Preparation method of molecular sieve composite catalyst Fe2O3/ZrO2/SO42 for desorbing CO2-rich amine solution

A SO42--, amine solution technology, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., to achieve the effects of good stability, easy access to raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

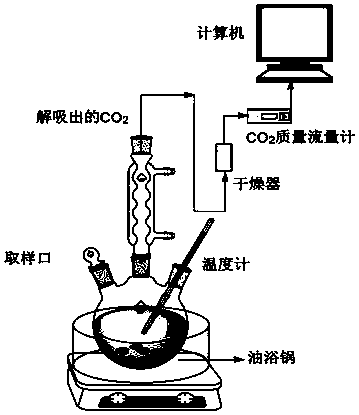

Method used

Image

Examples

Embodiment 1

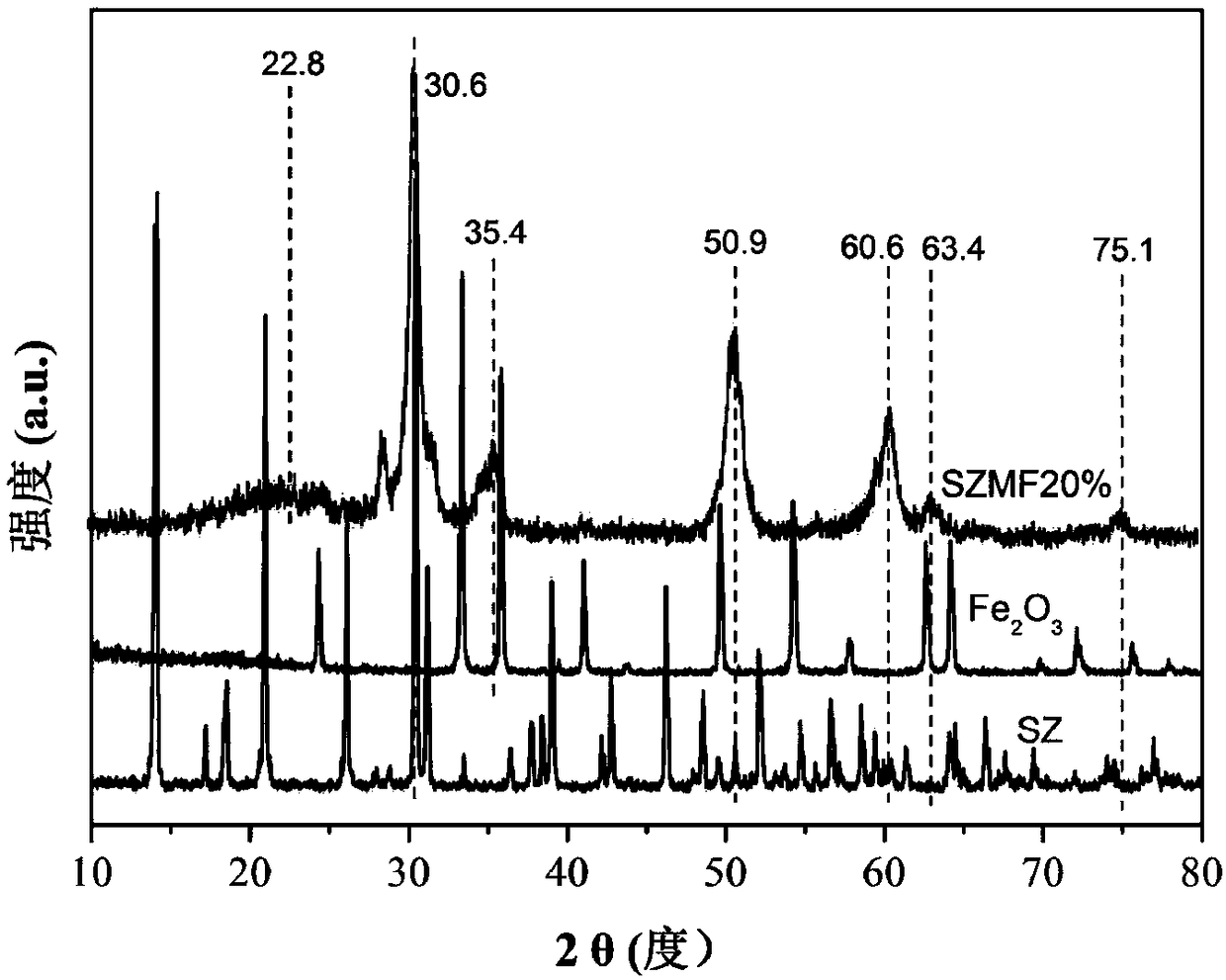

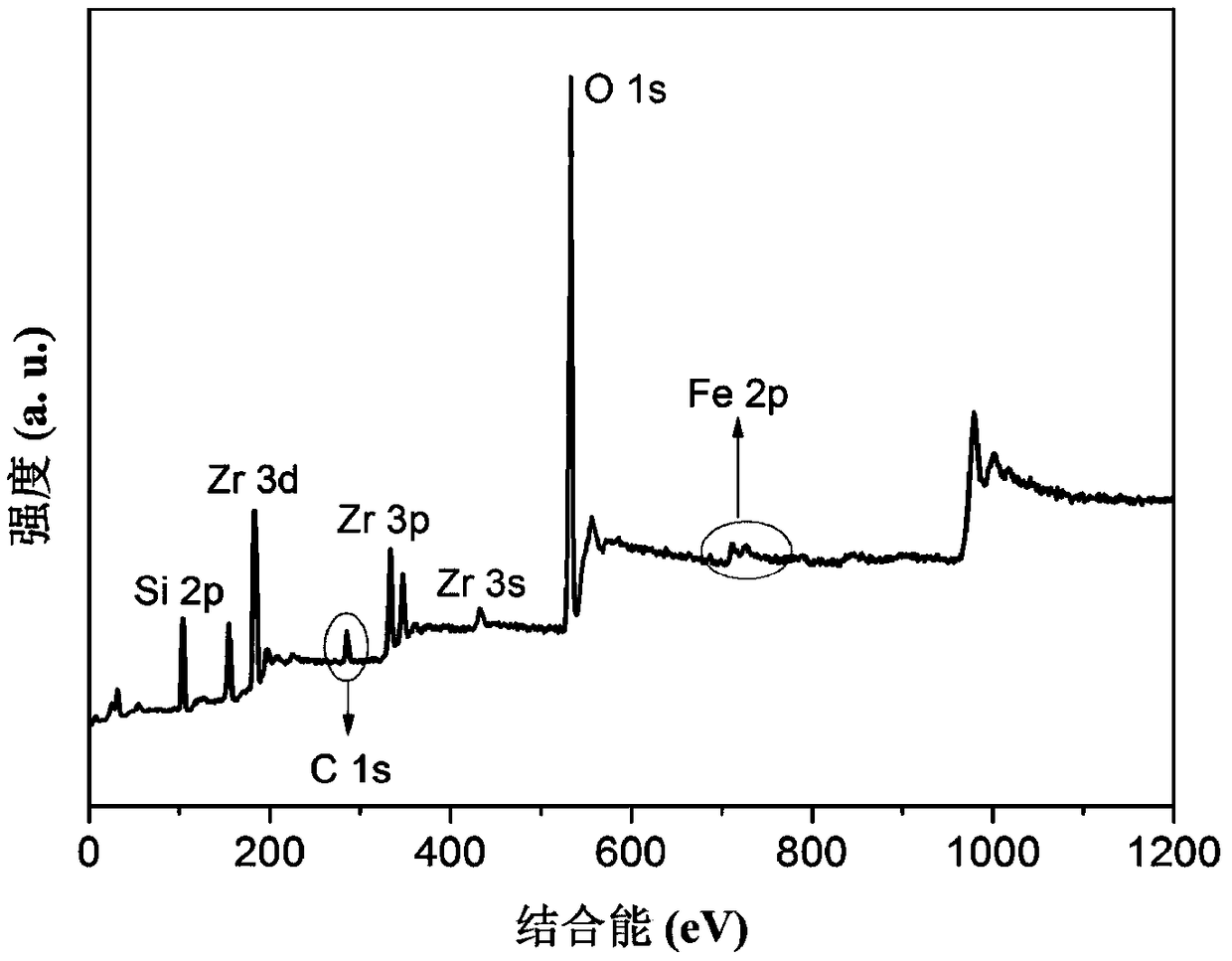

[0037] Example 1: Fe 2 o 3 -SO 4 2- / ZrO 2 -MCM-41 molecular sieve catalyst

[0038] 20.3g of zirconium sulfate hydrate Zr(SO 4 ) 2 .4H 2 O and 3.6g ferric nitrate hydrate Fe(NO 3 ) 3 .9H 2O solution and methanol solution to obtain 0.5mol / L mixed solution A; heat the mixed solution A at a certain temperature for 0.5h to obtain mixed solution B; after the mixed solution B is cooled to room temperature, add 7g of MCM-41 molecular sieve powder , and stirred for 5h to obtain the mixed solution C; the mixed solution C was ultrasonically treated for 0.5h, so that several substances were fully mixed to obtain the mixed solution D; the mixed solution D was dried at 120°C for 14h, and finally the sample was placed in In a muffle furnace, calcined at 700 °C for 3 h to obtain the target product catalyst, Fe 2 o 3 -SO 4 2- / ZrO 2 -MCM-41, where ZrO 2 The mass ratio to MCM-41 is 1:1, Fe 2 o 3 The mass ratio to MCM-41 is 1:20, abbreviated as SZMF20%.

Embodiment 2

[0049] With embodiment 1, its difference is that in catalyst preparation process ZrO 2 The mass ratio to MCM-41 is 1:1, Fe 2 o 3 The mass ratio to MCM-41 is 1:10, abbreviated as SZMF10%.

Embodiment 3

[0051] With embodiment 1, its difference is that in catalyst preparation process ZrO 2 The mass ratio to MCM-41 is 1:1, Fe 2 o 3 The mass ratio to MCM-41 is 1:30, abbreviated as SZMF30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com