Bamboo jointed board processing method

A processing method and technology of bamboo splicing, applied in the field of sheet metal processing, can solve problems such as the influence of outer surface flatness, thickness difference, defects, etc., and achieve enhanced stiffness and deformation resistance, small water expansion rate, and dimensional stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

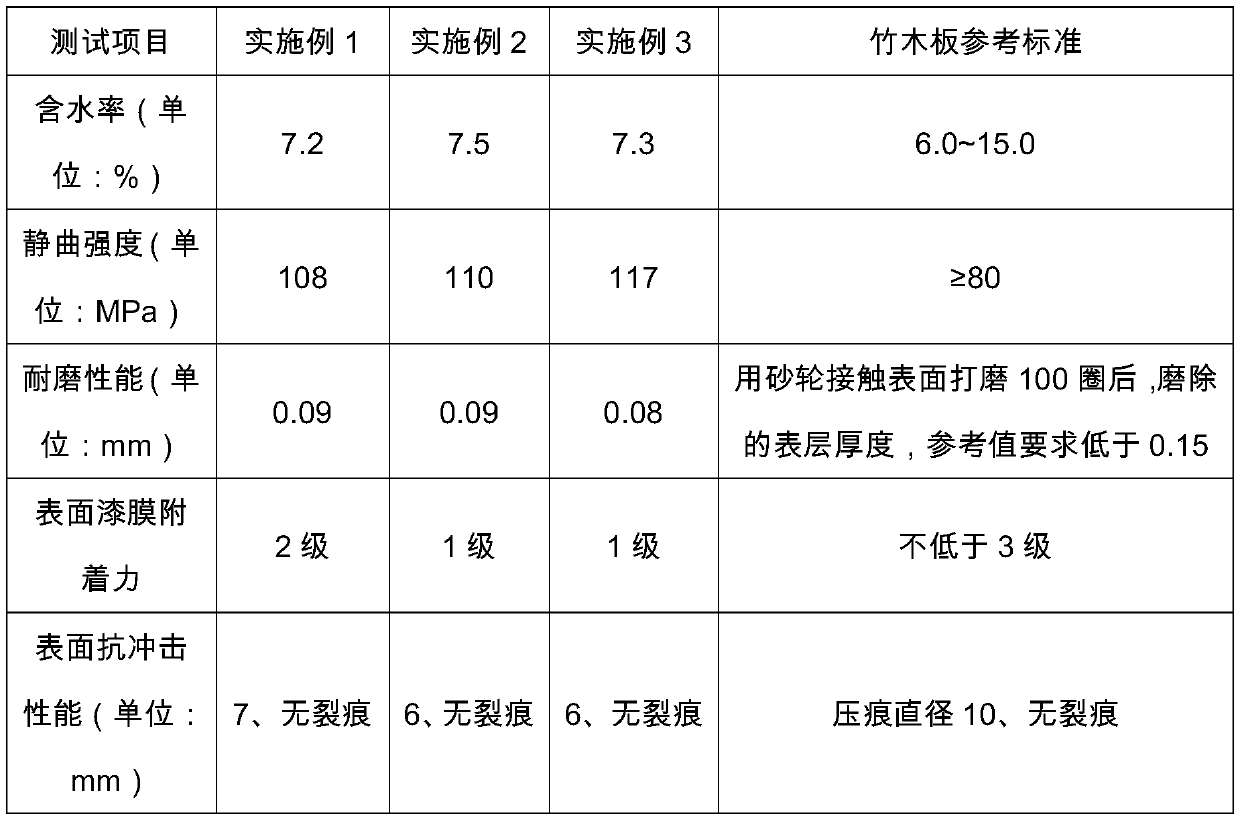

Examples

Embodiment Construction

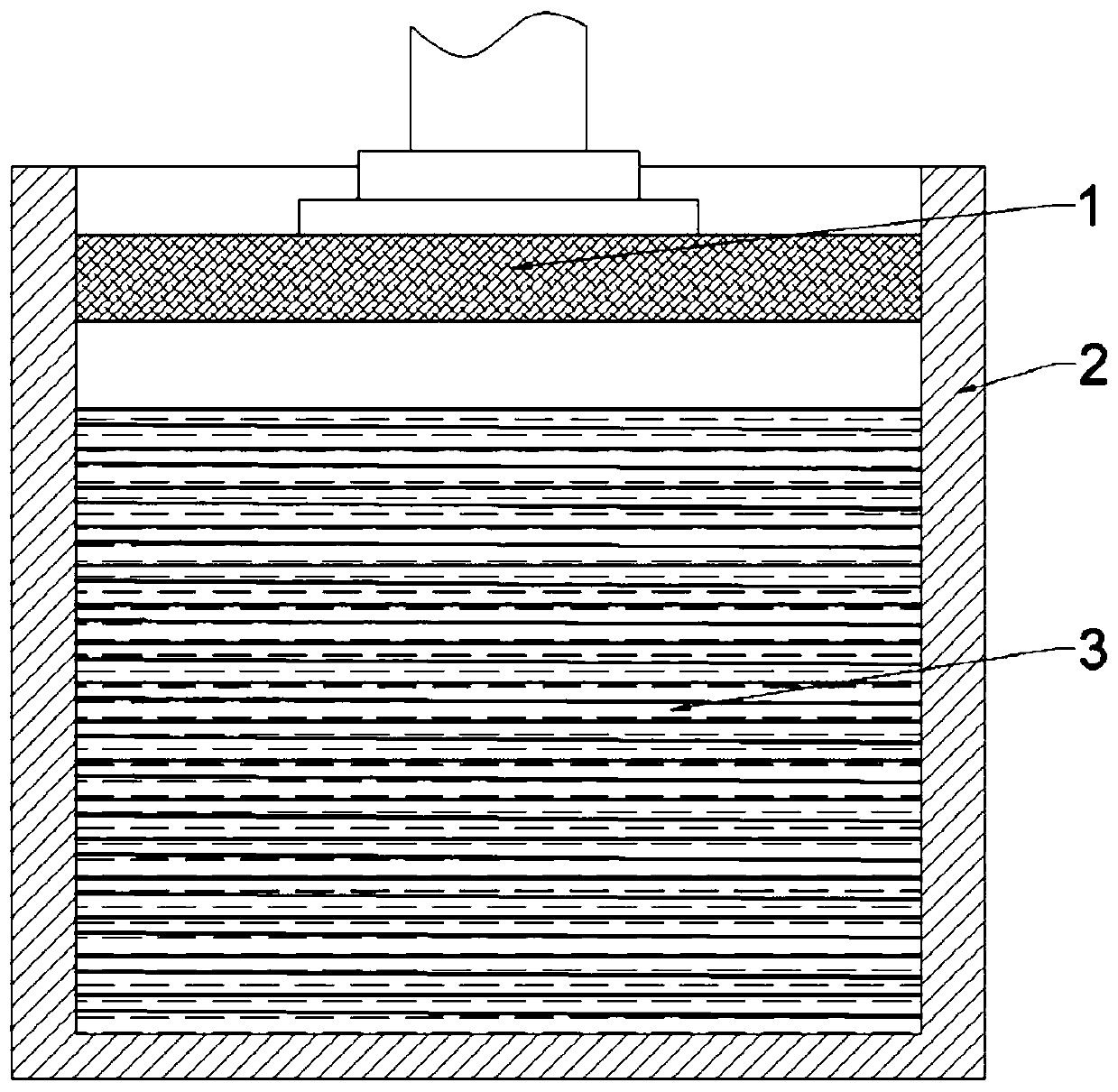

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] In embodiment one, bamboo board is made in the following manner when processing:

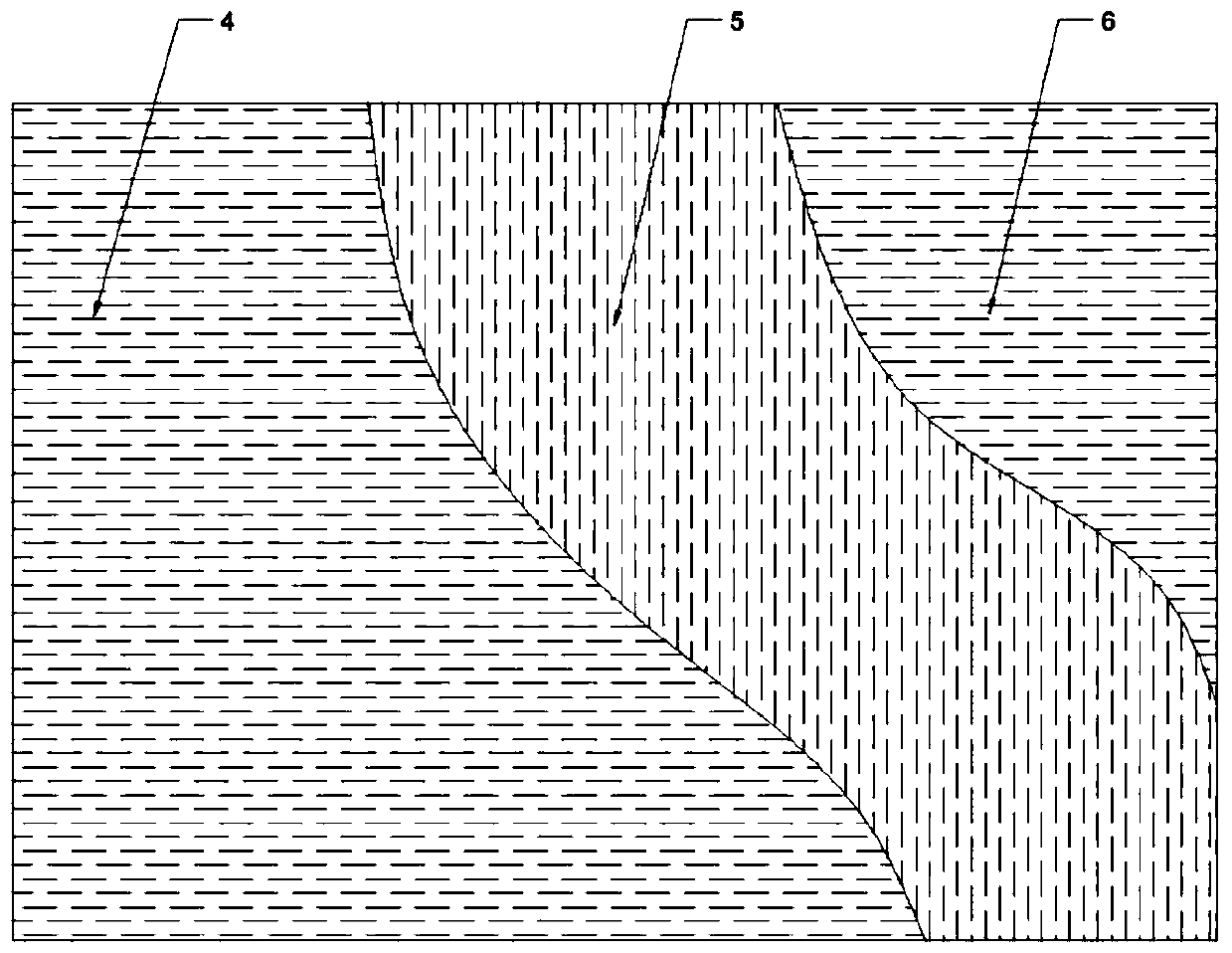

[0029] Select the fresh round bamboo with a water content of 45-50% as the raw bamboo material, remove the head and tail of the felled raw bamboo material after removing the green and yellow, and obtain the bamboo pole body part, and cut the bamboo pole body part into equal lengths to obtain the column tube. After cutting, the bamboo joints of the bamboo tube are cut off, ground and polished on the outer surface, and at the same time, the inner joints are opened, and the inner surface is milled and polished to obtain a bamboo tube body with smooth outer and outer surfaces. Then the above-mentioned bamboo tube is longitudinally cut into an axial slit along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com