Preparation method of high-performance magnetic ring

A high-performance, magnetic ring technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., to improve magnetic performance and avoid cracking due to excessive internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

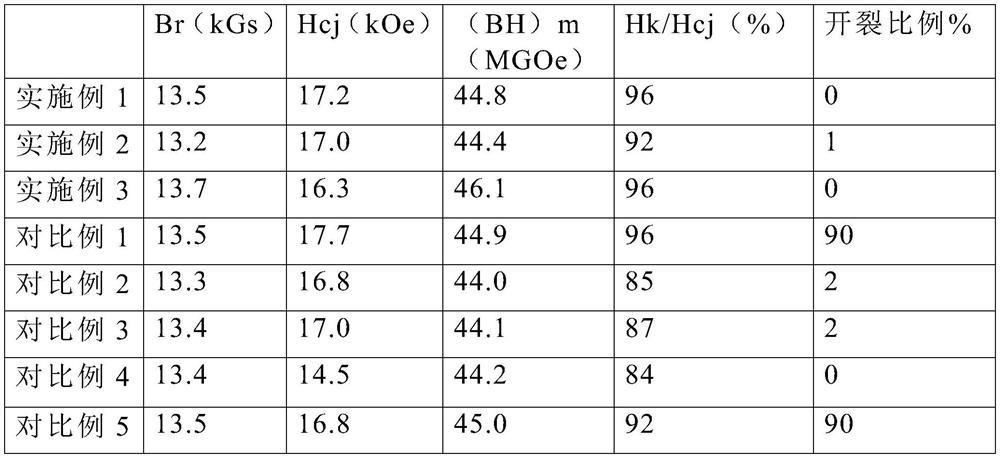

Examples

preparation example Construction

[0023] The preparation method of the high-performance magnetic ring of the present invention will be described in detail below. If there is no other definition for the technical or scientific terms used at this time, they are the meanings commonly understood by those skilled in the technical field of the present invention.

[0024] In this paper, the quick-setting sheet is the quick-setting sheet conventionally defined in the field, that is, the quick-setting sheet is obtained by melting the alloy raw material and casting it on a copper roller with a certain rotating speed.

[0025] In this paper, the average thickness of the quick-setting sheet is defined as the average value of the measurement data of any 100 quick-setting sheets, and the measurement tool can be a vernier caliper or a screw micrometer.

[0026] In this paper, the average thickness of the flaky crystals of the quick-setting sheet is defined as the arithmetic mean of the number of flaky crystals passing through...

Embodiment 1

[0045] The magnetic ring of this embodiment is prepared by the following steps:

[0046] 1) Using industrial raw materials PrNd (75wt% Nd) alloy, pure Dy, Fe, Co, Ga, Cu, Al, Zr metal by composition (PrNd) 30 Dy 1.8 Cu 0.15 Al 0.25 Ga 0.20 co 1.5 Zr 0.01 B 0.96 Fe 余 (wt%) batching, smelting the configured raw materials, casting and throwing the quick-setting sheet with an average thickness of 0.3mm, the melting temperature is 1480°C, the casting temperature is 1440°C, and the copper roll speed is 1.5m / s;

[0047] 2) Put the quick-setting sheet into a stainless steel barrel with a lid, and put it into a vacuum heat treatment furnace for heat treatment. The vacuum degree of heat treatment should be kept ≤4*10 -2 Pa, the heat treatment temperature is 900°C, and the time is 25h. The average thickness of the flaky crystals of the quick-setting sheet grows to 5.8 μm (the average thickness of the columnar crystals of the quick-setting sheet is about 3 μm without heat treatmen...

Embodiment 2

[0052] The difference between the manufacturing method of the magnetic ring in Example 2 and Example 1 is that the magnetic field strength used in the orientation molding in Example 2 is 1.2T, and the others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com