High polymer composite for embedded rail system

An embedded track and composite material technology, applied in the field of polymer composite materials, can solve the problems that cannot meet the three-way rigidity of the embedded track system, the construction process performance of vibration and noise reduction, and environmental protection, and achieve excellent temperature stability , high insulation resistance, and low water expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

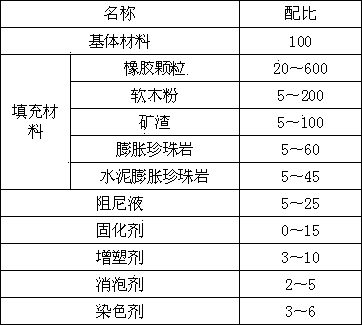

Method used

Image

Examples

Embodiment 1

[0038] Example 1: This example is a cast-in-place polymer composite.

[0039] Divide 100g of base material into two components, A and B, each 50g.

[0040] The specific steps are:

[0041] 1. Mixing of material A: mix components A and B of the base material at room temperature, stir for 1 minute, add 8 g of damping liquid, and mix and stir for 1 minute;

[0042] 2. Mixing material B: 20g of rubber particles (3-4mm in particle size), 8g of cork powder (100 mesh), 5g of slag (0.1-1mm in particle size), 6g of expanded perlite (0.5-1mm in particle size), cement Put 7g of expanded perlite (particle size 0.5-1mm) into a high-speed mixer and mix for 1min at room temperature;

[0043] 3. Pour the mixed material A into material B, then add 3g of polyoxyethylene oxypropylene glycerin, 4g of carbon black (N330), 6g of DOP, and mix and stir for 1min at room temperature;

[0044] 4. Pour the uniformly mixed material liquid in step 3 into the rail bearing groove coated with adhesive, an...

Embodiment 2

[0048] Example 2: This example is a cast-in-place polymer composite.

[0049] Divide 100g of base material into component A and component B, each 50g.

[0050] The specific steps are:

[0051] 1. Mixing of material A: Mix components A and B of the base material, stir for 1 minute, add 25g of damping liquid, and mix and stir for 1 minute;

[0052] 2. Mixing material B: 30g of rubber particles (with a particle size of 1-2mm), 8g of cork powder (50 mesh), 5g of slag (with a particle size of 0.5-1mm), 10g of expanded perlite (with a particle size of 1-2mm), cement Put 7g of expanded perlite (particle size 1-2mm) into a high-speed mixer and mix for 1min;

[0053] 3. Pour the mixed material A into material B, then add BYK 0660 3g, carbon black (N550) 4g, DOP 7g, mix and stir for 1min;

[0054] 4. Pour the uniformly mixed material liquid in step 3 into the rail bearing groove coated with adhesive, and cure at room temperature.

[0055] The test results are shown in Table 2:

[0...

Embodiment 3

[0057] Example 3: This example is a high temperature and pressure curing polymer composite material.

[0058] Specific steps:

[0059] 1. Mixing of material A: heat 100g of base material to 85°C, keep the temperature constant for 15min, add damping liquid and mix and stir for 1min;

[0060] 2. Mixing material B: 100g rubber particles (particle size 1-2mm), cork powder 50g (50 mesh), slag 15g (particle size 0.5-1mm), expanded perlite 11g (particle size 1-2mm), cement Put 20g of expanded perlite (particle size 0.5-1mm) into a high-speed mixer, mix for 1 minute, and put it in an oven at 85°C for 30 minutes at a constant temperature.

[0061] 3. Add 14g of curing agent (MOCA) at a temperature of 90°C to material B, and stir for 2 minutes.

[0062] 4. Pour material A into the mixture in step 3, add defoamer BYK 0660 5g, carbon black (N330) 6g, DOP 10g, mix and stir for 3 minutes, and keep the temperature at 85°C.

[0063] 5. Pour the mixture in step 4 into a mold with a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com