Noise-reducing and high-strength pc/abs alloy and preparation method thereof

A high-strength, ABS resin technology, applied in the field of polymer materials, can solve the problems of hindering the movement of molecular chains, ineffectiveness, and low addition amount, and achieves widening the glass transition temperature range, excellent noise reduction performance, and improved performance. Effect of damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

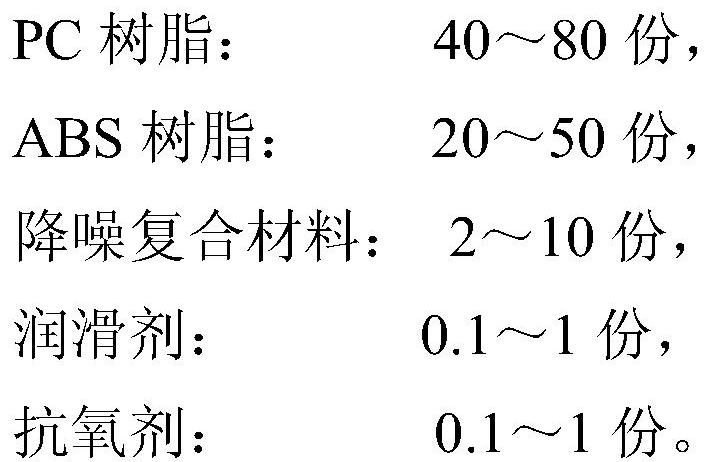

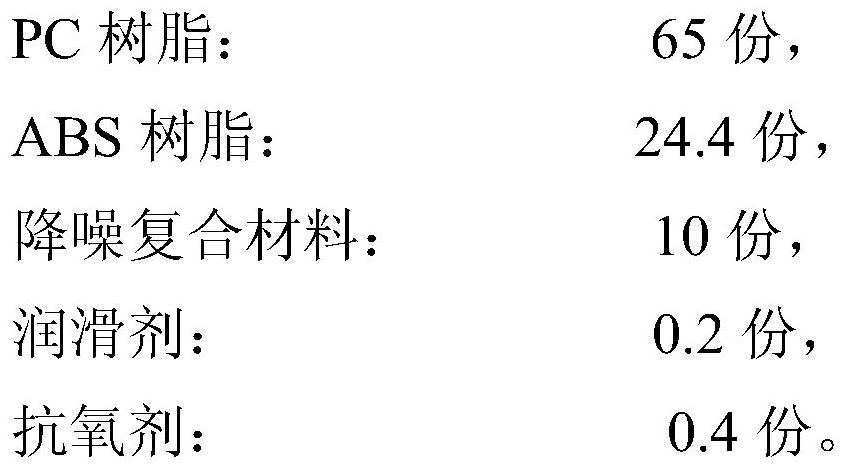

Method used

Image

Examples

Embodiment 9

[0064] Embodiment 9: Evaluation of Implementation Effect

[0065] With the sample that above-mentioned comparative example 1-6 and embodiment 1-8 obtain, product performance test method is as follows:

[0066] Bending strength: According to ISO 178, the test speed is 2mm / min;

[0067] Charpy notched impact strength: according to ISO 179;

[0068] Loss factor: use dynamic mechanical analysis DMA to test, at a heating rate of 10°C / min, from -30°C to 50°C;

[0069] Glass transition temperature (T g ): Under the protection of nitrogen, the temperature was raised from -30°C to 50°C at a heating rate of 10°C / min.

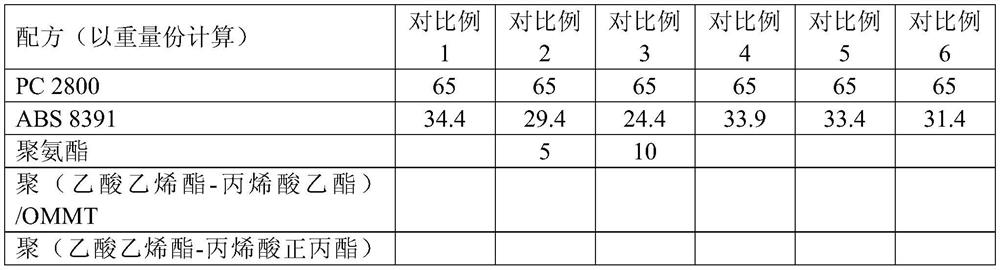

[0070] The test result of table 3 comparative examples 1-6

[0071]

[0072] The test result of table 4 embodiment 1-8

[0073]

[0074] It can be seen from comparative examples 1 to 3 that the loss factor can be improved by adding polyurethane, but due to the glass transition temperature T of polyurethane g At -60°C, so in the temperature range of -20°C to 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com