Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Zirconium(IV) sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium(IV) sulfate is the name for a family of inorganic compounds with the formula Zr(SO₄)₂(H₂O)ₙ where n = 0, 4, 5, 7. These species are related by the degree of hydration. They are white or colourless solids that are soluble in water.

Cerium oxide and zirconium oxide based composite rare earth oxide with favorable ageing resistance and high reduction activity and preparation method of cerium oxide and zirconium oxide based composite rare earth oxide

ActiveCN103191712AHigh reactivityTotal pore volumeCatalyst activation/preparationRare earth metal compoundsReduction ActivityZirconium hydride

The invention discloses a preparation method of a cerium oxide and zirconium oxide based composite rare earth oxide. The method comprises the following steps of: (1) weighting zircon salt with a certain mass and preparing a zircon salt solution; (2) mixing urea and sulfuric acid or sulfate to prepare an activating agent solution; (3) heating the zircon salt solution under the room temperature, meanwhile, slowly and dropwise adding the activating agent solution, controlling the temperature rise speed to ensure that the temperature is raised to 60 DEG C after the addition of the activating agent solution is finished, continuing to raising the temperature to 90-95 DEG C, and keeping the temperature for 20-100min to form a basic zirconium sulfate composite salt precursor solution; (4) preparing soluble cerate and rare earth metal salt, adding the soluble cerate and the rare earth metal salt into the basic zirconium sulfate composite salt precursor solution, and settling by using a soluble hydroxide or an aqueous solution of ammonia; and (5) filtering and cleaning precipitates, and then, calcining the precipitates to obtain the cerium oxide and zirconium oxide based composite rare earth oxide. The cerium oxide and zirconium oxide based composite rare earth oxide prepared by using the method provided by the invention has favorable ageing resistance and high reduction activity.

Owner:CHAOZHOU THREE CIRCLE GRP

Preparation method of molecular sieve composite catalyst Fe2O3/ZrO2/SO42 for desorbing CO2-rich amine solution

ActiveCN109453801AEasy to manufactureRaw materials are cheap and easy to getMolecular sieve catalystsDispersed particle separationMolecular sieveCo2 absorption

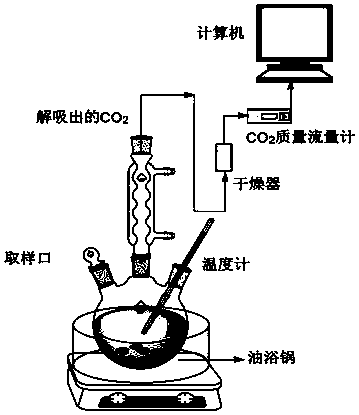

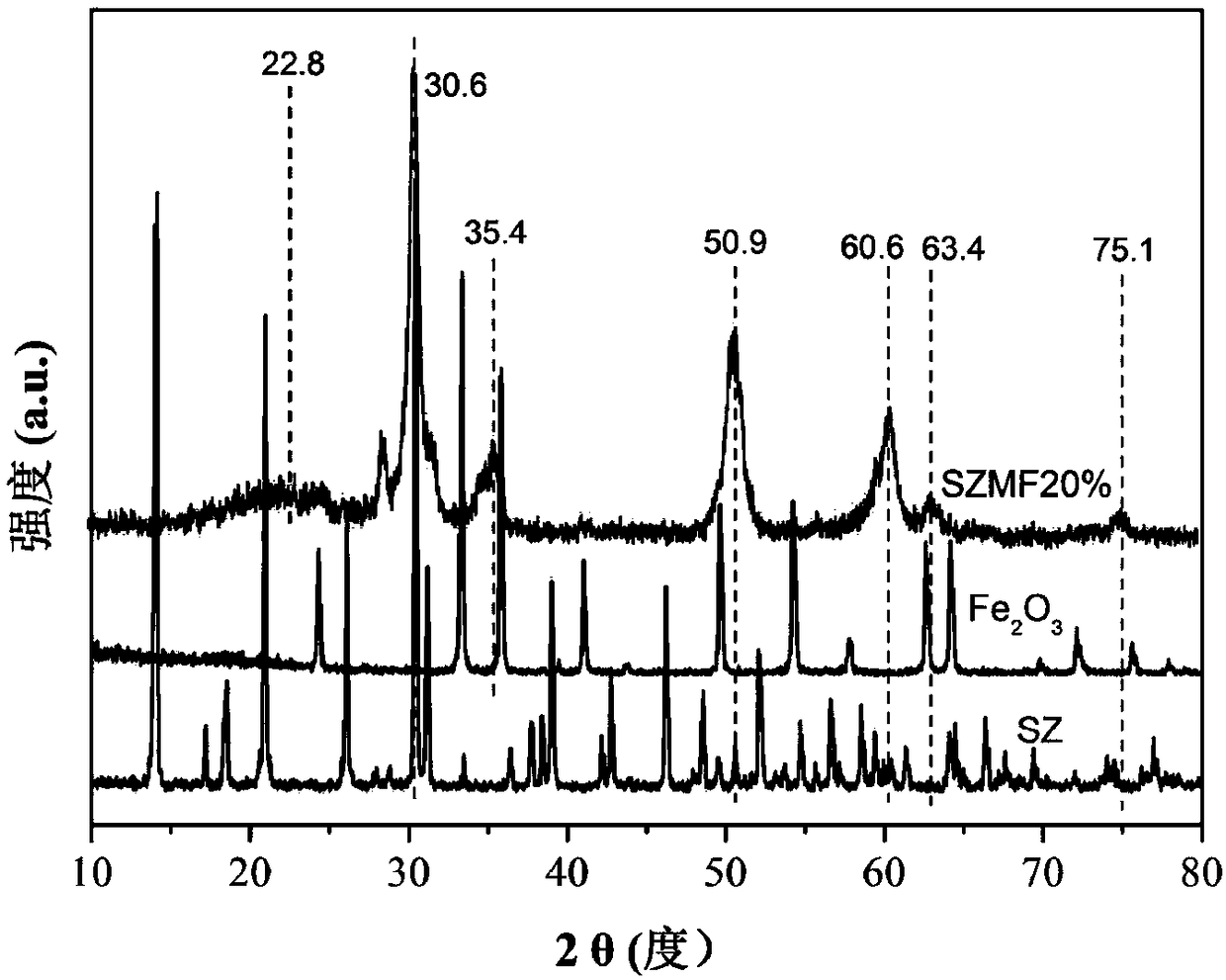

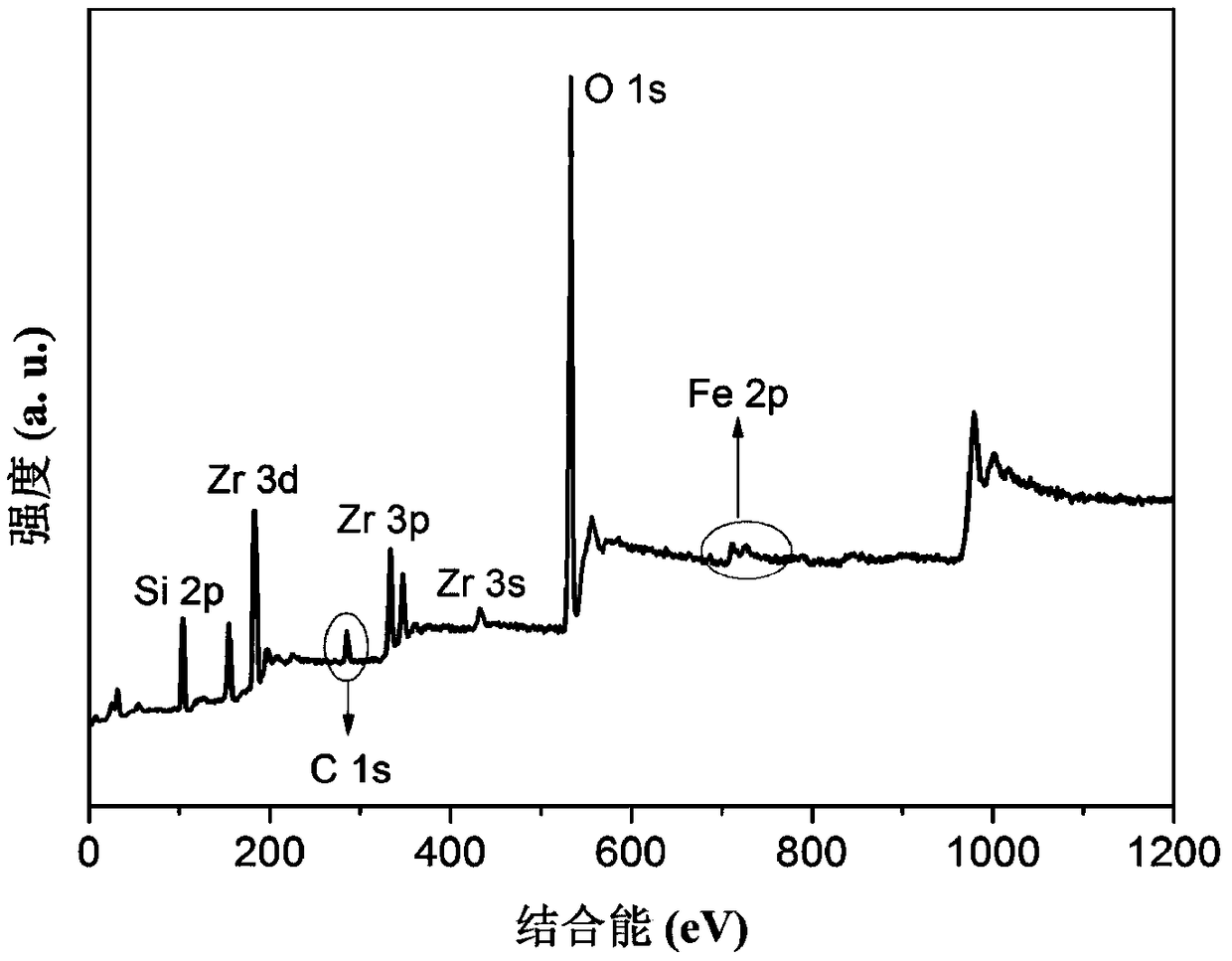

The invention discloses a preparation method of a molecular sieve composite catalyst Fe2O3 / ZrO2 / SO42 for desorbing a CO2-rich amine solution. The composite catalyst is obtained by loading Fe2O3 modified ultrastrong solid acid catalyst ZrO2 / SO42- onto a carrier molecular sieve. The preparation method comprises the following steps: dissolving soluble iron salt and zirconium sulfate into a methanol solution to obtain a mixed solution A; heating the mixed solution A for one hour at the condition of 50 DEG C to obtain a mixed solution B; cooling the mixed solution B to the room temperature, addingmolecular sieve powder, and stirring for 5 hours to obtain a mixed solution C; ultrasonically treating the mixed solution C for more than 0.5 hour to obtain a mixed solution D; and drying and calcining the mixed solution D to obtain the molecular sieve composite catalyst Fe2O3 / ZrO2 / SO42. Compared with the prior art, the catalyst of the invention is simple in preparation process, cheap and easy inobtaining raw materials; the catalytic desorption performance is better than that of the traditional molecular sieve catalyst, a single metal oxide and a single metal oxide physically mixed catalyst;the catalyst is easy to separate, good in stability and recyclable; and the absorption performance for carbon dioxide of the amine solution is not influenced.

Owner:HUNAN UNIV

Zirconium-loaded impregnation carbon defending against HCN and CNCl toxic agents and preparation method thereof

ActiveCN106513004AGuaranteed protective effectAvoid synergistic effectsHeterogenous catalyst chemical elementsCatalyst activation/preparationCerium nitrateAmmonium metatungstate

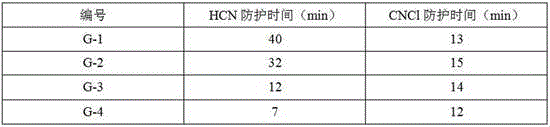

The invention discloses zirconium-loaded impregnation carbon defending against HCN and CNCl toxic agents. With coconut shell broken active carbon as a carrier skeleton material, the zirconium-loaded impregnation carbon is loaded with the following components in percentage by weight: 15-20% of Cu, 1-6% of Cl<->, 0.1-5% of W, 0.1-5% of V, 0.1-5% of Ce, 2-8% of Zr and the balance of active carbon, wherein Cu comes from basic copper carbonate, Cl<-> comes from ammonium chloride, W comes from ammonium metatungstate, V comes from ammonium metavanadate or zinc ammonium metavanadate, Ce comes from cerium nitrate or cerium oxide, and Zr comes from zirconium sulfate or zirconium oxychloride. In the zirconium-loaded impregnation carbon, an active carbon carrier is loaded with active components such as Zr, W, V, Ce and Cu by adopting certain technical means and technology, and the prepared impregnation carbon material has a certain defending effect against the HCN and CNCl toxic agents.

Owner:SHANXI XINHUA CHEM

Chrome-free metal compound tanning agent and preparation method thereof

InactiveCN103667543AImprove performanceOvercome incapacityTanning treatmentAluminium sulfateAluminum silicate

The invention discloses a chrome-free metal compound tanning agent which comprises the following components in percentage by weight: 60.0%-75.0% of zirconium sulfate, 10.0%-15.0% of aluminum sulfate, 10.0%-15.0% of titanyl sulfate and 5.0%-10.0% of sodium aluminum silicate. The invention further discloses a preparation method of the chrome-free metal compound tanning agent. The chrome-free metal compound tanning agent provided by the invention is good in comprehensive performance, simple in production process and environment-friendly; the preparation method of the environment-friendly chrome-free metal compound tanning agent is simple; in addition, the chrome-free metal compound tanning agent is good in compatibility with existing leather-making materials and easy to popularize.

Owner:WENZHOU UNIVERSITY

Beneficiation of zircon

InactiveUS7063824B1Improve fusionHigh reactionSulfate preparationTitanium halidesOpacifierAlkali carbonate

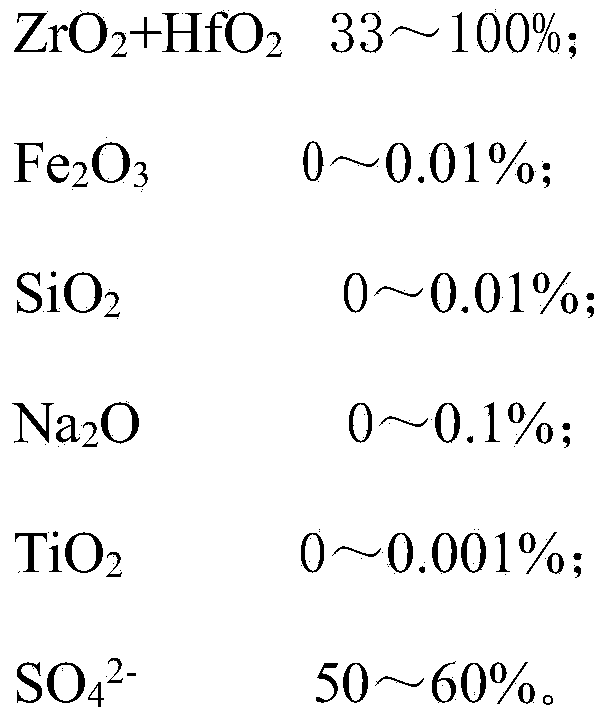

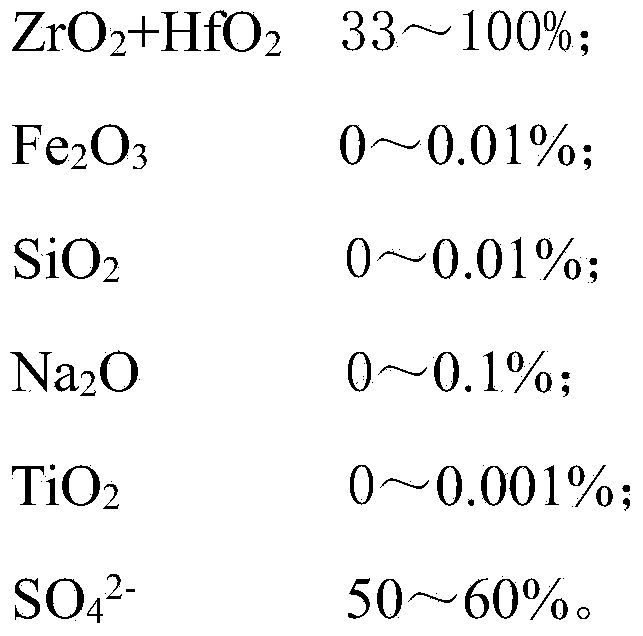

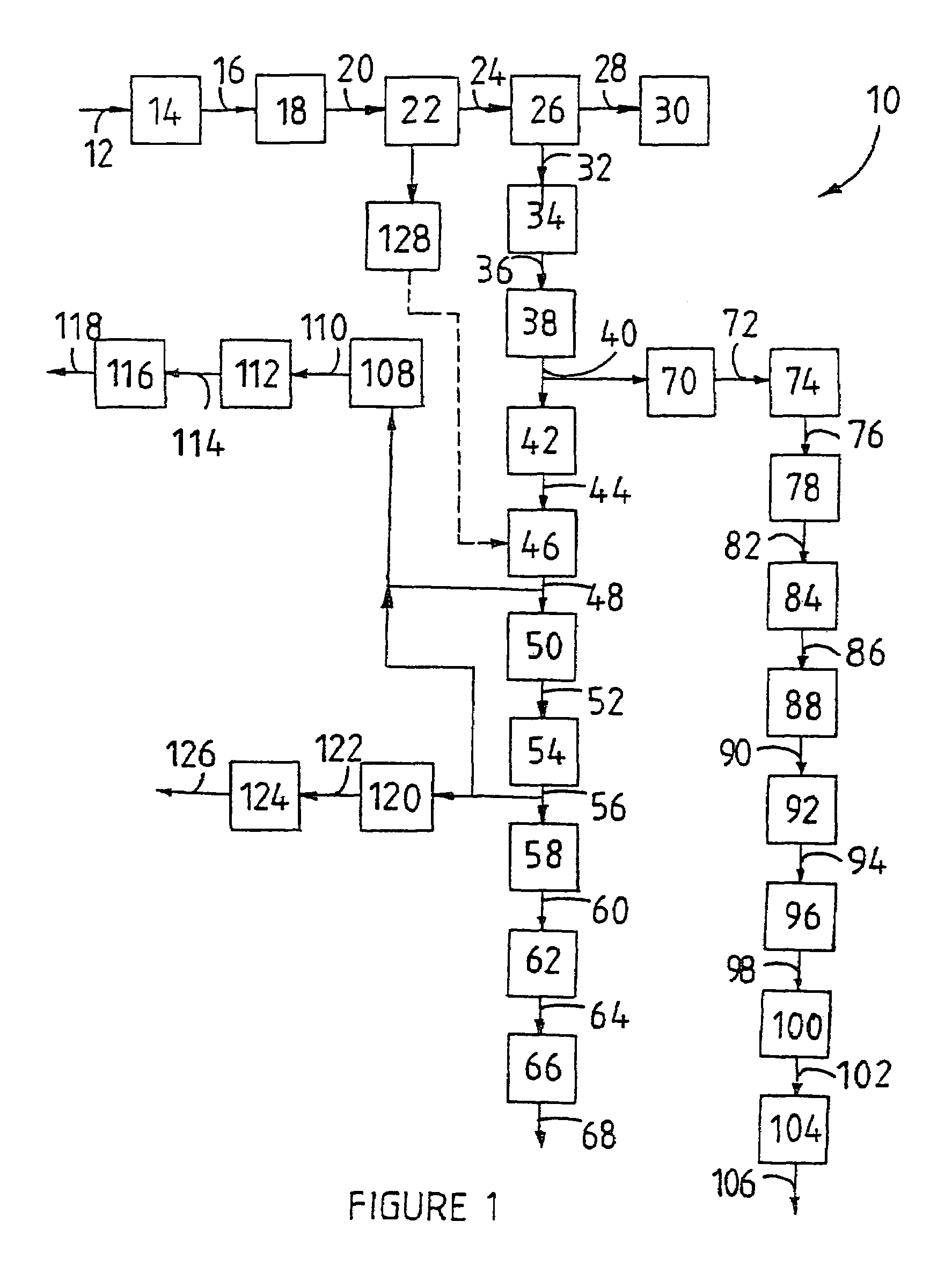

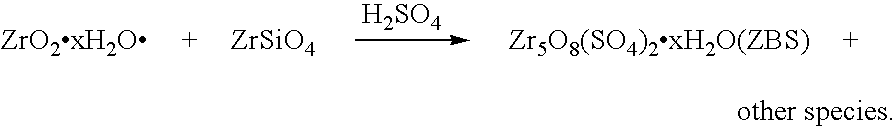

This invention relates to a process of treating a zirconium containing product such as zircon. The process comprises providing an alkali fusion decomposed zircon product (AFDZ) formed from reading zircon with a source of alkali metal at elevated temperatures, and treating the AFDZ to form a solid containing hydrated zirconium oxide and / or hydrated zirconium basic carbonate (hereinafter referred to as the hydrated zirconium product). The process further comprises treating the solid hydrated zirconium product to obtain in situ formation of basic zirconium sulphate as a solid thereon. The invention also relates to such a process for producing zircon derived material suitable for pigments and to such a process to produce opacifier material. The invention also relates to products of such processes.

Owner:PRETORIA UNIV OF

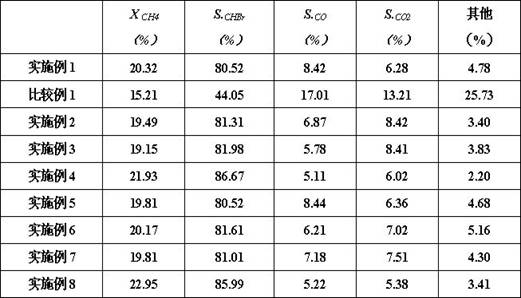

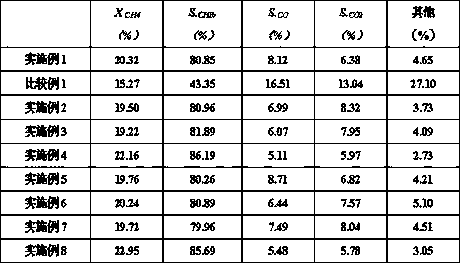

Preparation method of high-activity methane halogen oxidation catalyst

ActiveCN108067259AHigh selectivityImprove conversion ratePhysical/chemical process catalystsHalogenated hydrocarbon preparationHalomethaneSolid acid

The invention discloses a preparation method of a high-activity methane halogen oxidation catalyst. The preparation method comprises following steps: (1), aluminum oxide is subjected to co-impregnation by a mixed solution containing gallium and nickel and then is dried and subjected to high-temperature roasting treatment, and modified aluminum oxide is obtained; (2), zinc is supported to modifiedaluminum oxide prepared in the step (1), and after drying and roasting, zinc supported aluminum oxide is prepared; (3), zirconium sulfate solid acid and aluminum hydroxide slurry are mixed, and aluminum hydroxide slurry containing zirconium sulfate solid acid is obtained; (4), zinc supported aluminum oxide is subjected to spray soaking by the aluminum hydroxide slurry containing zirconium sulfatesolid acid and prepared in the step (3), and after drying and roasting, the methane halogen oxidation catalyst is prepared. According to the catalyst prepared with the method, conversion rate of methane and selectivity of a target product methyl halide can be increased simultaneously, deep oxidation of methyl halide is inhibited, and yield of methyl halide is obviously increased.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

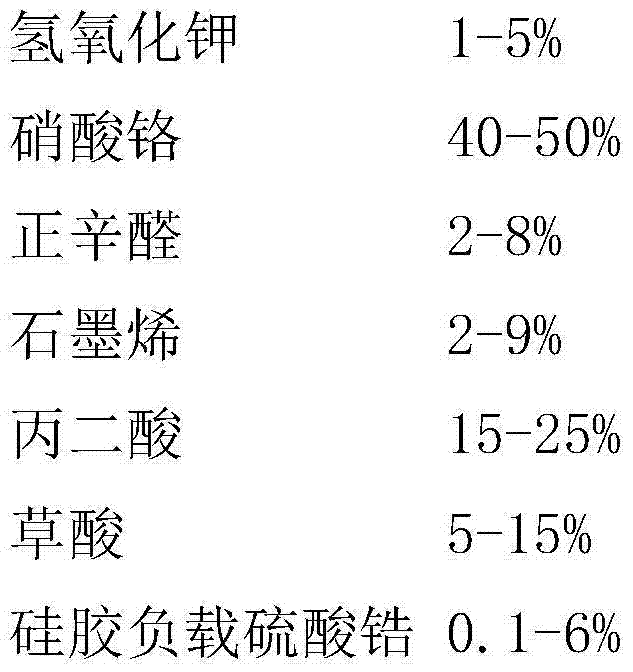

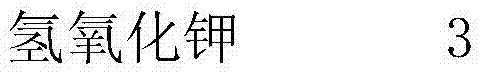

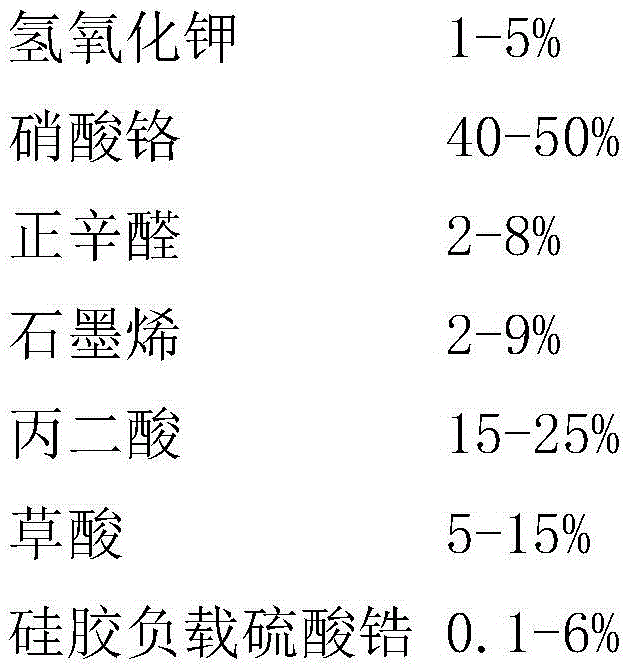

Passivation treating agent for chromium-plating steel part

ActiveCN103924230AExtend the life cycleReduce concentrationMetallic material coating processesPotassium hydroxideSilica gel

The invention provides a passivation treating agent for a chromium-plating steel part, and relates to the technical field of chemical engineering. The passivation treating agent comprises the following components in percentage by mass: 3% of potassium hydroxide, 45% of chromium nitrate, 5% of n-octanal, 4% of graphene, 20% of malonic acid, 10% of oxalic acid, 3% of silica gel-loading zirconium sulfate and the balance of tertiary butanol. The passivation treating agent provided by the invention is long in using period, does not contain hexavalent chromium and hydrogen peroxide or other strong oxidants, facilitates wastewater treatment and is an environment-friendly passivation agent. The passivation treating agent is low in concentration and production cost, relatively economic and practical and capable of improving the salt mist resistance and corrosion resistance of a metal surface and prolonging the service life of the steel part.

Owner:ANHUI HUAXING METAL

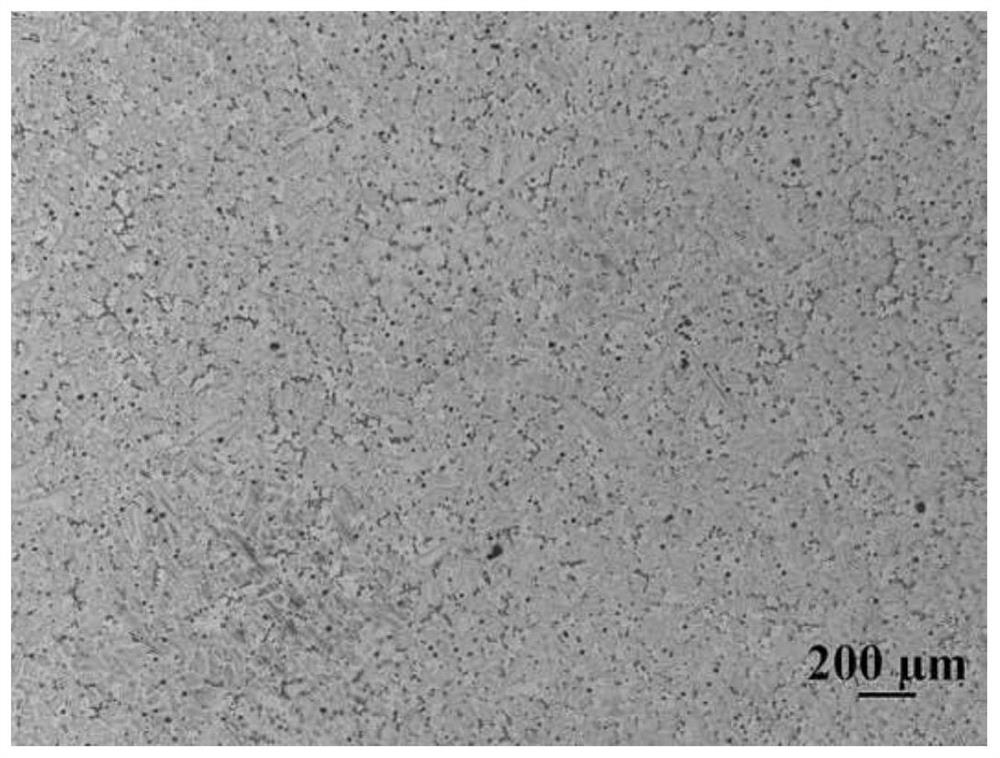

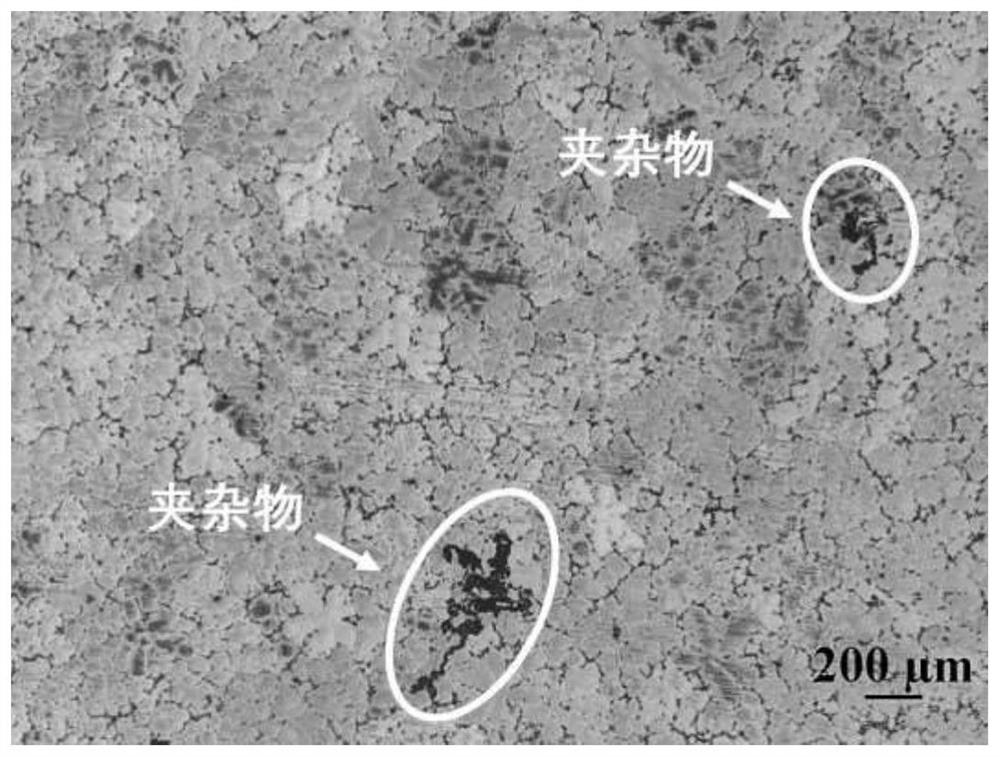

Magnesium-rare earth alloy melt purification and refinement composite treatment flux and application thereof

ActiveCN113278839AIncrease the speed of wetting to capture inclusionsSpeed up the sinkingBarium dichlorideSulfate

The invention discloses a magnesium-rare earth alloy melt purification and refinement composite treatment flux. The mass percentage range of the components is as follows: 30-40% of magnesium chloride, 8-15% of potassium chloride, 8-15% of sodium chloride, 15-20% of barium chloride, 5-8% of barium sulfate, 10-15% of zirconium diboride and 10-15% of zirconium sulfate. A preparation method comprises the following steps of: melting and mixing magnesium chloride, potassium chloride, sodium chloride, barium chloride and barium sulfate, performing cooling and solidifying to obtain a refining agent composite salt block, and then mixing and sieving the refining agent composite salt block, zirconium diboride and zirconium sulfate to prepare the purification and refinement composite treatment flux. By adopting the composite flux disclosed by the invention, the melt purification efficiency can be improved; the Zr refining action time can be prolonged; the refining and purification treatment of the alloy melt can be realized in one step; and the preparation process of the magnesium-rare earth alloy melt can be greatly shortened.

Owner:SHANGHAI JIAO TONG UNIV

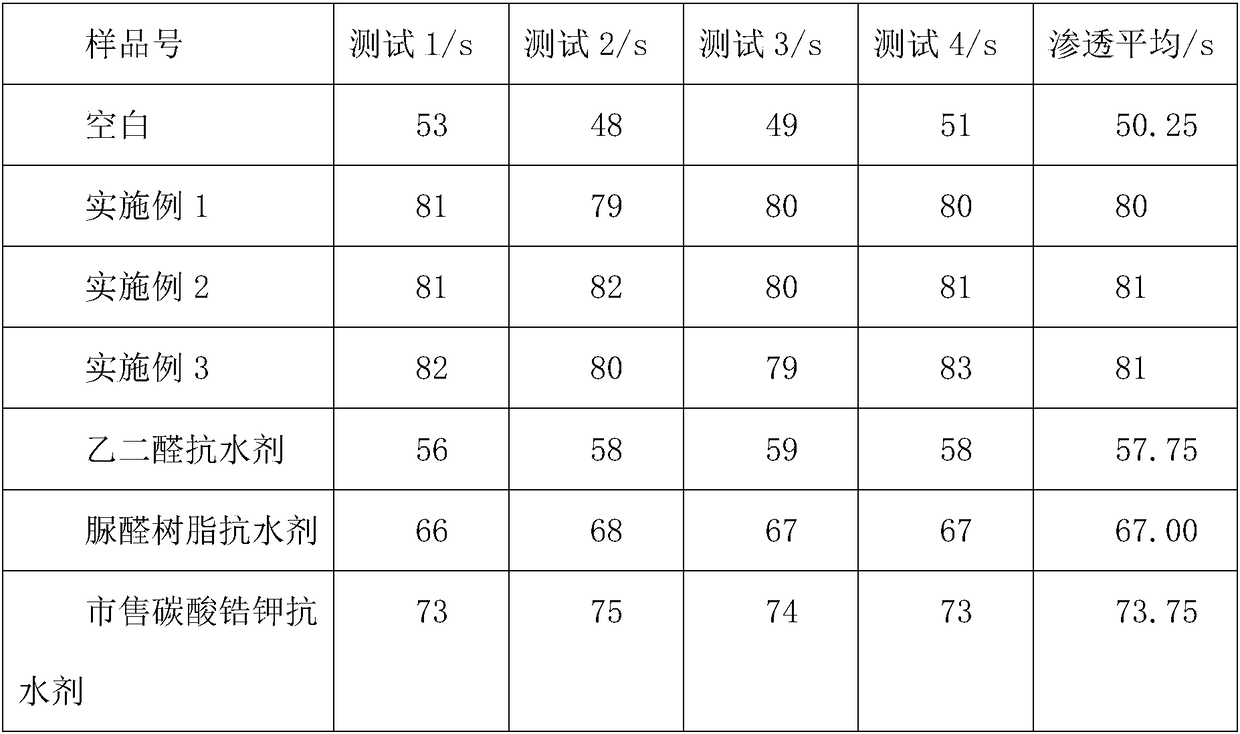

Potassium-zirconium-carbonate cross-linking water-resistant agent and preparing method thereof

Owner:JIANGXI KINGAN HI TECH

Popping reaction glaze and preparation method thereof

The invention discloses a popping reaction glaze which comprises a ground glaze and a overglaze, wherein a glaze material used in the ground glaze comprises the following components in parts by mass:22 parts of potassium feldspar, 15 parts of iodine, 20 parts of calcite, 5 parts of barium carbonate, 10 parts of zinc oxide, 15 parts of Jiepai mud and 38 parts of frit; a glaze material used by theoverglaze comprises the following components in parts by mass: 22 parts of iodine, 20 parts of calcite, 12 parts of frit, 10 parts of talc, 8 parts of zinc oxide, 5 parts of Guizhou soil and 15 partsof zirconium sulfate. According to the invention, the reaction pattern surface is large, the texture is clearer, and the pattern is larger.

Owner:醴陵市和兴瓷业有限公司

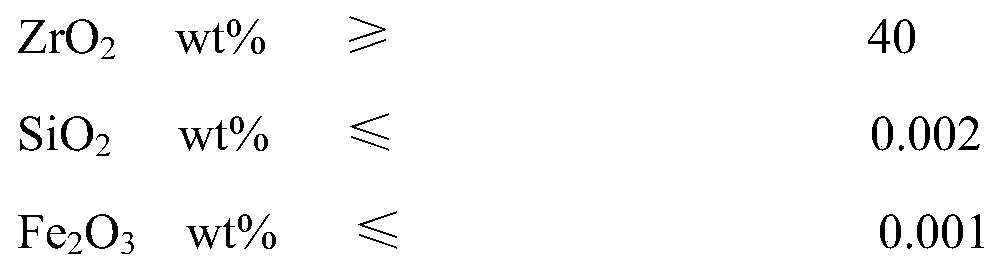

Preparation method of zirconium sulfate

The invention discloses a zirconium sulfate preparation method, which comprises: carrying out a reaction on crushed zircon sand and sulfuric acid for 3-5 h under a pressurization heating condition, sequentially adding water to wash and filter after the reaction is completed, collecting a filtrate, removing impurities from the filtrate, and crystallizing an obtained zirconium sulfate solution to obtain zirconium sulfate. Zirconium sulfate is prepared by directly reacting zircon sand with sulfuric acid under the conditions of heating and pressurizing, alkali fusion is not adopted, sodium hydroxide or sodium carbonate is avoided, the step of removing sodium is omitted, and high-purity zirconium sulfate can be obtained only through one-time crystallization.

Owner:绵竹市金坤化工有限公司

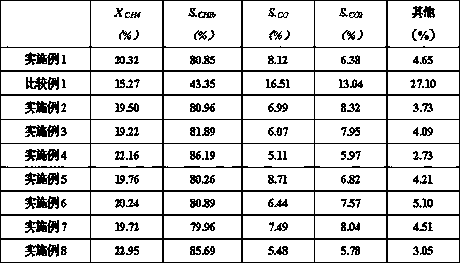

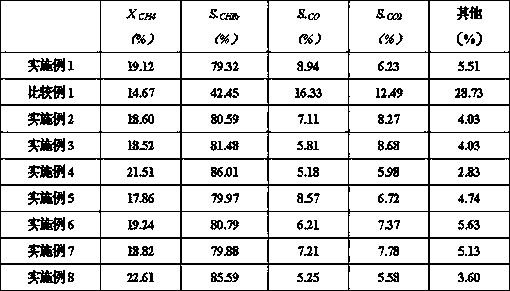

A kind of coal bed gas deoxidation catalyst and preparation method thereof

ActiveCN109772322BHigh activityStrongly activated methaneGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAluminium hydroxide

Owner:CHINA PETROLEUM & CHEM CORP +1

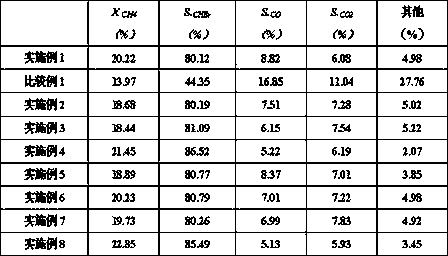

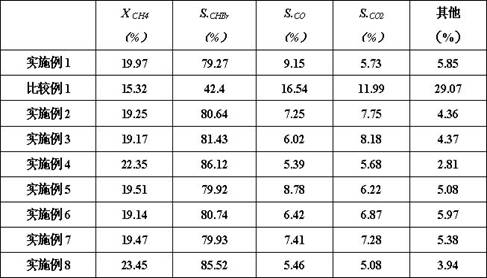

Preparation method of catalyst for methane oxyhalogenation

ActiveCN108067258AHigh selectivityImprove conversion ratePhysical/chemical process catalystsHalogenated hydrocarbon preparationHalomethaneAluminium hydroxide

The invention discloses a preparation method of a catalyst for methane oxyhalogenation. The method comprises the following steps: (1) silica is impregnated with a lanthanum and nickel mixed liquid, dried and then roasted at a high temperature, and modified silica is prepared; (2) zinc is supported on modified silicon oxide prepared in step (1), drying and roasting are performed, and zinc supportedsilicon oxide is prepared; (3) zirconium sulfate solid acid and aluminium hydroxide slurry are mixed, and aluminium hydroxide slurry containing zirconium sulfate solid acid is obtained; (4) the aluminium hydroxide slurry containing zirconium sulfate solid acid performs spray soaking on zinc supported silicon oxide, and the catalyst for methane oxyhalogenation is prepared after drying and roasting. The catalyst prepared with the method has the advantages that methane conversion rate and selectivity of halomethane as a target product are increased simultaneously, deep oxidation of halomethane is inhibited, and yield of halomethane is increased obviously.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Nanometer transparent heat-protecting glass and manufacturing technology thereof

InactiveCN106746639AGood heat insulationGood surface stressStrontium titanateManufacturing technology

The invention provides nanometer transparent heat-protecting glass and a manufacturing technology thereof and relates to the technical field of glass manufacturing. The nanometer transparent heat-protecting glass is mainly prepared from the following ingredients in parts by weight: 50 to 60 parts of silicon dioxide, 12 to 15 parts of sodium silicate, 7 to 13 parts of borax, 3 to 5 parts of calcium metasilicate, 0.05 to 0.2 part of arsenious oxide, 0.3 to 0.7 part of zinc oxide, 1 to 3 parts of magnesium carbonate, 0.2 to 0.4 part of zirconium sulfate, 0.2 to 0.4 part of calcium fluoride, 0.5 to 1 part of potassium feldspar, 0.3 to 0.5 part of ethylchlorosilane, 0.03 to 0.05 part of tungsten trioxide and 0.02 to 0.08 part of cobaltous oxide. The nanometer transparent heat-protecting glass is further prepared from the following ingredients in parts by weight: 0.2 to 1 part of nanometer strontium titanate, 0.05 to 1 part of 3,4-dimethylpyrazole phosphate and 0.02 to 0.08 part of yttrium oxide. The nanometer transparent heat-protecting glass provided by the invention has better thermal insulation capacity and higher light transmittance.

Owner:张眙宁

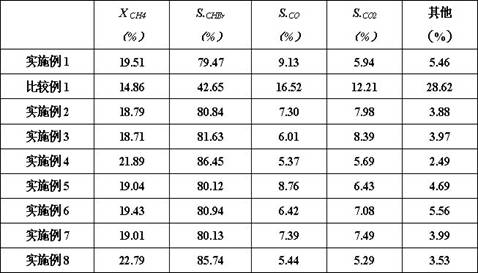

A kind of catalyst with shell core structure and its preparation method and application

ActiveCN108067263BHigh selectivityImprove conversion ratePhysical/chemical process catalystsHalogenated hydrocarbon preparationPtru catalystHalomethane

The invention discloses a catalyst with a shell-core structure and its preparation method and application. The core of the catalyst is zinc-loaded alumina, and the L acid content of the alumina is less than 0.2 mmol·g. ‑1 ;BET specific surface is 200~350m 2 / g; the pore volume is 0.3~0.6ml / g; the shell is alumina containing zirconium sulfate solid acid, where the weight ratio of zinc-loaded alumina to alumina containing zirconium sulfate solid acid is 10:1-2: 1; Based on the weight of alumina containing zirconium sulfate solid acid, the weight content of zirconium sulfate solid acid is 5wt%-10wt%. Based on the weight of zinc-loaded alumina, the zinc content in terms of oxide is 5wt%- 30wt%. The catalyst can simultaneously increase the conversion rate of methane and the selectivity of the target product halogenated methane, inhibit the deep oxidation of halogenated methane, and thereby significantly increase the yield of halogenated methane.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Catalyst for preparing methyl halide, preparation method and application thereof

ActiveCN108067298BHigh selectivityEnhance bromination reactionMolecular sieve catalystsHalogenated hydrocarbon preparationMolecular sievePtru catalyst

The invention discloses a catalyst for preparation of halomethane as well as a preparation method and an application of the catalyst. The catalyst has a core-shell structure, wherein the core is zinc-containing silicon oxide, the shell is aluminum oxide containing zirconium sulfate solid acid and a molecular sieve, the molecular sieve is at least one of a 5A molecular sieve, a 13X molecular sieveand mordenite, and the weight ratio of the zinc-containing silicon oxide to the aluminum oxide containing zirconium sulfate solid acid and the molecular sieve is (10:1)-(2:1); on the basis of the weight of aluminum oxide containing zirconium sulfate solid acid and the molecular sieve, the weight content of zirconium sulfate solid acid is 5wt%-10wt%, and the content of the molecular sieve is 1wt%-10wt%; on the basis of the weight of the zinc-containing silicon oxide, the content of zinc is 5wt%-30wt% based on oxide. The catalyst can increase the conversion rate of methane and the selectivity ofthe target product halomethane, inhibit deep oxidation of halomethane and further remarkably increase the yield of halomethane.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

A kind of methane halogen oxidation catalyst and its preparation method and application

ActiveCN108067286BHigh selectivityEnhance bromination reactionMolecular sieve catalystsHalogenated hydrocarbon preparationMolecular sievePtru catalyst

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Titanium-zirconium cross-linking agent and preparation method thereof

PendingCN114292636AEasy to operateEasy to industrializeDrilling compositionTitanium zirconiumPhosphoric acid

The invention belongs to the technical field of cross-linking agent preparation, and provides a titanium-zirconium cross-linking agent and a preparation method thereof. The titanium-zirconium cross-linking agent provided by the invention is prepared from the following raw materials: inorganic titanium, a ligand, inorganic zirconium, protonic acid and water, the inorganic titanium comprises titanium phosphate and / or titanium sulfate; the ligand comprises one or more of diethanol amine, triethanolamine, ammonium citrate and sodium gluconate; the inorganic zirconium comprises zirconium oxychloride and / or zirconium sulfate. According to the titanium-zirconium cross-linking agent, the titanium cross-linking agent and the zirconium cross-linking agent are introduced at the same time, so that the titanium-zirconium cross-linking agent has the advantages of the titanium cross-linking agent and the zirconium cross-linking agent at the same time, and the pH application range of the titanium-zirconium cross-linking agent is widened; meanwhile, the titanium-zirconium cross-linking agent has excellent temperature resistance. In addition, through selection of inorganic titanium, inorganic zirconium and the ligand, generation of alcohol small molecular compounds in the preparation process is avoided, and the titanium-zirconium cross-linking agent is good in stability and environmentally friendly.

Owner:昆山京昆油田化学科技有限公司

Magnetic porous iron-zirconium bimetal composite coagulant aid as well as preparation method and application thereof

ActiveCN111470604AQuick Adsorption CaptureEasy to separateWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateHydration reaction

The invention discloses a magnetic porous iron-zirconium bimetal composite coagulant aid as well as a preparation method and application thereof. Zirconium sulfate and ferric sulfate are dispersed inpure water, the pH is adjusted to be weakly alkaline, glacial acetic acid is added under the heating condition for a reaction to obtain an iron hydrate / zirconium oxide colloidal solution, and the ironhydrate / zirconium oxide colloidal solution reacts under the high-pressure and high-temperature atmosphere to obtain a target product. The synthesis process is simple, the surface of the prepared magnetic porous iron-zirconium bimetal composite coagulant aid is rich in hydroxyl, sulfate radical active groups and metal ion active sites, the coagulant aid exists in a water body in a colloid form, and the two effects of fluorine ion rapid adsorption and rapid coagulation assistance can be achieved at the same time. After a conventional flocculating agent is added, the colloid state can be immediately converted into a floc state and finally settles down, rapid separation of water and mud is achieved, secondary pollution to a water body is avoided, and the used magnetic porous iron-zirconium double-metal composite coagulant aid can be recycled and reused through soaking, magnetic recovery and drying.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Compound as well as preparation method and application thereof

ActiveCN109772371AHigh activityPromote enrichmentGaseous fuelsCatalyst activation/preparationOxygen vacancySulfate

The invention discloses a compound. The compound is prepared from copper-supported alumina, zirconium sulfate and a compound metal oxide NdCoO3-y with a perovskite structure, wherein y is oxygen vacancy; the weight ratio of the copper-supported alumina to the zirconium sulfate in the compound is (8 to 1) to (2 to 1); the weight ratio of the copper-supported alumina to the compound metal oxide NdCoO3-y with the perovskite structure in the compound is (10 to 1) to (5 to 1); and by taking the weight of the copper-supported alumina as reference, the content of the copper is 5 to 25 weight percentcounted by oxide. The preparation method of the compound comprises the following steps: mixing, kneading and molding the copper-supported alumina, the zirconium sulfate and the compound metal oxide NdCoO3-y with the perovskite structure, drying and calcining to obtain the compound. The compound has the advantages of high activity, low reaction temperature, simple preparation method, low cost and the like when being used for coalbed methane deoxygenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon tetrachloride decomposing catalyst, its production and use

InactiveCN1981933APractical industrial application valueCatalyst activation/preparationHalogenated hydrocarbon preparationSulfateAqueous solution

A catalyst for decomposing CCl4 is prepared through immersing its carrier in the aqueous solution of zirconium sulfate and / or zinc sulfate, adding the solution of inorganic alkali, baking, and calcining in inertial gas. It has high conversion rate, selectivity and long service life (1000 hr or longer).

Owner:中绿实业有限公司

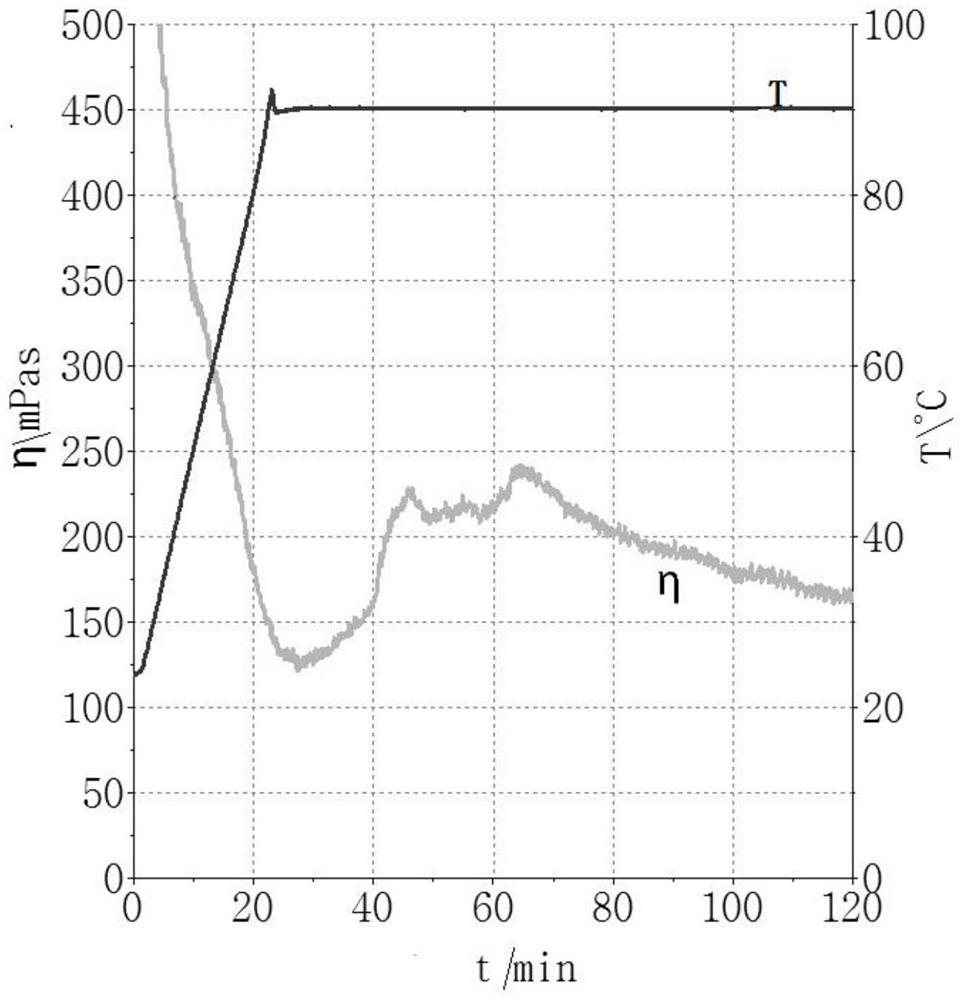

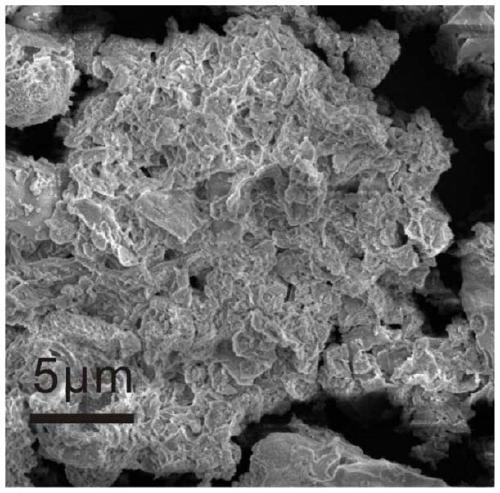

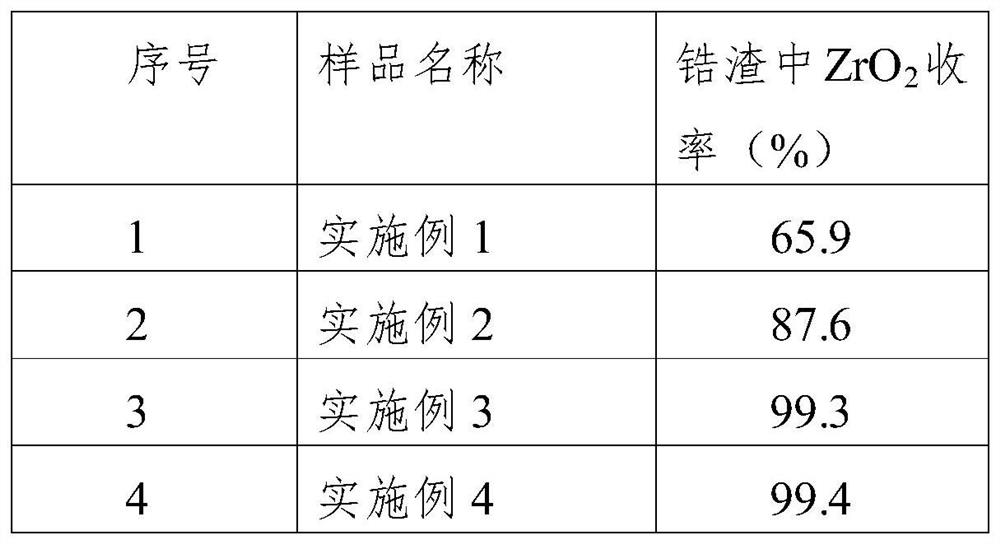

Recycling method of liquid zirconium sulfate hydrolysate for coating rutile titanium dioxide

PendingCN114736537AEmission reductionShort processInorganic pigment treatmentEnergy based wastewater treatmentHydrolysateSlag

The embodiment of the invention discloses a recycling method of liquid zirconium sulfate hydrolysate for coating rutile type titanium dioxide, and particularly relates to the field of coating of rutile type titanium dioxide, which comprises the following steps: step 1, zirconium slag comes from hydrolysate in a storage tank of zirconium sulfate solution for coating rutile type titanium dioxide, adding a proper amount of conversion accelerant according to the amount of the zirconium slag, and then performing crushing treatment; 2, adding zirconium slag and sulfuric acid mother liquor into the beaker, and stirring and mixing; 3, slowly pouring sulfuric acid with the concentration of 98% into the boiler, stirring, and controlling the reaction temperature and the reaction time; according to the method, external heating is not needed when the zirconium sulfate solution is prepared from the zirconium slag, the recycling rate of the zirconium slag reaches 99% or above, the problem of recycling of zirconium sulfate hydrolysate for rutile titanium dioxide coating is solved, discarding of waste in the storage stage of zirconium sulfate is reduced, the technological process for converting the zirconium slag into zirconium sulfate is shortened, and the production cost is reduced. And the reaction rate of the zirconium slag in the sulfuric acid solution is improved.

Owner:重庆思必水处理材料有限公司

Preparation process method of anhydrous zirconium sulfate

The invention discloses a preparation process method of anhydrous zirconium sulfate. The method comprises the following steps: adding ZrO2 into concentrated sulfuric acid, and reacting in a round-bottom flask with a reflux condenser; adding Zr (OH) 4 to serve as a reaction initiator to increase the reaction rate, wherein the mixture reacts under the magnetic stirring heating condition, the heatingtemperature is the boiling point (about 170 DEG C) of the solution, heating is stopped and stirring cooling is conducted to the room temperature after the reaction is conducted for 20 h, white precipitate appears in the solution, and anhydrous zirconium sulfate can be obtained after solid-liquid separation, wherein the solid-liquid separation of zirconium sulfate and concentrated sulfuric acid also comprises the following steps: mixing a concentrated sulfuric acid solution of suspended zirconium sulfate with deionized water according to a ratio of 1: 1, diluting, and carrying out suction filtration by using common filter paper.

Owner:严永生 +1

A kind of magnetic porous iron-zirconium bimetal composite coagulation aid and its preparation method and application

ActiveCN111470604BQuick Adsorption CaptureEasy to separateWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateHydration reaction

The invention discloses a magnetic porous iron-zirconium bimetal composite coagulation aid and its preparation method and application. Zirconium sulfate and iron sulfate are dispersed in pure water, the pH is adjusted to weak alkalinity, and glacial acetic acid is added under heating conditions for reaction. Finally, a hydrated iron / zirconium oxide colloidal solution is obtained, and the hydrated iron / zirconium oxide colloidal solution is reacted under a high-pressure and high-temperature atmosphere to obtain the target product. The synthesis process of the present invention is simple, and the surface of the prepared magnetic porous iron-zirconium bimetallic composite coagulant is rich in hydroxyl groups, sulfate radical active groups and metal ion active sites, and exists in the form of colloids in water bodies, which can simultaneously realize rapid It has two functions of adsorption and rapid coagulation aid. After adding a conventional flocculant, the colloidal state will immediately change into a floc state, and finally settle down to achieve rapid separation of water and mud without causing secondary pollution to the water body. After use, the magnetic porous iron-zirconium bimetallic composite coagulant aid is soaked Magnetic recovery, drying can be recycled.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

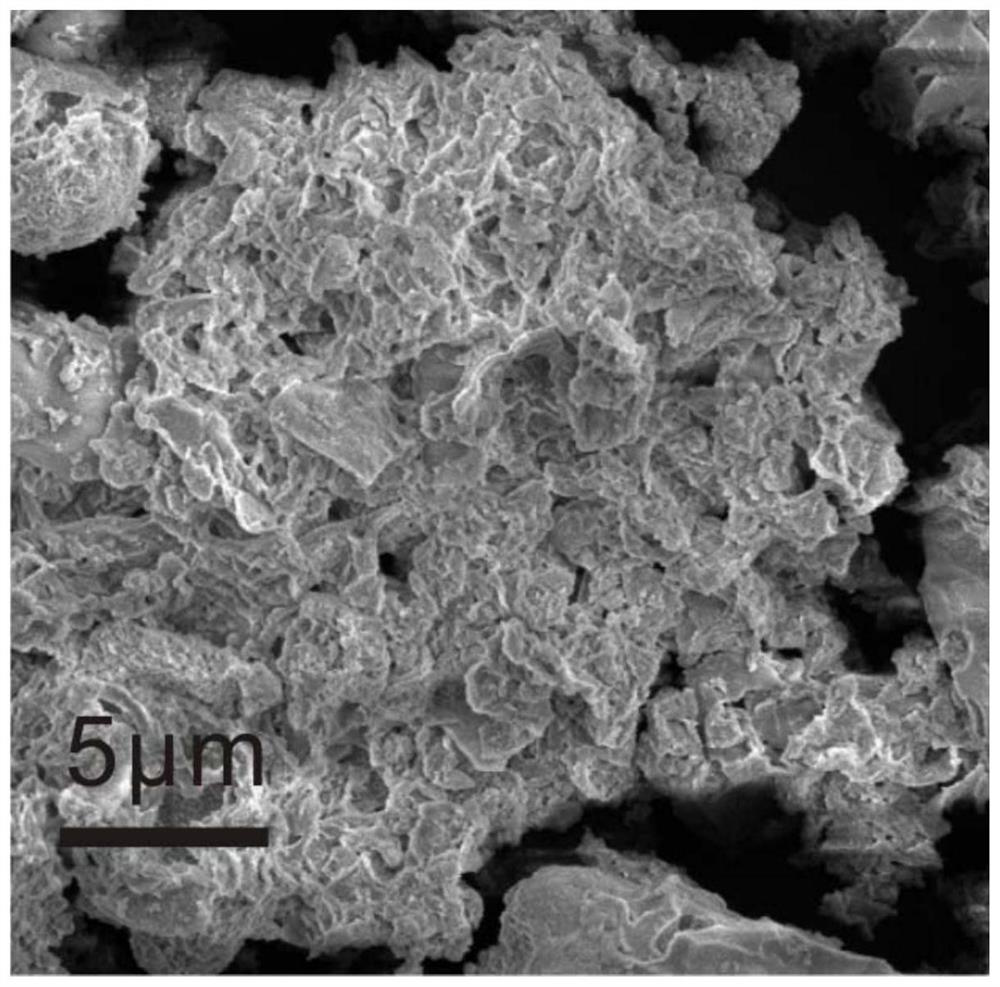

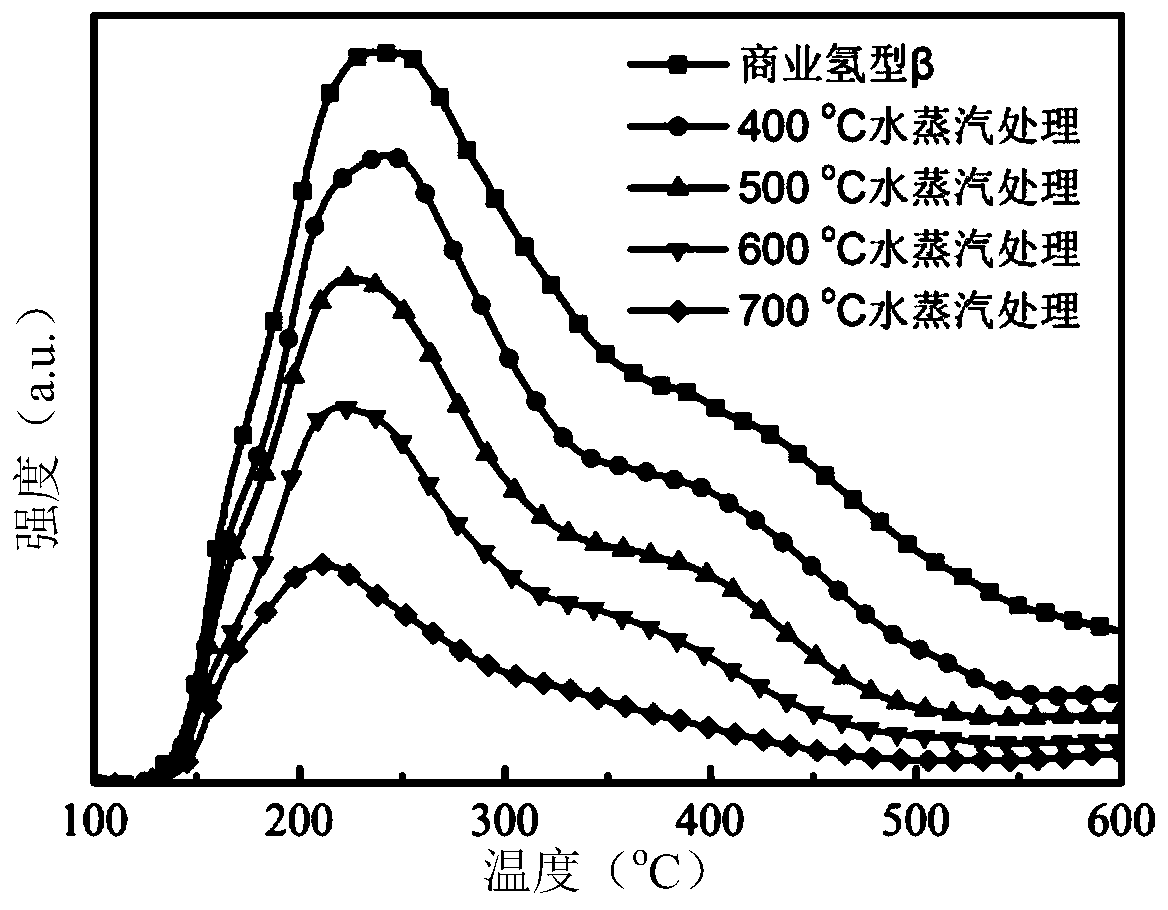

A modified β molecular sieve and its preparation method and application

ActiveCN108328624BOvercoming difficult regenerationAvoid churnMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

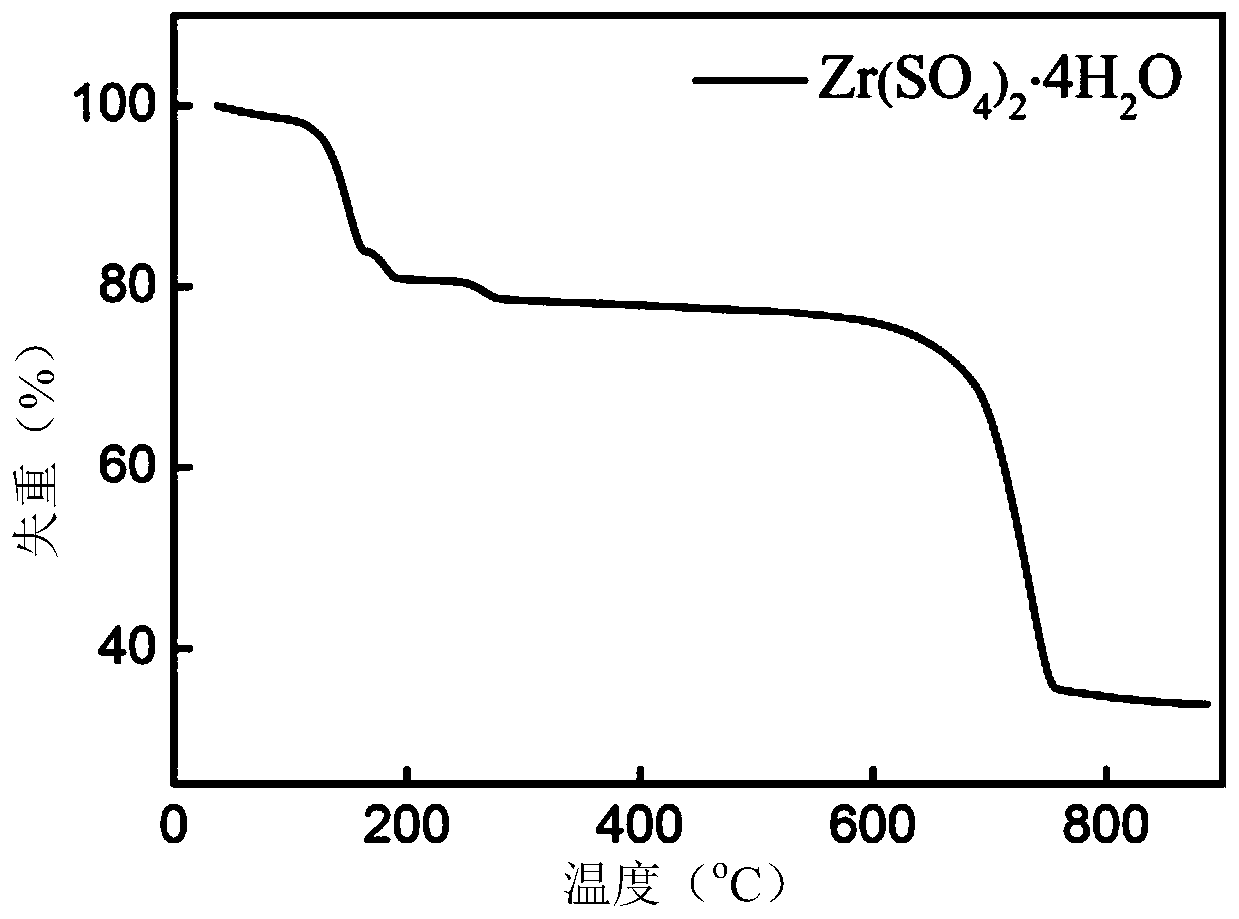

The invention provides a modified beta molecular sieve as well as a preparation method and an application thereof. The method comprises a step of performing water vapor modification treatment on a hydrogen type beta molecular sieve and a step of loading the water vapor modified hydrogen type beta molecular sieve with zirconium sulfate to obtain the modified beta molecular sieve, wherein water vapor modification treatment is performed at the temperature of 400-800 DEG C for 2-6 h; the load of zirconium sulfate is 0-50% of the mass of the water vapor modified hydrogen type beta molecular sieve.The defects that traditional ion exchange resin is difficult to regenerate, heteropolyacid and active components of a solid super acidic catalyst are easy to lose and the activity and selectivity of currently reported catalysts such as a beta molecular sieve, an HY molecular sieve and mordenite are low and the like can be overcome.

Owner:SHANDONG QILU HUAXIN HIGH TECH

Passivation treatment agent for chrome-plated steel parts

ActiveCN103924230BExtend the life cycleReduce concentrationMetallic material coating processesPotassium hydroxideSilica gel

The invention provides a passivation treating agent for a chromium-plating steel part, and relates to the technical field of chemical engineering. The passivation treating agent comprises the following components in percentage by mass: 3% of potassium hydroxide, 45% of chromium nitrate, 5% of n-octanal, 4% of graphene, 20% of malonic acid, 10% of oxalic acid, 3% of silica gel-loading zirconium sulfate and the balance of tertiary butanol. The passivation treating agent provided by the invention is long in using period, does not contain hexavalent chromium and hydrogen peroxide or other strong oxidants, facilitates wastewater treatment and is an environment-friendly passivation agent. The passivation treating agent is low in concentration and production cost, relatively economic and practical and capable of improving the salt mist resistance and corrosion resistance of a metal surface and prolonging the service life of the steel part.

Owner:ANHUI HUAXING METAL

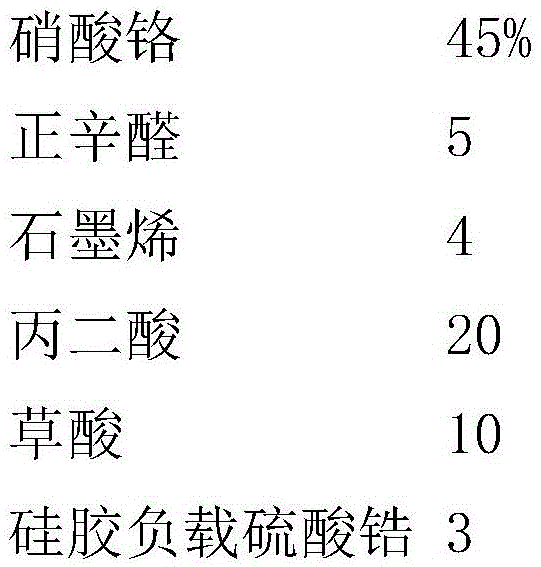

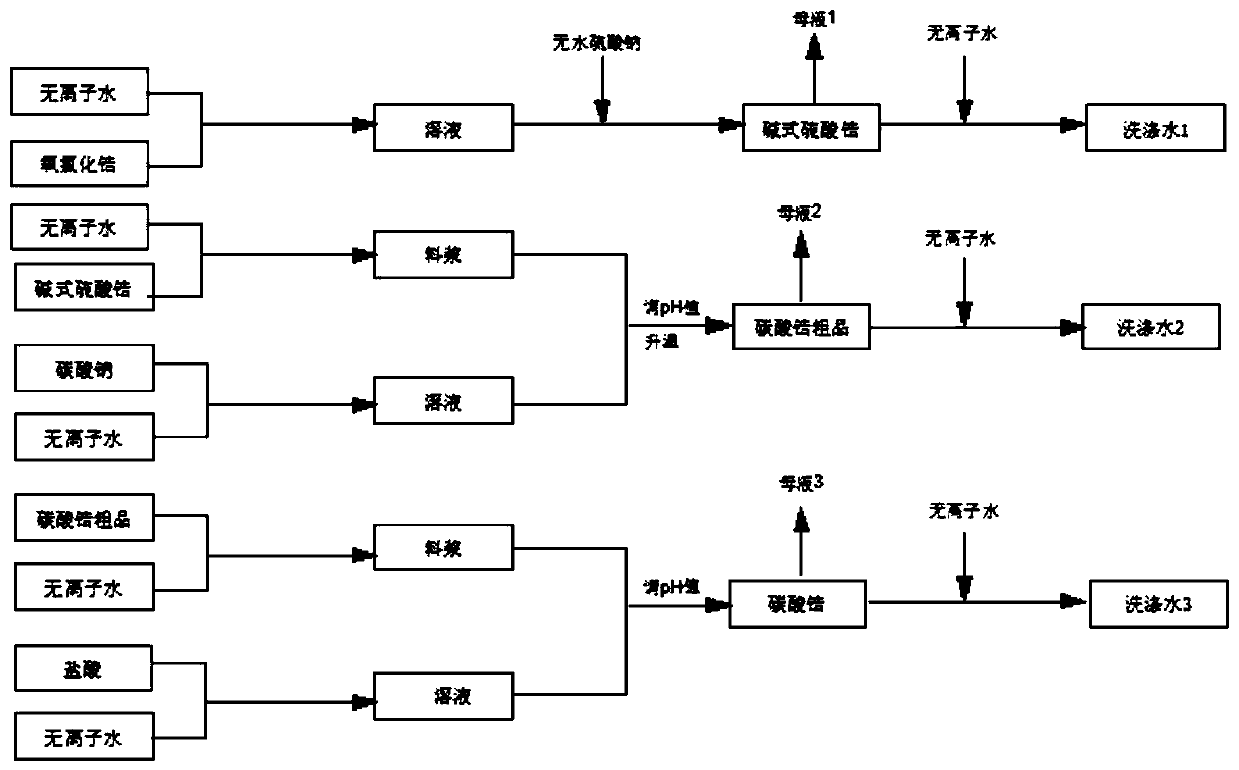

Environmentally friendly and low-cost industrial zirconium carbonate production method

ActiveCN107840363BLow costReduce consumptionZirconium compoundsZirconium oxychlorideSodium acid carbonate

The invention relates to an environment-friendly and low-cost production method for industrial zirconium carbonate, and belongs to a preparation method for zirconium compounds. The method is characterized in that washing water and filtered mother liquor produced in a crude zirconium carbonate work section and a product zirconium carbonate work section are used in an alkaline zirconium sulfate worksection and replace non-ionic water to be used as basic zirconium sulfate washing water, raw material zirconium oxychloride preparation water and raw material basic zirconium sulfate slurrying waterin a crude product zirconium carbonate device. The non-ionic water consumption per ton of zirconium carbonate products is reduced to 6.8 tons or less, 89.8% or more of anhydrous sodium sulfate is saved, 32.8% or more of sodium carbonate is saved, and the consumption of the product raw materials is totally reduced by about 342 yuan / ton. Most of the zirconium carbonate washing water and filtered mother liquor discharged by the zirconium carbonate product device are recycled. Most of the non-ionic water and carried chemicals are recycled, the production cost is greatly reduced and the load of a water treatment device is alleviated.

Owner:山东广通新材料有限公司

A kind of preparation method of highly active methane halogen oxidation catalyst

ActiveCN108067259BHigh selectivityImprove conversion ratePhysical/chemical process catalystsHalogenated hydrocarbon preparationPtru catalystAluminium hydroxide

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

A kind of methane oxyhalogenated conversion catalyst and its preparation method and application

ActiveCN108067261BImprove conversion rateHigh selectivityPhysical/chemical process catalystsHalogenated hydrocarbon preparationPtru catalystHalomethane

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

A kind of compound and its preparation method and application

ActiveCN109772371BHigh activityPromote enrichmentGaseous fuelsCatalyst activation/preparationOxygen vacancyPerovskite (structure)

A composite containing copper-loaded alumina, zirconium sulfate, and a composite metal oxide NdCoO having a perovskite structure 3‑y , y is an oxygen vacancy, and the weight ratio of the copper-loaded alumina and zirconium sulfate in the composite is 8:1-2:1, and the copper-loaded alumina and the zirconium sulfate with a perovskite structure in the composite Composite metal oxide NdCoO 3‑y The weight ratio is 10:1-5:1, based on the weight of aluminum oxide loaded with copper, the content of copper in terms of oxide is 5wt%-25wt%, the preparation method of the composite includes the following content: Copper alumina, zirconium sulfate and composite metal oxide NdCoO with perovskite structure 3‑y It is kneaded and shaped, and then dried and roasted to obtain a compound. The compound has the advantages of high activity, low reaction temperature, simple preparation method, low cost and the like when used for coal bed gas deoxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com