Lithium battery current collector, pole piece, lithium battery, preparation method thereof and application of lithium battery

A lithium battery and current collector technology, applied in the battery field, can solve the problems of low battery capacity, poor effect of lithium supplementation, long migration path of lithium ions, etc., and achieve the effects of high efficiency, easy control of conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

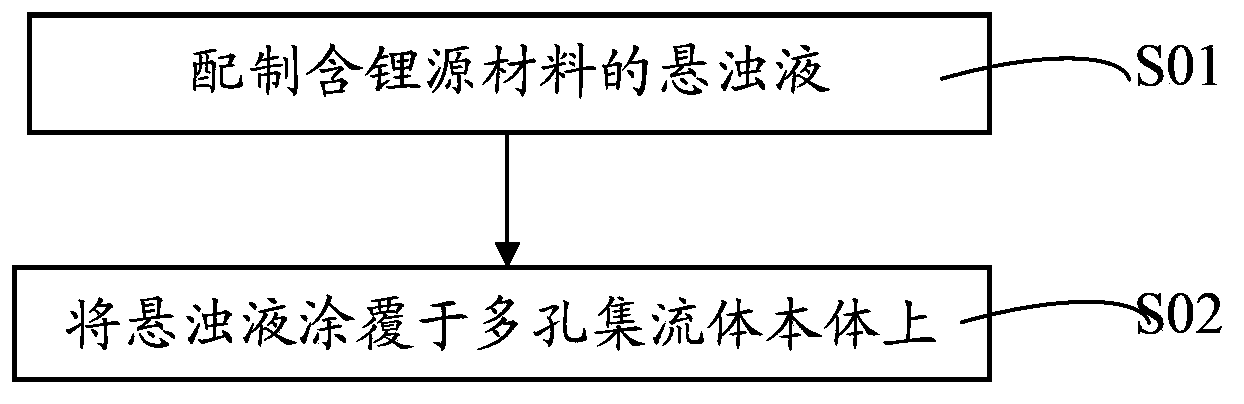

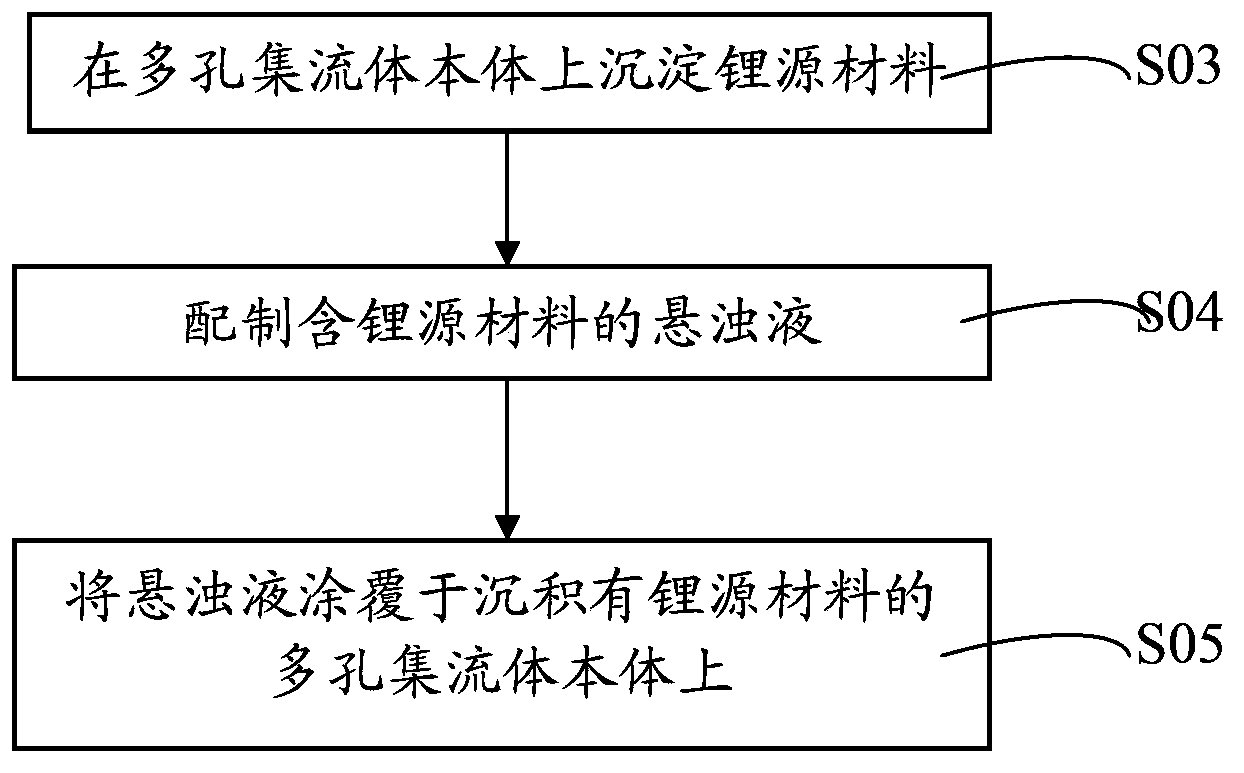

[0075] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned lithium battery current collector. For the process flow of the preparation method of the lithium battery current collector, please refer to figure 1 , including the following steps:

[0076] S01. Prepare a suspension containing lithium source material: disperse the above-mentioned lithium source material into a solvent containing a binder, and prepare a suspension; wherein, the mass ratio of the lithium source material to the binder is 1:(0.005~1:0.05);

[0077] S02. Coating the suspension on the porous current collector body: coating the suspension prepared in step S01 on the above porous current collector body, and then drying to obtain the lithium battery current collector.

[0078] Specifically, in the above step S01, the selection of lithium source materials and binders is as described above, and in order to save space, details are not repeated here. ...

Embodiment 1

[0120] A lithium battery current collector, the preparation method of which is:

[0121] The stabilized lithium metal powder-stabilized lithium MetalPowder (SLMP) of the FMC company of 3.8% by weight is dispersed in the NMP solution containing the PVdF polymer binder of 0.02% by weight to obtain a mixed solution, and then the copper foam is impregnated in the mixed solution, Vacuumize and immerse for 10 minutes, so that the above mixture can completely enter the foamed copper, and finally dry it under the protection of argon gas to obtain a porous current collector embedded with a lithium source, that is, the lithium battery current collector.

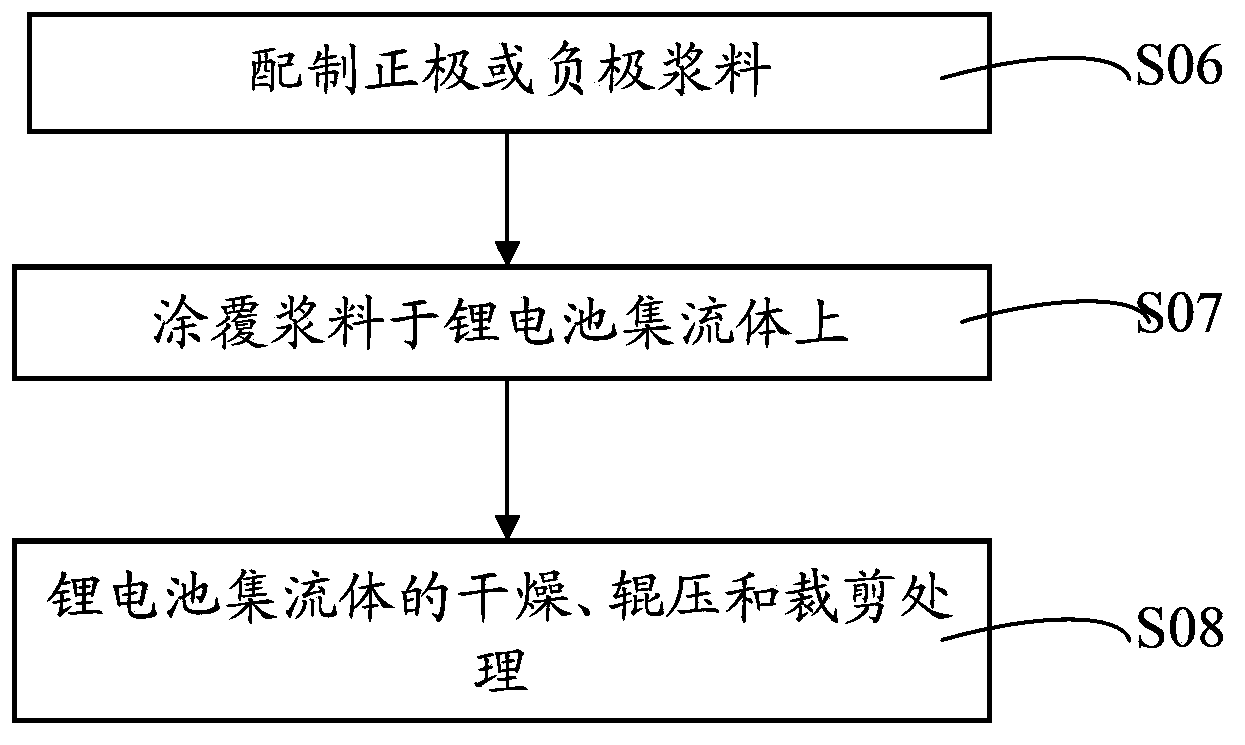

[0122] A lithium battery pole piece (lithium battery negative pole piece), the preparation method of which is:

[0123] 90% by weight of silicon-carbon composite material, 5% by weight of PVdF, 3% by weight of SP and 2% by weight of CNT were mixed in NMP solution to prepare negative electrode active material slurry, which was coated on...

Embodiment 2

[0129] A lithium battery current collector, the preparation method of which is:

[0130] Lithium metal is placed in an evaporation boat under a vacuum environment, and the lithium metal is heated sufficiently to evaporate the lithium metal; foamed copper is placed on the evaporation boat, and metallic lithium is evenly deposited in the foamed copper, thereby obtaining the lithium battery current collector.

[0131] A lithium battery pole piece (lithium battery negative pole piece), the preparation method of which is:

[0132] Mix 90% by weight of silicon-carbon composite material, 5% by weight of PVdF, 3% by weight of SP and 2% by weight of CNT in NMP solution to prepare negative electrode active material slurry, which is coated on the intercalated lithium On the source of foamed copper, dry at 100 ° C, and roll to obtain the negative electrode sheet of the lithium battery.

[0133] Preparation of lithium secondary battery:

[0134] Preparation of negative electrode sheet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com