Anti-stress cracking agent, preparation method and application thereof as well as anti-stress PC (Poly Carbonate) polyester

An anti-stress cracking and anti-stress technology, applied in the field of materials, can solve problems such as long cycle, fast cooling speed, and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

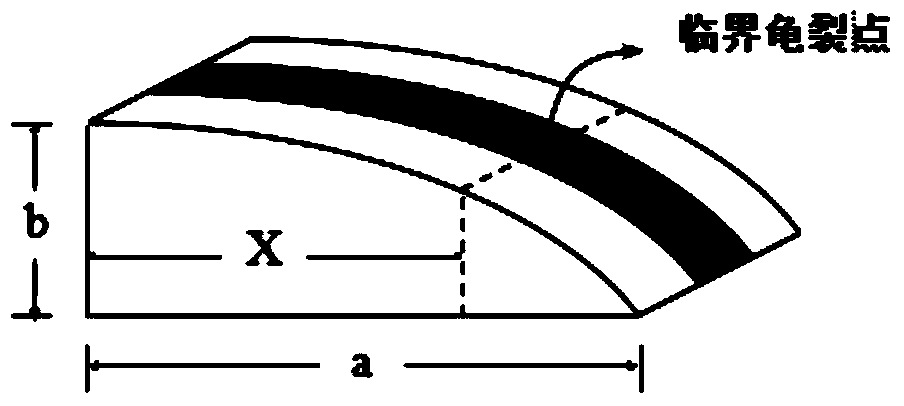

Image

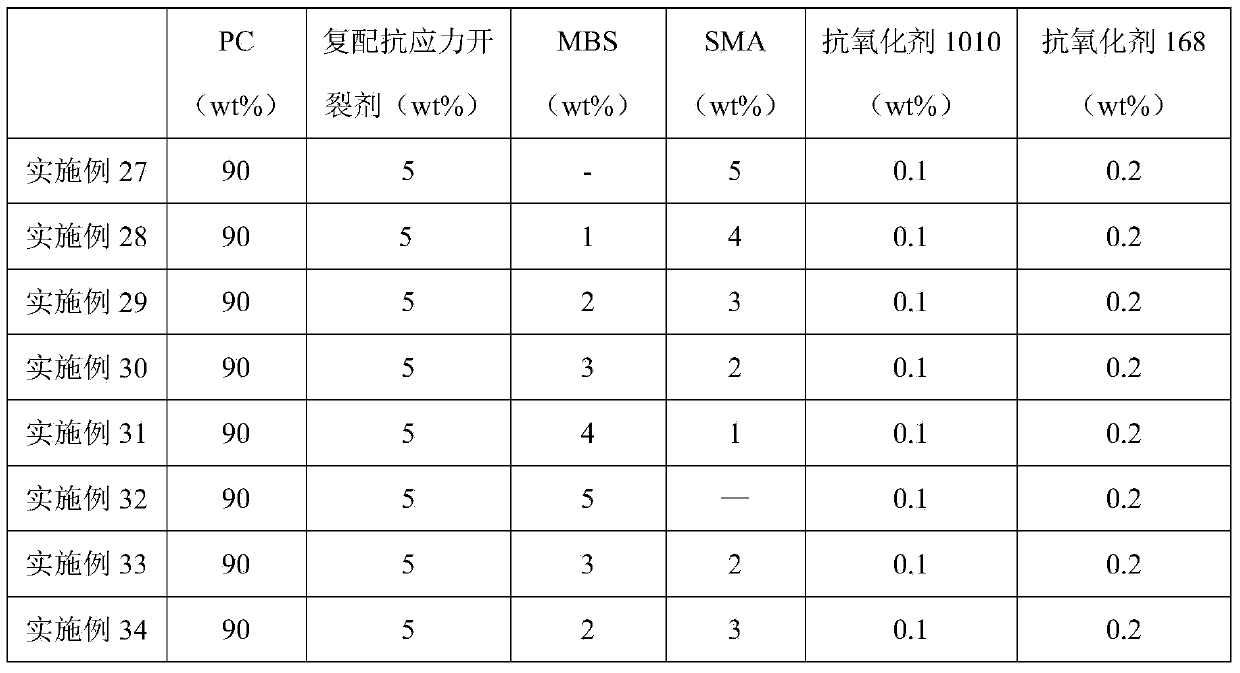

Examples

Embodiment 1~5

[0037] Embodiment 1~5: the preparation of anti-stress cracking agent

[0038] The raw materials were weighed according to the ratio in Table 1, and the anti-stress cracking agent was prepared.

[0039] Table 1:

[0040]

[0041] The preparation method of Examples 1-5 is: mix maleic anhydride, styrene, and linear low-density polyethylene uniformly in proportion, adopt dibenzoyl peroxide (BPO) as an initiator, and add an amount of 0.1% of the total amount of raw materials. ~0.3%, obtained by melting and grafting on a twin-screw extruder. When extruding through the extruder, the temperature of each section of the screw barrel is: the temperature in the first temperature zone is 170-175°C; the temperature in the second temperature zone is 180- 185°C; the temperature in the third temperature zone is 190-195°C; the temperature in the fourth temperature zone is 195-200°C; the temperature of the machine head is 190-200°C; the speed of the main engine: 30-40 rpm.

[0042] ...

Embodiment 6~10

[0055] Embodiment 6~10: the preparation of anti-stress cracking agent

[0056] The raw materials were weighed according to the ratio in Table 3, and the anti-stress cracking agent was prepared.

[0057] table 3:

[0058]

[0059] The preparation method of Examples 6-10 is: mix maleic anhydride, styrene, and hydrogenated SBS uniformly in proportion, use dibenzoyl peroxide (BPO) as the initiator, and add 0.1-0.3% of the total amount of raw materials , prepared by melting and grafting on a twin-screw extruder, when extruding through the extruder, the temperature of each partition of the screw barrel is: the temperature in the first temperature zone is 170-175°C; the temperature in the second temperature zone is 180-185°C; The temperature in the third temperature zone is 190-195°C; the temperature in the fourth temperature zone is 195-200°C; the temperature of the machine head is 190-200°C; the speed of the main engine: 30-40 rpm.

[0060] Table 4 is the grafting rati...

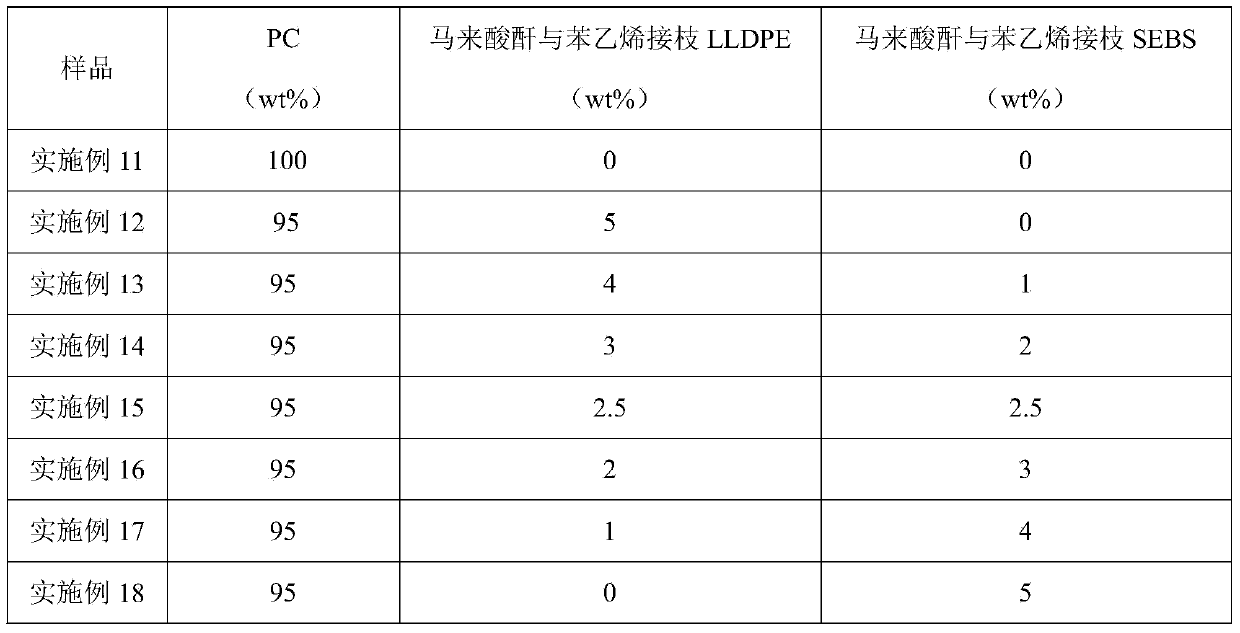

Embodiment 11~18

[0064] Examples 11-18: Preparation of stress cracking resistant PC

[0065] Table 5 is the percentage by weight of the components of the stress-cracking PCs of Examples 11 to 18, wherein the stress-cracking agent is the LLDPE grafted with maleic anhydride and styrene prepared in Example 2, and the one prepared in Example 7. One or both of maleic anhydride and styrene-grafted maleic anhydride-grafted SEBS.

[0066] table 5:

[0067]

[0068] The preparation method is:

[0069] The anti-stress cracking agent is fully mixed with PC resin under high-speed stirring, and then melted, kneaded, extruded, cooled, dried, pelletized and packaged through a twin-screw extruder; The temperature is: the temperature in the first temperature zone is 260-275°C; the temperature in the second temperature zone is 265-280°C; the temperature in the third temperature zone is 270-280°C; the temperature in the fourth temperature zone is 275-285°C; 275-290°C; host speed: 30-40 rpm.

[0070] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com