Manufacturing method of crop stalk mixing manufactured formaldehyde-free artificial board

A manufacturing method and technology of wood-based panels, which are applied in the direction of flat products, household components, household appliances, etc., can solve the problems affecting the industrial application of wood-based panels, high cost, large amount of glue, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

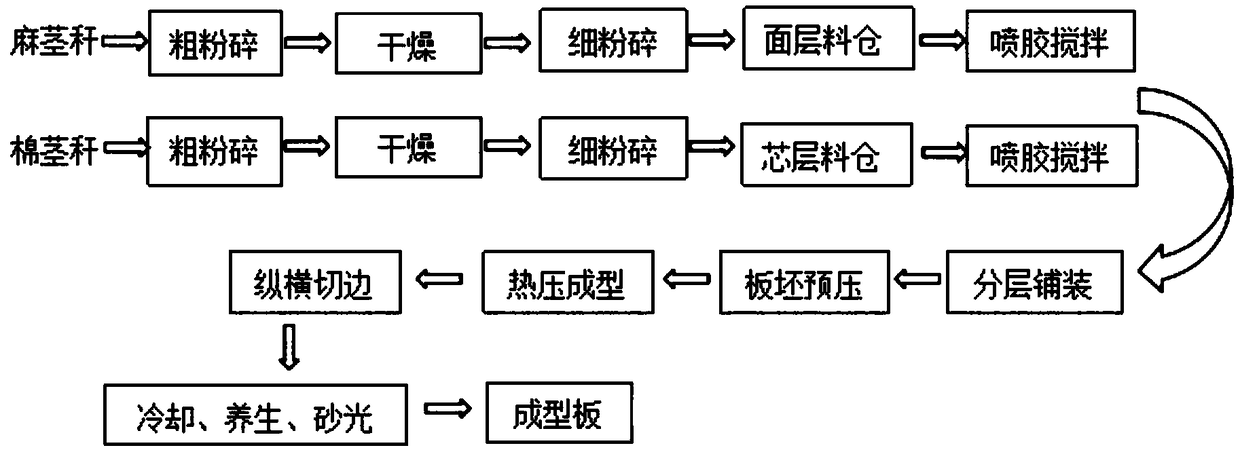

Method used

Image

Examples

Embodiment 1

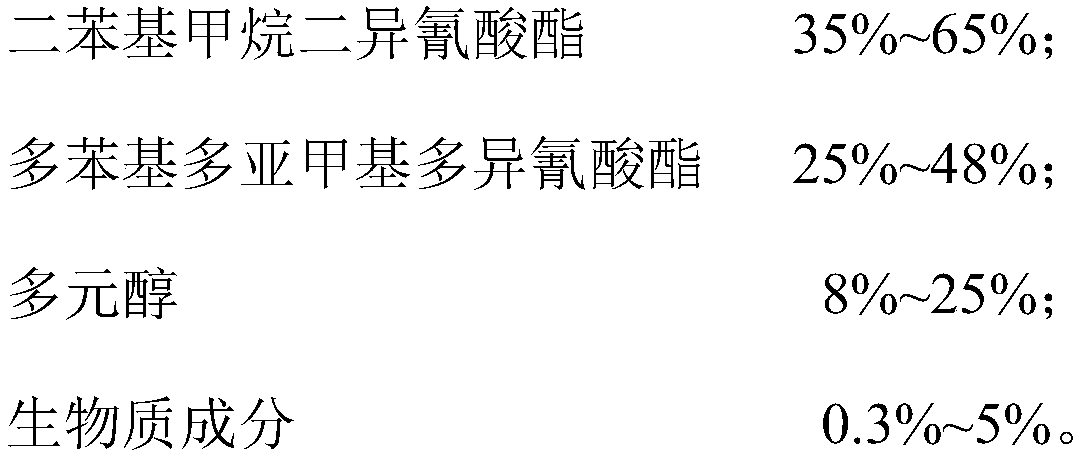

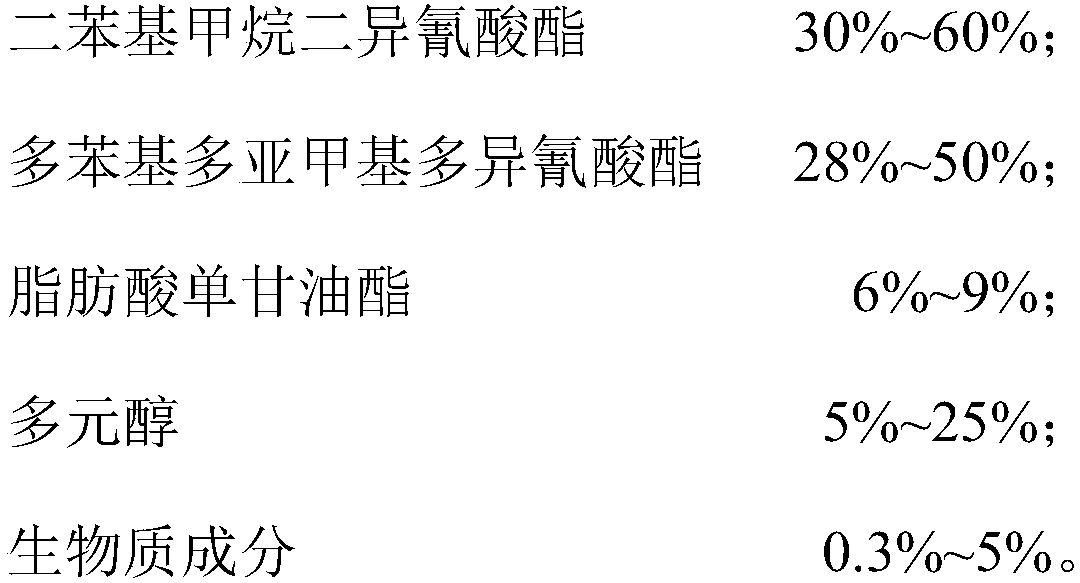

[0030] Step 1: Crushing the kenaf stalks is coarsely crushed, and the coarsely crushed stalks are dried by a tumble dryer so that the moisture content is in the range of 9% to 17%. The dried kenaf stalk raw materials are then passed through air selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 50-70 mesh, and then sent to the surface layer silo. The kenaf stalks in the surface layer silo are weighed, and the moisture content is measured by a moisture tester, and then sent to the first mixer, and the glue spraying device is controlled by PLC to spray glue, and the spray glue is controlled according to the corresponding weight. For the amount of glue, spray 3% of the first polymerized MDI glue with a weight of 3% of the dry weight of the kenaf stalks and 3% of a formaldehyde-free modifier with a weight of 3% of the dry weight of the kenaf stalks and stir and mix.

[0031] Step 2: Simultaneou...

Embodiment 2

[0038] Step 1: Crushing the jute stalks is firstly subjected to coarse crushing, and the coarsely crushed stalks are dried by a tumble dryer so that the moisture content thereof is within the range of 9% to 17%. The dried jute stalk raw materials are then passed through wind selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 50-70 meshes, and then sent to the surface layer silo. The jute stalks in the surface layer silo are weighed, and the moisture content is measured by a moisture tester, and then sent to the first mixer, and the glue spraying device is controlled by PLC to spray glue, and the glue spray is controlled according to the corresponding weight Amount, spraying into weight is the first polymerization MDI glue of 5% of jute stalk dry weight and the weight is 4% formaldehyde-free modifying agent of jute stalk dry weight and stirs and mixes.

[0039] Step 2: Simultaneously with st...

Embodiment 3

[0046] Step 1: Crushing jute stalks, hemp stalks, and flax stalks is firstly subjected to coarse crushing, and the coarsely crushed stalks are dried by a drum dryer so that the moisture content is within the range of 9% to 17%. The dried mixed hemp stalk raw materials are then passed through wind selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 50-70 mesh, and then sent to the surface layer silo. The mixed hemp stalks in the surface layer silo are weighed, and the moisture content is measured by the moisture tester, and then sent to the first mixer, and the glue spraying device is controlled by PLC to spray glue, and the spray glue is controlled according to the corresponding weight. For the amount of glue, spray the first polymerized MDI glue with a weight of 8% of the dry weight of the mixed hemp stalk and the formaldehyde-free modifier with a weight of 5% of the dry weight of the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com