Double heat type vibration laminar-flow grain dryer

A technology of grain dryer and vibrating layer, which is applied in the direction of food processing, preservation of seeds through drying, etc.

Active Publication Date: 2013-01-30

HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

View PDF10 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

More or less than this range, the price will be high, and it is difficult to achieve a drying tower with a daily output of more than 500T

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

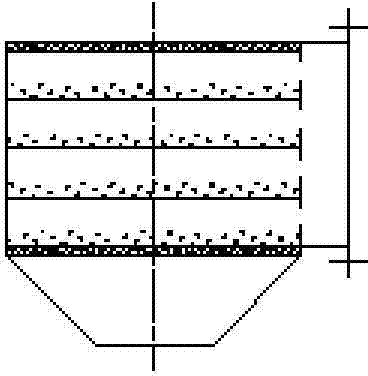

[0044] In the dual-heat vibrating laminar flow grain dryer described in Example 1, the vibrating material bed has 1-15 layers, preferably 5 layers, and commonly used within 10 layers, and the height of the material chamber is the highest The size is about 10 cm, generally less than 20 cm, and under special circumstances, it can also be within 25 cm.

[0045] Example 3:

Embodiment 2

[0047] Example 4:

Embodiment 3

[0049] Example 5:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

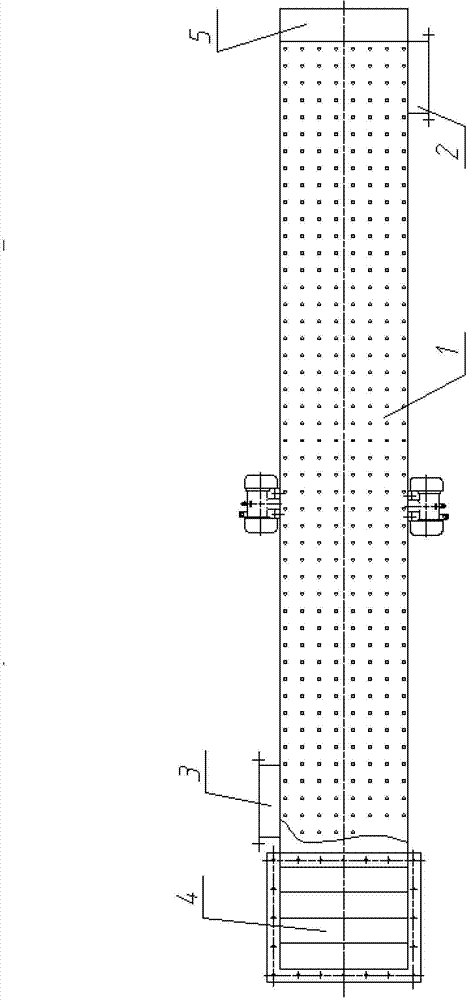

The invention relates to a double heat type vibration laminar-flow grain dryer. Currently, a vertical grain drying tower is commonly used for grain drying in the world. The heat source of the vertical grain drying tower generally is coal, fuel oil, burning rice husks or straws; a burning material combusts in a hot-blast stove and generates hot wind which is introduced into grain piles to dry grains; and such a drying manner has considerable disadvantages. The double heat type vibration laminar-flow grain dryer provided by the invention comprises a box (1) equipped with a damping device; the box is provided with an air inlet (2), an air outlet (3), a feed inlet (4) and a discharge outlet (5), a vibrating material bed (6) is arranged in the box, a material chamber is arranged above the vibrating material bed, and the feed inlet and the discharge outlet are communicated with the material chamber. The double heat type vibration laminar-flow grain dryer is used as a grain dryer or a rice airing machine.

Description

technical field [0001] The invention relates to drying equipment for grain and bulk materials, in particular to a dual-heat vibrating laminar flow grain dryer. Background technique [0002] Food is a necessity for human life, and all countries attach great importance to food production and reserves. The moisture content of freshly harvested grain is generally around 17%-32%, and the safe moisture content of stored grain is around 14%. Therefore, if it is necessary to store grain safely, it must be stored with precipitation to reach a safe moisture content. At present, the common way of grain drying in the world is to use a vertical grain drying tower. The heat source generally comes from coal, fuel oil, rice husk, and straw. The fuel is burned by a hot blast stove to generate hot air, which is passed into the grain pile to dry the grain. This drying method has many disadvantages: [0003] The flue gas after fuel combustion is generally about 150°C, and is directly dischar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23B9/08

CPCY02P60/85

Inventor 刘廷瑜

Owner HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com