Inorganic/organic composite proton fuel cell exchange membrane and preparation thereof

A fuel cell and exchange membrane technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components and other directions, can solve the problems of unsatisfactory material performance improvement, low mechanical strength of composite membranes, and unsatisfactory moisturizing properties, etc. The effect of improving fuel cell performance, superior performance and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

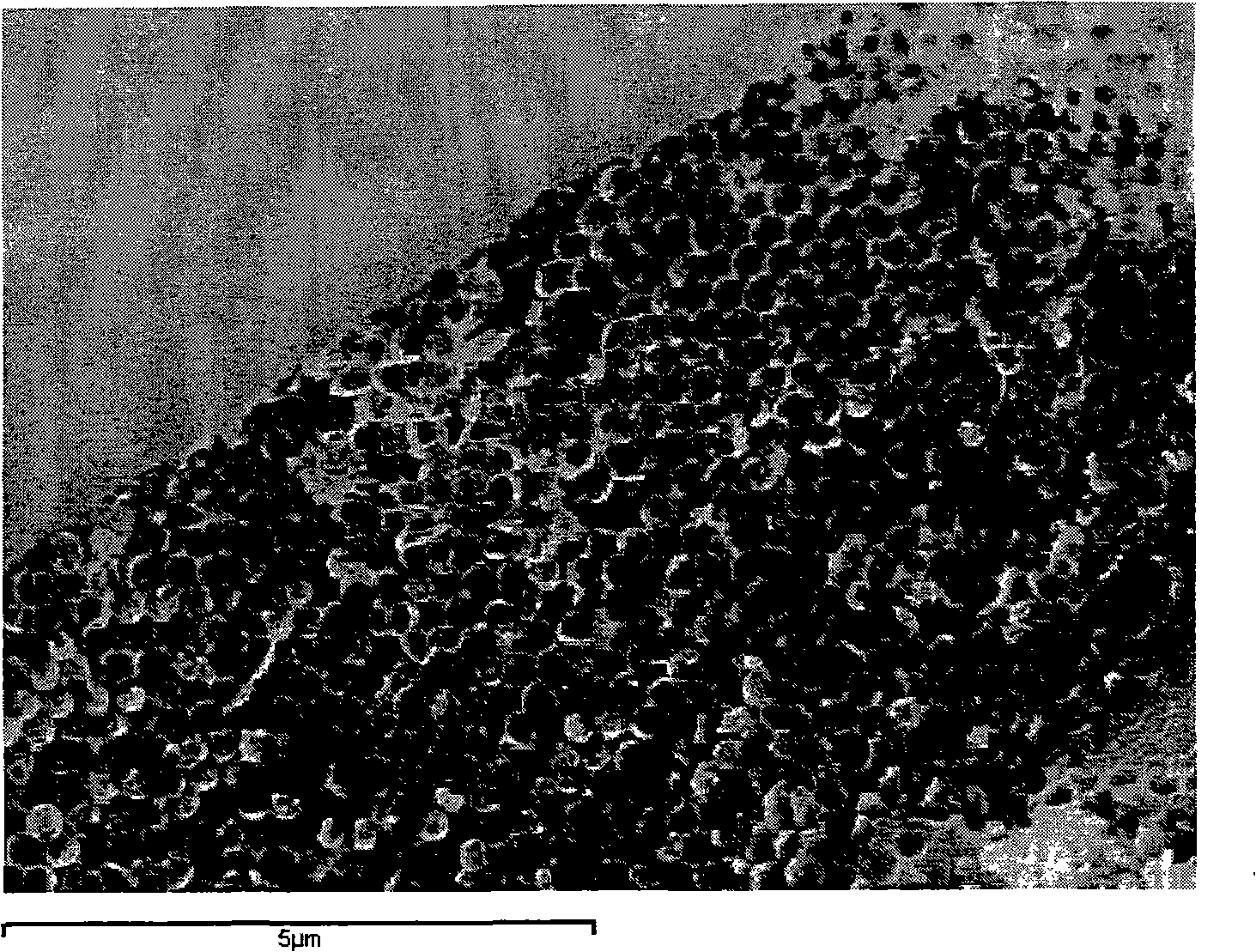

[0022] Three-dimensional mesh structure SiO 2 preparation

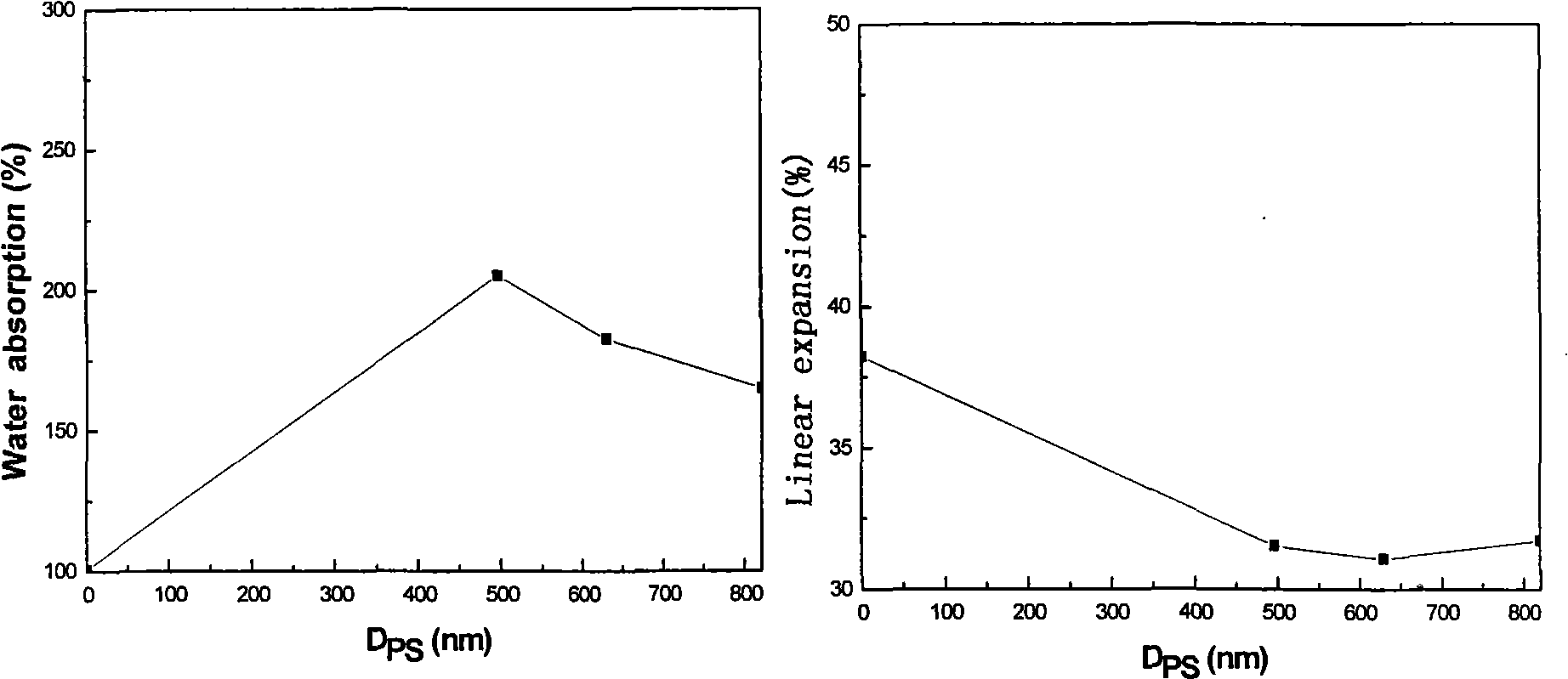

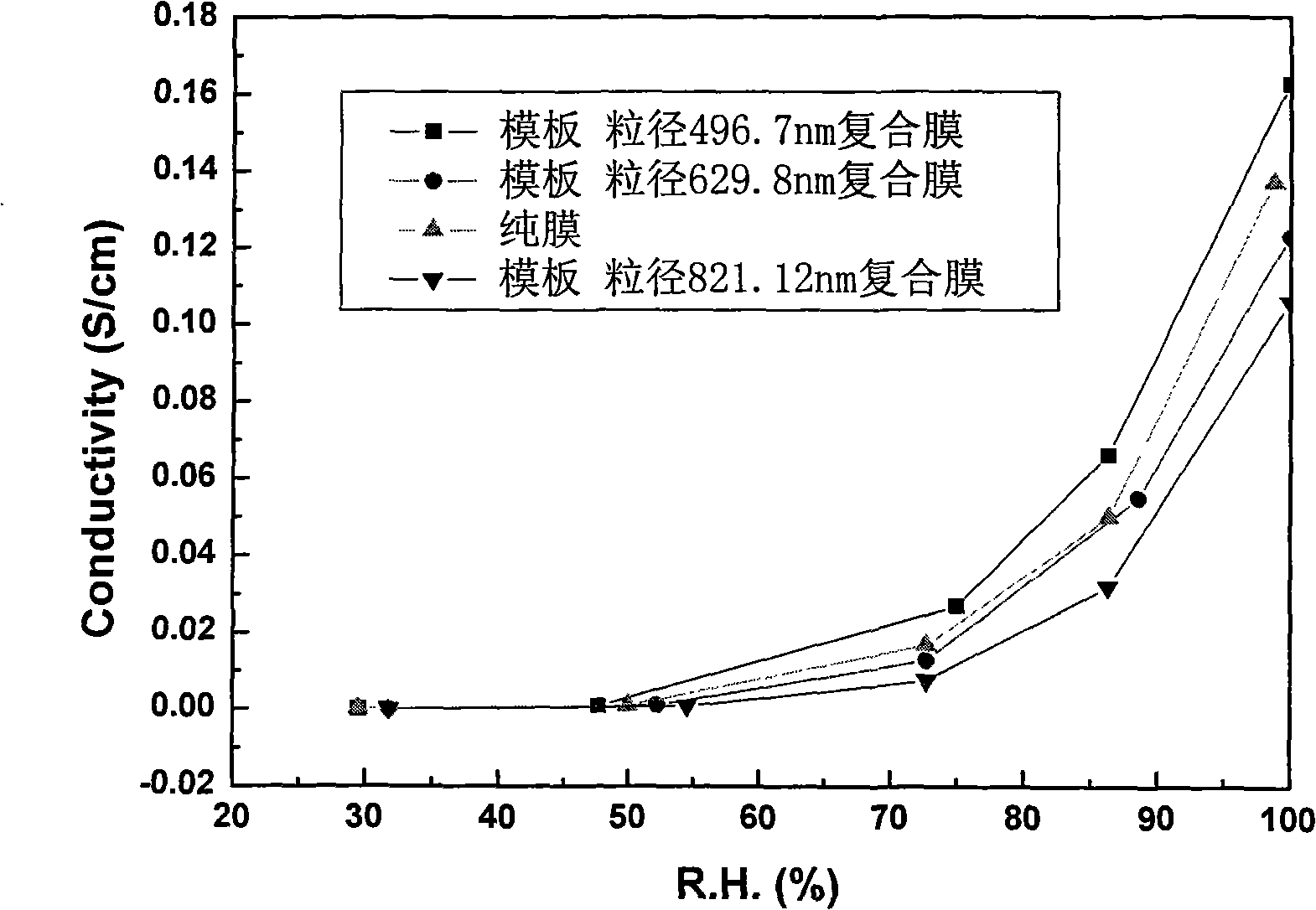

[0023] (1) Use monodisperse colloidal polystyrene microspheres with an average particle size of 496.7nm as the template material, and a particle size of 80nm SiO 2 The sol is mixed, and a template with a thickness of 60 microns is made by gravity sedimentation method, centrifugal sedimentation method or vertical substrate deposition method.

[0024] (2) At 600°C, the polystyrene microsphere template was burned for 5 hours, and the SiO with an average pore size of 315nm was measured. 2 template.

[0025] Preparation of composite membrane

[0026]Take 0.6 g of sulfonated polyetheretherketone (SPEEK) and add 5.4 g of N'N-dimethylpyrrolidone (NMP) to form a solution of about 10%. After stirring and dissolving, pour the SiO with three-dimensional mesh structure obtained above. 2 In the process, the solvent was evaporated at 80°C for 6 hours, and then the temperature was raised to 130°C for 30 minutes for aging to comp...

Embodiment 2

[0027] Embodiment 2: with embodiment 1, wherein colloidal polystyrene microsphere diameter is 629.8nm, SiO 2 The particle size is 80nm.

Embodiment 3

[0028] Embodiment 3: with embodiment 1, wherein colloidal polystyrene microsphere diameter is 821.12nm, SiO 2 The particle size is 80nm, and the polystyrene template particles can also be soaked and dissolved in tetrahydrofuran.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com