Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Low water expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composite material and prepration method thereof

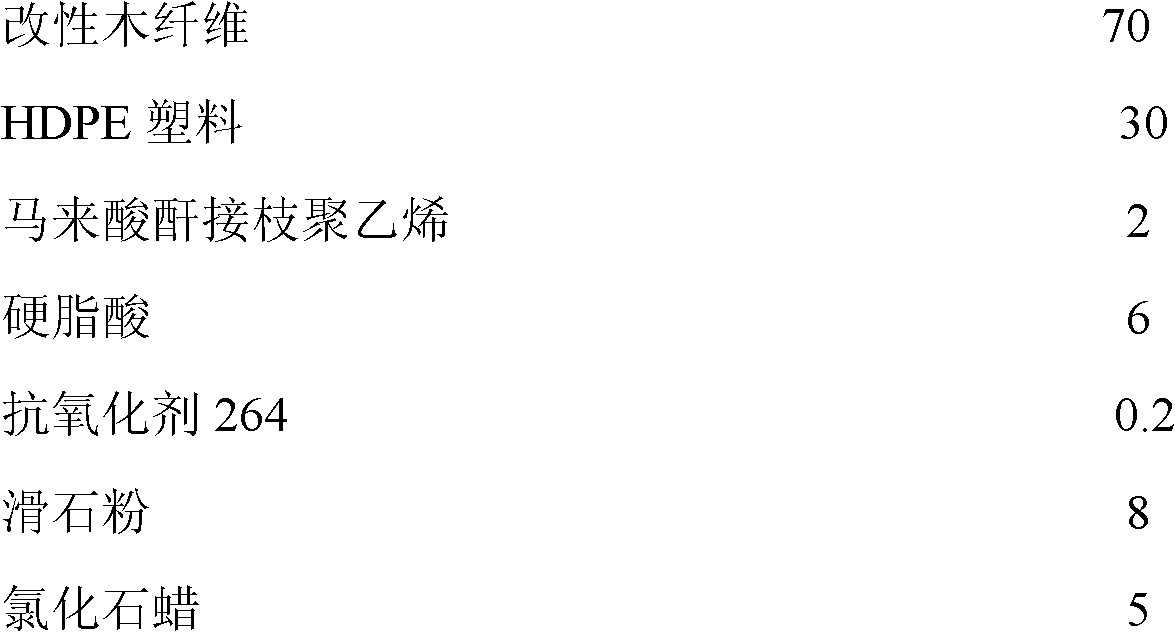

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

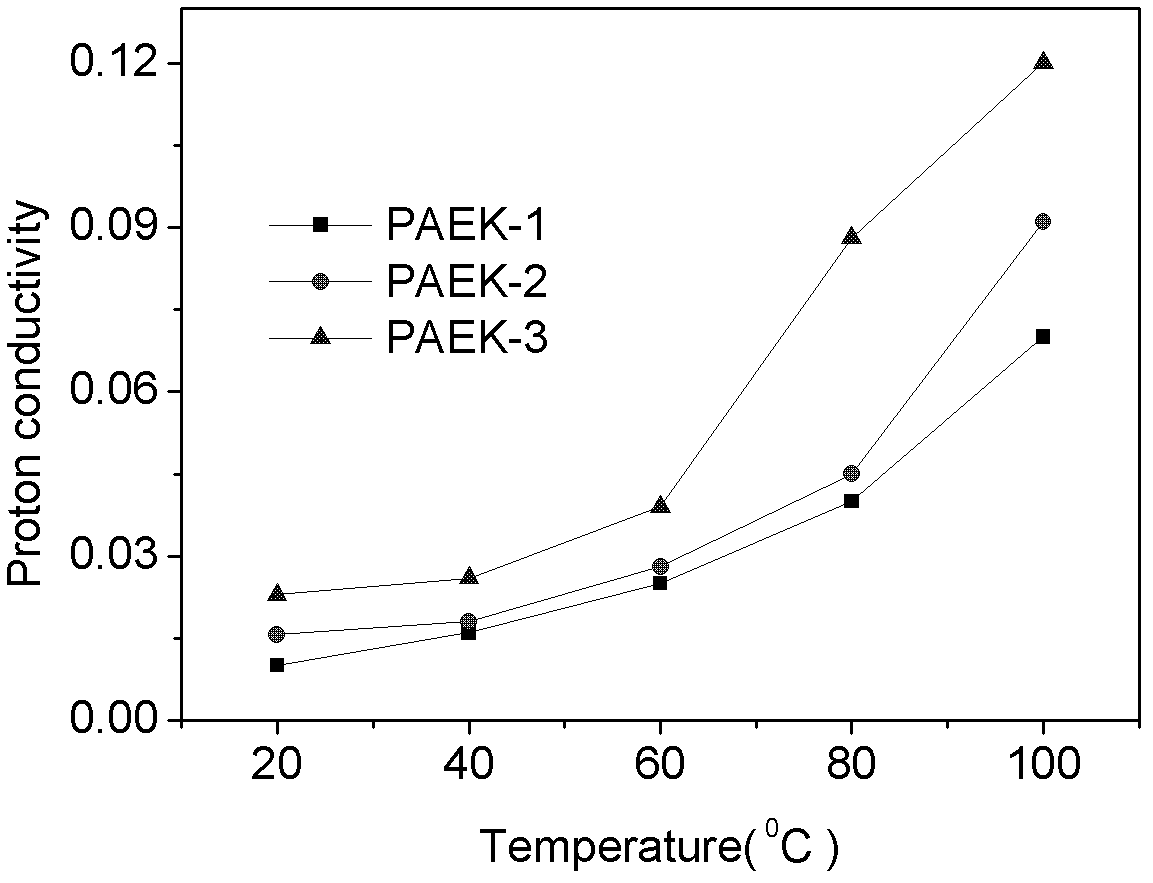

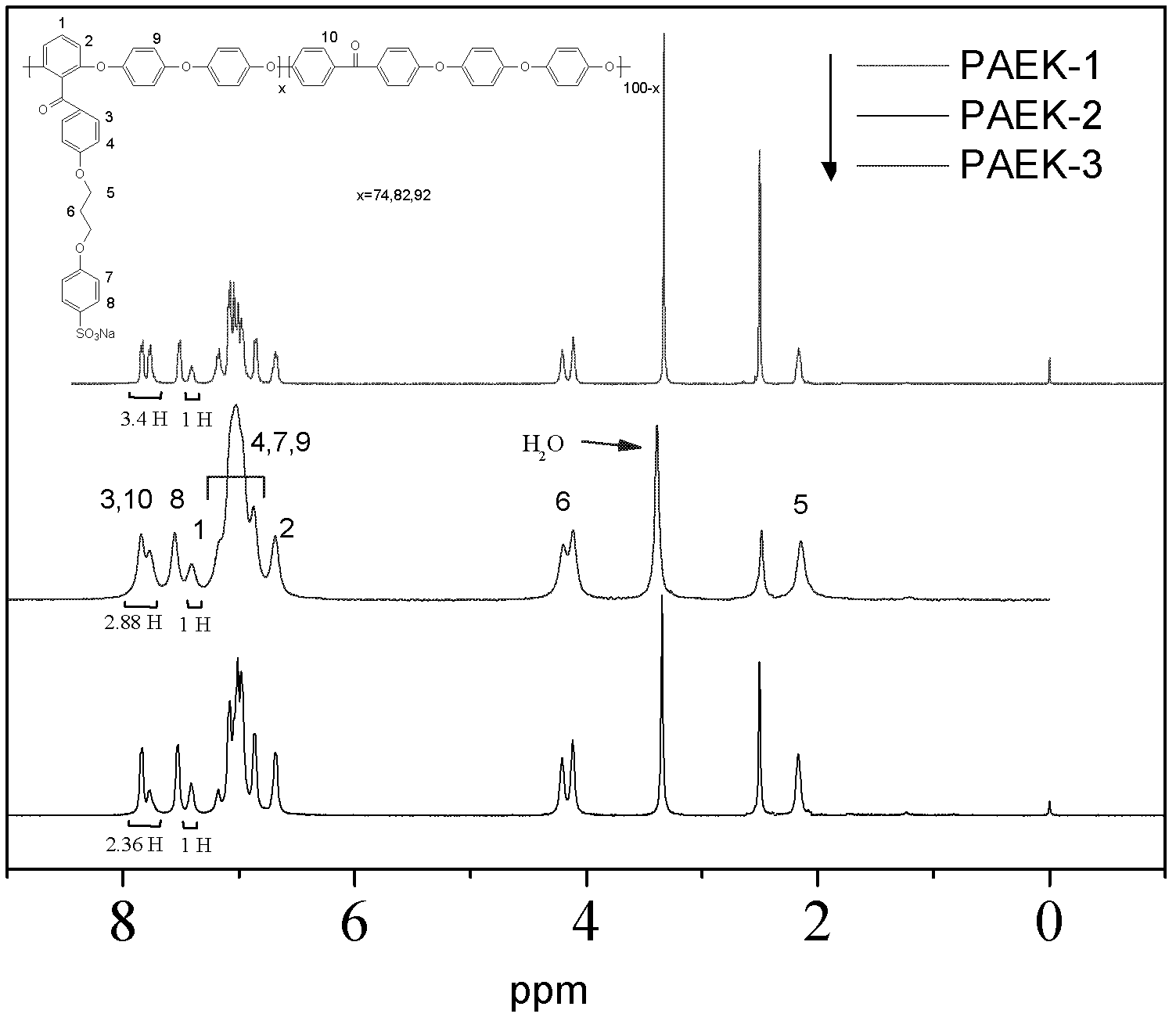

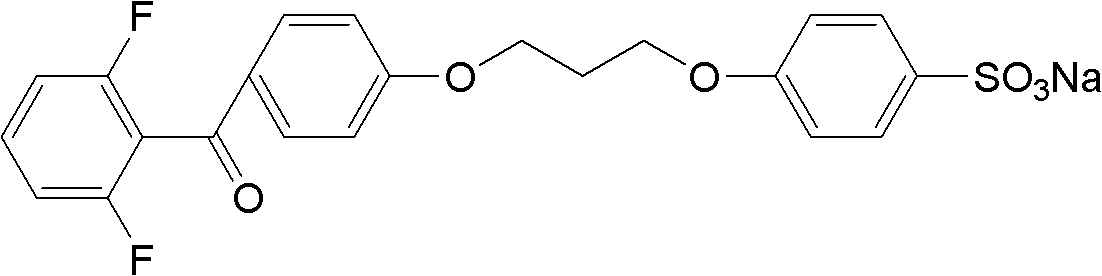

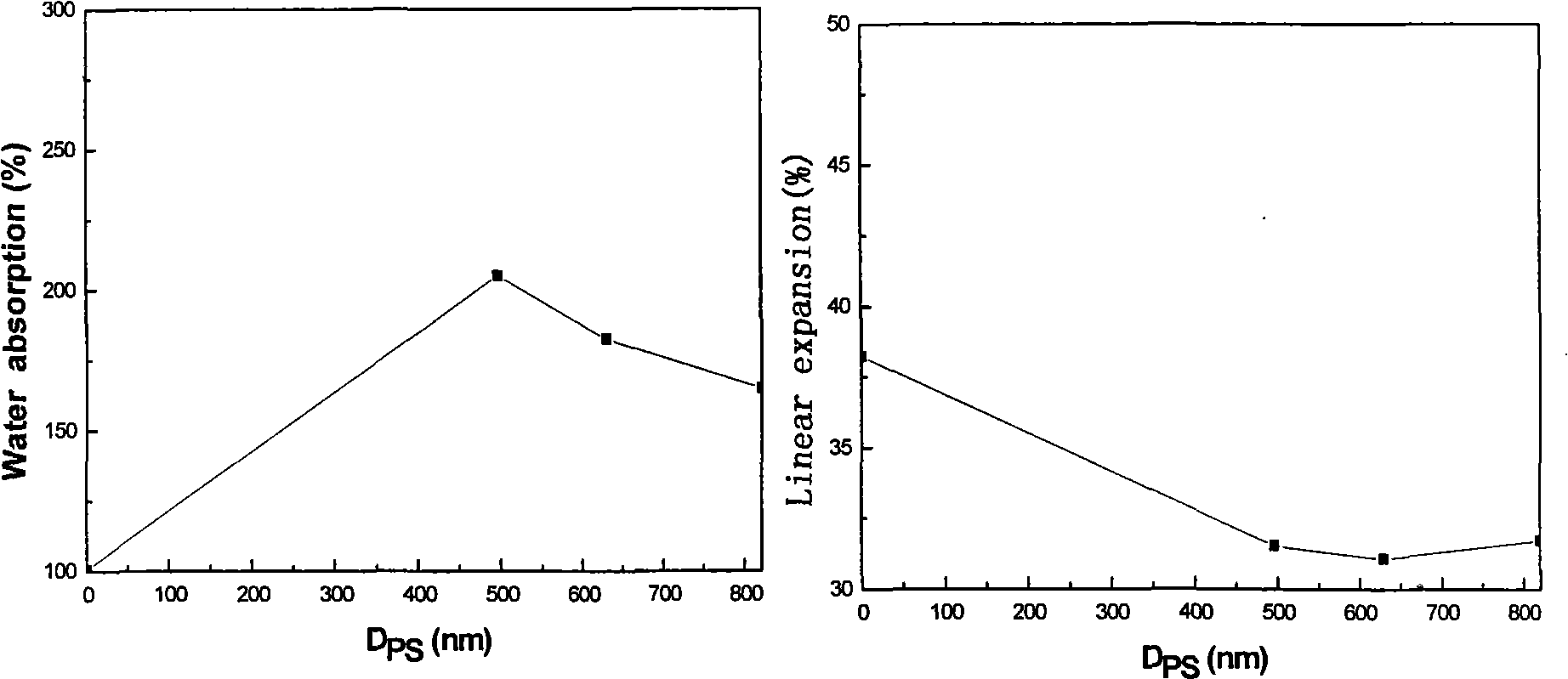

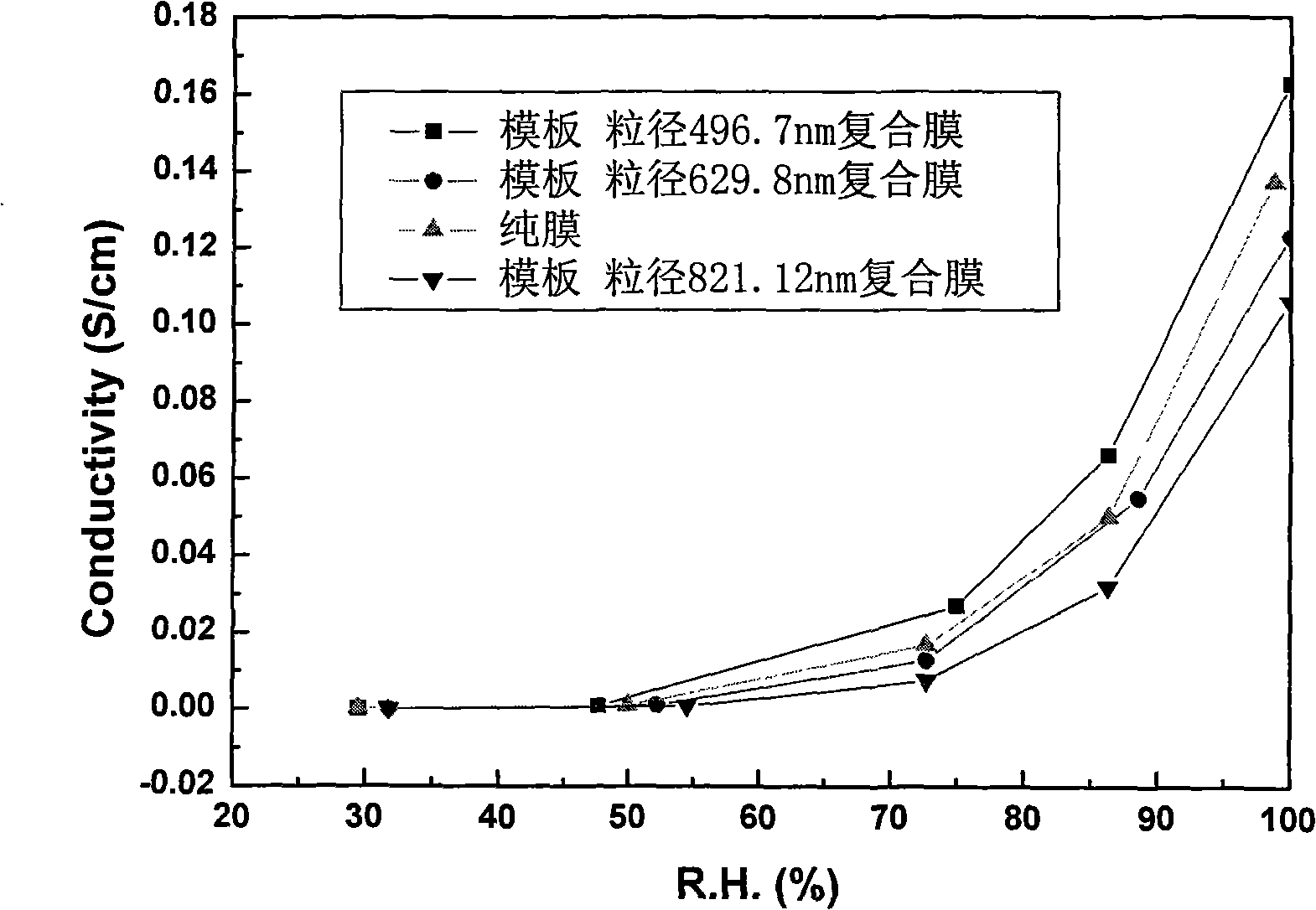

Side-chain sulfonic acid type polyarylether, preparation method thereof and application of polyarylether in preparation of proton exchange membrane

InactiveCN102585204ALow water expansionImprove proton conductivityCell component detailsFuel cell detailsSolventSide chain

The invention belongs to the technical field of high polymer materials and relates to a side-chain sulfonic acid type polyarylether polymer which has high thermal stability and is used in a proton exchange membrane of a fuel cell and a preparation method thereof. The preparation method comprises the following steps: adding a diphenol monomer, a sulfonated difluoro-monomer, a difluoro-monomer and anhydrous potassium carbonate in a three-necked bottle provided with a stirrer, a water-carrying device and a nitrogen hole, adding a solvent and an azeotropic dehydrant which accounts for 20% of the solvent by volume in the three-necked bottle, injecting nitrogen, and heating to reflux the azeotropic dehydrant; and refluxing for 2-5h to dehydrate, evaporating the azeotropic dehydrant, heating to 175-190 DEG C to react for 5-8h, then pouring the reaction mixture in water to obtain a polymer, grinding the polymer to fine particles by using a grinder, filtering by using a buchner funnel, washingwith deionized water and ethanol several times, and performing vacuum drying at 100-110 DEG C for 10-15h to obtain the side-chain sulfonic acid type polyarylether polymer with high thermal stability,good solubility and film-forming property and low water absorption rate.

Owner:JILIN UNIV

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin andthe like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

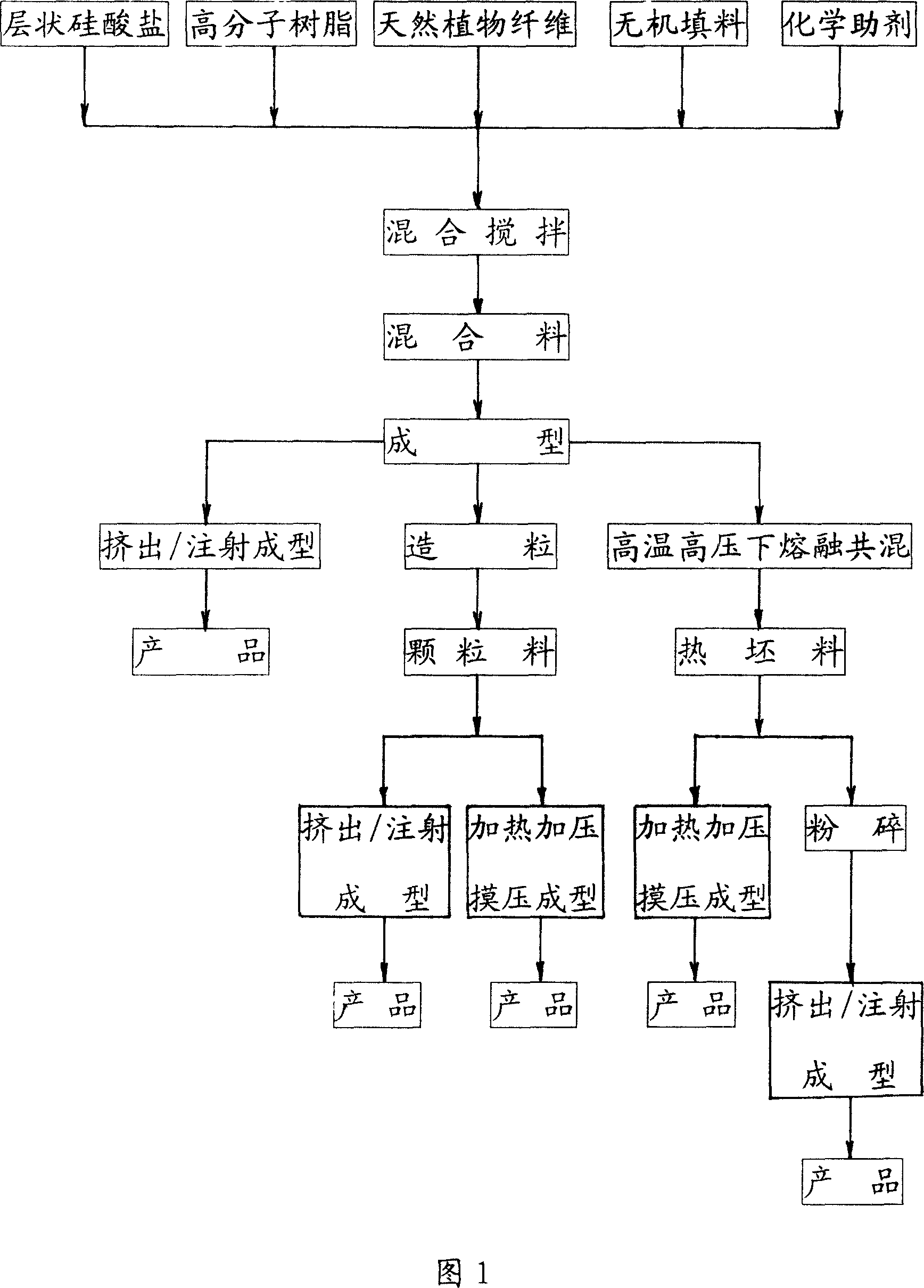

Nano composite woody material, and preparation method

A nano-class composite wooden material for plate, tube, or section is proportionally prepared from laminar silicate, high-molecular resin, natural plant fibers, inorganic filler, and chemical assistant through proportional mixing, and extruding out or injection moudling. It is possible to granulate before it is shaped.

Owner:赵永生

Wood plastic composite and preparation method thereof

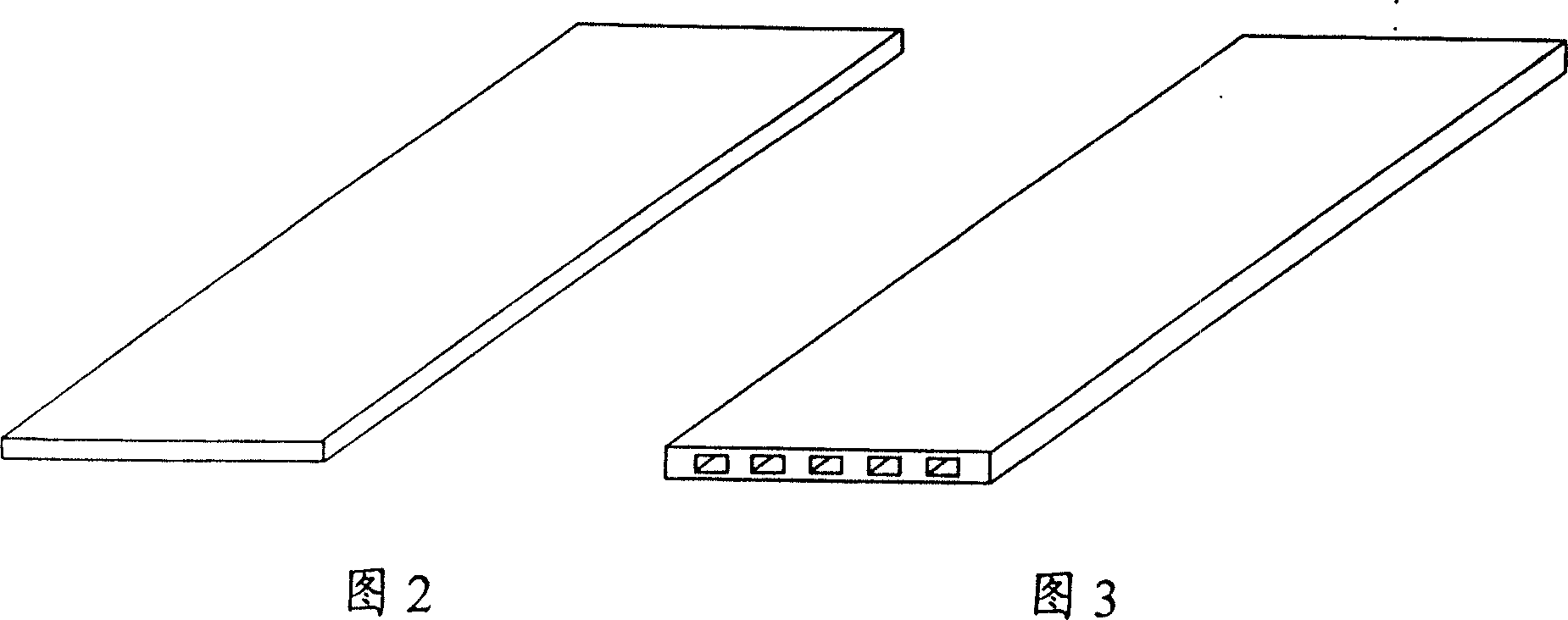

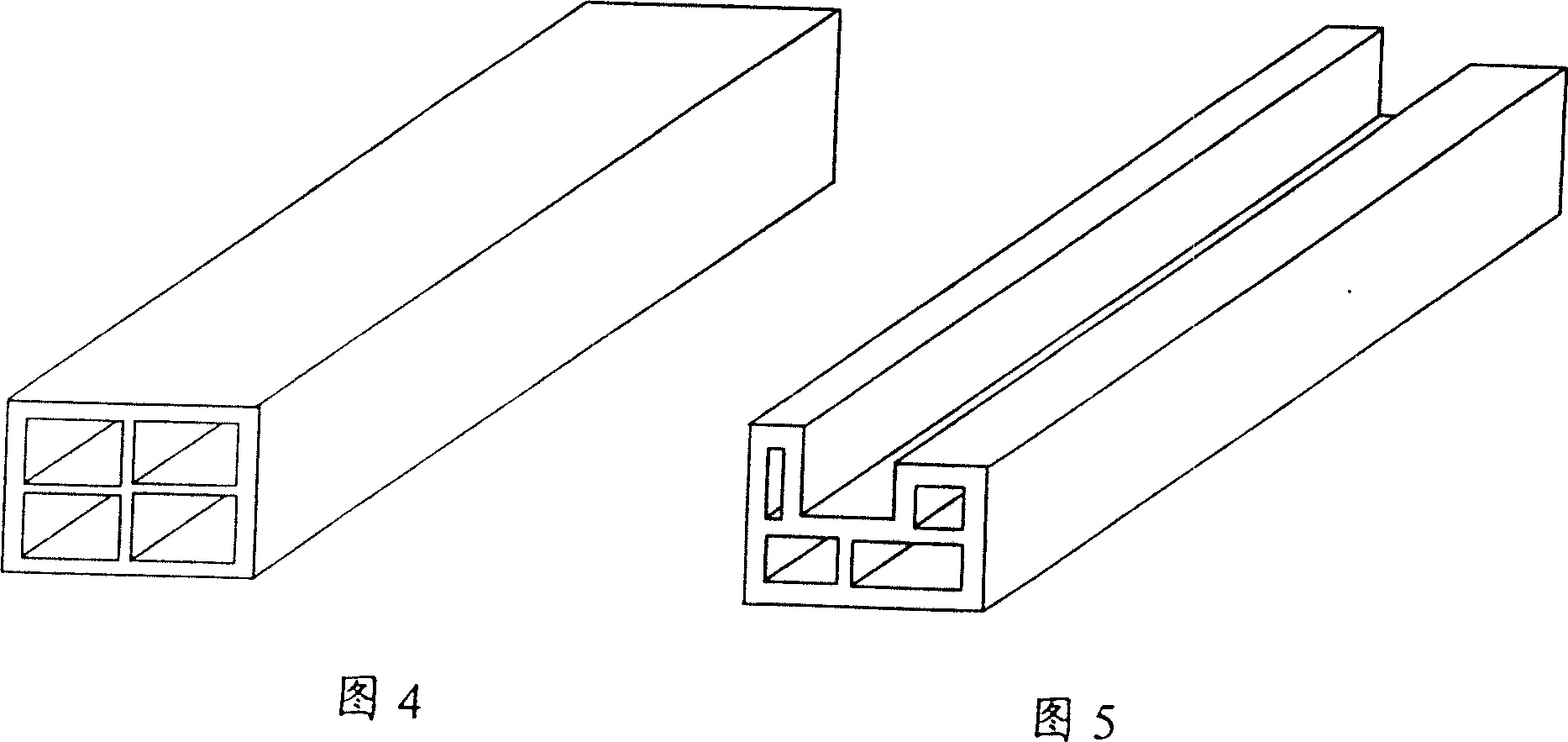

InactiveCN102304290AImprove mechanical propertiesReduce consumptionRaw material divisionThermoplasticForest industry

The invention discloses a wood plastic composite and a preparation method thereof. The wood plastic composite comprises the following raw materials according to parts by weight: 30-80 parts of modified wood fiber, 20-70 parts of plastic, 2-10 parts of compatilizer, 2-10 parts of lubricant, 0.2-1.0 part of antioxidant, 5-15 parts of filler and 2-10 parts of fire retardant. 'forestry three waste' wood wastes are prepared onto modified wood fibers with an explosion treatment method, wherein the modified wood fibers are mutually separated, and eh surface of the modified wood fibers is covered with lignin; then the modified wood fiber is compounded with plastic; and the product is extruded to form finished product material. According to the wood plastic composite, the technical problems of poor compatibility of wood fiber and thermoplastic plastics can be solved to realize the purpose of comprehensively utilizing the 'forestry three waste' wood and plastic, the wood can be omitted, and the additional value of the forest residue is increased. The wood plastic composite manufactured with the preparation method has high mechanical property, and strong tensile strength, bending strength and impact strength of composite material, and the industrial production of high-performance products, such as building engineering materials, can be realized.

Owner:BEIJING FORESTRY UNIVERSITY

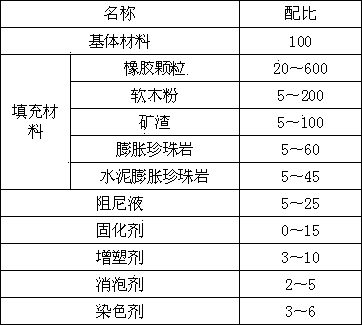

High polymer composite for embedded rail system

The invention discloses a high polymer composite for an embedded rail system, which comprises the following components by weight percentage: 100% of base material, a filling material, 2-25% of damping liquid, 0-15% of curing agent, an appropriate amount of defoaming agent, an appropriate amount of colorant and an appropriate amount of plasticizer, wherein the base material is polyurethane modified epoxy resin; the filling material comprises the following components by weight percentage: 20-100% of rubber particle, 5-200% of cork powder, 5-100% of slag, 5-60% of expanded perlite and 5-45% of cement expanded perlite. The high polymer composite can meet three-way rigidity requirements of the rail system, has good damping capacity and fatigue resistance, does not crack after three million fatigue tests, is excellent in electrical insulation, green and environment-friendly, and can be recycled and smashed as filling for repeated use.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

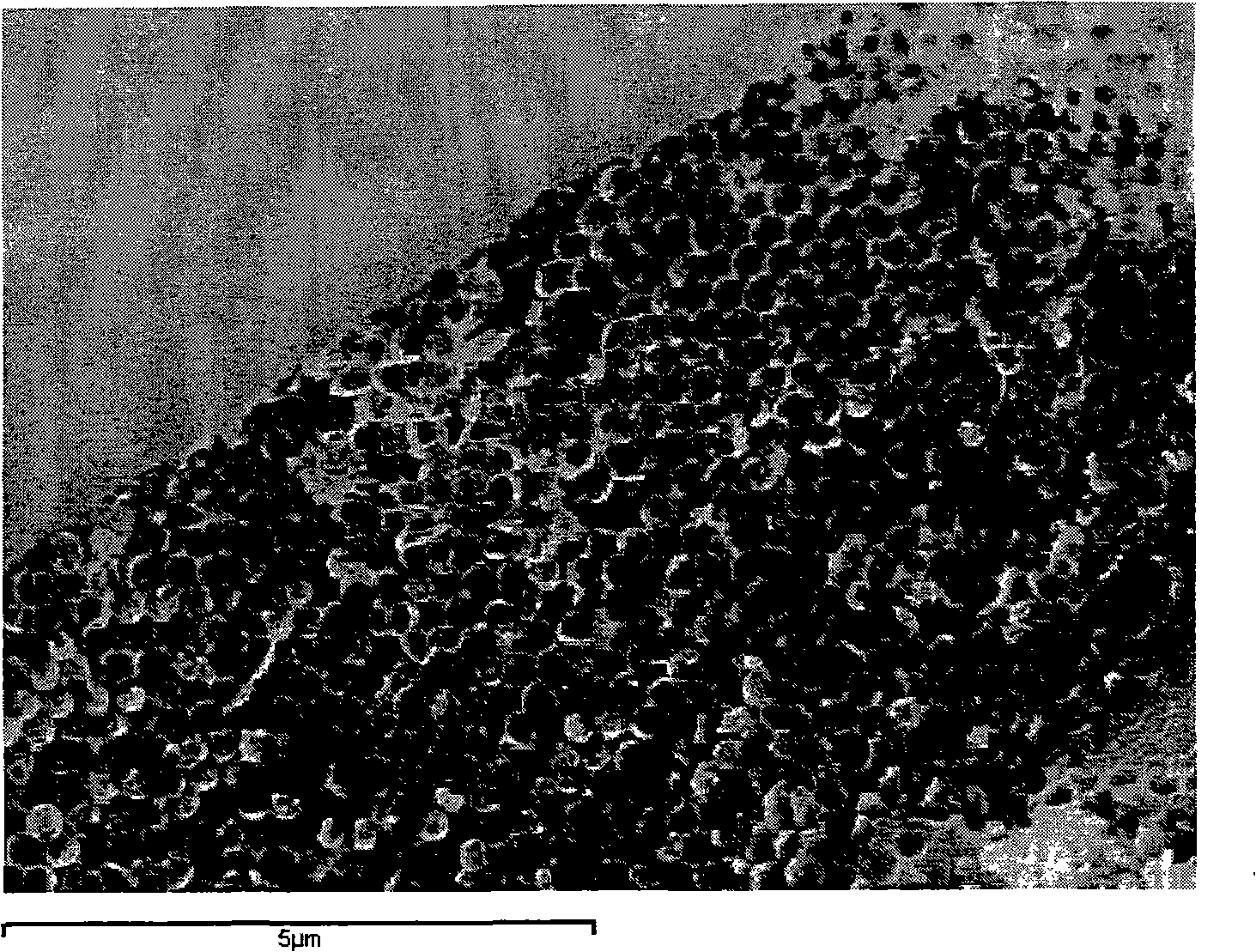

Inorganic/organic composite proton fuel cell exchange membrane and preparation thereof

InactiveCN101359743ALow costRich preparation technologySolid electrolyte fuel cellsFuel cell detailsHeteropoly acidMoisture

The invention provides an improvement to an inorganic / organic composite proton fuel cell exchange membrane and a preparation method thereof, which is characterized in that the inorganic / organic composite is composed by embedding perfluoro sulfonated polymer or non-perfluoro sulfonated polymer into SiO2 and / or TiO2 of a three-dimensional mesh structure. Inorganic particles form into a network structure with each other in the membrane, so as to not only enhance the mechanical strength of the composite membrane but also to obtain the composite membrane with good moisture, thereby effectively solving the contradiction between the proton exchange membrane and high conductivity rate at high temperatures, therefore, not only the obtained composite membrane has characteristics of high temperature and high conductivity rate, lower swelling rate of water absorption and the like, but also mechanical strength and thermal stability of the composite membrane can be correspondingly increased so as to improve the service life. The obtained membrane structure is characterized in that: the inorganic particles represent an orderly, uniform and open three-dimensional mesh structure, and the organic polymer substance of the conductive proton is filled in the three-dimensional mesh of the inorganic particles. The structural characteristic provides a good space configuration for adulterating other conductive substances (such as heteropoly acid). The inorganic / organic composite proton fuel cell exchange membrane has advantages that the obtained composite membrane is not only superior in performance, but also plays an important role in improving the performance of the fuel cell and reducing the battery costs, in addition, enriches the preparation technology of proton exchange membranes.

Owner:江苏新源动力有限公司

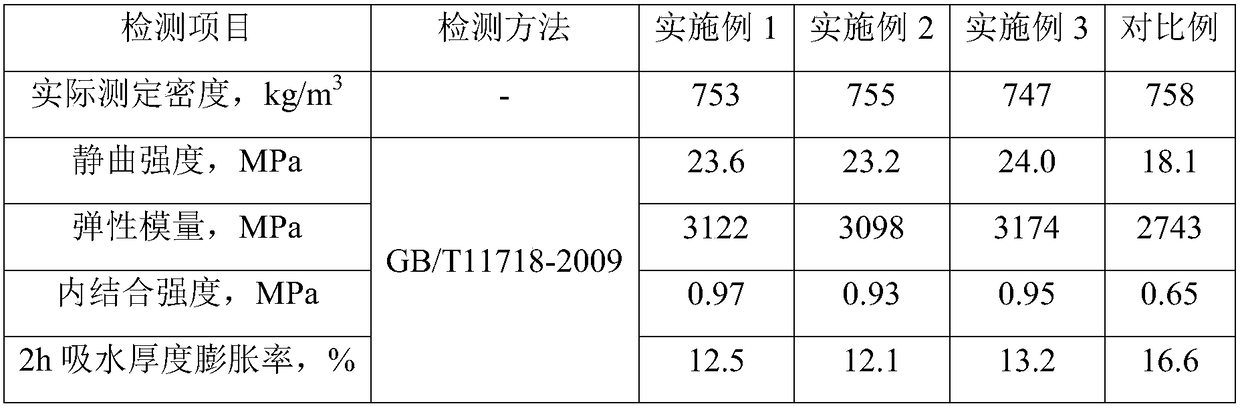

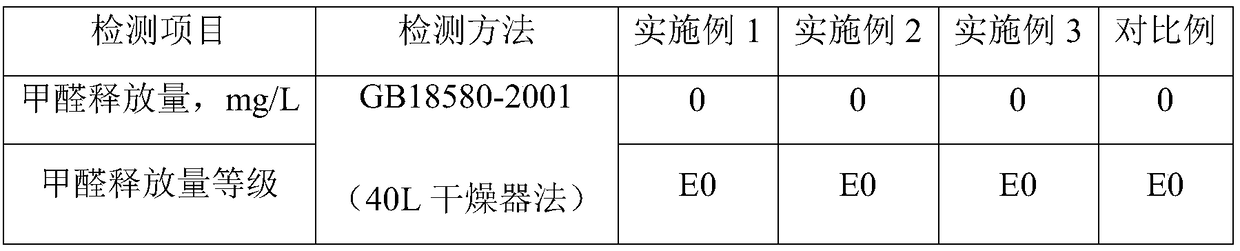

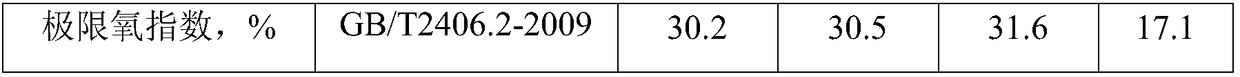

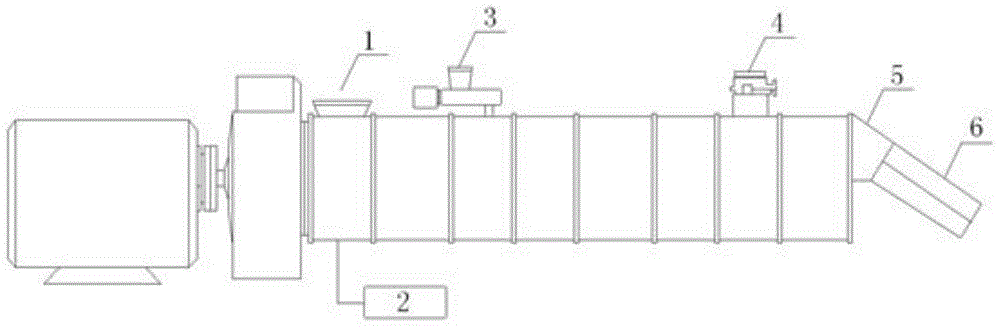

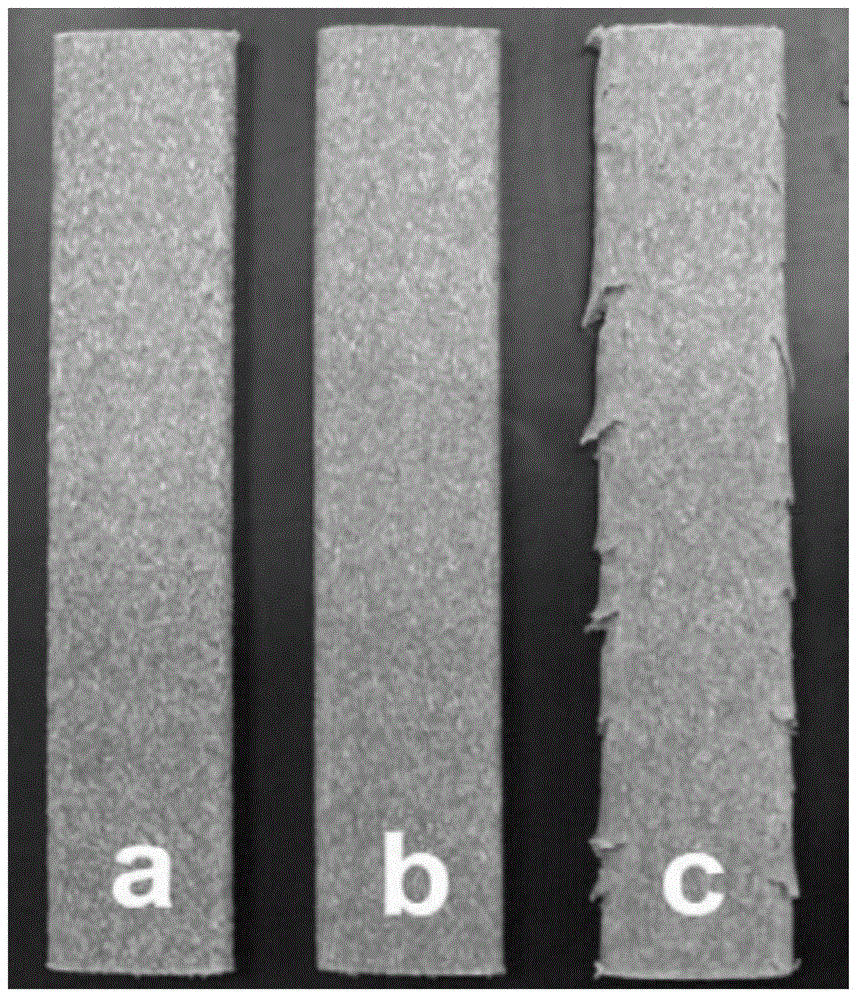

Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

ActiveCN108656305AHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberFiberboard

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

Organosilane crosslinked polyethylene wood-plastic composite material and preparation method thereof

The invention discloses an organosilane crosslinked polyethylene wood-plastic composite material and a preparation method thereof, relates to wood-plastic composite materials and preparation methods and aims at solving the problem of lowering of performance like strength, tenacity and creep resistance of a PE wood-plastic composite material in the long-time outdoor using process due to water absorbing. The organosilane crosslinked polyethylene wood-plastic composite material is prepared by polyethylene, plant fibers, lubricant, silane coupling agent, initiator, catalyst and antioxidant. The preparation method includes drying and grinding the plant fibers; mixing the plant fibers with polyethylene and the lubricant; mixing with the silane coupling agent, the initiator, the catalyst and the antioxidant; utilizing a double-screw extruder to obtain the organosilane crosslinked polyethylene wood-plastic composite material.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

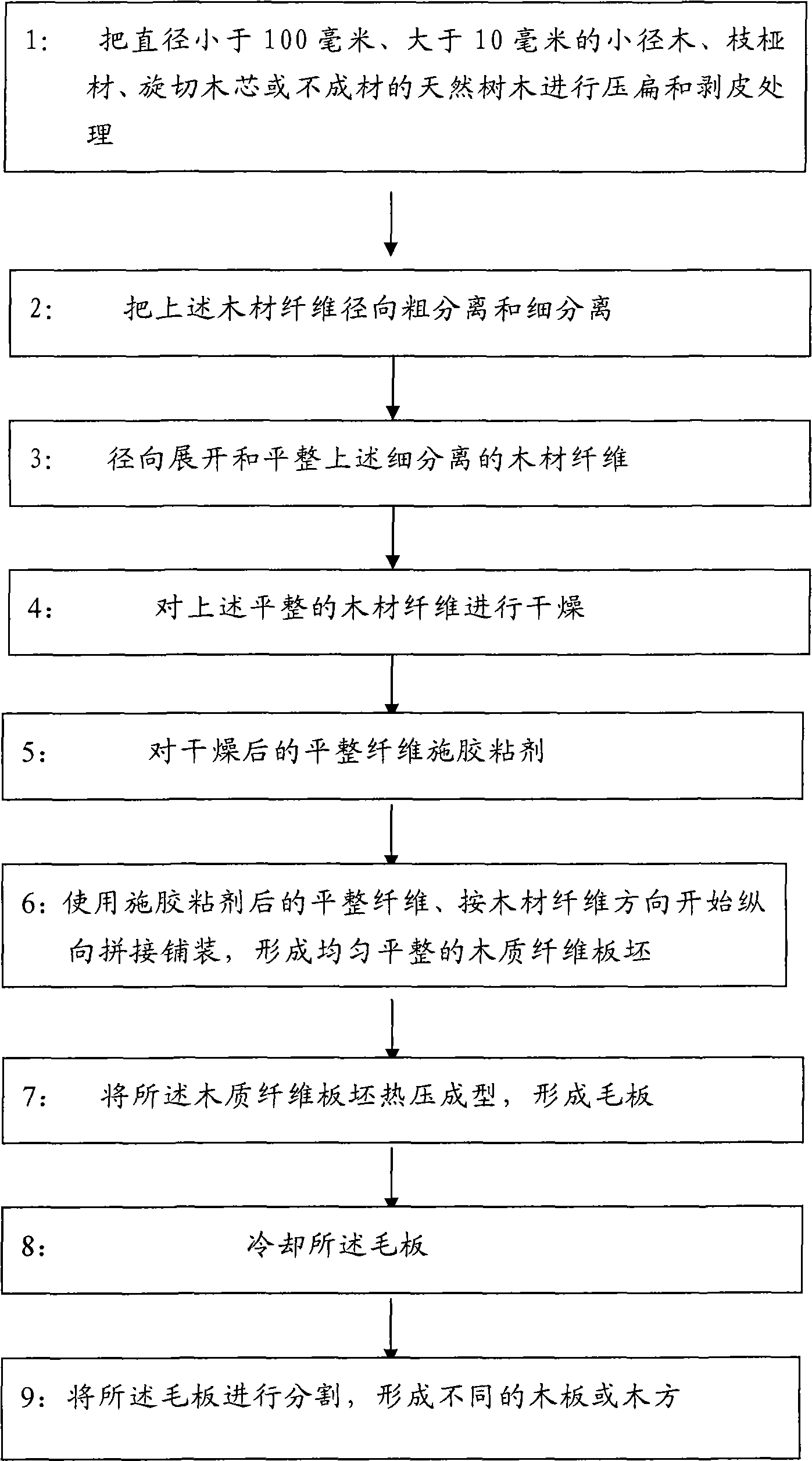

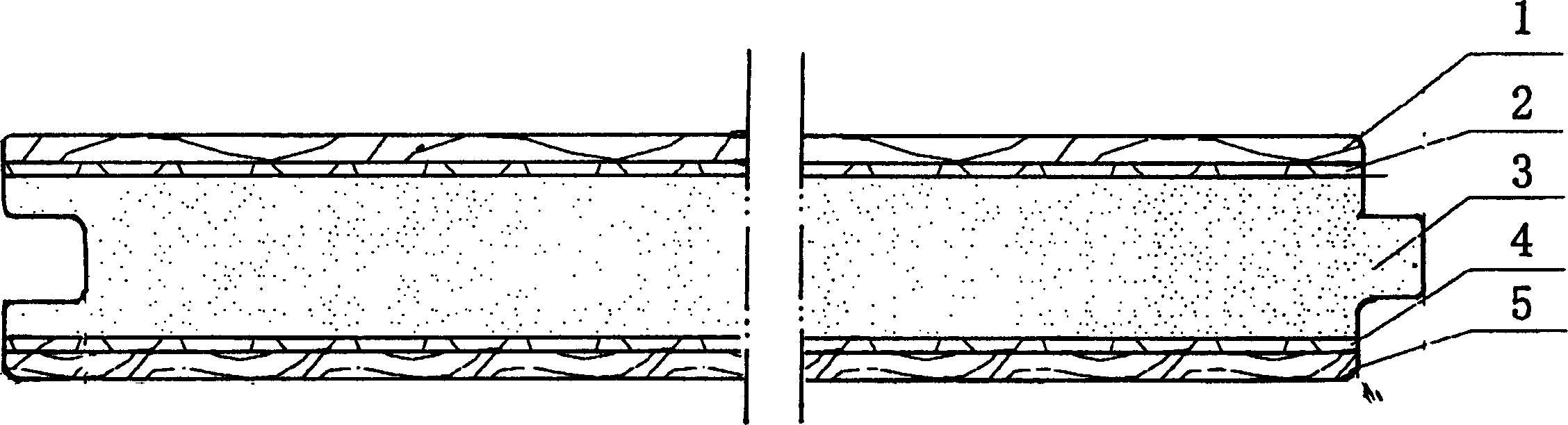

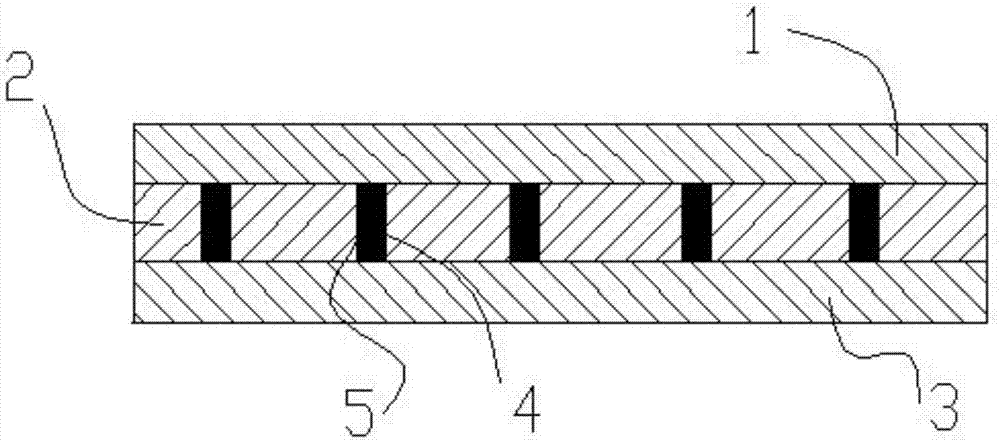

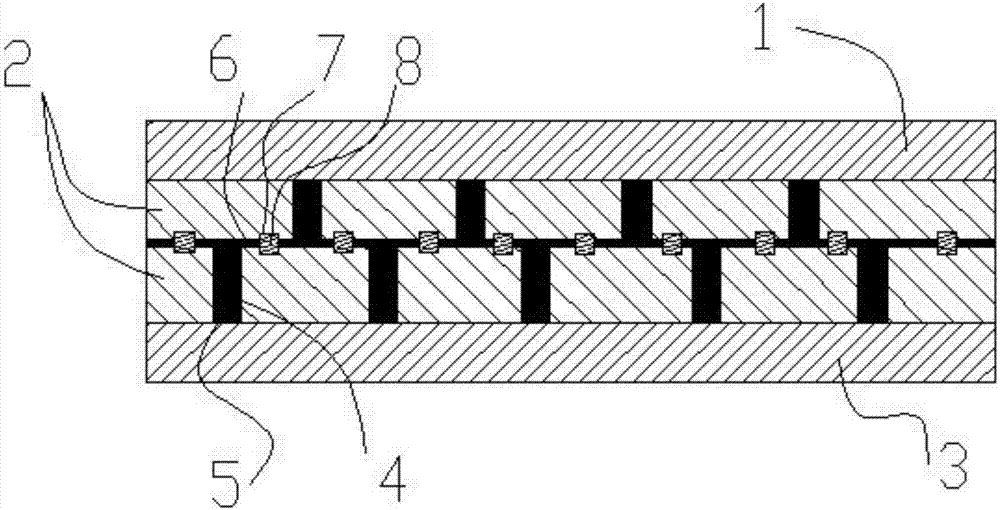

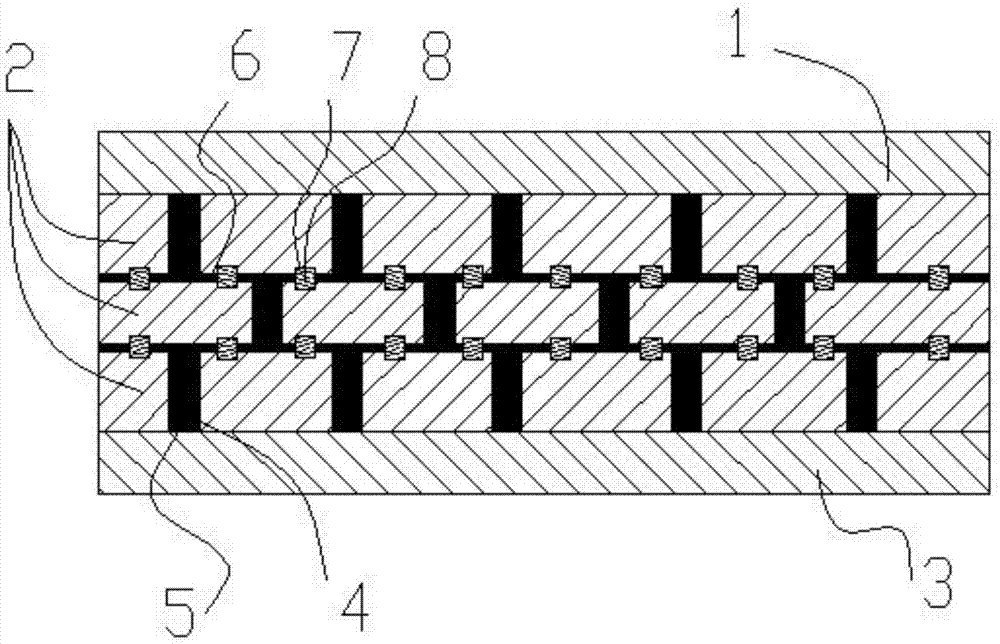

Preparation method for producing wood board or flitch beam

InactiveCN101544011ALow water expansionSmall natural deformationTree debarkingDomestic articlesHot pressAdhesive

The invention discloses a preparation method for producing a wood board or a flitch beam, which is characterized by comprising the following steps: a, flattening and peeling small wood, brushwood, rotary-cut heart wood or useless natural wood which has a diameter of less than 100 millimeters and more than 10 millimeters; b, radially and roughly separating and finely separating fibers of the wood; c, radially expanding or leveling the finely separated fibers of the wood; d, drying the level fibers of the wood; e, applying a bonding adhesive onto the dried and leveled fibers; f, starting longitudinally splicing and paving the leveled fibers obtained after bonding adhesive application along the direction of the fibers of the wood to form a uniform and level wood fiber board blank; g, forming the wood fiber board blank through hot press to form a rough board; h, cooling the rough board; and I, cutting the rough board to form different boards or flitch beams.

Owner:李成全 +1

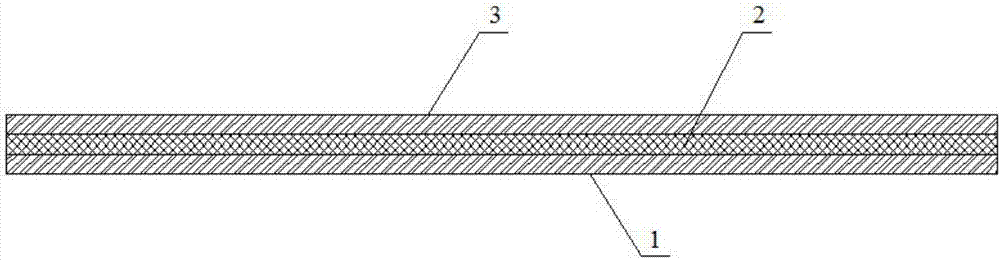

Sound insulation and noise reduction type composite bamboo fiberboard

ActiveCN107877624AImprove sound insulation and noise reductionGuaranteed physical and mechanical performanceLaminationLamination apparatusFiberNoise reduction

The invention discloses a sound insulation and noise reduction type composite bamboo fiberboard, and relates to the technical field of bamboo fiberboard processing. The sound insulation and noise reduction type composite bamboo fiberboard is composed of three layer structures of a bamboo fiber bottom board, a sound insulation and noise reduction layer and a bamboo fiber panel, and the sound insulation and noise reduction layer is arranged between the bamboo fiber bottom board and the bamboo fiber panel and is made of an asbestos wool-foamed aluminum-magnesium composite. According to the soundinsulation and noise reduction type composite bamboo fiberboard, the asbestos wool-foamed aluminum-magnesium composite serves as the sound insulation and noise reduction layer, so that the manufactured composite bamboo fiberboard has excellent sound insulation and noise reduction performance; and the sound insulation and noise reduction performance of the manufactured composite bamboo fiberboard is further enhanced by using the self-made bamboo fiber bottom board or bamboo fiber panel, meanwhile, physical and mechanical using performance of the composite bamboo fiberboard is ensured, and construction requirements of building decoration are met accordingly.

Owner:广西平乐爱森新材料有限公司

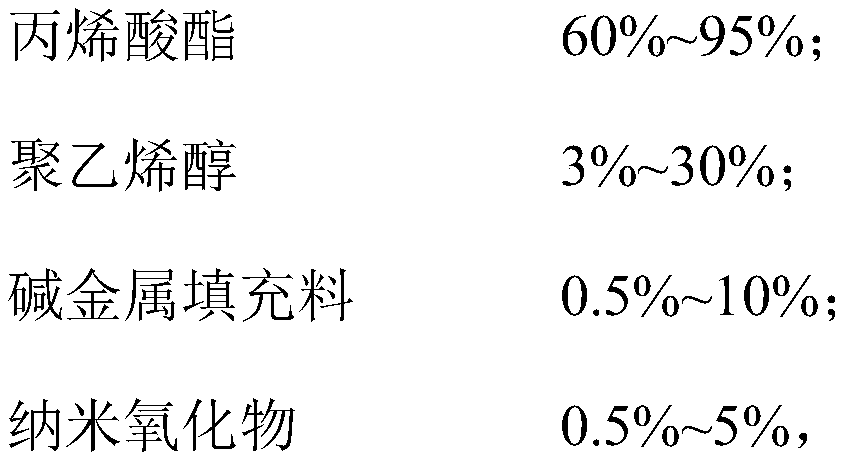

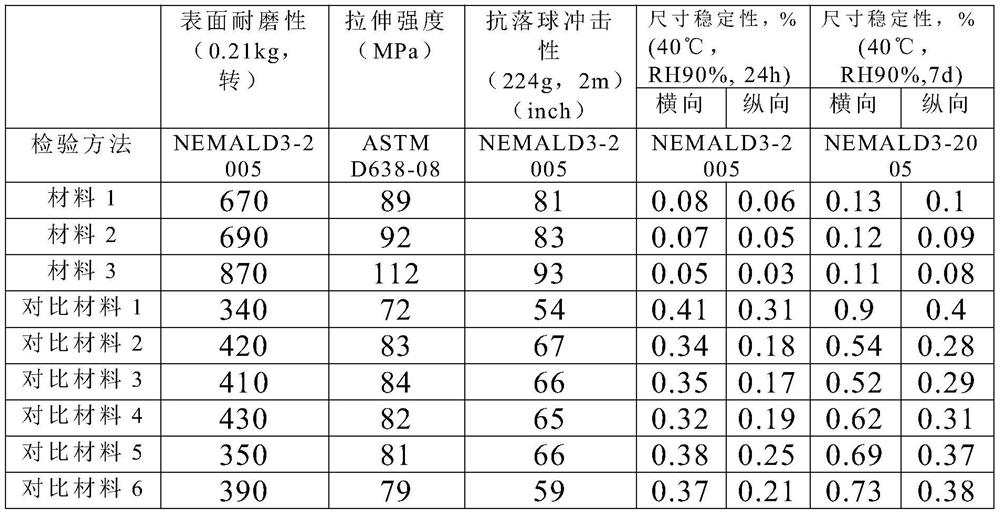

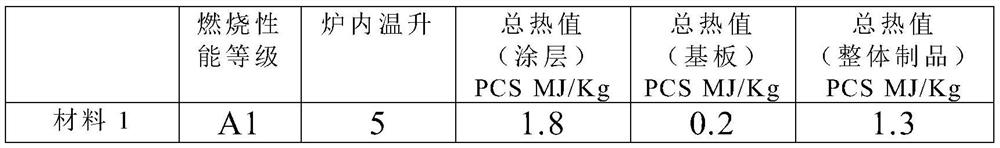

New preparation method of novel composite resin wood floor material

InactiveCN104327529AImprove flexural strengthLow water expansionFlooringProduction linePolyvinyl alcohol

The invention belongs to the filed of wood floors and discloses a new preparation method of a novel composite resin wood floor material. The preparation method of the composite resin wood floor material comprises the following steps: (1) preparing pine processed wastes, poplar saw dust and birch saw dust, and firstly drying the wastes and saw dust of different wood materials; (2) weighing 35-45 parts by weight of the pine processed wastes, 25-35 parts by weight of the poplar saw dust and 20-25 parts by weight of the birch saw dust, and mixing; (3) subsequently adding 10-15 parts of polyvinyl chloride resin, 3-6 parts of magnesium sulfate powder, 5-9 parts of polyvinyl alcohol and 4-10 parts of binary chlorinated paraffin resin into a high-speed mixer, and mixing until the materials are uniform; (4) extruding the uniformly-mixed materials in a production line to obtain the composite resin wood floor material.

Owner:ZHEJIANG HONGGAOLIANG WOOD

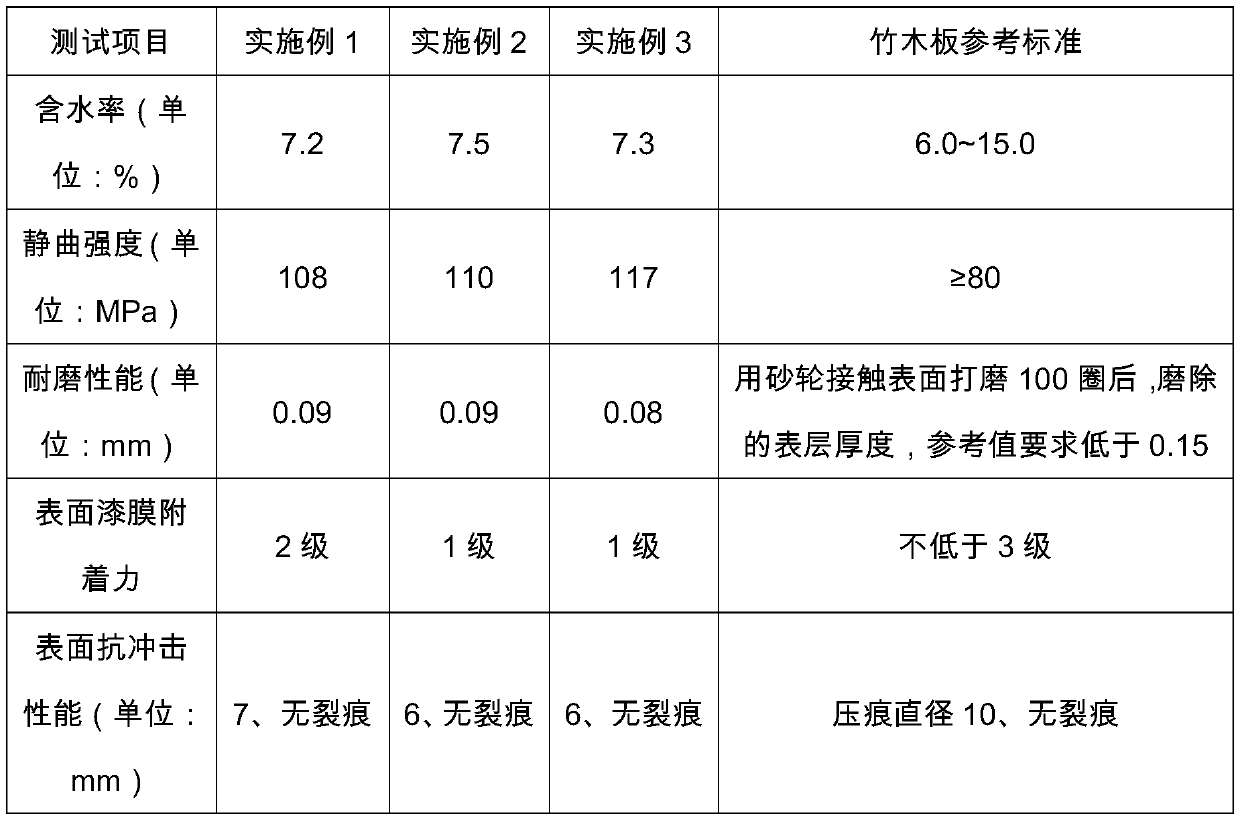

Process for preparing PVC (Polyvinyl Chloride) wood-plastic composite decorative board

InactiveCN107236204AImprove featuresImprove flame retardant performancePolymer sciencePolyvinyl chloride

The invention discloses a process for preparing a PVC (Polyvinyl Chloride) wood-plastic composite decorative board. The process comprises the following steps: (1) performing wood flour drying treatment; (2) performing wood flour modification treatment; and (3) mixing extrusion. According to the process disclosed by the invention, the raw materials are modified, the process is optimized, the overall characteristics of the PVC wood-plastic composite decorative board are well improved, the characteristics such as flame-retardant property, wear resistance, bending strength, board nail-holding ability and the like are well improved, the soaking swell rate is reduced, the comprehensive usage value is high, and the market competitiveness is high.

Owner:安徽吉美装饰材料有限公司

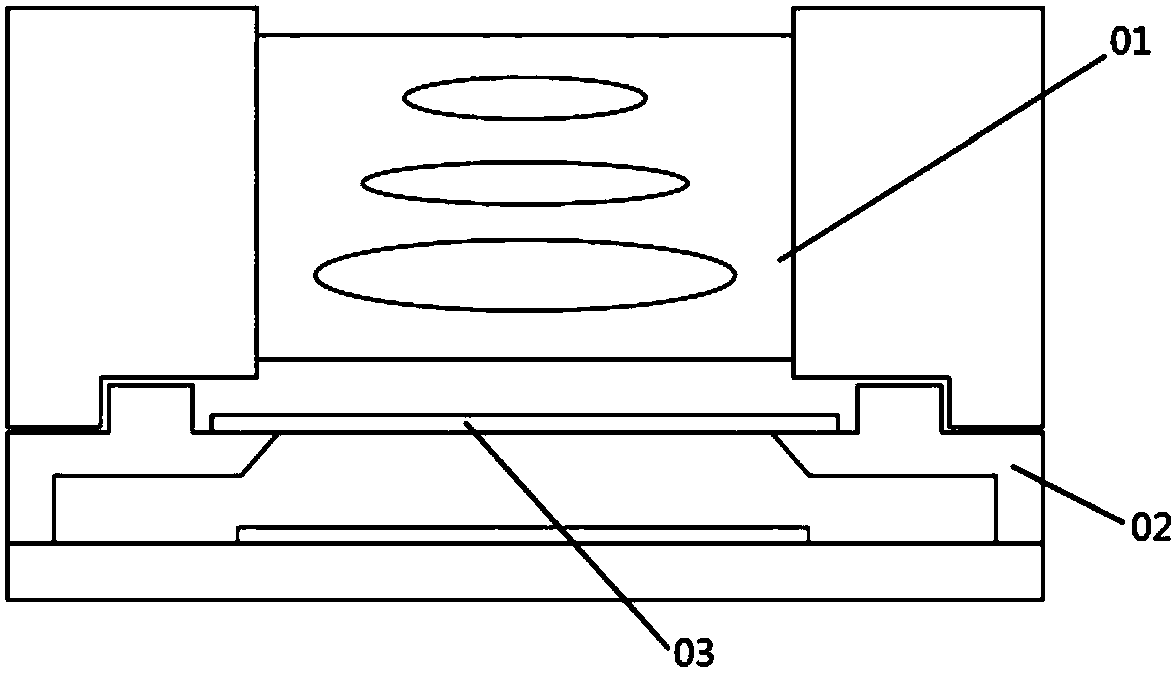

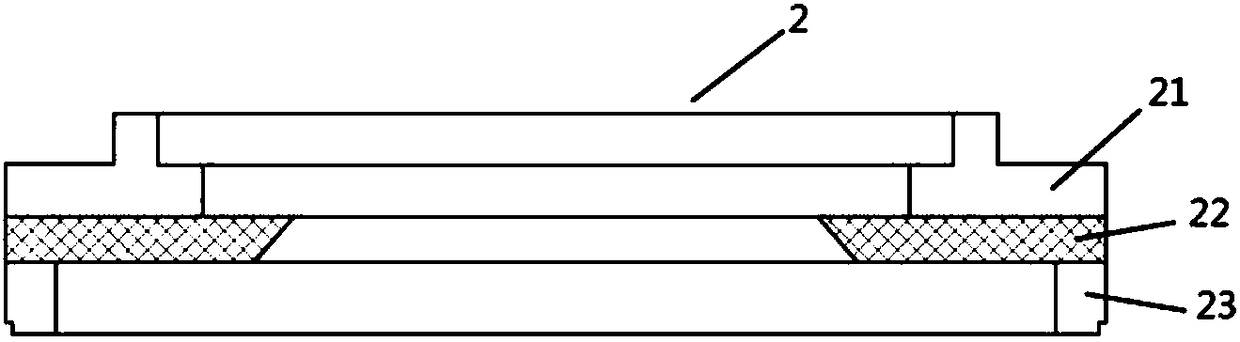

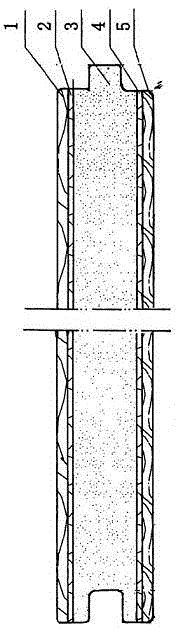

New-type camera module

PendingCN108668051AReduce volumeGuaranteed StrengthTelevision system detailsColor television detailsCamera lensMetallic materials

The invention provides a camera module, comprising lens assemblies and a base, wherein the base comprises a lens bearing part, optical filter bearing parts and cylinder parts. The optical filter bearing parts are made of a metal material and are integrated with the lens bearing part and the cylinder parts through utilization of an integration technology.

Owner:NINGBO SUNNY OPOTECH CO LTD

Bamboo jointed board processing method

InactiveCN111531662ACompensate for strength effectsImprove performanceWood treatment detailsCane mechanical workingRettingCeramic materials

The invention discloses a bamboo jointed board processing method which comprises the following steps: selecting a fresh round bamboo with the water content being 45-50% as a raw material bamboo, cutting the raw material bamboo at equal lengths, processing the cut bamboos into smooth bamboo joints with cylindrical structures, longitudinally split the bamboo joints to form axial gaps along the entire length, carrying out twice alkali liquor soaking and once warm supersaturated steam for softening treatment, carrying out flat pressing to form bamboo sheets, carrying out vacuum gum dipping treatment on the bamboo sheets, carrying out head-tail staggered superimposition in a die, carrying out hot pressing after superimposition, slicing along the bamboo fiber in the longitudinal direction, carrying out transverse and vertical staggered superimposition on the sliced bamboo sheets for three layers, gluing the parts between every two adjacent layers, and feeding the gummed bamboo in forming equipment for secondary hot pressing forming to obtain a finished product. The bamboo board prepared through the processing method takes a three-layer laminating structure and improves the uniform performance after the bamboo board is formed, so that the ageing resistance of the bamboo jointed board is further improved after the bamboo jointed board is made into a bamboo product, and the service lifeof the bamboo product is prolonged after the bamboo sheet is made into the bamboo product.

Owner:王海龙

Wood surface spraying process

InactiveCN108672240ALow water expansionAvoid easy water swelling damageRadiation/waves wood treatmentWood treatment detailsMaterial CrackAging resistance

The invention relates to the technical field of wood processing, in particular to a wood surface spraying process. According to the wood surface spraying process, wood materials can be subjected to spraying and air-drying treatment repeatedly. Through the wood surface spraying process, the water absorption expansion rate of the wood materials can be effectively reduced, after being manufactured into sketching easels, the wood materials can be effectively protected against water absorption, expansion and damage, and the ageing resistance of the wood materials is enhanced. The wood materials areput into preservative liquid, and the preservative effect of the wood materials is improved. Adhesive force of the preservative liquid to the wood materials is enhanced through ultrasonic treatment.The water content of the wood materials is reduced through hot air circulation drying. On one hand, the internal and external temperatures of the wood materials can be made uniform, and the phenomenonthat the surfaces of the wood materials crack and the interiors of the wood materials fracture due to sudden temperature rising is avoided; on the other hand, the water content of the wood materialscan be reduced, and robustness of the wood materials is improved. Finally, the wood materials are subjected to three-step freezing treatment, and the ageing resistance of the wood materials is improved.

Owner:天长市双丰文化用品有限公司

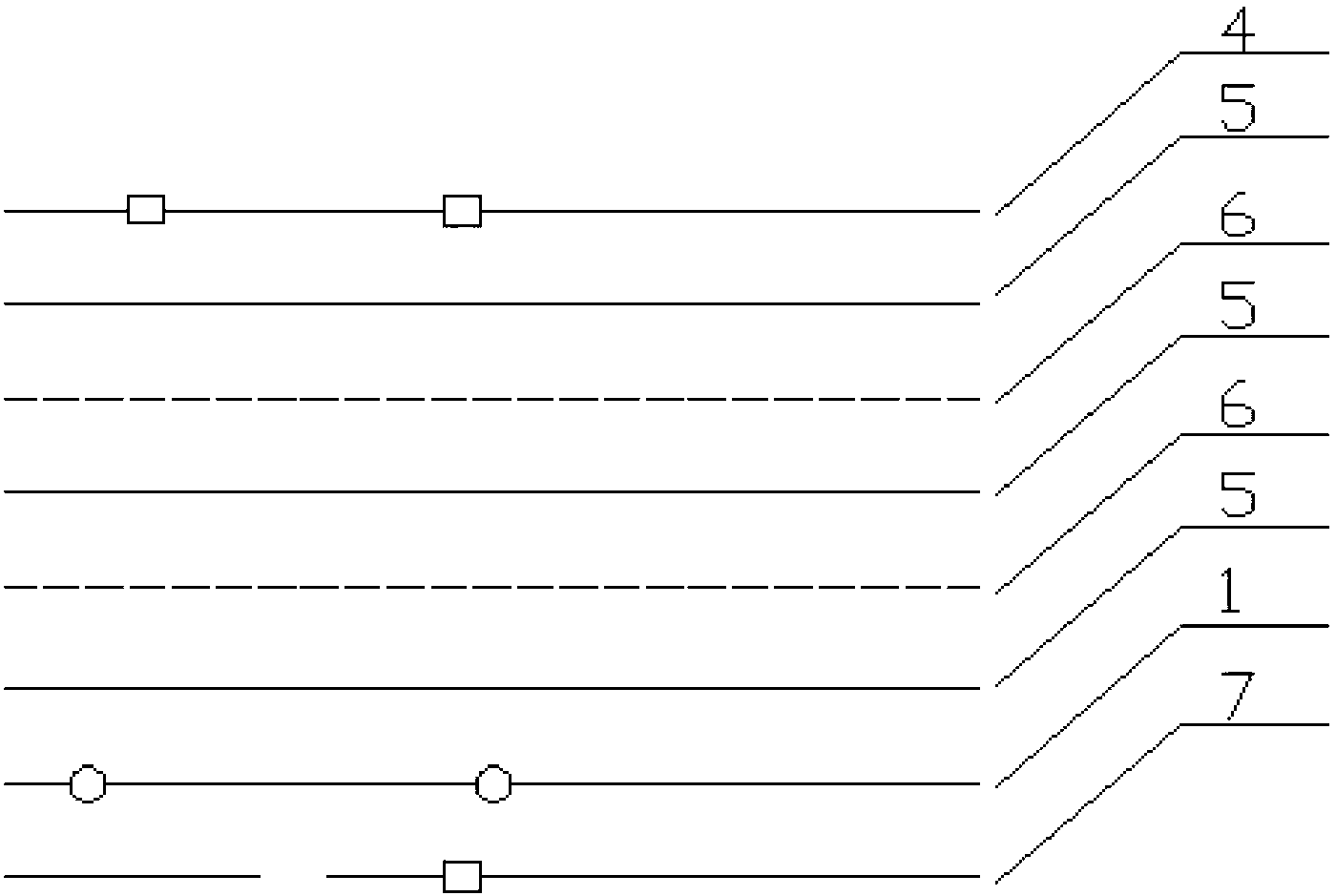

Novel macromolecule veneer bamboo polywood

ActiveCN106182957AHigh turnoverEasy constructionSynthetic resin layered productsWood veneer joiningEngineeringHot melt

The invention discloses a novel macromolecule veneer bamboo polywood. The novel macromolecule veneer bamboo polywood is formed by pressing bamboo mixed adhesives. The novel macromolecule veneer bamboo polywood comprises an upper plastic board, a lower plastic board and a wood layer located between the plastic boards and thermally molten with the plastic boards. The plastic boards include the upper plastic board and the lower plastic boards. The wood layer is formed by sequentially arranging bamboo chips in a criss-cross mode and pressing the bamboo chips through fixed adhesives; a padding area is formed in a gap with the size being 0.5-5 mm arranged at the contact position between the two bamboo chips, and the filling area is filled with a transverse overflow adhesive layer. According to the novel macromolecule veneer bamboo polywood, the density and mechanical strength are uniform, no separation layer appears, the structure is firm, the shear strength is high, the surface is smooth and not prone to water seepage, and the service life is greatly prolonged.

Owner:益阳桃花江竹业发展有限公司

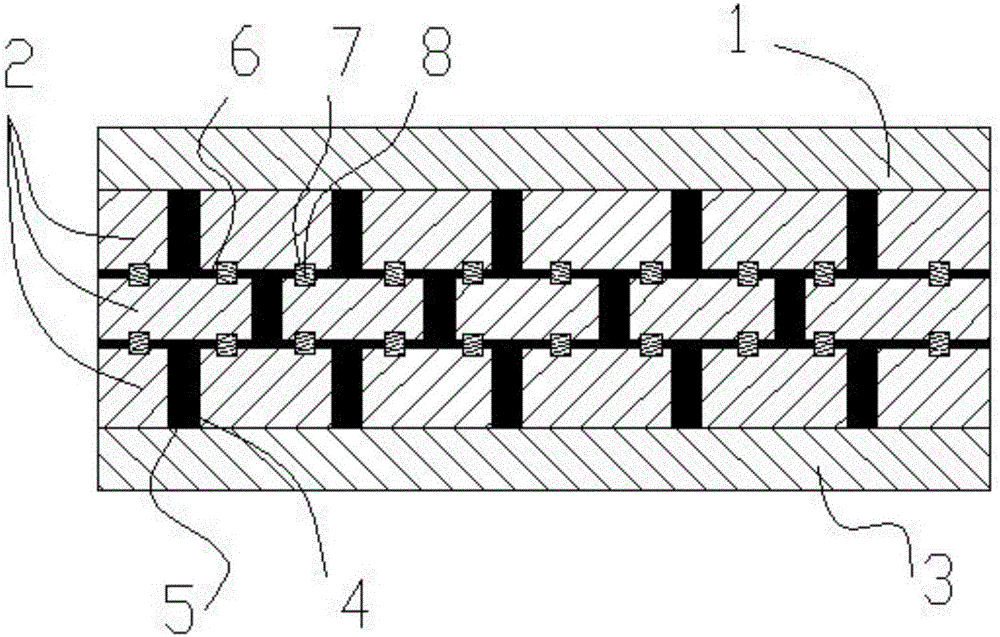

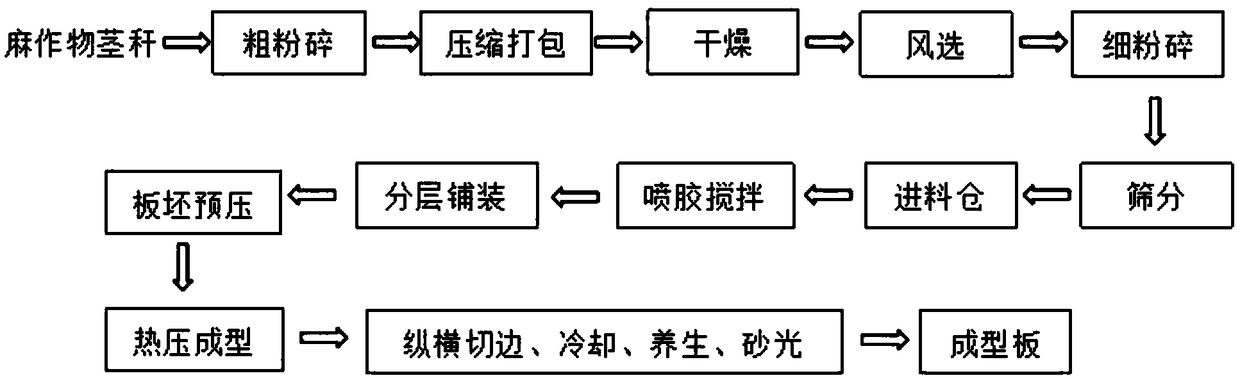

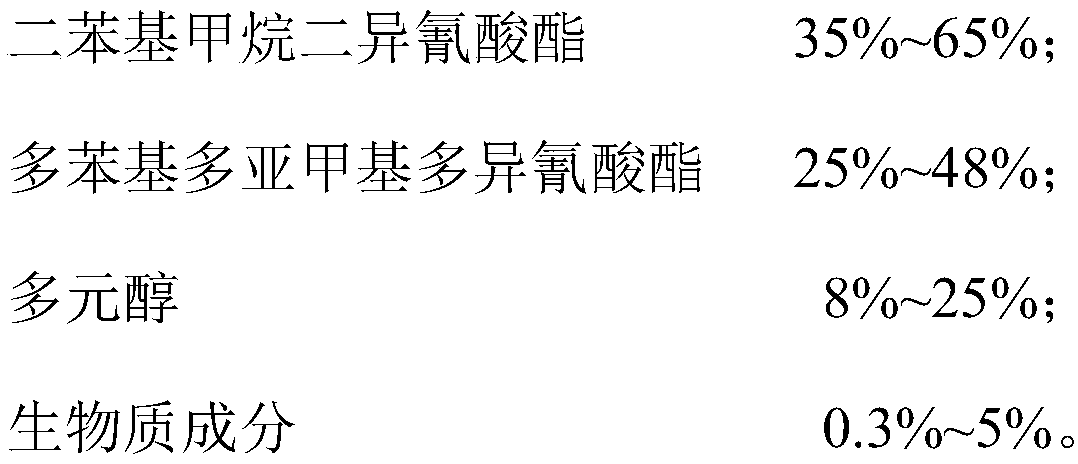

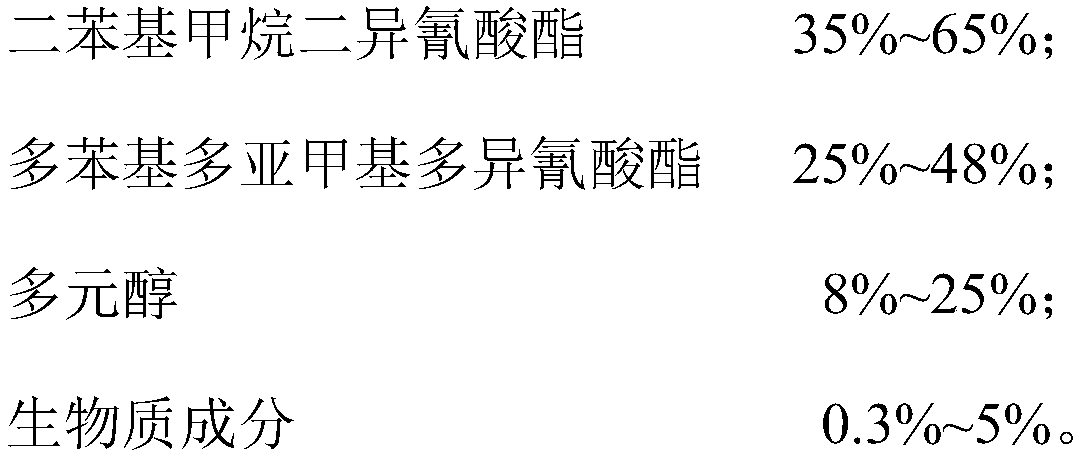

Method for producing formaldehyde-free artificial boards from hemp stalks

InactiveCN109483686AIncreased pre-compression strengthEasy to produceDomestic articlesFlat articlesPolymeric MDIEngineering

The invention provides a method for producing formaldehyde-free artificial boards from hemp stalks. The method for producing the formaldehyde-free artificial boards from the hemp stalks is characterized in that hemp crop stalks are used as raw materials and crushed to the fineness of 20-50 mesh, polymeric MDI adhesive with a weight of 2%-8% of the hemp crop stalks and a non-formaldehyde modifier with a weight of 2%-5% of the hemp crop stalks are added, and artificial boards are produced through mixing and stirring, pressing formation and post-processing. The method for producing the formaldehyde-free artificial boards from the hemp stalks utilizes the excellent structural characteristics of the hemp crop stalks, and realizes the technical method of large-scale production of the formaldehyde-free artificial boards from the hemp crop stalks.

Owner:上海世崛资产管理有限公司

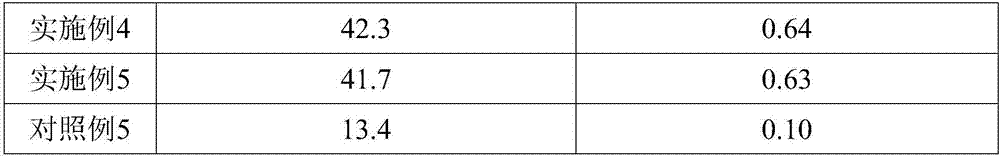

Low-expansion-rate waste tire rubber powder modified bamboo fiberboard and preparation method thereof

InactiveCN105082304AGood water and oil resistanceLow water expansionNon-macromolecular adhesive additivesProtein adhesivesFiberFiberboard

The invention discloses a low-expansion-rate waste tire rubber powder modified bamboo fiberboard. The low-expansion-rate waste tire rubber powder modified bamboo fiberboard is prepared by the following raw materials in parts by weight: 162-164 parts of bamboo fibers, a proper amount of 0.2% sodium hydroxide solution, 16.2-16.7 of soy isolate proteins, 1.5-1.6 of preservatives, 7-8 of waste tire rubber powder, 0.8-1 of ascorbyl palmitate, 1.3-1.6 of nanometer polytetrafluoroethylene, 1.5-1.8 of cyanuric acid melamine, and 0.4-0.6 of dimethyl dithioglycolic acid diisooctyl tin. The bamboo fiberboard uses the waste tire rubber powder for modifying, so that the board surface shows excellent hydrophobicity; and ascorbyl palmitate, nanometer polytetrafluoroethylene, cyanuric acid melamine and dimethyl dithioglycolic acid diisooctyl tin are used, so that the board is excellent in water and oil resistance, low in water expanding rate, excellent in ageing resistance, excellent in light resistance and suitable for manufacturing indoor and outdoor office furniture and floors.

Owner:ANHUI BAIYI FURNITURE

Multi-layer board integral hot pressing process

InactiveCN108437142AImprove anti-agingUniform temperatureWood working apparatusOther artistic work equipmentsMoistureHot pressing

The invention relates to the technical field of wood processing, in particular to a multi-layer board integral hot pressing process. The method comprises the following steps that firstly, repeatedly spraying and airing is carried out on a wood board so that the water absorption expansion rate of the wood board can be effectively reduced, then the wood board can be effectively prevented from beingprone to absorb water and damaged after being made into a drawing board, and the ageing resistance of the board is enhanced; then the wood board is placed into an anti-corrosion liquid, so that the anti-corrosion effect of the wood board is enhanced, then the moisture content of the wood board is reduced through hot air circulation drying, and therefore the inner temperature and the outer temperature of the wood board are uniform and consistent, the moisture content of the wood board is reduced, and the firmness of the wood board is improved; and finally, the wood board is subjected to coronatreatment, so that the static property of the wood board is enhanced, the adhesion of the subsequent wood board is better, then the wood board is bonded through an adhesive, hot pressing and freezingtreatment are carried out, and then the prepared multi-layer board is good in bonding effect and high in firmness.

Owner:天长市双丰文化用品有限公司

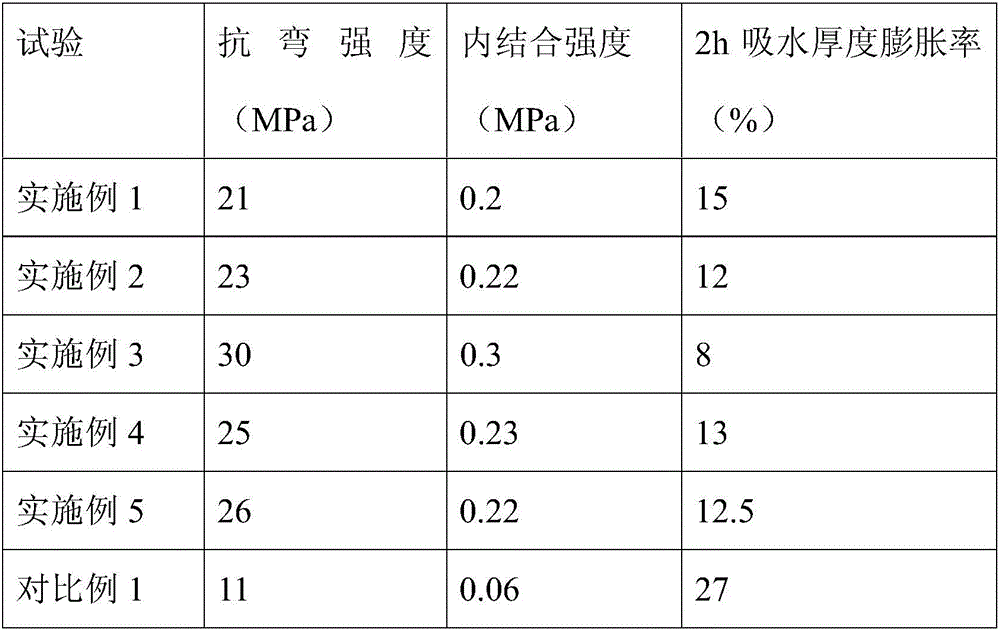

Straw particle board and preparation method thereof

InactiveCN106625978AImprove performanceEfficient use ofFlat articlesDomestic articlesAdhesiveCoupling

The invention discloses a straw particle board and a preparation method thereof. The method comprises the following steps: 1 spraying a phenolic adhesive or adhesive coupling agent mixed solution onto smashed straws till the smashed straws are completely wetted, stewing the straws, then drying the straws, and paving the straws to form a board blank; 2, covering the board blank with steel plates, and carrying out pre-pressing; 3, drying the pre-pressed board blank at 30 to 40 DEG C till the moisture content is less than 5 percent; 4, uniformly covering the surface of the dried board blank with a layer of sodium lignin sulfonate with the thickness of 1 to 3 mm, and carrying out moisture absorption at the humidity of 80 to 100 percent and the temperature of 60 to 65 DEG C till the moisture content is 6 to 8 percent; and 5, placing cushion blocks at the edges between the upper and lower steel plates of the board blank subjected to the moisture absorption, carrying out thermal pressing, and releasing the pressure to obtain the straw particle board. The straw particle board disclosed by the invention is high in performance and low in cost, and has the bending strength of 20 MPa or above and the internal combination strength of 0.2 to 0.3 MPa.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

A kind of preparation method of bamboo beam and bamboo beam prepared by this method

The invention relates to a material which is used for supporting buildings in the field of architectural engineering and particularly relates to a method for producing a bamboo cross beam and the bamboo cross beam produced through the method. According to the technical scheme, the method comprises steps of selecting and sawing bamboos; punching and primarily planing bamboos; conducting charring; conducting drying; conducting finish plane; conducting splice, wherein bamboo splints are spliced mutually through an adhesive along a length direction and a width direction, placed in a hot press and subjected to hot pressing to form veneers; conducting lamination, wherein veneers are laminated vertically through the adhesive in accordance with requirements, placed in the hot press and subjected to hot pressing to form an integral plate, and the lengths of the bamboo splints of every veneer are in the same directions; and conducting cutting, wherein the integral plate is cut along the direction of the bamboo splints so as to form cross beams and cross beams have radians along the length direction of the bamboo splints. By the aid of the method, the bamboo cross beam has good fireproof performance and high loading capacity.

Owner:浙江安吉双虎竹木业有限公司

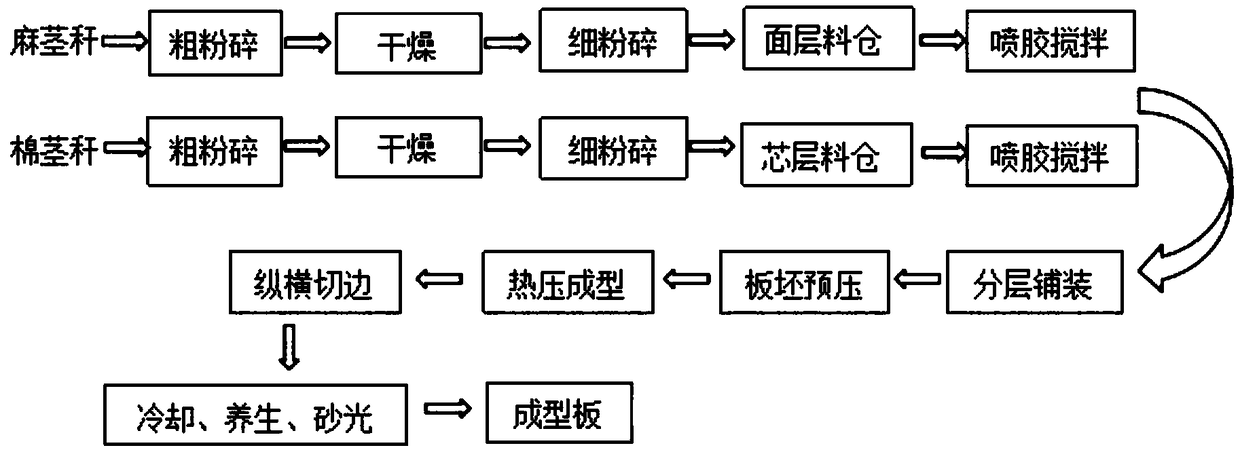

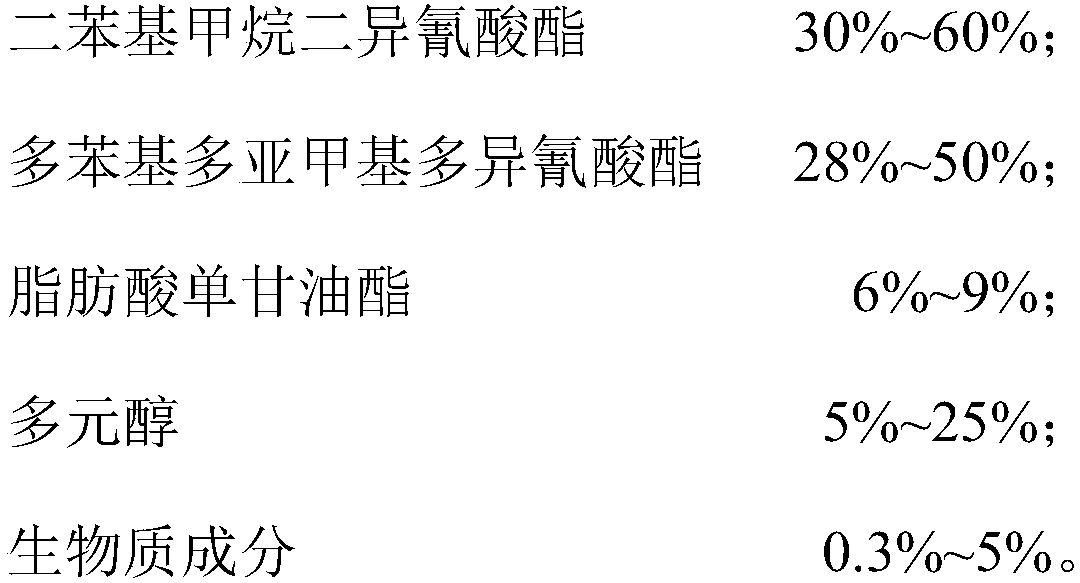

Manufacturing method of crop stalk mixing manufactured formaldehyde-free artificial board

InactiveCN109049263AEnhanced pre-compression strengthImprove efficiencyWood working apparatusFlat articlesFormaldehyde freeEngineering

The invention provides a manufacturing method of a crop stalk mixing manufactured formaldehyde-free artificial board. The manufacturing method of the crop stalk mixing manufactured formaldehyde-free artificial board is characterized by comprising the following steps that 1, hemp crop stalks are crushed, a first polymerized MDI adhesive which the weight accounts for 3%-8% of the hemp crop stalks and a formaldehyde-free modifier which the weight accounts for 3%-5% of the hemp crop stalks are added, and stirring and mixing are carried out; 2, cotton stalks are crushed, a second polymerized MDI glue which the weight accounts for 2%-6% of the cotton stalks and the formaldehyde-free modifier which the weight accounts for 2%-5% of the cotton stalks are added, and the stirring and the mixing arecarried out; 3, the cotton stalks which are stirred and mixed are used as a core layer, the hemp crop stalks serve as a surface layer, and layered laying are carried out to form a slab; and 4, compression molding is carried out on the slab, and post-treatment is carried out to obtain the artificial board.

Owner:上海世崛资产管理有限公司

Environment Protection composite floor board

The invention is an environmental-protection complex floor, comprising a surface layer being of a single wood plate with beautiful veins and tenacious quality and a bottom layer being of a singe wood plate with loose quality, and characterized in that it is provided with a core layer being of a formaldehyde-free stalk homogeneous flakeboard; the single wood plates in the surface and bottom layers are 1.5-2.5 mm thick. The invention solves the technical problems: the surface of the floor need be tenacious and wearable, and its bottom surface need be loose and contacts with the base well, it does not get damp and is not slippery, and it can save large amount of wood.

Owner:上海康拜环保科技有限公司 +1

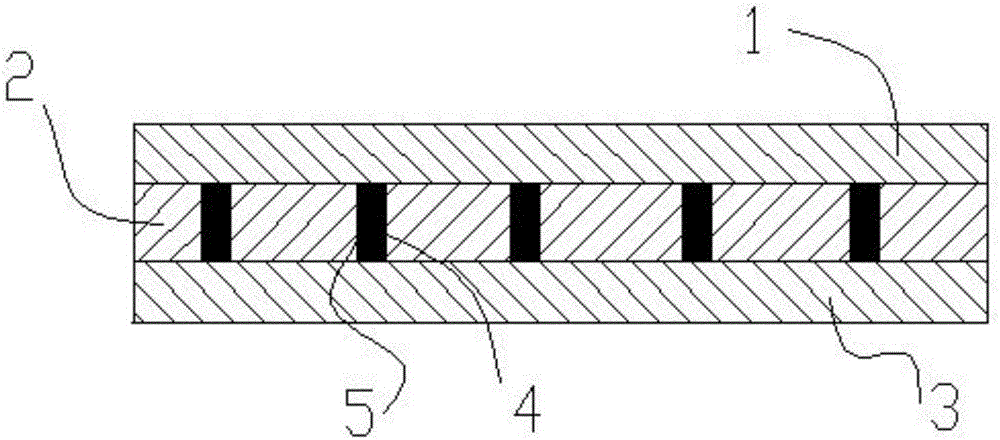

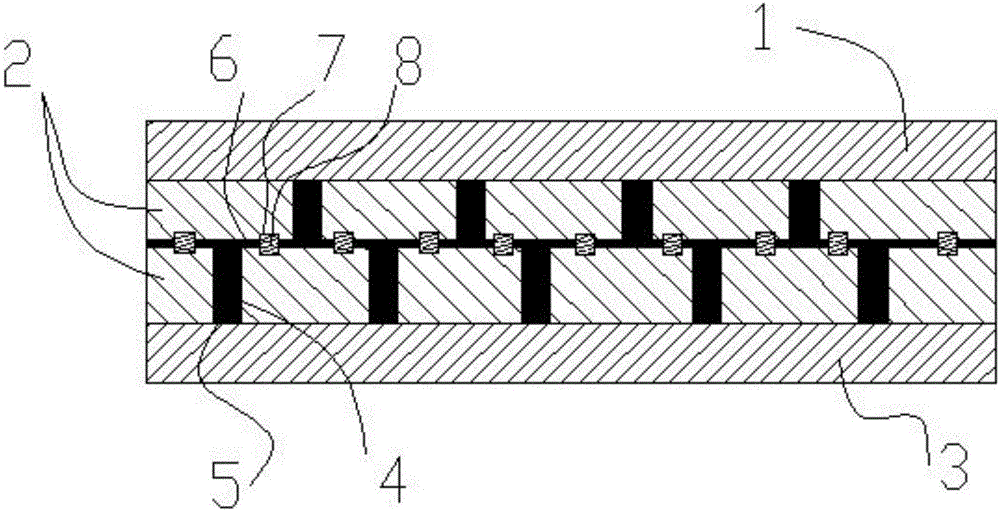

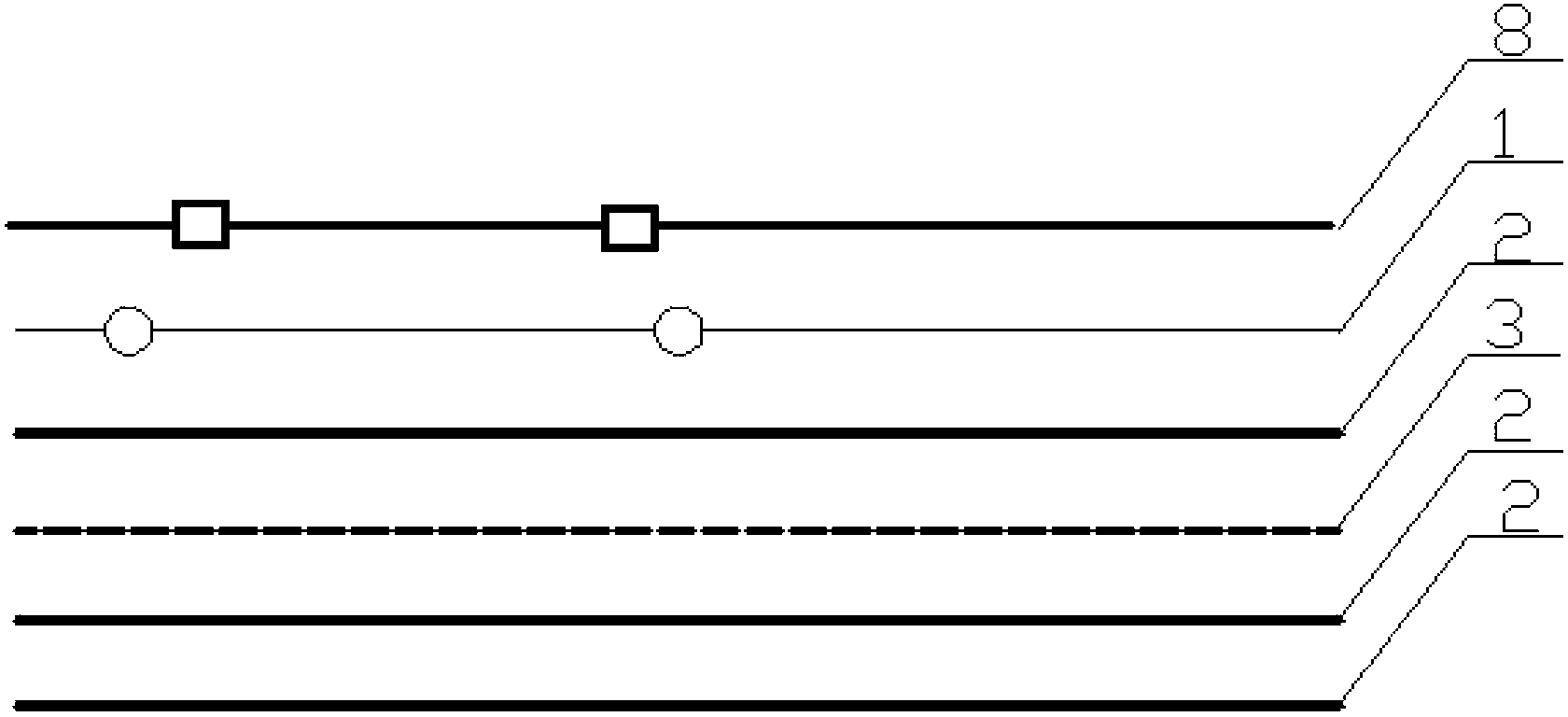

Bamboo-based interior lining board of railway boxcar and manufacturing method of interior lining board

ActiveCN103223681AElasticHigh surface hardnessLaminationLamination apparatusManufacturing technologyEngineering

The invention relates to the fields of manufacturing technology and application artificial board and discloses a bamboo-based interior lining board of a railway boxcar and a manufacturing method of the interior lining board. The bamboo-based interior lining board of the railway boxcar comprises a bamboo artificial board and a refractory board, wherein the bamboo artificial board comprises a plurality of layers; the outer layer is a bamboo mat which is soaked with phenolic aldehyde glue and dried at low temperature; one layer of longitudinal texture bamboo curtain which is soaked with phenolic aldehyde glue and dried at low temperature is arranged below the bamboo mat; one layer of transverse texture bamboo curtain which is soaked with phenolic aldehyde glue and dried at low temperature is arranged below the longitudinal texture bamboo curtain; and two layers of longitudinal texture bamboo curtains which are soaked with phenolic aldehyde glue and dried at low temperature are arranged below the transverse texture bamboo curtain. The bamboo-based interior lining board of the railway boxcar has high mechanical property and low water absorption expansion rate, has the advantages of high surface hardness, high wear resistance, excellent aesthetic degree, high impact resistance and no need of paint, and can be manufactured by selecting the width size of the bamboo-based artificial board as required.

Owner:ZHUJI GUANGYU BAMBOO IND

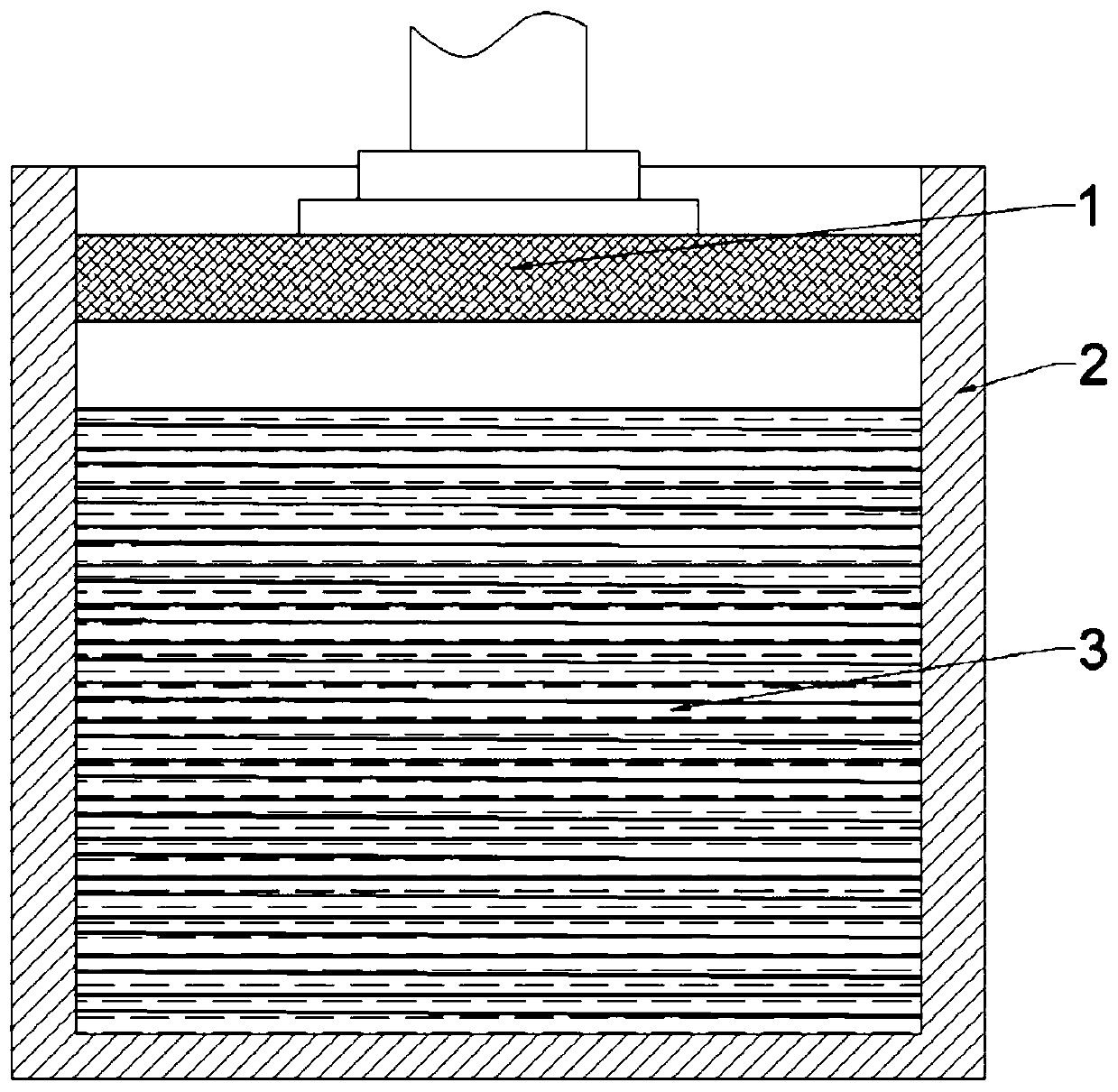

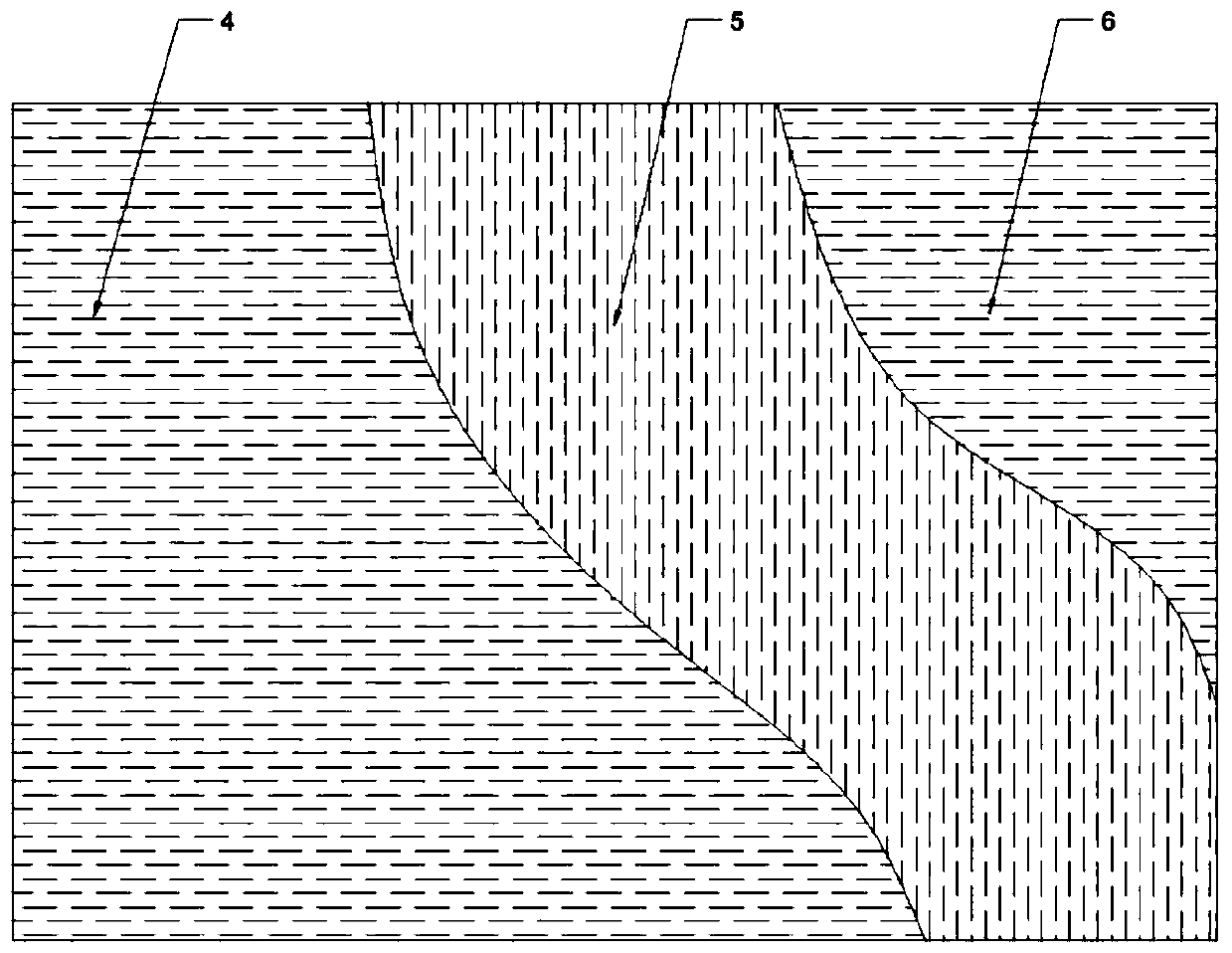

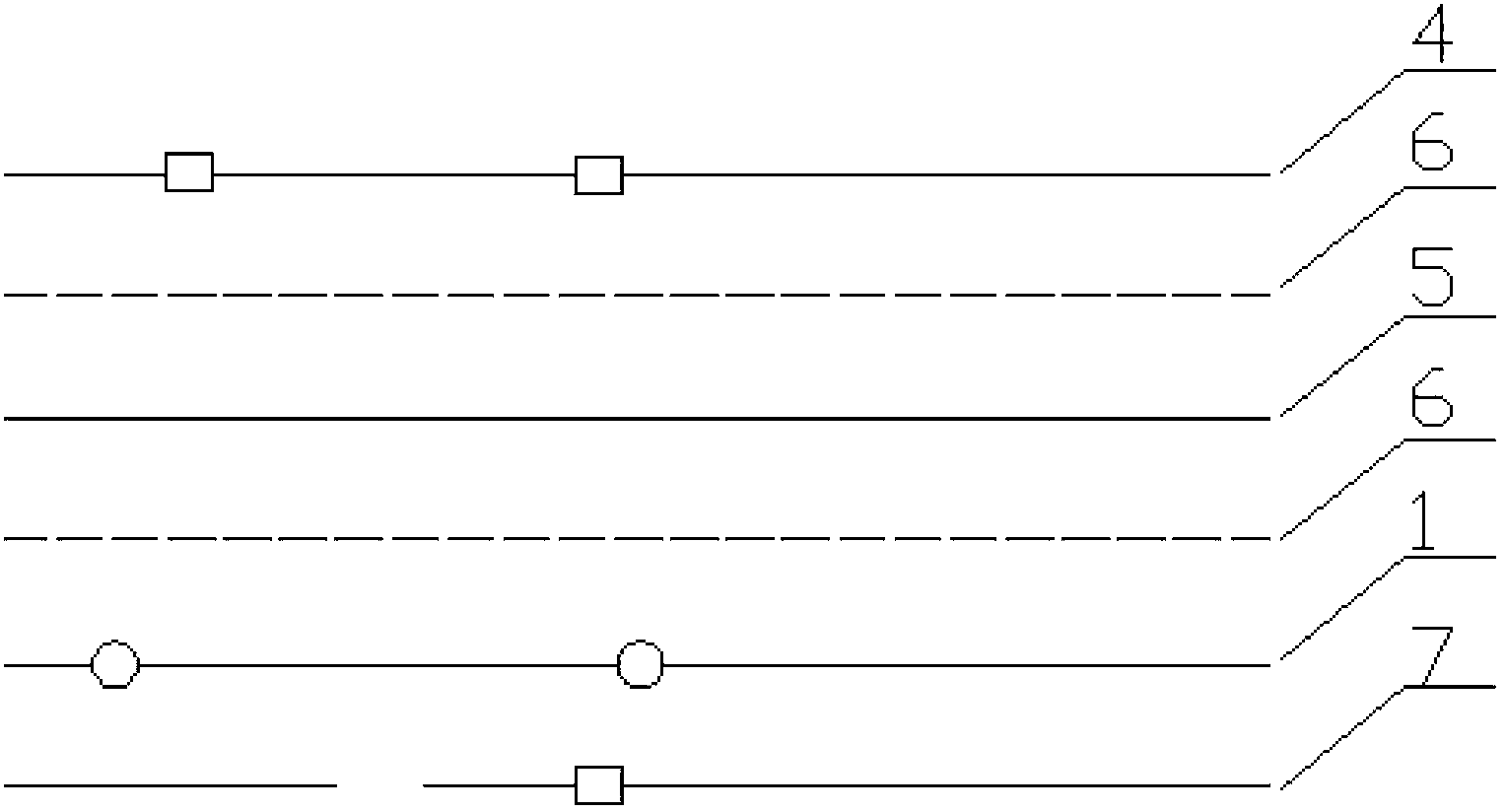

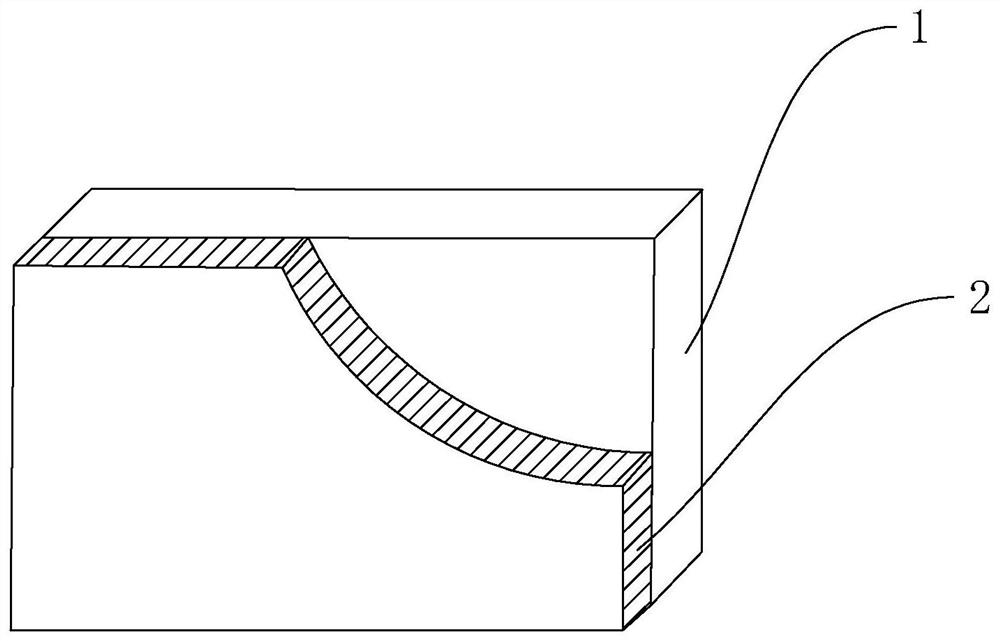

Energy-saving type humidity-regulating vitrified plate for building and preparation method thereof

ActiveCN111851858ALow water expansionUniform pore size distributionBuilding insulationsClaywaresCalcium silicateHoneycomb

The invention belongs to the technical field of building decoration materials and in particular relates to an energy-saving type humidity-regulating vitrified plate for a building and a preparation method thereof. In order to solve the problem that in the prior art, a material is easily affected with damp, problems of wet swelling, dry shrinking, and mildewing exist, and even if various damp-prooftreatments are carried out, the problems cannot be completely solved, the invention provides the energy-saving type humidity-regulating vitrified plate for the building. The energy-saving type humidity-regulating vitrified plate for the building is composed of a base material 1 and a humidity-regulating vitrified layer 2. The humidity-regulating vitrified layer 2 is arranged on the upper surfaceof the base material 1, the base material 1 is any one of a calcium silicate board, an inorganic honeycomb grouting board and a magnesium sulfate board, and the humidity-regulating vitrified layer 2 is 0.1-3 mm thick. The energy-saving type humidity-regulating vitrified plate for the building provided by the invention is relatively small in water absorbing expansion rate and uniform in material pore size distribution, has a better humidity-regulating function at relative humidity from 40% to 90%, is free of an obvious softening phenomenon on the surface, is pollution-resistant and can be scrubbed.

Owner:浙江艺玛材料科技有限公司

Eco-friendly composite floor made by different material combinations

An environmentally friendly composite floor, comprising a solid wood veneer with beautiful texture and tough texture on the surface layer and a solid wood veneer with soft texture on the bottom layer, characterized in that: a core layer of formaldehyde-free straw homogeneous particleboard is provided; The thickness of solid wood veneer is 1.5-2.5mm. The invention solves the technical problem that the surface of the floor should be tough and wear-resistant, the bottom surface should be soft and in good contact with the foundation, not damp and slippery, and a large amount of wood can be saved.

Owner:黑龙江万向鹏程科技发展有限公司

A new type of polymer veneer bamboo plywood

ActiveCN106182957BHigh turnoverEasy constructionSynthetic resin layered productsWood veneer joiningAdhesiveEngineering

The invention discloses a novel macromolecule veneer bamboo polywood. The novel macromolecule veneer bamboo polywood is formed by pressing bamboo mixed adhesives. The novel macromolecule veneer bamboo polywood comprises an upper plastic board, a lower plastic board and a wood layer located between the plastic boards and thermally molten with the plastic boards. The plastic boards include the upper plastic board and the lower plastic boards. The wood layer is formed by sequentially arranging bamboo chips in a criss-cross mode and pressing the bamboo chips through fixed adhesives; a padding area is formed in a gap with the size being 0.5-5 mm arranged at the contact position between the two bamboo chips, and the filling area is filled with a transverse overflow adhesive layer. According to the novel macromolecule veneer bamboo polywood, the density and mechanical strength are uniform, no separation layer appears, the structure is firm, the shear strength is high, the surface is smooth and not prone to water seepage, and the service life is greatly prolonged.

Owner:益阳桃花江竹业发展有限公司

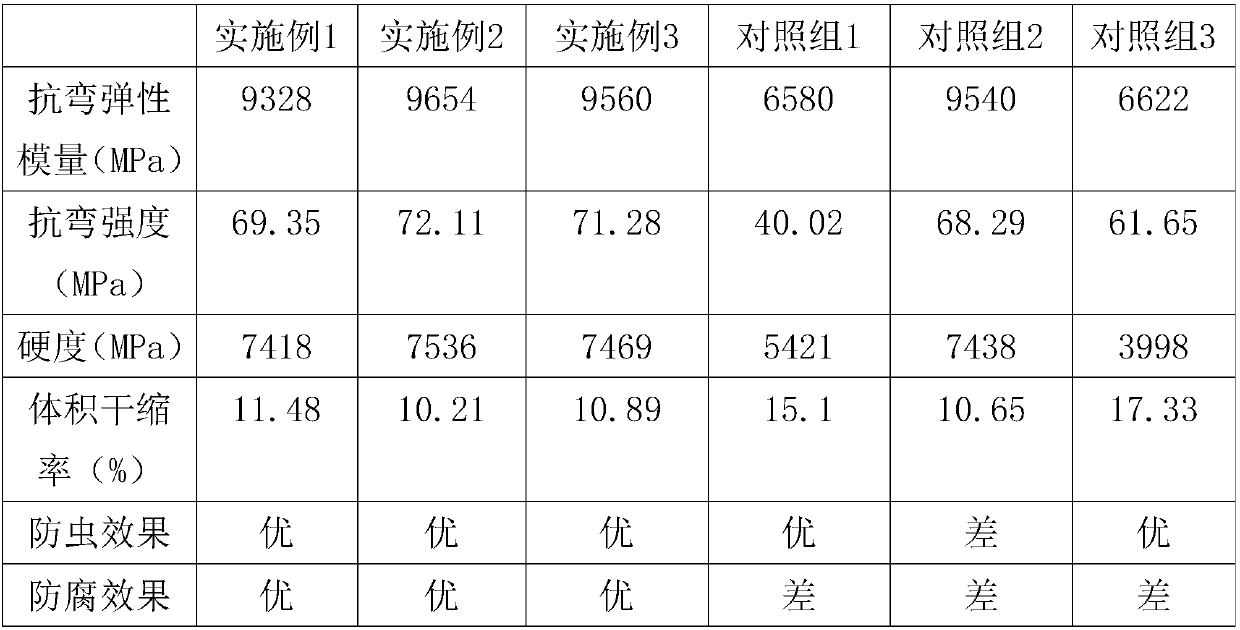

Method for producing wood fiber glued board and application

InactiveCN101462284BImprove physical and chemical propertiesHigh hardnessWood veneer joiningAdhesive application devicesSolid woodWood fibre

The invention provides a method for making a wood-fiber laminated wood. The method comprises: gluing raw materials like small-diameter materials, small wattles and so on into a primary square material; planing the square material into even splints by the modes of mechanical cutting, planing, sawing and so on; gluing the splints into various boards. The wood-fiber laminated wood keeps the originalfiber tissues and natural textures of the small-diameter materials. Compared with ordinary logs, the physicochemical performances of the laminated wood are improved greatly, and rigidity, density, static bending strength, anti-impact strength, elastic modulus and so on are 2 to 4.5 times higher than those of the ordinary logs. The laminated wood also has the performances which the ordinary logs do not have, such as corrosion resistance, borer proofing, no deformation, no crack, water resistance and so on, and can replace solid wood used for furniture, floors, building materials and occasions with special requirements.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com