Light-weight anti-cracking cement foaming heat insulation plate

A technology of cement foaming and thermal insulation boards, which is applied in the field of thermal insulation materials, can solve the problems of insufficient impact resistance of thermal insulation boards, difficult construction technology, high density of thermal insulation boards, etc., and achieve excellent flame retardant and fireproof performance, outstanding thermal insulation performance, Effect of improving impact resistance and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

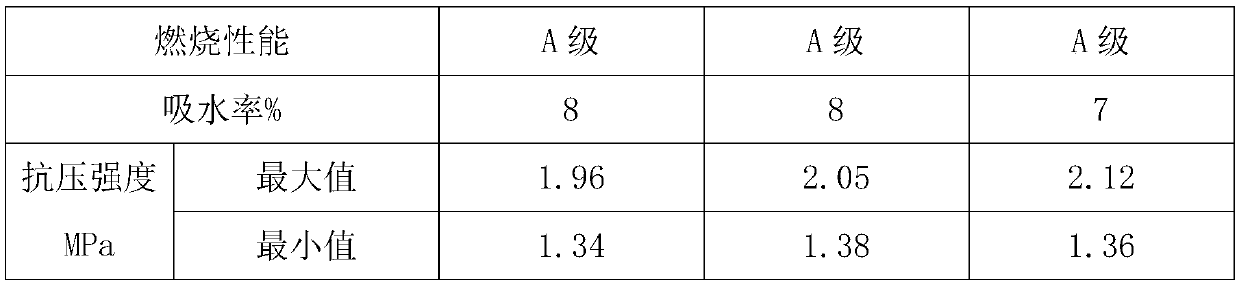

Embodiment 1

[0030] A lightweight anti-cracking cement foam insulation board, which contains the following components in parts by mass: 70 parts of Portland cement, 25 parts of fly ash, 15 parts of nano-bentonite, lightweight ceramic powder elastomer 10 parts, 3 parts of inorganic fiber, 2 parts of water glass, 1 part of water reducer, 7 parts of foaming agent, 1.3 parts of foam stabilizer, 250 parts of water.

[0031] In the present embodiment, the preparation method of lightweight ceramic powder elastomer comprises the following steps:

[0032] Mix light ceramic powder, n-butyl methacrylate, silane coupling agent and deionized water into the reaction kettle at a mass ratio of 17:2:1:50, at a temperature of 60°C and a speed of 450r / min Fully stir for 20 minutes, then let stand naturally for 1.5 hours, filter the product and dry to obtain the required surface-modified light ceramic powder; 85 parts of modified polyurethane, 13 parts of EPDM rubber, 3 parts of epoxy resin, 4 parts of zinc ...

Embodiment 2

[0042] A lightweight anti-cracking cement foam insulation board, which contains the following components in parts by mass: 80 parts of Portland cement, 30 parts of fly ash, 20 parts of nano-bentonite, lightweight ceramic powder elastomer 18 parts, 6 parts of inorganic fiber, 5 parts of water glass, 1.4 parts of water reducer, 10 parts of foaming agent, 2.5 parts of foam stabilizer, 280 parts of water.

[0043] According to the parts by mass, the insulation board contains the following components: 75 parts of Portland cement, 27 parts of fly ash, 18 parts of nano-bentonite, 15 parts of light ceramic powder elastomer, 5 parts of inorganic fiber, 3 parts of water glass, 1.2 parts of water reducer, 8.5 parts of foaming agent, 2 parts of foam stabilizer, 265 parts of water.

[0044] In the present embodiment, the preparation method of lightweight ceramic powder elastomer comprises the following steps:

[0045] Mix light ceramic powder, n-butyl methacrylate, silane coupling agent a...

Embodiment 3

[0055] A lightweight anti-cracking cement foam insulation board, which contains the following components in parts by mass: 75 parts of Portland cement, 27 parts of fly ash, 18 parts of nano-bentonite, lightweight ceramic powder elastomer 15 parts, 5 parts of inorganic fiber, 3 parts of water glass, 1.2 parts of water reducer, 8.5 parts of foaming agent, 2 parts of foam stabilizer, 265 parts of water.

[0056] In the present embodiment, the preparation method of lightweight ceramic powder elastomer comprises the following steps:

[0057] Mix light ceramic powder, n-butyl methacrylate, silane coupling agent and deionized water into the reaction kettle at a mass ratio of 17:2:1:50, at a temperature of 63°C and a speed of 480r / min Stir fully for 23 minutes, then let stand naturally for 1.8 hours, filter and dry the product to obtain the required surface-modified light ceramic powder; 85 parts of modified polyurethane, 13 parts of EPDM rubber, 3 parts of epoxy resin, 4 parts of zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com