Sublimation bed employing carrier gas guidance structures

a guidance structure and sublimation bed technology, applied in the direction of coatings, metallic material coating processes, chemical vapor deposition coatings, etc., can solve the problems of poor vapor/solid contact time, insufficient ratio of solid source surface area to vapor volume, and progressively more difficult to saturate the carrier gas. , to achieve the effect of increasing the ratio of exposed solid source surface area and increasing the vapor/solid contact tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

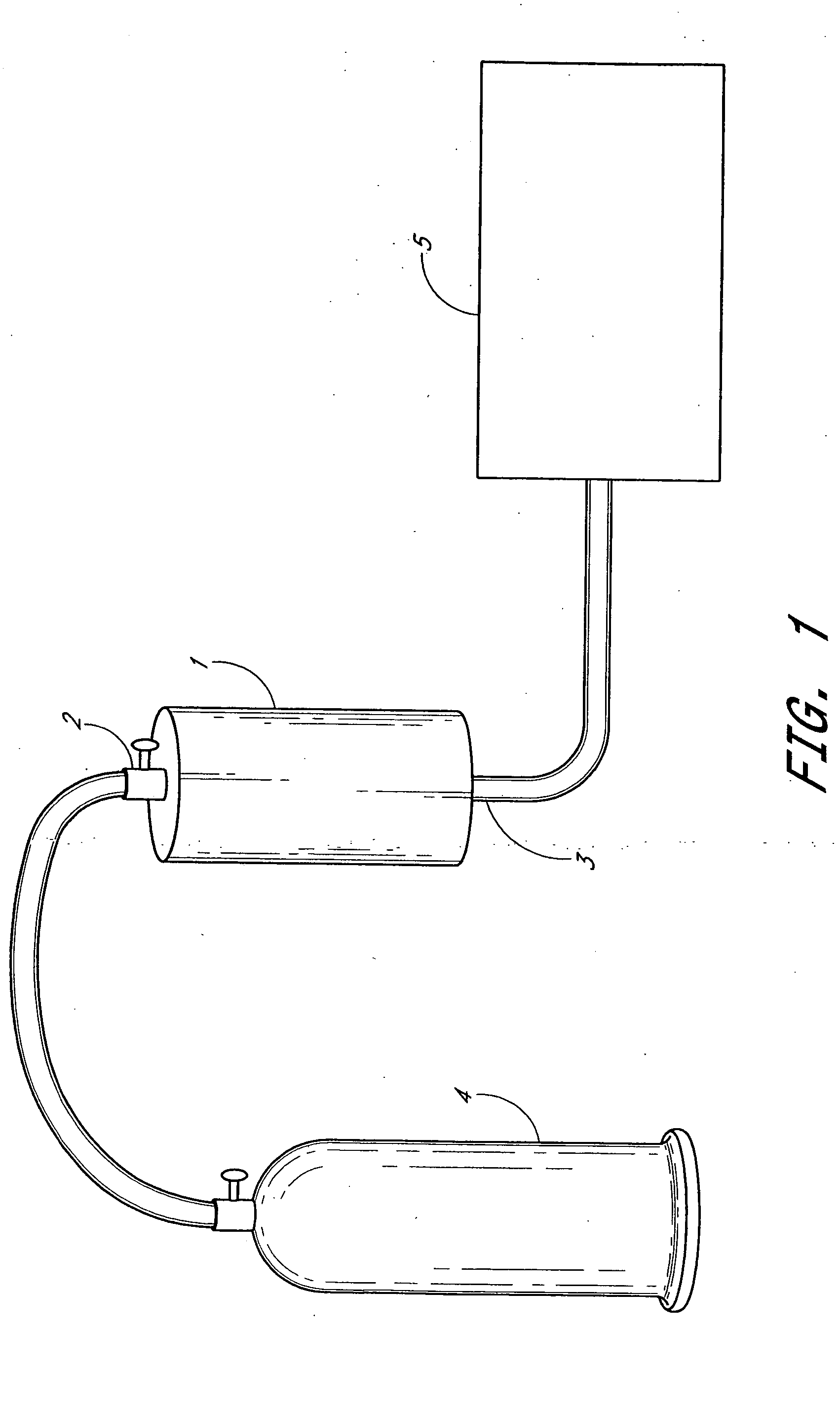

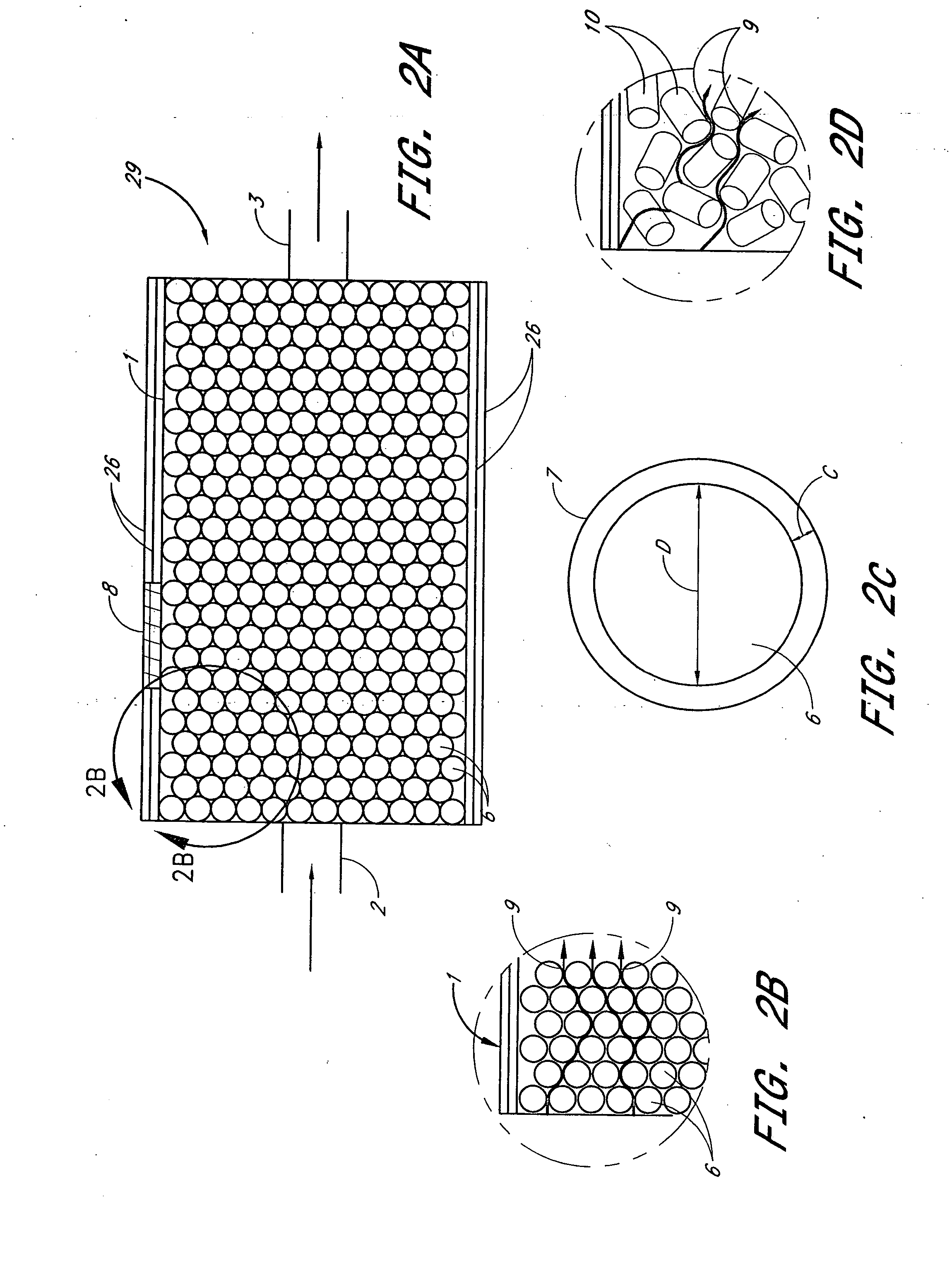

[0140] In preferred embodiments of the present invention, the effective bed length is increased greatly without necessitating a proportionate increase in the length of the sublimation vessel. This increase in effective length is facilitated by guidance structures, including support elements coated with solid source material and flow guides, each of the guidance structures being configured to channel the carrier gas through contact pathways designed to saturate the carrier gas over a relatively short distance (as measured by the direct distance between the carrier gas inlet and the outlet) and to expose the carrier gas to a large surface area of subliming solid source material.

[0141] A non-limiting example of potential sublimation bed parameters made possible by solid source coated beads, or spheres, as determined by the Alcoa CSS computer program, follows in Table 1:

TABLE 1Potential Sublimation Bed Parameters Using Non-Porous Spheresand an HfCl4 CoatingSphere Diameter (mm)4Bed Di...

example 2

[0143] In certain preferred embodiments, the sublimation bed is capable of producing a substantially plug flow, i.e. approaches an ideal plug flow. One advantage of configuring preferred embodiments to flow a substantial plug flow is that ideal plugged flow residence time distribution (or plug flow mixing behavior) effectuates a concentration at the vessel outlet which stays constant with time up to the vessel residence time (V / Q, where V=−vessel volume and Q is the volumetric flow rate). If you make the residence time of the reactor much longer than the pulse time, the entire pulse length will remain at Csat. Therefore, if reactor or vessel (holding the powder or precursor coated support medium) is long and / or convoluted (e.g., coiled path, helically guided path, tortuous path through coated beads, etc), then the residence time is high. Advantageously, in preferred embodiments employing ALD, each pulse of flow into the vessel will preferably push a “slice” of carrier gas saturated ...

example 3

[0146] The preferred embodiments shown in FIGS. 15-20B were modeled and the results are represented by the plot shown in FIG. 24, showing the residence time distribution (RTD) curve for the vessel with shelves. The plot shown in FIG. 24 is the result of a fluid mechanical modeling of packed vessel embodiments and it shows that the RTD is very close to that of an ideal PFR. The individual data points are shown in Table 4 below. The plotted results substantially equates to a dispersion model with a very low DL / uL. In other words, the resulting curve is similarly shaped to the plug flow curve in FIG. 23. This plotted curve shows the response of the vessel to a step function change in concentration at the inlet. This is the J(theta), or Residence Time Distribution (RTD) function. Its conventional definition is the fraction of the effluent stream having a residence time less than theta.

[0147] Co is the concentration of the tracer fluid step at the inlet and C is its concentration at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| vapor pressure | aaaaa | aaaaa |

| vapor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com