Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

A technology of crop straw and fiberboard, which is applied in the field of straw fiberboard, can solve the problems that hinder the popularization and application of interior decoration materials, lack of strong gluing effect of synthetic resin, and no flame retardant effect, so as to achieve improved mechanical properties, low price, and improved gluing The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

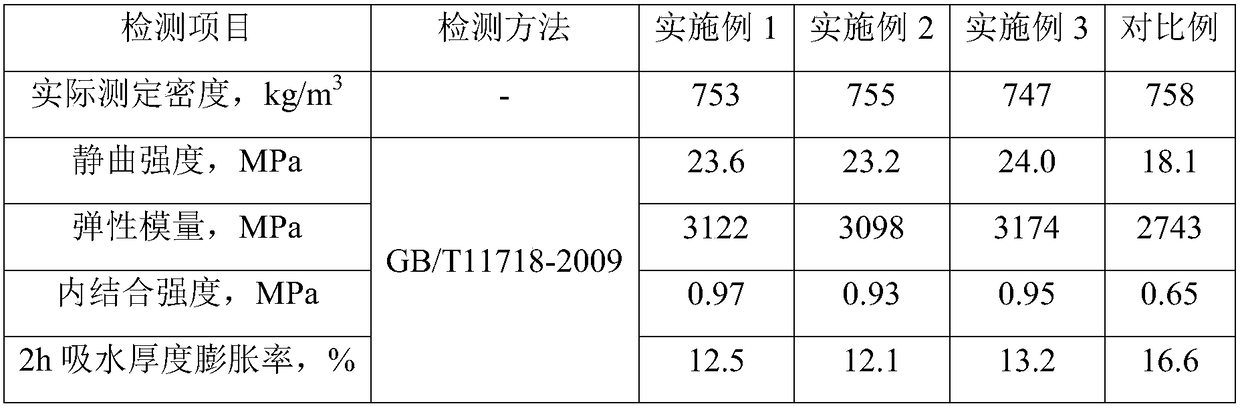

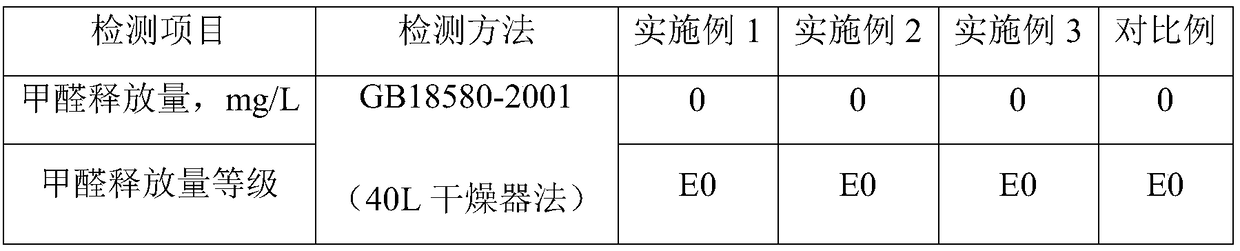

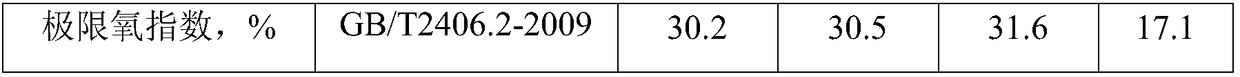

Examples

Embodiment 1

[0046] The crop straw environmentally friendly flame-retardant glue-free fiberboard of this example is prepared by the following method:

[0047] 1) Take dry wheat straw and dry sorghum straw and cut them to a length of 20-30 mm, soak them in water at room temperature for 12 hours, take them out, squeeze to remove excess water, and obtain wheat straw softening material with a water content between 60% and 65%. Sorghum straw softening material;

[0048] 2) The wheat straw softening material is subjected to steam explosion, the steam temperature is 185° C., the explosion pressure is 3.5 MPa, and the explosion time is 2.5 minutes. After the steam explosion, it is naturally dried to obtain wheat straw fibers;

[0049] The sorghum straw softening material was subjected to steam explosion, the steam temperature was 195°C, the explosion pressure was 3.5MPa, and the explosion time was 3.5min. After steam explosion, it was naturally dried to obtain sorghum straw fibers;

[0050] 3) Af...

Embodiment 2

[0058] The crop straw environmentally friendly flame-retardant glue-free fiberboard of this example is prepared by the following method:

[0059] 1) Take dry wheat straw and dry sorghum straw and cut them to a length of 20-30 mm, soak them in water at room temperature for 14 hours, take them out, squeeze to remove excess water, and obtain wheat straw softening material with a water content between 60% and 65%. Sorghum straw softening material;

[0060] 2) The wheat straw softening material is subjected to steam explosion, the steam temperature is 190°C, the explosion pressure is 3.0MPa, the explosion time is 3.0min, and the wheat straw is naturally dried after steam explosion to obtain wheat straw fibers;

[0061] The sorghum stalk softening material was subjected to steam explosion, the steam temperature was 200°C, the explosion pressure was 3.0 MPa, and the explosion time was 4.0 min. After steam explosion, it was naturally dried to obtain sorghum straw fibers;

[0062] 3) ...

Embodiment 3

[0070] The crop straw environmentally friendly flame-retardant glue-free fiberboard of this example is prepared by the following method:

[0071] 1) Take dry wheat straw and dry sorghum straw and cut them to a length of 20-30 mm, soak them in water at room temperature for 16 hours, take them out, squeeze to remove excess water, and obtain wheat straw softening material with a water content between 60% and 65%. Sorghum straw softening material;

[0072] 2) The wheat straw softening material is subjected to steam explosion, the steam temperature is 190° C., the explosion pressure is 3.2 MPa, and the explosion time is 3.0 min. After steam explosion, it is naturally dried to obtain wheat straw fibers;

[0073] The sorghum straw softening material was subjected to steam explosion, the steam temperature was 195°C, the explosion pressure was 3.2MPa, and the explosion time was 3.5min. After steam explosion, it was naturally dried to obtain sorghum straw fibers;

[0074] 3) After mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com