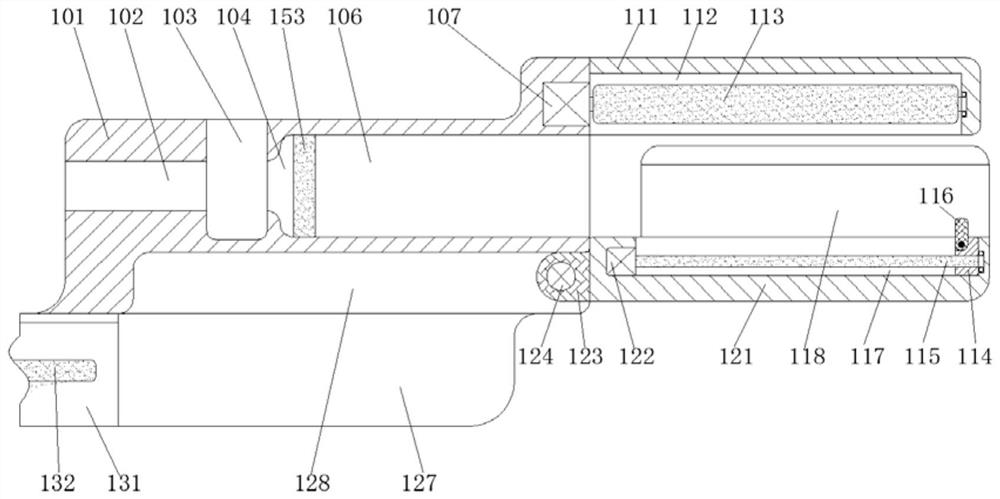

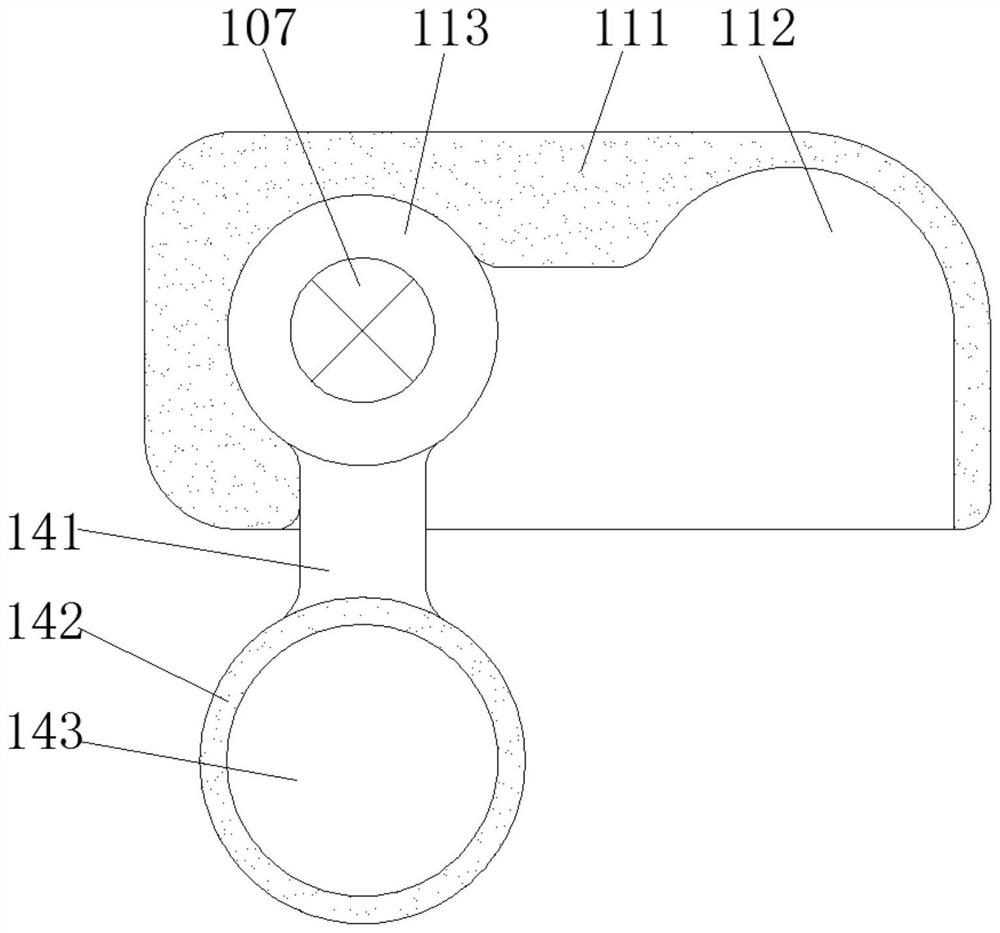

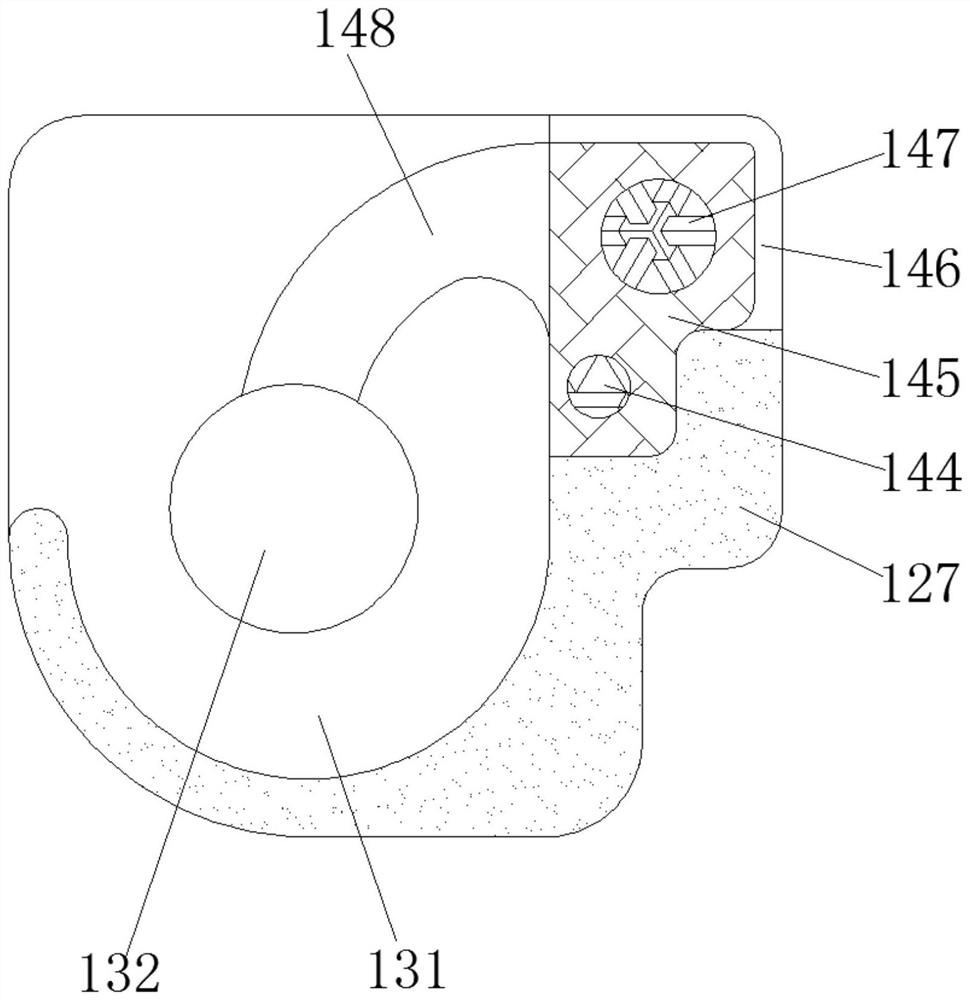

A granular material vibrating cooler comprises a ventilating mechanism, wherein a material cooling chamber and a vibrating mechanism are fixedly mounted on the a base, a material inlet and an air outlet are arranged on the upper portion of the material cooling chamber, and a material outlet is arranged on the lower portion, air inlets are evenly arranged on two corresponding lateral wall of the material cooling chamber, the air inlet is connected with an air inlet pipe, the ventilating mechanism which is mounted in the material cooling chamber is provided with a plate-frame skeleton and a certain amount of air grooves. An opening of the air groove is arranged downwards, the air grooves which have at least two layers are alternately arrayed in parallel and penetrated through and fixed on the plate-frame skeleton, two ends of the air groove are positively faced to the air inlets and communicated with the air inlets. The plate-frame skeleton is connected with the ventilating mechanism by penetrating the two lateral wall of the material cooling chamber through a connecting piece. The granular material vibrating cooler adopts the mode that cold air blast is combined with vibration, which has a good cooling effect on high temperature material, in particular to composite fertilizer which is being cooled. The invention cools completely, which can not being hardened, and is benefit to popularization and application.

Owner:河南金谷干燥工程技术有限公司

Forging process for forge piece

ActiveCN107282839AShort heating timeIncrease production rateHandling devicesSurface finishSurface cleaning

The invention discloses a forging process for a forge piece and aims to provide a forging process for a forge piece with high structural strength and surface smoothness. According to the technical scheme of the forging process, the forging process for the forge piece is characterized by comprising the following steps of (1) charging, (2) heating, (3) dummying, (4) die forging forming, (5) trimming , (6) heat treatment, (7) surface cleaning, (8) flaw detection and (9) inspection. The forging process is suitable for a forging machining process.

Owner:TAIZHOU YUPENG MACHINE FORGING

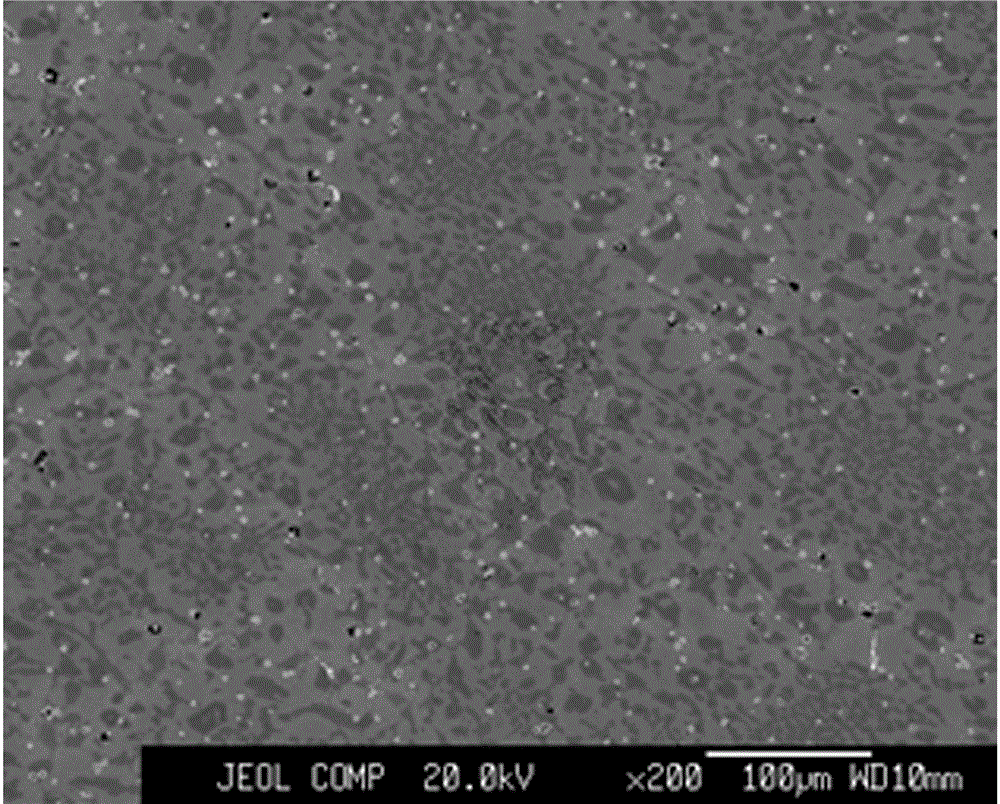

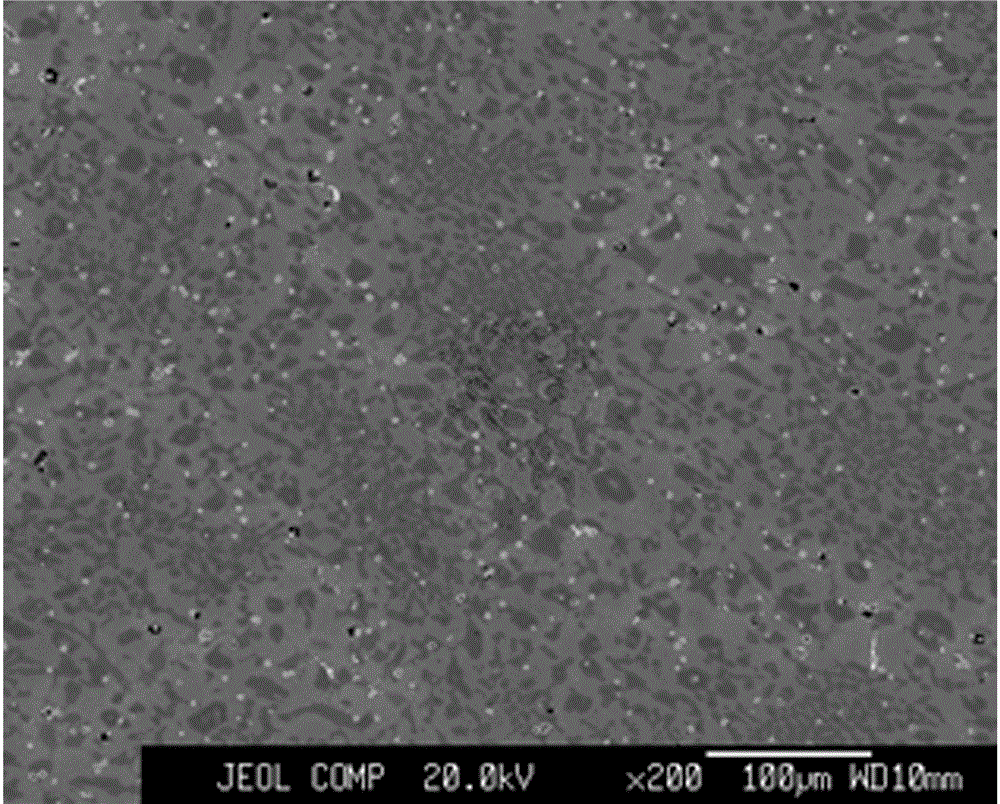

Hypereutectic high-chromium white cast iron and preparation method thereof

ActiveCN104060157AUniform compositionVarious ingredientsProcess efficiency improvementIntermediate frequencyFerrosilicon

The invention relates to a hypereutectic high-chromium white cast iron, which comprises the following components by mass percentage: 3.2-4.5% of C, 25-30% of Cr, 0.4-1.0% of Si, 0.4-1.0% of Mn, 1.5-3.0% of Ti, 3.5-5.0% of W, less than or equal to 0.04% of P and S, 0.02-0.05% of Al, 0.1-0.3% of Y, and the balance of Fe. A preparation method of the hypereutectic high-chromium white cast iron comprises the following steps: adding waste iron, pig iron and high carbon ferro-chrome in an intermediate frequency induction furnace with a vacuum system for melting, pre-deoxidizing ferrosilicon and ferromanganese, deoxidizing by using aluminium wire; adding ferrotungsten and ferrotitanium, vacuumizing, placing yttrium at bottom of ladle, dumping molten iron in the ladle, removing slag; when temperature of molten iron is reduced, pouring sand mold to obtain the hypereutectic high-chromium white cast iron; quenching, tempering, and discharging and cooling. The hardness HRC of the hypereutectic high-chromium white cast iron is 64-68, and the impact toughness is greater than 7J / CM<2>.

Owner:GUANGDONG INST OF NEW MATERIALS

Three-stage pressure-reducing preservation method for long-term storage of perishable fruits and vegetable

InactiveCN1672529AImprove cold damage resistanceImprove storabilityFruit and vegetables preservationFlavorThree stage

The present invention is three-stage pressure-reducing preservation method for long term storage of perishable fruits and vegetable, and belongs to the field of fruits and vegetable preserving technology. The three-stage pressure-reducing preservation method includes: 1) the first fruits and vegetable storing stage of 5-10 days at high vacuum of 5-20 KPa pressure to control water losing rate of 2-3.5 %; 2) the middle stage of 10-30 days in intermediate vacuum of 20-60 KPa pressure to control water losing rate of 1-2 %; and 3) final stage of 10-30 days at low vacuum of 60-100 KPa under humidity of 93-98 % without further water loss, to maintain the fresh state, flavor and post-mature performance. The present invention has long storage term of perishable fruits and vegetable.

Owner:JIANGNAN UNIV

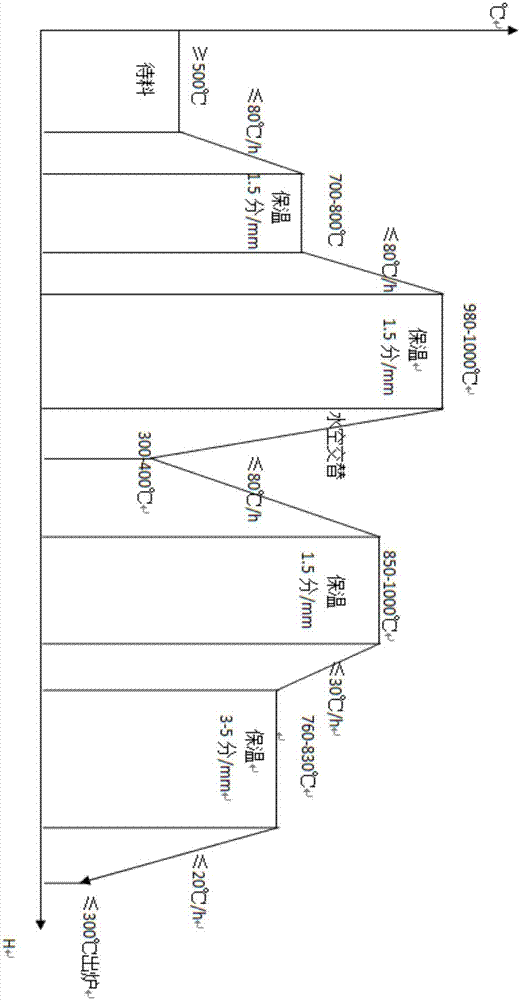

Heat treatment process for improving spheroidized structure of large-sized die flat steel forged material

ActiveCN107058717AImprove the level ofImprove uniformityFurnace typesHeat treatment furnacesCarbidePearlite

The invention discloses a heat treatment process for improving the spheroidized structure of a large-sized die flat steel forged material. The purpose is to improve the spheroidized microstructure of the forged material. The process combination of post-forging red sending annealing material waiting+superfine treatment+isothermal spheroidizing annealing treatment is designed. Precipitation of secondary net carbide can be reduced through post-forging red sending annealing material waiting, and preparation is made for subsequent superfine treatment and isothermal spheroidizing annealing. During superfine treatment, normalizing heating adopts one time of preheating, complete burning of steel is ensured, inner and outer temperatures are uniform, normalizing cooling adopts water and air alternate cooling, cooling intensity is improved, thus coarse grains produced by high-temperature forging are refined, the net carbide structure is eliminated, and then small and uniform globular pearlites and a few of dispersively distributed granular carbide are obtained through isothermal spheroidizing annealing. The heat treatment process has the following beneficial effects that with the adoption of the treatment process, the coarse structure of the steel is eliminated, structure uniformity is improved, the carbide level is improved, and the microstructure reaches the AS1-AS4 level.

Owner:FUSHUN SPECIAL STEEL SHARES

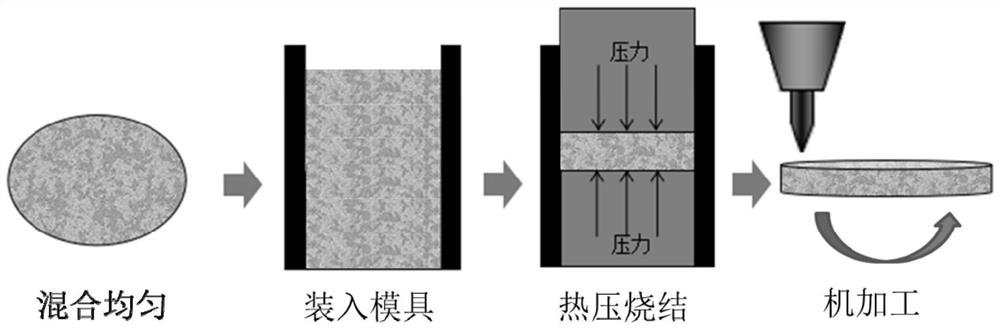

Preparation method of tantalum-silicon alloy sputtering target material

InactiveCN112030120AHigh densityUniform structureVacuum evaporation coatingSputtering coatingSilicon alloyTantalum

The invention relates to a preparation method of a tantalum-silicon alloy sputtering target material. The preparation method comprises the following steps of (1) uniformly mixing tantalum powder and silicon powder; (2) loading into a mold and sealing; (3) carrying out hot pressed sintering treatment on the sealed mold at 1130-1170 DEG C so as to obtain a tantalum-silicon alloy sputtering target crude product; and (4) machining to obtain the tantalum-silicon alloy sputtering target material. According to the preparation method, the tantalum-silicon alloy sputtering target material with the purity and density meeting the requirements can be prepared, the density reaches 99 percent or above, energy consumption and cost can be reduced, and the preparation method is suitable for large-scale popularization.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

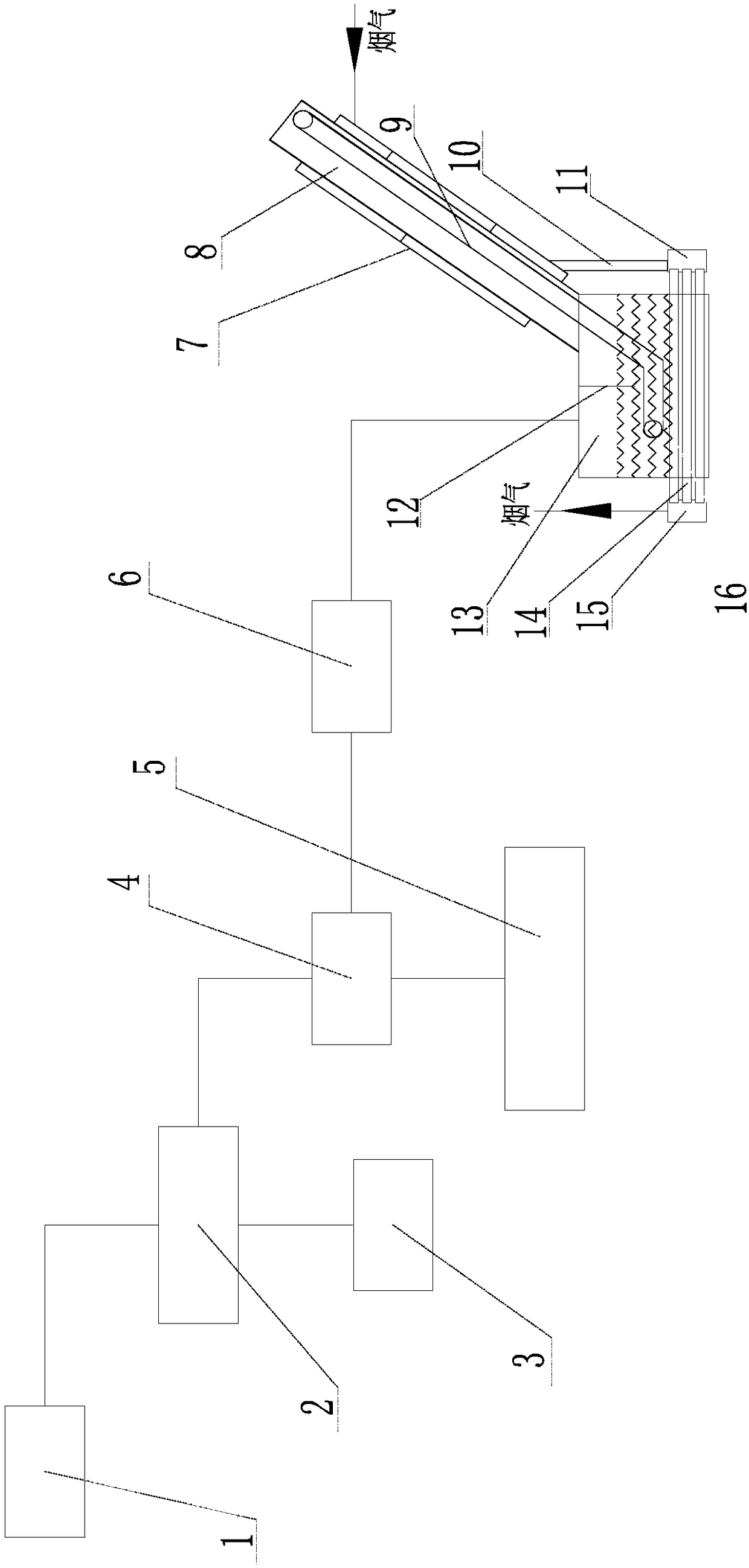

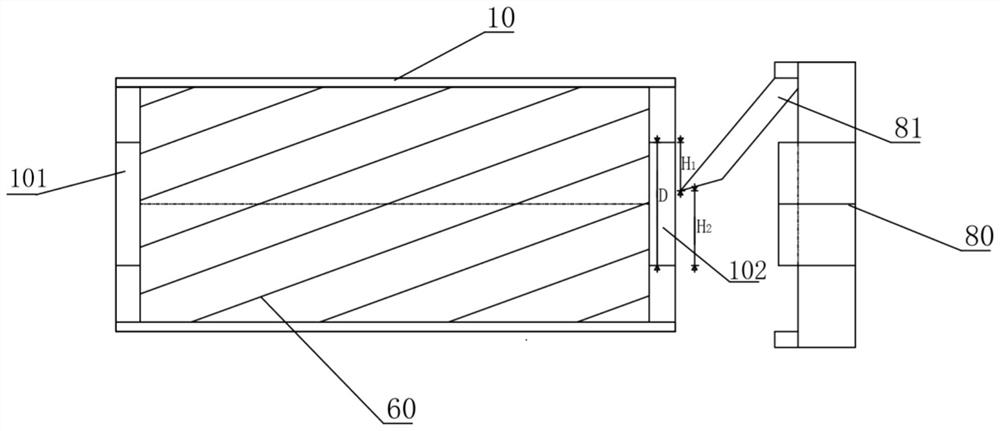

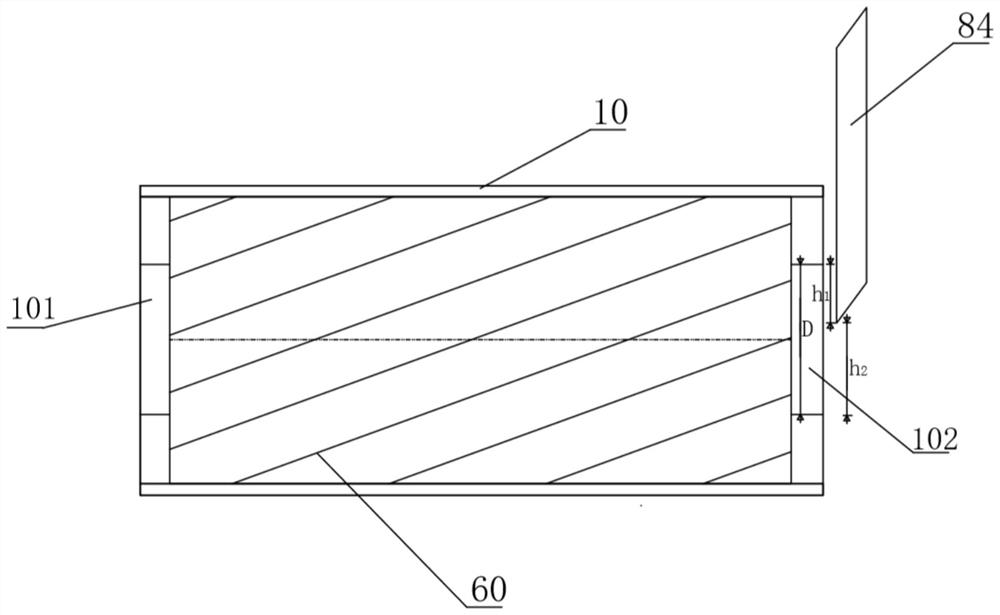

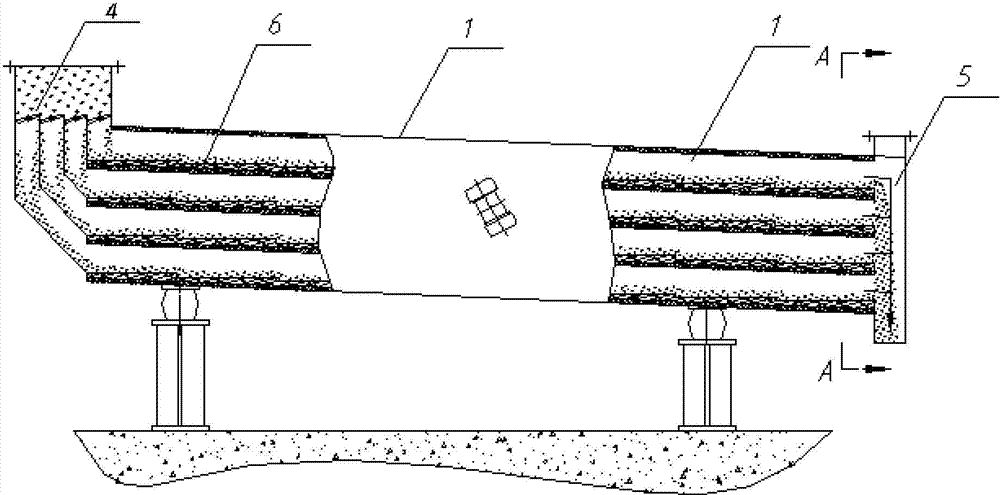

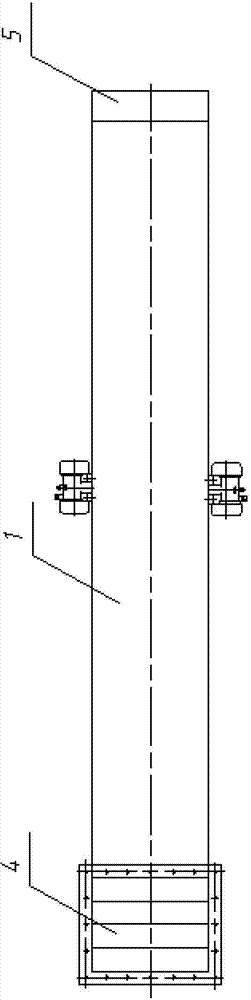

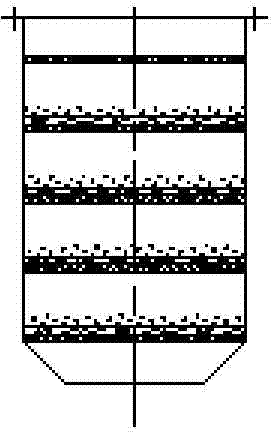

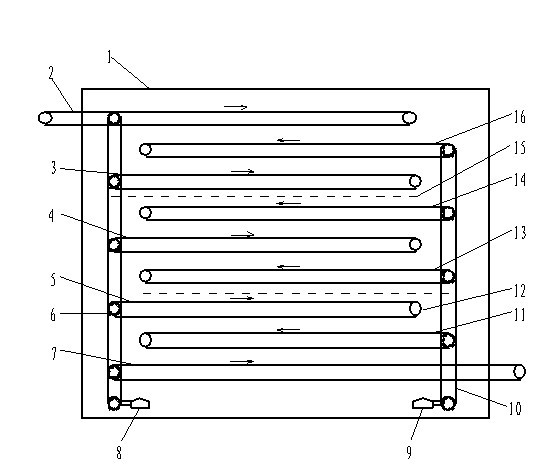

Double heat type vibration laminar-flow grain dryer

ActiveCN102894078AIncrease contact timeFully switchFood processingSeed preservation by dryingHot air ovenEngineering

The invention relates to a double heat type vibration laminar-flow grain dryer. Currently, a vertical grain drying tower is commonly used for grain drying in the world. The heat source of the vertical grain drying tower generally is coal, fuel oil, burning rice husks or straws; a burning material combusts in a hot-blast stove and generates hot wind which is introduced into grain piles to dry grains; and such a drying manner has considerable disadvantages. The double heat type vibration laminar-flow grain dryer provided by the invention comprises a box (1) equipped with a damping device; the box is provided with an air inlet (2), an air outlet (3), a feed inlet (4) and a discharge outlet (5), a vibrating material bed (6) is arranged in the box, a material chamber is arranged above the vibrating material bed, and the feed inlet and the discharge outlet are communicated with the material chamber. The double heat type vibration laminar-flow grain dryer is used as a grain dryer or a rice airing machine.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

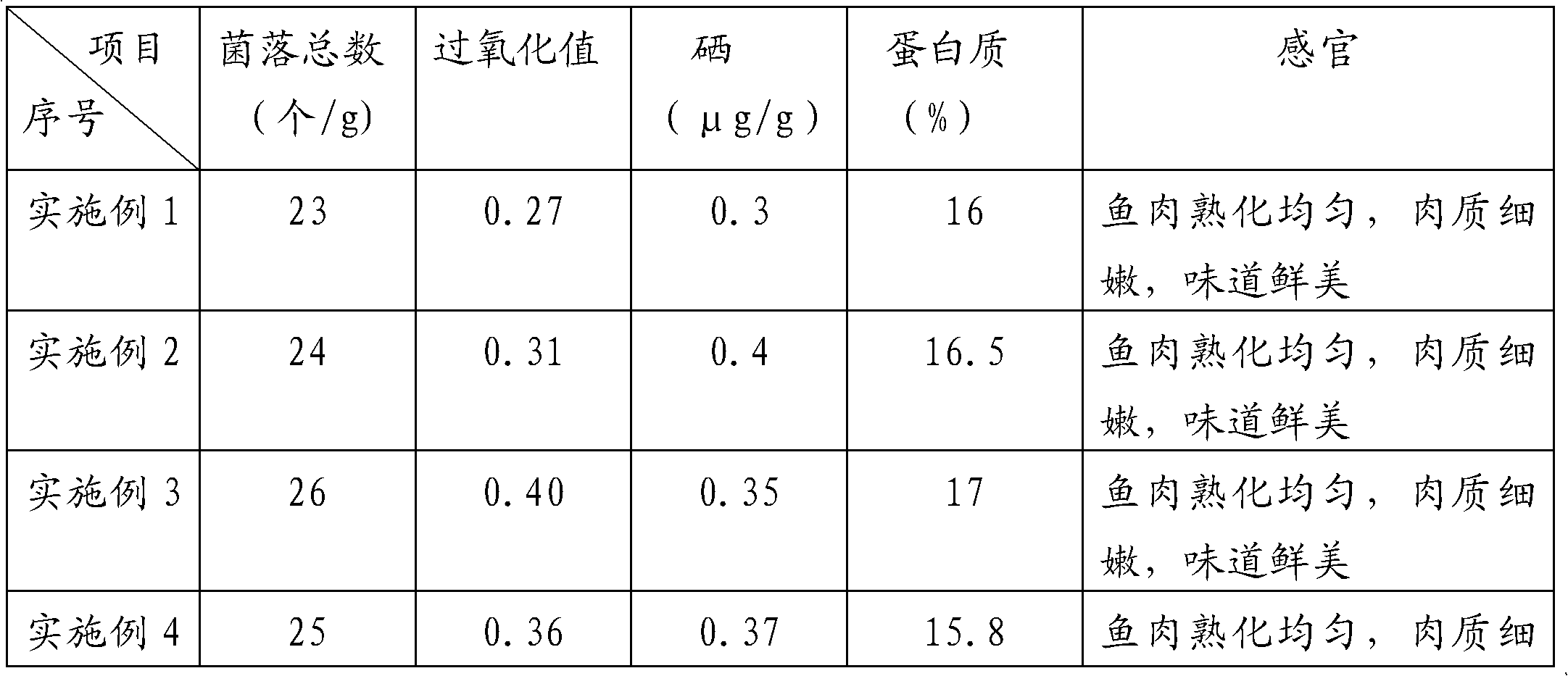

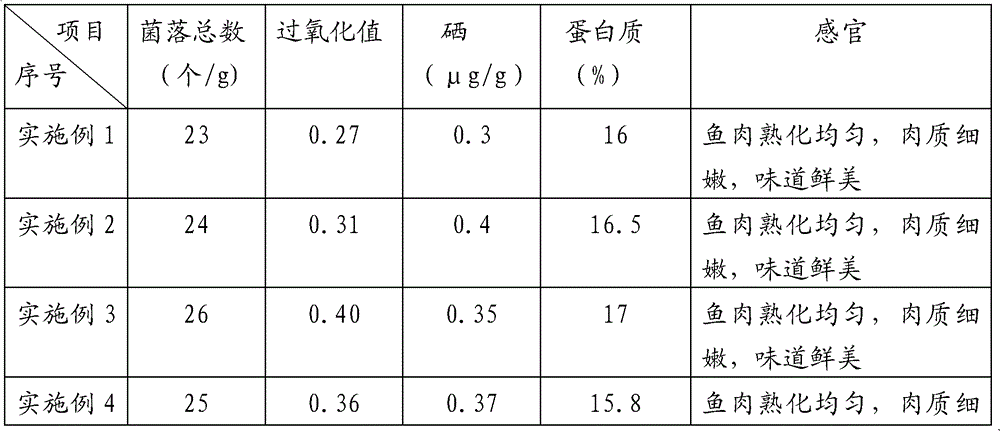

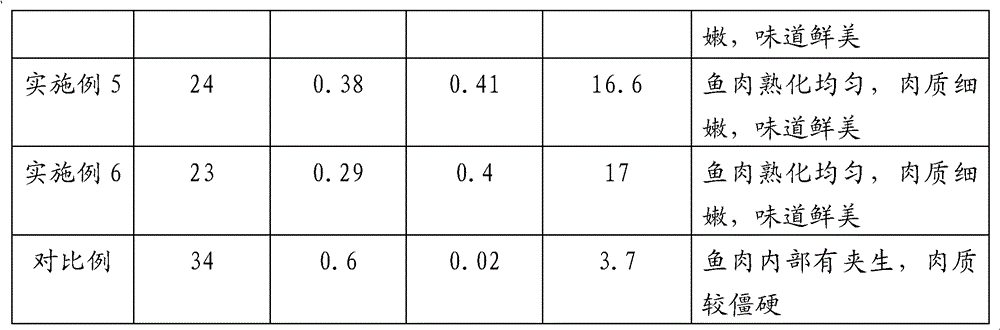

A processing technology of microwave heat penetration of large yellow croaker

InactiveCN102273655ALow microwave powerUniform microwave densityFood preparationFleshProduct processing

The invention discloses a processing technology for the microwave heat penetration of pseudosciaena crocea richardson, and belongs to the field of the processing of marine products. The technology comprises the following steps of: injecting seasoning liquid into preprocessed pseudosciaena crocea richardson, preheating the pseudosciaena crocea richardson by using microwaves of 2,450 MHz, performing microwave curing on the preheated pseudosciaena crocea richardson, sealing, freezing and storing. In the technology, the pseudosciaena crocea richardson is subjected to microwave heat penetration stage by stage, namely the processed pseudosciaena crocea richardson is subjected to first microwave preheating and second microwave curing, the two-time penetration time of fish flesh does not exceed 25 minutes, and the curing time of the fish flesh is shortened greatly compared with the conventional cooking time (about 70 minutes), so that the nutritional ingredients of the pseudosciaena crocea richardson are kept effectively, the phenomenon of burnt or half-cooked fish flesh is avoided, and the technical problems of continuous processing of processed goods of the pseudosciaena crocea richardson and the like are solved.

Owner:福建福鼎海鸥水产食品有限公司

Preparation method of reinforced mesh of glass grinding wheel for gasket

InactiveCN104764328AHigh hardnessImprove flatnessGlass making apparatusCharge supportsBoron oxideSilicon dioxide

The invention relates to a preparation method of a reinforced mesh of a glass grinding wheel for a gasket. The method reinforced mesh is formed by drawing, returning, warping and weaving a glass raw material formed by mixing SiO2 (Silicon Dioxide), Al2O3 (Aluminum Oxide), CaO (Calcium Oxide), MgO (Magnesium Oxide), B2O3 (Boron Oxide), K2O (Potassium Oxide), Na2O (Sodium Oxide) in an alkali-free tank furnace, and then processing a coating, weft-finishing, slicing, drying and resin curing. The preparation method has the advantages of simpleness and easy operation; furthermore, the reinforced mesh of the glass grinding wheel for the gasket has good rigidity and flatness, a slicing grinding wheel can be ensured to have good end face run-out, and the cost of the gasket can be greatly reduced because the cost is about 25% of a PTFE mesh; furthermore, the reinforced mesh is thin in thickness, uniform grinding holes can realize isolation and heat transfer, and the uniformity of the inner and outer temperature can be realized when the grinding wheel is sintered.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

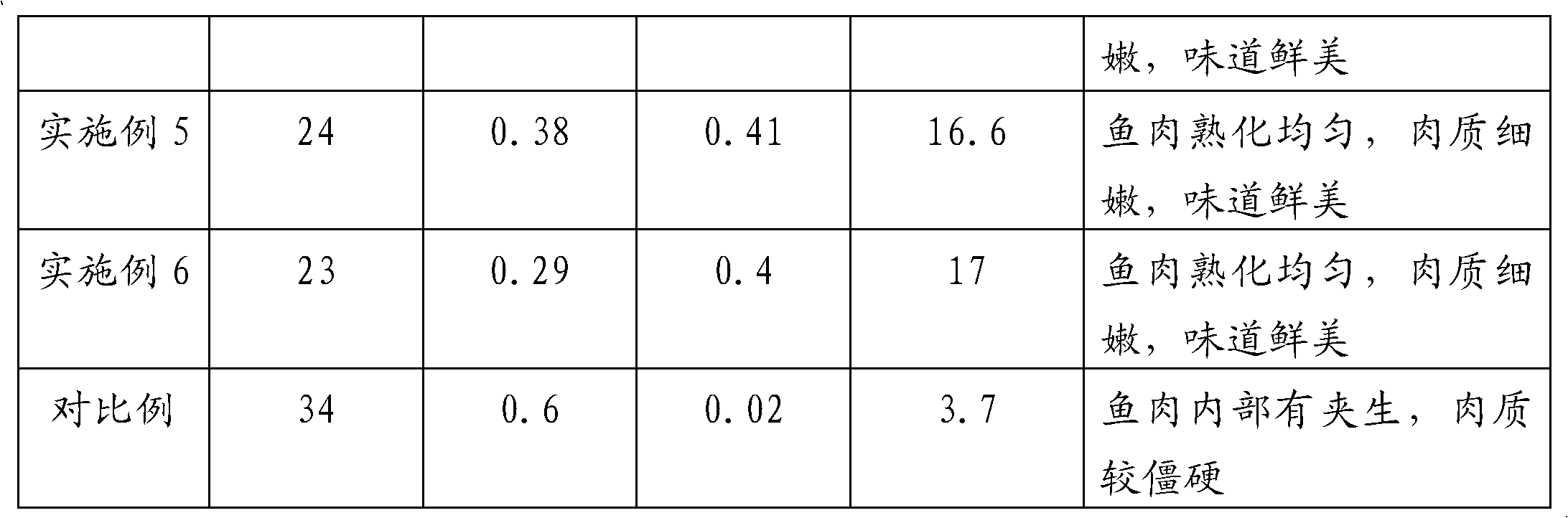

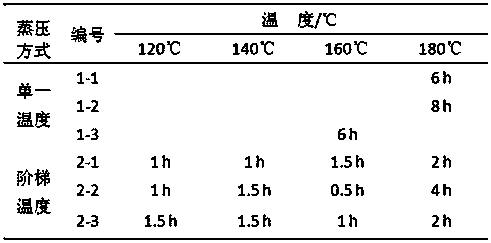

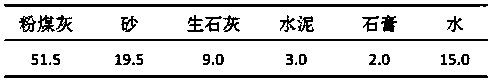

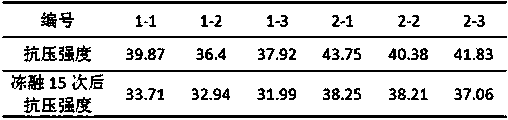

Coal ash baking-free brick stepped temperature autoclaved curing method

ActiveCN103737706AReduce cracking and falling cornersHigh strengthCeramic shaping apparatusSocial benefitsBrick

The invention provides a coal ash baking-free brick stepped temperature autoclaved curing method which solves the problems that an existing coal ash baking-free brick autoclaved curing method is overhigh in curing temperature, overlong in curing period and large in energy consumption, a baking-free brick is ripe outside and raw inside, low in strength and poor in freezing resistance, and the baking-free brick cracks and corners of the brick fall off. The method comprises four stages, the heat preservation temperatures of the four stages are 110-120 DEG C, 130-140 DEG C, 150-160 DEG C and 180-200 DEG C respectively, the time of the first three stages for heat preservation is 0.5-2 hours, and the time of the fourth stage is 2-6 hours. By means of the method, the internal temperature and the outside temperature of the coal ash baking-free brick are small, size changing is even, the cracking and corner-falling phenomena can not happen, the strength of the coal ash baking-free brick is improved, high-temperature autoclaved curing time is shortened, and energy consumption is lowered. The method can also be used for processing baking-free bricks, aerated concrete and the like made of other waste residues, the economic benefits and the social benefits are obvious, and the method has good application prospects.

Owner:ZHONGBEI UNIV

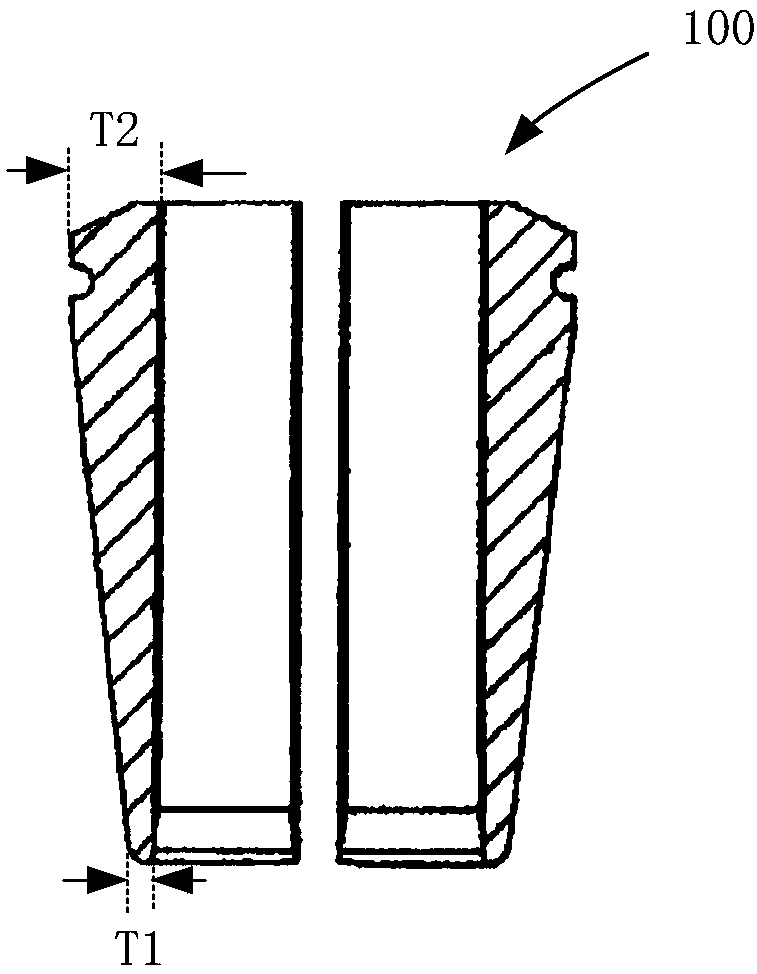

Carbonitriding method for thin-walled steel parts

ActiveCN108342680AEasy to organizeQuality assuranceSolid state diffusion coatingQuenchingThin walled

A carbonitriding method for thin-walled steel parts comprises the steps of carbonitriding, quenching and tempering. Specifically, as for the step of carbonitriding, adopted atmosphere includes propane, methyl alcohol and ammonia gas, the adopted carbonitriding carbon potential is 1.06+ / -0.03%, the adopted carbonitriding temperature is 870+ / -5 DEG C, and the adopted carbonitriding time is 300+ / -5 min. By means of the carbonitriding method for the thin-walled steel parts, the performance of the thin-walled steel parts can be improved, and the process cost is reduced.

Owner:厦门真冈热处理有限公司

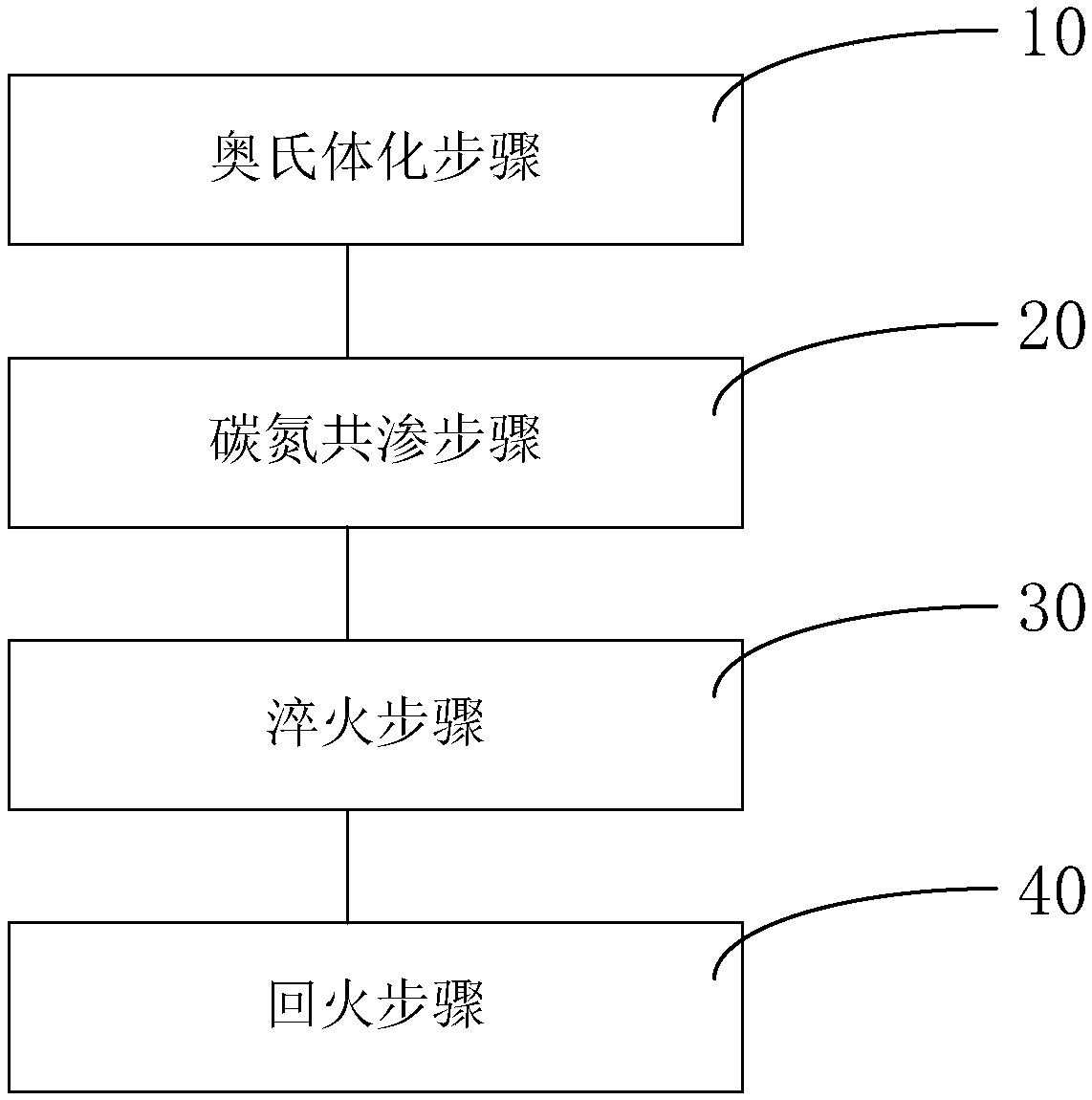

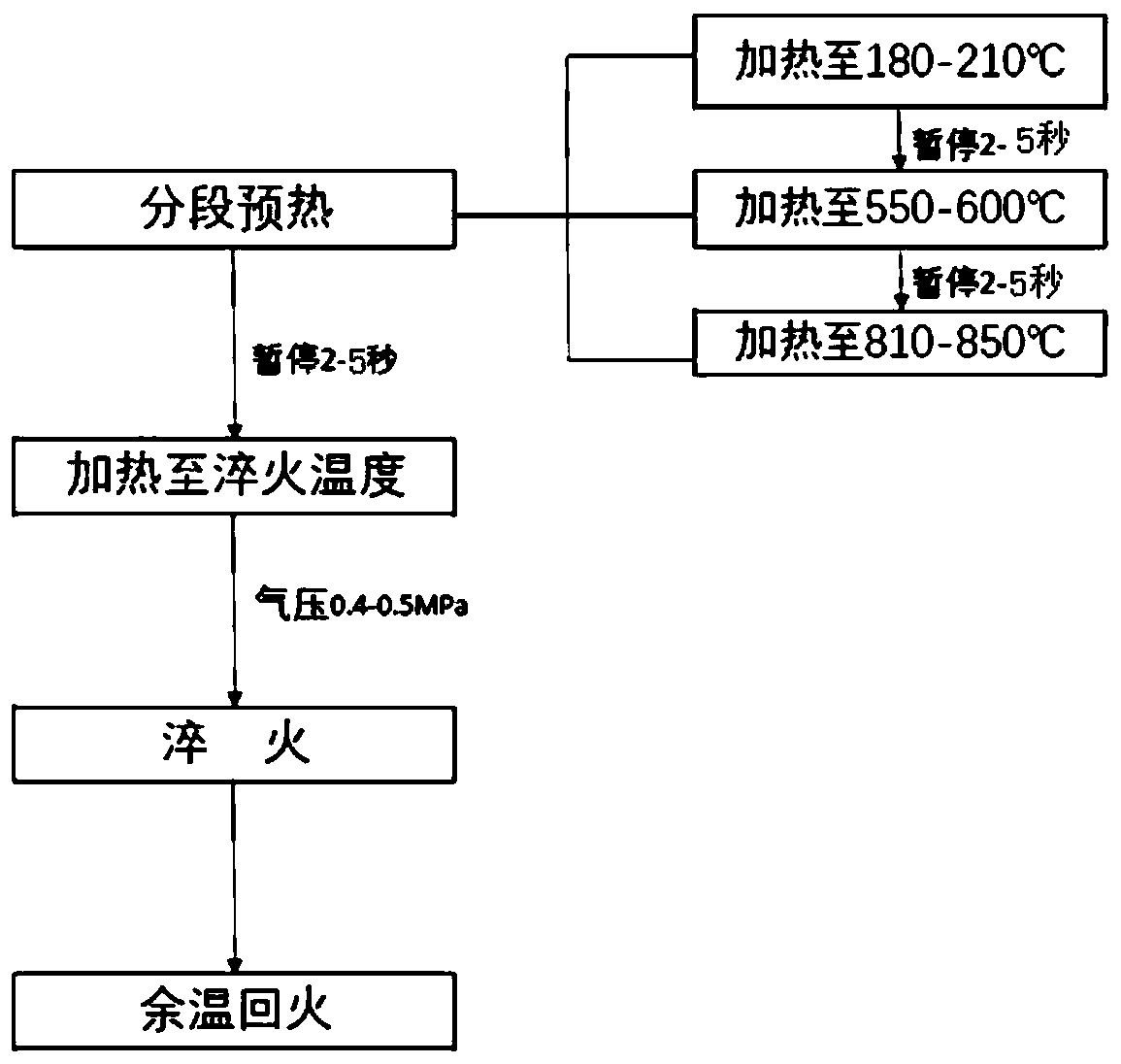

Induction quenching process for hardening alloy cast iron camshaft by using compressed air

InactiveCN110964898AEven temperature inside and outsideReduces the possibility of crackingFurnace typesIncreasing energy efficiencyPhysicsCast iron

The invention provides an induction quenching process for hardening an alloy cast iron camshaft by using compressed air, which comprises the following steps: S1, preheating is carried out: the camshaft is heated to 180-210 DEG C in an induction manner in a first stage, heating is suspended for 2-5 seconds, in a second stage, after the camshaft is inductively heated to 550-600 DEG C, heating is suspended for 2-5 seconds, and in a third stage, after the camshaft is inductively heated to 810-850 DEG C, heating is suspended for 2-5 seconds, wherein the heating rates of the three stages are all 40-50 DEG C / s; S2, heating to a quenching temperature is carried out: induction heating is carried out on the camshaft preheated in the step S1 to 900-940 DEG C at a heating rate of 40-50 DEG C / s; S3, quenching is conducted, specifically, compressed air with the pressure of 0.4-0.5 MPa is adopted as a quenching medium to quench the camshaft, and the camshaft is cooled to 250-300 DEG C; and S4, afterheat tempering is carried out. The alloy cast iron camshaft product quenched by using the process method disclosed by the invention does not crack in the quenching process, and the hardness index of the quenched alloy cast iron camshaft product can meet the technical requirements, so that the rejection rate of the product is reduced, and the production cost is greatly saved.

Owner:荆州环球汽车零部件制造有限公司

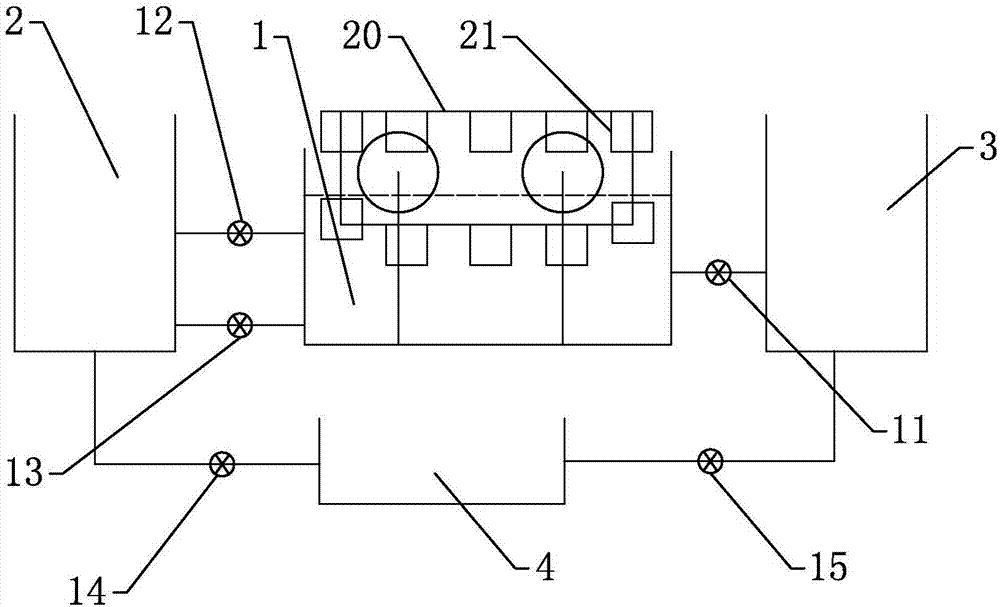

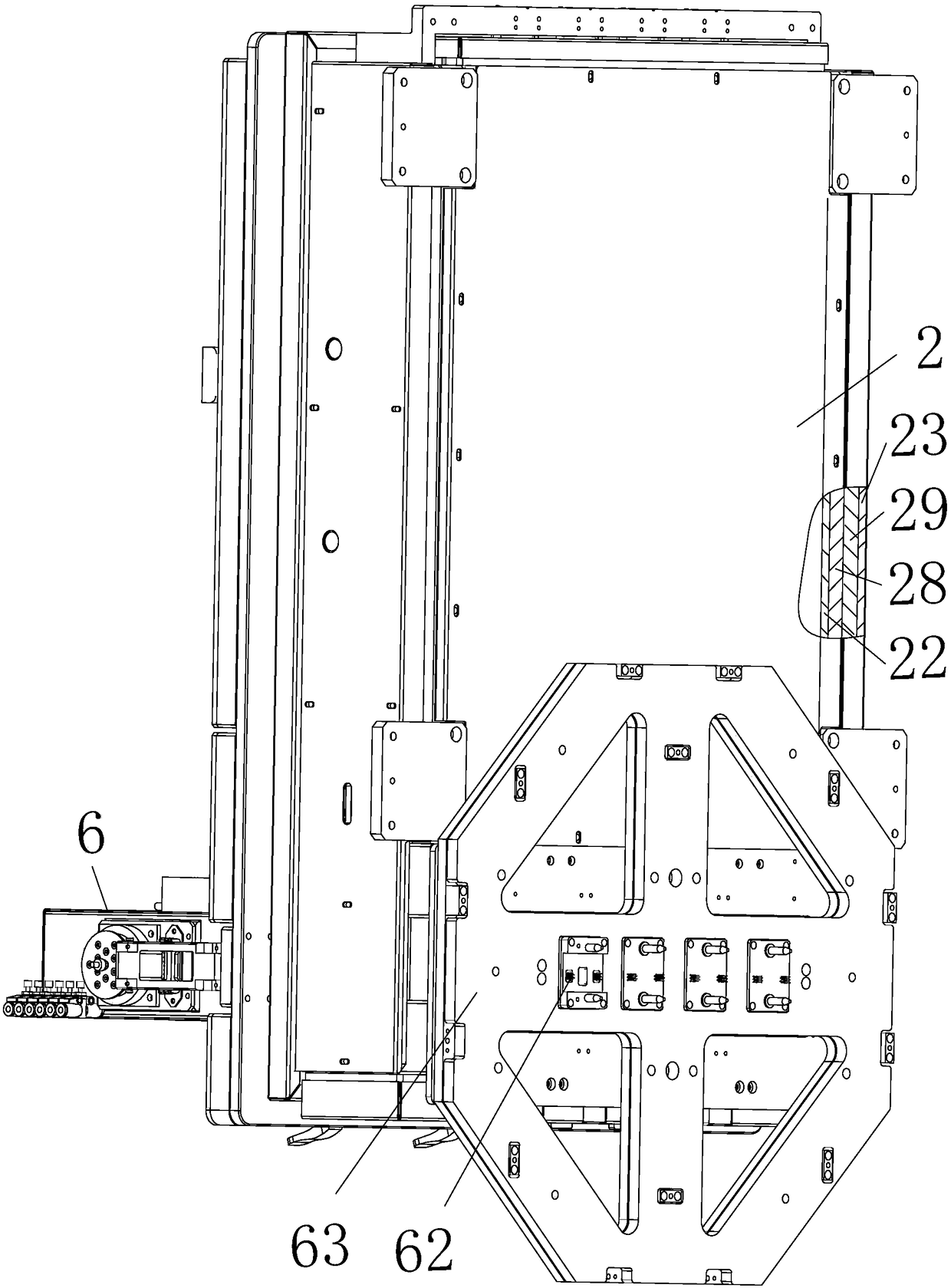

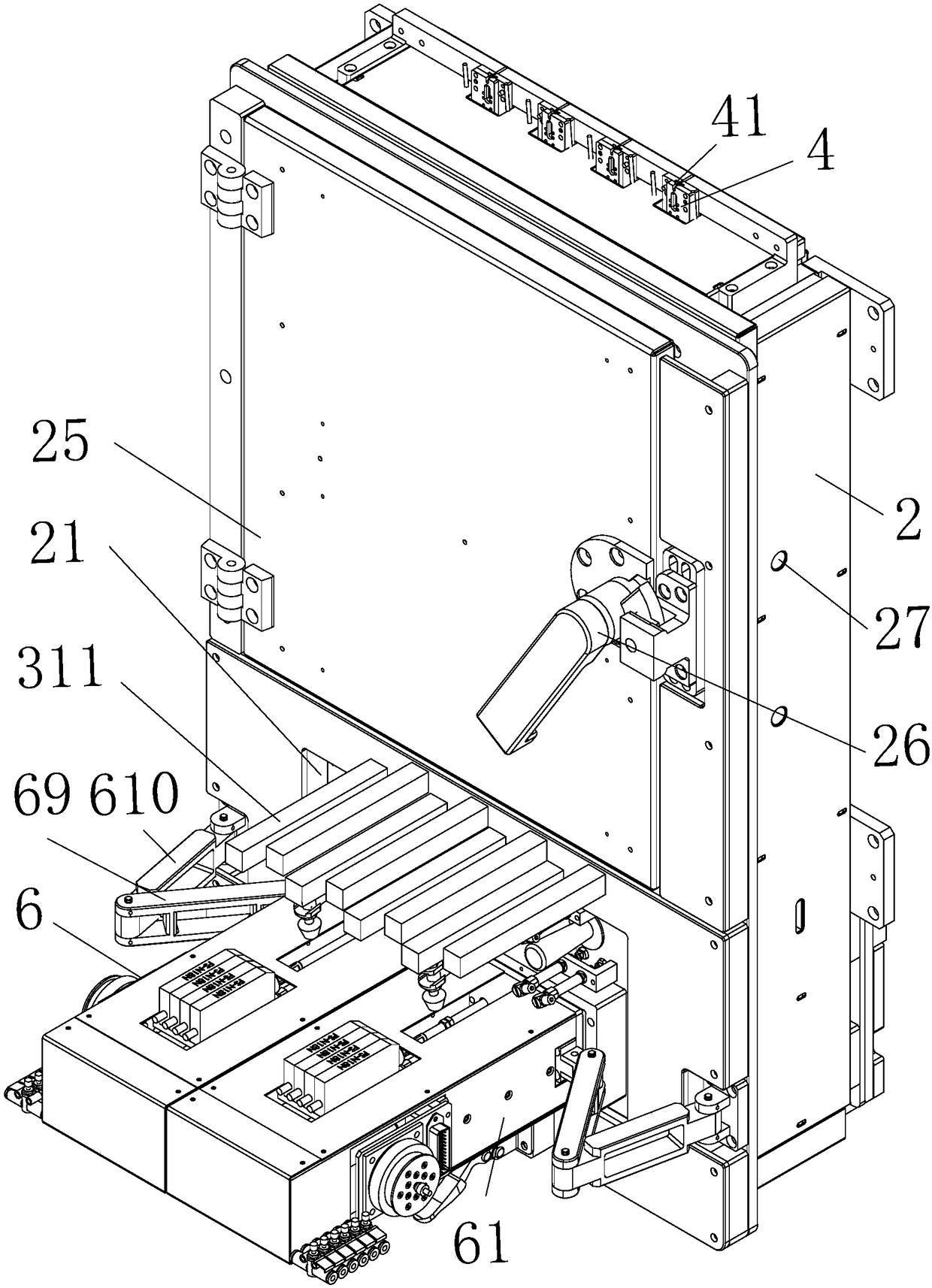

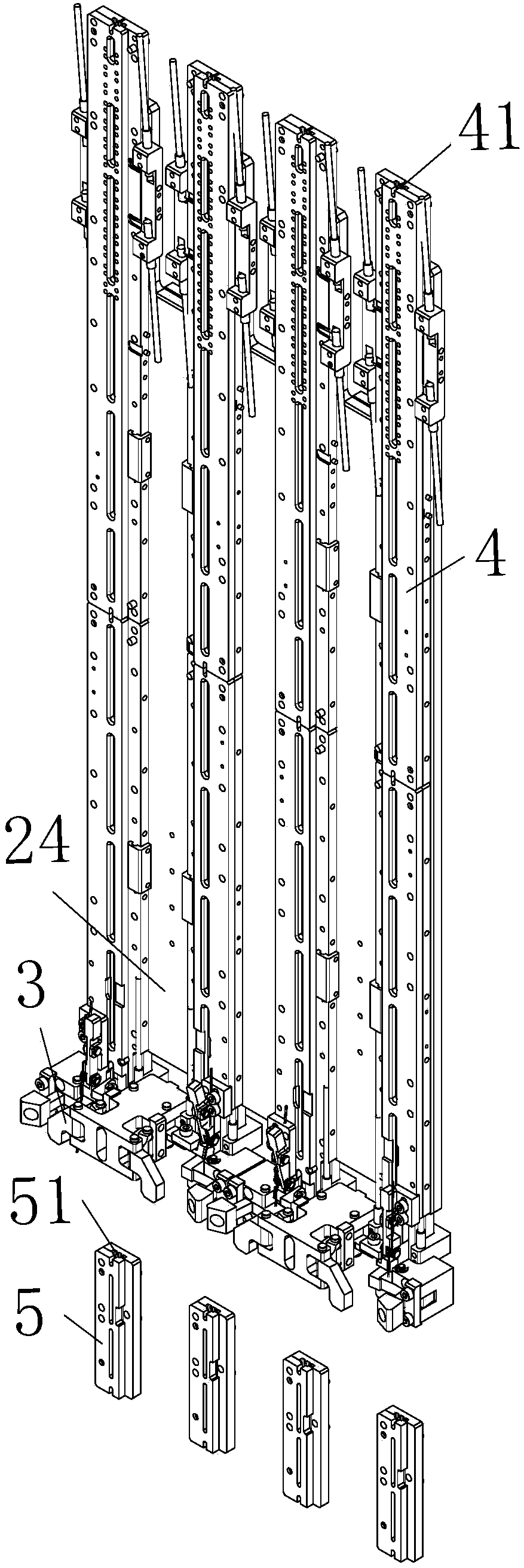

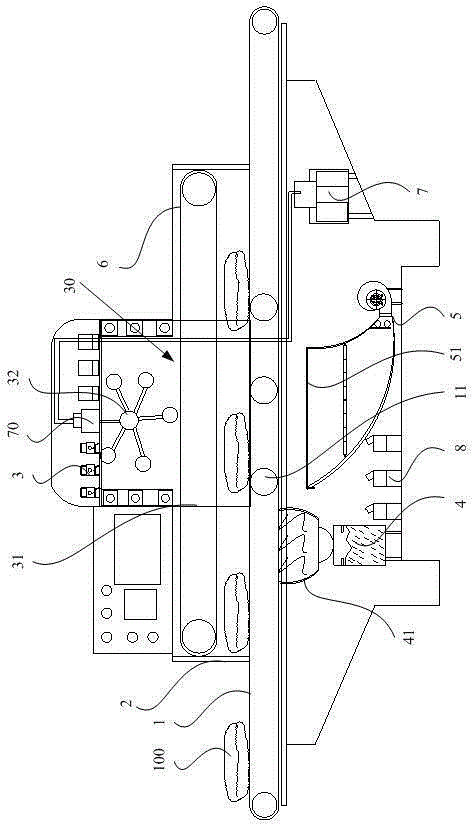

Heat preservation test device and heat preservation test method for high temperature automatic sorting machine

ActiveCN108311418AHigh temperature test accuracyEffective insulationSortingEngineeringInternal temperature

The invention provides a heat preservation test device and a heat preservation test method for a high temperature automatic sorting machine. The heat preservation test device for the high temperatureautomatic sorting machine comprises a heat preservation box body, multiple vertical upper rails, multiple vertical lower rails, a drawer hole, and a test feeding drawer, wherein the heat preservationbox body is provided with a heater, the vertical upper rails are arranged in the heat preservation box body, gradation mechanisms are arranged at the lower ends of the vertical upper rails, the numberof the vertical upper rails and the number of the vertical lower rails are the same, the vertical upper rails and the vertical lower rails are in one-to-one correspondence, and the drawer hole penetrates through the front end and the back end of the heat preservation box body. The test drawer includes a drawer body and a test end plate, wherein the drawer body is arranged in the drawer hole and is provided with test feeding mechanisms with the number being the same with the number of the vertical upper rails, the test end plate is provided with test connection heads which are in one-to-one correspondence with the test feeding mechanisms, and the test end plate is connected with the front end of the drawer body. The upper ends of the vertical upper rails stretch out of the upper end of theheat preservation box body. The lower ends of the vertical lower rails stretch out of the lower end of the heat preservation box body. The heat preservation test device for the high temperature automatic sorting machine can effectively keep the temperature for a heated integrated circuit, so that the internal temperature and the external temperature of the integrated circuit are uniform and precision of a high temperature test is relatively high.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

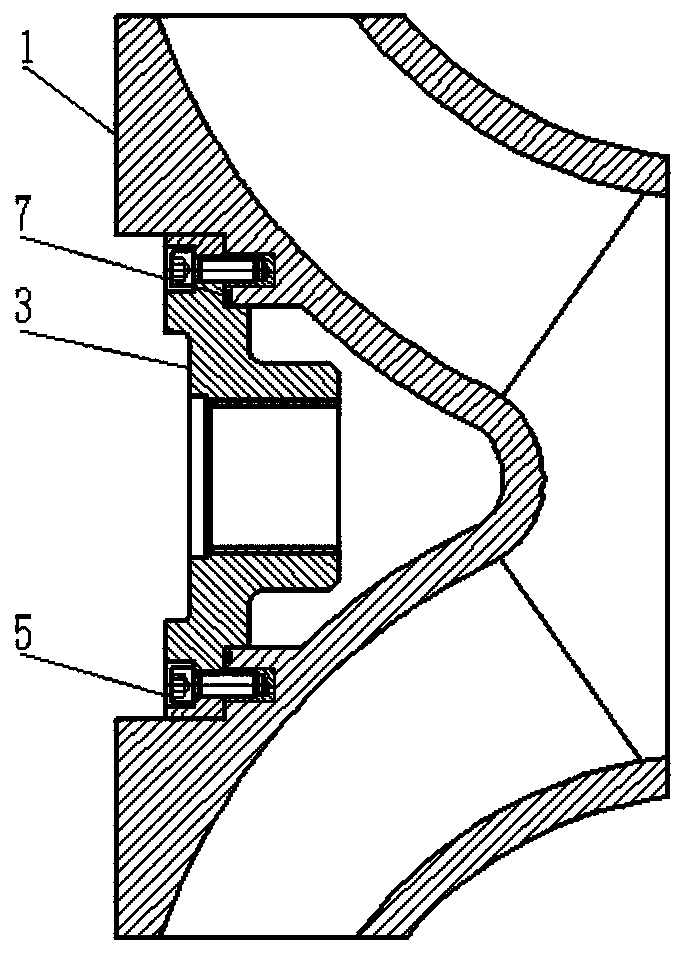

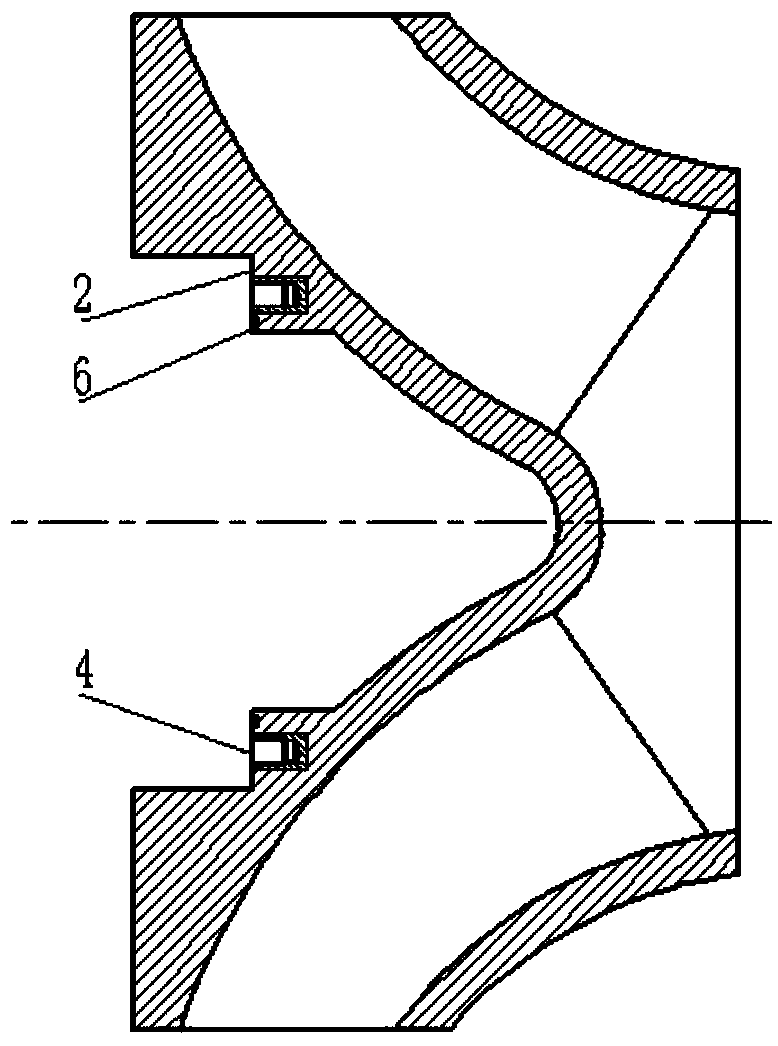

Efficient and wear-resisting double entry pump impeller and preparation method thereof

The invention relates to the technical field of double entry pumps, in particular to an efficient and wear-resisting double entry pump impeller and a preparation method thereof. A wear-resisting layercomprises, by weight, 20-40 parts of modified natural fibers, 40-60 parts of modified filler, 1-2 parts of a surfactant, 1.2-2 parts of a dispersing agent, 0.6-1.2 parts of nickel powder and 40-50 parts of polyvinylpyrrolidone. Thus, in the efficient and wear-resisting double entry pump impeller and the preparation method thereof, linear cellulose is wound around the peripheral sides of the natural fibers, the strength of the natural fibers can be improved through the winding manner, and the firmness of graphene on the outer portions of the fibers can be improved; meanwhile, one end of the cellulose can be inserted into a graphene flake layer, the adhesion amount of graphene matter on the fibers can be improved, and therefore the steadiness and reliability of the wear-resisting layer canbe enhanced; and slurry of the prepared wear-resisting layer is uniform and stable through the good mixing dispersity of the modified high-stability and high-reliability fibers.

Owner:SANLIAN PUMP IND CO LTD

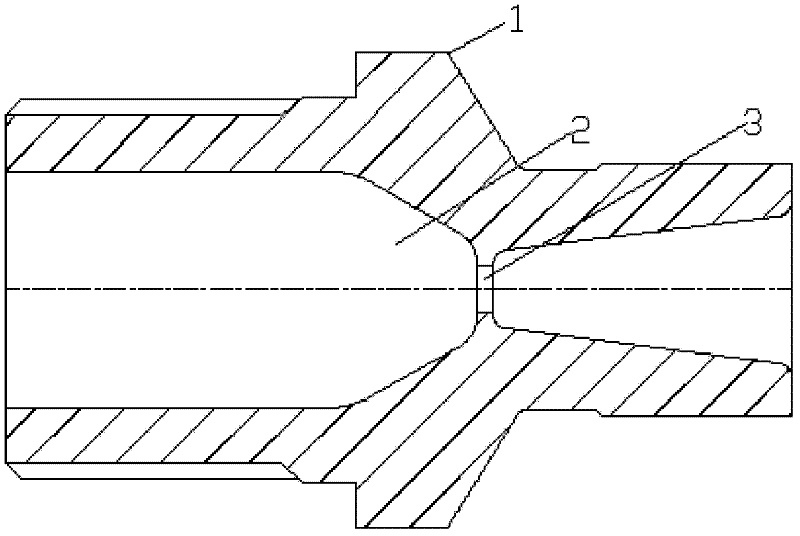

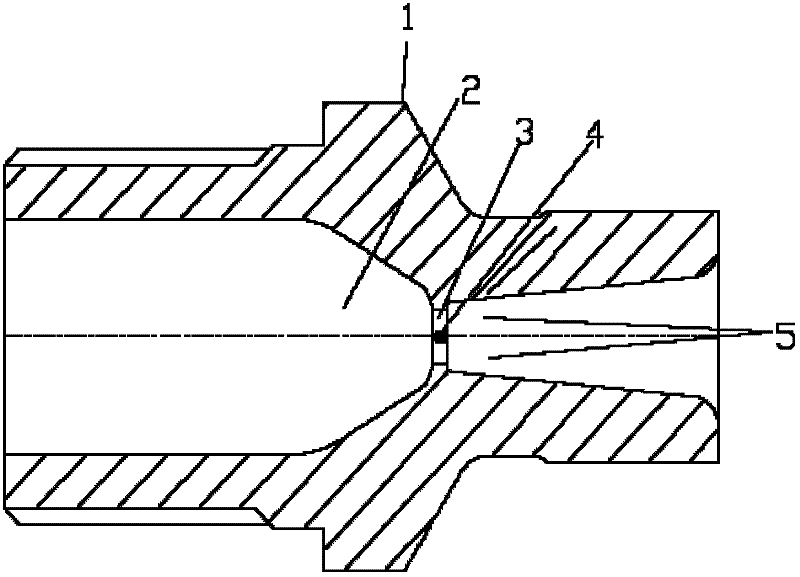

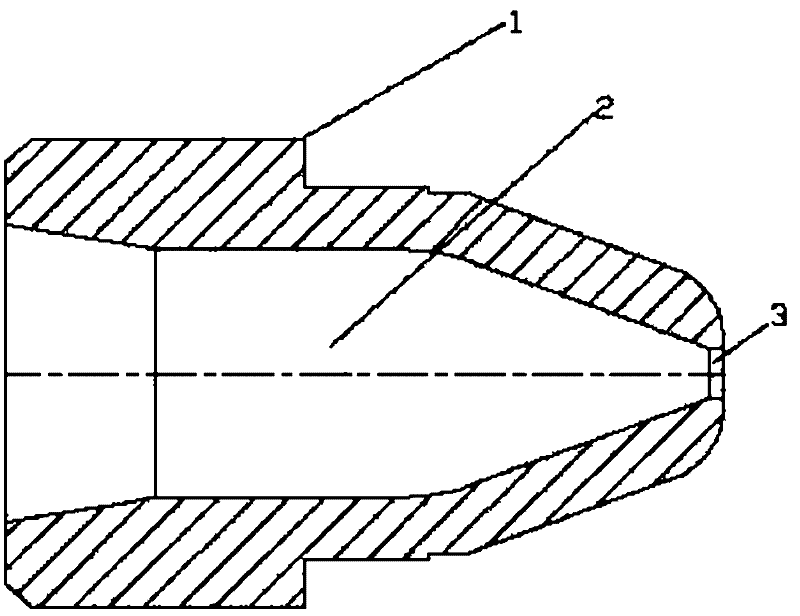

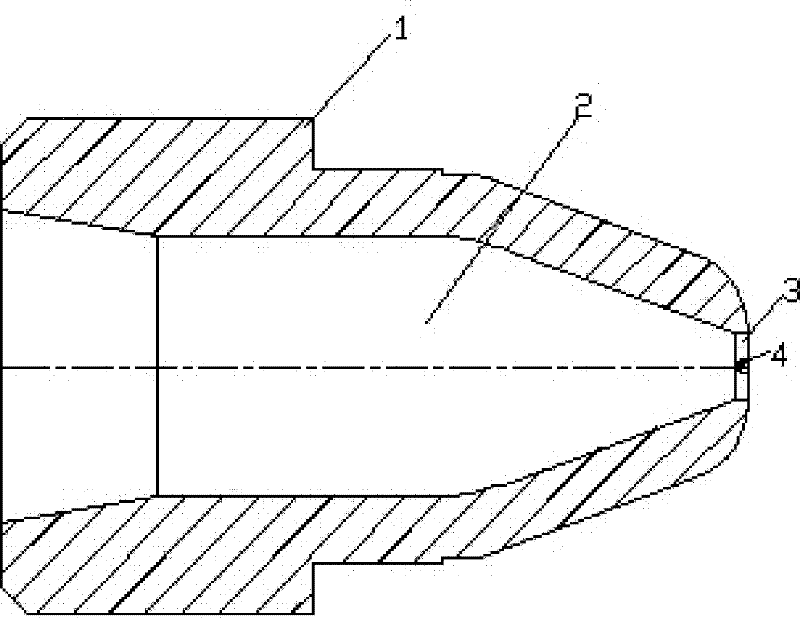

Hot nozzle core structure special for white pigment

The invention relates to a hot nozzle core structure special for a white pigment. The hot nozzle core structure comprises a nozzle core, a runner of the nozzle core and a pouring gate at an end part of the nozzle core, wherein the runner of the nozzle core is communicated with a runner of a hot nozzle body, and the pouring gate is used for discharging the pigment; and the pouring gate is provided with a grille, and the pouring gate is divided into a plurality of shunting ports by the grille. The scheme adopted by the invention is mainly used for solving the problem that the phenomena of wire drawing and drooling easily occur when the existing hot nozzle core special for the white pigment is used for extruding the pigment, and the qualified rate of products is increased.

Owner:SUZHOU HTS MOLD

Wood surface spraying process

InactiveCN108672240ALow water expansionAvoid easy water swelling damageRadiation/waves wood treatmentWood treatment detailsMaterial CrackAging resistance

The invention relates to the technical field of wood processing, in particular to a wood surface spraying process. According to the wood surface spraying process, wood materials can be subjected to spraying and air-drying treatment repeatedly. Through the wood surface spraying process, the water absorption expansion rate of the wood materials can be effectively reduced, after being manufactured into sketching easels, the wood materials can be effectively protected against water absorption, expansion and damage, and the ageing resistance of the wood materials is enhanced. The wood materials areput into preservative liquid, and the preservative effect of the wood materials is improved. Adhesive force of the preservative liquid to the wood materials is enhanced through ultrasonic treatment.The water content of the wood materials is reduced through hot air circulation drying. On one hand, the internal and external temperatures of the wood materials can be made uniform, and the phenomenonthat the surfaces of the wood materials crack and the interiors of the wood materials fracture due to sudden temperature rising is avoided; on the other hand, the water content of the wood materialscan be reduced, and robustness of the wood materials is improved. Finally, the wood materials are subjected to three-step freezing treatment, and the ageing resistance of the wood materials is improved.

Owner:天长市双丰文化用品有限公司

Microwave sterilizing and drying equipment and method

InactiveCN105169432AEven temperature inside and outsideComprehensive and effective sterilizationDrying gas arrangementsRadiationProcess engineeringAir heater

The invention provides microwave sterilizing and drying equipment and a microwave sterilizing and drying method. The microwave sterilizing and drying equipment comprises a belt conveyor, a conveying tunnel, a microwave generator, a hot steam generator and an air heater, wherein a conveying belt of the belt conveyor is provided with air vents and is arranged in the conveying tunnel in a penetrating manner; the microwave generator is arranged inside the conveying tunnel; a steam outlet of the hot steam generator is communicated with the conveying tunnel; an air outlet of the air heater is communicated with the conveying tunnel; and the steam outlet and the air outlet are sequentially distributed in the conveying direction of the belt conveyor. A sterilizing effect and a drying effect are optimized by virtue of the microwave sterilizing and drying equipment, and the drying efficiency is improved.

Owner:山东科朗特微波设备有限公司

A high-efficiency wear-resistant double-suction pump impeller and its preparation method

The present invention relates to the technical field of double-suction pumps, in particular to a high-efficiency wear-resistant double-suction pump impeller and a preparation method thereof. The wear-resistant layer comprises the following components in parts by weight: modified natural fiber 20-40 40-60 parts of modified filler, 1-2 parts of surfactant, 1.2-2 parts of dispersant, 0.6-1.2 parts of nickel powder, 40-50 parts of polyvinylpyrrolidone, so, in this application, it is in the line Shaped cellulose is wound on the outer peripheral side of the natural fiber. The winding method can improve the strength of the natural fiber and the firmness of the graphene outside the fiber. The adhesion of the substance on the fiber can enhance the stability and reliability of the modified wear-resistant layer. This application uses the modified fiber with high stability and reliability and good dispersion to make the preparation of the wear-resistant layer slurry uniform. Stablize.

Owner:SANLIAN PUMP IND CO LTD

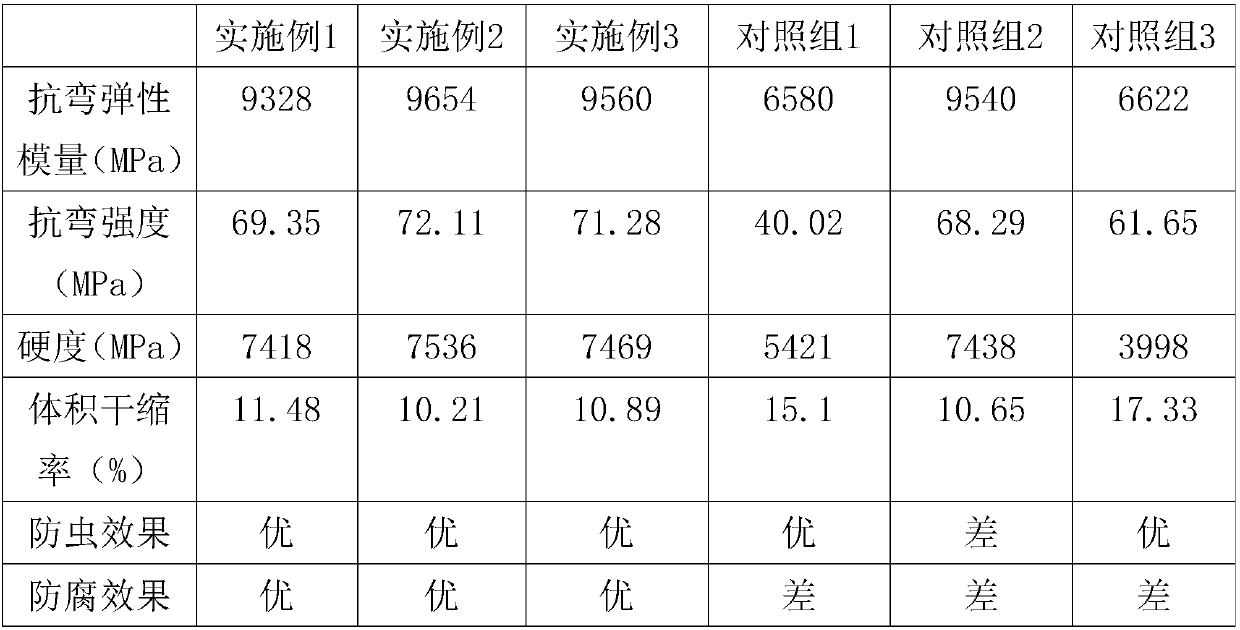

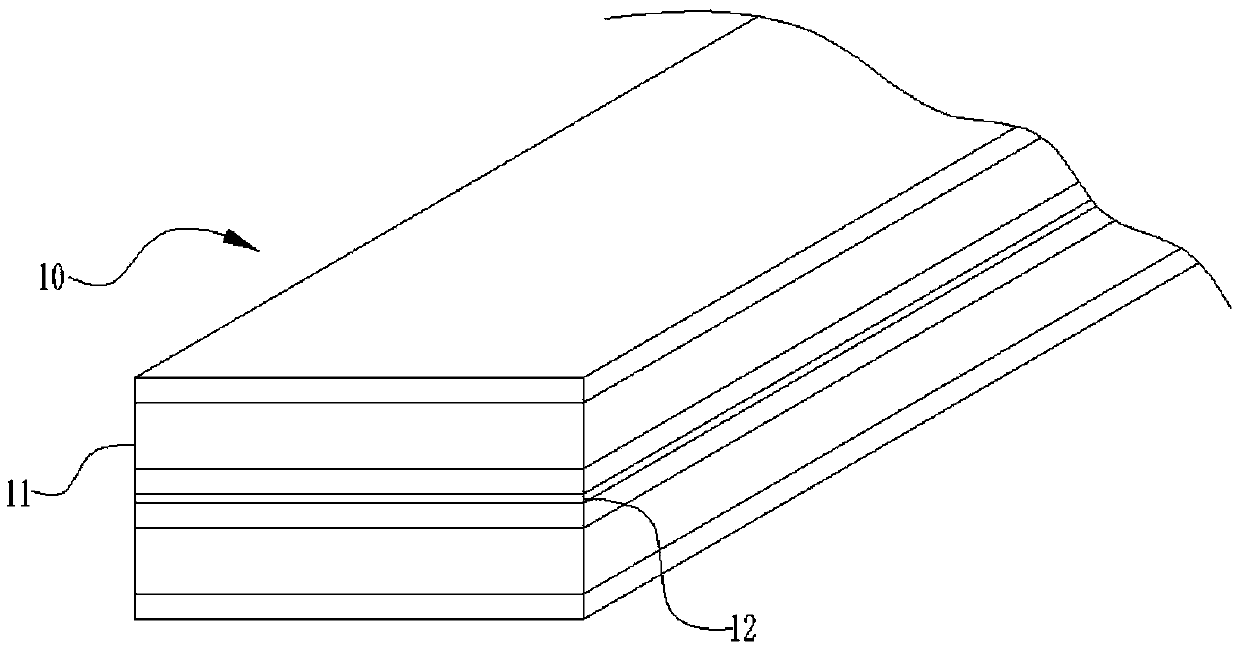

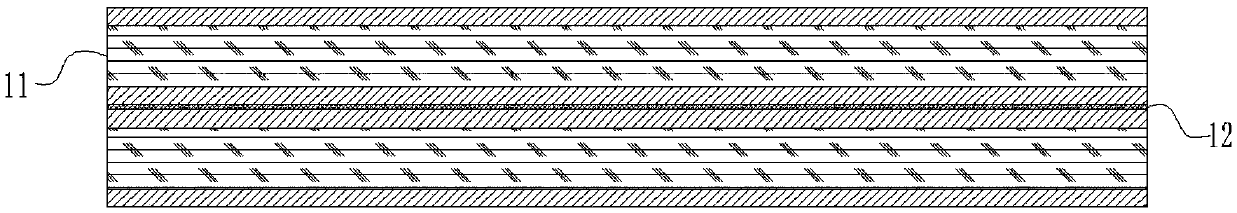

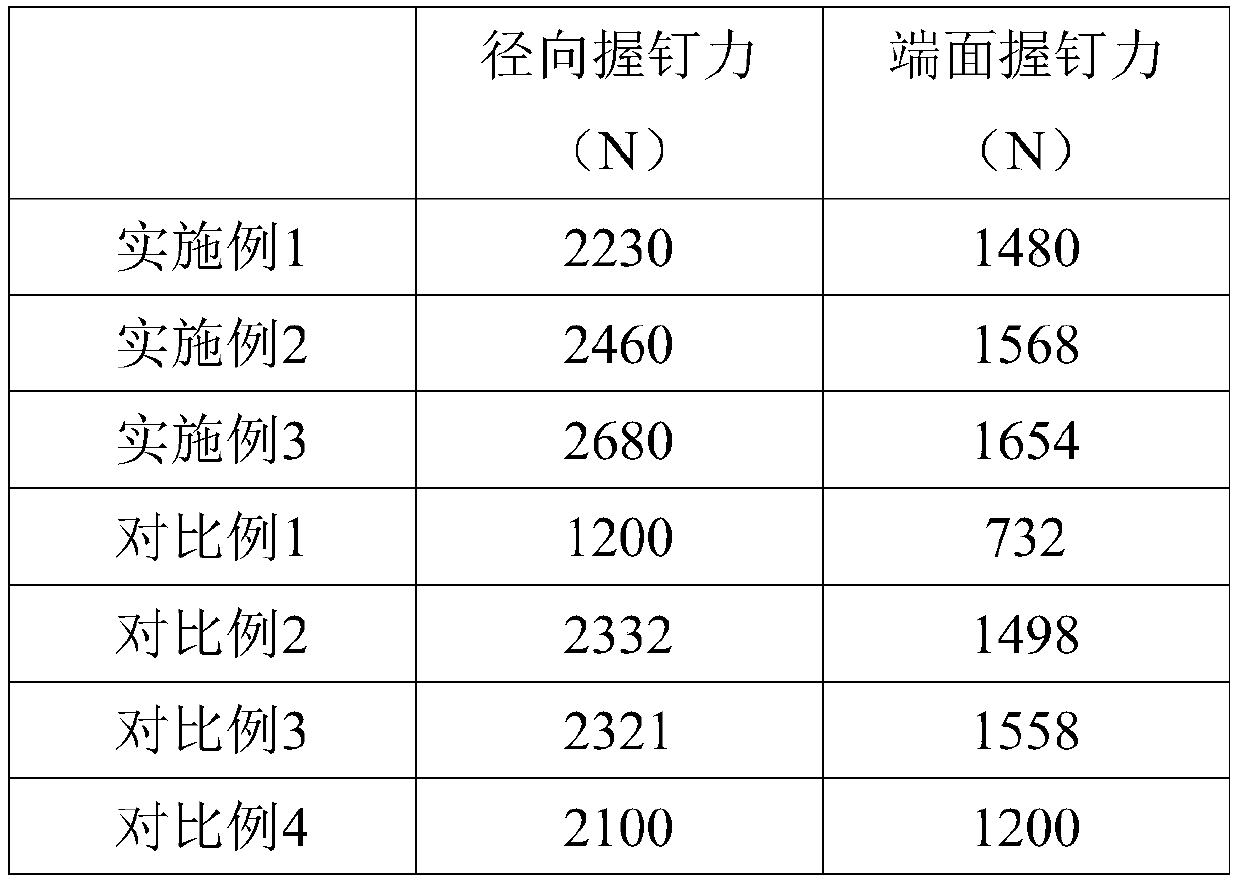

Multi-layer composite board

ActiveCN109591410AImprove nail holding powerFirmly connectedSynthetic resin layered productsWood treatment detailsMultiple layer

The invention relates to the technical field of PVC crust foaming boards, and particularly relates to a multi-layer composite board. The multi-layer composite board at least comprises two PVC crust foaming boards and an adhesive layer, wherein the adhesive layer is formed between the two PVC crus foaming boards, and the PVC crust foaming boards are adhered due to the adhesive effect of the adhesive layer to form the multi-layer composite board. Therefore, compared with the single PVC foaming board, the multi-layer composite board has flame-proofing, sound isolation, damping and other performance of the PVC foaming board, the connection performing of the multi-layer composite board serving as a connector is reinforced, the adhesive layer among multiple layers of PVC foaming boards can achieve the adhesion effect, the formed adhesion layer has certain elasticity, an opposite acting force for extruding a bolt can be generated at the joint between the adhesion layer and the bolt, and the nail-holding power of the multi-layer composite board can be further improved.

Owner:ANHUI SENTAI WPC GRP CO LTD

Pretreatment process and device for industrial continuous waste tire cracking production

PendingCN108085045AWarm up evenlyGuaranteed sealing performanceProductsReagentsProcess engineeringTemperature difference

The invention belongs to the technical field of waste cracking, and particularly relates to a pretreatment process and device for industrial continuous waste tire cracking production. The process canrealize the whole tire automatic feeding of waste tires; during the feeding, the whole tire cleaning, preheating and drying can be realized; the device consists of an impurity removal device, a cleaning device, a water sealing feeding device, a drying device and the like; impurities can be prevented from entering the subsequent cracking process along with the whole tire; meanwhile, the sealing ofthe feeding device is realized; the better connection with the cracking device can be realized; the weight of the sealing structure is reduced; meanwhile, the preheated whole tire enters the crackingprocess, so that the temperature difference can be reduced; the cracking efficiency is improved.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

Hot processing technology for automobile hub

InactiveCN105936971AReduce internal stressImprove toughnessFireproof paintsFurnace typesSolution treatmentFree cooling

The invention relates to a hot processing technology for an automobile hub. The hot processing technology comprises the following steps that firstly, the formed hub is fed into a solid solution furnace to be heated to 450-550 DEG C in 35-45 minutes, and the temperature is kept for 90-135 minutes; secondly, the hub obtained through solution treatment in the first step is immersed into a 65-75 DEG C cooling medium to be quenched for 180-240 seconds; thirdly, the quenched hub is subjected to first-stage aging treatment and second-stage aging treatment sequentially, the temperature of first-stage aging treatment is 120-125 DEG C, the time of first-stage aging treatment is 75-90 minutes, the temperature of second-stage aging treatment is 175-185 DEG C, and the time of second-stage aging treatment is 120-135 minutes; and fourthly, the hub obtained through aging treatment in the third step is taken out to be subjected to natural cooling. According to the hot processing technology, inner stress of the hub can be reduced effectively, and the hardness, toughness, tensile strength, compressive strength and other properties are improved.

Owner:SANMEN VOCATIONAL SECONDARY SPECIALIZED SCHOOL

Aluminum profile extrusion forming device

PendingCN113134520AUniform strengthNo need to consider consumptionExtrusion diesEngineeringMachining

The invention discloses an aluminum profile extrusion forming device which comprises a machining platform. An extrusion generation cavity with a rightward opening is formed in the machining platform, a transition opening is formed in the left end of the extrusion generation cavity in a communicating manner, and an aluminum profile outlet is formed in the left side of the transition opening; a die containing cavity used for containing an aluminum profile extrusion forming die is formed between the aluminum profile outlet and the transition opening, an opening of the die containing cavity faces upwards, and a heating chamber is arranged in the arc-shaped inner wall, close to the left end wall, of the peripheral side of the extrusion generation cavity; and a heat exchange block is arranged at the joint of the heating chamber and the extrusion generation cavity, and a vortex coil surrounding the heat exchange block is arranged in the heating chamber. According to the aluminum profile extrusion forming device, workers can be assisted in automatically carrying aluminum bars and completing aluminum profile machining.

Owner:FUJIAN SUNLIGHT SANYUAN ALUMINUM IND CO LTD

A kind of hypereutectic high chromium white cast iron and preparation method thereof

ActiveCN104060157BUniform compositionVarious ingredientsProcess efficiency improvementIntermediate frequencyFerrosilicon

The invention relates to a hypereutectic high-chromium white cast iron, which comprises the following components by mass percentage: 3.2-4.5% of C, 25-30% of Cr, 0.4-1.0% of Si, 0.4-1.0% of Mn, 1.5-3.0% of Ti, 3.5-5.0% of W, less than or equal to 0.04% of P and S, 0.02-0.05% of Al, 0.1-0.3% of Y, and the balance of Fe. A preparation method of the hypereutectic high-chromium white cast iron comprises the following steps: adding waste iron, pig iron and high carbon ferro-chrome in an intermediate frequency induction furnace with a vacuum system for melting, pre-deoxidizing ferrosilicon and ferromanganese, deoxidizing by using aluminium wire; adding ferrotungsten and ferrotitanium, vacuumizing, placing yttrium at bottom of ladle, dumping molten iron in the ladle, removing slag; when temperature of molten iron is reduced, pouring sand mold to obtain the hypereutectic high-chromium white cast iron; quenching, tempering, and discharging and cooling. The hardness HRC of the hypereutectic high-chromium white cast iron is 64-68, and the impact toughness is greater than 7J / CM<2>.

Owner:GUANGDONG INST OF NEW MATERIALS

Drum-type tea processing equipment

InactiveCN114304314ALarge speed control rangeWide applicabilityPre-extraction tea treatmentCoil arrangementsInsulation layerEngineering

The drum-type tea processing equipment comprises a drum, the outer wall face of the drum is sequentially wrapped with a heat insulation layer and a heat preservation layer from inside to outside, and a stepped intermittent electromagnetic induction heating system used for intermittently heating the drum is further installed on the outer side face of the heat preservation layer on the outer wall face of the drum. 6-8 leaf guide plates are mounted on the inner wall surface of the roller at equal intervals, and the leaf guide plates continuously extend to the discharge port of the roller from the feed port of the roller; the guide vane plate is of a spiral structure; the stepped intermittent electromagnetic induction heating system comprises N groups of electromagnetic heating coils and an isolation bracket for winding the electromagnetic heating coils; and a gap with the spacing width of 10-15cm is arranged between two adjacent groups of electromagnetic heating coils and is used as a low-temperature buffer zone. The stepped intermittent electromagnetic induction heating system can stably control the temperature in the roller to be 250-280 DEG C; by adopting the technical scheme, the energy consumption is reduced, and the tea processing quality is improved.

Owner:宁波市姚江源机械有限公司

Split impeller for large single-shell slurry pump

The invention relates to the technical field of slurry pumps, in particular to a split impeller for a large single-shell slurry pump. The split impeller comprises an impeller body. A positioning tableused for being in positioning fit with an impeller hub disc is arranged on the end face, close to a pump shaft, of the impeller body. The impeller hub disc is embedded into the positioning table andconnected and fixed through a connecting piece. In this way, according to the split impeller for the large single-shell slurry pump, the casting performance of the impeller can be improved, casting ismore facilitated through the shape of the split impeller body, the weight of materials of the impeller body is also decreased, the production cost of an enterprise is lowered, the split impeller bodyis convenient to machine and low in weight, the production cost of the enterprise is effectively lowered, the overall strength of the impeller is improved after assembling, the service life of the impeller is prolonged, parts have universality, and thus the split impeller has the advantages of simple structure and high efficiency.

Owner:SANLIAN PUMP IND CO LTD

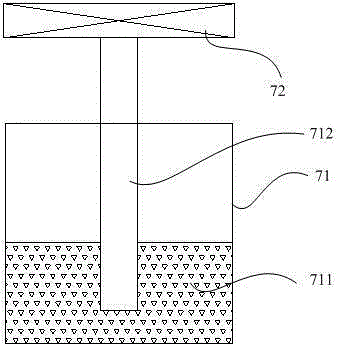

Vibrating hot film or heat pipe laminar flow grain dryer

The invention provides an oscillating heating-membrane heating-pipe laminar-flow grain dryer. Traditional tower type drying has great energy consumption during operation; the total power of a drying tower capable of drying 500 T of grains each day is 255 kw, which is totally operating power and is mainly used by a blower fan and an elevator without generation of drying heat. The oscillating heating-membrane heating-pipe laminar-flow grain dryer comprises a box (1) equipped with a damping device; the box is provided with a feed inlet (4) and a discharge outlet (5), an oscillating material bed (6) is arranged in the box, a material chamber (7) is arranged above the oscillating material bed, the feed inlet and the discharge outlet are communicated with the material chamber, and the bottom of the oscillating material bed is provided with a heating membrane (2) or a heating pipe (3). The oscillating heating-membrane heating-pipe laminar-flow grain dryer is used as a grain dryer or a rice airing machine.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

Processing technology for microwave heat penetration of pseudosciaena crocea richardson

InactiveCN102273655BHeating up fastShort heating timeFood preparationAdditive ingredientHeat penetration

The invention discloses a processing technology for the microwave heat penetration of pseudosciaena crocea richardson, and belongs to the field of the processing of marine products. The technology comprises the following steps of: injecting seasoning liquid into preprocessed pseudosciaena crocea richardson, preheating the pseudosciaena crocea richardson by using microwaves of 2,450 MHz, performing microwave curing on the preheated pseudosciaena crocea richardson, sealing, freezing and storing. In the technology, the pseudosciaena crocea richardson is subjected to microwave heat penetration stage by stage, namely the processed pseudosciaena crocea richardson is subjected to first microwave preheating and second microwave curing, the two-time penetration time of fish flesh does not exceed 25 minutes, and the curing time of the fish flesh is shortened greatly compared with the conventional cooking time (about 70 minutes), so that the nutritional ingredients of the pseudosciaena crocea richardson are kept effectively, the phenomenon of burnt or half-cooked fish flesh is avoided, and the technical problems of continuous processing of processed goods of the pseudosciaena crocea richardson and the like are solved.

Owner:福建福鼎海鸥水产食品有限公司

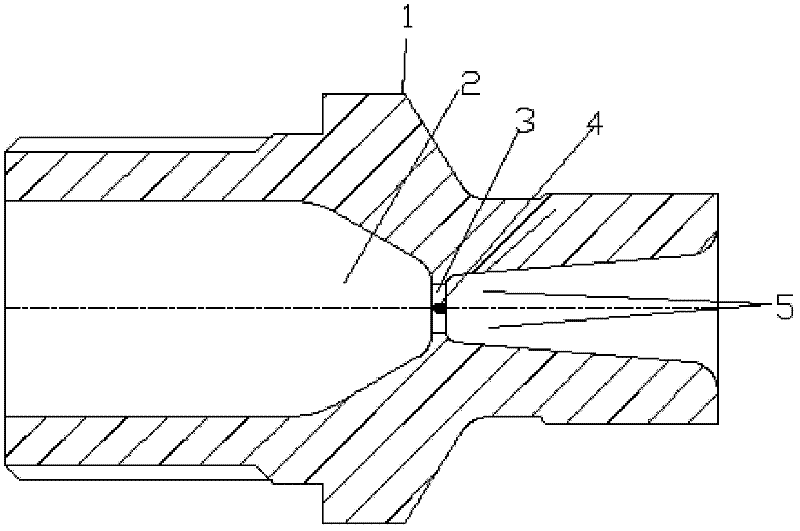

Hot nozzle core structure special for black material

The invention discloses a hot nozzle core structure special for a black material. The hot nozzle core structure comprises a nozzle core, a flow channel through which the nozzle core is communicated with a flow channel of a hot nozzle body, and a pouring gate which is formed at the end of the nozzle core and is used for a color material to flow out, wherein a grid is arranged at the pouring gate transversely. By using the scheme, the problem that the phenomena of drawing and drooling are caused easily when the color material is extruded by using the conventional hot nozzle core special for the black material is mainly solved; and the product yield is improved.

Owner:SUZHOU HTS MOLD

Method for baking treatment on preserved fruits and baking room therefor

ActiveCN102356797AShorten the timeImprove efficiencyConfectionerySweetmeatsRadioactive agentToxicant

The invention discloses a method for baking treatment on preserved fruits and a baking room therefor. The method comprises the following steps of putting a material needing to be dried into a microwave drying box, removing 50 to 60% of moisture of the material by microwaves, putting the material dried by microwaves into the baking room, and orderly carrying out baking in different temperature zones respectively having a temperature of 75 to 80 DEG C, a temperature of 80 to 90 DEG C and a temperature of 70 to 80 DEG C in the baking room to obtain baked preserved fruits, wherein total baking time is in a range of 8 to 10 hours. The method has the advantages that microwave heating is finished in a split second so that before entering the baking room, a material is heated to a certain temperature, and thus time is saved and efficiency is improved; microwave heating adopts a three-dimensional heating technology so that internal and external temperatures of a material in the baking room areuniform, and thus the problem that when a material individually enters into a high-temperature zone of the baking room, internal moisture of the material cannot be discharged is solved, and a phenomenon of dry exterior and wet interior is avoided; and microwave heating has a bactericidal effect and microwave sterilization adopts a physical sterilization method so that in microbe killing, toxicants or radioactive pollutants are not remained in a food, and thus the purposes of safety and no harm are realized.

Owner:CHENGUANG BIOTECH GRP CO LTD

Three-stage pressure-reducing preservation method for long-term storage of perishable fruits and vegetable

InactiveCN1294818CImprove cold damage resistanceImprove storabilityFruit and vegetables preservationFlavorThree stage

The present invention is three-stage pressure-reducing preservation method for long term storage of perishable fruits and vegetable, and belongs to the field of fruits and vegetable preserving technology. The three-stage pressure-reducing preservation method includes: 1) the first fruits and vegetable storing stage of 5-10 days at high vacuum of 5-20 KPa pressure to control water losing rate of 2-3.5 %; 2) the middle stage of 10-30 days in intermediate vacuum of 20-60 KPa pressure to control water losing rate of 1-2 %; and 3) final stage of 10-30 days at low vacuum of 60-100 KPa under humidity of 93-98 % without further water loss, to maintain the fresh state, flavor and post-mature performance. The present invention has long storage term of perishable fruits and vegetable.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com