Precipitation-hardening martensitic stainless steel 17-4PH smelting technology

A martensitic stainless steel, precipitation hardening technology, applied in the direction of process efficiency improvement, furnace type, furnace, etc., can solve the problems of not being able to adapt to the market demand for low gas and low inclusions, affecting product performance, etc., to reduce smelting time, Effects of avoiding stress cracks and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

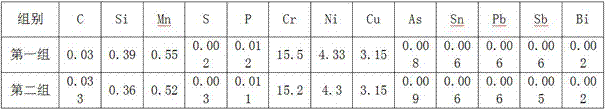

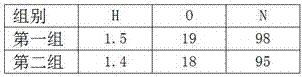

[0020] Precipitation hardening martensitic stainless steel 17-4PH smelting process, using the process route of EAF / IF-LF-VOD-LF-VD-IC, the composition is as follows: C≤0.07%, Si≤1.0%, Mn≤1.0%, P≤ 0.025%, S≤0.010%, Ni:3.00-5.00%, Cr:15.0-17.5%, Cu:3.00-5.00%, Nb:0.15-0.45%; the steps of the smelting process are as follows:

[0021] Step S01: Using steel scrap and pig iron with low five harmful elements as the raw material of the electric furnace, the electric furnace is melted and dephosphorized at low temperature in the early stage of oxidation to smelt molten steel with low phosphorus and five harmful elements, and the electric furnace taps steel [C]≤0.05%, [P] ≤0.003%, [As]≤0.010%, [Sn]≤0.006%, [Pb]≤0.005%, [Sb]≤0.005%, [Bi]≤0.005%, the tapping process is based on 2-3Kg aluminum iron per ton of steel Carry out deoxidation to avoid slag overflow;

[0022] Step S02: Use an intermediate frequency furnace to melt alloys such as ferrochromium, nickel, and copper plates, accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com