Wood plastic composite and preparation method thereof

A wood-plastic composite material and a manufacturing method technology, applied in the direction of separation of raw materials, etc., can solve the problems of poor compatibility and weak strength of wood-plastic composite materials, and achieve the effects of low water absorption expansion rate, improved compatibility, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

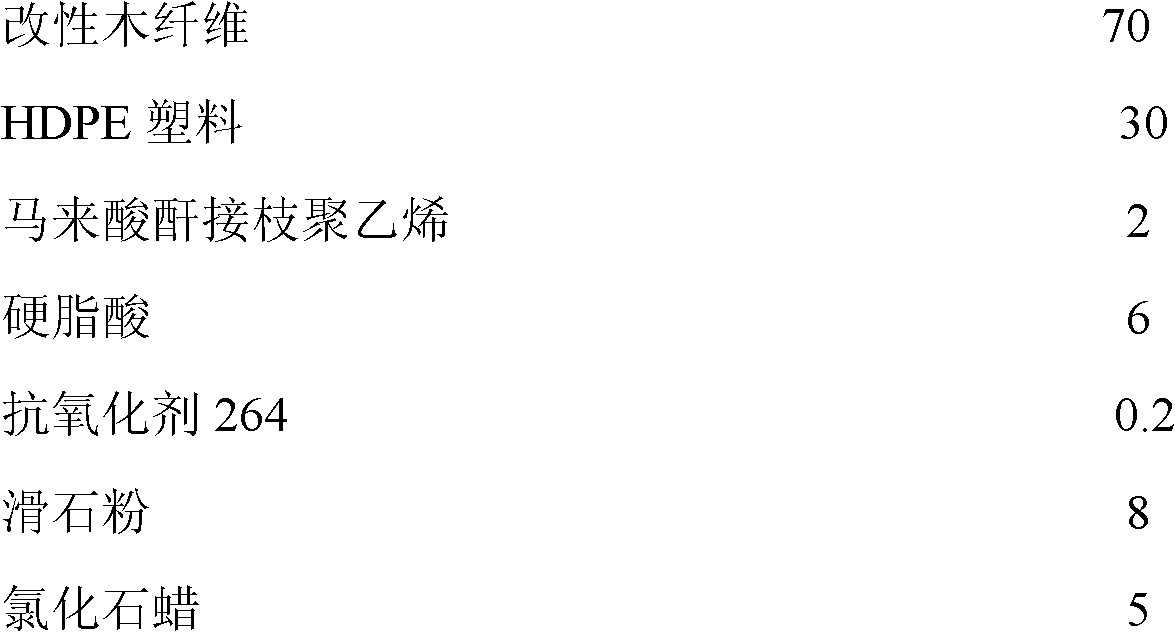

[0066] 1. Prepare materials according to the following proportions by weight:

[0067]

[0068] Among them, the molecular weight of high-density polyethylene (HDPE) is 40,000-300,000, and the density is 0.93-0.97g / cm 3 , the melt index (MI, g / 10min) is 0.3-0.5; the molecular weight of maleic anhydride grafted polyethylene is 10000-300000, the grafting rate is 1-2%, and the melt index is 0.5-0.6g / 10min; The molecular weight is 800-1300, and the chlorine content is 40-73%.

[0069] Wherein, the modified wood fiber is prepared according to the following steps:

[0070] A) Peel off the waste processing residues in the "Three Residues of Forestry" into a 20-40mm waste section and place it in the blaster (Beijing Forestry University; model: BL-08), open the steam inlet valve of the blaster, Introduce saturated water vapor with a relative pressure of 3.5MPa to make the relative pressure in the blaster reach 2.5MPa, keep it under this pressure for 30min, and steam the veneer wood...

Embodiment 2

[0083] 1. Prepare materials according to the following proportions by weight:

[0084]

[0085] Wherein, the molecular weight of described low-density polyethylene (LDPE) is 20000-30000, density 0.91g / cm 3 , melt index 0.5g / 10min; molecular weight of chlorinated polyethylene is 10000-300000, chlorine content is 40-60%.

[0086] Wherein, the modified wood fiber is prepared according to the following steps:

[0087] A) Cut the twig wood in the waste harvesting residues in the "three forestry residues" into waste sections with a length of 20-40 mm and place them in the blaster, open the steam inlet valve of the blaster, and feed in a relative pressure of 4.2 MPa Saturated water vapor, so that the relative pressure in the blaster reaches 4.0MPa, and keep it under the pressure of 4.0MPa for 5 minutes, and steam the waste of "three forestry residues";

[0088] B) Open the discharge valve of the blaster, so that the wood waste of "three leftovers" is blasted and sprayed into the...

Embodiment 3

[0095] 1. Prepare materials according to the following proportions by weight:

[0096]

[0097] Wherein, the molecular weight of the polypropylene (PP) plastic is 10000-300000, the melt index (MI, g / 10min) is 0.2-1; the molecular weight of the chlorinated polypropylene is 80000-150000, and the chlorine content is 40-60% ; The molecular weight of polyethylene wax is 2500-3000, and the density is 0.92-0.94g / cm 3 , Viscosity 0.7-1.2Pa · s (140 ℃).

[0098] Wherein, the modified wood fiber is prepared according to the following steps:

[0099] A) The shrub chip mixture in the waste harvesting residues in the "three forestry residues" is cut into a waste section with a length of 20-40mm and placed in the blaster, and the steam inlet valve of the blaster is opened, and the relative pressure is 4.0 The saturated water vapor of MPa makes the relative pressure in the blaster reach 3.0MPa, and keep it under the pressure of 3.0MPa for 30min, and steam the shrub chips;

[0100] B) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com